How a CNC Paper Roll Cutter Improves Cutting Accuracy and Speed

Accuracy and speed are essential in any production environment that works with paper materials. As demand grows for clean, consistent, and high-volume output, businesses increasingly rely on advanced solutions that deliver reliable performance. A CNC paper roll cutter plays a major role in meeting these expectations by offering highly controlled cutting technology that reduces errors and enhances operational efficiency. With the integration of smarter systems and automated controls, this equipment helps streamline workflows and supports consistent production.

Lists of Contents

Modern facilities no longer depend solely on manual adjustments or conventional devices that struggle to maintain uniformity. Instead, technology-driven machines now ensure every cut meets exact specifications without sacrificing speed. This major shift in how paper materials are processed has made the paper roll cutting machine a preferred choice for industries aiming to achieve precise, repeatable results. As expectations for productivity continue to rise, tools like the CNC paper roll cutter are becoming even more vital in day-to-day operations.

How Automation Enhances Cutting Accuracy

Automation is central to improving accuracy during the cutting process. A CNC paper roll cutter uses programmed instructions to control blade movement and pressure with exceptional precision. Because adjustments are handled digitally, there is little room for human error. This consistency ensures every sheet meets the desired length, width, and alignment requirements.

The automated system also maintains stable cutting paths even when handling large volumes of material. Traditional setups often lead to inconsistencies caused by manual effort or repetitive tasks. In contrast, a roll cutter machine provides exact control, preventing irregular edges or variations. This reliable performance means far less material waste and a smoother overall workflow.

The Role of Technology in Increasing Cutting Speed

Speed is just as important as accuracy in high-demand production settings. A paper roll cutting machine equipped with digital controls can complete jobs significantly faster than manual systems. Automation eliminates delays caused by constant repositioning or adjustments. Instead, the roll paper cutter performs rapid and continuous cuts that keep production moving efficiently.

Technology also optimizes how the machine handles materials. Sensors, tension management systems, and automated feeding mechanisms help maintain smooth motion throughout each cut. With fewer interruptions, the roll to sheet cutter can handle long runs while maintaining sharp precision. This makes it easier for businesses to meet tight deadlines or manage shifting workloads without sacrificing quality.

Why Consistency Matters in Paper Processing

Consistency ensures that each piece produced matches the required standards. For industries that depend on uniform sizes or clean edges, a CNC paper roll cutter offers dependable performance. When cuts vary, it can impact product quality, packaging, and downstream operations. Automated cutting prevents these inconsistencies by maintaining the same settings and measurements throughout the entire process.

A roll paper cutter reduces the likelihood of misalignment, distortion, or incomplete trimming. Since parameters remain stable from start to finish, the machine supports steady results that build reliability. This dependable performance helps reduce rework, improves quality control, and supports a more streamlined production environment.

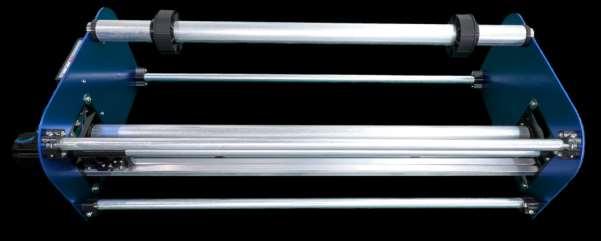

Krexil 60x12 Automated Roll Cutter

One of the advanced solutions available in the market is the Krexil 60x12 Automated Roll Cutter, designed to deliver precision, reliability, and high production efficiency. Built with a modern control system and durable components, it supports smooth cutting operations for various industrial applications. It is engineered for facilities that need dependable performance and accurate sheet conversion on a consistent basis.

Key Features:

Large 60-inch roll handling capacity for versatile material processing

High-precision cutting system engineered for clean and uniform sheet output

Automated controls for smooth, efficient, and user-friendly operation

Heavy-duty frame construction designed for long-term durability

Advanced alignment technology to maintain accuracy during continuous cutting

Low-maintenance design that reduces operational downtime

Supports multiple paper types and thicknesses for flexible production uses

This machine integrates seamlessly into modern production workflows and reflects the ongoing shift toward smarter, automated processes.

Improving Efficiency through Smart Controls

Smart controls integrated into a roll cutter machine simplify operation and significantly enhance efficiency. Operators can pre-program different settings based on the material type, cutting length, or processing speed. Once the machine begins running, it follows those commands without constant supervision. This approach saves time and reduces labor effort.

Because smart controls help maintain smooth processing, the roll to sheet cutter experiences fewer stoppages and requires fewer manual corrections. This uninterrupted workflow promotes higher productivity while ensuring long-term machine stability. The easier setup and operation also minimize training time for new staff, making the equipment a practical solution for growing businesses.

How a CNC Paper Roll Cutter Supports Versatile Applications

Modern industries often require versatile tools that can handle different material types and sizes. A CNC paper roll cutter fits this need by offering flexible cutting capabilities It can process various paper grades, coated materials, and specialty products with equal precision. This adaptability makes it suitable for packaging, printing, labeling, and other commercial applications.

The roll cutters are designed to handle multiple cutting styles and lengths, allowing operators to shift quickly between production tasks. This flexibility simplifies scheduling and reduces downtime. By supporting multiple applications, the paper roll cutting machine helps facilities manage diverse projects without needing separate equipment.

Reducing Waste and Increasing Material Utilization

Efficient material use is essential in any production environment, and one of the major benefits of a CNC paper roll cutter is its ability to reduce waste. The precision cutting mechanism ensures that each section is trimmed accurately, minimizing excess scrap. When the roll cutter machine maintains exact measurements, the amount of unused or discarded material decreases significantly.

Improved material utilization leads to lower costs and better sustainability practices. With cleaner cuts and fewer mistakes, businesses can make the most of their resources. This advantage becomes especially valuable during high-volume production, where even small reductions in waste can have a major impact on overall efficiency.

Safety and Reliability in Modern Cutting Systems

Advanced machines are designed not only for performance but also for safety. A roll paper cutter includes features that prevent accidental contact with the moving blade and protect the operator during setup. Automated systems reduce the need for handson adjustments, lowering the likelihood of injury.

The technology also supports long-term reliability. Consistent blade pressure, automated calibration, and digital controls help maintain stable operation over time. Because the CNC paper roll cutter requires less manual intervention, it experiences fewer operational risks. This combination of safety and dependability makes it a trusted choice for demanding production environments.

Enhancing Workflow Efficiency with Automated Integration

Integration with other production systems can further boost workflow efficiency. A modern roll to sheet cutter often links seamlessly with feeding units, stacking equipment, and packaging systems. This automation helps maintain consistent production flow from start to finish.

With synchronized operations, the roll cutters minimize bottlenecks and ensure that each section of the process moves at the correct pace. This cohesive setup reduces labor needs and shortens turnaround times. By supporting complete integration, the roll cutter machine strengthens overall production performance.

Why Modern Businesses Choose CNC Cutting Solutions

Many organizations choose a CNC paper roll cutter because it helps them remain competitive in fast-paced markets. The combination of accuracy, speed, and automation makes it a practical investment for long-term growth. As customer expectations evolve, businesses benefit from tools that support consistent output and high-quality results.

The paper roll cutting machine serves as a dependable solution that adapts to changing production demands. With strong cutting performance, lower waste, and enhanced automation, it allows companies to meet modern operational standards.

FAQs

What materials can a CNC paper roll cutter handle?

A CNC paper roll cutter can process different types of paper, coated materials, specialty sheets, and other flexible substrates depending on the machine's design.

Does a roll cutter machine require extensive maintenance?

Most systems need basic cleaning and routine checks, and the roll cutter machine minimizes the need for frequent manual adjustments.

Can a roll to sheet cutter improve workflow efficiency?

Yes, a roll to sheet cutter enhances workflow by maintaining consistent operation and reducing unnecessary interruptions.

Is a roll paper cutter suitable for large production runs?

A roll paper cutter is ideal for high-volume production because it maintains accuracy and speed with steady performance.

How does automation improve accuracy in roll cutters?

Automation in roll cutters ensures stable blade control, precise cutting paths, and reduced human error throughout the process.