CIRCUITRY

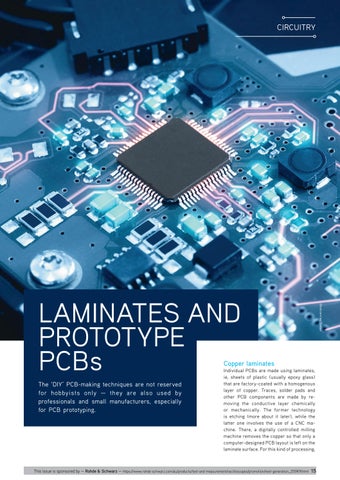

Copper laminates

The ‘DIY’ PCB-making techniques are not reserved for hobbyists only — they are also used by professionals and small manufacturers, especially for PCB prototyping.

Individual PCBs are made using laminates, ie, sheets of plastic (usually epoxy glass) that are factory-coated with a homogenous layer of copper. Traces, solder pads and other PCB components are made by removing the conductive layer chemically or mechanically. The former technology is etching (more about it later), while the latter one involves the use of a CNC machine. There, a digitally controlled milling machine removes the copper so that only a computer-designed PCB layout is left on the laminate surface. For this kind of processing,

This issue is sponsored by — Rohde & Schwarz — https://www.rohde-schwarz.com/au/products/test-and-measurement/oscilloscopes/promotion/next-generation_255909.html 15

iStock.com/Jay_Zynism

LAMINATES AND PROTOTYPE PCBs