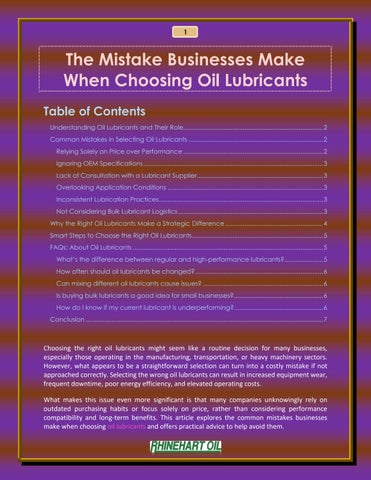

The Mistake Businesses Make When Choosing Oil Lubricants

Understanding Oil Lubricants and Their Role

Oil lubricants are essential fluids used to reduce friction between moving parts in machinery and engines. They serve to minimize wear and tear, control temperature, prevent corrosion, and ensure smooth operation. Beyond these basic functions, modern oil lubricants are engineered to meet specific industry requirements ranging from high-speed manufacturing tools to heavyduty construction equipment.

When selecting lubricants, it’s not just about reducing friction. It's also about ensuring that the product aligns with the equipment’s technical requirements and the environmental conditions in which it operates.

Common Mistakes in Selecting Oil Lubricants

Relying Solely on Price over Performance

One of the most frequent errors businesses make is choosing oil lubricants based on price alone. Low-cost lubricants might seem economical at first but can lead to long-term losses. Inferior or generic lubricants may not provide the protection required by advanced machinery, leading to premature wear, frequent repairs, and even system failure.

High-performance lubricants, although initially more expensive, are often more cost-effective in the long run due to their efficiency, extended equipment life, and reduced downtime.

Ignoring OEM Specifications

Original Equipment Manufacturer (OEM) specifications are provided for a reason—they outline the exact requirements needed for optimum performance. Using lubricants that do not meet these specifications can void warranties, decrease equipment life, and reduce operational efficiency. Businesses must ensure that the oil lubricants they select comply with these standards.

Lack of Consultation with a Lubricant Supplier

Another mistake is not engaging with a knowledgeable lubricant supplier. Many businesses opt to make decisions in-house without leveraging the technical expertise of suppliers. A reputable lubricant supplier can provide insights into the latest innovations, help analyze machinery needs, and suggest appropriate bulk lubricants tailored to specific applications.

Overlooking Application Conditions

Environmental and operational conditions significantly impact lubricant performance. Factors such as temperature extremes, humidity, contamination risks, and load intensity can alter how a lubricant behaves. For instance, a lubricant that works well in a temperate indoor setting may degrade rapidly in an outdoor or high-heat environment. Customizing your oil lubricants to match these conditions is essential.

Inconsistent Lubrication Practices

Even the best oil lubricants will fail to deliver results if they are not applied properly or consistently. Lack of a well-defined lubrication schedule or mixing incompatible products can cause performance issues. Businesses must establish clear lubrication procedures and training for staff to maintain consistency.

Not Considering Bulk Lubricant Logistics

When purchasing in large quantities, logistics can become an issue. Poor storage practices can lead to contamination, degradation, or leakage. Choosing bulk lubricants should come with a plan for proper storage solutions, delivery schedule, and usage tracking. A good lubricant supplier will help with storage recommendations and provide support for handling and safety practices.

Why the Right Oil Lubricants Make a Strategic Difference

Making a well-informed decision when it comes to oil lubricants isn’t just about preserving equipment it’s about optimizing your entire operation. Businesses that take lubrication seriously often experience improvements that ripple across departments, from procurement to production.

Here are some:

Protect Capital Equipment: Proper oil lubricants extend equipment life, reducing replacement costs and maximizing ROI.

Simplify Supply Chain: Using standard bulk lubricants across operations streamlines procurement and inventory.

Ensure Reliable Operations: Correct lubrication reduces breakdowns and keeps machines running consistently.

Gain Maintenance Insights: High-performance lubricants often support oil analysis, enabling predictive maintenance.

Boost Brand Reputation: Minimizing downtime helps meet deadlines and maintain product quality, enhancing customer trust.

Smart Steps to Choose the Right Oil Lubricants

To avoid common pitfalls and make oil lubricants a competitive advantage, companies should follow a clear decision-making framework. Here’s a step-by-step guide:

Know Your Equipment: Identify critical machines and their usage levels to match lubricant needs.

Assess Operating Conditions: Consider temperature, humidity, load, and contamination risks.

Review Technical Data: Check TDS/SDS for viscosity, compatibility, and safety details.

Test for Compatibility: Ensure new lubricants work with existing oils and machine materials.

Work with Experts: Choose a lubricant supplier that offers technical support and equipment audits.

Standardize Lubrication Practices: Create clear procedures for storage, handling, and application.

Track Results: Monitor key metrics like wear, temperature, and efficiency to measure lubricant performance.

FAQs: About Oil Lubricants

What’s the difference between regular and highperformance lubricants?

High-performance lubricants are formulated with advanced additives and synthetic bases that offer superior protection, longer service intervals, and better resistance to extreme conditions compared to regular lubricants.

How often should oil lubricants be changed?

The change interval depends on equipment type, operating environment, and the lubricant used. Always follow OEM guidelines and monitor oil conditions for best results.

Can mixing different oil lubricants cause issues?

Yes. Mixing different types, especially those with incompatible additives, can lead to chemical reactions that degrade performance or damage equipment. Always consult with your lubricant supplier before switching or mixing.

Is buying bulk lubricants a good idea for small businesses?

Not always. Bulk purchasing makes sense when there’s sufficient usage to prevent oil from expiring in storage. Smaller businesses should assess consumption rates and storage capacity before committing to bulk orders.

How do I know if my current lubricant is underperforming?

Signs include increased equipment noise, overheating, leaks, reduced efficiency, or more frequent breakdowns. Oil analysis can provide a clearer picture of lubricant health.

Conclusion

The selection of oil lubricants is far more critical than many businesses realize. A careless decision based on habit, price, or lack of information can severely impact machinery health, operating costs, and overall productivity. Businesses must shift from a short-term, price-focused approach to one grounded in performance, compatibility, and expert guidance.

To avoid costly mistakes, companies should collaborate with a qualified lubricant supplier, respect OEM specifications, and embrace high-performance lubricants when appropriate. Even small improvements in lubrication strategy can yield significant benefits in efficiency, reliability, and cost savings. In today’s competitive environment, choosing the right oil lubricants is not just a maintenance decision it’s a strategic investment in your business’s future.

We're here to help — get in touch today. Contact: 8017569681 E-mail: info@rhinehartoil.com