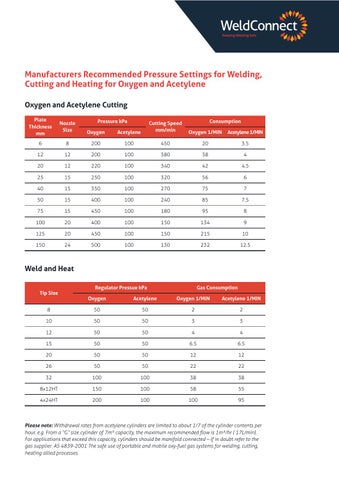

Manufacturers Recommended Pressure Settings for Welding, Cutting and Heating for Oxygen and Acetylene Oxygen and Acetylene Cutting Plate Thickness mm

Nozzle Size

Oxygen

6

8

12

Pressure kPa

Consumption

Acetylene

Cutting Speed mm/min

Oxygen 1/MIN

Acetylene 1/MIN

200

100

450

20

3.5

12

200

100

380

38

4

20

12

220

100

340

42

4.5

25

15

250

100

320

56

6

40

15

350

100

270

75

7

50

15

400

100

240

85

7.5

75

15

450

100

180

95

8

100

20

400

100

150

134

9

125

20

450

100

150

215

10

150

24

500

100

130

232

12.5

Weld and Heat Tip Size

Regulator Pressue kPa

Gas Consumption

Oxygen

Acetylene

Oxygen 1/MIN

Acetylene 1/MIN

8

50

50

2

2

10

50

50

3

3

12

50

50

4

4

15

50

50

6.5

6.5

20

50

50

12

12

26

50

50

22

22

32

100

100

38

38

8x12HT

150

100

58

55

4x24HT

200

100

100

95

Please note: Withdrawal rates from acetylene cylinders are limited to about 1/7 of the cylinder contents per hour, e.g. From a “G” size cylinder of 7m³ capacity, the maximum recommended flow is 1m³/hr ( 17L/min). For applications that exceed this capacity, cylinders should be manifold connected – If in doubt refer to the gas supplier. AS 4839-2001 The safe use of portable and mobile oxy-fuel gas systems for welding, cutting, heating allied processes.