S T R U C T U R E S STEEL FRAME Save Time. Save Money. Build Better.

About Us

Few Benefits of Our System

Westline - Steel Frame Structures is a family-owned business with 70 years of combined experience in the construction industry. Having constructed over 300 new homes and worked with brands such as Heineken, Britvic, Johnsons and Leeds City Council. Because of this, we understand first-hand the importance speed and reliability has and how this can impact both the cost and outcome of the build.

material steel is highly efficient.(Strength to ratios)

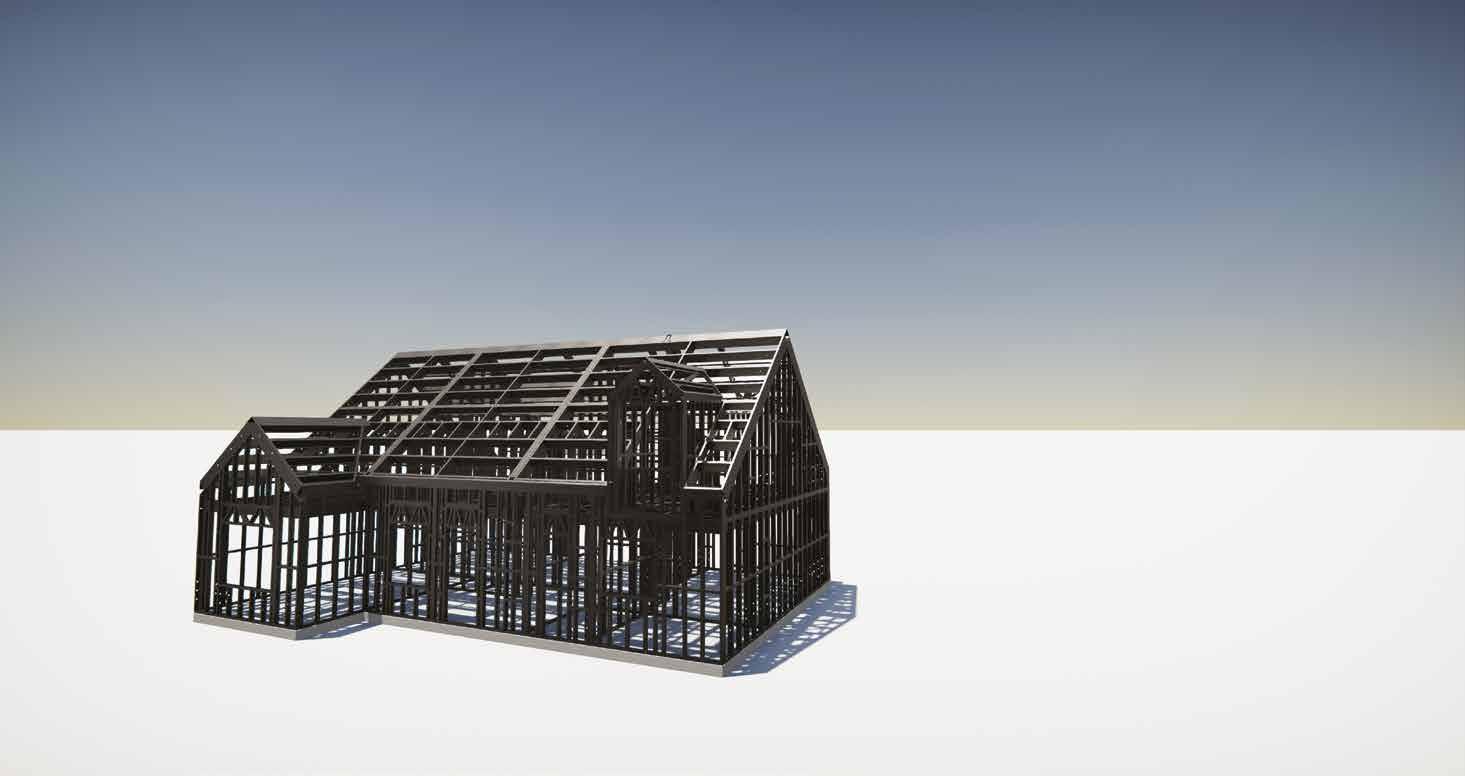

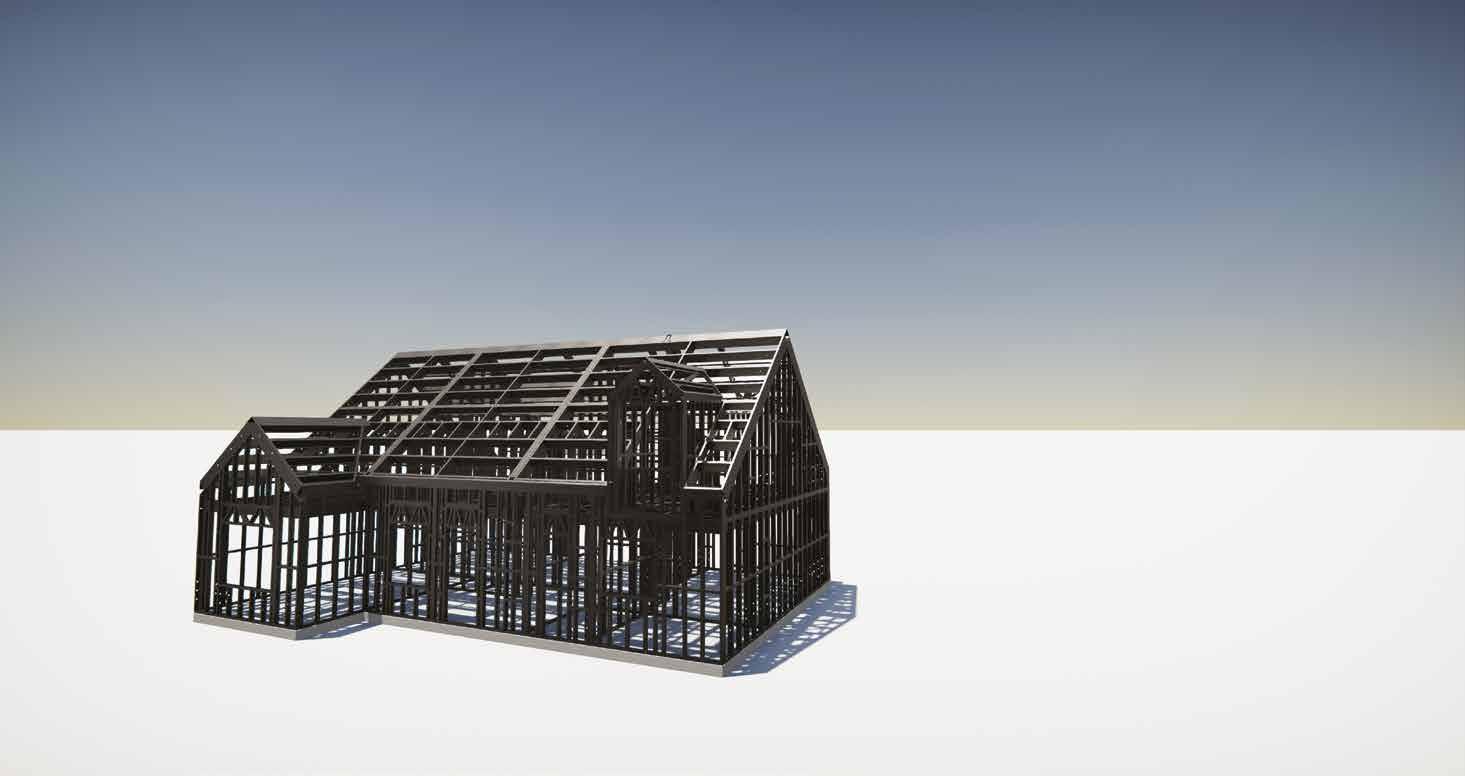

Our steel framing process utilises the latest in modern technology to swiftly and efficiently roll carefully designed light gauge steel components. This results in builds taking less time and costing less due to various efficiencies.

Foundations can be optimised with the reduction in weight

Dimensionally stable leading to tolerances of +0/-2mm

production process has the flexibility to produce accurate components whether singularly or multiple batches time and again

faster erection than traditional build envelope for follow-on trades

Infill

waste of less than 3% (of which all is waste on site

Engineered piece build into concrete /hot rolled framed construction.

100mm, in 1.0, 1.2, and 1.6mm gauge

200+mm options available up to 2.0 mm gauge

Head and base track with vertical studs at max 600c/c deflection track/brackets included

Fully formed openings

Fully designed system supplying a complete kit

Compound sections are factory produced (quality assured)

Materials bundled to suit on site installation

Wind posts and fixings can be inclusive

Just a Few Benefits of Our System...

Our light gauge steel frame designs are compliant with all major warranty providers (NHBC, Premier LABC)

FRAME

As a material, steel is highly efficient due to its excellent strength to weight ratio. Allowing for a potential reduction in foundation requirements

Dimensionally stable leading to tolerances of +0/-2mm or better

The production process has the flexibility to produce highly accurate components whether singularly or based on multiple batches time and again

>30% faster erection than traditional build

Rapid dry envelope for follow-on trades

Process waste of less than 3%

LOAD BEARING

Achievable

U-Values of 0.15 - 0.25

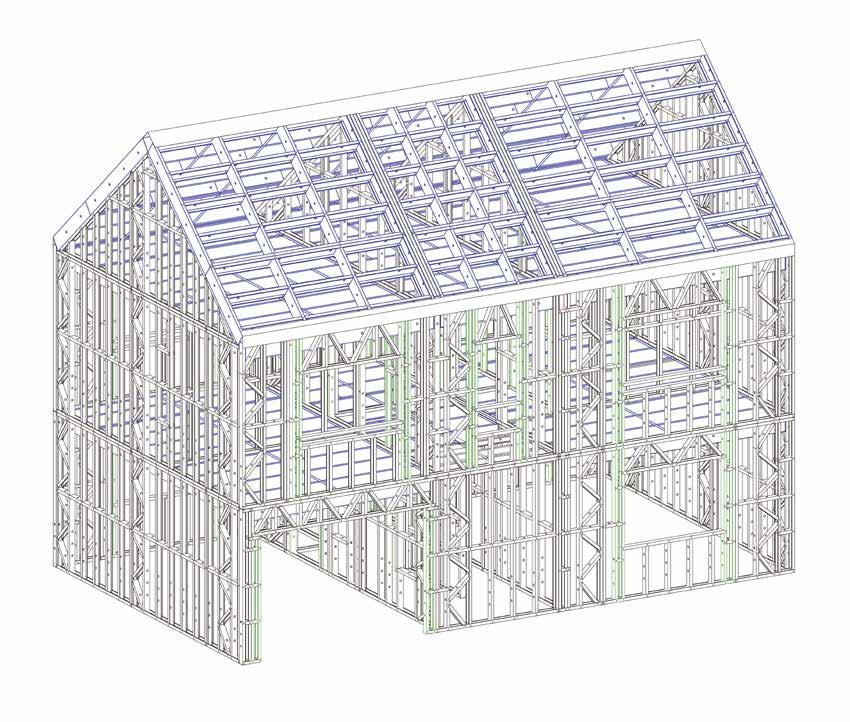

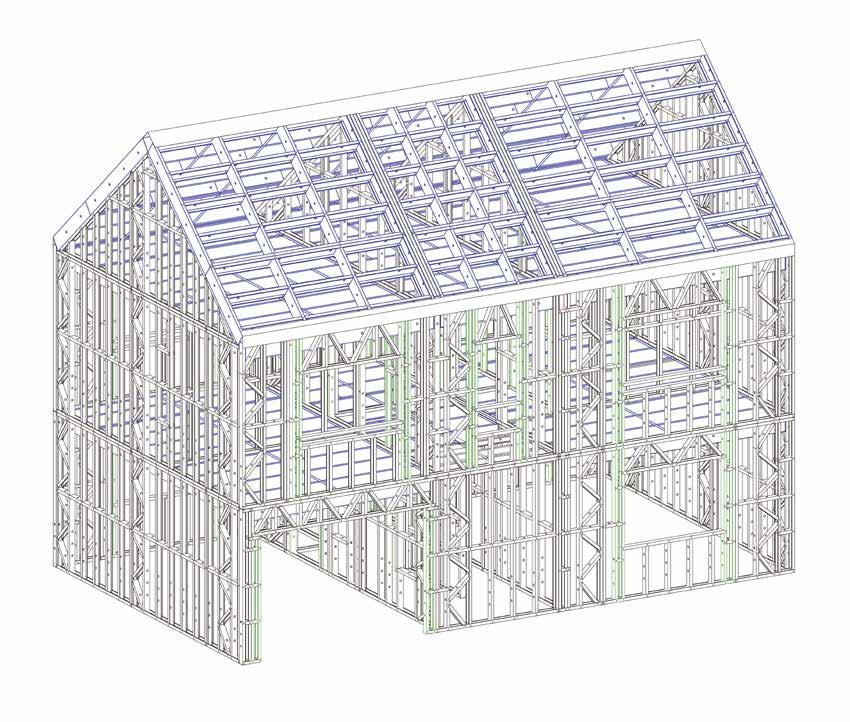

Our Panels

Engineered pieces built into concrete/hot rolled framed construction

100mm, in 1.0, 1.2, and 1.6mm gauge

250mm options available up to 2.0 mm gauge

Head and base track with vertical studs at max 600c/c deflection track/brackets included

Fully formed openings

Fully designed system supplying a complete kit

Compound sections are factory produced (quality assured)

Materials bundled to suit on site installation

Wind posts and fixings can be inclusive

Experience engineering

Expertly designed

Full project management

Dedicated install

Panels are factory assembled

Walls can be pre-boarded/ insulated

Floor cassettes can be pre-boarded

Roof cassettes can be pre-boarded/insulated

In-house engineering In-house design Full project management

install Panels are factory assembled Walls can be pre-boarded/insulated Floor cassettes can be pre-boarded Roof cassettes can be pre-boarded/insulated Load bearing panel

Dedicated

INFILL

Enquiry

We offer a detailed and transparent pricing model. When we receive an enquiry or request for a tender, one of our in-house estimators will provide a fixed quote for whatever the requirements of the project are.

Design Manufacture

Using the latest in CAD technologies our design partners will create detailed GAs including project

En

STEEL

You’ll receive your own dedicated as your consistent point of contact throughout the process

ACCOUNTS MANAGER

We offer a detailed and transparent pricing model. When we receive an enquiry or request for a tender, one of our in-house estimators will provide a fixed quote for whatever the requirements of the project are.

Steel Frame Structures operates the latest in cold rolling technology using Howick framing machines. The approved design data is transferred directly from our computers through to the software on our framing machine. The overall process ensures...

OFF-CUTS WASTE TO LANDFILL 0

FULLY RECYCLED ACCURACY TO 0.5MM

Our team will then assemble modular sections in a dedicated assembly area using specified drawings.

Our QA system allows for all elements to be fully identifiable, ensuring full traceability from every operative working on the steel, all the way back to the original steel coil.

ounsist css.

FRAME

%

Production Process

ISO controlled quality and precision to EN standards

State-of-the-art machinery and sophisticated roll-forming machines produce self-jigging components ready for assembly

Bespoke CAD/CAM interface using CNC technology to achieve exact dimensions

Every frame uniquely ID-labelled with project, frame no., order no., weight, GA site drawings reference

Delivery & Installation

Lorries are loaded in a precise order that allows for minimal journeys to site. In addition, unloading is made easy as elements are bundled together. This results in a reduction in emissions and overall a more efficient build.

Our installation team will work in-line with your programme, reliably constructing your frames swiftly and accurately.

Our Light Gauge Steel Framing (LGSF) components are:

Light & Inert

Offer Waste Free Installation

All required drawings & fixings are supplied

CAREFULLY LABELLED & BOXED

Sections are exported directly from design model complete with any service holes/connections

Each section is uniquely marked and fully traceable

Frames are assembled in factory from sections, fully self jigged and accurate to +0/- 2mm.

Boarding and/or insulation are applied in factory, other ancillaries are also possible.

Panels are then bundled into packages in accordance with the construction phasing.

FRAME STRUCTURES

Can be Installed in Most Weather Conditions.

BENEFITS

Steel in this form is:

Durable

Accurate

Reliable

Recyclable and sustainable

Highly adaptable - fully integrates with hot rolled steel (all sections of U Beams and Columns)

Full traceability of materials

Well developed method of construction with a large amount of technical information. (SCI, BCSA etc)

Dimensionally stable during and after construction (non-shrink, non-warping)

Largely unaffected by weather

Ethical procurement

FRAME

STRUCTURES

OUR PROJECTS

Westline - Steel Frame Structures have been involved with various housing projects.

Here are just a few examples

– 36 houses, 3 and 4 bed semis, 4 bed detached and 3 sets of 2 bed terraces

Gotts Park – Leeds

Old Lane

– 36 houses, 3 and 4 bed semis, 4 bed detached and 3 sets of 2 bed terraces

Gotts Park – Leeds

Old Lane

Contact us today to learn more about how your next project can benefit from our light gauge steel framing system. S T R U C T U R E S www.westlineuk.com STEEL FRAME info@westlineuk.com 0191 410 2636 Contact Westline - Bede House Westline Industrial Estate, Birtley County Durham, DH2 1AU

– 36 houses, 3 and 4 bed semis, 4 bed detached and 3 sets of 2 bed terraces

Gotts Park – Leeds

Old Lane

– 36 houses, 3 and 4 bed semis, 4 bed detached and 3 sets of 2 bed terraces

Gotts Park – Leeds

Old Lane