timber 2022 Industry Yearbook

TIMBER TECHNOLOGY

Topics include: visual strength grading, timber connections, timber frame construction

TECHNICAL FEATURES

Sustainability: timber and carbon

The durability of CLT

UKCA marking for fire doors

INSPIRATIONAL CASE STUDY

Ibstock Place School Refectory: a grand timber hall with an intricate lattice roof And the winner is: Wood Awards 2021

FIND A SUPPLIER BM TRADA certified companies

“Award winning, Ilulissat Icefjord Centre, is a unique building placed in a breathtaking environment in Greenland. Flame retardant treated oak panels with Woodsafe PRO”

“

“We can still improve - and we will”

I remain unwavering in my belief that wood will be the building material of choice in the future”

- Thomas Bengtsson, founder and CEO Woodsafe Timber Protection

Credits to: Adam Mørk

Credits to: Adam Mørk

timber 2022 Industry Yearbook

TIMBER TECHNOLOGY

Topics include: visual strength grading, timber connections, timber frame construction

TECHNICAL FEATURES

Sustainability: timber and carbon

The durability of CLT

UKCA marking for fire doors

INSPIRATIONAL CASE STUDY

Ibstock Place School Refectory: a grand timber hall with an intricate lattice roof And the winner is: Wood Awards 2021

FIND A SUPPLIER BM TRADA certified companies

Published in 2022 by: Chiltern House, Stocking Lane

Hughenden Valley, High Wycombe

Buckinghamshire HP14 4ND

t +44 (0)1494 569600

e timberadvice@bmtrada.com

w www.bmtrada.com

While every effort is made to ensure the accuracy of the articles included, the company cannot accept liability for loss or damage arising from the information supplied. The opinions expressed do not necessarily represent or reflect the views of the publisher.

All rights reserved. No part of this publication may be reproduced, stored in a retrieval system, or transmitted in any form, by any means, electronic, mechanical, photocopying, recording or otherwise, without the prior permission of the copyright owners.

© 2022 Warringtonfire Testing and Certification Ltd

The publisher gratefully acknowledges the support of the firms whose advertisements appear in this publication. While every care has been taken in compiling this publication, the publisher cannot accept responsibility for any inaccuracies, or for the products or services advertised.

All photographs and illustrations are © Warringtonfire Testing and Certification Limited unless otherwise credited.

Production by:

Open Box Media and Communications

13 Premier House, St Paul’s, Birmingham B3 1RB

t +44 (0)121 200 7820

e inside@ob-mc.co.uk

w www.ob-mc.co.uk

We are committed to sustainable forest management and this publication is printed by Buxton Press who are certified to ISO14001:2015 Standards (Environmental Management System). Buxton prints only with 100% vegetable based inks and uses alcohol free printing solutions, eliminating volatile organic compounds as well as ozone damaging emissions.

07 Welcome: foreword

Providing timber expertise

Welcome to another edition of BM TRADA’s Timber Industry Yearbook and a fresh collection of technical timber articles.

09 News: industry updates

A year of change

Spotlight on 2021 activities and initiatives.

16 Events: Wood Awards

Celebrating communal school life

Highly commended for the Education & Public Sector Award, Ibstock Place School Refectory is a reimagined grand timber hall that offers a soothing visual and aural space for pupils.

20 Events: Wood Awards And the winners are...

A look at those who came top in the 2021 Wood Awards.

Timber technology

22 Advisory service

BM TRADA: technical timber, our experts and services

Ben Sharples gives an overview of expertise provided by the BM TRADA technical timber team.

26 Wood knowledge Timber training: who benefits?

Phil O’Leary explains how BM TRADA’s courses can help companies apply best practice principles.

29 Wood knowledge

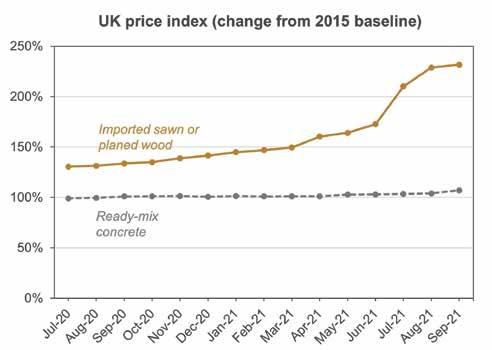

How to become a competent visual strength grader

Nick Clifford explains what visual strength grading is and gives an overview of the specialist training available from BM TRADA.

32 Wood knowledge Specifying and sourcing timber in construction

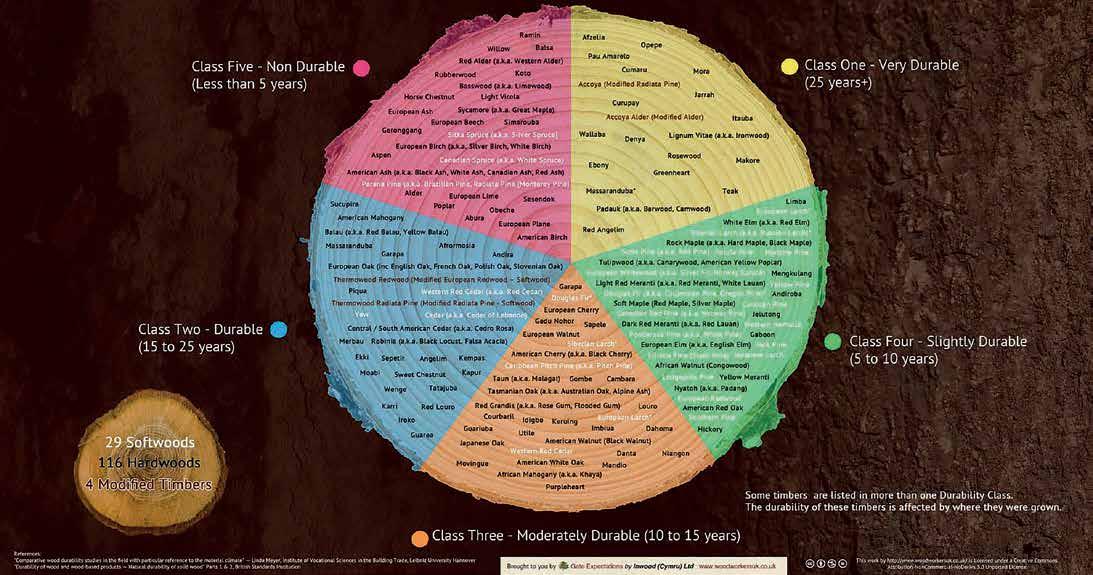

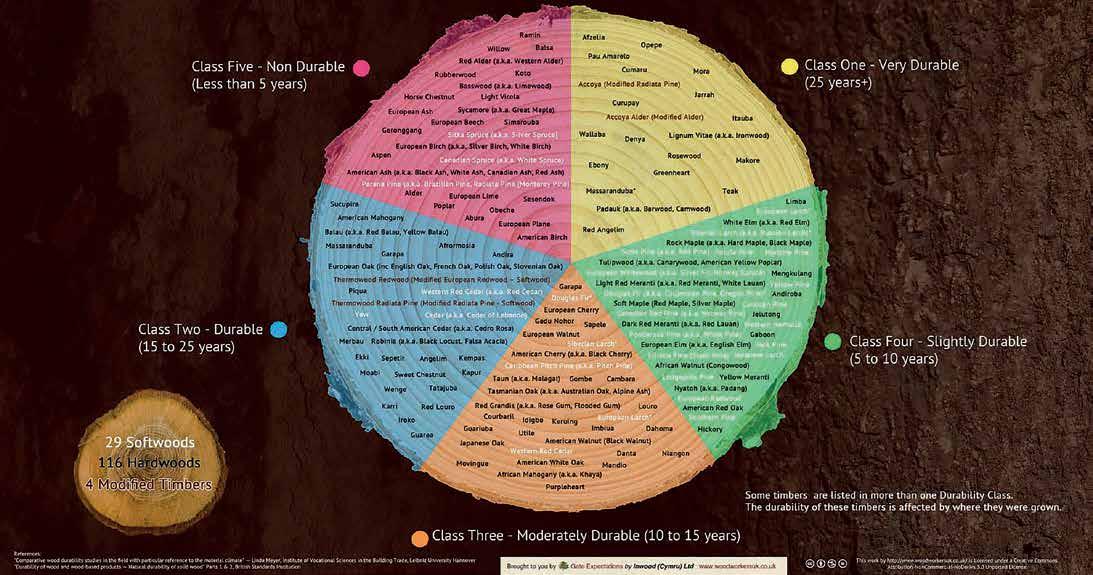

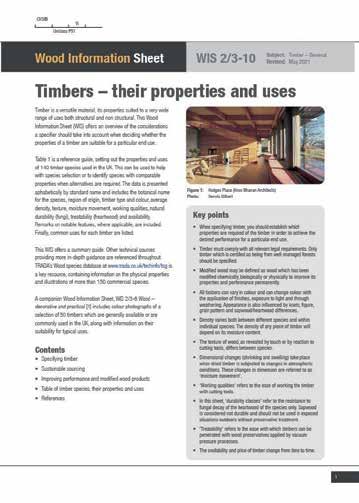

An extract from Wood Information Sheet 2/3-10 Timbers – their properties and uses, which had a major update in 2021.

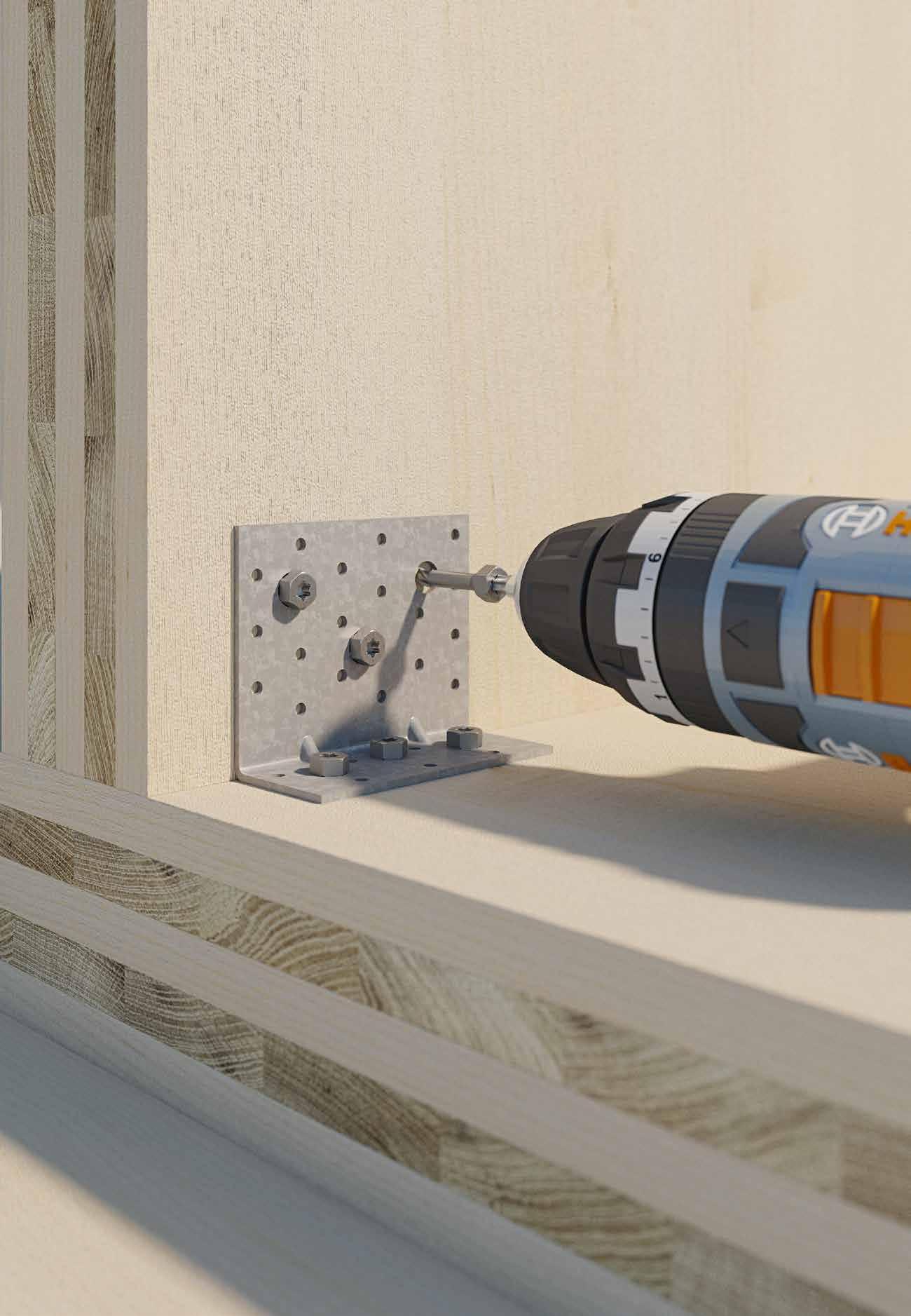

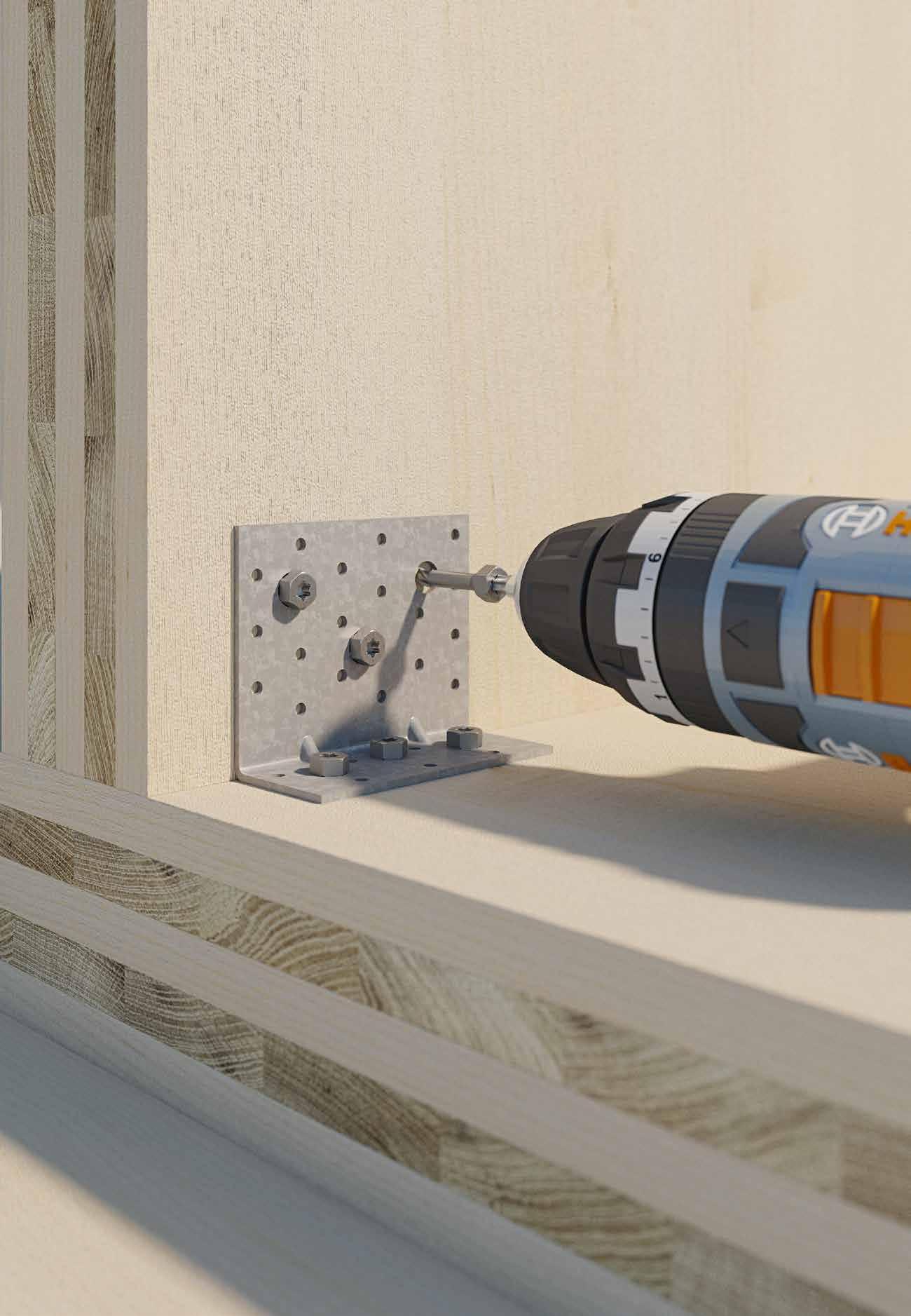

34 Engineering An introduction to timber connections

An extract from BM TRADA’s newest publication series with guidance for engineers.

37 Timber frame The importance of cavity barriers

Robin Lancashire explains the key role of cavity barriers and how they can limit the spread of fire.

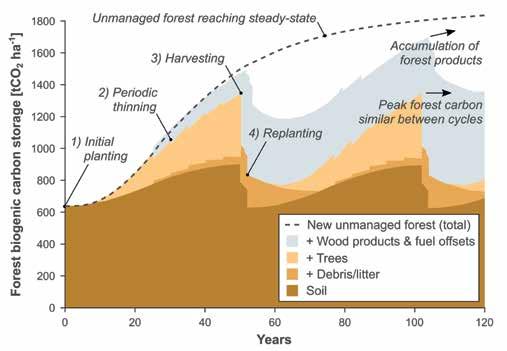

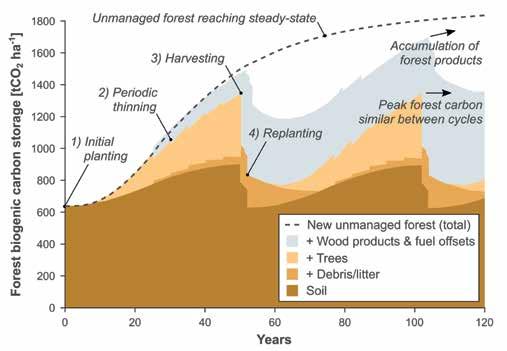

41 Timber structures: sustainability

Storage solutions: timber and carbon

Toby Maclean discusses the key factors relating to the timber carbon store, both in new timber growth and in harvested wood products.

47 Timber structures: sustainability

Are timber structures good for the planet?

Will Hawkins investigates how a sustainably built environment offers carbon benefits.

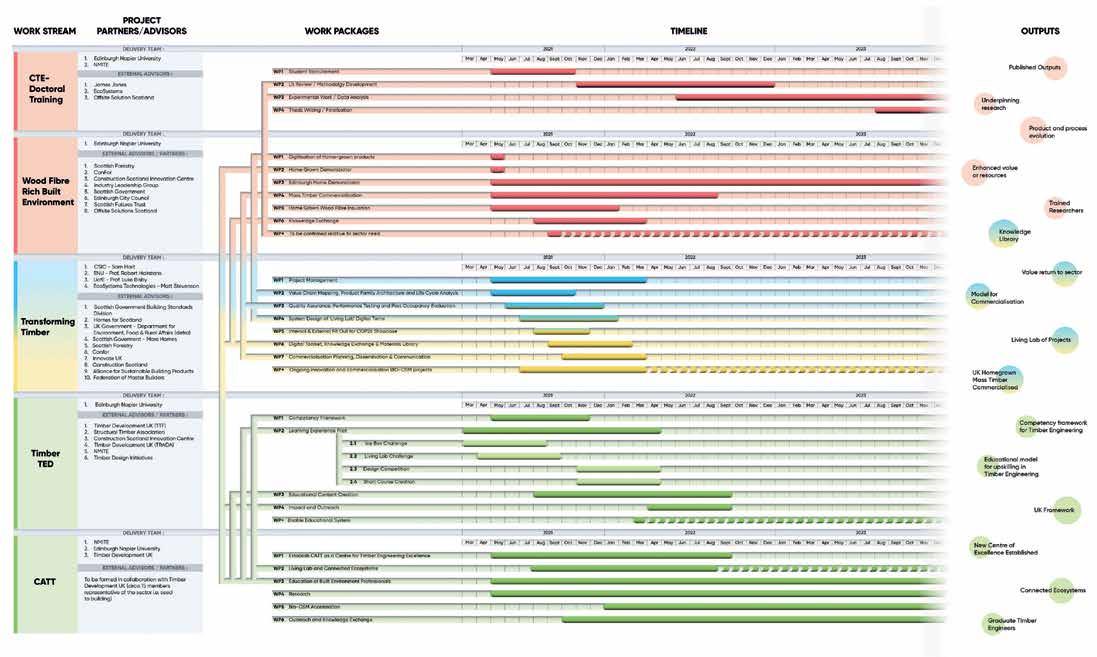

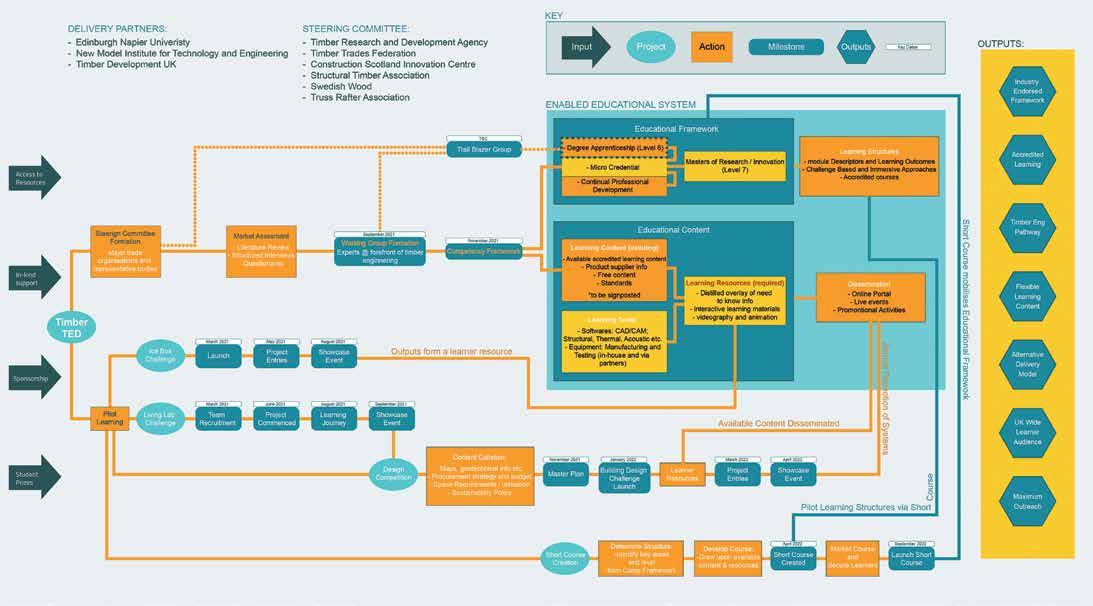

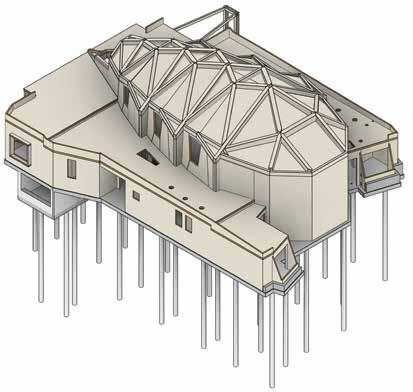

ISBN: 978-1-909594-93-7

Cover image: The Welcome Building RHS Garden Bridgewater

Photo: Peter Cook

54 Timber structures: sustainability

Material matters: low-carbon timber design

Will Arnold considers how the efficient use of timber in construction can contribute to a more sustainable future.

04 | Timber 2022 Welcome Contents

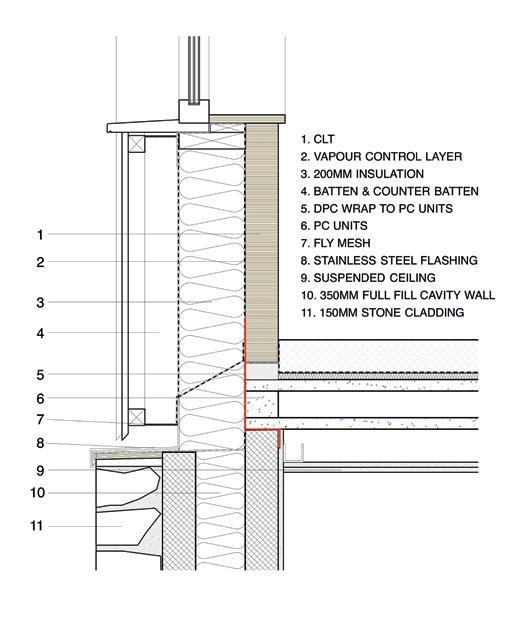

63 Timber structures: sustainability

Affordable low-carbon timber homes: a balancing act Jae Cotterell outlines the challenges of construction budgets versus sustainability.

68 Timber structures: sustainability

Timber structures in building refurbishment

The retention, repair and retrofit of timber building structures has now become a priority to preserve the embodied carbon stored in the building fabric. James Walker describes the skills required.

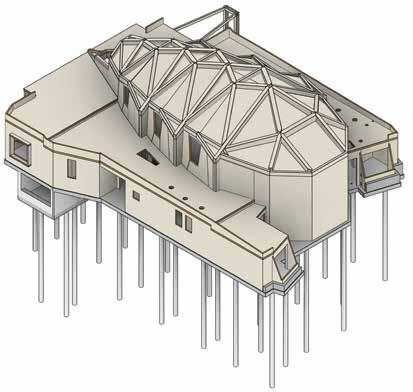

77 Timber structures: off-site construction

Manufacturing a biogenic built environment

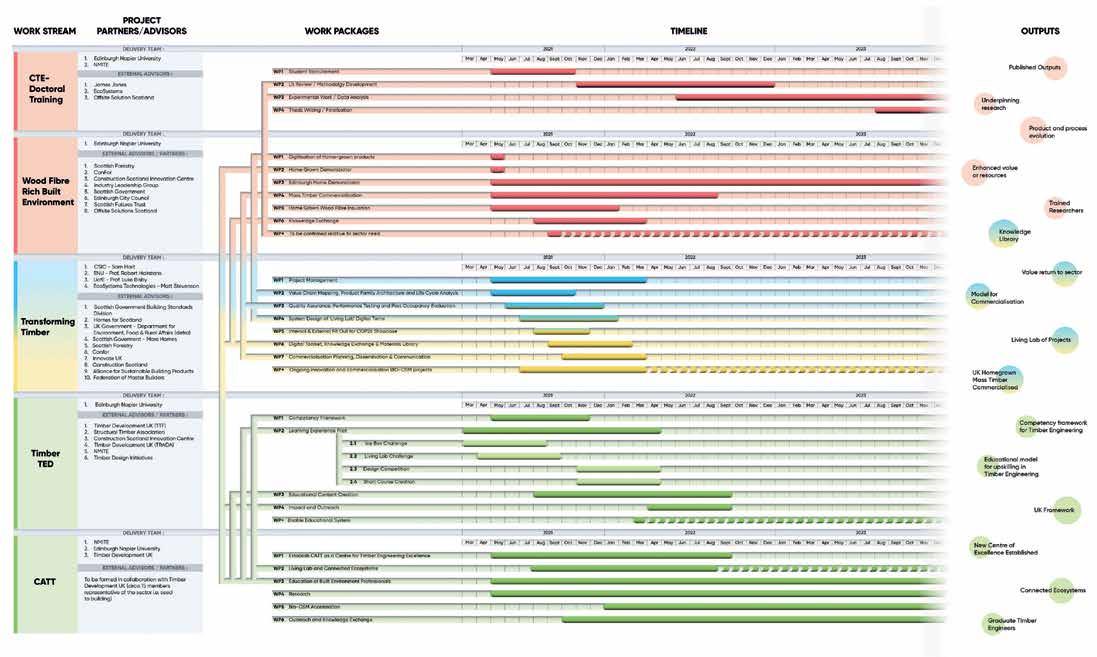

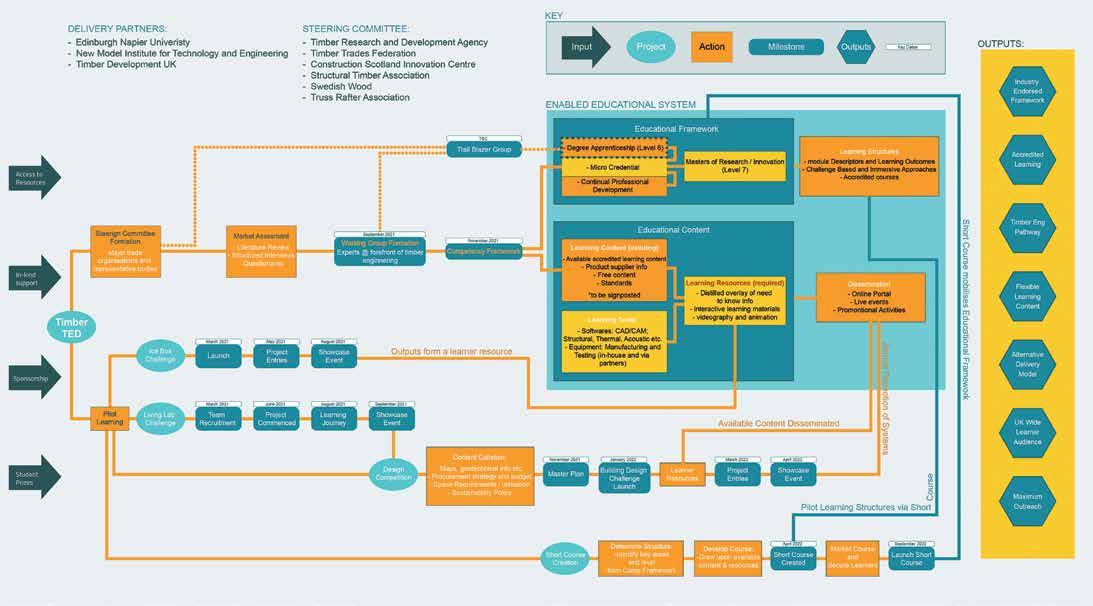

Robert Hairstans discusses the Biogenic Built Environment Framework: collaborative projects where research, innovation, commercialisation and education work in concert.

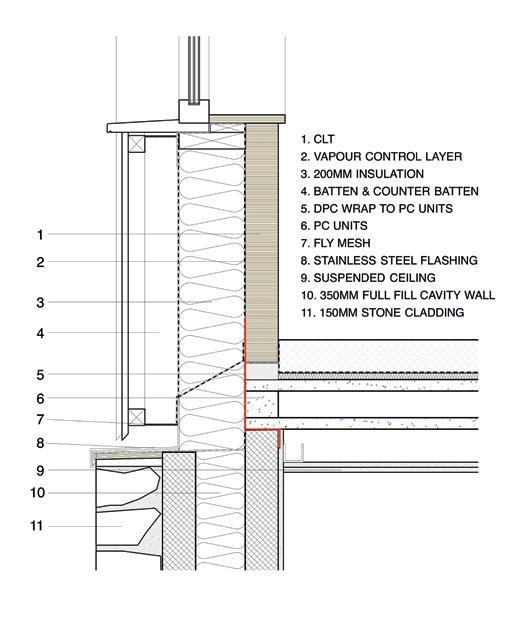

84 Timber structures: engineered timber CLT for private residential projects

Lee Murphy talks to three architects about their recent CLT projects.

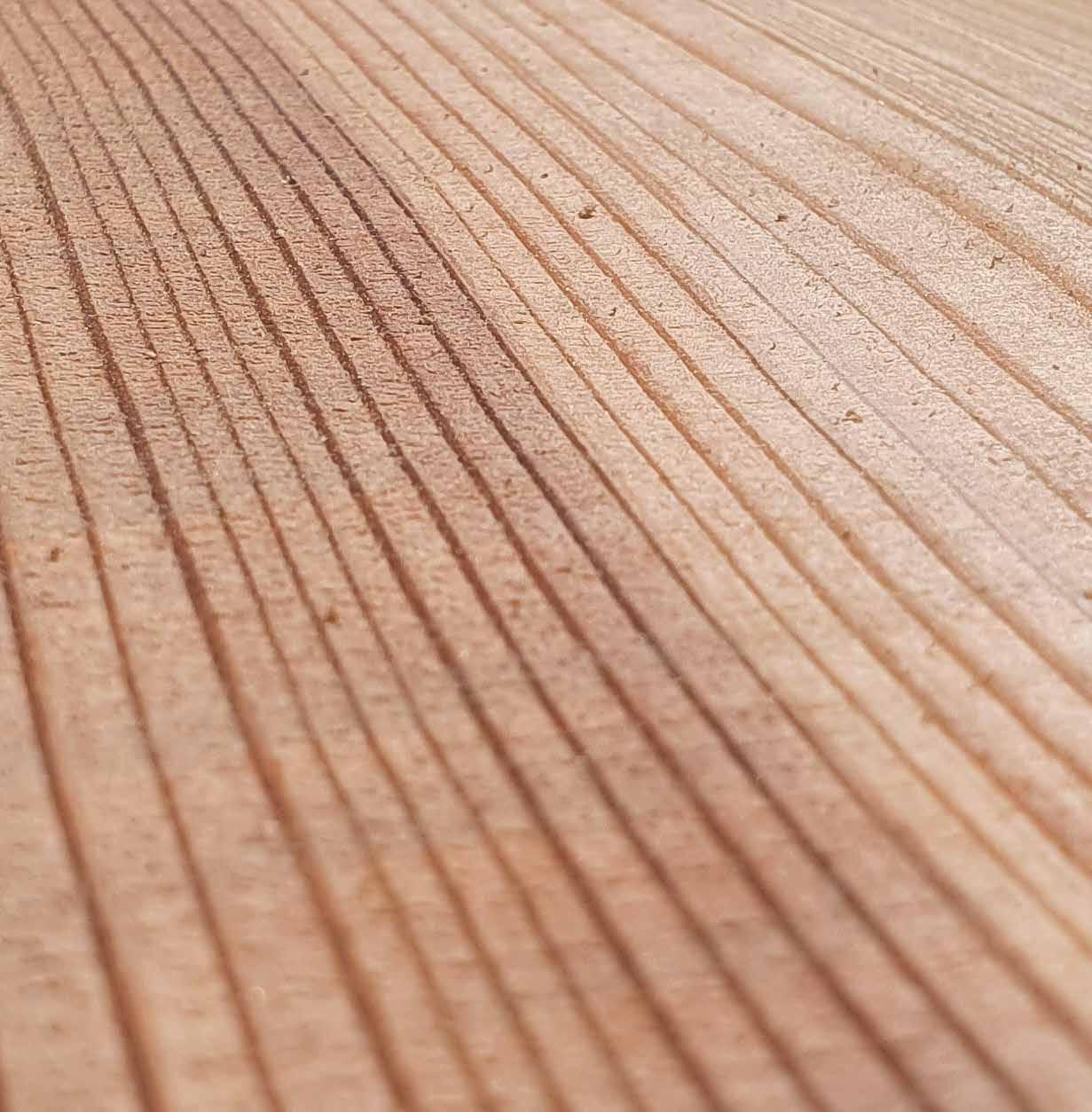

93 Timber structures: engineered timber Moisture dynamics: the durability of CLT

Lewis Taylor summarises the findings from research on moisture dynamics in CLT by BM TRADA and Stora Enso.

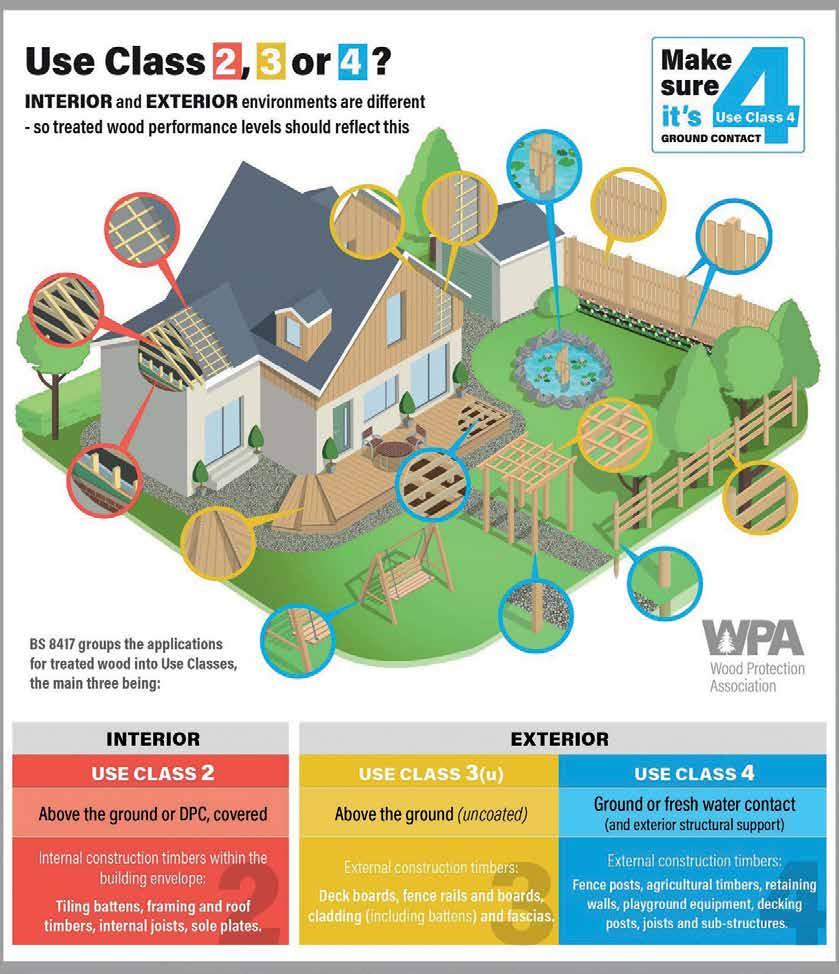

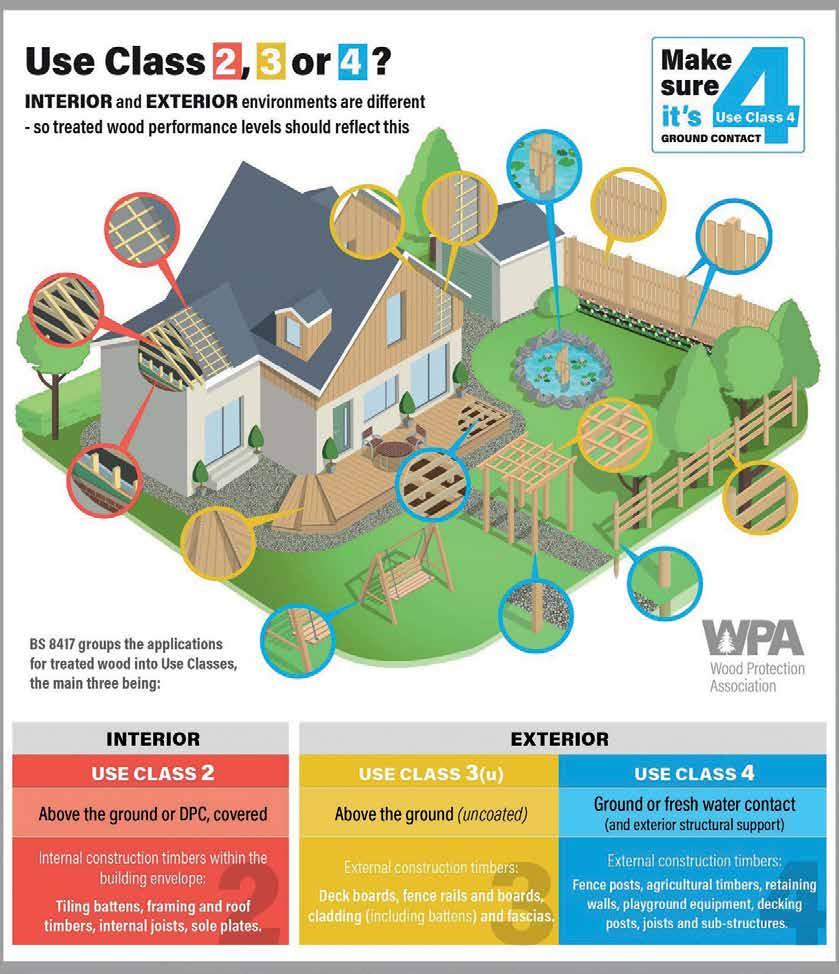

96 Protection: preservation

Understanding how to protect timber

Kevin Underwood explores the external factors that can have a negative effect on timber and ways that timber can be protected.

105 Protection: preservation Product information in the wood protection sector

Gordon Ewbank explains how the new Code for Construction Product Information (CCPI) will help reinforce the drive for change in treated wood product information.

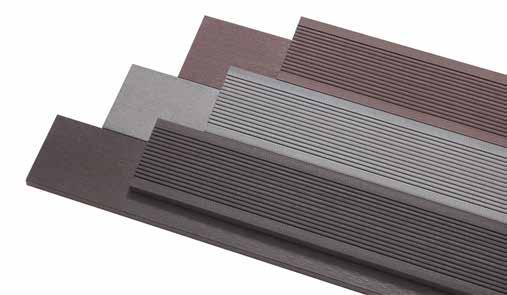

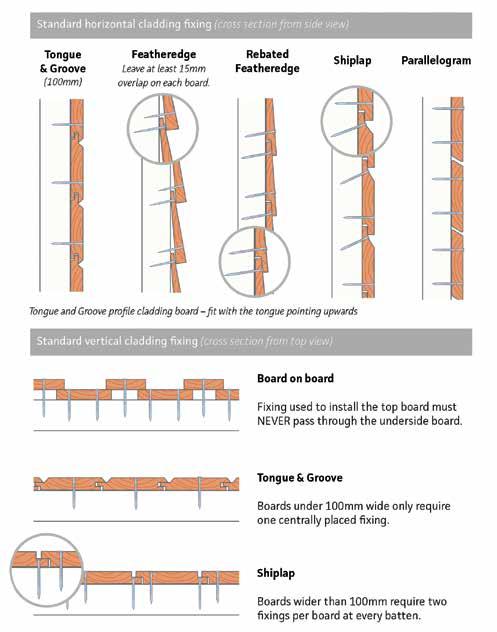

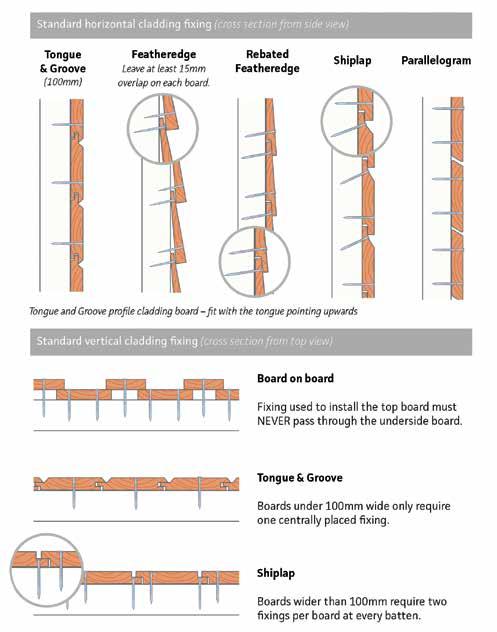

115 Landscape and exteriors: cladding

Avoiding common clangers

Janet Sycamore identifies issues that can affect a cladding project.

120 Landscape and exteriors: specification

Timber for use in garden and landscape construction

Paul Hensey explains how to specify timber for external use.

127 Joinery: case study

Innovative renovation

How windows and staircases can be used to transform a space, no matter the size.

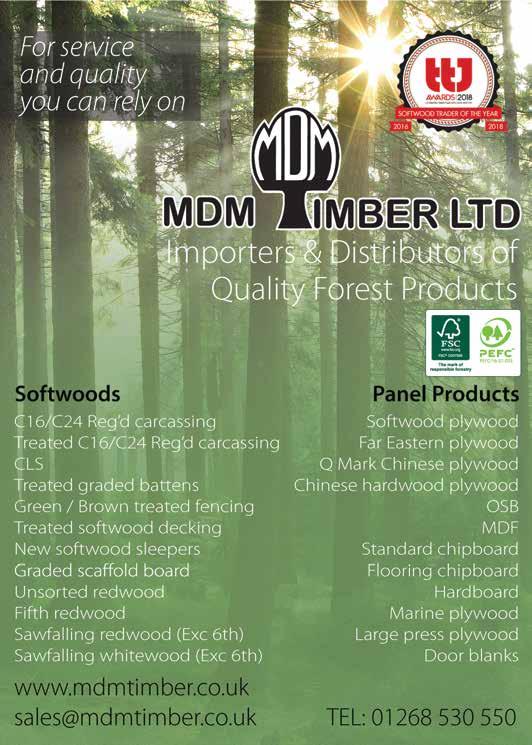

132 Joinery: fire doors

UKCA marking for pedestrian doorsets with fire-resisting and smoke control characteristics

There is still significant confusion among fire door manufacturers regarding UKCA marking. Peter Barker explains the current regulatory and legislative landscape.

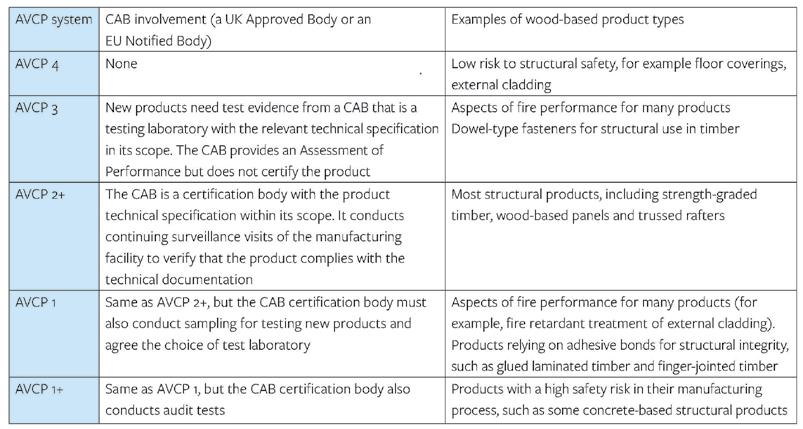

145 Materials: certification

Explaining UKCA marking

Making sense of the post-Brexit changes to the certification of construction products.

158 Materials: timber flooring

Sustainable wood flooring: an analysis

Peter Kaczmar discusses how to establish the environmental credentials of timber flooring products.

170 Education: architecture

Studio Bark – No Building As Usual

Addressing learning, diversity and the climate emergency through a live build.

Tabitha Binding reports.

175 BM TRADA: bookshop Publications

The best books on timber design and construction.

177 BM TRADA: directory Certified companies

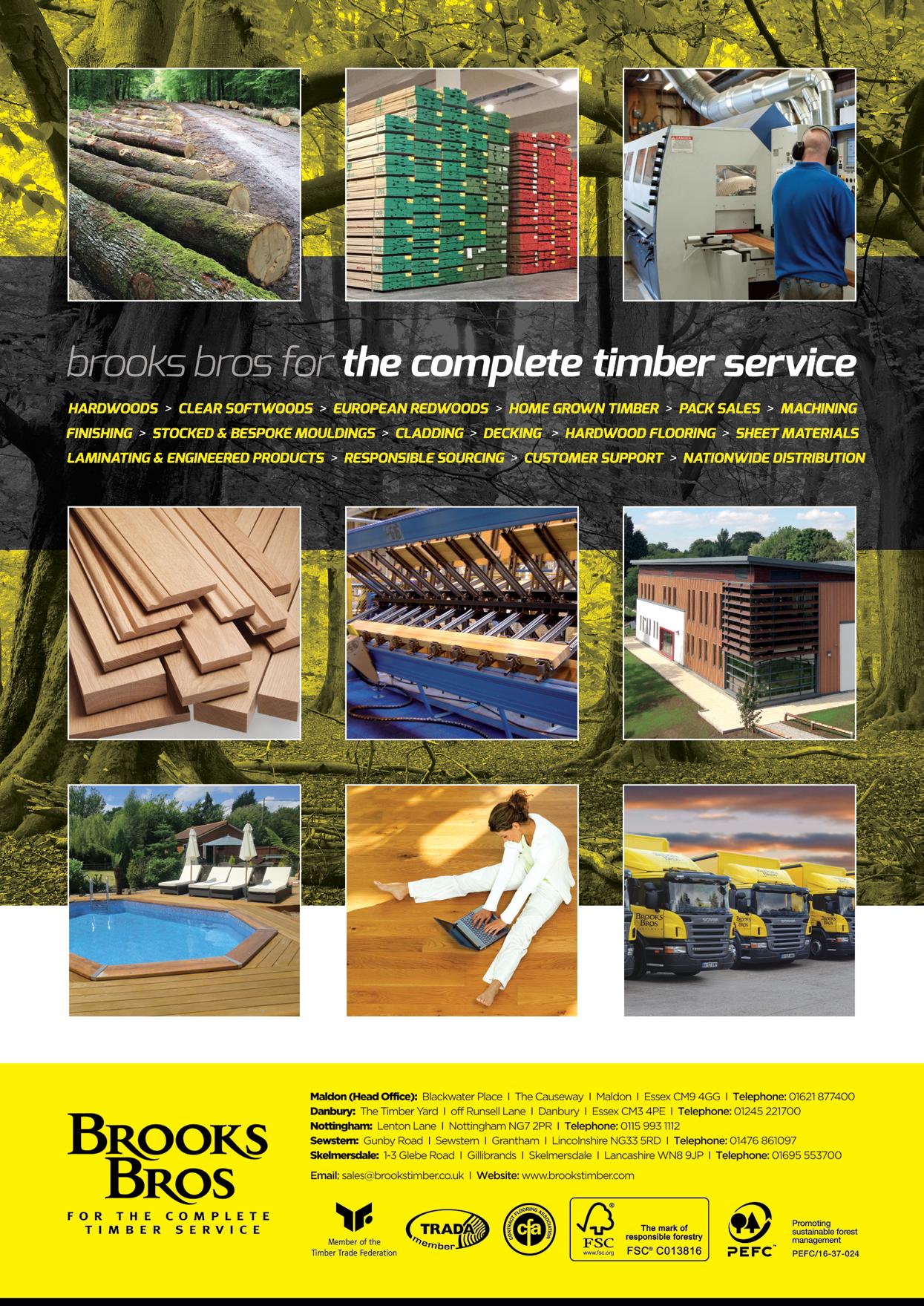

BM TRADA certified companies for the supply of timber products and services.

Timber 2022 | 05 www.bmtrada.com TRADA Contents Welcome

16 84

Providing timber expertise

Welcome to another edition of BM TRADA’s Timber Industry Yearbook and a fresh collection of technical timber articles.

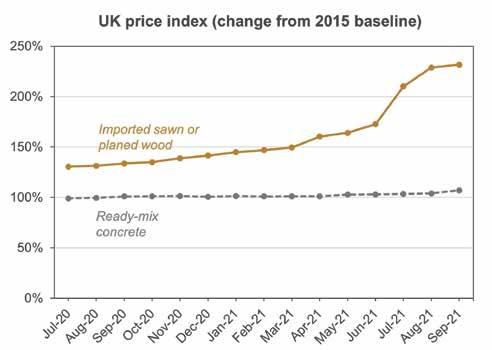

Following a year of upheavals related to the pandemic and the post-Brexit transition, 2021 became the best performing year in several decades for many across the timber industry. There has been an incredible demand for timber, driven partly by the need for sustainable building solutions, and the industry has worked extensively to meet it. Raw material prices soared.

Additionally, the market for garden offices, DIY projects and general home improvements flourished as remote workers spent more time in their homes. Furthermore, we have seen an uptake in the specification of timber by professionals driven to do their part to achieve net zero carbon. We are in a state of transition and we have seen this reflected first-hand in the thirst for knowledge about the practicalities of using timber, as demonstrated by callers to BM TRADA’s technical helpline.

It is against this backdrop that many of the articles included in this edition of Timber 2022 have been written, and thus reflect the ongoing developments and changes within the timber industry at this time.

Technical timber knowledge

Written by our BM TRADA technical timber team, on the topics of wood knowledge, engineering and timber frame best practice, Timber 2022 includes articles covering:

• visual strength grading (p29)

• timber properties and uses (p32)

• an introduction to timber connections (p34)

• cavity barriers in timber frame construction (p37).

We have also provided an introduction to this team and the services and training that they provide.

Sustainable construction

We continue to focus on the increasing need to build more sustainably during the climate emergency. Articles addressing these issues cover:

• how carbon is stored in timber (p41)

• how timber structures are good for the planet (p47)

• how to achieve low-carbon timber design (p54)

• examples of affordable low-carbon homes (p63)

• timber structures in building refurbishment (p68).

How we can help you

BM TRADA informs and assists those working in the timber industry through the provision of highquality independent advice. In 2022, we’re upping the game on every front.

Publications and the BM TRADA Bookshop

We remain committed to running the BM TRADA Bookshop and maintaining our publications and technical information. These publications can be bought from our bookshop at bookshop.bmtrada.com and through other well-known suppliers.

Technical helpline

BM TRADA’s technical team of experts answer thousands of your calls every year. We are delighted to announce that we are going to continue offering this service free of charge for the entirety of 2022.

We respond to everyone who calls with queries and will try to assist with straightforward advice or point you in the right direction, whether that’s to a specific publication or another service.

Webinar programme

Following on from a year experimenting with technical webinar programmes, we’re continuing to run these throughout 2022. We will be repeating two series that were incredibly popular – Structural timber engineering in early spring and Fundamentals of timber in late spring –as well as delivering new ones, which are intended to help people on learning journeys alongside their work.

We hope you enjoy Timber 2022. n

Timber 2022 | 07 www.bmtrada.com

Welcome Foreword

Need we say more? or call: 01786 819 225 uk.westfraser.com UK’S ONLY MANUFACTURER OF ZERO-ADDED FORMALDEHYDE OSB UK’S MOST SPECIFIED P5 FLOOR UK’S FIRST MANUFACTURER MDF

A year of change

Spotlight on 2021 activities and initiatives.

Post-Brexit legislative change

The UK Construction Products Regulation (UK CPR) – the new regulatory framework for construction products following the UK’s departure from the EU – came into effect on 1 January 2021, with recognition of the CE mark to cease in Great Britain by the end of the year.

However, the Government confirmed in August that businesses will have an extra year to start using UKCA marking, the new product safety marking in the UK. This enables CE-marked goods to continue being placed on the market in Great Britain until 1 January 2023 where businesses were due to begin using the UKCA marking by the end of 2021, including for construction products.

Technical advice

It is imperative that those involved with construction products – including manufacturers and importers – understand their new obligations. To aid this transition, BM TRADA has provided an overview of the new UKCA marking requirements in a new free technical bulletin – launched initially in February, and further updated in spring 2022 to reflect the legislative changes mentioned above. See page 145 for an extract from this bulletin >>

Timber 2022 | 09 www.bmtrada.com

Llanbedr – affordable timber housing in Wales

News Industry updates

Photo: Willams Homes

There’s

Better, connected. www.timberconnection.co.uk Get Lost

nothing James loves more than to lose himself in our warehouse, amongst thousands of cubic metres of imported hardwoods and premium grade softwoods to find the perfect pack for you.

Brand-new guidance on timber and carbon is also due to be published in spring 2022 and will be available to buy from the BM TRADA Bookshop. Part of the Wood Information Sheet series, WIS 2/3-72 Carbon and timber in construction for building designers is a timely in-depth review of all the complex issues around the subject, and provides holistic guidance on whole-life carbon calculations and how to minimise carbon emissions in the built environment.

Another imminent publication is the Research Summary Crosslaminated timber and moisture, which outlines the findings of extensive research undertaken by BM TRADA in collaboration with Stora Enso. This summary includes:

• information about the performance of end-grain sealers, adhesive tapes, panel joint types, and temporary protection membranes on rates of water uptake

• the influence of solar gain and temperature on water uptake

• drying rates

• implications for designers and contractors of crosslaminated timber.

Our full programme of webinars also launched in 2021 with great success and attracted more than 3,000 sign-ups across the year. Experts from BM TRADA and Warringtonfire – including Lewis Taylor, Phil O’Leary, Peter Barker, Hugh Mansfield-Williams and Mostafa Jafarian – presented on topics such as fire performance, UKCA marking, structural timber engineering, the nature of wood and moisture in timber.

Publications in progress

Part 1 of Timber connections: a guide for engineers is an exploration of the underlying theory of connections and will be particularly helpful for engineers who find this topic challenging. Planned additions to this series include Part 2 – Further topics, Part 3 – Worked examples and Part 4 –Proprietary connectors, which will be released during 2022.

The series will assist the engineer with connection typology, design detail and the steps involved in verification by calculation. Technical illustrations, calculations and worked examples support the comprehensive textual analysis of the topics and challenges of timber connections.

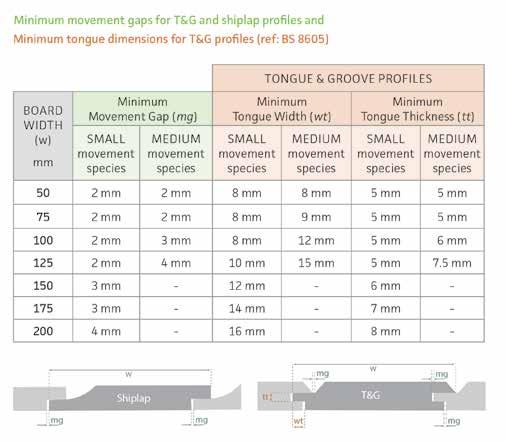

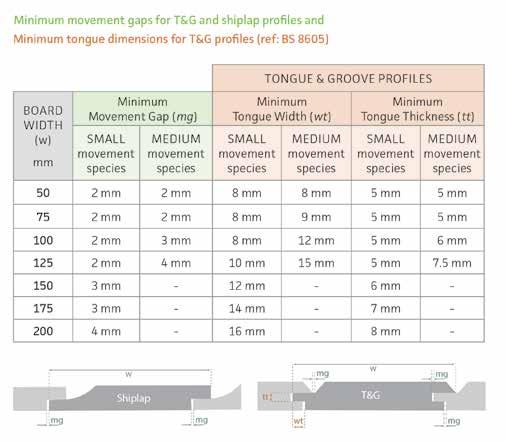

There is also considerable demand for best practice information on how to design, specify and install cladding, particularly in response to evolving regulatory requirements. The long-awaited 4th edition of External timber cladding is being prepared by Dr Ivor Davies and BM TRADA’s technical consultants. This enlarged edition contains guidance on the key recommendations in BS 8605-2. It explains their background and practical application, while giving additional guidance that is not available in the BS 8605 series.

The new edition of External timber cladding, to be published in 2022, will include:

• an outline of the benefits of timber compared to other cladding materials

• discussion of each stage in the design and construction process

• expanded guidance on fire safety and structural performance

• new construction details for the main connections and junctions on a timber-clad wall

• information on the latest material options such as modified woods and surface coatings.

Home-Grown Homes

Since launching in April 2018, the Home-Grown Homes project team has been diligently investigating Wales’ potential to become a high-value forest nation. Home-Grown Homes, of which BM TRADA was a key delivery partner, concluded at the beginning of 2021 with a full report for the Welsh Government identifying which supply chain interventions may be most effective and how they might be applied, as well as a comprehensive list of outputs.

The project’s key findings and recommendations are summarised in the project report, while practical tools and guidance have also been developed for social housing developers, architects and engineers, timber frame manufacturers and wood processors, forestry managers and land owners.

Robin Lancashire, BM TRADA’s senior timber frame consultant, has been involved since the project launch and co-wrote the output Making the right choices – a guide to improving the build quality of new build timber frame social housing with fellow BM TRADA consultants Lewis Taylor, Adam Moring and Gavin Fidler.

These resources are all available for free download on the Woodknowledge Wales website. >>

Timber 2022 | 11 www.bmtrada.com News Industry updates

— our Mission

Train Emergency Services, International Search & Rescue and HM Armed Services

Exceed project and customer expectations as standard

— our services

62 Peterborough r oad Southampton, Hampshire, S o 14 6HX 023 8033 4929 | 07920 038057

jon@fallenandfoundartisans.co.uk

Mill trees into shoring timber to aid in rescue operations and humanitarian rescue efforts

Provide timber for a variety of projects, bespoke products, construction and crafts

Mobile Sawmilling - Logosol B1001 Bandsaw Mill | Chainsaw Milling - Granberg Alaskan Mills

Forestry – Hand Cutting and Timber Production | Arboricultural Consultancy and Contracting

Bespoke Furniture Production and Commissions undertaken | Re-purposed Forestry and Arboricultural Timber Sales Freelance LANTRA Instructor (Ground Based Chainsaw operations)

12 | Timber 2022

RE- CLAIM RE- SAW RE- PLANT

RE SCUE RE- PURPOSE

to respond to incidents and capacity building missions

Awards

Two highlights of the UK timber industry calendar are the much-anticipated ceremonies of the Wood Awards and the TTJ Awards. Both continued with some adjustments as a result of the ongoing pandemic.

The TTJ Awards 2021 – its 25th anniversary – proceeded as a hybrid event, allowing people to tune in from across the UK. Winners on the day included timber mainstays English Woodlands Timber, Arnold Laver, Accsys Technologies and International Plywood.

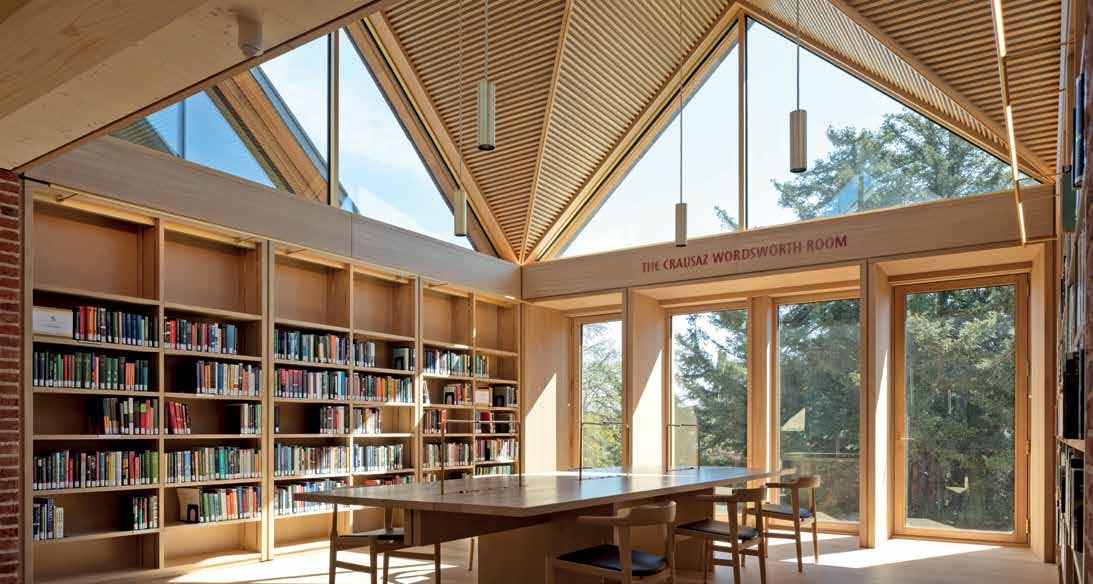

The Wood Awards 2021 – see page 20 for more – saw Magdalene College Library, a ‘tour de force of architectural design and achievement’, take the coveted Gold Award to become the latest winner of winners. Other winners included The Alice Hawthorn, St John Street, The Boathouse, Built: East Pavilion, The Welcome Building RHS Garden Bridgewater, Gayles Farm 5 and the Iso-Lounge Chair.

This year, however, also saw the addition of the FSC® Furniture Awards to the UK calendar – a new extension of the awards that have been running in Italy since 2019. Organised by the Forest Stewardship Council®, the goal of the FSC® Furniture Awards is to recognise and celebrate the commitment of FSC®-certified companies in the indoor and outdoor furniture categories.

Twelve awards for indoor and outdoor furniture were given to FSC®-certified companies active in the furniture sector across Italy, the UK, Germany, Poland and Croatia.

Two UK-based companies – Community Products (UK) Ltd and Buoyant Upholstery Ltd – were on the winners’ list for environmentally friendly outdoor furniture and play equipment for toddlers, and exemplary corporate social responsibility policies respectively.

TRADA and TTF merger

TDUK is a new cross-sectoral organisation formed by the merger of the Timber Research and Development Association (TRADA) and the Timber Trade Federation (TTF) in 2021.

TRADA and TTF operated as separate brands initially but as of December 2021 the combined organisation is now known as TDUK (Timber Development UK), with a new brand identity. Many plans are in progress for the new organisation, including a sustainability committee which has to date produced a technical paper on carbon calculation. n

References

• www.bmtrada.com/certification-services/third-partycertification-non-fire/ukca-marking-for-construction-products

• woodknowledge.wales

• Books, Wood Information Sheets and Research Summaries mentioned are available to buy from bookshop.bmtrada.com

• Assessing the carbon-related impacts and benefits of timber in construction products and buildings, Technical Paper, TDUK, November 2021

Timber 2022 | 13 www.bmtrada.com

News Industry updates

Magdalene College Library.

FSC-A000503

Photo: Niall McLaughlin Architects / Nick Kane

TIMBER DEVELOPMENT UK

Timber Development UK has been formed from the merger of two of the largest and longest established organisations in the supply chain, Timber Trade Federation (TTF) and Timber Research and Development Association (TRADA).

Bringing these two associations together as one will create the largest, most comprehensive supply chain body in the UK, spanning from sawmill to specifier and all points in between.

We want to use this new organisation to capitalise on the growing interest in designing with timber and to act as an agent of change towards more sustainable, low carbon forms of construction.

We will help facilitate this by

•Enabling greater dialogue throughout the supply chain, from designers to manufacturers to suppliers, all within the same organisation;

•Developing the UK’s largest, most comprehensive online library of technical specification and design guidance;

•Providing regular training, CPD and webinars to hear from other practitioners and share best practice;

•Working with the UK university network via our University Engagement Program (UEP) to ensure the next generation of specifiers is equipped with the information and tools to confidently design with timber;

•Delivering the tools, training, guidance and auditing to ensure only correctly marked, legal and sustainable timber products are placed on the UK market;

•Developing supply-chain level market data to make accurate business decisions on purchasing and supply;

•Publicising and promoting the benefits of timber via our newsletters, magazines and digital outputs;

•Promoting best practice via competition such as The Wood Awards, the University Design Challenge and other activities;

•Facilitating and hosting networking and discussion opportunities via lectures, dinners, exhibitions and drinks evenings around the country.

Timber Development UK will be launching as a fully integrated organisation in summer 2022. In the meantime please visit www.trada.co.uk and www.ttf.co.uk to keep up to date on our activities.

SOURCING

NETWORKING EVENTS

e: ttf@ttf.co.uk | p: 020 3205 0067 | w: ttf.co.uk THE BUILDING CENTRE, 26 STORE STREET, LONDON, WC1E 7BT This image has been modified | Please see Built East Pavilion. Winner of Small Projects category at the Wood Awards | Architect: OGU Architects + Donald McCrory Architects | Timber Distributor: International Timber | Find out more www.woodawards.com

SPECIFYING GUIDANCE

TRAINING

Celebrating communal school life

Highly commended for the Education & Public Sector Award, Ibstock Place School Refectory is a reimagined grand timber hall that offers a soothing visual and aural space for pupils.

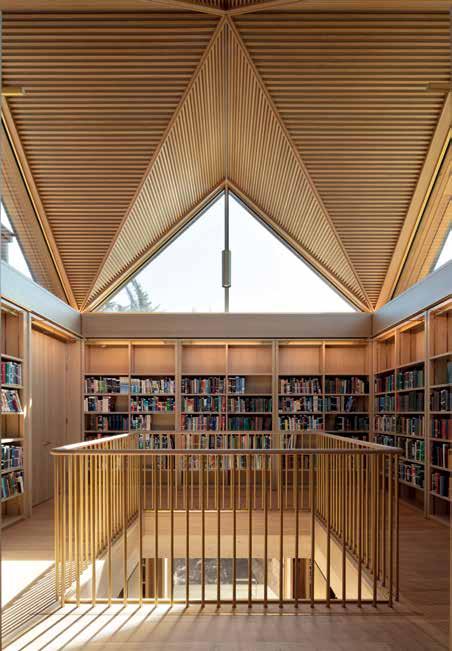

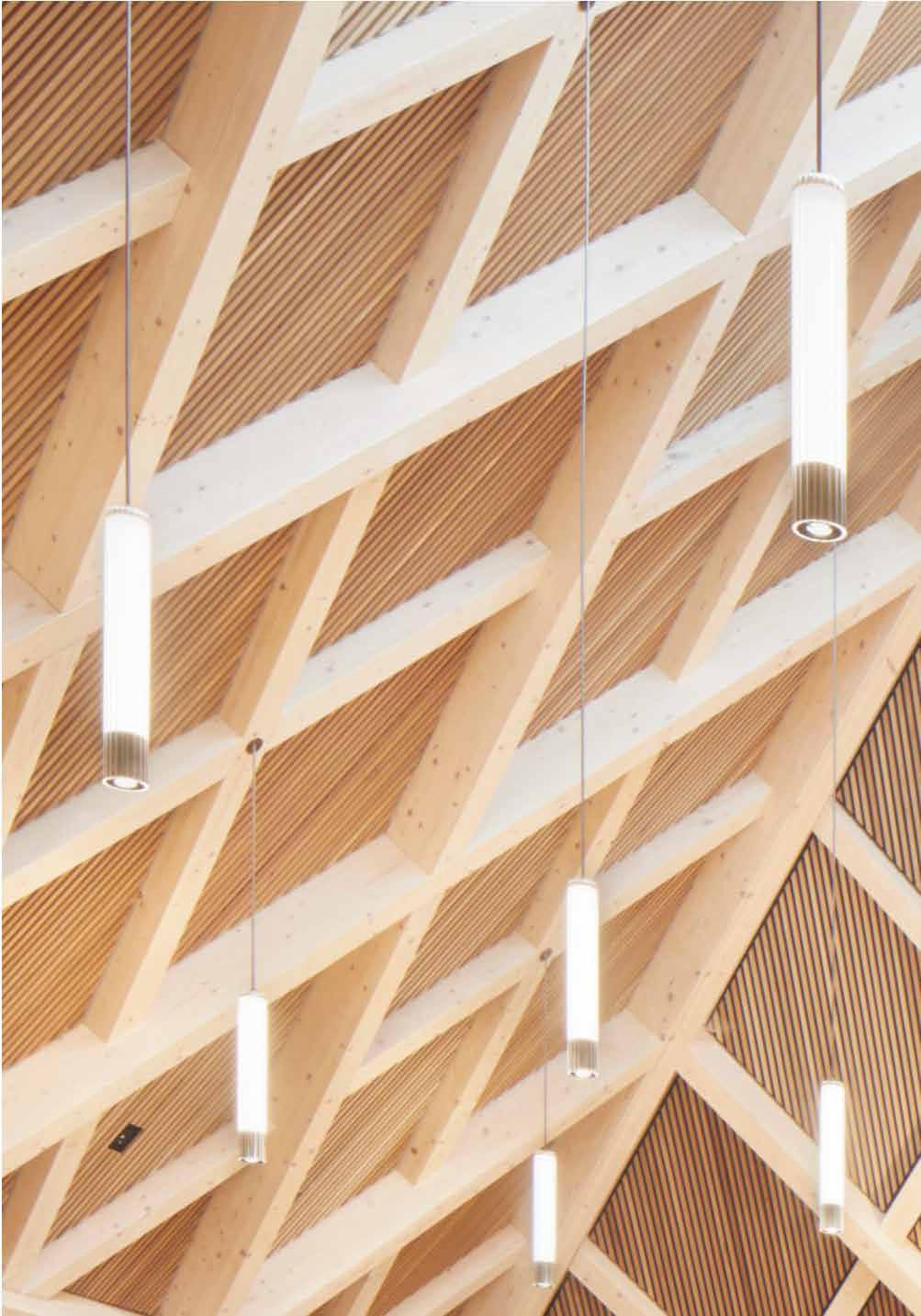

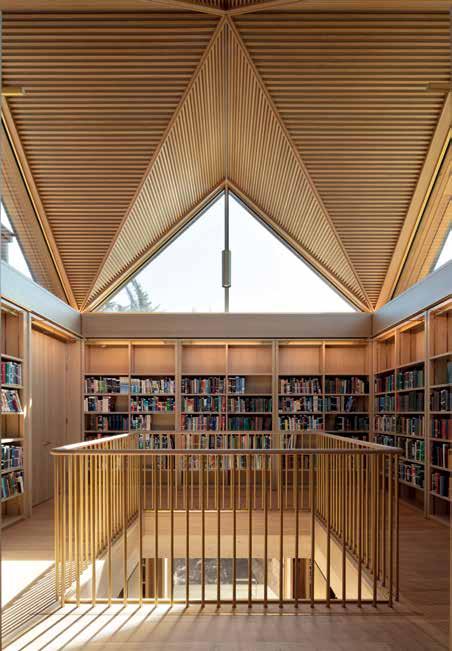

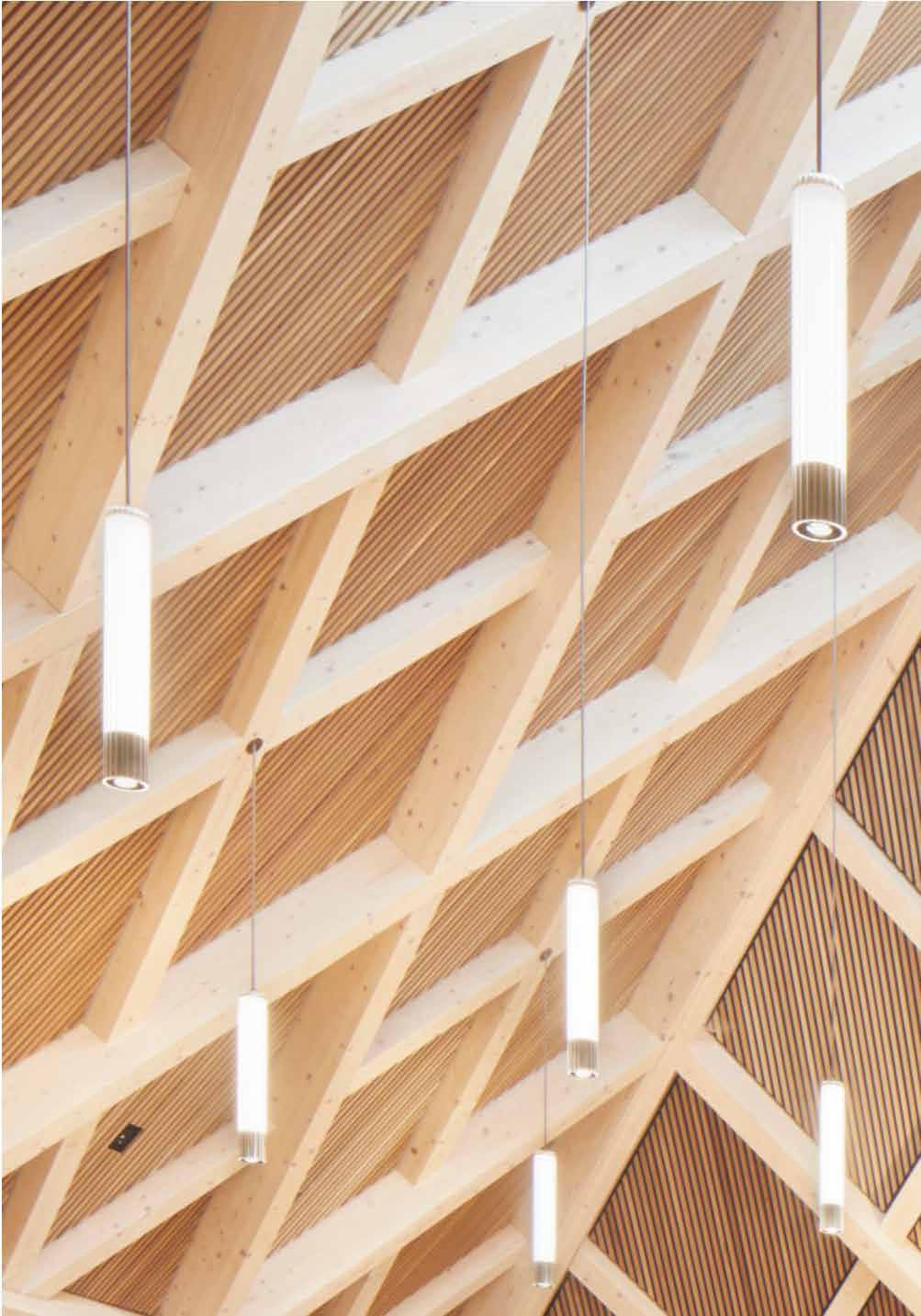

Maccreanor Lavington Architects has created a new school refectory with three dramatic vaulted roofs, each a diamond-grid lattice of glued laminated (glulam) timber beams rising to a glazed lantern. It stands in the grounds of Ibstock Place School in Roehampton, south-west London, and the three vaulted volumes define the primary functions of the building –dining hall, servery and kitchen.

Every day 1,200 pupils come here for lunch – the dining hall can seat up to 500 pupils at any one time – and the lofty spaces aim to help celebrate communal school life. As the architect explains: ‘To create an interior that was celebratory while warm, welcoming and comfortable to use, we naturally looked at timber, both as a structural element and as a finish. In our practice, we use timber for its low-carbon qualities, visual warmth and character; and because of the quality and programming benefits that prefabrication of timber components can offer.’

The transformation

Ibstock Place is a private co-educational school for pupils from nursery to sixth form, and occupies the house and grounds of a former 16-bedroom Edwardian mansion with additional school buildings – theatre, classrooms and new refectory – all set between mature trees in the original landscaped gardens. Running alongside the eastern garden boundary, the refectory has a backdrop of mature London plane trees, and its external materials, clay-tiled roofs and London stock brickwork walls make reference to the neighbouring buildings on the site. The gentle roof pitches descend to relatively low eaves to reduce the visual impact of the large internal volumes. A colonnade with brick piers runs along the main facade of the refectory and links it to paths leading to other parts of the school. >>

Events Wood Awards FSC-A000503 / PEFC/16-44-002 16 | Timber 2022

Project details

Ibstock Place School Refectory

Completion date: December 2019

Building type: Refectory

Location: Roehampton, south-west London

Architect: Maccreanor Lavington Architects

Structural engineer: engineersHRW

Main contractor: Feltham Construction Ltd

Structural timber supply and installation: Constructional Timber (Manufacturers) Ltd, Barnsley

Joinery: D Smith, Royston; AAS Projects and Design, Rickmansworth

Timber suppliers: Mosser Leimholz GmbH (glulam), Austria; X-Lam Dolomiti Srl (CLT), Italy; Havwoods UK (floor)

Timber elements: Roof structure, wall linings, staircases, handrails and balustrades, internal linings and acoustic panels, doors, windows and floors

Timber species: PEFC™-certified Austrian spruce, FSC®-certified American white oak, FSC®-certified European oak

Ibstock Place School Refectory

Photo: Jack Hobhouse

Ibstock Place School Refectory

Photo: Jack Hobhouse

Events Wood Awards

Each roof structure has a similar hierarchy of elements: a series of primary 160mm x 520mm glulam beams with secondary 160mm x 440mm glulam beams incline in opposite directions to create the main diagrid. They rise from the steel ring beam at the eaves to a timber ring beam at the lantern or to the corner hip beams. Fixed between them are inclined 160mm x 200mm glulam beams, creating a subsidiary diamond lattice.

The team also considered the idea of using the glulam beams as a two-way spanning diagrid. As Greg Nordberg of engineersHRW explains:

‘This format reduced the stresses on individual members but created more onerous connections, meaning that equivalent sized sections would be required. Overall, the hierarchical approach was just as efficient and more economical.

‘The stiffness of the roof geometry and the truss action of the roof were considered with separate models to provide an envelope of forces for element design and examine alternative load paths for disproportionate collapse.’

Although the refectory is built on the footprint of former dining facilities, the architect has trebled the usable floor area by inserting a generous sixth form study area, mezzanine gallery and part of the servery above the kitchen, and by excavating a generous basement for stores.

The lattice structure is exposed and the diamond-shaped spaces between the inclined glulam beams are filled with oak-slatted panels that provide acoustic absorption. The glulam beams rise to projecting glazed lanterns, which fill the deep spaces below with natural light and support the natural ventilation strategy. Below the roof, the internal walls are panelled with matching oak slats; doors and floor finishes are also made from oak.

Roof design

In shape, the timber roof structures are truncated pyramids with a complex geometry; they enclose spaces of different sizes and rise at different inclinations to lanterns that are of different size but all terminate at the same height.

The corner hip beams act in compression to transfer the bulk of vertical loads from the roof to the steel ring beam. At the eaves, the first floor structures to the smaller hall and the kitchen provide restraint to the ring beam to reduce deflection under vertical loads. The in-plane action of these floors transfers lateral loads to diagonally braced bays at the corners of the building. The lanterns consist of welded steel frames that transfer horizontal loads across the openings at the top of the roof and stiffen the edges of the ring beam.

The geometry of the diamond grid lattice was fine-tuned to minimise variations in size of the oakslatted acoustic panels set between them. As a result, only four different sizes of diamondshaped panel were used throughout the project and they are of a manageable size for manual handling. The oak

18 | Timber 2022

A colonnade runs along the main facade of the refectory, linked by paths to other parts of the school.

Photo: Jack Hobhouse

The timber-lined bays are attractive and comfortable places to eat.

Photo: Jack Hobhouse

During assembly the glulam beams were supported by an internal loadbearing scaffold.

Photo: Constructional Timber

Events Wood Awards

slats are lined with acoustic fabric panels and incorporate concealed cabling for lighting, data and other services. They were prefabricated and fully finished off-site.

The assembly of beams at different inclinations was complex; the glulam had to be fabricated with millimetre precision and connections to it had to be designed and fabricated. The inclined 160mm x 520mm and 160mm x 440mm glulam beams are connected by concealed hangers or galvanized flitch plates depending on their load requirements. Connections between the glulam beams and the steel ring beam structure that supports them are made with galvanised steel plates, which were specially developed for the project by engineersHRW and specialist timber contractors Constructional Timber. The glulam roof structures are overlaid with a cross-laminated timber (CLT) deck that contributes to the in-plane stiffness of the inclined roof planes.

Roof installation

Once the timber-faced steel ring beam at the eaves was installed, a loadbearing scaffold was erected that mimicked the internal volumes of the roofs. The upper timber ring beams at the lanterns were fixed in position onto the scaffold together with the four corner hip beams that were dropped into place by crane and

rotated to their final positions. The bases of the main glulam beams were then craned onto angled reveals set in the eaves ring beam and positioned at the correct angle onto the roof lantern ring beam or corner hip beam. The scaffolding gave tolerance to position these elements and allowed the roof to support its own weight while the rest of the structure was installed.

Andrew King of Constructional Timber adds: ‘With restricted site access, all deliveries were arranged using only rigid vehicles, which was challenging as the corner hip beams were nearly 11m long and weighed 1.2 tonnes. For the installation sequence, it was key to fix the level of the lantern ring beams off the loadbearing scaffold supplied by the main contractor. The lantern ring beams were levelled to the correct height before the twin hip beams were craned into position. The members were all supplied fully protected and with their fire treatment applied so as to reduce site time and potential for damage.’

Timber finishes

It was important to the architect to ensure that the different timbers used – spruce glulam structure, oak timber linings and joinery, and oak engineered wood floors – would harmonise in the long term, in particular to avoid the possibility that the glulam might be affected by sunlight exposure and become a contrast to the more muted hue of the aged oak finishes. The practice worked closely with the timber coating company Renner Wood Coatings, which undertook accelerated ageing of the different finishes in its laboratory and produced a whitetinted fire-proof finish that is UV-stable.

Sustainability

The refectory has been awarded a BREEAM ‘Excellent’ rating for its long lifespan and low-carbon impact in use. Timber is the primary material for structure and finishes, and is all either PEFC™- or FSC®-certified. Passive measures include lanterns for stack ventilation and daylight, colonnades that contribute to shading and cooling, together with on-site renewables. n

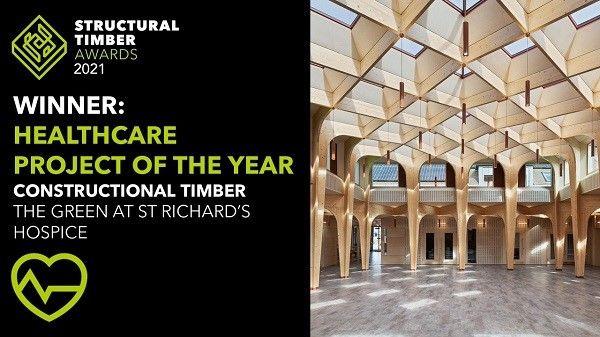

Awards

Wood Awards 2021, Education & Public Sector – Highly commended

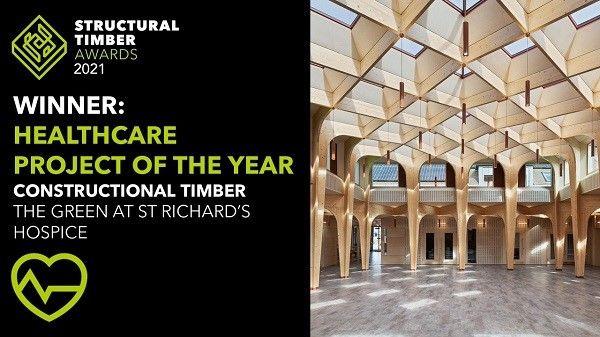

Structural Timber Awards 2021, Architect of the Year – Finalist

Structural Timber Awards 2021, Project of the Year – Winner

AJ Architecture Awards 2021, School Category – Winner

New London Awards 2021, Learning Category – Winner

Further information

To find out more and download the full case study, visit www.trada.co.uk/casestudies

Timber 2022 | 19 www.bmtrada.com

FSC-A000503

/ PEFC/16-44-002

Oak-slatted acoustic panels are fitted between the glulam beams.

Photo: AAS Projects & Design Ltd

And the winners are…

A look at those who came top in the 2021 Wood Awards.

3The Alice Hawthorn

North Yorkshire

This charming country pub has transformed its accommodation offering with the addition of 12 guest rooms, eight of which are made entirely of timber frame. The home-grown Douglas fir frame is complemented by larch cladding and poplar ply sarking. Winner of the Commercial and Leisure Award

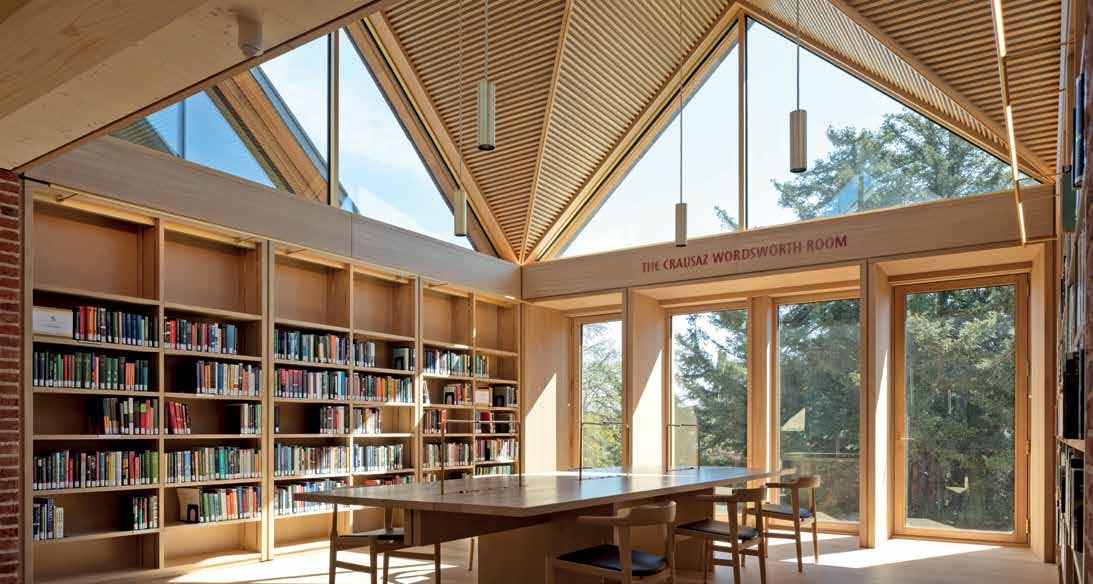

4Magdalene College Library Cambridge

The new Cambridge University library has a glued laminated (glulam) and cross-laminated timber structure, and is populated with oak shelves and tables. The roof is formed from a grid of timber lanterns that bring light in but limit glare and overheating. Winner of both the Gold Award and the Education & Public Sector Award

3St John Street London

This Victorian apartment was reimagined using solid oak joinery, including bookshelves, wall panelling and pocket doors. Oak chevron parquet flooring throughout and lime-washed birch plywood in the bedrooms add to the careful calibration and crafted joinery. Winner of the Interiors Award

20 | Timber 2022

Photo: Niall McLaughlin Architects / Nick Kane

Events Wood Awards

Photo: Hufton + Crow

Photo: Emil Eve Architects / Mariell Lind Hansen

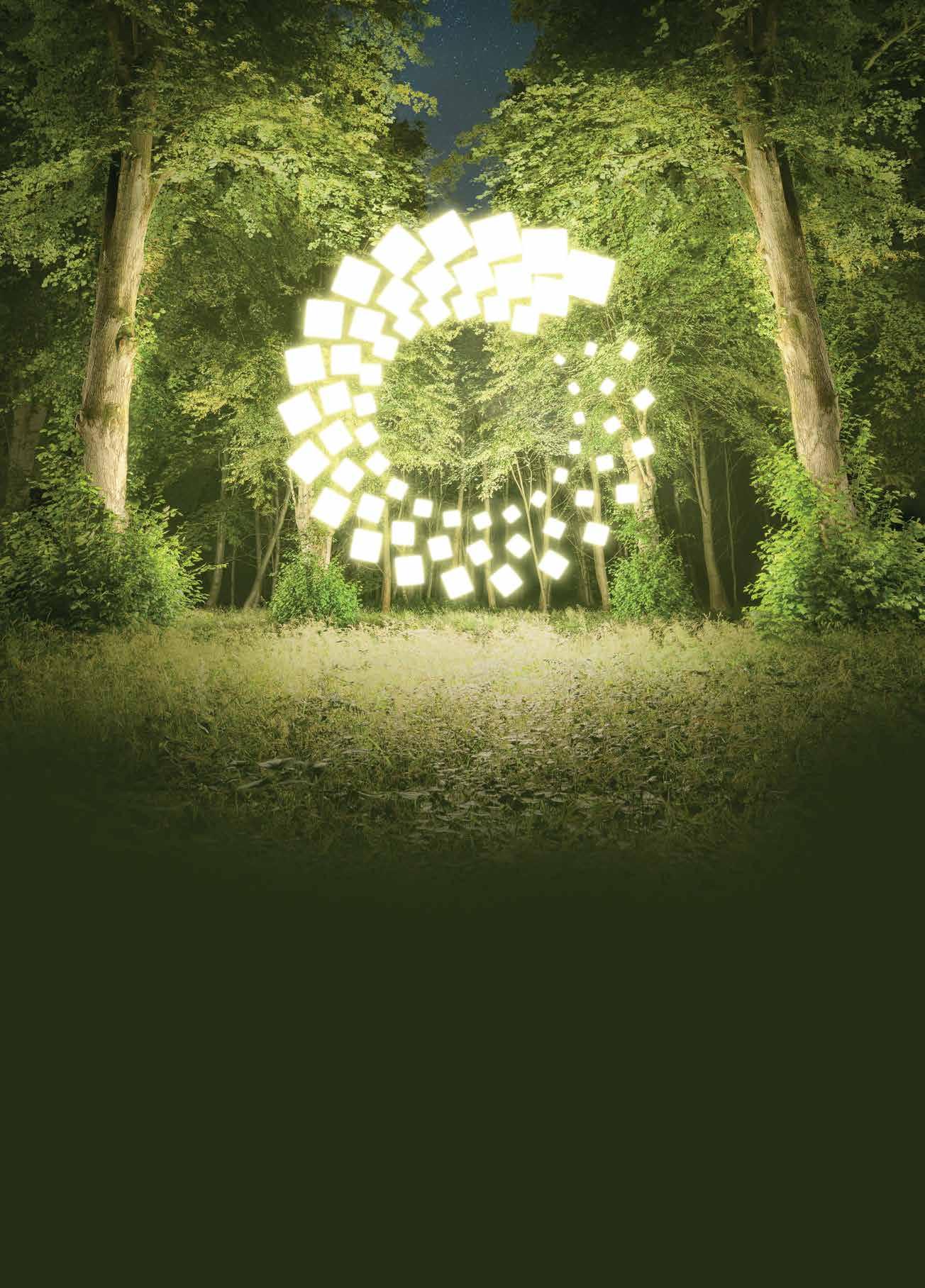

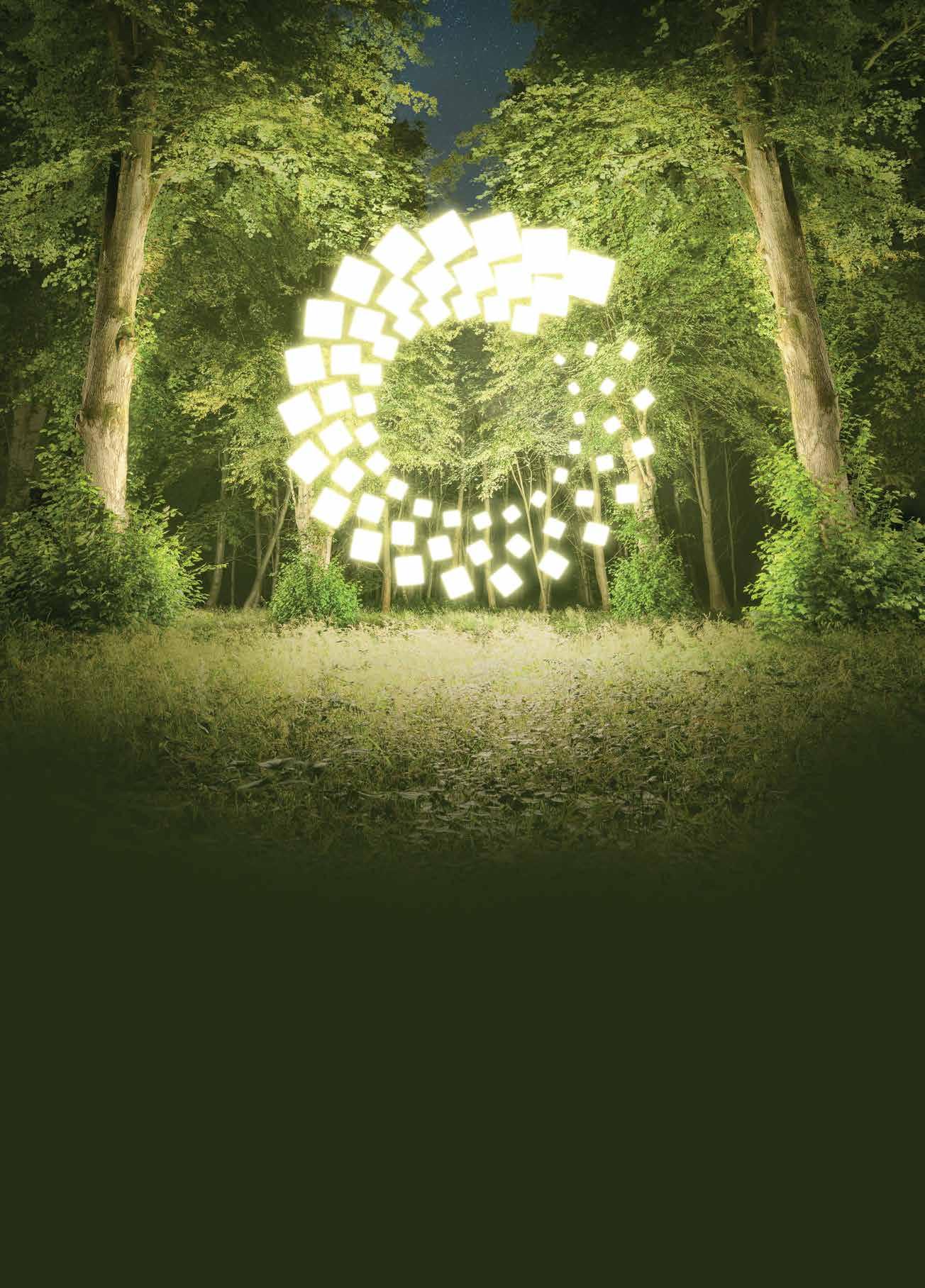

5The Welcome Building RHS Bridgewater Manchester

This visitor centre sits on the site of the new Royal Horticultural Society garden of Worsley New Hall. The roof comprises a glulam timber diagrid supported by structural glulam ‘trees’. Timber decking extends from the building to the lake and the roof is clad in vertical larch.

Winner of the Structural Award

4The Boathouse

Devon

Yellow cedar tiles and cladding adorn the roof and exterior of this practical and beautiful family home. Inside, the upstairs floor is made from Douglas fir and the long, straight grain of the wood has been deliberately exposed on all levels to show off its beauty.

Winner of the Private Building Award

Belfast

The Belfast truss used in this pavilion’s design represents the area’s history of manufacturing ingenuity. Traditional craft skills were combined with innovative technologies to create bespoke building components that could be rapidly assembled on site.

Winner of the Small Project Award

For more information on each of the Wood Awards winners, visit www.woodawards.com

Timber 2022 | 21 www.bmtrada.com

Events Wood Awards

Photo: OGU Architects / Joe Laverty

Photo: Jim Stephenson 5Built: East Pavilion

Photo: Peter Cook

BM TRADA: technical timber, our experts and services

Ben Sharples gives an overview of expertise provided by the BM TRADA technical timber team.

BM TRADA helps companies that are using timber in building projects – whether at the design stage, during construction, or when retaining timber during historical building restoration.

Its technical timber team offers specialist expert consultancy, advice and training in all aspects of the timber and construction industries, providing value-adding services to construction and engineering clients, product manufacturers and insurers, as well as to the education sector. There is a wealth of knowledge within a team of qualified individuals who, between them, have dozens of years of combined experience in working with timber.

Introducing some of BM TRADA’s timber consultancy experts...

Phil O’Leary

Technical Manager, leading BM TRADA’s technical timber team.

Together with a wealth of knowledge and experience in the visual strength grading of timber, Phil specialises in:

• condition surveys, performance assessments and determining the structural strength of timber in many situations

• timber quality, performance characteristics, deterioration and preservation

• serving as an expert witness in establishing the causes of timber failures

• developing and presenting highly regarded topical and bespoke training courses on a range of timber subjects.

Phil also sits on the BSI’s Wood Preservation Committee and the Wood Protection Association’s Technical Committee. See page 26 for Phil’s article on timber fundamentals and how training is used in companies to develop wood knowledge.

Hugh Mansfield-Williams

Wood Technology Technical Manager for the assessment and certification of construction products and systems.

Hugh has particular expertise in:

• products for loadbearing timber structures

• evaluating product type testing and calculation

• routes to approval for construction products so that they can be placed on the market.

Hugh participates in standards development and other technical committees in both the UK and Europe. See page 145 for Hugh’s article on UKCA marking.

22 | Timber 2022

Timber technology Advisory service

Dr Keerthi Ranasinghe

Principal Engineer for Structural Timber at BM TRADA and Warringtonfire.

Keerthi is a technical expert on structural timber, with a wide range of experience in structural investigations. He is a member of BSI committees on structural engineering, and the UK representative on European Working Groups responsible for Eurocode 5.

Keerthi is author of several specialist publications, including:

• Eurocode 5 Span Tables

• Timber connections: a guide for engineers

• TimberSizerPro and TimberConnectionsPro to Eurocode 5 software.

Additionally, he is:

• revising editor for the Manual for the Design of Timber Building Structures to Eurocode 5 (2nd ed).

• a project team member for the technical editing of the connections chapter of the second generation of Eurocode 5, due for release in 2023.

Keerthi delivers CPD training and workshops on structural timber engineering and on Eurocode 5 at both BM TRADA and the Institution of Structural Engineers UK. See page 34 for an extract from his latest publication, Timber Connections: a guide for engineers.

Robin Lancashire

Senior Timber Frame Consultant in BM TRADA’s technical timber team. Robin has a long and distinguished career in promoting best practice in timber frame construction.

Holding a BSc in Building and with more than 20 years’ experience in the industry, Robin was instrumental in developing BM TRADA’s frameCHECK service; his technical expertise has helped countless architects, main contractors, developers, housing associations, building control and warranty providers with impartial advice during design, construction and in use.

When he’s not providing professional advice, Robin:

• delivers practical training on timber frame technology

• represents BM TRADA on the Structural Timber Association’s Technical Committee

• is a regular speaker at industry conferences

• contributes to trade journals.

Robin has co-authored several important books, including Timber frame construction (5th ed), the acknowledged technical manual for the timber frame industry. See page 37 for Robin’s article on the importance of cavity barriers in timber frame construction.

www.bmtrada.com Timber technology Advisory service

>>

Nick Clifford

Senior Technical Timber Consultant in BM TRADA’s technical timber team.

Nick has more than 20 years’ experience in providing clear, concise, high-quality advice on timber-related issues to architects, engineers, contractors, developers, conservation bodies and public clients.

A qualified visual strength grader for timber with expertise in species identification, fungal decay, insect damage and wood preservation, Nick specialises in:

• carrying out independent condition surveys and inspections, diagnosing defects and writing expert witness reports

• assessing the condition of timber structures, flooring, cladding and decking.

Nick teaches visual strength grading and speaks regularly on timber-related subjects. See page 29 for Nick’s article on visual strength grading.

Lewis Taylor

Senior Timber Frame Consultant in BM TRADA’s technical timber team.

A highly respected expert in the science, technology and regulation of timber frame building, Lewis also consults on thermal performance, thermal bridging, airtightness, low-energy design and acoustic control. Most of his professional work is carried out under BM TRADA’s frameCHECK service and he:

• leads some of the timber industry’s latest research results on timber moisture content

• conducts independent quality inspections and condition surveys, evaluates design details, and investigates defects and their remedy

• speaks at trade events and delivers CPD.

Lewis is on the Technical Committees for both the Trussed Rafter Association and Robust Details and is co-author of several books, including the technical manual Timber frame construction (5th ed). See page 93 for Lewis’s article on his recent CLT and durability work.

frameCHECK

BM TRADA’s nationwide frameCHECK service offers architects, engineers, contractors and housing associations independent thirdparty advice on the design and build quality of timber-framed buildings.

BM TRADA services

The BM TRADA technical timber team can assist with any project involving any aspect of timber. Some of the types of consultancy we are often involved with include:

• Timber condition and structural surveys

• Design detail evaluation

• Timber frame inspection and consultancy

• Timber joinery inspections

• Timber cladding and decking inspections

• Timber and insect species identification

• Timber coatings inspection, testing and consultancy

• Timber expert witness services

• Timber training

About the author

Ben Sharples Commercial Lead Timber Services, BM TRADA

Ben works closely with the technical timber team to ensure that we deliver our full potential and provide the excellence within the construction industry that we strive to achieve.

Further information

For technical advice or consultancy services, contact the BM TRADA technical timber team on +44 (0) 1494 569601 or visit www.bmtrada.com/advisory-services

Timber 2022 | 25 www.bmtrada.com Timber technology Advisory service

Timber training: who benefits?

Timber training can help individual practitioners or a whole team of employees from the start of a building process right through to completion. BM TRADA develops and delivers courses for clients across and along the whole supply chain. These courses become a necessity for some suppliers; for example, the Visual Strength Grading course is designed to train delegates to strength grade timber, and forms an important part of the process for companies to place structural timber on the market.

Timber properties and uses

In recent years we have been more frequently asked by a broad range of users or suppliers of timber and timber products to deliver courses on timber as a material. These clients range from retailers and timber suppliers to engineers and architects, manufacturers and installers.

Often the first thing we are asked to provide is a course on a list of products and/or an end use. This can be challenging and sometimes limiting. To help with this we set up a course on Timber Properties and Uses, which provides delegates with a broad knowledge of how timber behaves and performs in any application and can be applied to most timber species and timber-based products.

Applying the principles

The following example illustrates and reinforces the importance of concepts that we are trying to convey.

A builder goes to his local timber merchant with their client, who is decidedly fussy about the quality of the timber they want to source to make bespoke wide planked flooring. A young lad named Steve shows the pair the best quality timber they have in stock and discovers during the conversation that the floorboards are going to be laid over underfloor heating.

Now Steve has been on one of our training courses and remembers an exercise with various scenarios that we use to show how to work out the expected shrinkage (and expansion) of timber. The aim of the exercise is to show how shockingly large the amount of shrinkage can be in a floor and how to reduce the risk of having large gaps developing between boards. We look at how to determine the moisture content of timber at the start of a given set of conditions (temperature and relative humidity), and work out the subsequent shrinkage after the underfloor heating has been turned on. We then show the difference between large, medium and small movement timbers, and demonstrate how to design and lay the floor to reduce and accommodate the shrinkage.

Steve remembered and knew that wide gaps between adjacent boards is a common complaint from end users. He couldn’t (and wasn’t expected to) remember any of the figures or numbers from the training exercise. However, he recalled that the moisture content at time of laying was important and that it was prudent to have narrower boards so that there were more gaps to accommodate the shrinkage. That is to say the more gaps you have, the narrower the average gap is between adjacent boards and, therefore, there is significantly less risk of unsightly or unacceptable large gaps appearing.

He managed to convince the builder and their client to select considerably narrower boards to make the bespoke flooring.

So, who gained from this advice? All three parties did. The builder’s client had a floor that behaved and functioned as they wanted and expected; the builder wasn’t called back to undertake costly repairs or be involved in a dispute; the timber merchant gained a reputation for being knowledgeable and wasn’t dragged into a potential dispute regarding the quality of the timber.

The combination of course content and an attentive attendee paid off.

26 | Timber 2022

Phil O’Leary explains how BM TRADA’s courses can help companies apply best practice principles.

Timber technology Wood knowledge

Scots pine at Keldy forest

Learning outcomes

Understanding how and when timber shrinks and swells, the difference in the three different planes in timber, the difference between species, fibre saturation point – knowledge of all these factors, and more, can be applied to timbers in most uses, if not all.

What is fibre saturation point and what are the three planes of timber? What are two of the properties that make Western red cedar a better choice for external cladding than oak in regards to their response to changes in moisture content? Well, I’m not going to tell you today, but you can probably find three out of the four answers fairly easily by searching online.

However, do you know what else you need to know? It’s difficult to type in search terms when you don’t know what you should be researching because you are not aware what questions you should be asking and you don't know what you don't know.

Fundamentals of timber

Following on from our Timber Properties and Uses course (which takes approximately a day to deliver), we have developed an eight-part series (45 minutes each), called Fundamentals of Timber. Part of the challenge is that there is not one logical order to follow, as so many of the principles of and topics relevant to timber are interrelated. But we have devised an order that we think best addresses the key issues.

Delegates who have attended Module 1: ‘What you need to consider when using and specifying timber’ will have a good understanding of what topics to research. While this first module doesn’t go into any details or explain any of the principles, the subsequent seven modules do. This is a huge subject area and although we can’t cover everything in this course, the fundamentals are fully explained.

Other courses

BM TRADA offers specific courses on topics such as timber frame, scaffold board grading or Eurocode 5, but the principles in Fundamentals of Timber still apply and give you a good grounding and better understanding of working with timber. n

About the author

Phil O’Leary Technical Manager, Timber Consultancy BM TRADA

Further information

For more information on BM TRADA timber training courses, visit www.bmtrada.com/training

Timber 2022 | 27 www.bmtrada.com

Timber technology Wood knowledge

Cupping can occur if timber is not specified and designed correctly

70 Cowcross St London EC1M 6EJ 0203 780 7355 ianchalkarchitects.com

How to become a competent visual grader

There are many benefits to employers who have a qualified grader on staff. Nick Clifford outlines what visual strength grading is and gives an overview of the specialist training available from BM TRADA.

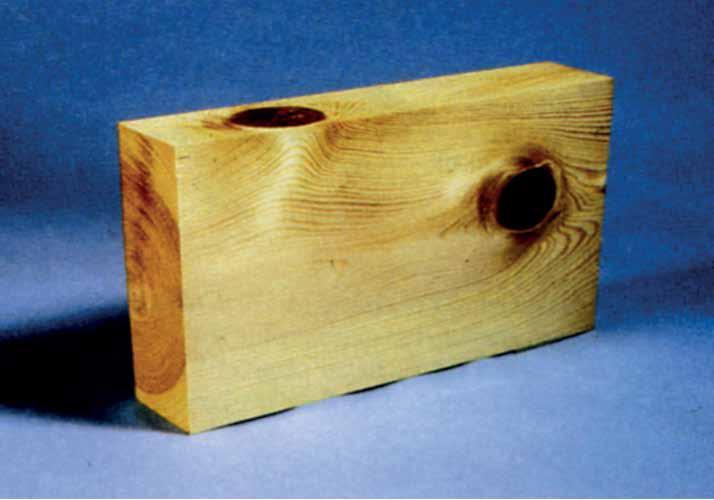

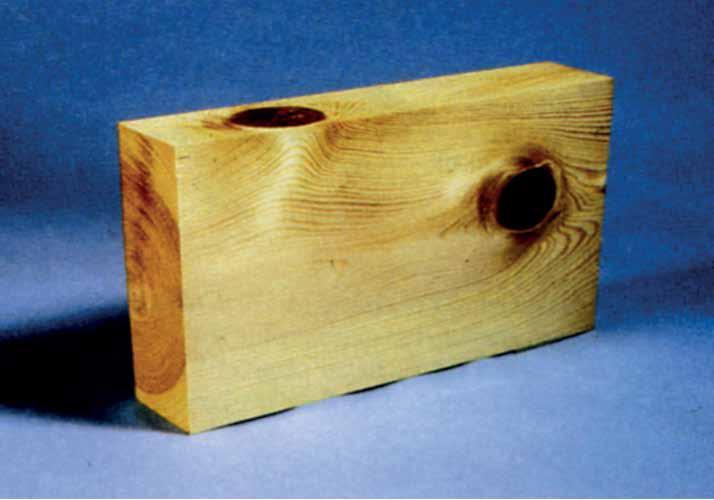

The days when there were plentiful resources of virgin growth logs from which large, long, near-perfect structural timbers could be cut are long gone. Modern timber markets must use smaller and younger trees grown and harvested sustainably. Yields would be too low if perfect timber was always required for structural applications, so wood with naturally occurring strength-reducing features is used.

What is strength grading?

Strength grading is the evaluation of these features, either by machine or visually. BM TRADA’s Visual Strength Grading (VSG) course teaches delegates how to:

• recognise and measure strength-reducing defects

• apply the appropriate strength-grading rules

• categorise each piece based on its quality.

You might question why trained visual strength graders are needed today when machines can efficiently grade high volumes of timber for structural uses, but there are distinct advantages to both methods. Visual graders can easily switch back and forth between grades, lengths and cross-section sizes, which is an advantage where smaller volumes of timber are needed in a range of sizes and grades. Visual graders are also mobile and have the potential to travel for grading at multiple sites, whereas machine grading needs a significant initial cost outlay and the machines are usually large, immobile and better suited for high volumes of a single grade or cross-section size in a single location.

Strength-reducing features

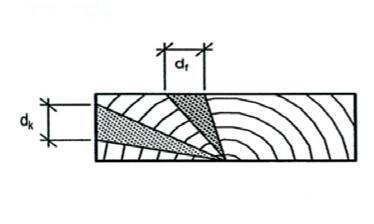

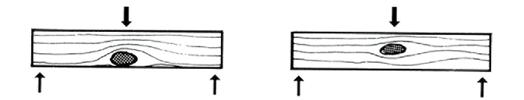

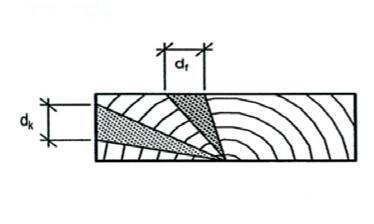

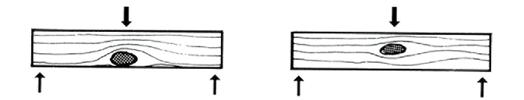

A basic principle of visual strength grading is to evaluate the effect of wood’s naturally occurring strength-reducing features on the cross-section (width x thickness) at the worst-affected point along the length of an individual piece. Some grading rules

change based on the grade or the size of the cross-section. Other rules stay the same for all grades. Knot rules are based on their size as well as their location within the piece. A grader must be able to select the right knot or cluster to assess when there are several to choose from and apply the rules accordingly.

Grain direction is very important as it can significantly reduce strength and must be measured and deemed within (or not) the allowable slope of grain, remembering that the maximum slope limit changes for different grades. Wane, which occurs as a consequence of processing, is also frequently present because square or rectangular lengths are cut from round logs. It reduces the cross-section but it is acceptable, within limits.

Biological attack

Biological attackers reduce the strength of a piece by an indeterminate amount. Fungal decay and most wood-boring insect damage is therefore unacceptable in structural timbers and is not allowed. However, mould and sap-stain fungi are allowed, since they only affect the aesthetics and not the strength of a piece. >>

Timber 2022 | 29 www.bmtrada.com Timber technology Wood knowledge

A graded section of timber should display the relevant strength class stamp

Shrinkage

Shrinkage caused by drying (either naturally over time or by kilning) sets up stresses that can cause fissures in wood, particularly in larger sizes, and also distortion such as bow, twist and spring. The depth of splits/fissures/checks/shakes, as well as the length (but not their width), influences loadbearing capacity so there are rules for allowable fissures. Checks or shakes (fissures that do not entirely pass through the whole cross-section) have limits on their length but they are unlimited if their depth is less than half the thickness of a piece. Fissures passing through the full thickness are correctly called splits, and these have much tighter limits as their influence on strength is much greater. Permissible limits for fissures vary for different grades and cross-section sizes.

Qualification and assessment

Delegates who pass a BM TRADA VSG course and exam are deemed competent strength-graders. They must join a third-party certification scheme to receive their personal grader number and stamp before they can structurally grade timber for commercial use. Certification schemes include regular audits to check grading records are maintained and up to date, and also to regularly assess individual grader performance as part of their ongoing monitoring.

Regular assessments of graders are important not just because good-quality graders often produce higher yields than poor graders, but also because grading skills can quickly become rusty without sufficient practice: incorrectly graded structural timbers potentially carry huge liabilities. BM TRADA consultants have investigated failed timbers that have caused injuries and unfortunately the occasional fatality. We have also been asked to comment when disputes arise over timber quality. One of the first things we check, or are asked, is whether or not the piece met the grade that was stamped on it.

Visual strength grading courses

The following aspects of visual strength grading are covered by BM TRADA’s specialist courses.

Terminology

Basic terms such as GS or SS, C16 and C24, D24, D30, THA, TH2 that are common for structural timber in the UK will be familiar to those who have attended a VSG grader course. A competent grader must understand the difference between strength grade and strength class. Different timber species have a wide range of properties, including their strength, so categorising the timber by quality (grading) isn’t the full picture when it comes to assigning a strength class. It’s important to know the species and source of the wood, for example whether it was imported, or grown in the UK.

30 | Timber 2022

Knot distribution Knot position

Edge and face knots

Timber technology Wood knowledge

A piece of timber being visually strength graded

Species recognition

The species recognition aspect of the course helps delegates to begin to separate one timber from another based on macro-features such as knot size, colour and distribution, as well as grain pattern, heartwood/sapwood boundary and rate of growth. This helps to ensure that the correct strength class is assigned and stamped on the wood after grading.

Examination and assessment

Understanding the principles of strength grading is tested through an exam. If you can identify the defects in a piece and measure them correctly, you have a great chance of passing. The courses are not memory tests and people are not expected to memorise the numerous grading rules and variations between grades – in the real world you can check the rules as you grade using the appropriate standard, so you can refer to the rules that are included in the course booklet at any time throughout the course and exam.

BM TRADA softwood VSG courses run several times each year and the hardwood VSG courses run once or twice annually. Attending a BM TRADA VSG course guarantees an improved understanding of timber. Passing the course and

the exam authorises delegates to carry out strength grading for their company, while all delegates will be better placed to talk to customers and clients with a greater knowledge of not just structural timber, but of wood generally. n

About the author

Nick Clifford Senior Timber Technical Consultant BM TRADA

Further information

To find out more about BM TRADA’s Visual Strength Grading courses, visit www.bmtrada.com/training/timber-training

Further reading

• WIS 2/3-10

Timber properties and uses, BM TRADA, 2021

• WIS 4-7 Timber strength grading and strength classes, BM TRADA, 2021

Timber 2022 | 31 www.bmtrada.com

Timber technology Wood knowledge

Different types of wood, such as the hardwood pictured, have different properties so it is important to know the species and the source of the wood

Specifying and sourcing timber in construction

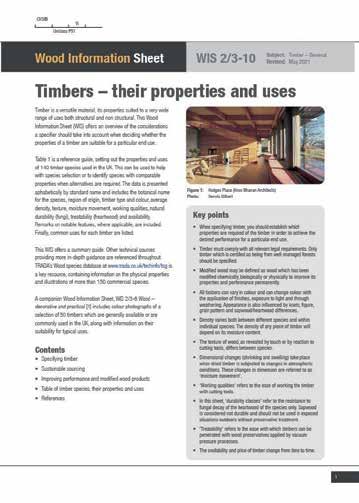

The following is an extract from Wood Information Sheet 2/3-10 Timbers – their properties and uses, which had a major update in 2021.

Timber is a versatile material, its properties suited to a very wide range of uses both structural and non-structural. Wood Information Sheet (WIS) 2/3-10 offers an overview of the considerations a specifier should take into account when deciding whether the properties of a timber are suitable for a particular end use.

Specifying timber

While trees capture carbon dioxide from the atmosphere, store carbon as a ‘building block’ of timber and release oxygen back into the atmosphere, timber is both renewable

and recyclable. Timber has therefore gained a very welldeserved reputation for being an environmentally friendly and versatile material.

Timber is used widely in a range of applications and evidence of its versatility is all around us. It can be used for numerous external and internal purposes, ranging from structural posts, beams, joists and rafters, to nonstructural external timber cladding, fencing, windows and doors, and interior flooring. It is also used for furniture and specialist uses such as musical instruments and tool handles.

32 | Timber 2022

Timber technology Wood knowledge

Hodges Place (Knox Bhavan Architects). Photo: Dennis Gilbert

When choosing from the range of timber species available, a specifer should establish which properties are required of the timber to achieve the desired performance for a particular end use.

Sustainable sourcing

Prior to 31 December 2020 and the UK’s final departure from the EU Customs Union and the European single market, timber traded in the UK had to comply with the EU Timber Regulation (EUTR).1 Since 1 January 2021, the UK construction industry must follow the UK Government’s own Timber and Timber Products Placing on the Market Regulations (UKTR).2 While the UKTR has many of the same requirements as the EUTR, it will lead to some changes for timber suppliers. The EUTR requires that timber placed on the European market is supplied in accordance with the relevant national laws of the country of origin. It also requires evidence of supply chain traceability. Under UKTR, operators must collect and demonstrate much more detailed due diligence procedures. They are obliged to ensure there is ‘negligible risk’ of illegally harvested timber entering their supply chains, for example; your timber supplier will have dealt with this requirement.3

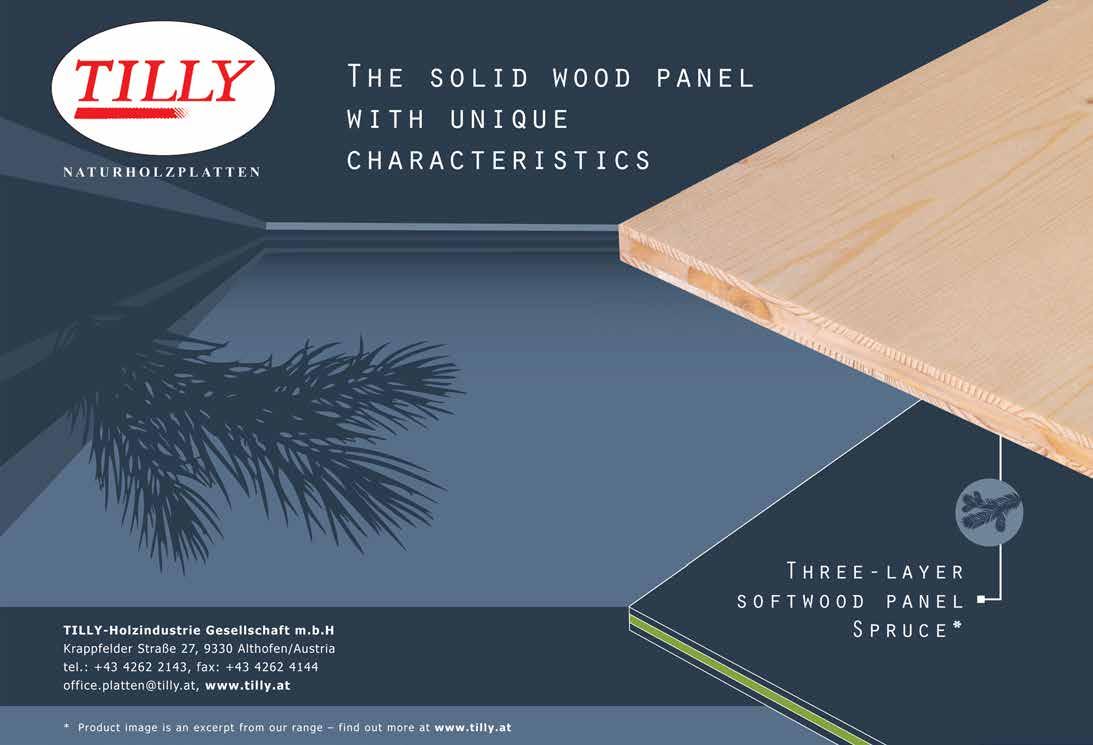

Chain of custody certification schemes to support the sustainable sourcing process are available, such as those operated by the Forest Stewardship Council® (FSC®) and the Programme for the Endorsement of Forest Certification (PEFC™). These third-party certification schemes verify that timber suppliers are part of an unbroken ‘chain of custody’ system, which provides proof that the timber used to process or manufacture an end product was sourced from a well-managed forest. Certification labels on the end product demonstrate compliance with schemes such as those maintained by FSC® and PEFC™.4

Some species, notably tropical hardwoods prized for their decorative features, are no longer readily available. For example, rosewood (Dalbergia nigra) is listed under Appendix I to the Convention on International Trade in Endangered Species (CITES), meaning trade is severely restricted, whereas other Dalbergia spp. may be available. For an indication of whether a species is under threat or endangered, refer to:

• Checklist of CITES Species5

• The IUCN Red List of Threatened Species.6

British-grown timber is available for a number of end uses, particularly for sawn timber, particleboard and fibreboard.7 n

Further information

The full version of this Wood Information Sheet is available to buy from bookshop.bmtrada.com

References

1. Regulation (EU) No 995/2010 of the European Parliament and of the Council of 20 October 2010 laying down the obligations of operators who place timber and timber products on the market

2. www.gov.uk/guidance/regulations-timber-and-flegt-licences

3. More information can be found at gov.uk

4. For more information, see WIS 2/3-58 Sustainable timber sourcing, BM TRADA, 2019

5. http://checklist.cites.org

6. www.iucnredlist.org

7. For more information, see WIS 2/3-67 Specifying Britishgrown timbers, BM TRADA, 2022. This WIS contains a detailed set of species data sheets for a number of Britain’s timbers including oak, ash and Douglas fir

8. For more information, see WIS 2/3-63 Modified wood products, BM TRADA, 2021

Timber 2022 | 33 www.bmtrada.com

FSC-A000503 / PEFC/16-44-002 Timber technology Wood knowledge

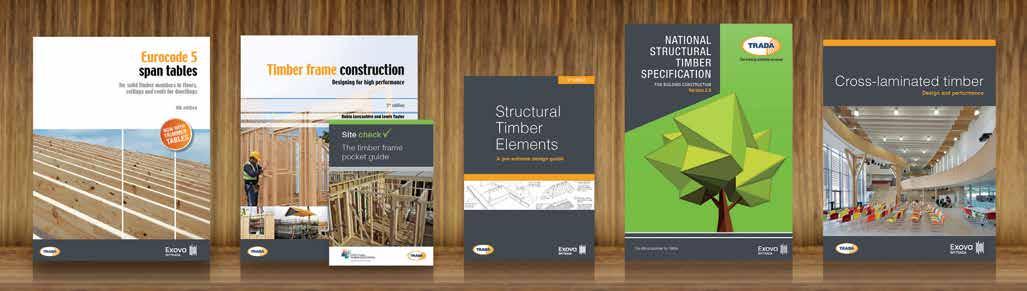

An introduction to timber connections

The following extract comes from BM TRADA’s newest publication series with guidance for engineers.

Timber has been used as a construction material for generations. From the early Japanese ‘Tateana Dwellings’ to the architecture of the Victorian era of England, the ingenious use of timber as a construction material is evident, through techniques developed independent of country or continental boundaries.

Local abundance of the material and the ease of conversion with the most basic of tools meant that solutions to some of the fundamental problems of construction seemed to have been found with relative ease in timber. The forming of a rudimentary curved notch on the underside of a round log to form a gravity fit in early cabin constructions, for example, is still used today, albeit with modern tools that allow this joint to be made more precise.

Studying the evolution of timber roofs from ancient times to the modern trussed rafter constructions, one can clearly see how our understanding of the modern ‘triangulated’ structures has been heavily influenced by the ingenuity of early timber constructions.

Understanding timber

Being a natural material with varying properties and limitations in available sizes, designing with timber warrants a specialist understanding of the product. Strength and stiffness properties of timber are dependent on the species of wood and the geographical region of growth, as well as on the humidity and the temperature of the environment to which the structure is exposed. Duration of loading also has an effect. All these should be considered when designing structures with timber.

Optimising the use of available sizes of the material makes designing connections an integral part of any timber engineering project, with anisotropy and the variability of the material adding greater complexity to the problem.

Resolving connections

Most complex timber engineering projects require the connections to be resolved first, or at least in parallel with the sizing of the members, as the member sizes are most likely to be governed by the requirements of the connections. Intensity of the loads to be transferred between timber members across a joint, and the geometry of the group of fasteners forming the connection, will determine the stress levels generated within the timber surrounding each fastener.

34 | Timber 2022

Royal Academy Music Recital Room. Photo: Adam Scott

Timber technology Engineering

When such stresses are managed through proper calculations and appropriate detailing, localised failures within members, which could ultimately lead to the failure of the connection and the structure as a whole, can be easily prevented.

At the most basic level, timber connections can be classified as:

• all-timber (carpentry) connections

• connections involving metal fasteners or connectors

• glued connections.

Combinations of these three types are also possible and are widely used.

Metal fasteners or connectors

Connections involving metal fasteners or connectors can be further divided into two main groups based on the mechanism of force transfer between the fastener and the timber members being connected. The first group involves dowel-type fasteners, such as nails, staples, bolts, dowels and screws, where the loads being transferred across the joint generate bending and tensile stresses in the fasteners, as well as embedment and shear stresses within the timber along the shank of the fastener. These are the most frequently used fasteners in contemporary connections.

The second group also involving metal fasteners are the surface or partial penetration fastener types such as punched metal plate fasteners, nailing plates, toothed metal plate fasteners, split and shear ring fasteners, where the load transfer is related to the surface area of the timber members and associated metalwork.

Dowel-type connections

Dowel-type connections involve the most common metallic fastener types in use, which includes nails, staples, bolts, dowels and screws. In discussing these connections, it is vital to understand the characteristics of these fasteners, their specifications and the load-carrying mechanisms involved.

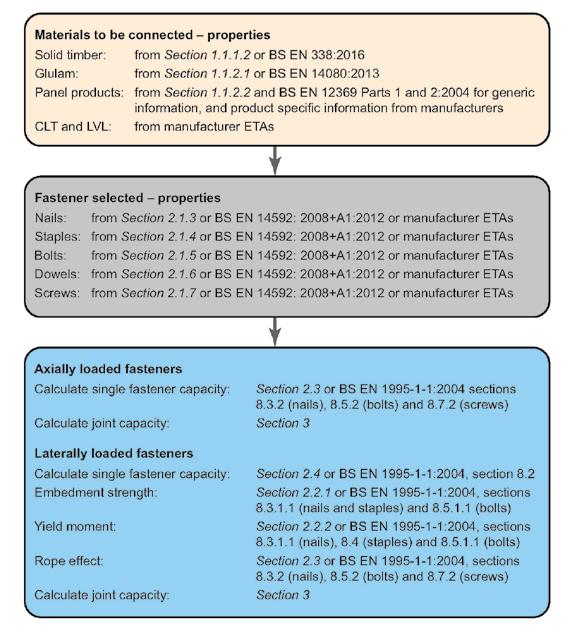

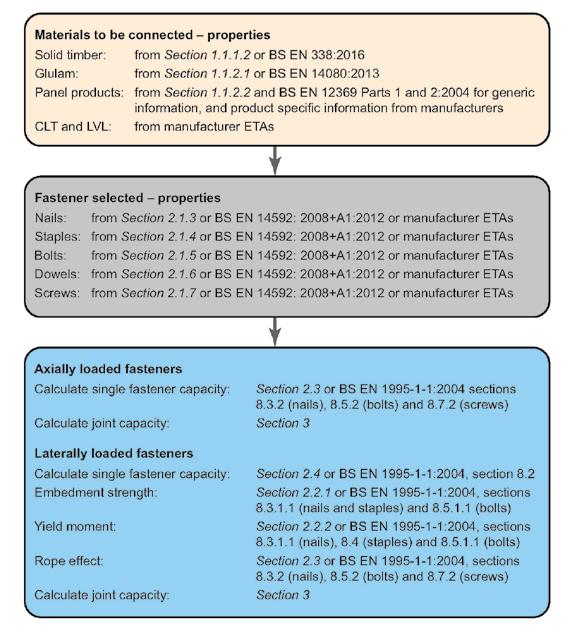

Modern design methods for connections, such as the European Yield Model based calculations presented in Eurocode 5, require the designers to establish the capacity of an individual fastener in a given joint, before looking at combining them in a group to form the joint.

The sequence of steps shown in Figure 1 should be followed to calculate the capacity of dowel-type connections, for which the dimensions of the materials to be connected are assumed. Some of these dimensions may need modification later to suit the calculations, or a different connection specified if the member sizes should remain unaltered. n

Further information

Timber connections: a guide for engineers. Part 1 – Theory is available to buy from bookshop.trada.co.uk

• Part 1 – Theory aims to explain the theoretical principles of timber connections, primarily the dowel-type connections.

• Part 2 will supplement Part 1, containing advanced topics such as fire resistance, brittle failure and durability.

• Part 3 will contain worked examples highlighting some of the principles discussed in the first two parts.

• Part 4 will look at recent connection exemplars, with the focus on engineering aspects.

• Part 5 will complete the series by looking at proprietary connectors commonly available on the market.

Further reading

• Ross, P., Hislop, P., Mansfield-Williams, H., Young, A., Concise illustrated guide to timber connections, ISBN 978-1-90510-851, BM TRADA, 2012

• WIS 2/3-36 Design of structural timber connections, BM TRADA, 2017

Timber 2022 | 35 www.bmtrada.com

Timber technology Engineering

Figure 1: Connections design flow diagram

36 | Timber 2022

ENGINEERING EXPERTS Harmony Timber Frame is a leading manufacturer of off-site construction and engineered Timber Frame Kits.

Harmony Timber Frame UK, Unit 1b/2a, Canterbury Ind Park, Island Road, Hersden, Canterbury, Kent, CT3 4HQ

TIMBER

• Fabric First • Reduced Site Construction Time • Accurate • Manufactured Offsite • Environmentally Friendly For more information contact us today on: 01227 209 087 www.harmonytimber.co.uk

GLULAM ROOF & FLOOR CASSETTES

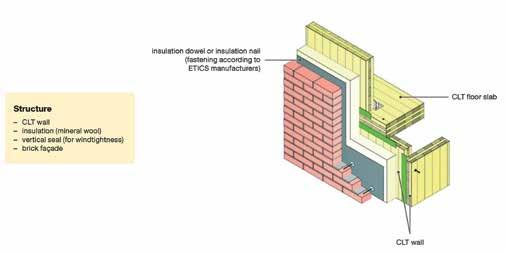

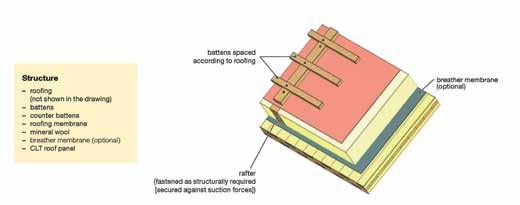

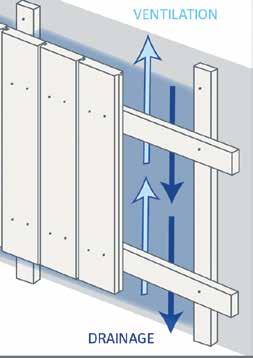

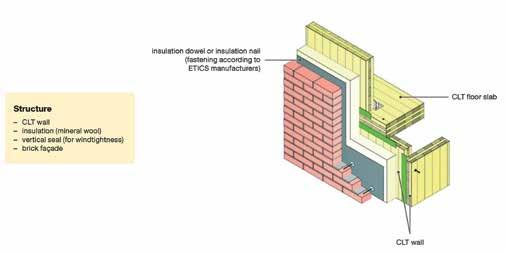

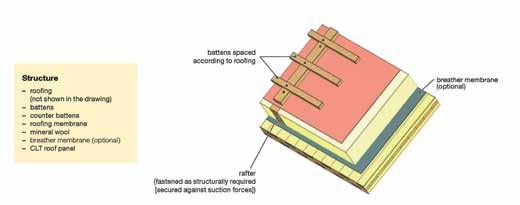

The importance of cavity barriers

Robin Lancashire explains the key role of cavity barriers in timber frame construction and how they can limit the spread of fire.

While the importance of cavity barriers is increasingly recognised, the construction industry still needs to concentrate on ensuring that they are installed correctly, so that in the event of a fire they can perform as intended.

Cavity barrier performance

Recent fire events in various building types have turned attention to the performance of cavity barriers and how they are installed in buildings. The cavity barrier plays a critical role in preventing fire and smoke from travelling unseen through what can be an extensive network of connected spaces in a building. Acting much like a chimney, a cavity can allow fire and smoke to travel fast and unseen, making it difficult to fight fires, causing extensive damage and risking lives. National building regulations tell us where cavity barriers should be installed, what they should be constructed of and how they should be fitted. There are some regulatory differences between the nations that make up the UK, both in terminology and specific requirements, but the principles are all the same – limit the spread of fire in a cavity.

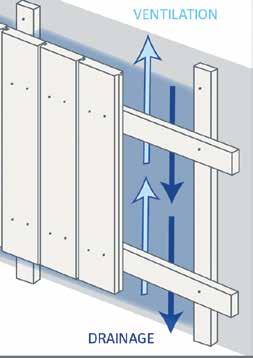

Balancing ventilation and fire safety

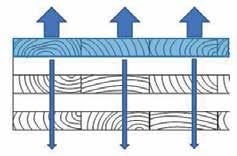

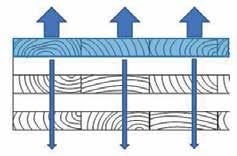

When building with timber frame, it is important to accommodate the requirement for cavity barriers along with the need to provide an environment where timber elements can remain dry and below the decay threshold (a moisture content of 20% or less). Timber frame construction needs a drained and vented external wall cavity behind all types of cladding. This provides a space where moisture vapour that travels though from the warm side of the wall to the cold side can ventilate away, without forming as damaging interstitial condensation.

The external wall cavity is also a line of defence from the outside: it prevents wind-driven rain or leaks through the cladding from directly wetting the timber frame structure by letting moisture drain away freely. The challenge therefore is to provide cavity barriers where required, while allowing the timber frame structure to drain and vent.

Timber Frame Construction (5th edition) is the go-to publication for those designing and building with this increasingly popular material. The cladding chapter of the book provides detailed sections of various cladding types, along with information on how external wall cavities are closed at required locations, while still providing the necessary drainage and ventilation.

Fire resistance

It may be surprising to learn that timber is listed in the building regulations as a material that can be used to provide the necessary fire resistance of a cavity barrier. However, it is the material of choice for cavity barriers around window and door openings, and with claddings that are supported by the timber frame structure. In the event of a fire, the timber slowly chars at a predictable rate so it can provide the required period of fire resistance. It can be installed in continuous lengths, is reasonably robust during construction and fulfils other roles while acting as a cavity barrier. >>

Timber 2022 | 37 www.bmtrada.com

Timber cavity barrier around a window

Timber technology Timber frame

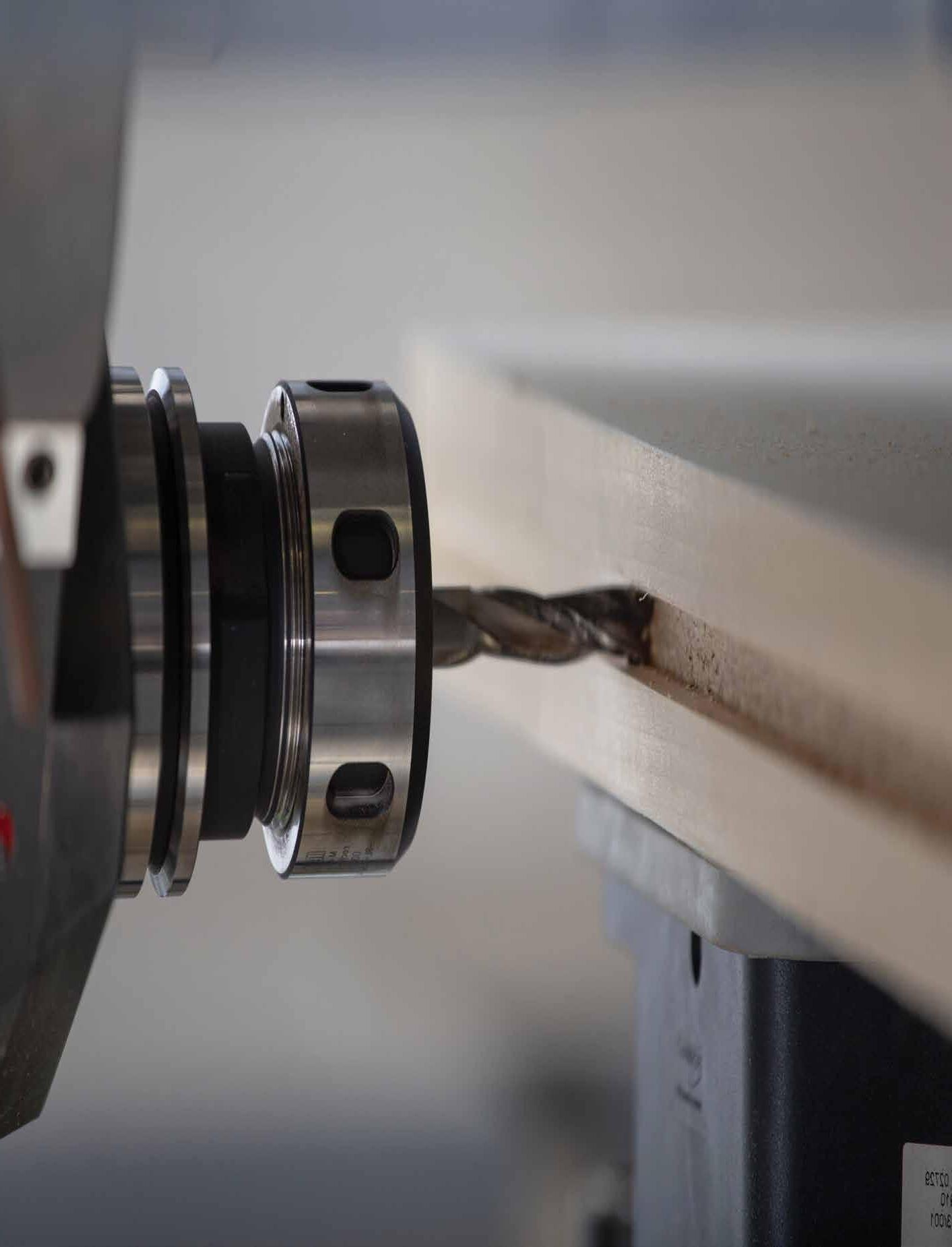

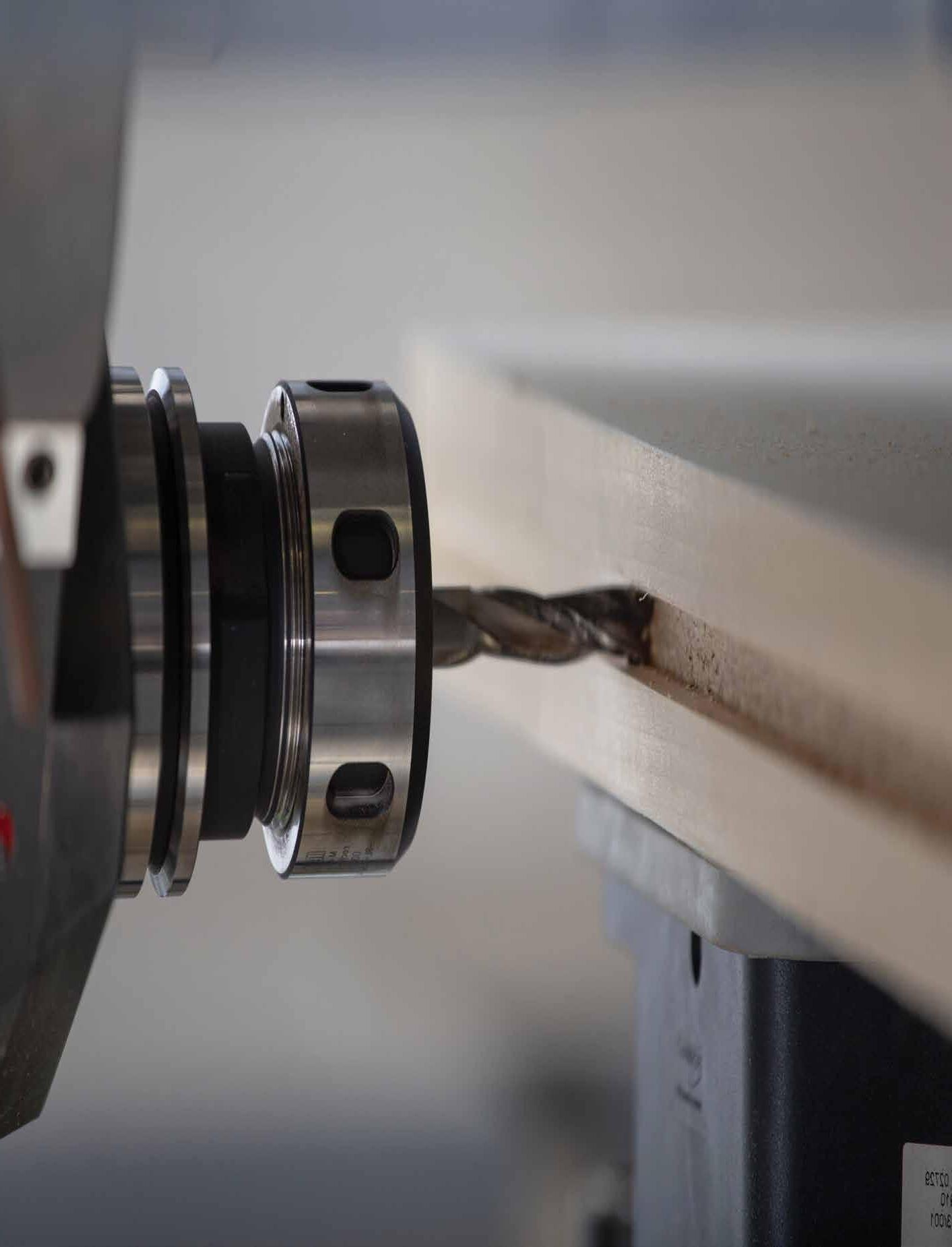

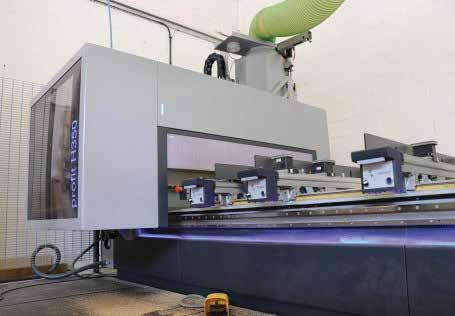

Whether it’s a bespoke one-off design or multiples, Timber Frame Management (TFM) has sustainability and climate change at the forefront when designing and manufacturing your project.

Timber is a natural carbon store and a renewable resource which makes it an ideal and environmentally conscious building material. The offsite manufacturing process produces less waste than traditional construction meaning less material ends up in landfill. Even after transportation, timber often has a negative carbon footprint.

TFM have recently invested in a new wood fired heater so that even the small off cuts from the optimised CNC cutting process in the factory are used to warm the building.

Join forces with us on your next project and become a part of the sustainable building revolution.

• Speed of build

• Low carbon footprint

• Reduced build times

• Positive environmental impact

• Significantly reduced carbon compared with traditional build methods

Join forces with us on your next project and become a part of the sustainable building revolution.

The typically red polythene covered strips of mineral wool that adorn many timber frame buildings under construction are a common sight: these perform well as a cavity barrier if they are fitted in a continuous line and are sized to be installed under compression to fully close the cavity. Remember that in the event of a fire, the polythene sleeve quickly burns, providing no support to keep it in place. Precise sizing to ensure a compression fit of the mineral wool core is therefore critical to stop these strips falling down the cavity and failing. They can also be easily damaged or dislodged during the construction phase.

Although more expensive than timber or mineral wool, intumescent cavity barriers are gaining popularity. In the early stages of a fire and exposure to heat, they are designed to swell up, closing the cavity against further fire and smoke. In their inactive state they can contribute to good drainage and ventilation through a clear cavity. This can simplify detailing and reduce the need for what can be unsightly drainage slots.

Party walls

Cavities are not only found in external walls. The other key area where they occur is in party walls. Timber frame buildings rely on cavities to reduce acoustic transfer between areas of the same building. These cavities need closing at compartment lines to prevent fire and smoke having a direct route between them. Hard materials cannot be used as cavity barriers here as these would provide a route for acoustic transfer, so wire reinforced mineral wool or polythene sleeved mineral wool cavity barriers tend to be used in these locations. It is critical that they are fixed and sized to close the cavity and remain in place at compartment lines.

While most cavity barriers are installed at edges of cavities and along compartment lines, there are other locations where they are required by national building regulations. The relevant statutory documents should be consulted. n

BM TRADA frameCHECK

BM TRADA’s frameCHECK team specialises in providing consultancy on the design and construction of timber frame buildings. Its work assists all those involved in timber frame construction by helping to ensure that buildings can be detailed and constructed to best practice. Typical consultancy work involves evaluating drawing details and visiting sites under construction to provide specific advice. Whether you are an architect, contractor, surveyor or building owner, consider using the frameCHECK service, which has been helping raise the standards of timber frame construction for more than 25 years.

Timber 2022 | 39 www.bmtrada.com About the author Robin Lancashire Senior Timber Frame Consultant BM TRADA Further information For technical advice or consultancy services, contact the BM TRADA technical timber team on +44 (0) 1494 569601 or visit www.bmtrada.com/advisory-services Further reading • Timber frame construction, 5th edition, ISBN 978-1-900510820, BM TRADA, 2011 • WIS 0-3 Introduction to timber frame construction, BM TRADA, 2020

Sheathing with breather membrane over Flexible cavity barrier of wire reinforced mineral wool or approved cavity barrier Cavity barrier: Typically proprietary third party approved sleeved mineral wool cavity barriers Party wall Party wall junction with external wall Timber technology Timber frame

Junction of element firestopped with plasterboard linings

Sill detail

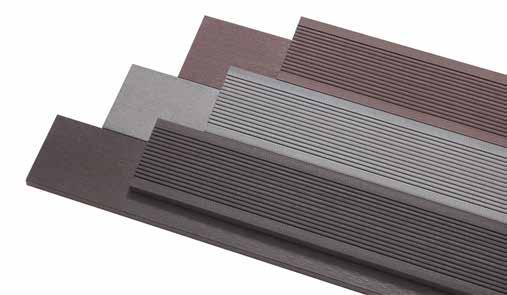

LET’S BUILD A DURABLE AND SUSTAINABLE FUTURE FOR GENERATIONS TO COME BY MAKING THE MOST OF EVERY TREE.

A WIDE RANGE OF TIMBER PRODUCTS: Glulam, CLT, C24, cladding, decking, fencing and landscaping timbers, UC4 15/20-year warranted timbers, wood composite cladding, decking and fencing and wood pellets.

LOCALLY SOURCED AND CERTIFIED TIMBER SPECIES: Pine, Douglas Fir, Spruce.