Aluminum nameplates are the unsung heroes of industrial and commercial identification. These rugged, sleek, and highly versatile plates are more than just labels they’re a long-term solution for organization, compliance, safety, and branding.

Why Aluminum Nameplates are more than Just Labels

At first glance, a nameplate may seem like a minor detail. But if your labels fade, peel, or wear off, your operations can suffer. Misidentified assets, safety violations, and regulatory issues all stem from something as seemingly simple as poor labeling.

That’s where aluminum nameplates come in. They’re built to withstand environmental extremes and provide a professional, permanent marking system for your business.

Key Benefits:

Extreme durability: Withstand heat, moisture, abrasion, and UV rays.

Highly customizable: Suitable for logos, barcodes, text, and compliance markings.

Corrosion-resistant: Ideal for marine, outdoor, or industrial environments.

Professional appearance: Elevates brand perception and operational order.

Where You’ll Find Aluminum Nameplates in Action

Aluminum nameplates are used in diverse industries, each with their challenges:

Industry How Aluminum Nameplates Are Used

Manufacturing Machine IDs, safety instructions, serial plates

Healthcare Medical device labeling, sanitized equipment tags

IT & Electronics Server labels, aluminum asset tags, cable identifiers

Transportation VIN tags, regulatory compliance, aluminum identification tags

Energy & Utilities Electrical panel plates, pole tags, inspection markers

Hospitality & Retail Custom aluminum signs, room numbers, brand signage

How Aluminum Nameplates Solve Industry-Specific Labeling Challenges

Rather than focusing on how they’re made, let’s explore how aluminum nameplates solve realworld challenges across industries. From harsh weather conditions to tamper-prone environments, aluminum labeling offers purpose-built solutions for the challenges different sectors face every day.

Problem: Industrial Environments Damage Labels

Solution: Aluminum nameplates resist oil, abrasion, vibration, and heat.

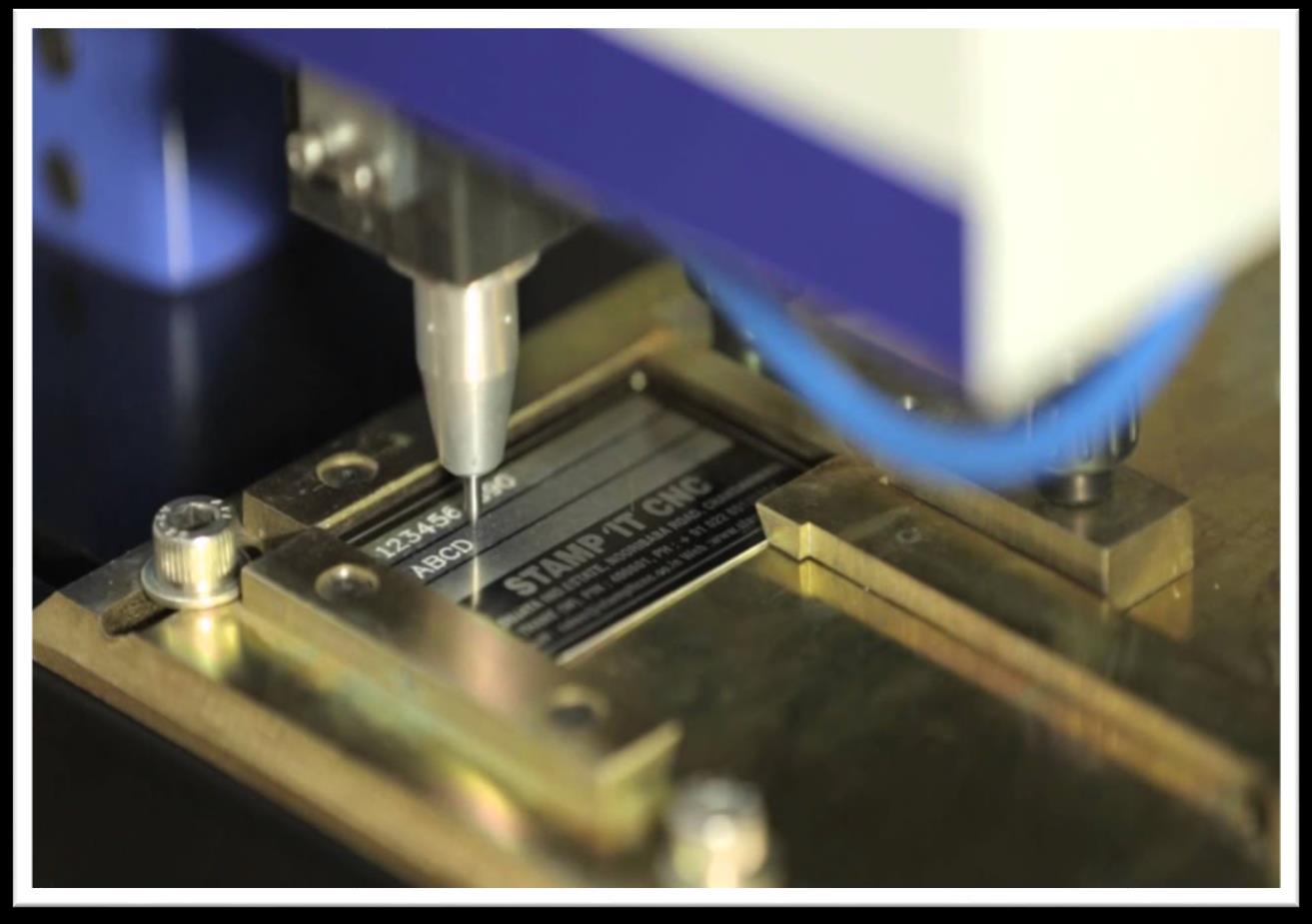

Factories, processing plants, and assembly lines expose labels to physical stress. Unlike stickers or plastic tags that tear or melt, aluminum engraved nameplates remain readable after years of machine wear, cleaning solvents, and temperature changes. Their rugged construction makes them the preferred choice for machinery ID, maintenance schedules, and operating instructions.

Problem: Outdoor Signage Fades and Wears Out

Solution: Anodized aluminum delivers long-term UV and weather resistance.

For facilities with outdoor signage or infrastructure in exposed locations (like utilities, construction, or telecom), custom aluminum signs made with anodized coatings won’t crack,

fade, or rust. They’re excellent for directional signs, hazard warnings, and pole-mounted information built to survive all seasons.

Problem: Asset Tracking Needs Permanence

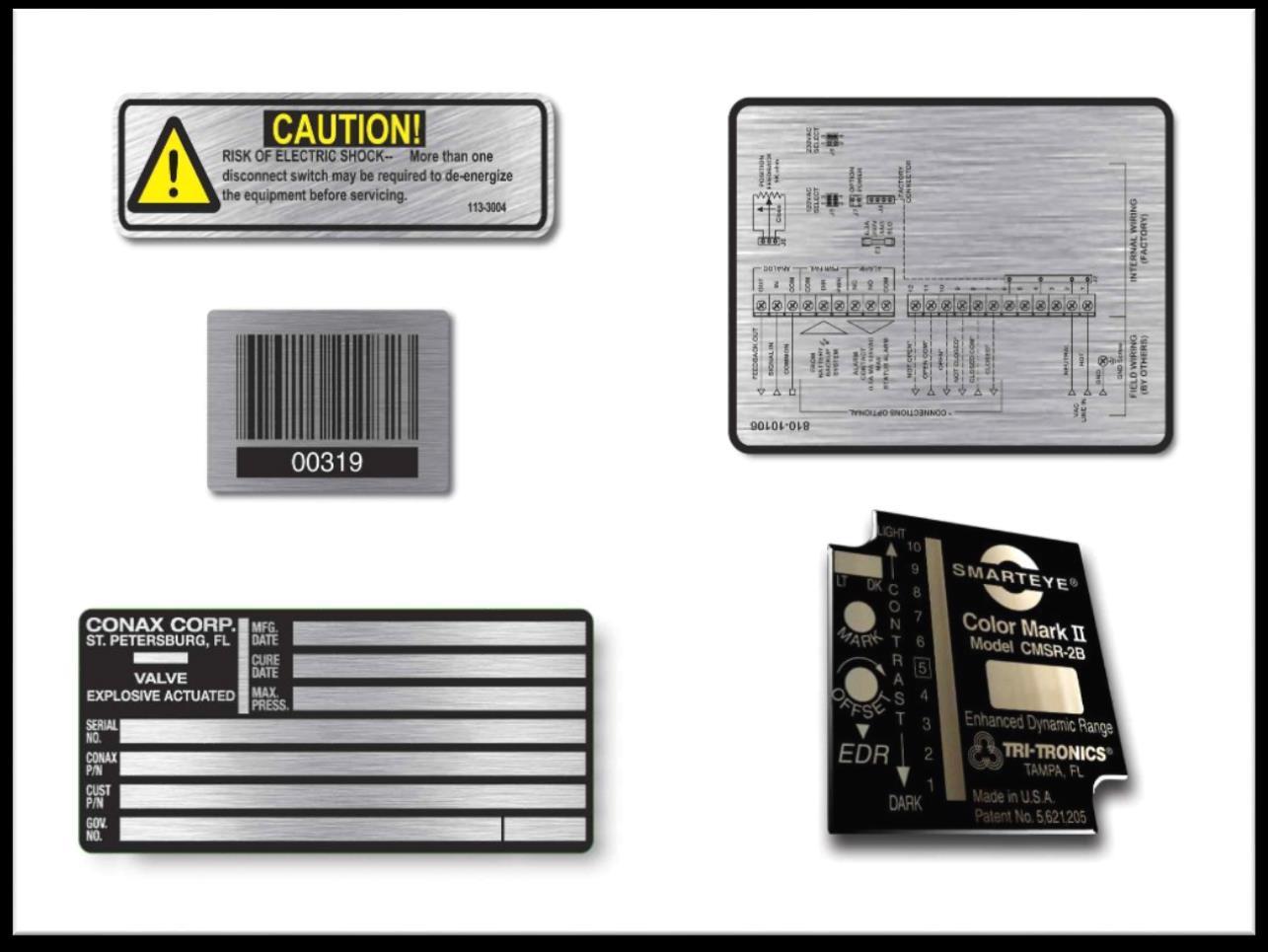

Solution: Tamper-proof aluminum asset tags offer long-term traceability.

IT departments, laboratories, and logistics companies need consistent and secure labeling for expensive equipment. Aluminum asset tags feature sequential numbers, barcodes, and even QR codes. With tamper-evident adhesive or permanent rivets, they ensure assets remain trackable through multiple life cycles, audits, and transfers.

Problem: Chemicals and Cleaners Destroy Labels

Solution: Corrosion-resistant coatings protect vital information.

In environments such as pharmaceuticals, labs, or food production, regular sanitization and chemical exposure are unavoidable. Aluminum nameplates with protective clear coats or anodized finishes resist corrosion from alcohol, acids, detergents, and other aggressive cleaning agents unlike plastics that dissolve or peel.

Problem: Limited Space for Identification

Solution: Compact aluminum tags provide highly readable detail in limited space.

When space is limited on circuit boards, electrical cabinets, or tools aluminum tags can be made incredibly compact without losing legibility. Laser marking ensures even tiny alphanumeric strings or technical codes are permanently readable under magnification, useful for serial data or regulatory info.

Instead of focusing only on how nameplates are made, businesses should focus on what problem they need to solve. Aluminum nameplates are incredibly versatile, and their adaptability to different environmental, technical, and regulatory conditions is what truly sets them apart.

Design Customization: Beyond the Basics

Modern aluminum nameplates are no longer just dull metal plates with stamped numbers. They can be designed to reflect your brand and meet your functional needs

Customizable elements include:

Size and shape.

Serial numbers and barcodes.

Company logos.

QR codes or NFC chips.

Color-coded finishes.

Different mounting options: adhesive, rivet holes, magnetic.

These elements make it easy to use aluminum tags not just for identification, but also for process control, warranty validation, or interactive asset tracking.

Aluminum Nameplates in Harsh Environments

The real test of any labeling solution is how it performs when the going gets tough. Aluminum nameplates stand out because they’re built for extremes.

Condition

High Heat (e.g., ovens, engines)

Performance of Aluminum Nameplates

Withstand temperatures up to 650°C (engraved/anodized types)

UV Exposure (outdoor use) No fading or cracking, even after years in sunlight

Chemical Contact (labs, plants)

Anodized options resist solvents, oils, and corrosive liquids

Humid/Marine Environments No rusting; corrosion-resistant even with saltwater exposure

Abrasion or Impact

Engraving remains intact even when the surface gets scratched

Eco-Friendly and Sustainable Choice

Aluminum isn’t just strong it’s sustainable. It’s 100% recyclable and many manufacturers use recycled aluminum in the production process. By choosing aluminum tags, you reduce plastic waste and opt for a long-term solution that doesn’t require frequent replacement.

Use Case Highlight: Asset Management with Aluminum Tags

Let’s say your organization manages thousands of tools, laptops, or lab equipment. Paper tags wear off. Vinyl labels peel. But aluminum asset tags—engraved with barcodes or QR codes—stick with your assets for life.

With serialized numbering, scanning systems, and tamper-evident features, aluminum asset tagging streamlines audits, reduces loss, and improves accountability. And with magnetic or screw-mounted options, you can even reuse them.

FAQs:

Everything You Wanted to Know About

How long do aluminum nameplates last?

Aluminum Nameplates

Depending on the finish and environment, aluminum nameplates can last 10–20+ years without fading or degrading.

Can aluminum tags be color-coded?

Yes! Anodizing allows for color finishes that help with organization, branding, or safety identification.

Can I order aluminum nameplates in small quantities?

Absolutely. Many suppliers offer low minimum order quantities and full customization for prototypes or limited needs.

What’s better—printed or engraved aluminum nameplates?

Engraved tags are best for durability. Printed options work well for logos and full-color graphics but may be worn in harsh environments.

Can I include QR codes or barcodes on aluminum nameplates?

Yes. Modern printing and engraving methods, backed by expert service, can render scannable codes with high accuracy.

Conclusion: Why Settle for Temporary? Go Aluminum

When labels fail, the cost is more than just inconvenience it can lead to errors, delays, and even safety risks. That’s why industries around the world are investing in aluminum nameplates. They’re the smart, sustainable, and reliable choice for any application that demands longevity and professionalism.

Whether you're looking for custom aluminum signs, aluminum identification tags, or robust aluminum asset tags, one thing is clear aluminum has you covered. Durability meets design. Function meets form. And your labeling challenges meet their match.

Contact:

E-mail: sales@industrialnameplates.ca