Industrial equipment requires precise identification for safety, operational efficiency, and regulatory compliance. Nameplates play a crucial role in this process by providing essential information such as model numbers, serial numbers, operational guidelines, and safety warnings. Proper labeling ensures seamless maintenance, efficient troubleshooting, and enhanced workplace safety. Without accurate identification, mismanagement of equipment can lead to operational delays and potential hazards.

Importance of Nameplates for Industrial Equipment

Identification and Traceability

Nameplates help in identifying machinery and equipment, ensuring that workers and maintenance personnel can easily access relevant details. These identification markers include numbering tags that streamline inventory management and equipment tracking, reducing errors in operations. Proper traceability allows quick resolution of technical issues and ensures compliance with industry standards. With clear labeling, industries can optimize workflows and reduce downtime caused by equipment misidentification.

Safety and Compliance

Industrial environments require strict adherence to safety regulations. Properly labeled equipment ensures compliance with industry standards, reducing the risk of accidents. Customized nameplate help display warnings, operational instructions, and emergency shutdown procedures, keeping personnel informed and safe.

Durability and Reliability

Industrial nameplates must withstand extreme conditions, including high temperatures, chemicals, and heavy wear. Using high-quality materials such as stainless steel, aluminum nameplates, or engraved plastics ensures that the labels remain legible and intact for years.

Email: sales@industrialnameplates.ca

Durable nameplates contribute to long-term cost savings by eliminating frequent replacements. Choosing weather-resistant and corrosion-proof materials further enhances the longevity of industrial nameplate tags.

Types of Nameplates for Industrial Use

Engraved Nameplates

Engraved nameplates are durable and resistant to harsh environments. These are commonly used for control panels, equipment instructions, and asset identification. Laser engraving and chemical etching techniques ensure high precision and longevity. The deep engraving process ensures that markings remain visible even after years of exposure to tough conditions. This makes them ideal for industrial settings with high levels of wear and tear.

Numbering Tags

Numbering tags are essential for asset tracking, inventory control, and identification of individual components. These tags help organize largescale industrial operations by assigning unique identifiers to equipment, ensuring proper documentation and traceability. They allow for quick identification of parts, reducing delays in maintenance and repairs. With an efficient numbering system, industries numbering tags can prevent asset misplacement and optimize resource allocation.

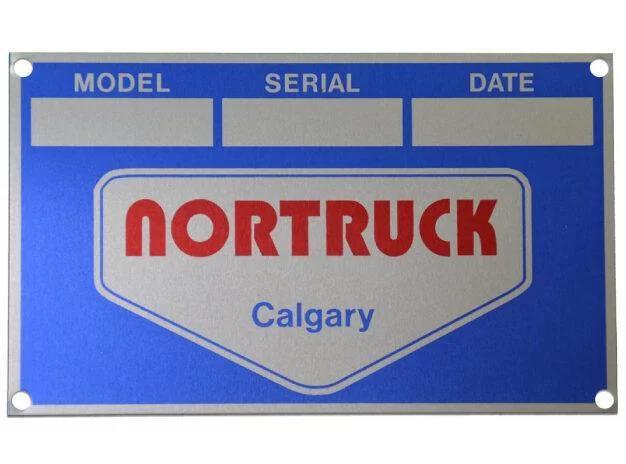

Custom Nameplates

Custom nameplates cater to specific industrial requirements, including material selection, size, and design. Whether for branding, compliance, or operational purposes, a customized name plate ensures that crucial information is effectively displayed. These nameplates may feature barcodes, QR codes, or RFID tags for advanced tracking capabilities.

Warning and Safety Nameplates

Customized name plates with warning labels alert employees to potential hazards, helping reduce workplace incidents. These plates include emergency instructions, voltage ratings, and protective equipment guidelines, ensuring compliance with safety protocols. Properly designed safety labels help workers respond swiftly to emergencies.

Email:

Benefits of Custom Nameplates for Industrial Equipment

Enhanced Organization

By using numbering tags and industrial nameplates, businesses can efficiently categorize and track assets. This systematic organization leads to better maintenance scheduling and equipment longevity. Organized labeling reduces confusion during inventory audits and stock management.

Compliance with Industry Standards

Many industries mandate the use of specific nameplates for regulatory compliance. Customized name plates can be designed to meet OSHA, ANSI, and ISO standards, ensuring that equipment labeling meets legal requirements. Compliance with these standards not only prevents legal penalties but also fosters a safe work environment. Proper documentation and labeling also streamline inspections by regulatory authorities.

Improved Aesthetic and Branding

Besides functionality, a custom name plate can enhance the professional appearance of machinery. High-quality nameplates with company logos and branding elements contribute to a cohesive industrial environment. Branded nameplates create a uniform look across industrial facilities, reinforcing corporate identity. They also improve the presentation of equipment for clients and stakeholders visiting the site.

Email:

Choosing the Right Industrial Nameplates

When selecting nameplates, various factors must be considered to ensure longevity and effectiveness. The choice of material, design, and attachment method should align with the industrial setting and specific application. Investing in the right nameplate solution ensures durability and efficient information dissemination.

Material Selection

Materials like stainless steel, aluminum, and polycarbonate offer durability and resistance to environmental factors. Stainless steel is corrosion-resistant, making it ideal for harsh conditions, while aluminum is lightweight and versatile. Choosing the right stainless steel material extends the lifespan of the nameplate and reduces maintenance costs.

Mounting and Adhesion Methods

Different mounting options, such as adhesive backing, rivets, or screws, should be chosen based on the surface and application. A securely attached nameplate ensures long-term usability. Adhesive-backed nameplates work well for smooth surfaces, while riveted options are more suited for rugged industrial settings.

Maintenance and Care of Industrial Nameplates

Proper maintenance extends the lifespan of numbering tags and nameplates. Regular cleaning prevents dirt and grime buildup, ensuring readability. Harsh chemicals should be avoided on printed nameplates to prevent fading. Periodic inspections can identify potential damage and allow for timely replacements. Investing in protective coatings further enhances nameplate durability and readability over time.

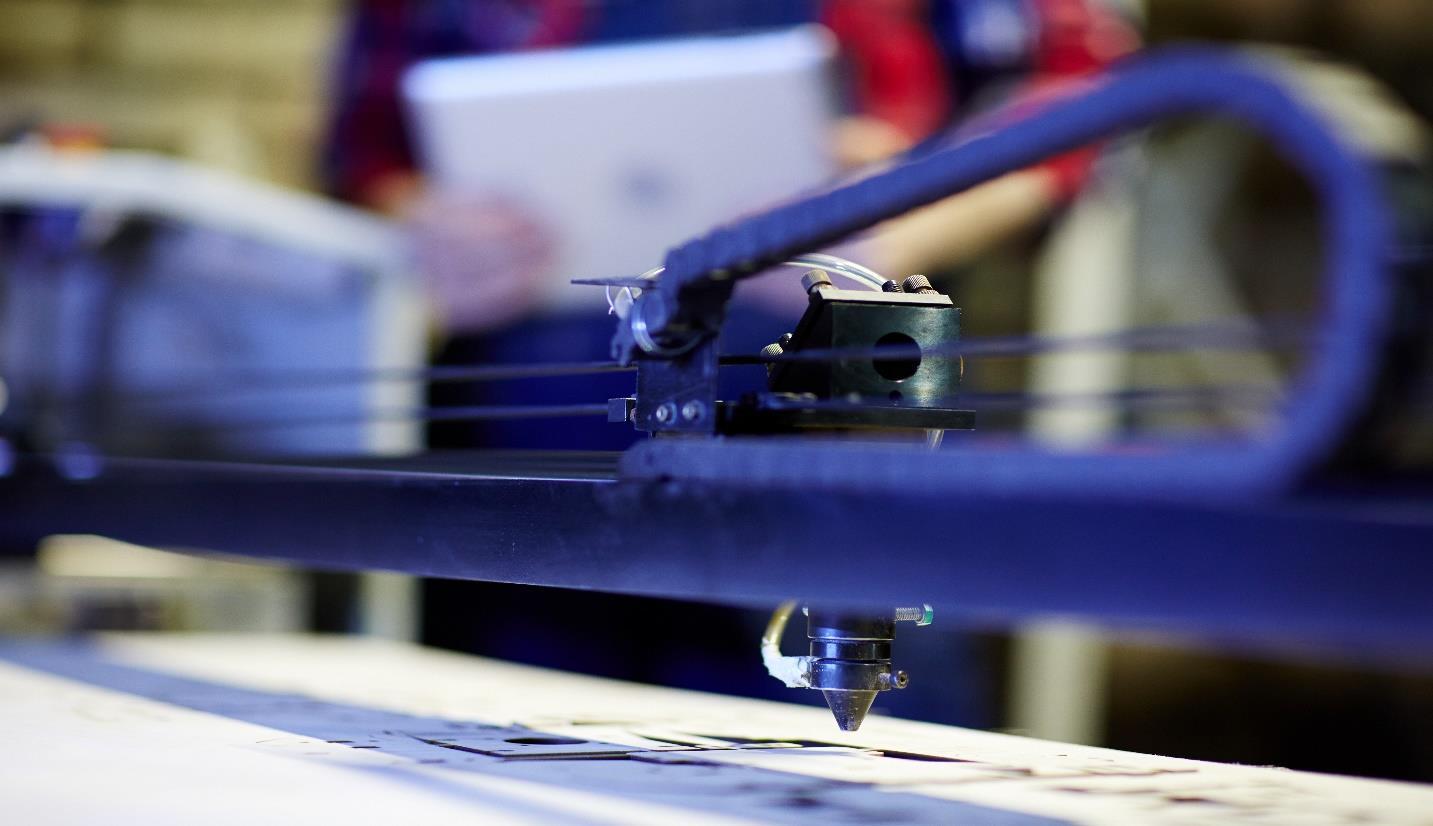

Printing and Engraving Techniques

Laser engraving, embossing, and custom screen printing are common methods used for creating industrial nameplates. Each technique has its advantages, depending on the required durability and environmental exposure. Laser engraving provides permanent markings that withstand extreme wear. Embossing adds texture, making nameplates easier to read under different lighting conditions.

Customization Options

A customize nameplate can include color coding, barcodes, and special coatings for enhanced readability. Selecting the right customization label options ensures that the nameplates fulfill specific industrial needs.

Email:

Customization enhances equipment organization and efficiency while improving brand recognition. By incorporating anti-tamper features, industries can prevent unauthorized modifications to equipment details.

FAQs

What are the common materials used for industrial nameplates?

Industrial nameplates are typically made from stainless steel, aluminum, brass tags, and polycarbonate. These materials offer durability and resistance to environmental conditions.

How do customized nameplates improve safety?

Customized nameplates display crucial safety information, including operational instructions and hazard warnings, reducing the risk of workplace accidents and ensuring compliance with safety standards.

What are numbering tags used for?

Numbering tags help with asset tracking, inventory management, and equipment identification. They provide unique identifiers to industrial equipment, simplifying record-keeping and maintenance.

Can nameplates be used in extreme conditions?

Yes, industrial nameplates are designed to withstand extreme temperatures, moisture, chemicals, and heavy-duty use. High-quality materials and engraving advanced techniques enhance their durability.

Conclusion

Industrial nameplates play a critical role in equipment identification, safety, and compliance. Numbering tags, customized nameplates, and other identification markers enhance operational efficiency and workplace safety. Choosing the right custom industrial labels, and maintenance practices ensures long-lasting and effective nameplates. By investing in high-quality nameplates, industries can improve organization, adhere to regulations, and create a safer work environment.