TIMBER 2023

imber Indus t r y Ye a r bo ok 2023 Topics include: Part L and timber frame, wood borers, assessing plywood quality TIMBER TECHNOLOGY BM TRADA certified companies FIND A SUPPLIER Circular economy, durable timber structures, new fire regulations, treated timber, joinery skills TECHNICAL FEATURES - The New Library, Magdalene College - Ibstock Place School Refectory - Homerton College Dining Hall OUTSTANDING USE OF TIMBER

t

Woodsafe Exterior WFX flame retardant treated wood. Pictures shows spruce (stained), western red cedar and thermowood pine

Woodsafe Exterior WFX flame retardant treated wood. Pictures shows spruce (stained), western red cedar and thermowood pine

Flame retardant cladding by Woodsafe enables the architects vision and creative possibilities to build in wood. Woodsafe ensures the right conditions for contractors to build with the only renewable building material available.

Trustworthy investment and Co2 neutral production of flame retardant treated wood. We are offering accoya, douglas fir, wrc, larch, pine, wrc shingle, nobelwood, frake, poplar, oak, birch and more. Our services include flame retardant impregnation for interior and exterior use, as well as raw material, processing and surface treatment when needed.

• Certificate of Constancy of Performance

• Durability of reaction to fire performance

• WPA Benchmark, approved treater

• ISO certification

• Sustainability report and manual

| EN14915:2013

| EN16755 INT1, INT2, EXT

| Certificate nr:1901-1

| 9001:2015, 14001:2015

| Sustainability report

• We use trustworthy RISE (No.body 0402) for all test, control and certifications.

Find out more at | www.woodsafe.com

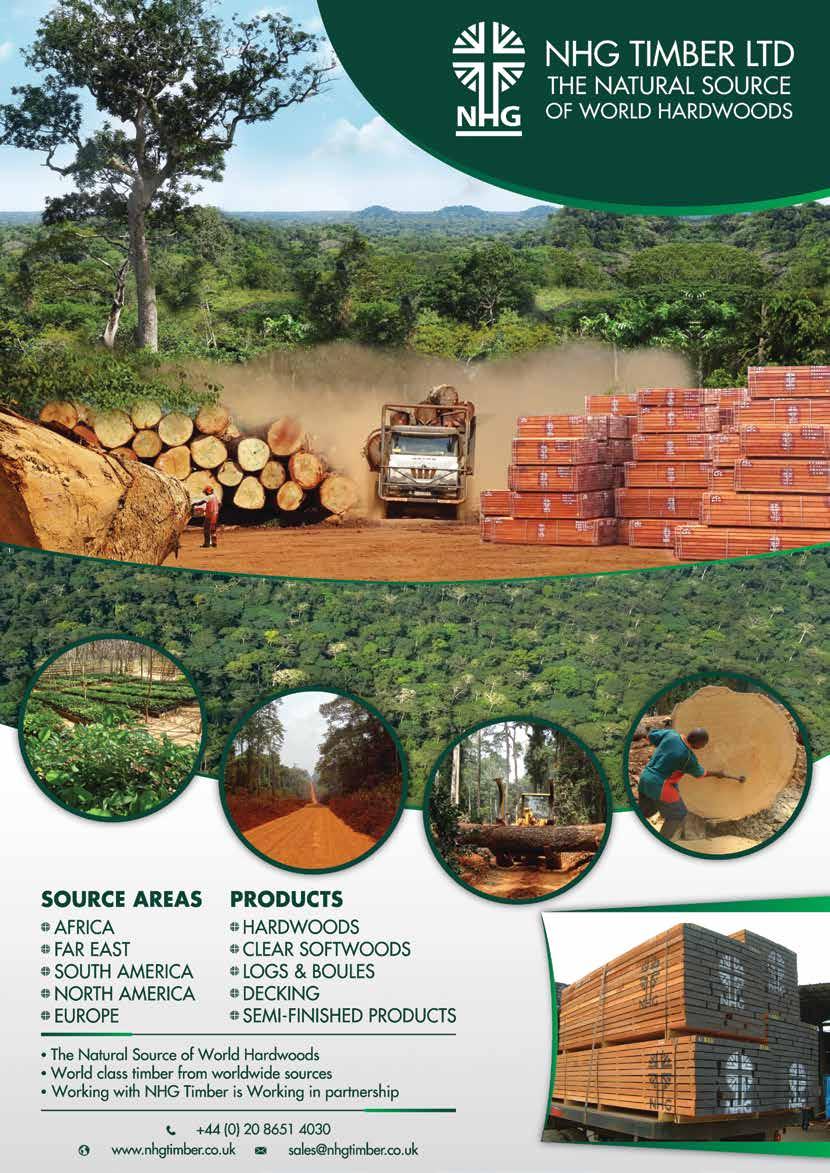

the complete timber service HARDWOODS > CLEAR SOFTWOODS > EUROPEAN REDWOODS > HOME GROWN TIMBER > PACK SALES > MACHINING > FINISHING STOCKED & BESPOKE MOULDINGS > CLADDING > DECKING > HARDWOOD FLOORING > LAMINATING & ENGINEERED PRODUCTS SHEET MATERIALS > RESPONSIBLE SOURCING AND OTHER CONTROLLED SOURCES > CUSTOMER SUPPORT > NATIONWIDE DISTRIBUTION Maldon (Head Office): Blackwater Place I The Causeway I Maldon I Essex CM9 4GG I Telephone: 01621 877400 Danbury: The Timber Yard I off Runsell Lane I Danbury I Essex CM3 4PE I Telephone: 01245 221700 Nottingham: Lenton Lane I Nottingham NG7 2PR I Telephone: 0115 993 1112 Sewstern: Gunby Road I Sewstern I Grantham I Lincolnshire NG33 5RD I Telephone: 01476 861097 Skelmersdale: 1-3 Glebe Road I Gillibrands I Skelmersdale I Lancashire WN8 9JP I Telephone: 01695 553700 Email: sales@brookstimber.co.uk I Website: www.brookstimber.com

t imber

Indus t r y Ye a r bo ok

2023

Part L and timber frame, wood borers,

plywood quality TIMBER TECHNOLOGY BM TRADA certified companies FIND A SUPPLIER Circular economy, durable timber structures, new fire regulations, treated timber, joinery skills TECHNICAL FEATURES - The New Library, Magdalene College - Ibstock Place School Refectory - Homerton College Dining Hall OUTSTANDING USE OF TIMBER

Topics include:

assessing

Published in 2023 by: Chiltern House, Stocking Lane

Hughenden Valley, High Wycombe

Buckinghamshire HP14 4ND

t +44 (0)1494 569601

e timberadvice@bmtrada.com

w www.bmtrada.com

While every effort is made to ensure the accuracy of the articles included, the company cannot accept liability for loss or damage arising from the information supplied. The opinions expressed do not necessarily represent or reflect the views of the publisher.

All rights reserved. No part of this publication may be reproduced, stored in a retrieval system, or transmitted in any form, by any means, electronic, mechanical, photocopying, recording or otherwise, without the prior permission of the copyright owners.

© 2023 Warringtonfire Testing and Certification Ltd

The publisher gratefully acknowledges the support of the firms whose advertisements appear in this publication. While every care has been taken in compiling this publication, the publisher cannot accept responsibility for any inaccuracies, or for the products or services advertised.

All photographs and illustrations are © Warringtonfire Testing and Certification Limited unless otherwise credited.

Production by:

Open Box Media and Communications

13 Premier House, St Paul’s, Birmingham B3 1RB

t +44 (0)121 200 7820

e inside@ob-mc.co.uk

w www.ob-mc.co.uk

We are committed to sustainable forest management and this publication is printed by Buxton Press who are certified to BS EN ISO 14001: 2015 (Environmental Management System). Buxton prints only with 100% vegetable based inks and uses alcohol free printing solutions, minimising volatile organic compounds as well as ozone damaging emissions.

07 Welcome: foreword Working together

Welcome to the 2023 edition of BM TRADA’s Timber Industry Yearbook and a fresh collection of technical timber articles.

09 News: industry updates

The timber sector in 2022

Spotlight on last year’s activities and initiatives.

14 Events: 2022 award winners

Celebrating outstanding use of timber

Celebrating the worthy winners across last year’s building design awards such as the RIBA Stirling Prize, RIBA National and Regional Awards, Wood Awards and IStructE Structural Awards.

Timber technology

20 Wood knowledge

Your timber questions answered

Phil O’Leary tackles just a few of your questions from BM TRADA’s popular webinar series.

22 Wood knowledge What is eating my timber?

Nick Clifford discusses your concerns about insect infestation in wood and explains how to reduce the risks.

26 Wood knowledge

Top tips on how to buy good quality plywood

Gavin Fidler clears up some common misunderstandings about plywood before outlining some tips for buying quality plywood that can be used safely for structural applications.

30 Wood knowledge

How to inspect and assess used scaffold board

Phil O’Leary explains how to maximise the service life of your scaffold boards while preventing health and safety failures.

32 Regulation Streamlining standards across construction

Hugh Mansfield-Williams and Keerthi Ranashinghe discuss the need to embrace change in guidance for the timber industry.

34 Timber frame

Part L and timber frame

Robin Lancashire looks at how designers and contractors can apply the recent changes to Approved Document L while assuring safety and performance benefits without conflict.

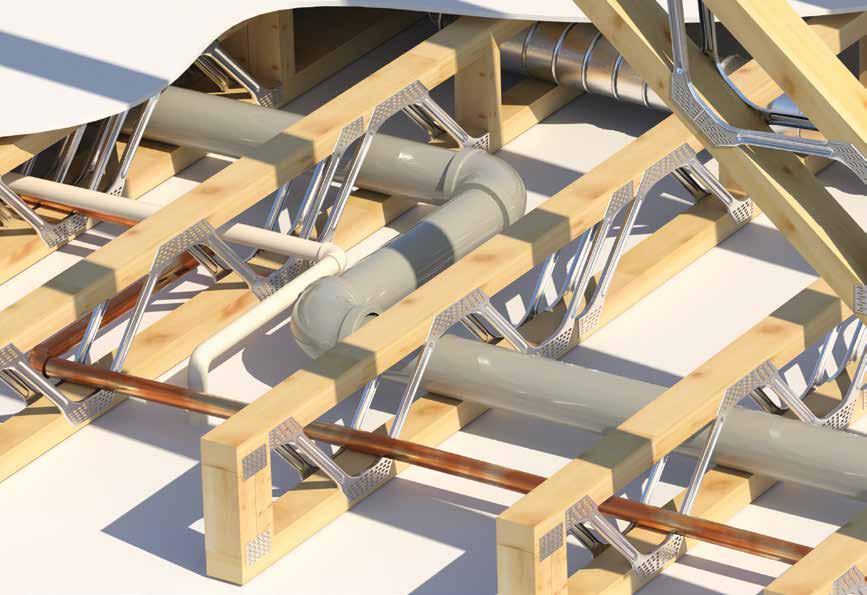

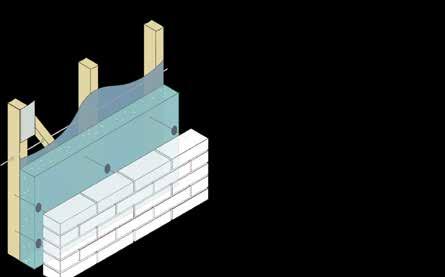

38 Timber frame Moisture and timber in construction

Lewis Taylor and Andrew Pitman introduce timber’s relationship with water and the ways to account for it in building design.

40 Timber frame

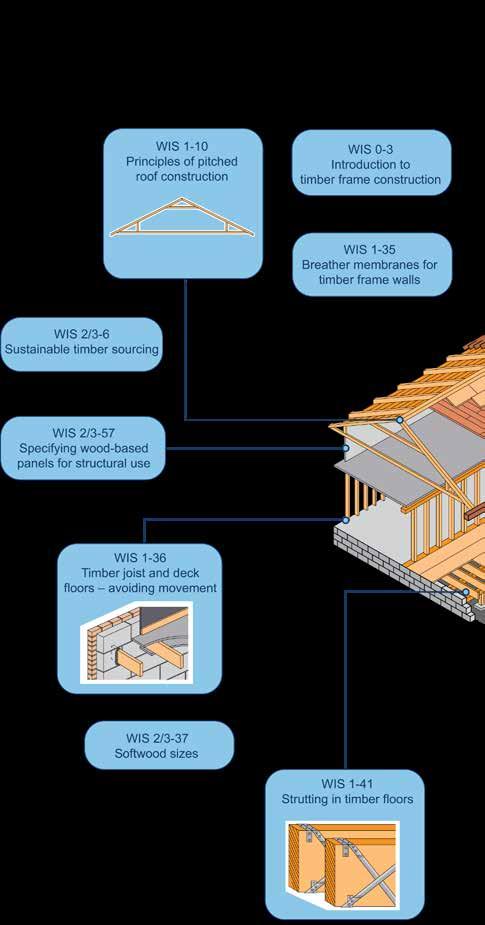

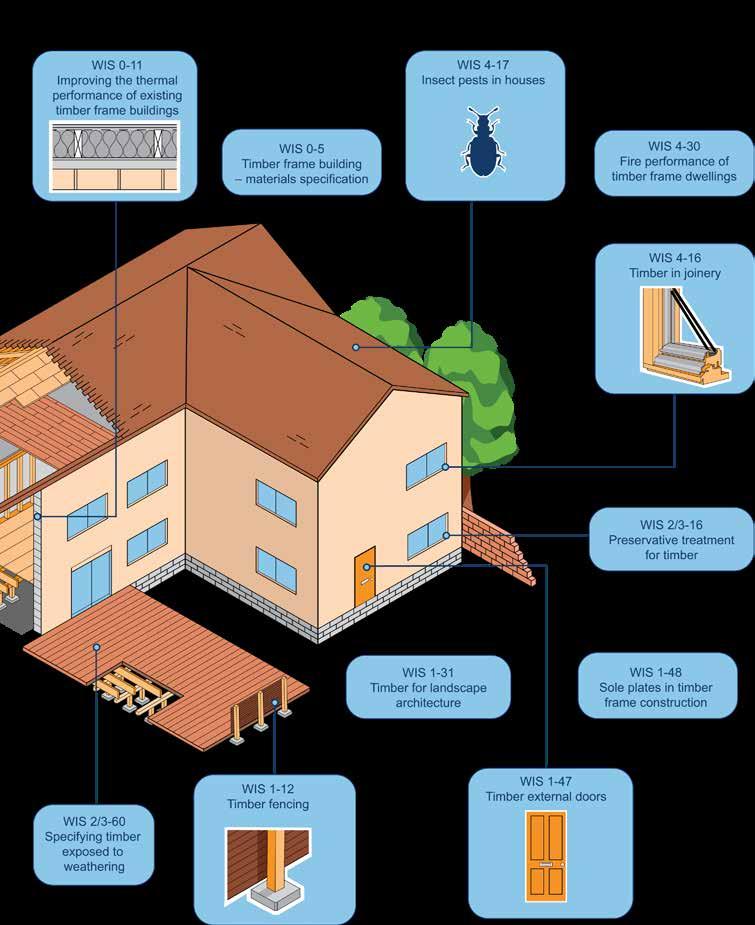

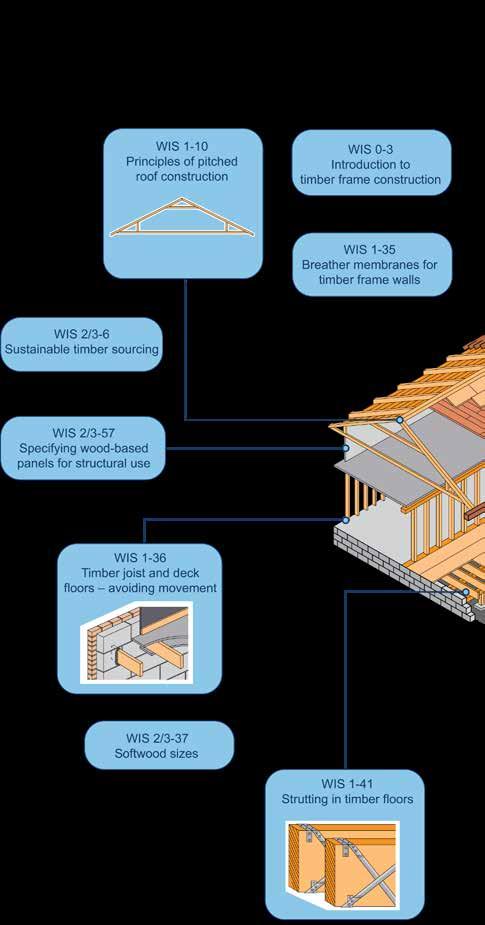

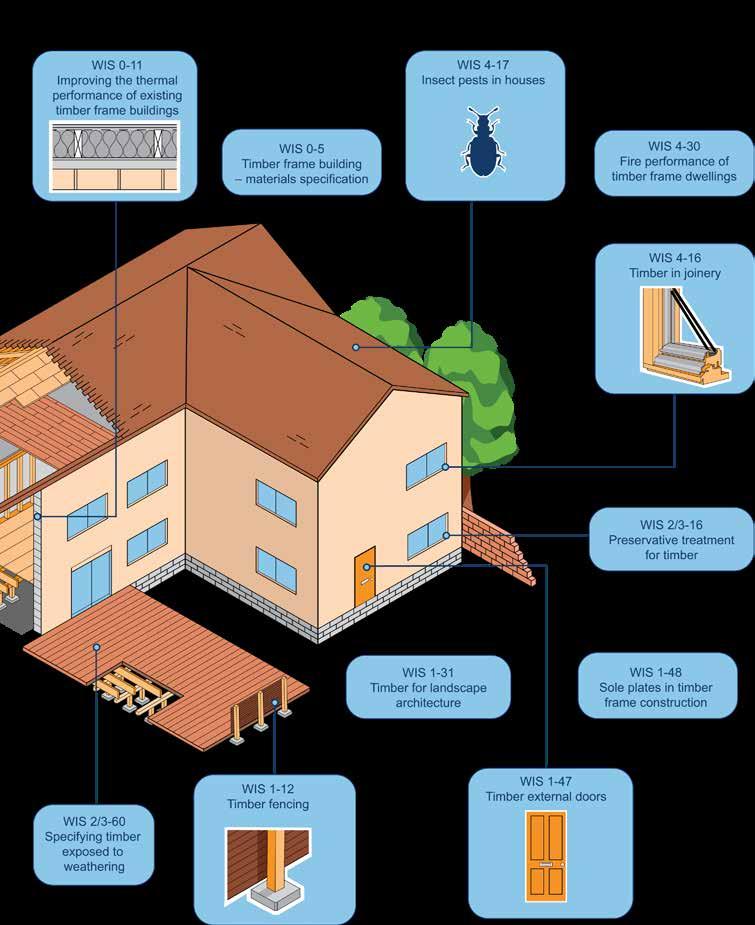

The WISdom of timber

BM TRADA Wood Information Sheets provide specifiers, builders and suppliers with concise guidelines on timber challenges.

ISBN: 978-1-915554-01-7

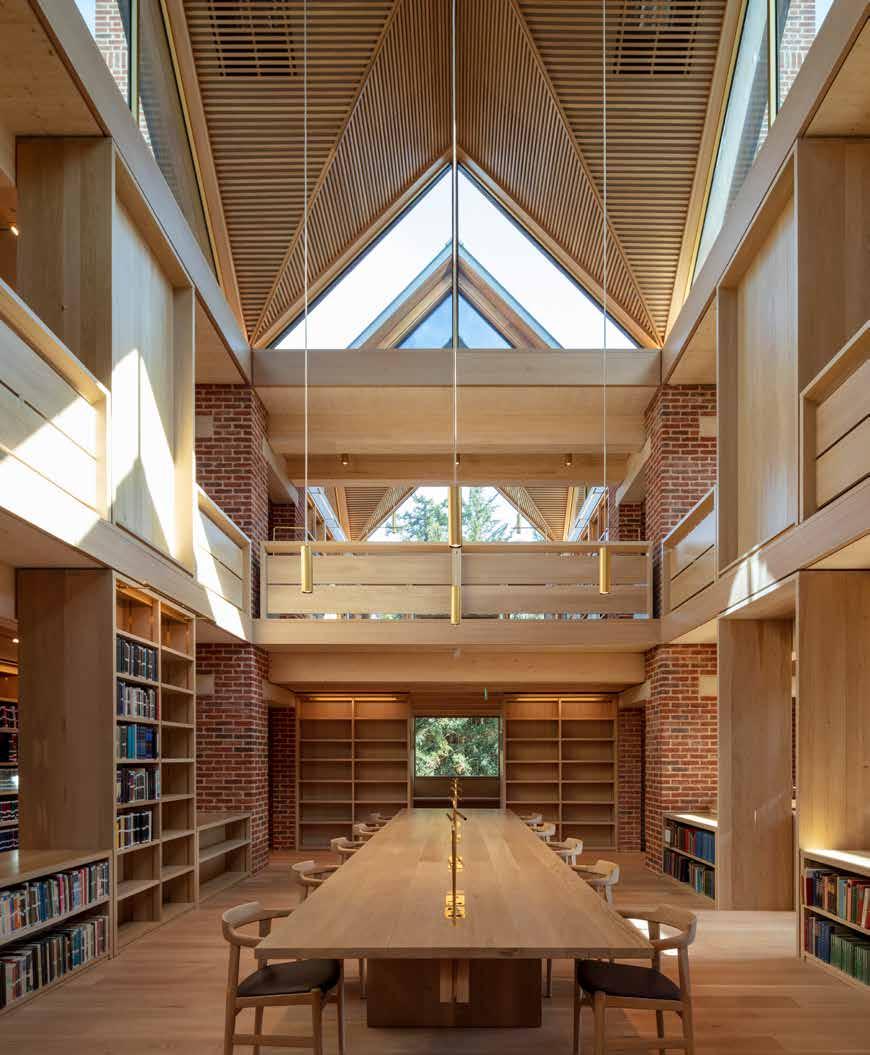

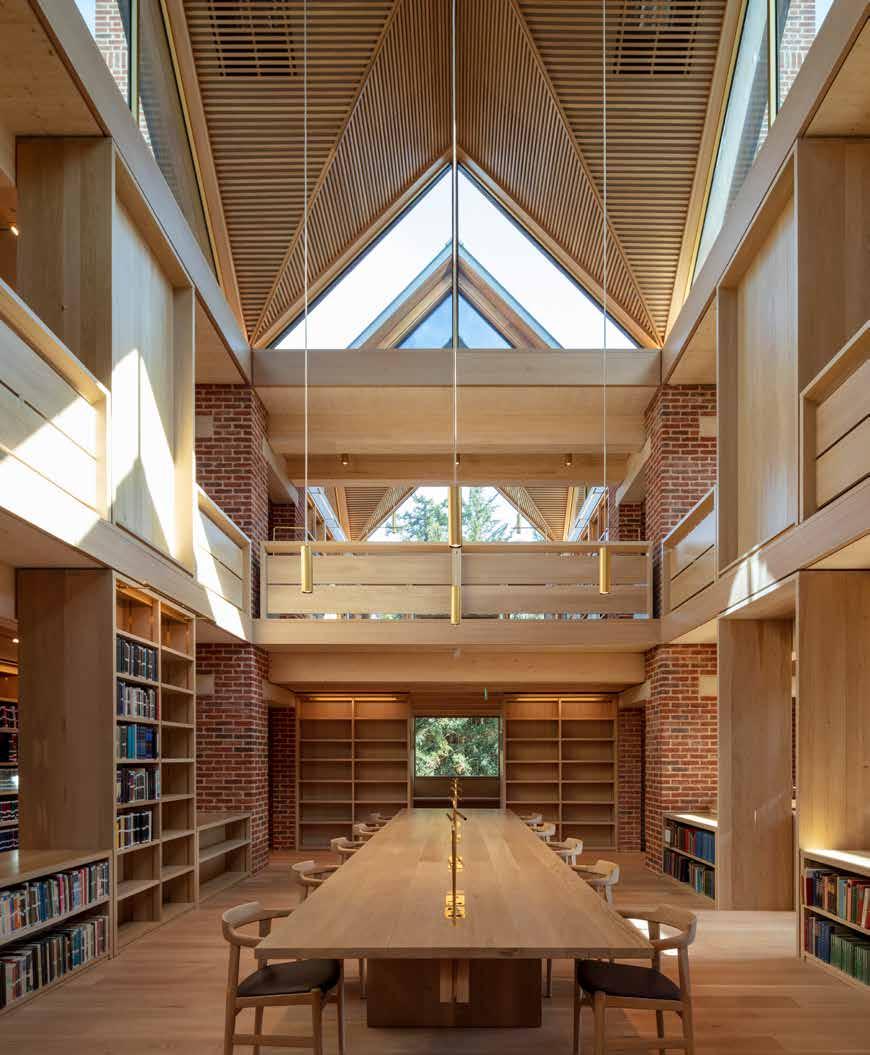

Cover image:

The New Library, Magdalene College

© Niall McLaughlin Architects

Photo: Nick Kane

42 Timber structures: sustainability

Accelerating change in a climate emergency

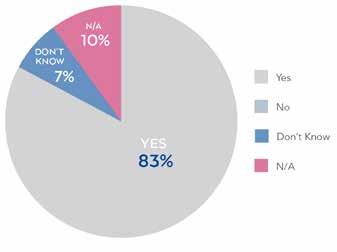

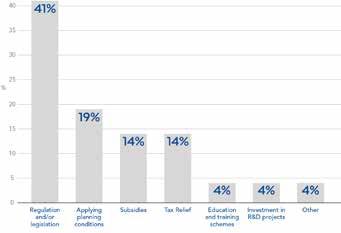

Gary Newman discusses the complex challenges associated with the net zero carbon agenda across different stakeholders.

04 | Timber 2023 Welcome Contents

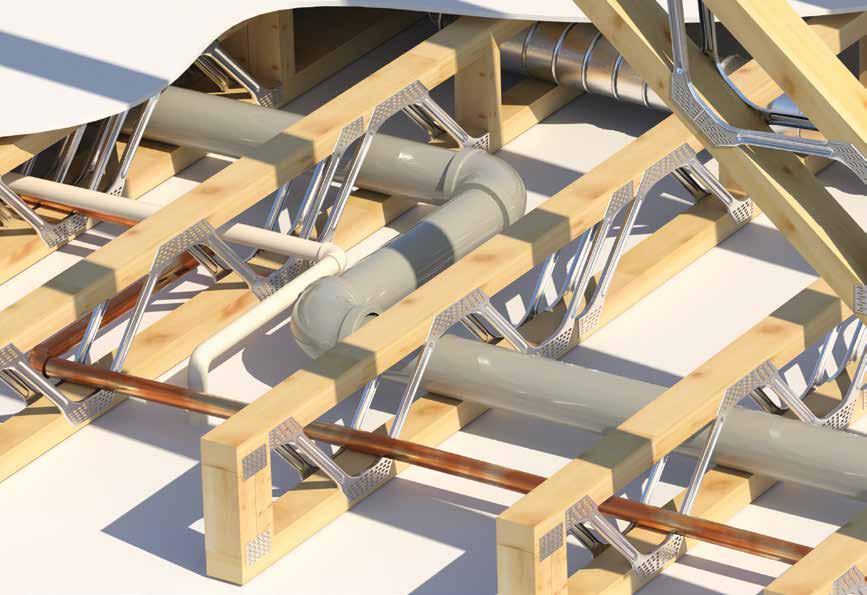

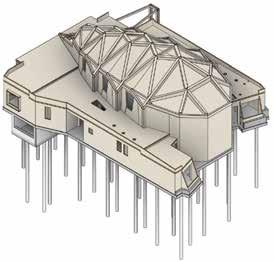

49 Timber structures: off-site construction

Unlocking the potential of modern construction

Matt Holman considers how to help unlock the potential of modern methods of construction.

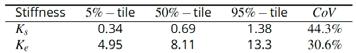

54 Timber structures: engineered timber

How to avoid structural timber design failure

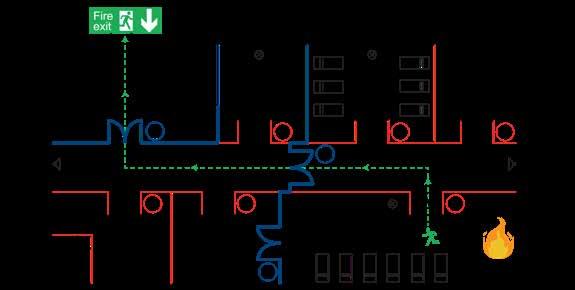

Ishan Abeysekera highlights aspects of timber that engineers used to designing in more traditional materials should be aware of.

64 Timber structures: moisture

Designing durable timber structures

Andrew Lawrence discusses how wood differs from steel and concrete and, therefore, needs a different approach to design.

71 Timber structures: guidance

How to draft a BSI framework for competence

We interview Matt Thompson, the technical writer responsible for the PAS 8671:2022 document.

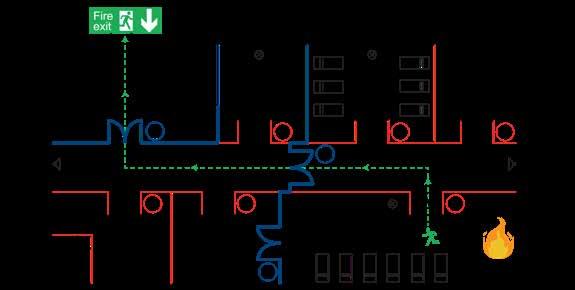

79 Timber structures: fire

Taking on the hot topic of fire regulation

Peter Barker and Ross Newman offer expert commentary on recent changes to building regulations and guidance.

89 Protection: fire Getting started with fire protection

Peter Barker and Ross Newman discuss important changes in fire legislation that affect your responsibilities as duty holder.

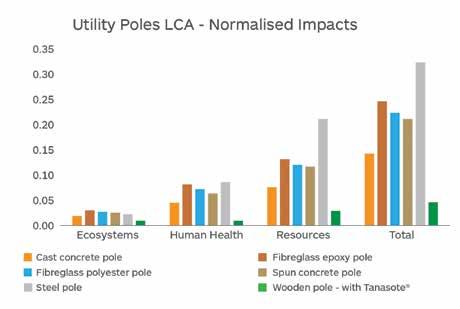

97 Protection: preservation

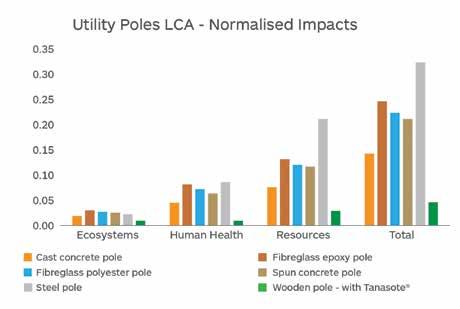

The environmental impact of treated timber

Dr Steve Uphill demonstrates the application of the Life Cycle Analysis ‘ReCiPe’ method to assess treated timbers.

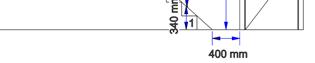

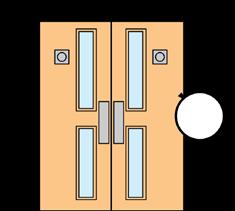

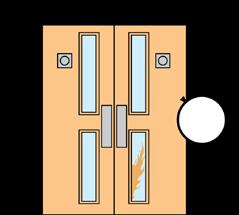

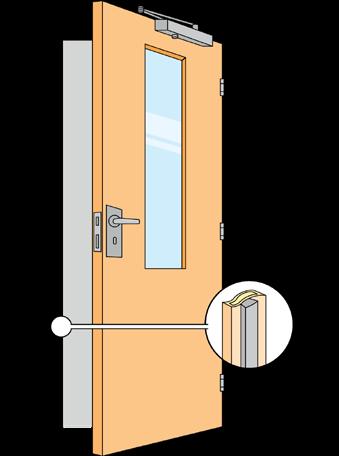

119 Joinery: fire doors

Adding assurance with third party certification

Peter Barker’s guide to certification for fire doors.

127 Joinery: skills

A complete approach to tackling the skills shortage

Helen Hewitt discusses how skills and talent recruitment must remain a key priority for the construction sector, and how to engage the next generation in joinery and woodworking training.

130 Joinery: skills

Making working with wood accessible

We look at just some of the many community hubs and national projects aimed at making traditional skills more accessible.

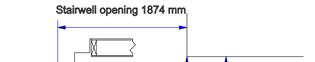

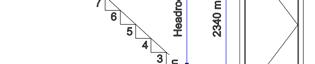

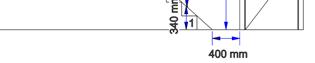

135 Materials: certification

Understanding product certification and markings

Hugh Mansfield-Williams lays out the current situation around the adoption of UKCA marking for construction products.

142 Materials: timber for construction

Douglas fir: the wood of the future

Sabrina Pedrono and Elisabeth Piveteau-Boley look at the wealth of applications for UK and European Douglas fir.

153 Materials: sustainability Timber in the circular economy

Industry experts give their opinion on how we might tackle problems faced when maximising the service life of timbers as the construction industry learns to embrace a more circular economy.

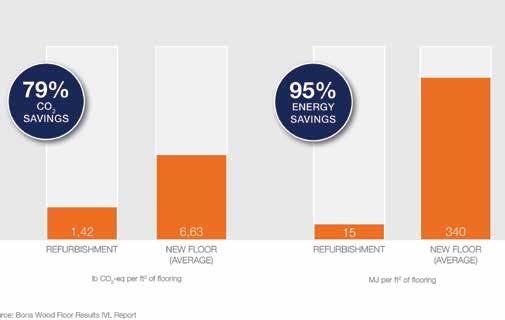

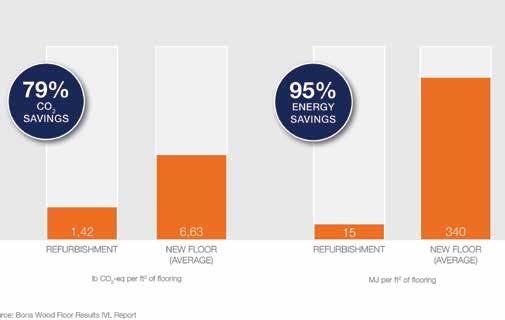

160 Materials: timber flooring

The sustainability of refinished wood floors

Alex Stacey discusses new research that suggests wood flooring can be refinished, extending its service life.

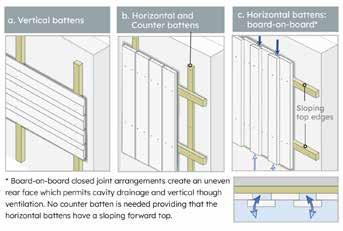

Dispelling decking and cladding misconceptions

105 Landscape and exteriors: decking and cladding

Janet Sycamore looks at specification of key components to help keep your decking and cladding looking beautiful for longer.

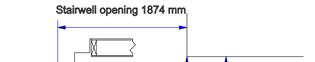

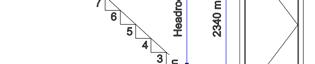

113 Joinery: stairs

Staircases step-by-step: a geometry lesson

Mark Milner delivers an expert guide on how to get the maths right and build a well-fitting straight-flight private staircase.

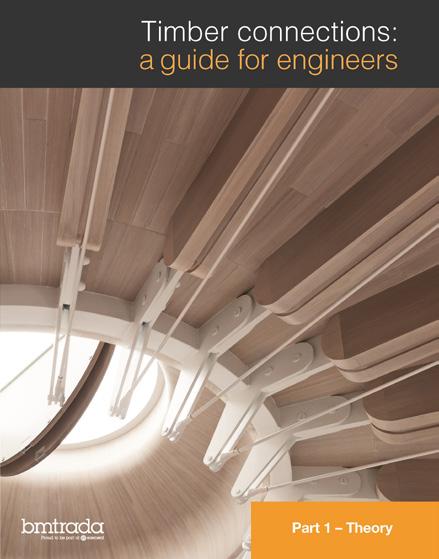

167 BM TRADA: bookshop Publications

The best books on timber design and construction.

169 BM TRADA: directory Certified companies

BM TRADA certified companies for the supply of timber products and services.

Timber 2023 | 05 www.bmtrada.com TRADA Contents Welcome

14 54

Working together

Welcome to another edition of BM TRADA’s Timber Industry Yearbook bringing together articles to help you meet the current economic and market challenges head on.

As the UK economy stagnated, 2022 was a year of rising supply chain and production costs, associated increases in the price of energyintensive materials, and a suppression of the housing market and commercial construction. However, while year-on-year market comparisons show significant reductions against previous years, the outlook for 2023 remains less bleak than was expected by industry experts. Against a challenging economic backdrop, global demand for timber continues to grow and the benefits timber delivers as a construction material will continue to drive demand.

In the 2023 edition of our Timber Industry Yearbook, we look at how we can help you continue to achieve your core goals, despite ongoing economic difficulties. Whether through the direct support offered by BM TRADA’s technical helpline, or via our publications, courses and webinars, we aim to make up-to-date, targeted and demand-driven industry knowledge accessible to you all.

Technical timber knowledge

Written by our BM TRADA technical timber team, on topics to include wood knowledge, engineering, regulation, timber frame and off-site construction. New articles cover:

• wood borers

• how to buy quality plywood

• regulatory updates

• moisture in timber.

Timber structures, skills and materials

Once again, we cover key topics relating to timber structures and expand our section looking at timber as a material, to include:

• sustainability and the circular economy

• off-site construction

• engineered timber

• fire

• skills

• timber species and applications.

How we can help you

BM TRADA informs and assists those working in the timber industry through the provision of high-quality independent advice. In 2023, we will be here to help as always.

Technical helpline

BM TRADA’s technical team of experts answer thousands of your calls and emails every year. We are delighted to continue offering this service free of charge throughout 2023.

Timber technical helpline: 01494 569601

Email: timberadvice@bmtrada.com

We respond to everyone who calls with queries and will try to assist with straightforward advice or point you in the right direction, whether that is to a specific publication or another service.

Publications and the BM TRADA bookshop

We are committed to maintaining our publications and technical information, working with technical experts to ensure you can be up to date as our industry evolves.

All BM TRADA publications can be purchased via our bookshop at bookshop.bmtrada.com and through other well-known suppliers.

Webinar programme

To meet growing demand, our incredibly successful year of webinars in 2022 will be repeated and expanded upon in 2023. Look out for repeated series of both Structural timber engineering and Fundamentals of timber, as well as new topics from both internal and external experts. For a few tasters extracted from just a few of our webinars, read: Designing durable timber structures, and How to avoid structural timber design failure

We hope you enjoy Timber 2023. n

Timber 2023 | 07 www.bmtrada.com

Welcome Foreword

Our UK-made net carbon negative sheet materials are the number one choice in the construction, furniture and DIY sectors.

uk.westfraser.com

The timber sector in 2022

As we head towards spring, Ben Sharples looks back at 2022 and discusses the interaction our expert timber consultants, BM TRADA’s laboratories and services, and our wider group management continues to enjoy with the wider timber industry.

It was more than impressive to see timber markets rally to pre-pandemic numbers during the first half of 2022, despite the impact of the Ukraine crisis on timber imports, issues caused by the Northern Ireland Protocol and import warnings around birch plywood from the Far East. As we headed into the winter months, we faced a decline in demand, a reduction across imports and an impact on prices. However, the increase in energy prices inflated the value of timber products.

We are taking a stand for a better built environment

While events continued to be affected by the lockdown lull in the early months of the year, the BM TRADA team was able to attend Futurebuild in Excel, London on 1–3 March 2022. Many of our technical consultants presented talks and our marketing team hosted a stand. It was very enjoyable to get out and about to meet some of our customers face to face once more.

BM TRADA and the Element Group

In 2022, TRADA merged with the Timber Trade Federation to become Timber Development UK (TDUK) and BM TRADA’s managed services contract with TRADA ended. Throughout the year, BM TRADA continued to serve the timber industry as it always has, and always will. Everything BM TRADA does is designed to help our customers to develop better products and processes; get their products to market on time; save time and money; and minimise the risk associated with product and process development as well as product production.

Today, BM TRADA is part of the Element Group. Element is the fastest growing testing, inspection, certification and calibration business in the world. >>

Timber 2023 | 09 www.bmtrada.com

James Jones’s office building

News Industry updates

Photo: Dapple Photography

Just

Better, connected. www.timberconnection.co.uk

like Kevin, Timber Connection know how important flexibility is in business today. In an ever-changing landscape we’re adapting to trading conditions before your very eyes, ensuring we’ll have what you want exactly when you want it.

forward ordering to just in time deliveries, from consignment call off deals to ex quay and on water options, we have the solutions.

Connection, we’re easy to do business with.

From

Timber

Flexibility

Carbon and timber in construction

In May 2022, as part of our remit to publish sector-specific information, we published a brandnew Wood Information Sheet with the help of Toby Maclean, Allt environmental structural engineers.

WIS 2/3-72 Carbon and timber in construction for building designers discusses key sustainability topics in relation to timber in buildings: carbon emissions, carbon stores and the complex relationship between timber in the built environment and the forests it was sourced from. It also provides methods to minimise carbon use and to maximise the carbon store and explains procedures for calculating the embodied carbon in a building according to a life cycle assessment (LCA).

Embodied Carbon Bill

The handy new Wood Information Sheet on carbon in timber construction became available just prior to Jerome Mayhew’s reintroduction of the Embodied Carbon Bill in the second half of June. The motion follows on from a campaign by the construction industry for the inclusion of a ‘Part Z’ in the Building Regulations and aims to ensure legal limits are in place to reduce embodied emissions. It requires the construction industry to report on whole-life carbon.

Debated by the House of Commons at length in November 2022, the bill failed to achieve government support, with the then UK Government. DLUHC Minister Dehenna Davison MP noting that SMEs were struggling economically as it was, and suggesting the time wasn’t right for such a regulatory change. However, the sentiment of the bill does have the full support of the UK Government and will be revisited by Parliament at a more opportune time.

BM TRADA and Warringtonfire marked 50 years of fire testing

In June 2022, we celebrated a major milestone, with the 50th anniversary of fire testing at Warringtonfire’s High Wycombe laboratory in the UK. In June 1972, the very first commercial fire test was undertaken at the newly completed testing laboratory. Since then, Warringtonfire has remained at the forefront of the testing industry by building a world-class

team of experts and collaborating with trade associations and standards committees. Our team of technical experts continue to play a pivotal role in raising standards in the fire protection industry, making tomorrow safer than today.

Now thought to be the UK’s oldest existing fire resistance testing laboratory, Warringtonfire’s impact can be found every day, in offices, airports, schools and hospitals.

New graduate engineering scheme

Coinciding with the 50th anniversary of fire testing at Warringtonfire’s High Wycombe laboratory, BM TRADA formalised its approach to graduate recruitment at Warringtonfire. The two-year programme comprises four rotations through key areas of the business: Reaction to Fire Testing, Fire Resistance Testing, Technical Assessments and Quality, prior to a three-week ‘flexible placement’ to focus on a selected topic. The new graduate engineers also undertake external IFE Level 1, 2 and 3 qualifications.

In 2022, the scheme received over 200 applications for just four places from recent graduates with a minimum of a 2:1 degree classification in a STEM subject. The new graduate scheme will continue in 2023.

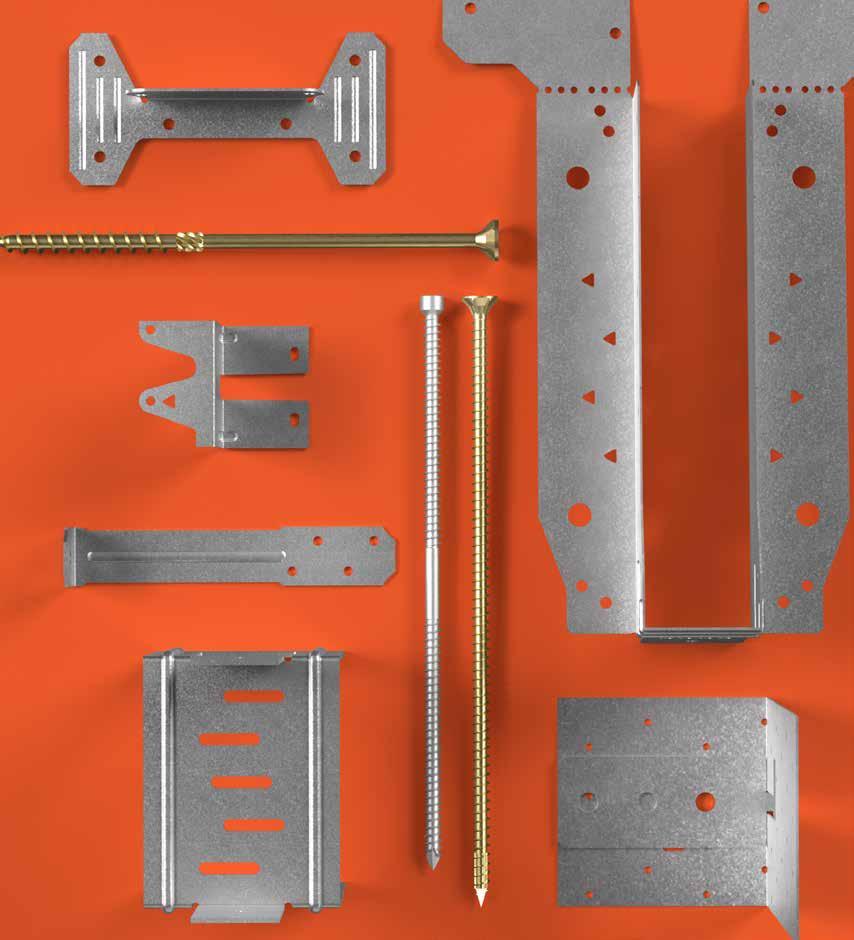

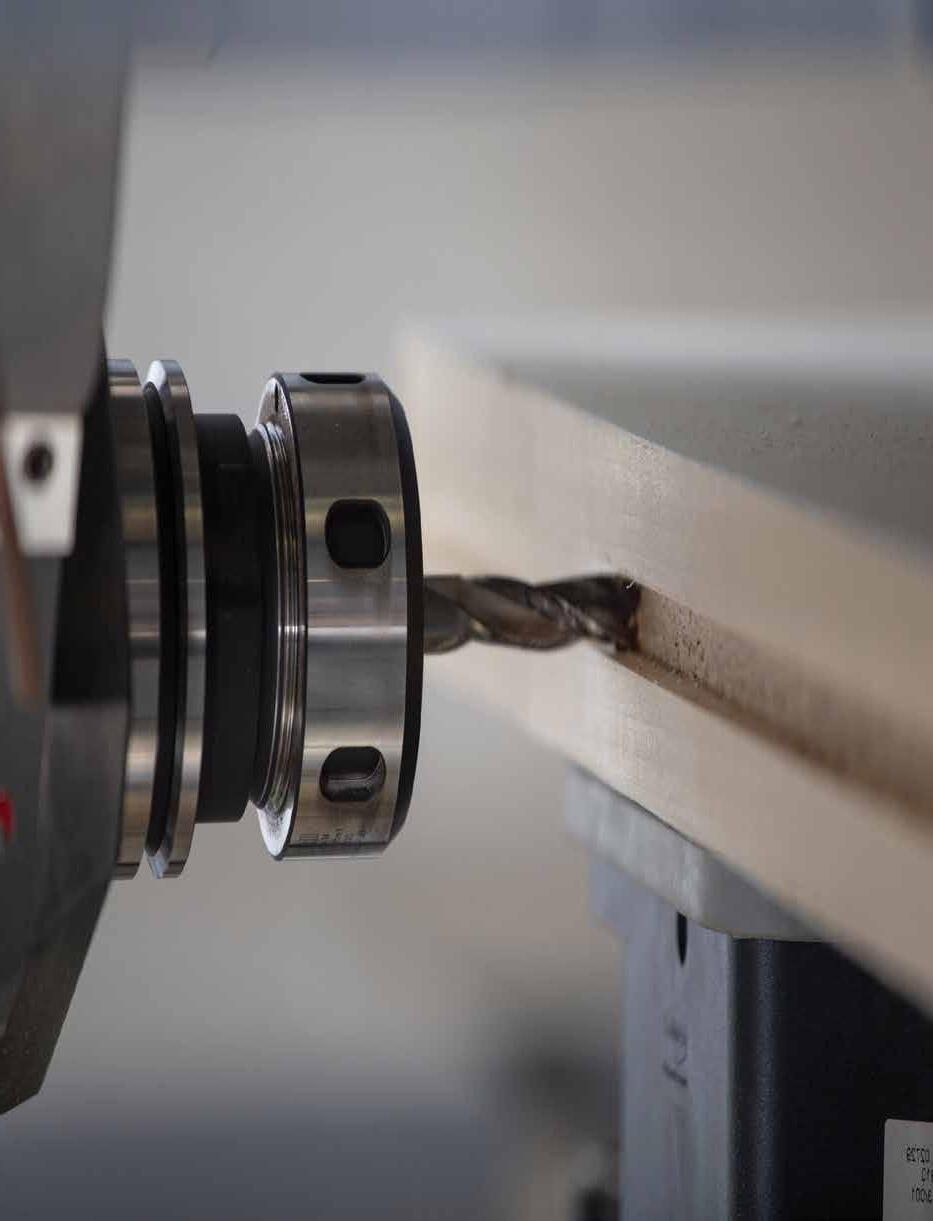

Timber lab refurbishment and fastener and fixing testing

In August, BM TRADA unveiled its modernised timber laboratory following an extensive refurbishment and investment. The three-month long revamp at its High Wycombe facility brings significant savings in energy usage and included a complete overhaul of the laboratory’s layout. The space is now divided into two dedicated areas, with one room designated for timber inspection and timber species analysis, and the other room for woodworking and timber testing.

Alongside the new layout, the laboratory was stripped down and a host of new equipment installed. This includes new storage, dust extraction units, boil tanks and water baths for woodwork testing; and a range of microscope equipment to analyse timber specimens. We also fitted new tools and rigs for fastener and fixing testing for structural timber connections, which will be operated under Element Material Technology’s Warringtonfire brand.

As well as timber construction, we’ve witnessed more demand for timber species verification from a wide variety of markets. We house one of the largest libraries of referenced timber specimens, known as a xylarium, in the country at our High Wycombe site. With our new laboratory and equipment, we can continue improving on this service and providing even more accurate advice and knowledge on different types of wood species. >>

Timber 2023 | 11 www.bmtrada.com

1 WIS 2/3-72 Wood Information Sheet Carbon and timber in construction for building designers CI/SfB (D9) i1 + z3 Uniclass P51: P99: C65 Timber is largely made from carbon: its use in construction results in both carbon storage and carbon emissions. Understanding how to manage carbon emissions and calculate embodied carbon helps to maximise the environmental benefits of building with timber. Carbon dioxide (CO ), along with other greenhouse gases emitted to the atmosphere, leads to increasing global temperatures. The current concentration of CO in the atmosphere is the highest it has been for at least two million years [1] and has increased by 12% in the first 20 years of the 21st Century alone [2]. Even small rises in global temperatures can have catastrophic effects on the climate and ecosystems. This publication discusses the following topics in relation to timber in buildings: carbon emissions, carbon stores and the complex relationship between timber in the built environment and the forests it was sourced from. It also provides methods to minimise carbon use and to maximise the carbon store, and explains procedures for calculating the embodied carbon in a building according to a life cycle assessment (LCA). This Wood Information Sheet (WIS) is an overview of the subject with signposts to more detailed sources listed at the end. Contents Carbon and timber Carbon emissions from buildings Calculating whole-life carbon for a building Minimising built environment carbon emissions Carbon stores The carbon impact of timber in construction Whole-life carbon emissions and global temperature increases Transport emissions (LCA module A4) End-of-life emissions (LCA modules C1–C4) Key points Carbon emissions from buildings are categorised as embodied carbon or operational carbon. Calculating a building’s lifetime carbon emissions follows the principles for life cycle assessments (LCAs) set out in BS ISO 14040 [3]. It is almost always a lower-carbon alternative to start with an existing building and to retrofit it than to build new. The objective for new timber building is to delay the emission of the carbon stored in the building for as long as possible. To minimise carbon emissions, build efficiently and choose materials that result in lower overall embodied carbon. The maximum size the carbon store in the built environment can grow to is limited by the amount of timber that is introduced to it and the average service life of that timber. Subject: Timber – general Published: February 2022 Figure 1: James Jones’s office building Photo: Dapple Photography

News Industry updates

- Timber frame, Glulam, Oak, engineered timber and steel

- Buildings up to eight storeys tall

- Houses, apartments, schools, hotels, student accommodation and garages

- Feature trusses, framed buildings

Chartered Engineers and Designers specialising in Timber Frame

- Design packages with structural calculations and manufacturing drawings for walls, floors, roofs and frames

- Fabrication detailing for steelwork

- Trussed roof and floor designs

- NHBC certification

01252 7 82366

12 | Timber 2023 Established for 30 years Independent design consultancy Professional and reliable service

info@rushmooreng.co.uk www.rushmooreng.co.uk

Buildings Safety Act, Fire Safety Act and RRFSO

This year, the industry had to embrace an update to Approved Document B, which now permits structural timber for use in the external walls of all buildings up to 18 metres in height. This new package of improvements was introduced to strengthen and clarify building regulations and fire safety guidance as part of wider reforms.

The introduction of the Fire Safety Act 2021, the Fire Safety (England) Regulations 2022, and changes implemented by the Building Safety Act 2022 brought amendments to The Regulatory Reform (Fire Safety) Order (RRFSO). The updated RRFSO now takes a broad view of responsibility, and some may not realise they have legal responsibilities for fire protection. The changes impose important duties and responsibilities for protection of people from fire in all premises other than private homes.

BM TRADA’s fire experts worked hard all year to deliver updates on the implications of these regulatory changes, which are covered in several editorials within these pages.

CLT and moisture research now freely available

Summarised in our 2022 Timber Industry Yearbook, our technical consultancy team worked with Stora Enso to report on research carried out on The moisture of dynamics of crosslaminated timber. The two-part research project looked at both wetting risk during construction and drying rates. Results allow us to determine moisture distribution behaviour. In October 2022, the important research results were presented at UK Construction Week.

CE to UKCA marking

The UK Government’s Department for Levelling Up, Housing and Communities (DLUHC) updated its guidance on the Construction Products Regulation in Great Britain and Northern Ireland on Friday 9 December 2022. The new guidance reflects the Government’s decision that it will continue to recognise the CE mark on construction products for another 2.5 years, to allow businesses until 30 June 2025 to prepare for the UKCA mark, which is a change from the 31 December 2022 date stated in previous guidance.

DLUHC stated, “Our intention is to end recognition of the CE mark in GB on the 30 June 2025. Current rules, which allow for continued recognition of the CE mark, will remain in place until legislation is laid to end recognition of the CE mark.”

We will continue to offer services for UKCA marking during the extension period and will assist with completing any programme of works that you are currently undertaking.

Webinars and courses

Thanks to all participants who attended one or more of BM TRADA’s webinars and courses in 2022. Your participation led to record registrations with webinar attendance routinely hitting levels around the allowed maximum of 1,200 at the beginning of the year. Even as we all became more able to get back to normal post-lockdown, you continued to enjoy regular online presentations from both our internal experts and external guest speakers. Courses also did well, and we were very happy to add a third date for our Timber Frame Construction training course when the original two scheduled dates sold out.

We look forward to extending the invitation to further webinars and courses in 2023. We will continue to keep you all up to date as our sector evolves, introducing new topics and presenters as possible while maintaining the BM TRADA tradition of sharing critical foundational knowledge to anyone interested in learning about timber and construction with timber. n

About the author

Ben Sharples Commercial Lead, Timber Services BM TRADA

Ben works closely with the technical timber team to ensure that we deliver our full potential and provide the excellence within the construction industry that we strive to achieve.

Timber 2023 | 13 www.bmtrada.com

News Industry updates

Photo: Anders Vestergaard Jensen

Celebrating outstanding use of timber

This year has produced another crop of worthy winners across key 2022 building design awards such as the RIBA Stirling Prize, RIBA National and Regional Awards, Wood Awards and IStructE Structural Awards. Here, we showcase just a few of them...

RIBA Awards 2022

In June 2022, the Royal Institute of British Architects (RIBA) recognised its selection of 29 of the UK’s best new buildings as winners of the 2022 RIBA National Awards for architecture. Key trends highlighted by this year’s winners include venues that unite communities, future forward housing and the restoration and adaptation of existing buildings.

At the awards announcement ceremony, RIBA President, Simon Allford said, “At a time when we need to bring people together and plan for a sustainable future, this year’s RIBA National Award-winning buildings offer much hope. This is a powerful collection of buildings that show, despite the economic, political and social turmoil of the last few years, how great architecture can emerge even in challenging conditions.”

Stirling Prize

RIBA awards its Stirling Prize to the building judged to be the best and overall winner in the UK. This year, the award went to The New Library, Magdalene College by Níall McLaughlin Architects, as featured on our front cover.

“A unique setting with a clear purpose – The New Library at Magdalene College is sophisticated, generous, architecture that has been built to last […] The light-filled, warm-wood interior lifts spirit and fosters connections […] Well-designed environments hugely improve student success and wellbeing,” said Allford.

RIBA National winners

Several National Award winners incorporated timber and engineered wood in innovative ways. >>

Events 2022 award winners 14 | Timber 2023

RIBA East Award 2022, RIBA National Award 2022 and RIBA Stirling Prize 2022

The New Library, Magdalene College

Contractor: Cocksedge

Structural Engineer: Smith & Wallwork

Project Management: Savills

Quantity Surveyor/Cost Consultant: Gleeds

Acoustic Engineer: Max Fordham LLP

Environmental/M&E Engineer: Max Fordham LLP

Building Control: MLM

© Nick Kane

© Nick Kane

Events 2022 award winners

RIBA London Award 2022, RIBA London Sustainability

Award 2022 and RIBA National Award 2022

Harris Academy Sutton by Architype for London

Borough of Sutton

Contractor: Willmott Dixon

Structural Engineer: Price & Myers

Quantity Surveyor/Cost Consultant: Synergy

Landscape Architect: Churchman Thornhill Finch

Services Engineer: BDP

Educational Consultant: Lloyd Wilson Partnership

Planning Consultant: Nathaniel Lichfield & Partners

CLT Provider: KLH UK

WARM Low Energy Building Practice: Passivhaus Certifiers

Harris Academy Sutton by Architype for London Borough of Sutton won the RIBA London Award 2022, RIBA London Sustainability Award 2022 (sponsored by Michelmersh) and RIBA National Award 2022 (sponsored by Forterra). On its awards webpages, RIBA explains that Harris Academy Sutton is the UK’s first Passivhaus-certified secondary school, and the largest Passivhaus school in the country. Sustainable larch panels were used to vertically clad the larger mass of the school, while inside the cross laminated timber structure is celebrated and predominant across ceilings and walls.

London winner, Ibstock Place

School Refectory by Maccreanor Lavington, “encompasses a crisscross glulam structure, crowned with glazed lanterns. The ceiling is supported by cross laminated timber panels to the outside and inset oak linings to the inside that produces the feeling of awesome grandeur that one might expect of a banqueting hall. The judges praised the consistent architectural language delivered by the whitewood glulam, profiled oak wall and ceiling linings, timber and terrazzo flooring and simple glazed tiles.”

RIBA London Award 2022 and RIBA National Award 2022

Ibstock Place School Refectory by Maccreanor Lavington

Contractor: Feltham Construction Limited

Structural Engineer: HRW

Environmental/M&E Engineer: Max Fordham LLP

Quantity Surveyor/Cost Consultant: McBains

Planning Consultant: NTR Planning Ltd

Acoustic Engineer: Max Fordham LLP

Landscape Architect: Wynne-Williams Associates

Arboricultural and Ecology Consultant: Wharton Natural Infrastructure Consultants

BREEAM Assessor: Ingleton Wood

Principal Designer: McBains

16 | Timber 2023

© Jack Hobhouse

© Jack Hobhouse

Mæ architects, who were responsible for the Sands End Arts & Community Centre on behalf of Hammersmith & Fulham Council, explained to RIBA that, “The pavilions are constructed in CLT and glulam, with green stained timber panelling. The CLT frame and woodwool slab infill are left unfinished at ceiling level, heightening the feeling of light from high-level clerestory glazing. The sustainably sourced CLT frame not only sequesters carbon but it’s also lightweight, reducing foundation requirements.”

Smaller, private projects featuring outstanding use of timber and wood products that received awards included Mews House Deep Retrofit by Prewett Bizley Architects and Pitched Black by Gruff Architects. The latter features a first floor clad in black timber boards and pitched 10 degrees away from the boundaries which, according to the architects, diminishes the perceived mass of the building from neighbouring gardens. >>

Events

2022 award winners

Mews House Deep Retrofit by Prewett Bizley Architects

Contractor: Bow Tie Construction

Structural Engineer: Solid Geometry

Structural Engineers

Quantity Surveyor: PT Projects

Interior Design: Hannah Carter Owers

Environmental/M&E Engineer: Green

Building Store and Enhabit

Joinery: Tom Graham Workshop

Pitched Black by Gruff Architects

Contractor: Marval Developments

Structural Engineer: Built Engineers

Timber 2023 | 17 www.bmtrada.com

RIBA London Award 2022

RIBA London Award 2022

© Andrew Meredith

© French+Tye

IstructE’s Structural Awards 2022

This year’s Institution of Structural Engineers (IStructE) Structural Awards followed new judging criteria based on four key areas covering technical innovation, professional advocacy, social value and environmental impact – process, profession, people and planet! Ten winners were selected from a shortlist of 41 structural engineering projects.

Supreme Awards

Supreme Awards for Structural Engineering Excellence were presented to two projects that, while not relying on timber, demonstrated innovative and low carbon construction approaches. The HYLO project by Horden Cherry Lee Architects, which added 13 storeys on top of the original 16-storey building, received the Award for full exploitation of an existing structure to maximise retrofit potential. The Award for advancing the structural application of low carbon materials went to The Arc at Green School in Bali, Indonesia by Ibuku. Incorporating pioneering bamboo shell structures that span arches 19m wide by 13m high, the build relied on extensive testing to justify its design due to the variable material properties of bamboo.

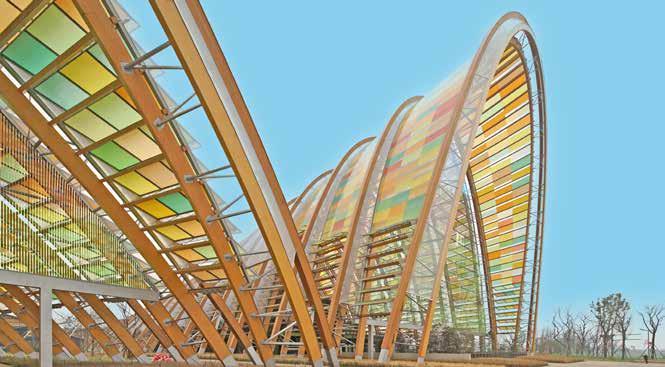

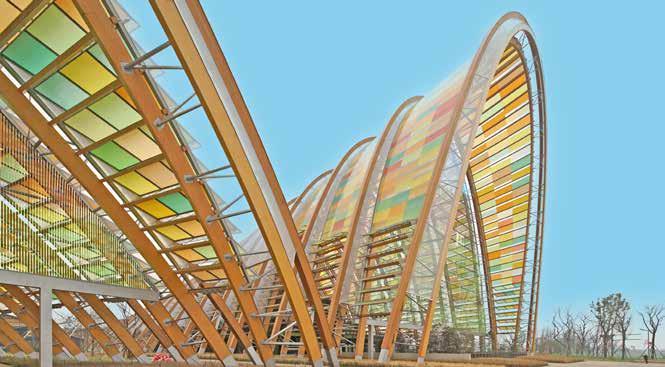

Largest timber structure in Asia

The Award for structural elegance through integrated design and construction went to Tianfu Agricultural Expo Main Hall. At over 75,000m2, this is the largest timber structure in Asia. A series of five vaults use unique Vierendeel-inspired (after Arthur Vierendeel truss design) timber chord and steel trusses with ETFE membranes to achieve clear spans up to 110m and heights up to 44m.

“Efficient, thoughtful and collaborative engineering at its best,” remarked one of the judges.

IStructE Award Winner: 2022 Award for Structural Elegance Through Integrated Design and Construction

Tianfu Agricultural Expo Main Hall

Key Attributes: People, Process

Location: Chengdu, China

Structural Designer: StructureCraft and China Architecture Design & Research Group

Client: Sichuan TianFu Agriculture Expo Investment Ltd

Architect: China Architecture Design & Research Group

Principal Contractor: Beijing Urban Construction Group Co Ltd

Key Contractors: Mule Studio – Parametric Design Consultant, Hasslacher Norica

Timber – Manufacturer

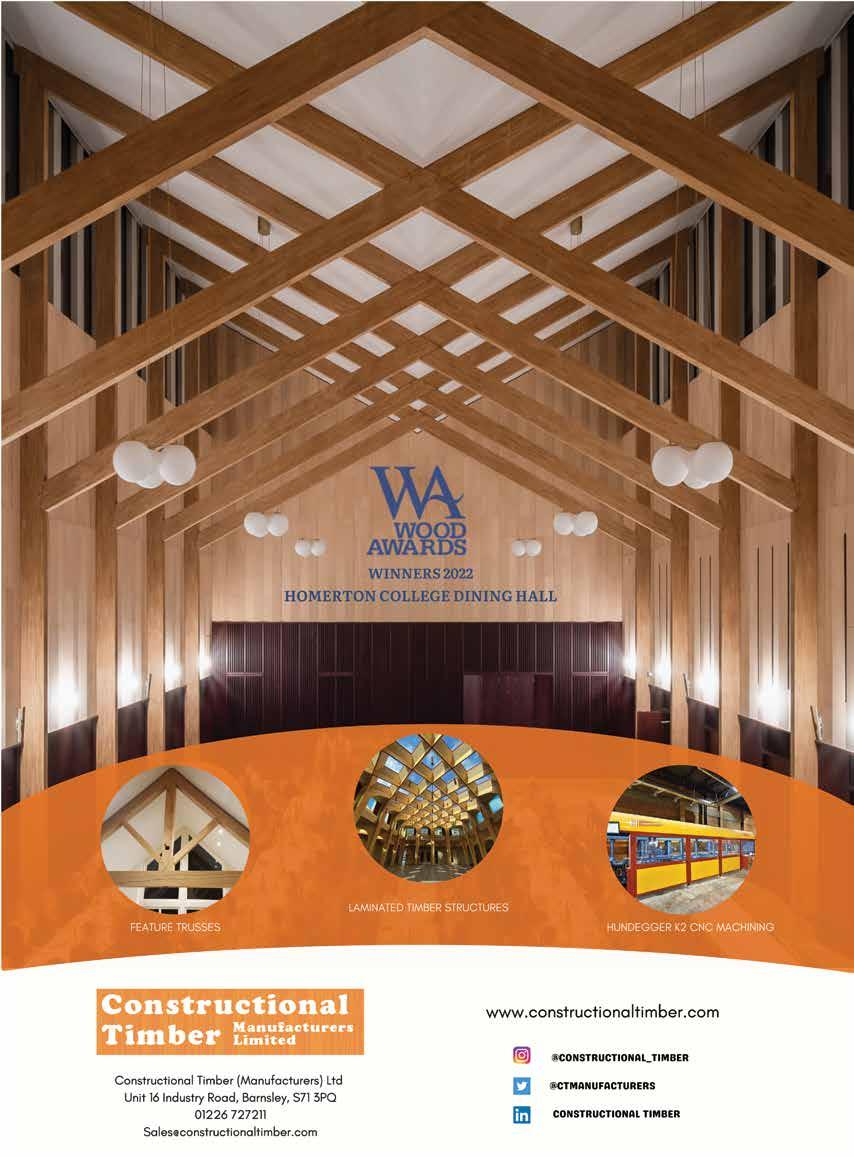

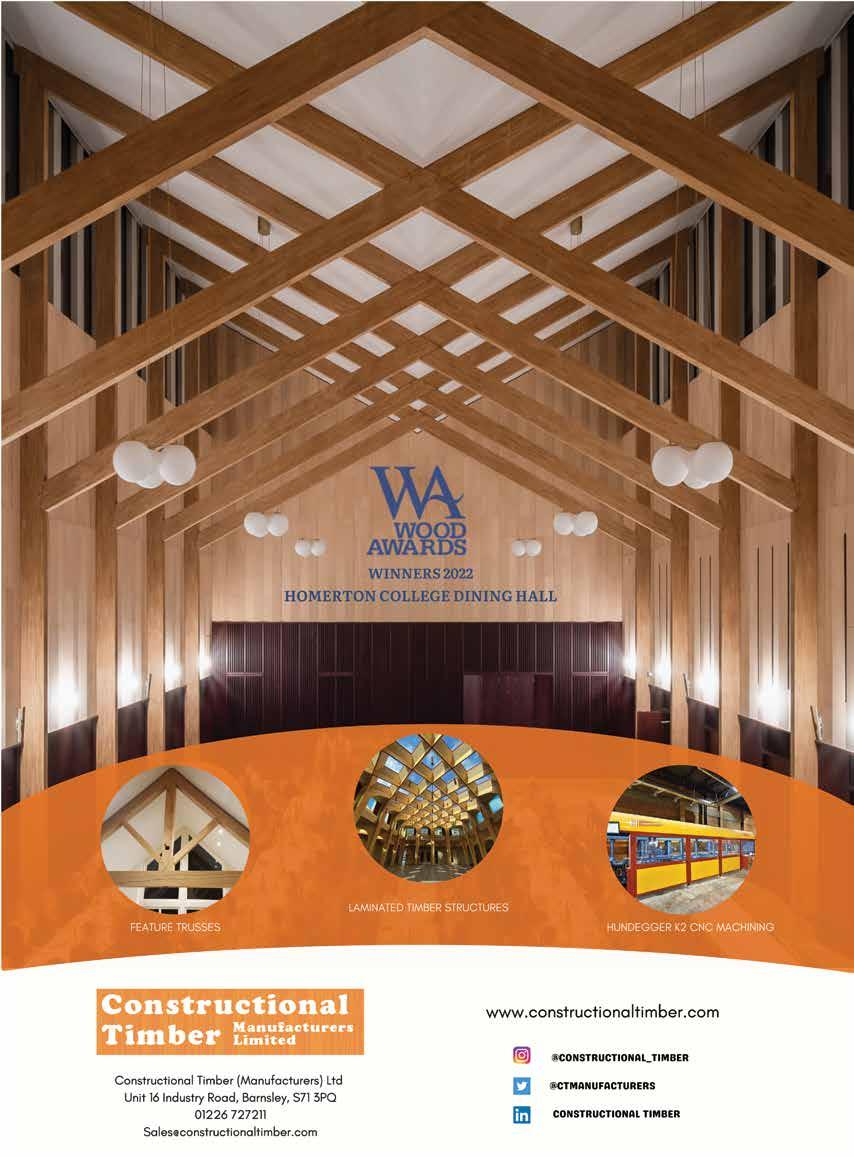

Wood Award Winners 2022

Established in 1971, the Wood Awards has a firmly established reputation for celebrating excellence in architecture and product design in wood. This year’s competition shortlisted 32 projects from more than 200 projects entered.

Gold Award

2022 Wood Awards Gold Award, Structural Award Winner

Homerton College Dining Hall

Building Type: Education & Public Sector

Location: Cambridge

Architect: Feilden Fowles

Structural Engineer: Structure Workshop

Main Contractor: Barnes Construction

Joinery Company: Classic Barfitting

Timber Supplier: Sierolam and Pfeifer

Timber Specialist Subcontractor:

Constructional Timber

Timber Species: Sweet chestnut, European whitewood/spruce (Germany), American ash

Having won the Gold Award, the University of Cambridge’s Homerton College Dining Hall was also awarded the UK’s best new timber building. Designed by architects Feilden Fowles and structural engineers Structure Workshop according to the award write up, “The hall incorporates sweet chestnut glulam trusses formed of four members which are connected at a central node and to the full-height columns on each side, while above these beams an engineered timber roof deck lends lateral stability. This combination of highperforming engineered timber with traditional joinery achieves an elegance, revealed in the butterfly truss design, which echoes traditional collegiate halls in its aesthetics, but also exploits the compressive strength of timber in its structure.”

18 | Timber 2023

Events 2022 award winners

© Jim Stephenson & David Grandorge

© StructureCraft

Category award winners

Other category award winners, from large commercial arenas through to intimate private homes, included ABBA Arena, Mews House, Douglas Fir House, and the Equal Access Project. A new category focused on ‘Restoration and Reuse’, highlighting projects using timber to preserve and enhance existing buildings, was scooped by The Water Tower by Tonkin Liu. In what judges described as a “reimagination of what architecture can be”, this project transformed an iconic but abandoned piece of local infrastructure into a beautiful, private residence.

Equal Access Project – Inner Portico

Building Type: Interior

Location: London

Architect: Caroe Architecture Ltd with Connolly Wellingham

Client/Owner: The Corporation of the Cathedral of St Paul in London

Structural Engineer: The Morton Partnership

Main Contractor: Sir Robert McAlpine

Joinery Company: NBJ (London) Limited

Mechanical and Electrical Engineer and Lighting Design: CBG Consultants

LVL Structural Frame: Buckland Timber Ltd

Remember Me Letterer and Artwork: Making Marks Ltd

Wood Supplier: Whippletree

Species: Home-grown oak (UK)

Events

2022 award winners

Mews House

Building Type: Private

Location: London

Architect: Russell Jones Limited

Structural Engineer: Techniker Consulting

Structural Engineers

Main Contractor: TAD Builders

Joinery Company: TAD Builders

Timber Supplier: Brooks Brothers Timber UK

Other Wood Suppliers: T Brewer & Company UK, Lilleheden Denmark, Tomasz Raczynski TAD Builders, Barth Innenausbau KGS, Andy Thompson, K and D Joinery

Larch Glulam Beams: Lilleheden

Cabinetry: Barth Innenausbau

Engineered Timber Joists: T Brewer Limited

Timber Species: European larch, Douglas fir, Siberian larch

New award in 2023

In November 2022, RIBA launched its new Reinvention Award that will recognise achievement in the creative reuse of existing buildings and shine a light on the importance of retrofitting and its contribution towards achieving net zero. The new award will champion projects celebrating the creative transformation of an existing building and the improvements to environmental, social or economic sustainability. n

Further information

RIBA Awards: www.architecture.com/awards

Structural Awards: www.istructe.org/structural-awards Wood Awards: www.woodawards.com

Timber 2023 | 19 www.bmtrada.com

2022 Wood Award winner: Private

2022 Wood Award winner: Interiors

The Water Tower © Dennis Pedersen, Taran Wilkhu, Mike Tonkin, Tonkin Liu

© Rory Gardiner

© Rory Gardiner

Your timber questions answered

Phil O’Leary tackles just a few of your questions from BM TRADA’s popular 2022 webinar series.

Q: What is the difference between ‘early wood’ and ‘late wood’?

Early wood (generally lighter coloured growth rings on the end grain of softwood and temperate hardwoods) develops during the early part of the growing season (spring wood). Cell walls are relatively thin and have larger lumina (cavities in individual wood cells) conducting water/ sap and nutrients up and down the tree. This is one of the primary functions of lumina.

Late wood (darker growth rings) forms later in the year (summer wood) as the tree lays down cells with thicker walls and smaller lumina, to provide strength to the trunk or branch of the tree.

Q: What does ‘dote’ mean in terms of defective timber?

A general term for fungal decay present in timber –sometimes referred to as incipient decay – and often found as localised patches/pockets of decay.

Q: How can you have more than 100% water content in a tree or timber?

When a tree is felled, it often has a relatively high moisture content because the tree is living and contains water taken from the ground as part of its growing process. Moisture content is expressed as a percentage of the dry weight of the timber. Therefore, if the weight of the water is more than the dry weight of the timber, the moisture content will be more than 100%.

Q: How can you distinguish mechanical failure vs moisture shrinkage as the cause of timber splitting?

A stress failure in the timber is usually identifiable by some key characteristics such as cross grain failure, breaks in the timber fibres and deformation of the member due to some form of overloading.

Fissures are a result of drying/shrinkage in a piece of timber. The fissures will follow the longitudinal grain direction and run at right angles to the growth rings across the cross-section.

We recommend you always consult with an expert if you feel there may be a structural issue for a timber member or structure.

Q: Can you coat fence posts in bitumen to extend the life of the timber section below ground?

See ‘How long will timber posts last in ground contact?’ on the Cladding and Decking

FAQs page on the BM TRADA website.

20 | Timber 2023

Timber technology Wood knowledge

Photo: Luhuanfeng

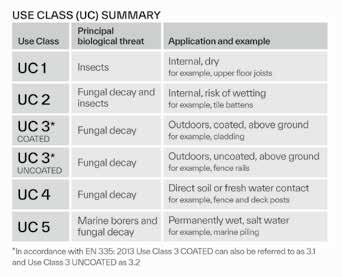

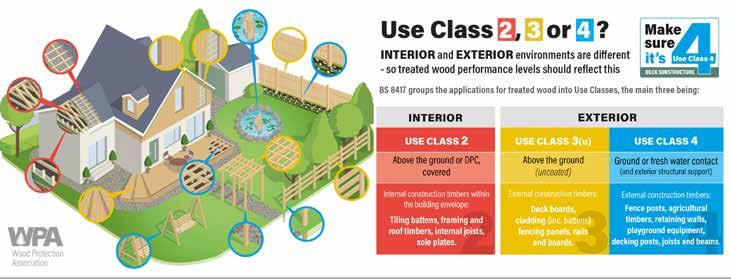

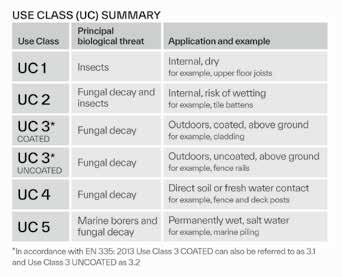

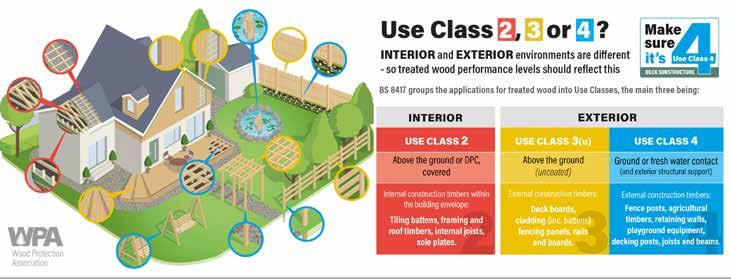

Q: What is the difference between Use Class and Service Class?

Defined in British and European Standards, Use Classes (UC) are based on differences in environment exposures and provide a guide to the risk of biodegradation due to decay and insect attack to timber components depending on their end use/application. The five classes are UC 1 to UC 5 with UC 1 being the least at risk, ie interior, dry. Use Class 4 is a situation where timber is in ground contact and/ or fresh water. Determining the Use Class can then help identify how naturally durable a timber species needs to be, or what level of preservative treatment is required to achieve the desired service life.

Service Class is a classification used by structural engineers/designers to determine the structural performance for timber elements to be used in construction based on the in-service conditions. The structural capabilities of timber change depending on its moisture content. The three Service Classes (1, 2 & 3) are determined by the moisture content of the timber which corresponds to the relative humidity and temperature expected in service, defined by Eurocode 5 (EN 1995-1-1).

Q: Is there a way to preserve timber’s natural colour without adding pigment or stain?

This is a common question that we get asked at BM TRADA, whether on the technical helpline or Q&A sessions at the end of training courses and webinars. There are a number of clear or varnish coating products that claim to have UV blockers or inhibitors. However, the reality is that these still provide relatively short-term protection to the timber surface from UV damage (greying) and will need to be reapplied at short intervals, particularly on south-facing elevations. BM TRADA does not recommend clear coatings for external timber because of the high maintenance cost caused by short life span and difficult preparation for new coating. The short answer is ‘no’. Coatings with pigment matching that of the natural timber colour remain the closest way of achieving a natural timber appearance.

Q: How can I arrange an inspection to investigate an infestation of wood borers?

Please get in touch with us by phone: 01494 569601 or by email: timberadvice@bmtrada.com

Q: I missed your webinar – will I have another opportunity to watch it?

Scan the QR code to register f or the next webinar series!

Phil O’Leary

Phil O’Leary is Technical Manager, Timber Consultancy, BM TRADA.

Phil has a wealth of knowledge and experience in the visual strength grading of timber, condition surveys, and the assessment of quality, performance characteristics and the structural strength of timber. He also sits on the BSI’s Wood Preservation Committee and the Wood Protection Association’s Technical Committee.

Timber 2023 | 21 www.bmtrada.com

Timber technology Wood knowledge

What is eating my timber?

Concerns about insect infestation in wood can arouse panic in the minds of many construction professionals, but expert Nick Clifford is happy to let you know the risks are not often as high as you may first believe.

There are, in fact, only a small number of wood-boring insects common in wood in UK buildings: the common furniture beetle (Anobium punctatum), deathwatch beetle (Xestobium rufovillosum), powder-post beetle (Lyctus brunneus), house longhorn beetle, (Hylotrupes bajulus), wood wasp (Xiphydriidae), and pinhole borer beetle (Platypodinae).

For their larvae to hatch and grow, adult females select wood with suitable moisture content and foodstuff in which to lay eggs. Most wood borers are confined to wet wood and are forest pests rather than pests of wood in buildings; others can only develop in certain wood species or even in certain regions of the tree, ie sapwood. This means that all wood can be protected from infestation by drying, excluding sapwood, selecting species naturally resistant to attack or treating with an insecticide.

Birch Plywood II Plywood Class LOW

Common Furniture Beetle

Vulnerability Heartwood Sapwood Coated Uncoated

Douglas

Death Watch Beetle

Powder Post Beetle

X

X

Pinhole Borer Beetle Birch has low resistance to insects and should not be used outdoors. Heat treatment during plywood production kills pests but panels remain vulnerable when moisture content rises above12% Insecticides or fumigation can irradicate CFB although further measures may be required for large infestations

House Longhorn Beetle Wood Wasp

Common Furniture Beetle

Vulnerability Heartwood Sapwood Coated Uncoated

Death Watch Beetle

Powder Post Beetle

X

X

Insect resistance Do Nothing Treat Fumigate Isolate Destroy

Beech 5 Insect resistance Do Nothing Treat Fumigate Isolate Destroy

fir Softwood 3-4 Durability Class HIGH Insect resistance Do Nothing Treat Fumigate Isolate Destroy Vulnerability Heartwood Sapwood Coated Uncoated Common Furniture Beetle Death Watch Beetle Powder Post Beetle House Longhorn Beetle Wood Wasp Pinhole Borer Beetle Elliotis Pine has moderate resistance to insects and is moderately durable Elliots Pine plywood tends to be Class III so is often covered in other materials. Insecticides or fumigation can irradicate CFB and HLB although further measures may be required for large CFB infestations Nothing X X Elliotis Pine Plywood III Plywood Class MED Insect resistance

House Longhorn Beetle Wood Wasp

Pinhole Borer Beetle Douglas fir has good resistance to insects. Even so, it is vulnerable when end grain is exposed, moisture content >12% and living sapwood present. Treatment will depend upon the beetle present. PBB or WW require no action. Fumigation may suffice for CFB and HLB respond to insecticides.

22 | Timber 2023

Timber technology Wood knowledge

Do Nothing Treat Fumigate Isolate Destroy Vulnerability Heartwood Sapwood Coated Uncoated Common Furniture Beetle Death Watch Beetle Powder Post Beetle House Longhorn Beetle Wood Wasp Pinhole Borer Beetle Beech has poor resistance to insects. Even so, it is only vulnerable when end grain is exposed, moisture content >12% and living sapwood present. Treatment will depend upon which beetle is present. PBB requires no action. Fumigation may suffice for CFB, although further action may be required X X

Hardwood Durability Class LOW

Timber 2023 | 23 www.bmtrada.com Timber technology Wood knowledge Do Nothing Treat Fumigate Isolate Destroy Vulnerability Heartwood Sapwood Coated Uncoated Common Furniture Beetle Death Watch Beetle Powder Post Beetle House Longhorn Beetle Wood Wasp Pinhole Borer Beetle Oak has good resistance to insects. It is only vulnerable to woodborers if end grain is exposed, moisture content is above 12% and living sapwood present Treatment will depend upon which beetle is present. PBB requires no action. Fumigation may suffice for CFB or PPB. Further action is required for DWB. X X X if rotten Oak Hardwood 2 Durability Class HIGH Insect resistance Do Nothing Treat Fumigate Isolate Destroy Vulnerability Heartwood Sapwood Coated Uncoated Common Furniture Beetle Death Watch Beetle Powder Post Beetle House Longhorn Beetle Wood Wasp Pinhole Borer Beetle Pine has moderatel to low resistance to insects. Even so, it responds well to preservatives and is only vulnerable when end grain is exposed, moisture content >12% and living sapwood present Treatment will depend upon the beetle present. PBB or WW require no action. Fumigation may suffice for CFB and HLB respond to insecticides. X X Pine Softwood 3-4 Durability Class LOW Insect resistance Do Nothing Treat Fumigate Isolate Destroy Vulnerability Heartwood Sapwood Coated Uncoated Common Furniture Beetle Death Watch Beetle Powder Post Beetle House Longhorn Beetle Wood Wasp Pinhole Borer Beetle Poplar has low resistance to insects and should not be used outdoors untreated Heat treatment during plywood production kills pests but panels remain vulnerable when moisture content rises above12%. Insecticides or fumigation can irradicate CFB although further measures may be required for large infestations X X Poplar Plywood III Plywood Class LOW Insect resistance Do Nothing Treat Fumigate Isolate Destroy Vulnerability Heartwood Sapwood Coated Uncoated Common Furniture Beetle Death Watch Beetle Powder Post Beetle House Longhorn Beetle Wood Wasp Pinhole Borer Beetle Eucalyptus has hgh resistance to insects and is durable for outdoor use. Treatment during plywood production kills pests making panels more durable for humid areas and outdoor use. Insecticides or fumigation can irradicate PPB although further measures may be required for large infestations X X Eucalyptus Plywood III Plywood Class HIGH Insect resistance Do Nothing Treat Fumigate Isolate Destroy Vulnerability Heartwood Sapwood Coated Uncoated Common Furniture Beetle Death Watch Beetle Powder Post Beetle House Longhorn Beetle Wood Wasp Pinhole Borer Beetle Iroko is resistant to insects. Even so, it imay be vulnerable when end grain is exposed, moisture content >12% and living sapwood present. Treatment will depend upon the beetle present. PBB requires no action Fumigation may suffice for PPB, although further action may be required X X Hardwood Iroko 1-2 Durability Class HIGH Insect resistance Do Nothing Treat Fumigate Isolate Destroy Vulnerability Heartwood Sapwood Coated Uncoated Common Furniture Beetle Death Watch Beetle Powder Post Beetle House Longhorn Beetle Wood Wasp Pinhole Borer Beetle Larch has good resistance to insects but is difficutl to treat. Even so, it is vulnerable when end grain is exposed, moisture content >12% and living sapwood present. Treatment will depend upon the beetle present. PBB or WW require no action. Fumigation may suffice for CFB and HLB respond to insecticides. X X Larch Softwood 3-4 Durability Class HIGH Insect resistance Do Nothing Treat Fumigate Isolate Destroy Vulnerability Heartwood Sapwood Coated Uncoated Common Furniture Beetle Death Watch Beetle Powder Post Beetle House Longhorn Beetle Wood Wasp Pinhole Borer Beetle Sapele is moderately resistant to insects. It is only vulnerable when end grain is exposed, moisture content >12% and living sapwood present. Treatment will depend upon which beetle is present. PBB requires no action. Fumigation may suffice for PPB, although further action may be required X X Hardwood Sapele 3 Durability Class MED Insect resistance Do Nothing Treat Fumigate Isolate Destroy Vulnerability Heartwood Sapwood Coated Uncoated Common Furniture Beetle Death Watch Beetle Powder Post Beetle House Longhorn Beetle Wood Wasp Pinhole Borer Beetle Spruce has low resistance to insects and should not be used outdoors untreated Heat treatment during plywood production kills pests but panels remain vulnerable when moisture content rises above12%. Insecticides or fumigation can irradicate CFB although further measures may be required for large infestations X X Spruce Plywood III Plywood Class LOW Insect resistance Do Nothing Treat Fumigate Isolate Destroy Vulnerability Heartwood Sapwood Coated Uncoated Common Furniture Beetle Death Watch Beetle Powder Post Beetle House Longhorn Beetle Wood Wasp Pinhole Borer Beetle Spruce has low resistance to insects. Even so, it responds well to preservatives and is only vulnerable when end grain is exposed, moisture content >12% and living sapwood present. Treatment will depend upon the beetle present. PBB or WW require no action. Fumigation may suffice for CFB and HLB respond to insecticides. X X

Softwood 4-5 Durability Class HIGH LOW Insect resistance

Spruce

Sweet Chestnut

How to manage the risk of wood-borer infestation

1. Purchase timber that was debarked and dried quickly after harvesting

2. Purchase seasoned or kiln-dried wood with reduced moisture content – but be aware that even properly dried wood can be infested if stored uncovered

3. When buying wood, inspect it for bore-holes, frass and other signs of insect damage

4. Consider using timbers that have been chemically treated under pressure for structural joists or trim

5. Control moisture during storage, as well as throughout and after construction. Larvae need more than 15% moisture to develop

6. Keep exposed wood covered in polythene or freshly coated with paint, varnish or stain

7. Stack firewood and any unprotected timber outside and away from outer walls

8. Immediately treat any timber with signs of infestation

9. Identify any beetles found, assess the damaged timber and evaluate the risk to other timbers

10. Use the life cycle of the beetle to trace back liability

Further information

BM TRADA’s technical team offers independent condition surveys and inspections, insect species identification, and assessment of timber structure, flooring, cladding and decking. For technical advice or consultancy services, contact us on +44 (0) 1494 569601, scan the QR Code or visit https://www.bmtrada.com/timber-services

About the author

Nick Clifford Senior Technical Timber Consultant BM TRADA

Nick is a qualified visual strength grader for timber with expertise in species identification, fungal decay, insect damage and wood preservation. With more than 20 years’ experience providing clear, concise, high-quality advice on timber-related issues, Nick also carries out condition surveys, writes expert witness reports and teaches visual strength grading.

Timber 2023 | 25 www.bmtrada.com Timber technology Wood knowledge

Do Nothing Treat Fumigate Isolate Destroy Vulnerability Heartwood Sapwood Coated Uncoated Common Furniture Beetle Death Watch Beetle Powder Post Beetle House Longhorn Beetle Wood Wasp Pinhole Borer Beetle Sweet Chestnut is susceptible to insects. Even so, it is only vulnerable when end grain is exposed, moisture content >12% and living sapwood present. Treatment will depend upon the beetle present. PBB requires no action Fumigation may suffice for CFB or PPB. Further action may be required for DWB. X X Hardwood

2 Durability Class LOW Insect resistance Do Nothing Treat Fumigate Isolate Destroy Vulnerability Heartwood Sapwood Coated Uncoated Common Furniture Beetle Death Watch Beetle Powder Post Beetle House Longhorn Beetle Wood Wasp Pinhole Borer Beetle Walnut has large pores and is less resistant to insect attack than other timber species. Even so, it is vulnerable only when end grain is exposed, moisture content >12% and living sapwood present. Treatment will depend upon which beetle is present. PBB requires no action. Fumigation may suffice for CFB or PPB. Further action is required for DWB. X X X if rotten Hardwood Walnut 3 Durability Class LOW Insect resistance Do Nothing Treat Fumigate Isolate Destroy Vulnerability Heartwood Sapwood Coated Uncoated Common Furniture Beetle Death Watch Beetle Powder Post Beetle House Longhorn Beetle Wood Wasp Pinhole Borer Beetle Western Red Cedar has good resistance to insects. Even so, it is vulnerable when end grain is exposed, moisture content >12% and living sapwood present Treatment will depend upon the beetle present. PBB or WW require no action. Fumigation may suffice for CFB and HLB respond to insecticides. X X Western Red Cedar Softwood 2-3 Durability Class HIGH Insect resistance

“You can reduce risk further simply by ensuring your timber is kept dry (with moisture levels below 12%) and treated appropriately for its intended use condition.”

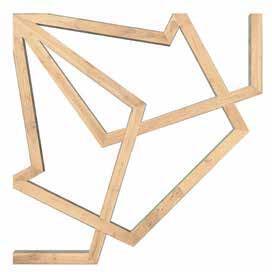

Top tips on how to buy good quality plywood

We might all think we know what plywood is, but the facts may surprise you. Gavin Fidler clears up some common misunderstandings about what plywood actually is before outlining some tips for buying quality plywood that can be used safely structural applications.

What is plywood?

The term ‘plywood’ is occasionally used as a ‘catch-all’ term for all wood-based panel products. However, just like other wood-based panel products such as particleboards, oriented strand board (OSB) and fibre building boards, plywood is a distinct product with specific features.

Plywood consists of an assembly of layers (plies) glued together, with the direction of grain in adjacent layers usually at right angles – a technique referred to as cross-graining. There are two types of plywood:

• Core plywood (or plyboard), such as blockboard and laminboard, have a central core of wood strips or other materials, with two or more outer wood veneers.

• Veneer plywood plies are all made of veneers orientated with their plane parallel to the surface of the panel.

Find out more about plywood and other wood-based panel products in our Wood Information Sheet: WIS 2/3-23

Introduction to wood-based panel products.1

What to look for when buying plywood

At the design phase, specifiers can determine performance standards by limiting the acceptable levels of knots, core gaps or voids, splits or surface flaws in the material. Plywood performance also relies heavily on the quality of glue used and, as market forces drive prices downwards, manufacturers make cost savings by using cheaper glues. Purchasers should be aware that it is visually impossible to tell a good plywood glue bond from a bad one as glue dyes can be used to disguise a poor-quality glue.

How to specify plywood for quality

When buying plywood, the details provided by a third-party certification stamp can be key to preventing the potential misunderstandings around quality that a simple visual inspection can raise. The stamp will include information on the grade or class of that product.

There are currently a number of European Standards and British Standards which deal with plywood grades.

• General European Standards for plywood:

o BS EN 635 which deals with the surface appearance2-6

o BS EN 636 which deals with the specifications7-10

• British Standard for marine plywood: BS 1088.11

Most plywood used in construction work will be more reliant on glue bond quality than aesthetics. In the UK market, reference is frequently made to the class of the plywood, which relates primarily to the bond quality achieved rather than the durability of the timber veneers.

What plywood to use and where

Class 1 plywoods are non-structural and will typically be used for interior furnishings only.

Class 2 plywood applications are typically where the boards will be protected from wetting but may be exposed to some degree of moisture during or following the construction phase. This can include floor decking, roof sarking and wall sheathing.

Class 3 plywoods are able to withstand full exposure to external weather conditions, but may not be when in ground contact. These boards are useful for external cladding, site hoarding, signage and playground equipment.

Class 2 and Class 3 structural grades are capable of carrying structural loads and will be marked with an ‘S’, eg BS EN 636-2S.

Marine plywood contains Class 3 glue bonds but is also fabricated using naturally durable timber species. This means the boards can resist fungal decay, making them useful in environments where they are permanently exposed to wetting, including external environments that are in contact with the ground.

Material sold as marine plywood without reference to BS 1088 may not be of the same quality.

26 | Timber 2023

Timber technology Wood knowledge

Top tips on how to buy and build with good quality plywood

1. Understand the difference between plywood types.

2. Never judge plywood purely on how it looks.

3. Look out for, and learn to read, certification stamps.

4. Use the correct class of plywood for each application to avoid failures.

5. Check that the right quality of glue and timbers have been used to manufacture your plywood.

6. Inspect plywood boards for surface damage, warping or signs of delamination.

7. Examine the edges for voids and look for uniform thickness across veneers.

8. Keep hold of your specifications and Declaration of Performance (DoP) documentation – these will cover you in cases of failure.

9. Keep a sample of your plywood for testing in case of failure.

10. Call the BM TRADA helpline for advice: 01494 569601.

How to I know my plywood is strong enough?

Design to Eurocode 512 requires characteristic design values for the product based on testing. For structural wood-based panels, these values are declared in the manufacturer’s Declaration of Performance (DoP) that is prepared before the product is placed on the market. There is an obligation for all parties in the supply chain to ensure this technical information is passed along the chain, encompassed within the UKCA/CE documentation.

Where a specific strength property is required, purchasers should include this requirement within the purchase specification and check the UKCA/CE documentation and the associated DoP for the goods received at delivery to ensure that specification is met.13

Is the plywood I bought and used going to fail on site?

Where plywood fails in service, laboratory testing can be undertaken to confirm whether the plywood was of the correct grade and of an appropriate quality. At BM TRADA, we have seen many examples of the wrong type or quality of plywood being used on site and subsequently failing.

BS EN 314 (parts 1 and 2)14,15 set out the methodology for plywood glue bond testing using the ‘shear test method’, where plywood test specimens are cut, exposed to moisture via a pre-treatment process which varies

according to glue bond class and then clamped in a testing machine where loading is applied in tension until failure. Once the specimen fails, both the failure load (in Newtons per square millimetre) and failure mode (wood fibre failure or glue failure) are calculated and rated against minimum performance requirements.

By retaining a small sample of any plywood you use in your construction, you will be able to have that product tested if the worst happens.

What to do if your plywood fails in service

As part of a plywood manufacturer’s factory production control system, they should be undertaking glue bond testing on batches of plywood to monitor and confirm performance. This testing is normally carried out by the manufacturer in their own laboratory but may be audited as part of any certification they hold.

Some UK plywood importers and distributors choose to undertake additional plywood testing, and TDUK requires its members to conduct third-party testing to verify the quality and performance of certain types of plywood that they place on the UK construction market.

The majority of plywood testing which BM TRADA undertakes relates to either failure of plywood in service or additional conformity testing for UK plywood importers. >>

Timber 2023 | 27 www.bmtrada.com

Timber technology Wood knowledge

Build with materials that make sense …

… for your health, pocket and planet.

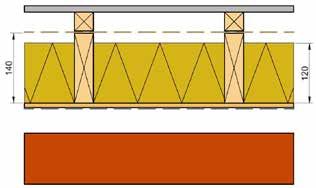

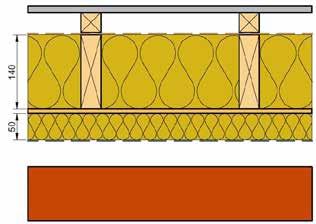

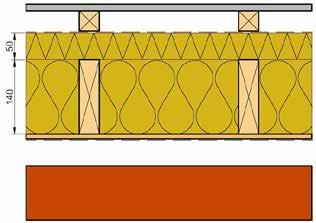

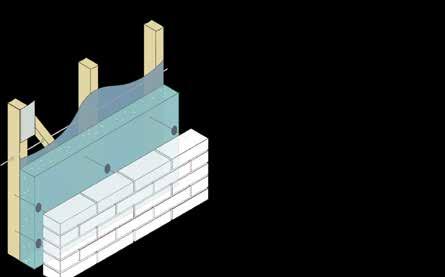

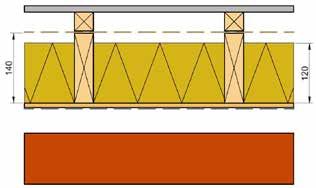

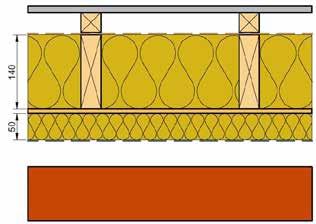

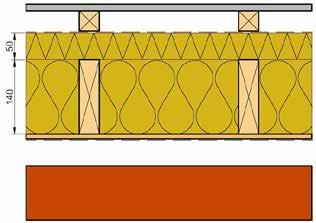

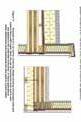

STEICO external wall

1 Timber Cladding

2 30 x 50 Counter batten

3 STEICOduo dry 60 mm

4 STEICOzell 160 mm

5 STEICOjoist 160 x 45 at 600 mm c/c

6 OSB 15 mm

7 Plasterboard 12.5 mm

As well as the high carbon storage potential of an engineered timber and wood fibre solution, STEICO products achieve building regulations code requirements with a wall thickness of less than 300mm.

Sustainable materials. Zero waste.

Our valuable raw material is used down to the last fibre for product manufacturing or energy generation.

CO2 storage: 66 kg CO2/m2

U-value = 0.18W/m2K

ENGINEERED BY NATURE

0,6

Bark

generation 0,2

Heartwood

Logs 2,3 m3 1,0 m3 STEICO

0,5

Woodfibre

m3

and rests for energy

m3

for pallets

LVL

m3

insulation

Quality Management ISO 9001:2015 Environmental Management ISO 14001:2015 UKTA - 22/6053

Plywood testing

BM TRADA has a timber testing laboratory and is UKAS accredited for plywood testing. Whether you are a plywood importer or distributor looking for additional conformity testing or have a project where plywood has failed prematurely in service, we can offer comprehensive testing and, if necessary, expert reports to suit your needs.

Call our technical services helpline on 01494 569601 or scan the QR code to find out more about our plywood testing services at www.bmtrada. com/timber-services/ plywood-testing

About the author

Gavin Fidler Timber Technical Consultant BM TRADA

References

1 WIS 2/3-23 Introduction to wood-based panel products, BM TRADA, 2020

2 BS EN 635-1:1995 Plywood. Classification by surface appearance – General, BSI

3 BS EN 635-2:1995 Plywood. Classification by surface appearance – Hardwood, BSI

4 BS EN 635-3:1995 Plywood. Classification by surface appearance – Softwood, BSI

5 DD CEN/TS 635-4:2007 Plywood – Classification by surface appearance – Parameters of ability for finishing, guideline, BSI

6 BS EN 635-5:1999 Plywood. Classification by surface appearance – Methods for measuring and expressing characteristics and defects, BSI

7 BS EN 636:2012+A1:2015 Plywood. Specifications, BSI

8. BS EN 636-1:1997 Plywood. Specifications – Requirements for plywood for use in dry conditions, BSI

9. BS EN 636-2:1997 Plywood. Specifications – Requirements for plywood for use in humid conditions, BSI

10. BS EN 636-3:1997 Plywood. Specifications – Requirements for plywood for use in exterior conditions, BSI

11. BS 1088:2018 Marine plywood. Requirements, BSI

12. PD CEN/TS 19103:2021 Eurocode 5. Design of Timber Structures. Structural design of timber-concrete composite structures. Common rules and rules for buildings, BSI

13. WIS 2/3-57 Specifying wood-based panels for structural use, BM TRADA 2021

14. BS EN 314-1:2004 Plywood. Bonding quality – Test methods, BSI

15. BS EN 314-2:1993 Plywood. Bonding quality –Requirements, BSI

Further reading

• PanelGuide, V4.1, Wood Panel Industries Federation and others, 2018

• BS EN 12369-1:2001 Wood-based panels. Characteristic values for structural design. OSB, particleboards and fibreboards, BSI

• BS EN 12369-2:2011 Wood-based panels. Characteristic values for structural design – Plywood, BSI

• BS EN 12369-3:2022 Wood-based panels. Characteristic values for structural design. Solid-wood panels, BSI

Timber 2023 | 29 www.bmtrada.com

Timber technology Wood knowledge

How to inspect and assess used scaffold board

Timber

Rare is a construction project that does not use scaffolding and scaffold boards. Enabling workers to access heights, timber scaffold boards are such a common component of most building sites it is easy to take them for granted. But failure of a scaffold board can lead to serious injury and loss of life. So, the integrity of timber scaffold boards is critical to health and safety on any building and construction site.

Assessing scaffold boards will ensure longterm safety

Knowing how to store timber scaffold boards correctly and how to carry out accurate inspection and assessment of those same boards will enable scaffolding companies and scaffolding contractors to keep boards in useful service despite appearances. Understanding inspection techniques, assessment specifications, and how to confidently reissue or withdraw scaffold boards from service will ensure worker safety and the long-term reputation of both supplier and contractor.

Every single timber scaffold board must be safe, every time

The average scaffold board is a well-trodden timber, subject to regular tear down, transport, storage, set up and reuse – over and over again. Often hired out to short turnaround project sites, the average board will quickly look battered and grubby.

During a busy working day, construction workers need to be able to assume that a scaffold board will still be strong enough to stand on safely even if it is several floors up on the exterior of a windswept, weather-beaten building under development or refurbishment. It is, therefore, a critical responsibility of anyone buying or hiring scaffolding, or managing a site with scaffolding, to ensure that every single scaffold board in use on that building site is fit for purpose, every single time it is put into use.

To ensure the maximum life of the scaffold board it must be checked regularly. Providing part of the surface or platform in scaffolding, scaffold boards must be supported at appropriate points along their length to enable them to bear the weight of anticipated loads.

New timber scaffold boards must meet standards

A scaffolding supplier must make sure each scaffold board meets the required strength specifications. New scaffold boards are cut to size, inspected and graded using British Standard BS 2482:2009.1

If you buy new scaffold boards, the supplier must be able to supply the paperwork and compliance marks to demonstrate those boards comply with the British Standard. However, as a scaffold board then works its way from one site to the next, it may undergo a quick clean and cursory inspection by potentially untrained eyes before being unceremoniously stacked for transport and storage. It is, therefore, up to you to carefully and knowledgeably inspect and assess each and every scaffold board again, before they are sent out for reuse.

While the requirement from end users is to use BS 2482 boards, some companies continue to use non-standard methods and even ungraded boards. Since 2017 the National Access & Scaffolding Confederation (NASC) audits only

30 | Timber 2023

Timber technology Wood knowledge

Timber scaffold boards are graded for strength rather than appearance.

scaffold boards may be scuffed, worn and covered in dirt, but are they still strong enough and safe to use? Phil O’Leary explains how to maximise the service life of your scaffold boards while preventing health and safety failures on your construction site.

accept the use of scaffold boards that comply with BS 2482. BS 2482 boards will have original end bands carrying the full marking requirements of the standard.

Even with intact end bands, a used scaffold board taken from storage might have picked up damage since its previous inspection. So, the ability for hands-on staff to knowledgably reinspect all boards is essential for a scaffolding company or contractor to get the best use from its scaffolding boards while ensuring safety levels are maintained.

Timber scaffold boards are graded for strength rather than appearance

Timber scaffold boards are most often made from European whitewood and are graded for strength rather than appearance. This grading allows for a certain number of visual defects such as knots and wane (bark or insufficient wood at a corner or along an edge, due to the curvature of the log) within defined limits But how can you tell when visual defects exceed those limits? When is a split, crack or fissure excessive? When can surface contamination, saw cuts or other mechanical damage make a board unsafe to use? When does the natural distortion of an organic, timber plank become dangerous warping? Can a surface fissure be simply cut out or must the entire timber scaffold plank be rejected? If those boards accidentally got wet while in storage, how can you tell if they are still safe to use? Must all damaged boards be discarded or can some be restored?

Book a training course

Delivered online or in person by Phil O’Leary

Grading scaffold boards

Typical course outline:

• Why grade timber scaffold boards?

• Specification of scaffold board

• Strength grading and scaffolding marks

• Strength properties of timber

• Timber structure and characteristics

Inspection of used scaffold boards

Typical course outline:

• Interpreting wood grain and distortion

• Visual inspection methods

• Mechanical inspection methods

• Assessing timber scaffold boards

• Timber storage

Are your scaffold boards safe?

Be certain that the scaffold boards on your site are safe to use. Mitigate risk associated with working at height. Maximise the life of your timber scaffold boards safely and demonstrate competency to your clients. Learn how to carry out on-site inspection and assessment of scaffold board with confidence. n

About the author

Phil O’Leary

Technical Manager and Timber Consultant BM TRADA

Further reading

For information about other BM TRADA timber training courses, please visit: www.bmtrada.com/training

Contact BM TRADA Training on 01494 840774 to book an in-house course or use the QR code to book onto a group training course now

References

1 BS 2482:2009 Specification for timber scaffold boards, BSI

Timber 2023 | 31 www.bmtrada.com

Timber

technology Wood knowledge

The integrity of timber scaffold boards is critical to health and safety on any building and construction site.

Photo: Sturti

Change is afoot: streamlining standards across construction

BM TRADA technical expert, Hugh Mansfield-Williams, and structural timber engineer

Keerthi Ranasinghe, are both members of several standards committees delivering guidance for the timber industry. Here they discuss strategic change facing that industry.

It is always risky to try to predict the future, and what follows is based on expert understanding around changes in UK timber and building industry Eurocode 5 yet to be published. So, while this article is somewhat speculative, I believe the time is ripe to lay out some of the prospective changes which timber and construction professionals might expect in the near future.

An overview of the next two years

While the new Eurocode 5 will not be published within the next two years, the general principles around what changes will be legislated by the various standards committees at a European level have been reached. It is only the technical details behind these changes that is still outstanding which, in the most part, can hopefully be resolved without the need for more voting. However, if technical details do need to go through a vote at the European level, the UK committee would then be able to adopt these agreed changes on principle. There is little reason to believe the process of publishing the new standard will be delayed.

Assuming the agreed changes are indeed adopted, we might carry out some reasonably qualified speculation.

Key changes to technical standards in discussion

Upcoming changes in regulation will be more akin to those currently practised in the steel industry. Engineers designing timber frame for the first time but with experience in steel or concrete construction will have a smoother transition. They will recognise some of the new methods coming through.