Maximize Efficiency with the Ultimate Roll Paper Cutter Tool

For businesses involved in printing, packaging, or any industry requiring the cutting of paper, the roll paper cutter is an indispensable tool. With its ability to streamline the cutting process, reduce waste, and improve productivity, investing in the ultimate roll paper cutter tool can transform how your business operates. In this article, we will explore how you can maximize efficiency by incorporating a high-quality roll paper cutter into your workflow.

What Is a Roll Paper Cutter?

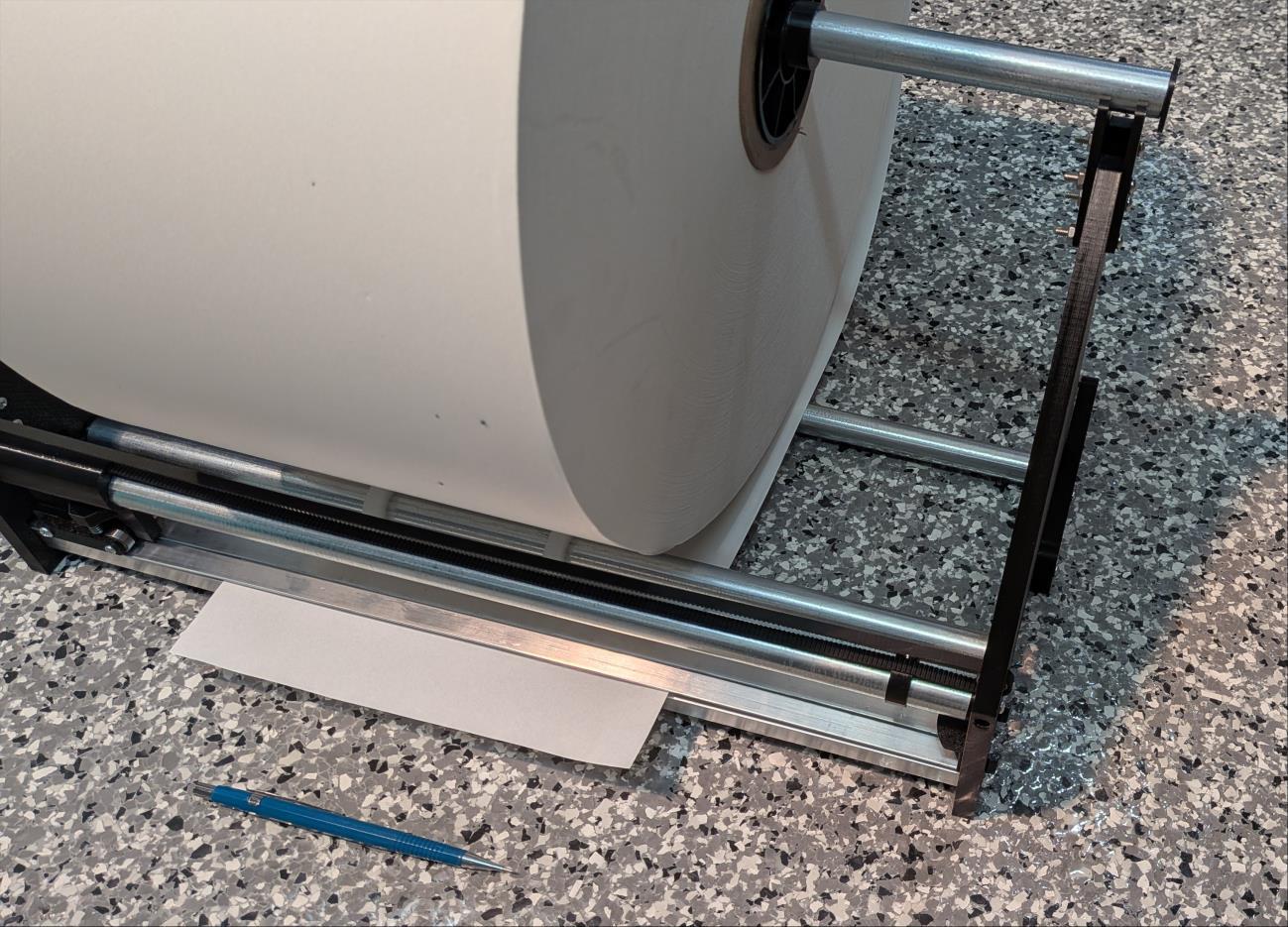

A roll paper cutter is a machine designed to cut large rolls of paper into smaller, more manageable sheets. These machines are essential for businesses that need to convert rolls of paper into specific sizes, whether for printing, packaging, or other industrial applications. With a roll paper cutter, businesses can achieve precise cuts in a fraction of the time it would take to do so manually

The Roll To Sheet Cutting Machine is a popular option for companies that require high-precision cutting for their paper products. This machine offers an automated solution for cutting large rolls of paper into sheets, ensuring consistent quality and size. By automating the process, businesses can significantly reduce human error and the time it takes to cut paper, ultimately leading to improved efficiency and lower production costs

How Does a Roll Paper Cutter Work?

Roll paper cutters operate by feeding a roll of paper into the machine, where it is unrolled and cut into sheets based on preset measurements. Depending on the model, the machine may use different mechanisms for cutting. The roll to sheet cutting machine uses rotary blades or guillotine-style cutters to slice through the paper accurately.

These machines come with adjustable settings that allow businesses to cut paper into various sizes, whether you need sheets of a specific length, width, or both. Many modern roll paper cutters also feature automatic feeding systems, which help streamline the process by ensuring that the paper is fed into the machine smoothly and without manual intervention. This helps improve productivity and reduces the need for manual labor.

Benefits of Using an Efficient Roll Paper Cutter Tool

Boosted Productivity and Speed

One of the most significant advantages of using a roll paper cutter is the boost in productivity. These machines are designed to perform high-volume cutting at a much faster pace than manual methods. What would take hours of manual labor can be completed in a matter of minutes with a roll paper cutter. This increase in speed allows businesses to handle larger orders, meet tight deadlines, and enhance overall throughput.

Moreover, the Roll To Sheet Cutting Machine eliminates the need for manual measurements and adjustments, which are common sources of delays in traditional cutting methods. With preset controls, businesses can ensure that every cut is made to the correct specifications without the need for constant oversight, resulting in smoother operations and fewer delays.

Reduced Waste and Improved Accuracy

Another benefit of selecting a CNC paper roll cutter is the reduction in material waste. When cutting paper manually, it’s easy for errors to occur, resulting in uneven cuts and wasted paper. A roll paper cutter, on the other hand, ensures that every cut is precise, reducing the likelihood of material waste. This can lead to cost savings and more efficient use of resources.

The Roll To Sheet Cutting Machine ensures that the paper is cut consistently, so businesses don’t need to worry about varying sizes or discrepancies in the final product. By reducing waste and improving accuracy, businesses can enhance the quality of their products and reduce operational costs

Cost-Effective Solution

While the initial investment in a roll paper cutter may seem significant, the long-term cost savings are undeniable. By automating the cutting process, businesses can reduce labor costs and increase overall production capacity. The machine’s speed and accuracy help minimize downtime and reduce the need for manual intervention, which translates into lower labor costs over time

In addition, roll paper cutters can help businesses save money by allowing them to purchase paper in bulk rolls rather than pre-cut sheets. Bulk rolls are often more affordable, and the ability to cut paper to the required size as needed ensures that businesses only pay for what they use, further contributing to cost savings.

Versatility and Flexibility

Roll paper cutters are versatile tools that can handle a wide range of paper types and sizes. From standard office paper to specialty materials used in packaging or printing, these machines are capable of cutting different materials with ease. The Roll To Sheet Cutting Machine, for instance, is designed to work with various types of paper, from plain and coated to heavier weights used for packaging applications.

The flexibility of these machines allows businesses to tailor their cutting processes to meet specific needs. Whether you need to cut paper into standard sheets, custom sizes, or even perforated sheets, a roll paper cutter provides the versatility required to handle a wide array of tasks.

Ease of Operation and Maintenance

Modern roll paper cutters are designed with user-friendliness in mind. Many machines come with intuitive controls and touchscreens that allow operators to set cutting parameters easily. This ease of use reduces the learning curve for new employees and minimizes the chances of operator errors, ensuring that the cutting process remains efficient and error-free.

In terms of maintenance, roll paper cutters are generally low-maintenance machines. Regular tasks like cleaning and blade replacement can be performed by in-house personnel, minimizing downtime and keeping the machine running smoothly. The durability and reliability of these machines make them an excellent long-term investment for businesses looking to improve their cutting processes.

How to Choose the Right Roll Paper Cutter

When selecting a roll paper cutter for your business, there are several factors to consider. The first thing to evaluate is the volume of paper cutting your business requires. For high-volume operations, the Roll To Sheet Cutting Machine is an ideal choice due to its high capacity and ability to handle large rolls efficiently.

Other factors to consider include the type of paper you typically work with, the required sheet sizes, and any specific features you may need, such as automatic feeding or digital controls. You’ll also want to ensure that the cutter is compatible with your existing equipment and that it can handle the paper thickness and material type you use most often.

Maintenance and Durability

Durability is another important consideration. You want a roll paper cutter that can withstand the demands of your business. Look for machines made with high-quality materials and that come with warranties or service packages that cover any potential issues. Additionally, consider how easy it is to maintain the cutter, as regular upkeep is essential to keeping the machine running at peak performance.

What are the advantages of using a roll paper cutter over manual cutting?

A roll paper cutter provides faster, more accurate cuts, reducing labor costs and minimizing waste. It also increases productivity by automating the cutting process and ensuring consistent, precise results

Can a roll paper cutter handle different paper types?

Yes, roll paper cutters are versatile and can handle a wide variety of paper types, including plain, coated, and specialty papers. Some models can also cut other materials like plastic or film.

How can a roll paper cutter improve production efficiency?

By automating the cutting process, a roll paper cutter significantly speeds up production times and eliminates the need for manual labor. It ensures accurate cuts and reduces downtime, allowing businesses to complete more orders in less time

Is the Roll To Sheet Cutting Machine suitable for high-volume operations?

Yes, the Roll To Sheet Cutting Machine is designed for high-volume operations. It can efficiently handle large rolls of paper, cutting them into sheets with high precision and speed, making it ideal for businesses with large production demands.

What should businesses consider when purchasing a roll paper cutter?

When purchasing a roll paper cutter, businesses should consider factors such as the volume of cutting required, the types of paper used, the required sheet sizes, and the machine’s ease of operation and maintenance. Durability and warranty are also important factors to ensure longterm investment.