Travel Fellowship Overview

This idea of traveling to see mass timber architecture in the Pacific Northwest started from a timber conference I attended in 2018, during which some architects spearheaded in mass timber design in Europe introduced their practice to the American audience. There is one question and answer I remembered clearly from Andrew Waugh of Waugh Thistleton Architects.

“Do you think wood has the ability to build skyscrapers, like steel and concrete do?”

“Potentially, but I don’t believe healthy cities need to rely too much on tall buildings.”

I am touched by his humble answer, in addition to seeing the presentation of those projects they executed so well, and curiosity aroused.

In North America, Oregon of U.S. and British Columbia of Canada have long been researching and building in timber. So this travel fellowship has provided me with a tremendous opportunity to look at those architecture in person.

Portland 08.26 B76 BUILDING 08.27 ALBINA YARD 08.29 CARBON 12 + CANYON 08.30 DISTRICT OFFICE Vancouver

11.15 RICHMOND OLYMPIC OVAL

11.17 UNIVERSITY OF BRITISH COLUMBIA

11.18 UNIVERSITY OF BRITISH COLUMBIA

11.19 NORTH VANCOUVER CITY HALL

11.22 UNIVERSITY OF BRITISH COLUMBIA

Mass Timber

Is a category of framing styles typically characterized by the use of large solid wood for wall, floor and roof construction, as well as structural columns and beams. Those solid woods are laminated together from dimensional lumbers. Products in the mass timber family include:

Cross-Laminated Timber (CLT)

Nail-Laminated Timber (NLT)

Glued-Laminated Timber (Glulam)

Dowel-Laminated Timber (DLT)

Structural Composite Lumber (SCL)

Wood Concrete Composites

Because of its strength and dimensional stability, mass timber offers a low-carbon alternative to steel, concrete and masonry for many applications. A complement to other wood framing systems, it can be used on its own, in conjunction with other wood systems such as postand-beam, or in hybrid structures with steel and concrete.

WOODB76 BUILDING

SKYLAB ARCHITECTS

20,000

COMPLETED IN

The wedge-shaped building features a new CLT structural system with an open ground level commuter oriented retail environments geared toward guests and tenants. The workspace above is wrapped in brick masonry with the building acting as an anchor for the Burnside Bridge and a gateway to the Portland eastside community.

Glulam post and beam , CLT panel and concrete vertical core together form not only the structural system but also exposed as interior finish of this mix-use retail / office building.

ALBINA YARD

LEVER ARCHITECTS

16,000 SF COMPLETED IN 2016

What is the construction type of Albina yard?

Type IIIB: Exterior walls are of noncombustible materials and the interior building elements are of any material permitted by code.

What is exterior and interior partition assembly?

Wood Stud.

What is stair assembly?

Primary structural frame: 0 HR Exterior bearing walls :2 HR

Interior bearing walls: 0 HR

Exterior nonbearing walls and partitions: depends on fire separation distance and occupancy group

Interior nonbearing walls and partitions: 0 HR

Floor construction and associated

secondary members: 0 HR

Roof construction and associated secondary members: 0 HR

In this case, rating is only required at egress and lot line.

Traditional wood frame stair installed on site. CLT panel is used for railing to express the mass timber quality of the building and make it a nice circulation stair. Some cracks happen afterwards in the CLT panel, but it is common and has no harm.

Prefabrication is an important portion in the design and construction process, do you have such experience before? No, it’s the office’s first time. The design process used Rhino, Vectors and sketchup.

What is the structural system?

Glulam timber frames + CLT panels. First floor slab is concrete. Elevator and egress stair enclosure are standard plywood shear wall. CLT floor function as diaphram.

What about the steel connections for timber structure?

All custom made and designed by architects, structural engineer and steel fabricator. Mock up is very useful during the process. Connections are hidden within the wood for aesthetic purposes.

Is this the first mass timber building your firm designs?

We’ve done conventional glulam beams and columns before as they are common in Pacific Northwest. But it’s the first CLT panel experience for us. We also designed new connection details.

What is the structural grid dimension? 20’ x 20’

THE RADIATOR

KAISER + PATH 38,000 SF

COMPLETED IN 2014

The Radiator is the first all-timber building of its scale in the past century. It played a key role in proving the financial viability of constructing large buildings with wood, reintroducing the design and build industries to the benefits of wood and kicking off a building boom in Portland.

--KAISER + PATH

The Glulam beams and columns with tongue & Groove floor make this building takes on a warehouse style. It’s a Type IIIA construction type, with oversized timber to accomodate fire rating. The steel connectors are not protected.

CARBON 12

+ PATH

SF

COMPLETED IN 2018

With Carbon12, Kaiser Group and Path Architecture have set a new standard for what’s possible in sustainable development in the United States. At 85 feet tall, Carbon12 is the tallest mass timber and cross-laminated timber building in the country (2018). Kaiser Group and Path Architecture worked with city and state officials to waive restrictive codes limiting the height of wood buildings, making Carbon12 and future tall wood buildings in the US possible.

(Drawings from nextportland.com)

What is the construction type of Carbon 12?

Type IIIA: exterior walls are of noncombustible materials and the interior building elements are of any material permitted by code.

What is the structure system of Carbon 12?

Primary structural frame: 1 HR

Exterior bearing walls :2 HR

Interior bearing walls: 1 HR

Exterior nonbearing walls and partitions: depends on fire separation distance and occupancy group

Interior nonbearing walls and partitions: 0 HR

Floor construction and associated secondary members: 1 HR

Roof construction and associated secondary members: 1 HR

Concrete foundation and slab on grade. CLT floors, Glulam columns and beams with a buckling-restrained steel brace frame core. Due to the seismic concerns in the Pacific Northwest, an all-wood lateral system could not be used.

What is the process of constructing Carbon 12?

Every piece is lifted and trucked to place. Every panel/beam/column is presealed and waterproofed to prevent staining during transporation and construction. No welder or formwork necessary on site. One whole level takes about 5 days. The steel connectors come directly from a Europe company called MyTiCon.

How do you maintain the open ceiling?

Building systems were hidden above soffits over the kitchen area, while fire sprinklers were also hidden with sidewall heads. The whitewash finish on the exposed wood also lightens the space while bringing a more modern aesthetic into the space.

What is the initial drive of building Carbon 12?

We entered the US Tall Wood Building Competition, and six minutes after receiving a letter that we were not selected as winner, we decided to build Carbon 12 anyway.

Floor/Ceiling

ICC-60 STC-60

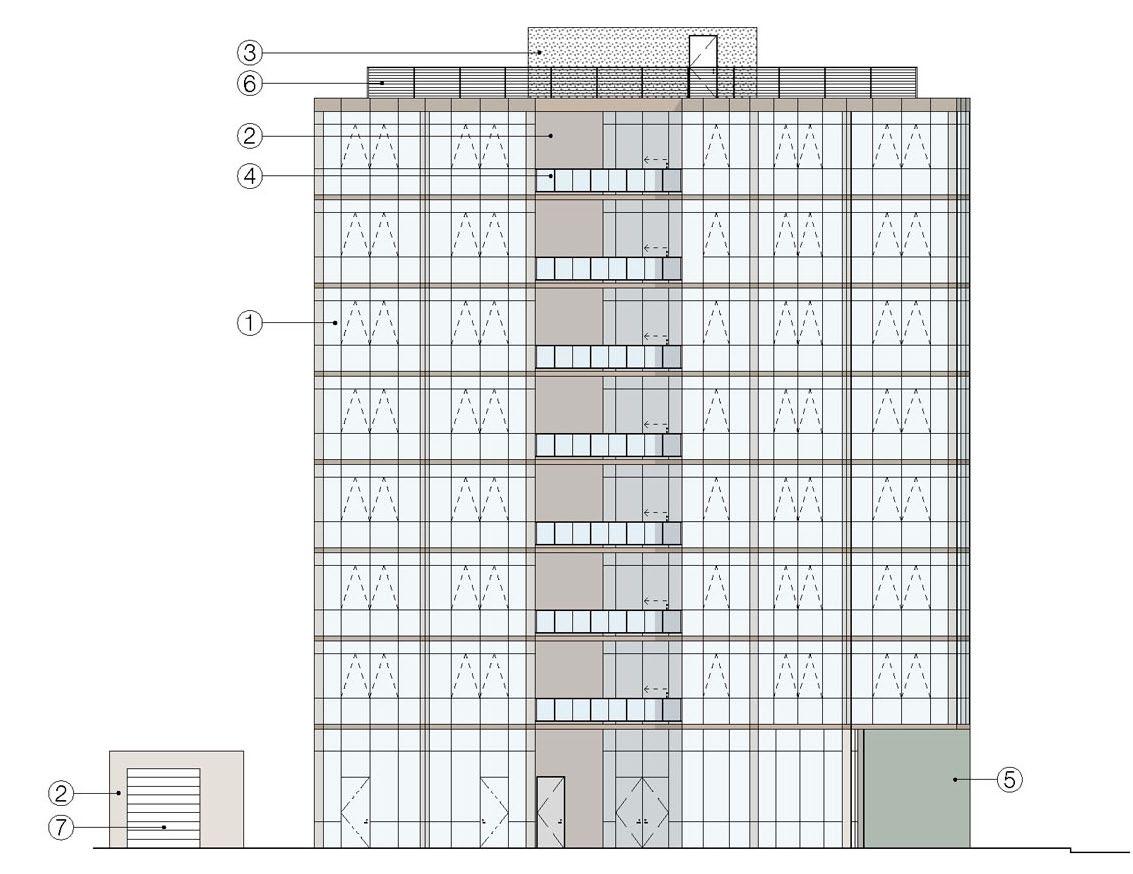

DISTRICT OFFICE

HACKER ARCHITECTS

90,400 SF

TO BE COMPLETED IN 2020

At six stories, the building includes five floors of new office space with groundfloor retail and restaurant space along an active multimodal thoroughfare. Glue-laminated columns and beams, and cross-laminated timber floors, are fully visible throughout the interior, a nod to the timber-heavy industrial past of the neighborhood. Double-height spaces lend volume and circulation to the interior, and allow tenants to create more intimate office layouts than a typical single-floor plan.

--HACKER ARCHITECTS

--HACKER ARCHITECTS

What is the construction type of District Office?

Type IIIA: exterior walls are of noncombustible materials and the interior building elements are of any material permitted by code.

a 32’ x 12’ grid with a concrete core.

What is the construction time?

7 people work on the whole structure, 12 weeks for mass timber to be erected in place. 15 weeks total including metal stud exterior and interior partitions.

Primary structural frame: 1 HR

Exterior bearing walls :2 HR

Interior bearing walls: 1 HR

Exterior nonbearing walls and partitions: depends on fire separation distance and occupancy group

Interior nonbearing walls and partitions: 0 HR

Floor construction and associated

secondary members: 1 HR

Roof construction and associated secondary members: 1 HR

What is the structure system of District Office?

Concrete foundation and slab on grade. CLT floors, Glulam columns and beams on

What is the biggest takeaway from this project?

First, make steel larger to accomodate tolerence. Timber pieces are very accurate because they come directly from factory. Second, think in wood and really use their property maximize identity and material efficiency.

What is new in District Office?

Because it’s a speculative office building, the client wants concrete floor topping, which disallows access floor method we’ve used before. So we came up with the corridor distribution system.

What other mass timber projects have you done?

“First Tech” is the first mass timber building, 5 stories / 156,000 SF. The current office space is called “Simple”, which is also a mass timber building and traditional joint with extra wood for protection.

First Tech uses access floor to allow clean ceiling scape. Small grid also eliminates secondary beam which expands exterior glazing and perception. During design, we provided steel and timber options side by side all the way during design to track the cost and aesthetic difference. Frame to frame comparison steel is cheaper, but taking foundation work, construction time and value to the tenant into account, it’s 4% less than steel construction.

RICHMOND OLYMPIC OVAL

CANNON DESIGN 506,000 SF COMPLETED IN 2010

When the City of Richmond was named the long-track speed skating venue for Vancouver’s 2010 Winter Olympic Games, they called for a landmark building that would showcase local wood and accommodate legacy use. Fast + Epp rose to the challenge, designing a roof structure that was the result of extensive field research into Olympic ovals in Lillehammer, Salt Lake City and Calgary.

Alongside Structure Craft, we proposed a world first – sweeping longspan timbersteel hybrid arches, which would support captivating ‘Wood Wave’ panels made from simple pine-beetle-kill 2×4 lumber.

-- Fast + Epp

The steel and timber hybrid arch structure allows all mechanical and electrical services to be hidden, creating a striking architectural expression. The beetlekilled perforated wood panel functions not only as a waving field of ceiling, but also enhances the space’s acoustic performance. (right)

By extending concrete buttresses up through the lower floors, the concrete structure is used to resist the outward thrust of the arches, avoiding visually heavy tie rods and large overturning forces on the soft foundation soils.(left)

ORCHARD COMMONS

PERKINS

WILL 447,994

IN 2016

We collaborated with students, the University, and Student Housing and Hospitality Services (SHHS), to create an outward-looking facility that invites the greater campus in, promoting diversity and social connection by bringing more activity and life to the heart of UBC. Our design cultivates interaction and chance meetings with transparent, interconnected spaces, and supports the wellbeing of occupants through views of nature, daylight, and the use of healthy materials. We have used wood in highly visible and strategic ways. For example, in shared spaces wood helps to create a sense of invitation, warmth, and generosity to foster social well-being

-- Perkins + Will

BROCK COMMONS

Completed in 2017, Brock Commons Tallwood House is an 18 storey, LEED Gold certified, 404-bed student residence building located at the University of British Columbia in Vancouver, BC. Extraordinary for its height, making it the world’s tallest mass wood tower at the time of its completion, Tallwood House is also extraordinary for the speed the timber structure and prefabricated facade went up in only 66 days. At 2,233 cubic meters, the building utilizes an extraordinary amount of timber that stores an impressive 1,753 metric tons of carbon dioxide and avoids production of 679 metric tons of greenhouse gas emissions. Key to receiving approvals and achieving economic viability was a “keep it simple” design approach that makes the building appear ordinary—extraordinarily ordinary—through encapsulation of the wood structure with gypsum board.

NORTH VANCOUVER CITY HALL

MICHAEL GREEN ARCHITECTURE

SF

IN 2012The City of North Vancouver’s 38,000 sq. ft. renovation project expanded the existing 1970’s modern heritage building into a recently vacated library structure, with a new bridging atrium. The design team’s goal was to create a very public building; about the community and for the community. The design is open and transparent. The main link between all departments and the public is found in the 67 metre (220 feet) long atrium space. The design creates a flexible, productive working environment for the diverse services offered to the public in the building, and reinforces the city’s aspirations to showcase their new sustainable city mandate.

-- Michael Green

-- Michael Green

5.25 in x 18 in Glulam timber columns support long span prefabricated roof modules made from LSL, which are typically used in industrial applications, but in this case provide warm yet inexpensive interior experience.

This cantilevered public gathering space is 46 feet from the building face, creating a nice entry plaza and big wood lattern effect. The floor is made of a composite system consisting of glulam beams topped with plywood and a 100mm concrete floor slab.

UBC CAMPUS ENERGY CENTER

DIALOG ARCHITECTS

SF

IN 2015

Redefines District Energy by making sustainable infrastructure that is visible and able to inform, educate and engage the campus community by speaking to both the process and broader energy issues. Comprised of a new high efficiency hot water heating plant and district hotwater distribution loop, the CEC replaces the campus’ pre-existing steam boiler plant constructed in 1925. The new system serves over 130 buildings, or 12 M square feet of campus development delivered through 14 km of underground insulated pipe. The 20,000 square foot building houses all process equipment including three 15 MW boilers with capacity for phased expansion to a total output of 80 MW.

from DIALOG)

UBC CIRS

PERKINS + WILL 61,000 SF COMPLETED IN 2011

The structure of CIRS is a hybrid system. The basement and ground level auditorium are cast-in-place concrete, with a roof of curved glulam beams supporting a solid wood roof over the auditorium. The upper floors have a frame of engineered wood members supporting a solid wood floor assembly. This floor and roof assembly is composed of lumber and plywood decking and performs to a 1-hour fire rating at each floor level. Due to the size of the members and the bulk of the system, the wood frame and assembly combination are considered to be heavy timber construction under the British Columbia Building Code. This designation allows the structure to be exposed without the need for additional fireproofing materials.

--PERKINS + WILL

Primary structure is glulam post and beam moment frame, on top of which lies the solid wood floor decking made of side nailed dimensional lumber. In the short direction, conventional plywood-sheathed light wood frame shear walls provide lateral stability, while in the long direction a wood moment frame is created with the combination of full height glulam columns and hollow box spandrel panels.

(Drawings from archdaily.com)

(Drawings from archdaily.com)

UBC BIOENERGY RESEARCH DEMONSTRATION FACILITY

MCFARLAND MARCEAU ARCHITECTS

IN 2012

The Bioenergy Research and Demonstration Facility is the first global demonstration of a commercial scale biomass heat and power system developed jointly by Nexterra Energy and GE Energy.

It is a “Living Lab” project resulting from the collaborative efforts of academics, researchers, operators and industry to demonstrate a new technology in energy production and construction methodology here at the UBC campus.

The structural system is comprised of glulam moment frames while the exterior walls, roof and floors are constructed with CLT panels.

--UBC

UBC EARTH SCIENCE BUILDING

Designed to inspire collaboration and creativity across disciplines, the new Earth Sciences Building lies at the heart of the science precinct on UBC’s Vancouver Campus.

The $75 million facility is home to Earth, Ocean and Atmospheric Sciences, Statistics, the Pacific Institute of the Mathematical Sciences, and the dean’s office of the Faculty of Science.

Constructed to LEED Gold standards, ESB is the largest panelized wood building and the largest application of cross laminated timber in North America. The building uses over 1,300 tons of BC sourced and engineered CLT – each ton of dry wood products sequesters sufficient carbon to keep between 1.8 and 2.0 tons of CO2 from being formed. The wood materials in the ESB will sequester about 2,600 tons of CO2.

(Drawings from archdaily.com)

PROPOSAL

FESTIVAL 2019 IN AMSTERDAM

IDEA COMPETITION - JURY COMMENDATION

IDEAS FOR NEW

CITY