Why Custom Decals Matter in Manufacturing

A

From marking equipment with operating instructions to directing material flow, custom decals provide a simple yet effective solution to a wide range of challenges on the factory floor.

Enhancing Efficiency and Organization

Imagine walking into a large manufacturing facility with rows of machines and countless components. Without clear labeling, employees could easily waste time searching for tools or misplacing parts. Customized labels help resolve these issues by clearly marking:

Machine controls and settings

Tool storage areas

Raw material and finished product locations

Maintenance zones

By having these visual indicators in place, workers spend less time asking questions or making assumptions, which significantly boosts operational efficiency.

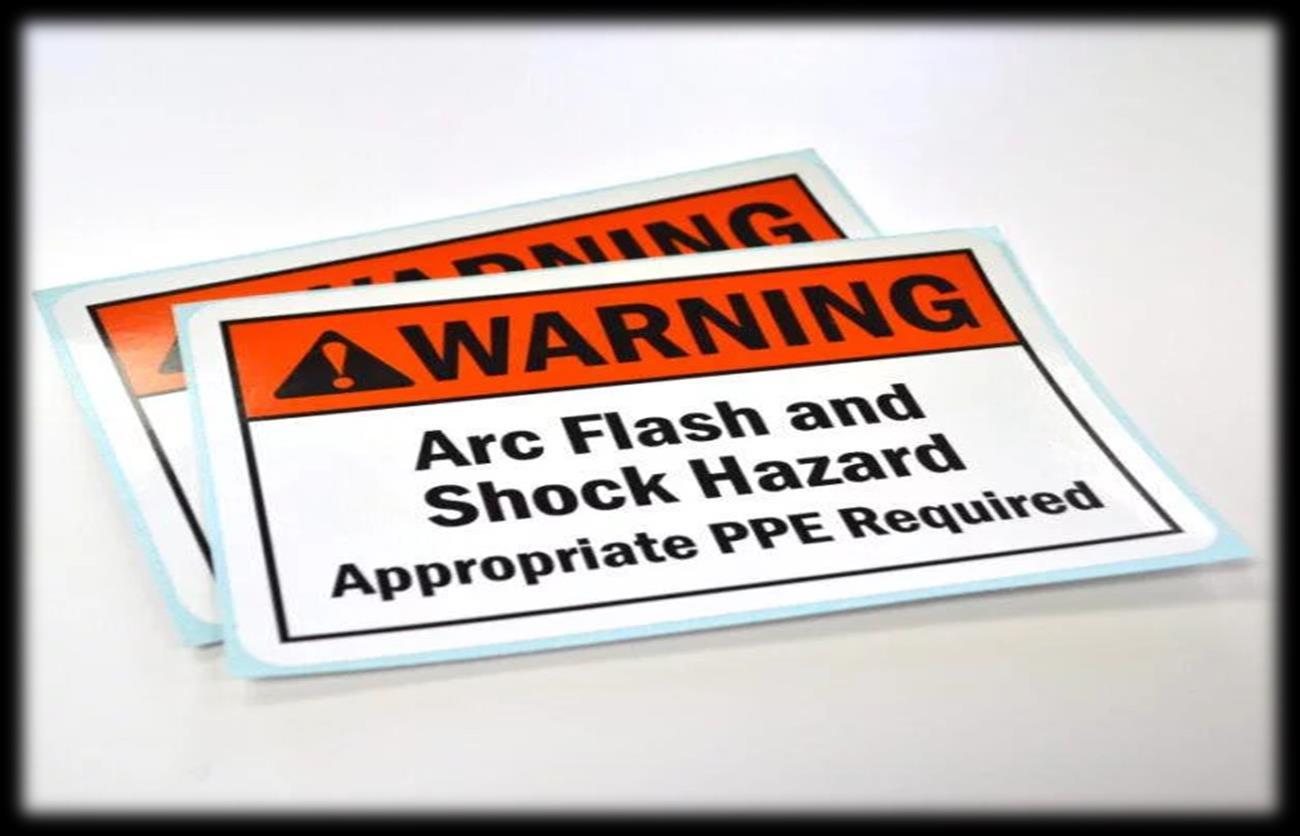

Boosting Safety with Warning Decals

Safety is paramount in any industrial environment. Heavy machinery, electrical components, and hazardous materials all pose risks if not handled correctly. Warning decals serve as immediate, eye-catching alerts for workers. Whether it's a “High Voltage” sign or a “Wear Safety Goggles” reminder, these decals help enforce compliance with safety protocols.

What makes them even more effective is the ability to customize them based on the specific risks present in a facility. Rather than relying on generic signs, there are many companies which are investing in custom industrial labels that directly address their unique challenges, improving workplace safety across the board.

Supporting Compliance and Standardization

Many industries operate under strict regulatory standards. Non-compliance can lead to fines, legal issues, or worse accidents. Business labels that are customized to meet these standards not only ensure compliance but also contribute to a well-organized and standardized production environment.

These labels can include:

Batch numbers

Inspection dates

Calibration data

Barcodes for traceability

Having this information displayed with custom decals means auditors and employees alike can easily verify compliance, helping to maintain quality control and reduce the risk of costly mistakes.

Improving Communication in Multilingual Workforces

In global or culturally diverse workplaces, language barriers can slow down processes and create safety hazards. Visual communication through icons, color codes, and simple graphics on decals design helps bridge this gap. Custom decals can be designed to include both text and universal

symbols, ensuring everyone, regardless of their native language, understands what is being conveyed.

This level of inclusivity not only streamlines production but also fosters a safer and more collaborative working environment, enhancing the overall service quality within the facility

Durable Solutions for Harsh Environments

Production lines often operate under tough conditions high heat, moisture, chemicals, or abrasion. Generic stickers or signs won't survive these environments. That’s why custom industrial labels are made using materials and adhesives engineered for durability. These labels are designed to resist wear and tear, ensuring they remain legible and intact even under the harshest conditions.

By investing in quality decals, industrial businesses avoid the need for constant replacements and ensure consistent communication over time.

FAQs: About Custom Decals in Production Line Processes

How do custom decals differ from standard labels?

These custom decals are tailored to specific needs whether it's size, shape, color, content, or material. Unlike off-the-shelf labels, they address unique challenges and branding requirements within a production line.

Can custom decals be used for digital tracking?

Yes, many customized labels include QR codes or barcodes that integrate with digital systems. This allows for easy inventory management, tracking of components, and quality control procedures.

What materials are best for industrial decals?

Vinyl, polyester, and polycarbonate are commonly used materials. These offer resistance to water, chemicals, and UV exposure, making them ideal for demanding industrial environments.

Are warning decals customizable for specific machinery?

Absolutely. It’s recommended. Warning decals should be customized based on the specific risks and safety requirements of the equipment they are used on.

How often should custom decals be replaced or updated?

While high-quality custom decals last a long time, it’s good practice to inspect them regularly every 6 to 12 months especially in high-wear areas. Replace them if they’re faded, peeling, or damaged to maintain clarity and effectiveness.

Conclusion

The production line is the heart of any manufacturing business, and ensuring its smooth operation is critical to success. While often underestimated, custom decals play a vital role in this process. From improving safety and compliance to enhancing communication and efficiency, their impact is both wide-reaching and essential.

Whether through warning decals that protect workers or custom industrial labels that aid in tracking and organization, the strategic use of customized visual communication can transform production environments for the better. When thoughtfully implemented, these tools contribute not just to streamlining operations but to building a smarter, safer, and more productive workplace. Contact:

E-mail: sales@industrialnameplates.ca