Vital magazine is a news and media resource managed by POET, the world’s largest producer of biofuels. Since 2008, Vital has provided readers with forward-thinking content that helps to advance an industry that provides renewable energy and bio-based products from the surface of the Earth. Vital seeks to educate readers about the state of the biofuels sector today and the breakthrough stories of innovation and sustainability of tomorrow by presenting a variety of insights and perspectives.

Each issue features in-depth, quality reporting on important topics, such as the fight against the climate crisis, innovation in agriculture, local and national policy landscapes and stories of the men and women advocating to advance bioethanol and other renewable bioproducts.

Vital by POET is committed to editorial excellence, along with high quality print production and distribution. In the spirit of its continued commitment to being good stewards of the environment, POET is proud to produce Vital using recycled paper when printed.

Additional reporting can be found online at vitalbypoet.com. The opinions and statements expressed by content contributors and advertisers in Vital are their own and do not necessarily reflect those of POET. Neither POET nor its third-party content providers shall be liable for any inaccuracies contained within Vital, or for any actions taken in reliance thereon.

Contact

4615 North Lewis Avenue Sioux Falls, SD 57104

vitalbypoet.com

Article Submissions

Direct all questions, comments and story ideas to: vital@poet.com

Advertising Information

605.965.2200

vital@poet.com

Publication Design & Layout

POET Communications

To Subscribe

Visit vitalbypoet.com to receive a digital magazine

Vital is published biannually by POET, LLC and other individuals or entities. All materials within are subject to copyrights owned by POET. POET, BPX, and other associated designs and logos are registrations or trademarks of POET, LLC. Growth Energy is a registration or trademark of Growth Energy, a non-profit corporation organized under the laws of the District of Columbia. Any reproduction of all or part of any document found in Vital is expressly prohibited, unless POET or the copyright owner of the material has expressly granted its prior written consent to so reproduce, retransmit or republish the material. All other rights reserved. For questions, contact the POET legal department at 605.965.2200.

The opinions and statements expressed by content contributors and advertisers in Vital are their own and do not necessarily reflect those of POET. Neither POET nor its third-party content providers shall be liable for any inaccuracies contained within Vital, or for any actions taken in reliance thereon.

©2025 POET, LLC. All rights reserved.

08 | Efficiency in Motion

How POET’s terminals keep bioproducts moving

14 | Trailblazing through the Heartland

POET announces a collaboration with Tallgrass to advance its carbon capture goals

18 | E15 Explained

What every driver needs to know about this lower-cost, high-performance fuel

34 | It’s All Relative

POET’s legacy is built on family and fueled by purpose

44 | POET Bioprocessing – Caro Stand Out for Culture

Company values aren’t just for show at POET

44 | Waste to Worth

POET helps dairy farms convert methane into clean energy

06 | In Sight By Jeff Broin

16 | Mechanic’s Corner

Automotive advice from Dr. Andrew Randolph

24 | Farm Fresh By Matt Ziegler

58 | Out of Left Field By Scott Johnson

| People of POET

By Jeff Broin, POET Founder and CEO

America is strongest when we lean into what we do best: building, growing, and fueling from within. Bioethanol is a unique product that allows us to do all three. And right now, with tariffs threatening to cause disruption across industries — including agriculture — it’s time we take a serious look at a powerful, homegrown solution that is already within our reach: year-round E15.

E15 (gasoline blended with 15% bioethanol) is more than just a cleaner, more affordable fuel choice. It’s a key to improving market stability for our nation’s farmers and rural communities while unlocking American energy dominance. We’ve seen it before: when biofuels win, rural America wins. Over the last two decades, as bioethanol became an essential component of the U.S. fuel supply and scaled up from 1% of gasoline to 10%, U.S. farm income nearly tripled and land values more than doubled.

Today, year-round E15 represents the next step in that value creation by generating reliable domestic demand for surplus corn, reducing our dependence on foreign oil, and empowering rural communities to play a central role in strengthening America’s energy future. A full transition from E10 to E15 across the U.S. would increase corn demand by 2.5 billion bushels per year and create over $66 billion in economic impact.

On the other hand, grain export strategies, which have been widely discussed as a solution, provide limited relief at best. In fact, the USDA has acknowledged that positive effects from shifting trade are minimal compared to the direct losses that tariffs cause to businesses and consumers. Simply put, we can’t trade our way out of this — we must create demand here at home.

American energy dominance is about building resilient energy solutions in America. Every gallon of bioethanol blended into our fuel displaces imported petroleum with a renewable fuel that’s grown by our farmers, produced in our communities, and used every day by drivers across the country. With E15, we’re not waiting on foreign demand or relying on foreign sources of energy. We’re creating our own.

That’s real energy independence, rooted in our soil.

In April, the Trump administration took a meaningful step by granting a summer waiver to allow uninterrupted E15 sales — a clear signal of support for America’s farmers. But this marks the fourth year in a row we’ve relied on a waiver, proving that a temporary solution is not enough. What we need now is a permanent, nationwide fix that ensures E15 can be sold year-round, every year, without relying on repeated administrative action.

POET was founded on the vision that agriculture and bioprocessing could revitalize rural communities, improve our environment, and change our energy future. Today, that vision is more important than ever. Supporting year-round E15 is not just good policy — it’s a common-sense solution that benefits farmers, consumers, and the U.S. economy.

Let’s fuel our future the American way with homegrown E15!

By Susanne Retka Schill

In recent years, POET has acquired four terminals that enhance the company’s ability to market and distribute its bioproducts to customers throughout the U.S. and around the world — but they all play very different roles.

“While each terminal operates with its own unique processes and characteristics, we all share a common purpose: to serve as a key transition point in delivering POET’s products to our customers, ensuring quality and efficiency throughout the supply chain,” said Austin Broin, General Manager of POET Terminal – Savannah.

POET Terminal – Savannah

Broin has managed the Savannah, GA, terminal since it was acquired by POET in 2022. The team at POET Terminal – Savannah transloads railcars filled with dried distillers grains (DDGS) into 40-foot containers bound for export, via the Port of Savannah just 4.5 miles away. The operation is split into two separate rail yards: one serviced by Norfolk Southern (NS Yard) and one by CSX/Georgia Central (GC Yard).

POET Terminal – Savannah can currently unload up to 150 cars each week, with plans to expand throughput in the future. “We have the capacity to store 26 cars on one track (GC Yard) and 22 on the other (NS Yard), but we don’t unload every car on the track each day - the target is 30 cars/day between the two yards” Broin said.

POET’s Savannah facility transloads DDGS directly into containers, with the capacity to load up to 2,100 containers per month, though actual throughput has averaged slightly lower. Daily operations require coordination among multiple partners, including steamship lines, a local trucking company, an inspection provider, and the Georgia Port Authority.

The logistics are complex: POET’s team must schedule vessel bookings, arrange drayage from the Port, load and store containers onsite, and return them promptly to avoid detention costs while ensuring timely shipments. The documentation process is equally detailed. POET’s export team in Sioux Falls prepares comprehensive shipment documents for every load and forwards them to overseas customers. These documents are essential for cargo release at the destination port.

Broin added the Savannah terminal handles about fifty percent of all containers shipped by POET, with most of the DDGS coming from POET’s Eastern Corn Belt facilities. Other POET containerized shipments are either loaded by the plants themselves or by third-party transloaders.

POET Terminal – Camilla

Further south in Georgia, just an hour north of the Florida state line, POET Terminal – Camilla receives bioethanol and DDGS by rail from a short line railroad with connections to both CSX and the Norfolk Southern railroads. Once a 100 milliongallon-per-year bioethanol production facility, the plant was idled during the COVID pandemic, transitioning in 2020 to operate as a terminal. POET acquired the facility in 2021 and began upgrades, improving the bioethanol handling and adding DDGS in 2023.

“At first we struggled to keep up with truck demand here because we weren’t built as a terminal,” said Georgia Taylor, Terminal Manager at POET Terminal – Camilla. “We were taking existing equipment that we used to unload denaturant rail cars to unload bioethanol rail cars into storage tanks. It would take us an hour and 45 minutes to do one rail car.” But the team has come a long way. Today they can unload three rail cars in a little over an hour, “and we stay way ahead of truck demand.” Camilla handles between 4.5 million and 5.5 million gallons a month of bioethanol, primarily shipped to the big blending terminals in Albany and Bainbridge, GA.

On the DDGS side, Camilla both transloads DDGS from rail cars directly to trucks, as well as to its flat storage, unloading between 13 and 15 rail cars each week. “We have good blending capabilities,” Taylor said, which makes Camilla unique in the POET system for being able to blend accurately to specification. “Our customers are pretty much in our backyard,” she added, “with some loads going into Alabama and Florida.”

While the bioethanol tanker truck drivers load themselves from the facility’s rack, needing little assistance, the eight members of Camilla’s team load all DDGS.

POET Terminal – Bossier City

West of Camilla in northwest Louisiana, POET Terminal – Bossier City is quite different from its eastern counterparts, not handling any DDGS. Four POET team members transload bioethanol from rail cars to trucks. Located on the Canadian Pacific Kansas City rail line, the facility can hold about 35 cars, although it usually gets about 15 cars at a time, said Terminal Supervisor Justin Hedgepeth.

The Bossier City team unloads four to five rail cars daily that will fill three and a half to four fuel tankers. “Opening up a car and hooking it up to the truck probably takes five minutes, and then it takes roughly 20-22 minutes to pull product from the car into the truck,” Hedgepeth said.

Unlike other POET terminals handling bioethanol where tanker drivers load themselves, the Bossier City crew loads each tanker. “There’s a lot of manual labor that comes with this job,” Hedgepeth said. “Lifting heavy, heavy things. What makes us most unique is just the manual labor part of it.” In late 2024, the facility averaged 20 to 23 trucks loaded each day.

POET took over operational control of the facility in December 2019 from a thirdparty operator.

Located in the Texas hill country just south of Austin, Texas, POET Terminal – Buda was purchased by POET in 2021 as part of its acquisition of the Flint Hills Resources bioethanol assets. Buda unloads a 108-car unit train in a day. Located on a rail siding just off the Union Pacific main corridor, Buda utilizes an integrated thirdparty contractor whose team of nine splits the unit train for offloading half the train at a time.

“Start to finish, a complete unit train takes about 16 hours — splitting it up, offloading, unhooking, building it back up,” said Scott Rachels, Terminal Manager at POET Terminal – Buda. The offloading is performed by an integrated third-party operator and monitored by four POET team members, taking approximately eight hours for the unit train.

“We have six offload pumps, so we can offload a little over 10,000 gallons a minute,” Rachels said. Buda gets a unit train every five to 10 days.

Each rail car in the 108-car train holds about 28,800 gallons, enough bioethanol to fill the facility’s two aboveground storage tanks, each holding just under four million gallons. The drivers of the fuel tankers picking up bioethanol load their own trucks, in a system just as efficient as the rail offloading. “We can load a 7,800-gallon truck in about 12 minutes,” Rachels said,

“doing anywhere from 80 to 120 trucks a day. Monthly it adds up to between 15 million and 18 million gallons.”

Trucks go as far north as Waco and south to Corpus Christi, delivering bioethanol to major oil companies’ blending and pipeline terminals. “We supply a large portion of the market in central Texas with bioethanol,” he added.

Buda’s high-speed, efficient terminal handles an impressive volume each week. “We’re probably the biggest POET-owned bioethanol terminal as far as throughput,” Rachels said. “But to put it in perspective of how much POET produces, even if we had 12 months of the maximum throughput we’ve seen, we’re only moving 216 to 230 million gallons annually. Compare that to the three billion gallons POET produces each year.”

Its four strategically located terminals have played a key role in POET’s robust and efficient logistics network, allowing the company to seamlessly deliver bioethanol and DDGS to customers across the U.S. and beyond. Each facility plays a unique role, from high-volume rail offloading in Buda to precision blending in Camilla, laborintensive transloading in Savannah, and handson tanker loading in Bossier City. Together, these terminals help POET meet customer demand with speed, flexibility, and reliability, ensuring that its bioproducts reach key markets while strengthening the company’s position as a leader in feeding and fueling the world.

POET announces a collaboration with Tallgrass to advance its carbon capture goals

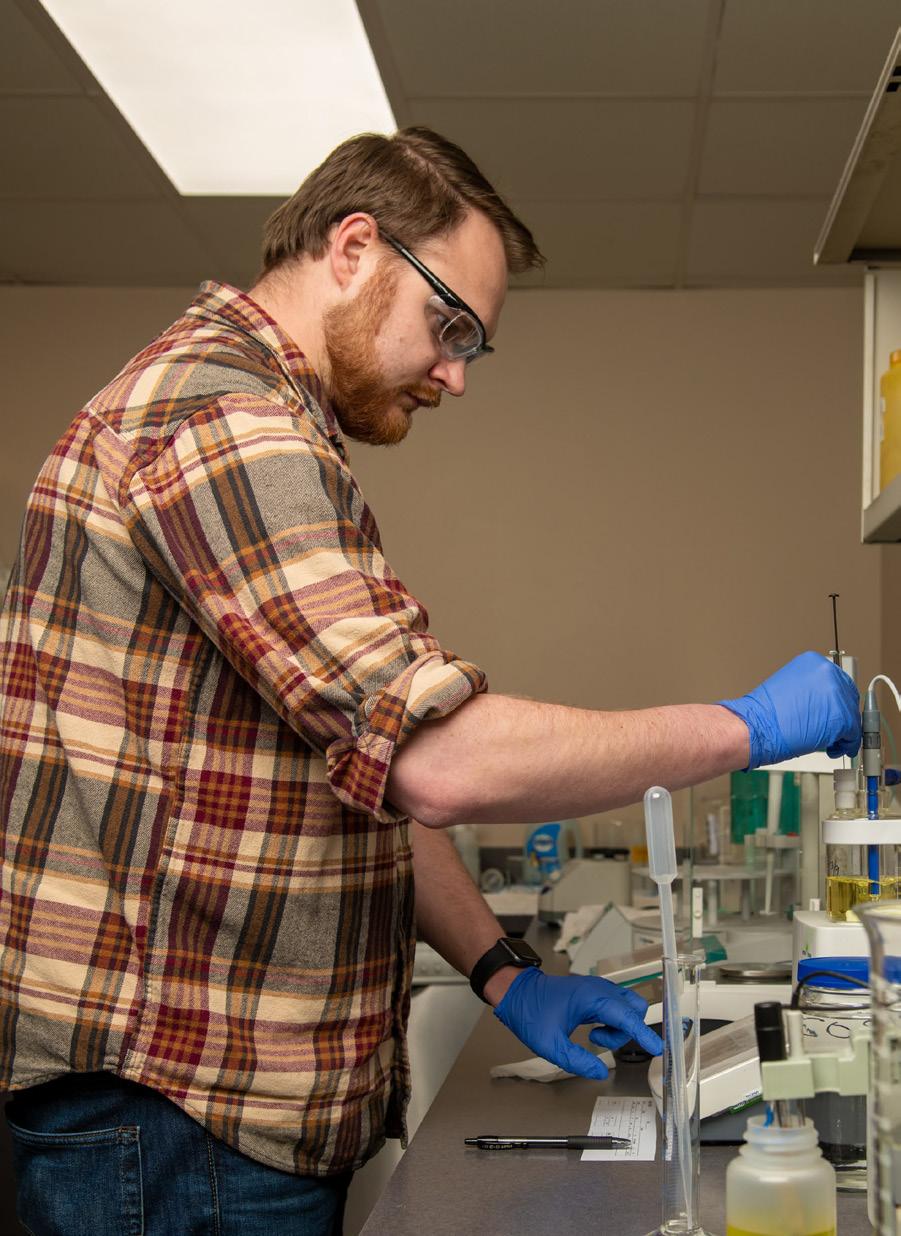

By Erin Branick, POET Media Manager

In an exciting step for continued innovation in bioethanol production, POET, the world’s largest biofuel producer, has announced a groundbreaking partnership with Tallgrass, a leading infrastructure company. Through this collaboration, POET’s bioprocessing facility in Fairmont, Nebraska, will connect to the Tallgrass Trailblazer carbon dioxide (CO2) pipeline, paving the way for permanent underground carbon sequestration in Wyoming. This collaboration isn’t just about safely storing carbon; it’s about creating new opportunities for agriculture, bioethanol, and rural communities.

At POET, every part of the corn kernel is utilized, from the starch that produces bioethanol and purified alcohol to the protein, fiber, and oil used in POET’s animal feed ingredients and other bioproducts. Now, to fully maximize the cyclical CO2 in corn — and complement POET’s existing bioCO2 products — carbon capture and sequestration will play a crucial role.

By capturing bioCO2 from the bioethanol production process and safely sequestering it underground, POET continues to position itself at the forefront of innovation while unlocking new market opportunities for Nebraska’s corn growers and bioethanol producers.

“We are excited to be collaborating with POET in Nebraska and are proud that our work with them will broadly benefit the Nebraskan communities associated with the project and continue to add value across the state’s bioeconomy,” said Alison Nelson, Segment President of CO2 Origination at Tallgrass.

The Trailblazer project is currently under construction and will begin operations in 2025. Tallgrass is in the process of converting an existing natural gas pipeline that has operated safely for over a decade to transport CO2, minimizing the need for additional pipeline infrastructure. This conversion also reduces environmental impact and expedites the deployment of essential carbon capture technology.

POET’s commitment to the Trailblazer project extends beyond its own operations. The partnership stands to benefit the broader agricultural economy by expanding access to low-carbon fuel markets and enhancing the value of corn crops in Nebraska and across the Midwest.

The project also provides direct financial benefits to landowners who have agreed to host the pipeline on their property through the Trailblazer Community Benefits Agreement. Other near- and long-term benefits of this agreement include commitments to fund nonprofits and equip and train first responders. Additionally, communities along the project’s route will see increased economic activity and infrastructure investment as the project progresses.

Projects like Trailblazer illustrate how bioethanol producers can remain competitive and bring even greater value to corn producers. POET’s participation underscores the company’s commitment to continuous improvement, ensuring that biofuels remain a vital part of the global energy transition.

POET and Tallgrass are proving that collaboration, technology, and a shared commitment to innovation can drive meaningful change. By pursuing carbon capture, POET is securing new opportunities for farmers, strengthening rural communities, and leading the charge toward a cleaner, more resilient energy future led by American ingenuity.

“POET is excited to join the Tallgrass Trailblazer project,” said Jeff Broin, POET Founder and CEO. “Carbon capture is a tremendous opportunity to create significant value for farmers and bioethanol producers while strengthening rural communities and counties in Nebraska and across the Midwest. We believe this initiative — and similar carbon capture projects — will play an important role in unleashing even more opportunities for agriculture in the future.”

By Dr. Andrew Randolph, Technical Fellow at Richard Childress Racing

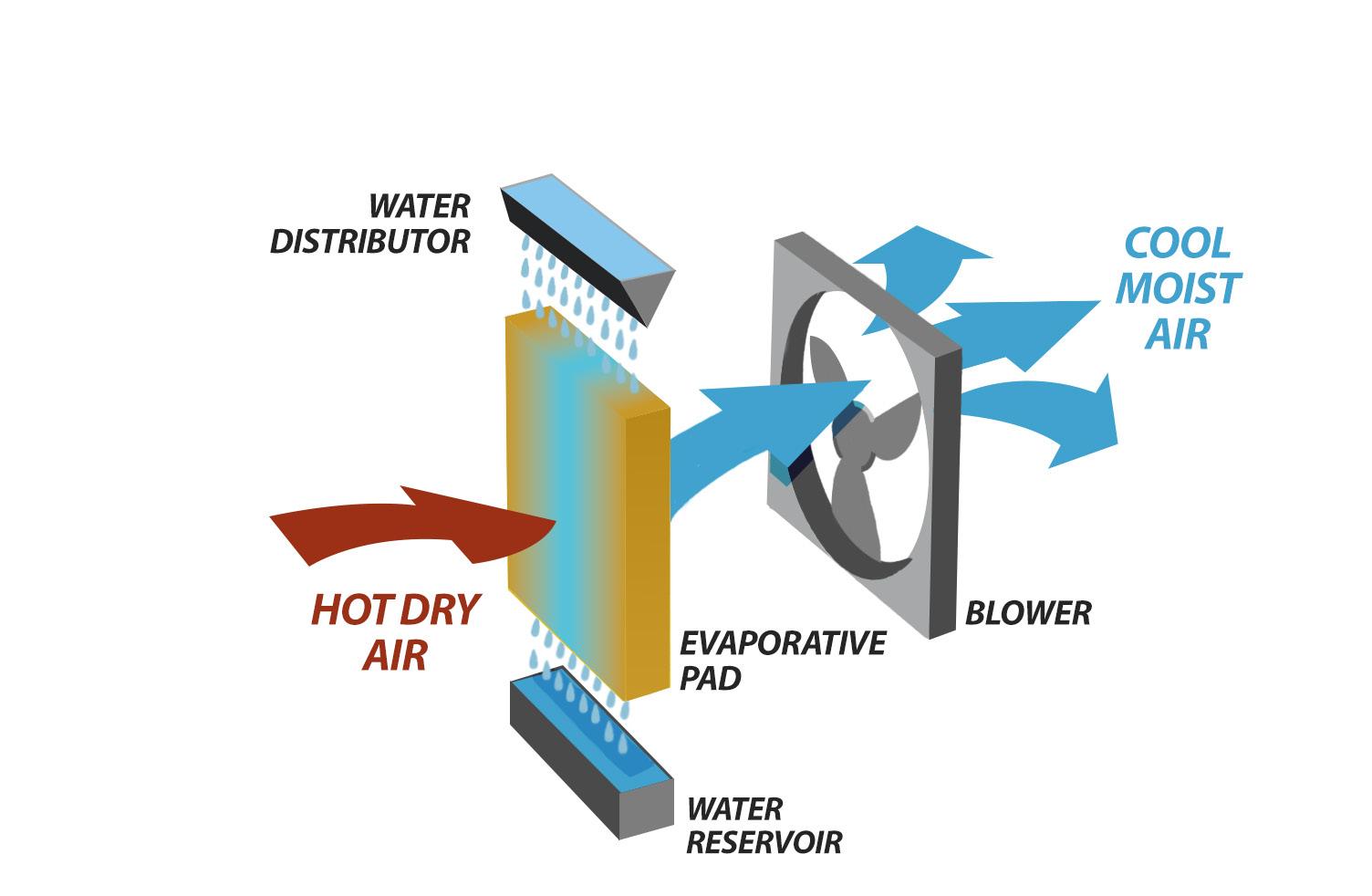

Let’s discuss evaporative cooling, the mechanism by which our bodies regulate temperature. When it is too warm, we sweat, and the liquid cools our skin as it evaporates.

A similar phenomenon is used to cool down homes and businesses in many hot, dry areas, like the desert regions of the Southwest. In these systems, water is evaporated from hot air, emitting much cooler, moist air. You’ll also often see this principle utilized by restaurants with outdoor patio seating areas, which spray mists of atomized water to make them more comfortable on hot days. Evaporative cooling is preferable relative to the traditional refrigeration systems required in areas with higher humidity because it is much less energy intensive.

All liquids have an associated heat of vaporization, which is a measure of the cooling that results from vaporizing a given mass. The table compares the cooling effect of a given mass of water to the cooling effect of gasoline and bioethanol. Water has a very high heat of vaporization, meaning that the vaporization process removes significant heat from the surrounding air. Indeed, this is one reason why both our bodies and evaporative coolers are so good at regulating temperature.

Gasoline has a very low heat of vaporization. In other words, your body would not be able to cool itself very well if you were to sweat gasoline. Bioethanol has about 2.5 times the heat of vaporization of gasoline, but still far less than water. The cooling effect you feel when using hand sanitizer is from the evaporation of bioethanol, the predominant ingredient.

Why does this matter to your engine? Engines rely on fuel vaporization to cool internal components such as valves and pistons. In fact, under prolonged acceleration, engines inject extra fuel for the sole purpose of cooling critical components. The higher heat of vaporization of bioethanol enhances this cooling effect relative to gasoline, thereby providing engine protection and longevity.

Another benefit of increased heat of vaporization is increased resistance to knock. The high-octane benefits of bioethanol are well understood, but higher octane underrepresents the knock resistance benefits. This is because the Motor Octane Test procedure specifies a fixed intake temperature for the fuel-air blend, where, in reality, the induction temperature of an engine running with bioethanol in the fuel is reduced by the higher heat of vaporization. Knock is perpetrated by heat, so reduced induction temperatures provide a knock resistance benefit not comprehended in the Motor Octane Number (MON).

In short, just as sweat cools our bodies on a hot day, bioethanol cools and protects your engine — naturally enhancing performance, durability, and efficiency in ways traditional gasoline simply can’t match.

By Matt Merritt

In June of 2011, the U.S. Environmental Protection Agency (EPA) issued the first bioethanol waiver in more than 30 years, giving Americans the opportunity to use a new fuel called “E15.”

Since then, the 15% bioethanol blend has seen steady growth in the nation’s fuel supply. Today, it is available at more than 3,700 retail locations in 33 states and has fueled more than 100 billion miles driven by American consumers.

Yet, despite its growing popularity, many people are still unfamiliar with what E15 is and why it’s an excellent — even superior — fuel option. So, what exactly is this high-octane, clean-burning fuel, and why is it a gamechanger for drivers across the country?

A simple percentage

It wasn’t that long ago that E10 (10% bioethanol blend) was a new idea in the U.S., and the biofuels industry faced the challenge of making Americans comfortable with something other than petroleum. Now, nearly every gallon of gasoline sold in the country has at least 10% bioethanol, and consumers don’t think twice about putting it in their vehicles.

E15 represents a tremendous opportunity to use even more American-made fuel, but the next challenge once again lies in educating the public.

“The 15 in E15 is just the percentage of the bioethanol in the fuel. It’s a blend of 15% bioethanol into unleaded gasoline. That’s the simplest explanation,” said Doug Berven, Vice President of Corporate Affairs at POET.

E15 is approved by the EPA for all passenger cars, light trucks, and medium-duty vehicles model year 2001 and newer. That approval came after a battery of tests on numerous makes and models of vehicles to ensure it was safe.

“It’s the most tested fuel ever. It’s approved for all cars 2001 and newer, and the reason it only goes back to 2001 is because they can’t test every single classic car on the planet,” Berven said. “Model year 2001 and newer represents 98% of the vehicles on the road today.”

Bioethanol replaces the harmful, petroleum-based chemicals used to boost octane, said Russ Evans, Master Certified ASE Mechanic and host of the Under The Hood podcast. Bioethanol is high in octane, and that additional 5% boosts the overall octane of the fuel by another point, taking it from the standard 87 in E10 up to 88. Because of that, some stations label E15 as “Unleaded 88.”

Octane prevents premature combustion and improves engine efficiency, so bioethanol allows for better design and performance, Berven said.

“Car manufacturers are making smaller, higher compression engines to get better efficiency out of those engines,” he said. “Since 2005, engine efficiency has improved by 39%, and a lot of that has to do with higher octane and better engines.”

“If you get more octane, you’re building engines more efficiently and getting more miles per gallon. They just run better,” Evans said.

Evans says he would love to see even more bioethanol in fuel and often runs E30 in his own vehicles. “Ideally, 92, 93, 94 octane would be amazing to see at the pump someday,” he said.

Don’t take their word for it. Look to the people who make a living getting the most out of their engines.

“Bioethanol holds the world speed record on both land and water. It is a high-octane, huge-horsepower fuel, and that’s why all of the performance racing leagues use it,” Berven said. “IndyCar uses 100%. NASCAR uses 15%, and a higher blend would benefit the league even further. Drift racing, speedboat racing, all of these performance sports want to get the benefits of the really high octane content of bioethanol.”

Looking beyond just the engine benefits of E15, the fact that it is a clean and sustainable fuel has even greater benefits for the world.

Bioethanol reduces harmful emissions by 46% compared to regular gasoline. According to the bioethanol advocacy group Growth Energy, moving from E10 to E15 nationwide would lower America’s greenhouse gas emissions by 17.63 million tons per year, the equivalent of removing 3.85 million vehicles from the road. That means cleaner air for all of us.

To help paint that picture, Evans likes to point out that caterers use bioethanol to fuel the burners that keep food warm at events. Imagine if they used gasoline instead.

“You would have black soot pouring out under the food,” he said.

Berven said E15 is the best near-term option to continue making progress on the sustainability of liquid fuels.

“The only reason we’re cleaning up the fuel supply is because bioethanol is cleaning it up,” he said. “Gasoline is not cleaner today. Bioethanol is clean, and the more bioethanol in the fuel supply, the cleaner it will be. It’s just very simple.”

Bioethanol is less expensive than gasoline, but consumers get even more value from it because it replaces petroleum-based octane enhancers, which are among the most expensive components in gasoline.

Berven pointed out that bioethanol is a dollar less than the aromatics it replaces, and recently that’s been as high as $2. Saving money on that portion of the fuel formulation makes an instant difference in the final cost consumers see at the pump.

“E10 is already a huge benefit to the consumer, and E15 is just an added benefit,” Berven said. “At the pump, we reduce the price by 40 cents with just 10% bioethanol, and then E15 typically reduces it by another dime.”

Critics of E15 claim consumers will see a drag on their mileage with E15. If this sounds familiar, it was one of the main criticisms of E10 when that fuel was first introduced.

Evans said he has not seen that bear out in reality. People who look only at the energy content of the fuel are missing the bigger picture, he says.

“Typically, if anything is lost in miles per gallon, it’s made up in the performance. They cancel each other out,” he said.

Berven agrees.

“You may get better mileage, you might get a little less mileage, but overall, the general consumer is not going to be able to see any difference whatsoever between E10, E15, E0,” he said. “That’s just a reality, and I would say that all cars are going to benefit from bioethanol because it acts as a solvent. It keeps the engine clean. It also burns more efficiently, so it takes less energy to burn bioethanol.”

‘Go for it’

E15 is not the end goal for the bioethanol industry — it is simply the next step. Leaders like POET and Growth Energy continue to educate the public about the all-around benefits of this high-performance fuel so it can continue to improve the fuel supply, benefiting consumers in the U.S. and around the world.

Evans said E15 checks all the boxes for what consumers want — we just need to help them realize it.

“People want to go to the pump and pay the lowest price possible as long as it doesn’t damage their car,” he said. “Bioethanol is the lowest-cost option, and it’s great for your vehicle, so go for it!”

By Matt Ziegler, National Corn Growers Association Director of Public Policy

Inflation, tariffs and the economy are the talk of the town in Washington these days. And advocates have been making a strong case that these concerns are precisely why American consumers need consistent, year-round access to higher blends of bioethanol.

The reason is simple: Bioethanol saves drivers money at the pump, is good for the environment, and is an economic engine for farmers and rural America. It also is homegrown and provides the United States with energy security. Bioethanol has something for everyone.

Unfortunately, though, the nation still operates on a dated policy that interrupts access to E15 during the summer months.

Bioethanol supporters like the National Corn Grower’s Association (NCGA) have worked with the U.S. Environmental Protection Agency to provide waivers that allow for continued access to this fuel over the last several summers, but this approach does not provide farmers or consumers with the long-term certainty they need. And as the nation struggles with inflation and higher gas prices, we need a long-term and permanent fix.

Enter the Nationwide Consumer and Fuel Retailer Choice Act, which would allow for year-round access to higher bioethanol blends like E15.

State and national corn grower leaders and allies — including those in your state — have been working to help get this legislation across the finish line.

A win was nearly secured in December when legislation designed to keep the government funded through March included language eliminating the outdated E15 policy. At the eleventh hour, the language was removed, much to our disappointment.

We re-upped our efforts this year. We recently sent the leadership in the House and Senate a letter with close to 9,000 signatures from farmers and our allies calling for action.

We also teamed up with congressional sponsors of the bill as they held a press conference on Capitol Hill this month to rally support for our efforts.

As some in Washington talk about what they’re against; we are in a unique position to talk about what we are for. And luckily, we have some heavy hitters on our side, including President Trump who has expressed his support for eliminating barriers to bioethanol.

But while we have a lot going for us, we also have several challenges. If inflation, tariffs and economic concerns are helping us make our case, they also are causing a lot of distractions, impeding our ability to attract the attention of policymakers and the media.

We are also having to navigate a very divided Congress. This includes divisions in each party and between Democrats and Republicans. We had hoped, for example, to include language that would address this issue in a new bill to fund the government, but because Republican control of the House is so tight, Speaker Mike Johnson (R-La.) kept the legislation strictly focused on government funding, so he wouldn’t lose votes.

But I still think there are many opportunities over the days ahead to get this legislation passed and signed by the president. We will need you to help us achieve this goal. If you’re not already a member, consider joining your state corn grower group and sign up for the National Corn Growers Association’s advocacy alerts, so you can make your voice heard on this and other issues.

While America runs on bioethanol, public policy wins are fueled by people like you and the thousands of corn growers across the country! So, join our efforts.

Here’s to working toward permanent E15 win in the near future.

Heather Baker fuels POET with heart and helps her community thrive

By Holly Jessen

Heather Baker has a simple but meaningful life goal: “Being kind to people,” she said.

As far as Scott Tuttle, General Manager at POET Bioprocessing – Macon, is concerned, Baker is achieving her goal and then some.

“A lot of high-performing people are not the easiest to get along with,” he said. “She is a very high-performing person who is also extraordinarily easy to get along with.”

Baker has worked for POET since May 2002, two years after the Missouri facility first started producing bioethanol. She worked first in accounting and was promoted to her current role as administrative coordinator in 2019.

Tuttle can’t say enough good things about Baker, who always tries to do things to make life better for those around her. He considers her knowledgeable, efficient, and competent. “She’s kind, she’s always helpful, she’s not impatient with people,” he said.

That, plus her longtime knowledge of the company, is why Tuttle also described her as a combination den mother and guru on the mountain. Baker really showcases this when working with newly hired POET team members, answering any questions they may have about benefits and company policies.

“She just makes being an employee a lot easier,” Tuttle said.

Another part of her job involves planning events, including a fall family party, plant milestone celebrations, and the facility’s Christmas party. That underscores what Baker enjoys most about her job at POET — the variety.

“It’s never the same,” she said. “Each day it seems like there’s something different than the day before.”

When Baker isn’t working, she volunteers. It’s no surprise that she also exemplifies kindness in that role.

She’s a member of the Macon Elks Lodge, where she volunteered first on the veteran’s committee, followed by the activities committee. She especially enjoys working with other Elks to provide meals to veterans during the Christmas season. “We give back to the community quite a bit,” she said. “That’s the part I like the most, being able to participate in giving back.”

A.J. Hoskam, exalted ruler of the Elks Lodge, said Baker “takes the bull by the horns” by having everything well planned in advance. On top of that, she brings joy to any room she’s in. “She is the type of person you want to rub off on others to keep spreading that type of kindheartedness,” he said.

Baker later added volunteering at the Missouri Veterans Cemetery-Jacksonville. The catalyst in adding that to her busy schedule was the implementation of POET’s volunteer time off program, which Baker said is great for the company and its team members.

“POET gets their name out in the community, and team members get the opportunity to use time for something they care about to make a difference in the community,” she added.

Cemetery director Alison Evans said finding enough volunteers has been a challenge, so she was grateful when Baker stepped up to pull weeds and tidy up the landscaping. The next year, Baker and other volunteers helped prepare for the annual Memorial Day event by placing 2,000 flags, one at each gravesite.

That included one flag for Baker’s grandfather. “I got to place the flag on his headstone, so that was kind of special,” she said.

Evans said that wasn’t Baker’s only contribution; she also recruited additional volunteers for the event, including other POET team members.

“Wherever Heather goes, wonderful outcomes are sure to follow, as she wholeheartedly dedicates herself to giving back to the community,” Evans said. “It’s only appropriate that her life’s ambition is to spread kindness, as that genuinely reflects who she is.”

When Baker isn’t at work or volunteering, she loves to spend time with her family, which includes two adult sons. The oldest lives in Maryland, and her youngest son lives in Macon with her two grandchildren. She also enjoys camping, fishing, and traveling with her husband, Tim.

In a world that could always use more kindness, Heather Baker is a shining example of what it means to lead with heart. Whether she’s supporting her coworkers at POET, organizing events, or serving her community, she brings a spirit of service and compassion to everything she does — leaving a lasting impact that extends far beyond the workplace.

At some point, technology and nature fell out of rhythm. POET is getting us back in rhythm with nature, and paving the way to a new, sustainable future with an ever-expanding suite of clean energy solutions.

The world’s leader in plant-based bioproducts. // poet.com

While an emergency waiver secures E15 for Summer 2025, the industry pushes for a permanent fix

By Matt Ward, POET Senior Manager of Government Affairs

As lawmakers worked to avoid a government shutdown at the end of 2024, a major opportunity to secure year-round sales of E15 slipped through the cracks. Originally included in a bipartisan Continuing Resolution (CR) package spearheaded by Senators Deb Fischer (R-Neb.) and Tammy Duckworth (D-Ill.), as well as Representatives Adrian Smith (R-Neb.) and Angie Craig (D-Minn.), the E15 legislative fix had widespread support from congressional leadership and industry stakeholders. But objections to the size of the package resulted in all policy items, including the E15 provision, being stripped before a pared-down “skinny CR” was passed.

The effort to secure E15 access didn’t end there. The Environmental Protection Agency (EPA), in coordination with the Department of Energy, granted an emergency fuel waiver allowing the nationwide sale of E15 during the 2025 summer driving season, marking a major win for American consumers, farmers, and the biofuels industry. The waiver, which was recommended under President Trump’s January executive order declaring a national energy emergency and issued by the EPA in April, will ensure uninterrupted access to E15 through the summer months.

This emergency action mirrors similar waivers granted in 2022, 2023, and 2024 and was widely supported by bipartisan lawmakers, fuel retailers, and agriculture advocates. The decision follows a strong push from a coalition of U.S. Senators, led by John Thune (R-S.D.) and Dick Durbin (D-Ill.), who called on the administration to extend the Reid Vapor Pressure (RVP) waiver in light of ongoing global fuel market volatility.

“Utilizing American ethanol year-round is a direct solution to reinforcing our energy supply and reducing consumer costs,” the senators wrote in an April letter to President Trump. “The issuance of a nationwide waiver for the 2025 summer driving season is a clear path toward these shared goals.”

The emergency waiver builds upon previous momentum as several Midwestern states — including Iowa, South Dakota, Nebraska, and Minnesota — were granted year-round access to E15 in February. That action, requested by eight governors, provides parity between E10 and E15 and gives regulatory certainty to fuel suppliers and refiners in those states.

EPA Administrator Lee Zeldin praised the flexibility of the agency’s approach, noting that it “underscores EPA’s commitment to consumer access to E15 while ensuring a smooth transition for fuel suppliers.”

Although we applaud these short-term wins, industry leaders continue to push for a permanent legislative solution. Growth Energy, the nation’s largest biofuels trade association, applauded a recent letter from 16 state Attorneys General calling on Congress to pass the Nationwide Consumer and Fuel Retailer Choice Act, which would provide national parity for E15.

“There’s no reason for delay. President Trump wants E15, and we have bipartisan, bicameral support in Congress,” said Growth Energy CEO Emily Skor. “This longoverdue fix will bring certainty to the marketplace, save consumers money, drive rural growth, and reinforce American energy dominance.”

As summer approaches, American drivers can continue to fuel up with E15, knowing it supports U.S. agriculture, lowers emissions, and saves them money at the pump. But the long-term goal remains clear: securing a stable, permanent future for biofuels nationwide.

With temporary solutions in place, the race is on to ensure E15 remains a viable, accessible, and consistent fuel option for American drivers. As advocates push forward, one thing is clear: the fight for year-round E15 is far from over.

POET’s legacy is built on family and fueled by purpose

By Megan Mulgani

The individuals who work at POET are more than just a group of colleagues; they’re a team, united by a shared mission and a passion for purpose-driven work. You might even hear them refer to themselves as “family” — and sometimes, that sense of family isn’t just figurative.

POET is a family-founded company built on the values of hard work, integrity, and a commitment to making the world a better place. Those same principles continue to shape the culture today, bringing together not just coworkers, but generations of team members. So it’s no surprise that many POET team members have found their own family members — who share similar values — drawn to fulfilling careers at the company as well.

Whether it’s siblings, spouses, parents and children, or extended family, these connections can be an asset, with camaraderie, trust, and mutual support creating a strong foundation for a thriving business.

Discover how three of the many families within POET are working side by side to build a brighter future.

Andrew Willard, Plant Manager, POET Bioprocessing – Fairbank

Mitch Willard, EH&S Specialist, POET Bioprocessing – Fairbank

With only 10 feet separating their offices at POET Bioprocessing – Fairbank, IA, it’s easy for brothers Andrew and Mitch Willard to stay connected –and share a laugh whenever the moment calls for it.

“It’s fun to be able to razz my little brother every day,” said Andrew, who has served as plant manager for a year and previously worked as an operations manager.

“I don’t know how many times I’ve heard, ‘We’re going to go tell your mom what you two are doing,’” said Mitch.

Joking aside, the brothers have always had a close relationship, and working together helps them maintain their bond. “With our busy lives and kids at home, I don’t know how often we’d see each other outside of work. Working 10 feet apart, we get to spend every day together, which is pretty awesome,” Mitch said.

Andrew has worked for POET’s Fairbank facility for almost four years since it was acquired from Flint Hills Resources, where he worked previously. Mitch came on board nearly three years ago when the right position became available and Andrew encouraged him to apply. Each brother has around 16 years of experience in the bioethanol sector.

Both find fulfillment in different aspects of their roles. Andrew enjoys the challenge of troubleshooting problems and seeing his team grow. Mitch takes pride in the plant’s collaborative and supportive environment.

Andrew and Mitch agree that you don’t have to actually be family to feel like family at POET. “The atmosphere at POET is like a whole big family,” said Mitch. “POET puts forth that you should enjoy being around the people you work with. That definitely makes it enjoyable to show up to work every day.”

According to Andrew, “Working long hours is not bad when you’re surrounded by people you like being around.”

Blaine Gomer, General Manager, POET Bioprocessing – Big Stone

Blake Gomer, General Manager, POET Bioprocessing – Groton

To use a sports analogy, father-son duo Blaine and Blake Gomer play the same position for Team POET — General Manager — but one is a seasoned veteran and the other a newly promoted rookie.

Blaine, who has more than 23 years of experience as general manager under his belt, left a career in dairy manufacturing to take the reins at POET Bioprocessing – Big Stone, SD, when it opened in 2002. He was drawn to POET because of the opportunity to work with farmers and contribute to a sustainable future.

Blake, who was promoted to general manager at POET Bioprocessing – Groton, SD, last year, started as an engineering intern at the company and went to work full-time as an operator after college. He has worked in various roles for the company over 15 years, most recently as Groton’s plant manager.

Although their plants are 85 miles apart and their professional paths cross only once or twice a month, Blaine and Blake love being part of one POET team.

Blaine emphasizes that POET’s positive culture, outstanding people, and strong purpose make it an exceptional place to work. Working in the same company as his son is a bonus. “Professionally, we don’t talk as often as one might think,” Blaine said. “Work-wise, I stay out of his way. He makes his own decisions.”

Blake loves that “there’s always a challenge to get to work on,” as well as unlimited opportunities for professional growth at POET. He says that his working relationship with his dad is “still in development” now that they are in the same role. “I’ve always tried to carve my own path with my career. Now that we’re both GMs, I feel like we’ll be bouncing ideas and thoughts off each other.”

The most important commonality Blaine and Blake share is pride in POET’s status as the world’s leader in biofuels and its mission to make the world a better place. They’re working toward a brighter future for the next generation — including Blake’s two young kids.

“I am working for my grandkids’ future, making the world a better place for them,” Blaine said. Blake agreed: “I do it for my family, my kids. There are so many unknowns for the future, embracing our vision, mission, and culture at work, as well as at home, may someday end up inspiring them as well.”

Matt Sauer, Maintenance Manager, POET Bioprocessing – Hanlontown

Lucas Sauer, Maintenance Manager, POET Bioprocessing – Lake Crystal

Benton Sauer, Plant Technician, POET Bioprocessing – Lake Crystal

The way in which brothers Matt and Lucas Sauer both ended up working for POET involves a referral, but not in the traditional sense.

“I say it like this: I didn’t refer Lucas to POET. I referred POET to Lucas,” said Matt, a maintenance manager who has worked in various roles for POET Bioprocessing – Hanlontown, IA, since 2007. “It’s a family-first, faith-friendly company that has been a great fit for my family and me. So I knew it would be a great fit for him and his family, too.”

The brothers grew up on a wheat farm in western Oklahoma. Matt moved to Iowa years ago to be closer to his wife’s family. Lucas stayed with his family in Oklahoma, where he worked in the oil and natural gas field until Covid hit and oil prices went negative. “I didn’t lose my job, but I pretty much got demoted. Matt knew what I was going through and that the Lake Crystal plant was hiring for a maintenance manager.” After serious discussions with his wife and kids, Lucas interviewed and accepted the position. He’s had no regrets, as his three sons have made new friends and flourished in school.

One of those sons, Benton, joined his dad at POET Bioprocessing – Lake Crystal, MN, a few years later as a summer intern helping with landscaping and maintenance. It eventually turned into a full-time position as a plant technician.

All three Sauers say it’s rewarding to work for a company with such a powerful mission. “Energy-wise, POET provides a great, viable alternative to fossil fuel. But what really sold me is the local impact POET has. Each plant buys tons of corn, which supports farmers to help them feed their families and fund their community. There’s a huge impact on the economy of each POET site,” Lucas said.

Benton agrees that he’s proud of the environmental impact POET makes and sometimes reflects on how “just a little grain of corn makes all this!”

At POET, the concept of family extends far beyond blood relations — it’s woven into the company’s culture, mission, and daily work. Whether team members share a last name or simply a common purpose, the sense of unity and support among them is the key to their success.

Congressman Randy Feenstra

By Paige Lindgren, POET Director of Public Affairs

Tell our readers a bit about yourself.

From the Field of Dreams in Dyersville to the 43 bioprocessing facilities across the state, Iowa has long been synonymous with American corn and bioethanol production. Few know the true widespread impact of U.S. agriculture like Congressman Randy Feenstra, who represents Iowa’s 4th District in the U.S. House of Representatives and sits on the House Agriculture Committee. Congressman Feenstra, who represents one of the leading congressional districts in the nation for agricultural production, has been an ardent advocate for Iowa’s corn growers and biofuel producers since elected to Congress in 2020. We recently sat down with him to learn more about his background, his priorities in Congress, and the importance of American agriculture and bioethanol in his district.

I was born and raised in Hull, Iowa — a town of about 2,500 people in Northwest Iowa. It’s where I met my wife Lynette, and we raised our four kids. Before being elected to Congress, I was the head of sales at The Foreign Candy Company and worked at Iowa State Bank in Hull, overseeing the insurance division across nine branches. I also served as City Administrator of Hull, Sioux County Treasurer, and Chairman of the Iowa Senate Ways and Means Committee, during which I wrote and Iowa Governor Kim Reynolds signed, the largest income tax reduction in state history at the time. Furthermore, I taught business and economics at my alma mater, Dordt University. In addition to earning my bachelor’s degree from Dordt, I also received my master’s degree in public administration from Iowa State University and completed my doctorate in business administration with an emphasis in healthcare administration from Northcentral University. Now, I am grateful to represent Iowa’s 4th Congressional District in the U.S. House of Representatives, which spans Northwest, Northcentral, and Southwest Iowa.

Every year, I travel to all 36 counties across my district at least twice, which I’ve dubbed my 36 County Tour. Whether I’m meeting with farmers and biofuel producers or main street businesses and schools, the topic of biofuels almost always comes up, and that’s not a coincidence. Roughly every other row of corn and soybeans goes to the production of bioethanol and biodiesel. In my district, that is especially true because no other congressional district produces more bioethanol and biodiesel than mine — and that’s truly a testament to the hard work, ingenuity, and innovation of our farmers and biofuel producers. Our crops are batteries that have unlimited potential to lower gas prices, grow our farm economy, and reduce our dependence on foreign sources of energy. It’s a message that we have to share with the nation and the world because we grow the solution to American energy independence in Iowa and across the Midwest.

In 2023, according to the Renewable Fuels Association, nearly 52,000 jobs were tied either directly or indirectly to the biofuels industry while more than $3 billion was contributed to household incomes and another $6.5 billion in economic activity was generated — all in Iowa alone. Additionally, in 2023, Iowa’s 42 bioethanol plants produced approximately 4.6 billion gallons, and our state’s 10 operating biodiesel facilities generated 350 million gallons of biodiesel. That being said, Iowa accounts for about 30% of U.S. bioethanol production and 21% of U.S. biodiesel production. Biofuels power our economy forward, create good-paying jobs, keep our rural communities strong, and bolster U.S. energy production at a time when we need to increase our energy dominance most.

Why do you think it’s important for consumers to have access to higher blends of biofuels — like E15 — at the pump?

The answer is simple. Higher blends like E15 offer our families more affordable options at the pump, generate more economic opportunities for our farmers, and lessen our reliance on foreign countries — like Venezuela and Saudi Arabia — for our nation’s growing energy demands. One way that we can immediately increase domestic demand for corn and bring prices down at the pump for consumers is by passing year-round E15 nationwide permanently. This minor amendment to federal law would not cost taxpayers a penny, but would generate incredible economic benefits for our families, farmers, bioethanol producers, and economy at large. E15 typically costs 40 cents to $1.00 less than non-bioethanol gasolines, providing more affordable options for consumers at the pump while simultaneously increasing domestic corn demand by over two billion bushels, in turn improving farmer profitability. We have to be bold with biofuels policy if we are going to grow our rural communities, turbocharge the farm economy, and truly advocate for American farmers and energy producers. I have been a leading voice in Congress for efforts to establish this common-sense policy fix. Yearround, nationwide E15 is a critical piece of the biofuels puzzle and there is no reason to delay its implementation. That is why your advocacy and involvement are so important — because we need farmers and producers at the grassroots level to stand up and make their voices heard. I will continue to be an outspoken champion of biofuels and year-round E15. Our economy and our country would benefit immensely from this simple policy fix.

Ready to join the thousands of members who are already making their voices heard? Visit poetpac. com or email poetpac@poet.com to join POET PAC today!

Contributions to POET PAC are not tax-deductible for federal income tax purposes. Contributions to POET PAC will be used in connection with federal elections and are subject to the limits and prohibitions of federal law. The maximum an individual may contribute to POET PAC is $5,000 per year ($10,000 per couple). Corporate and foreign national contributions are not permitted under federal law. Please make checks payable to POET PAC. Federal law requires us to use our best efforts to obtain and report the name, mailing address, occupation and name of employer for each individual whose contributions aggregate in excess of $200 per calendar year. Your contribution to POET PAC is strictly voluntary.

Paid for by POET PAC (www.poetpac.com) and not authorized by any candidate or candidate committee.

Company values aren’t just for show at POET

By Andrea Van Essen

In an industry where efficiency and technical skills can easily take precedence over personal benefits, POET’s bioprocessing facility in Caro, Michigan has built a culture appreciated by team members and the local community alike.

From the people-focused environment to its commitment to giving back to the community, POET Bioprocessing – Caro exemplifies the “One POET” spirit.

Built in 2002, the plant was originally slated for a location about 30 miles away, but the Caro community ultimately proved a better fit. To date, the plant has produced over 1.3 billion gallons of bioethanol and provides 47 jobs in the area.

“My understanding is that Caro was very receptive to having us here, and I feel like they’re still very happy to have POET as an active part of the community,” said Doug DeLand, General Manager of POET Bioprocessing – Caro.

DeLand has been with POET for almost five years, having transitioned from another company’s bioethanol division.

“The culture there had changed significantly, and I had a friend who encouraged me to apply at POET. I’m thankful to be here because POET has a knack for seeing the differences in people and plants and helping team members grow. It’s truly a bottom-up company rather than topdown,” he said.

It’s an approach centered around team members providing feedback and input, not simply taking orders. The company’s philosophy is that good ideas can come from anywhere.

“I’ve visited eight different facilities, and each has their own personality, yet they all contribute to the whole. Employees impact the success of their plant, which snowballs into success for POET. We understand that we’re all accountable, but we also get to celebrate the wins,” DeLand explained.

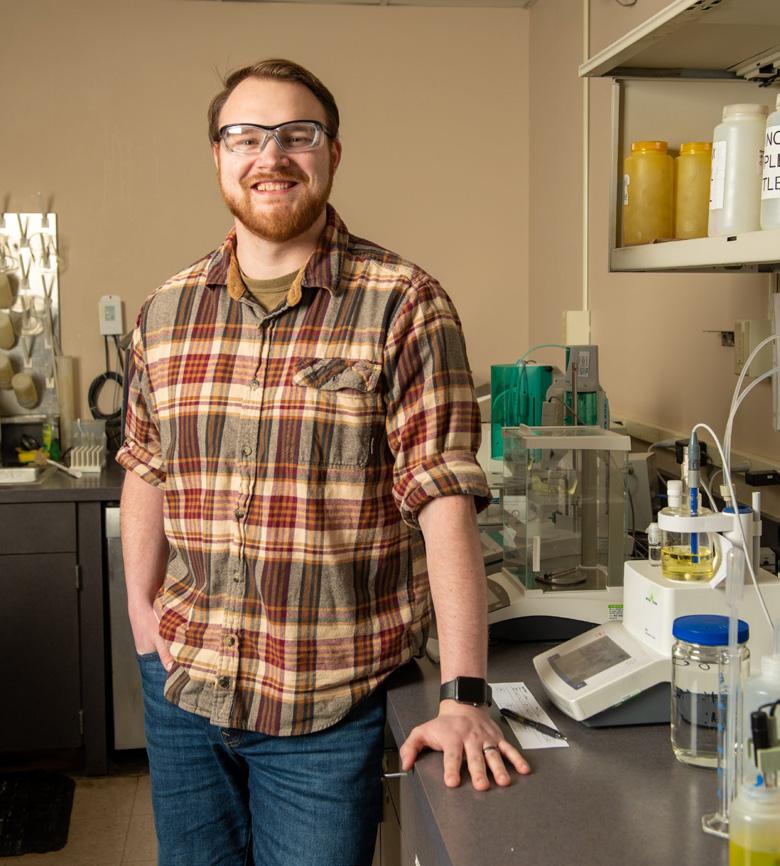

Plant Manager Zach McCotter has been with the facility for just under two years, and he says POET has the best workplace culture he’s experienced by far.

“I’ve been in manufacturing leadership positions for basically my entire career, and one of the biggest things for me has been that I’m empowered to do the right thing, to push that positive culture forward, and to do what it takes to make people happy,” he said.

McCotter says that, as a leader, he appreciates being able to reward and encourage team members.

“I always have the freedom to give someone a shout-out, go get a gift card to reward them, or take them out to lunch. There’s never hesitation or push-back when it comes to taking care of people, and I think that’s extremely important,” he said.

Employees at POET – Caro also enjoy the opportunity to get involved in their community.

POET has long been committed to giving back to the communities it calls home, and when DeLand took over as general manager, he aimed to step up even further. One of the first things he did was get out in the community and see where POET could get involved.

“I met with the mayor, the Chamber, and all the principals of the local schools, and said, ‘We want to make the most impact without spinning our wheels — how can we help?’” he said.

Today, the Caro plant is active with the local tech center, supporting them with donations and bringing students out for tours, participating in the schools’ “Adopt a Family” program to provide assistance to area families in need, and supporting charities like the Women’s Advocacy Center, as well as local sports sponsorships, like Little League baseball, trap shooting, and tee ball.

McCotter sits on the plant’s donation committee and says he enjoys being able to choose organizations within the community to give back to. He also appreciates that community members feel comfortable and connected enough to approach POET with needs and requests of their own.

“In a few years, we went from townspeople asking, ‘What’s POET?’ to saying, ‘I’ve heard of you guys, and everyone loves you. If you’re ever hiring, let me know,’” DeLand said.

“Every company I’ve ever worked for claims to have a positive work-life balance, but that’s never really been true until working here.”

-Luke Hollin, Quality Manager at POET Bioprocessing - Caro

Additionally, all team members receive a certain amount of paid time off for volunteer work throughout the year, which they can use to support local organizations of their choice.

“I think that’s significant because a lot of people can’t afford to take a few hours off to serve at the local food pantry, and POET gives them that opportunity,” he said.

For Luke Hollin, Quality Manager at POET – Caro, that benefit has proved meaningful to his faith life and the church he serves.

“On top of my role at POET, I’m also a credentialed minister in the Assemblies of God. When I first interviewed with POET, I didn’t realize it was a company with Christian roots, but as I learned more, it’s been eye-opening to see a company that supports team members’ faith,” Hollin said.

He appreciates that, in addition to having a life enrichment advisor on staff as a resource, POET provides optional opportunities for Bible studies and even offers a weekly prayer team. He says the volunteer hours have helped him remain involved in his church.

Zach McCotter, Luke Hollin, and Doug DeLand outside of POET Bioprocessing – Caro

“I serve as a young adult leader, and because I have so much involvement there, it’s great to be able to go help with special events and not worry about being away — my workplace actually endorses it,” he said.

Hollin also highlights the company’s commitment to building employees up from within. He started out as a lab technician and quickly advanced when the quality manager role opened.

“I was probably underqualified at the time, but they saw potential and encouraged me,” he said.

Since then, Hollin has begun a master’s program in business, with the hopes of continuing to advance in the company, preferably locally in Caro. POET has supported his pursuits by paying for that education through its tuition reimbursement program.

He emphasizes that POET is honest and follows through when it comes to company values.

“Every company I’ve ever worked for claims to have a positive work-life balance, but that’s never really been true until working here,” he said.

“People understand that burnout is real, and you’ll be able to be a better employee if you have the time you need with your family. In Caro, that is spearheaded by Doug [DeLand], POET lives up to that standard of making sure family comes first.”

DeLand points to the plant’s low turnover as a result of those values, noting that at least four staff members have been with Caro for 22 years as part of the original team, and a large portion of the staff have 10+ years of experience.

“These days, you’re lucky to find people who have more than five years at one company, so for someone to stay 22 years really says something,” he said.

“We have dedicated folks who want to make a career out of what they do here. There’s a lot of industry in the area, but you don’t get the culture at other companies. It says something for POET and for Caro that we continue to have one of if not the lowest turnover rates in the company,” he said.

DeLand added that the atmosphere at Caro is light and positive, and said there are a lot of friendships between coworkers outside of the plant.

“We have a really tight group. Our personality is really that family culture where people care about each other, and that keeps people happy,” he said.

McCotter also emphasizes that conflict is extremely low with so many long-tenured team members.

“Everyone knows and understands each other and what they need. Everyone’s always willing to help out, whether it’s one department helping another or one shift coming in to help another shift. We’re consistently helping others out, and it just keeps everyone a little bit closer,” he said.

Whether it’s finding ways to build up employees from within through training, encouragement, and promotion, or providing benefits like community outreach and a tight-knit family atmosphere, the Caro plant stands as a shining example of the “One POET” mentality.

By Ryan Welsh, Growth Energy Director of Sales & Marketing

In 1948, under the southern sun and the roar of moonshine-inspired machines, NASCAR was born. The early days were raw drivers raced in stock cars that really were “stock,” straight from the showroom floor, often tweaked in the same garages where whiskey stills once bubbled. Back then, engines were simple flathead V8s, more muscle than science, powered by grit and a need for speed. The gas was the same you got for your pickup at the pump and octane was a term rarely used.

As the 1950s rolled in, manufacturers joined the game. Ford, Chevy, Chrysler — they all saw racing as a showroom battleground. Bigger engines appeared. Hemis roared. Horsepower surged. The 426 HEMI, unleashed by Dodge in 1964, was a monster, dominating tracks so fiercely that it was briefly banned. NASCAR responded with a new set of rules — safety, parity, and a bit of politics steering the future. On the fuel side of things, the bigger V8s demanded better fuel. High octane gas, “race gas” with lead additives, came onstage and became the norm.

In the ‘70s and ‘80s, technology crept in. Carburetors were still king, but engineers were pushing limits. Wind tunnels tuned the bodies; dynos tuned the hearts. Engines still thundered with V8 power, but teams got smarter. Restrictor plates were introduced in 1988 after Bobby Allison’s car went airborne at Talladega — a reminder that power, unchecked, could be dangerous. Additives in the fuel were also a technological advancement bringing more octane and efficiency.

The 2000s saw the dawn of the “modern era.” Fuel injection replaced carburetors in 2012 after more than 60 years, bringing NASCAR in line with the rest of the automotive world. Engines became precision instruments — still roaring, still V8s, but now governed by data, sensors, and ECUs. Teams battled not just on the track but with software and simulation. Leaded fuel was phased out and replaced by unleaded fuel.

Today’s NASCAR fuel, Sunoco Green E15, is a high-performance bioethanol blend. It burns cleaner, greener, and mirrors the direction the world is moving. And yet, it still fuels the same basic beast: a naturally aspirated V8 pushing 750 horsepower, screaming down straightaways at 200 miles per hour. Each engine built by hand, inspected like fine jewelry, and pushed to the edge.

Now, the thunder of V8s still echoes through Daytona, Charlotte, and Talladega, a reminder that in this sport, engines aren’t just machines — they’re the soundtrack of speed, legacy, and the chase. According to Matt Wiles, the Vice President and COO of ECR Engines, the V8 isn’t going anywhere. The sound is too valuable to the product. And the demand for bioethanol on the track is only growing. Its clean and high-octane qualities add up to a superior fuel that can only be rivaled by a $50 to $60 per gallon synthetic fuel. RCR and ECR tested up to E30, and NASCAR has taken notice. “I’d expect we will see higher blends in the near future in NASCAR,” said Matt.

From moonshine runners to million-dollar machines, NASCAR’s engine and fuel story is one of relentless evolution—innovation, steel, fire, and the heartbeat of American racing.

By Ryan Turpin

Since its inception in 1987, POET has been creating practical solutions to big problems at the intersection of energy and agriculture. Now the company has risen to that challenge once again, but in a new way, handling the engineering, procurement, and construction of a waste-to-energy system serving a cluster of dairy farms near Estelline, South Dakota.

Energy production has become an increasingly widespread part of waste management in recent years. This is especially true in industries with large amounts of organic waste, which serves as a renewable raw material. This includes agriculture, food processing, and wastewater treatment, where biowaste can be converted into biogas, biofuels, or other renewable energy sources through advanced waste-to-energy technologies.

Dairy farms deal with more than their fair share of biowaste in the form of manure. It’s typical for manure to be washed into holding ponds called “lagoons,” where it remains until later being used to fertilize pastures. In this environment, the manure begins to break down and release methane into the atmosphere. This is significant because methane traps heat much more effectively than carbon, leading experts to believe that methane emissions may be responsible for a quarter or more of the global temperature changes being measured today.

Enter digesters — enclosed systems that use microbes to break down manure and capture the resultant methane instead of releasing it. After manure is digested, nutrient-rich digestate can be used as fertilizer (a higher-quality fertilizer that improves soil health, according to some dairy farmers), while the captured methane can be purified and turned into renewable natural gas, or RNG.

By increasing the supply of RNG, projects like this help reduce reliance on fossil natural gas, which remains a major contributor to carbon emissions. RNG can be used in its place, providing a cleaner alternative for heating, electricity generation, and other uses of energy. As more industries and utilities transition to renewable energy sources, RNG helps with the decarbonization of sectors that have historically depended on fossil fuels.

“This project represents wins for everyone involved,” said Brandon McLellan, POET Director of Project Management. “Methane is prevented from getting to the atmosphere, which benefits everybody, and the farms have new income streams and more efficient operations. Then there are the buyers and end users of the natural gas, who now have a more sustainable energy source.”

The point about income streams is an important one. Requiring large investments and long-term commitments, these kinds of projects have to come with bankable results. For dairy farmers, those results can take many forms, including substantial federal tax credits, participation in carbon offset markets, the direct sale of RNG, and more. In addition, of course, they’re getting a practical, straightforward, and environmentally sound system for managing millions of pounds of waste.

“It was also a great project for us as a team,” added McLellan. “Value-add agriculture is what we’re passionate about at POET, and it’s nice to take that passion and our unique expertise in the area and apply those to new designs and customers.”

When asked if the uniqueness of the project presented any challenges for POET’s engineering team, Senior Process Engineer Jim Geraets had this to say:

“The biggest learning curve for us wasn’t on the technical side. It was more about incorporating new processes, especially for procurement, logistics, and communication, to account for the needs and wishes of different owner groups and other stakeholders.”

Working with new vendors and design criteria, Geraets pointed out, required additional effort from POET to ensure all specifications were met and construction could be undertaken as efficiently as possible. This included extensive communication with overseas suppliers and modifying certain parts and equipment to meet the National Electrical Code.

Safety standards and protocols get special attention in a waste-to-RNG project, where flammable gases are handled under pressure, corrosive sulfur compounds can lead to equipment failure or dangerous working conditions, and reliable containment is crucial. POET’s engineers proved more than capable and were able to draw on the company’s long history of creating operationally resilient systems and managing complex risks in design.

“All in all, it went very smoothly,” said Geraets. “We’re a small, nimble team, and that helps us diagnose and solve problems quickly. As always, we learned some things along the way, and we’re definitely prepared to take on similar projects going forward.”

The project was described as “substantially complete” at the beginning of 2025 and, at full capacity, is expected to produce enough RNG to power around 14,000 residential homes annually. In the grand scheme of renewable energy supply, it represents a small step. But for dairies looking to grow their bottom line and simultaneously manage their environmental impact, investing in a waste-toenergy scheme can be a huge leap forward.

More broadly speaking, each viable project in the waste-to-energy landscape further spreads awareness and demonstrates the potential benefits, which can extend to whole communities in the form of reduced emissions and cleaner air quality. For POET, the work done is proof positive of a continued focus on merging sustainable innovation with agricultural processes. In the long run, that simply means working together to create a better world for everyone.

By Scott Johnson, A Thinker of Thoughts (and POET Data Systems Administrator)

We’ve been talking about inflation lately. And by “lately,” I mean since 1913 when the U.S. started tracking the Consumer Price Index.

Older generations revel in telling us that a dozen eggs used to cost 37 cents. A loaf of bread was barely a nickel. An original 57 Chevy only set you back $2,400. But I remind my parents their first cell phone was more expensive than my current superior device — and mine doesn’t require its own duffel bag carrying case.

These financial anecdotes from elders can seem tiresome and irrelevant, but they force them on us anyway. I’m not immune to the allure of spewing tales of economic volatility, but surely the fiscal fables of my youth are far more fascinating. As my sister says when sharing life lessons with her children, “Let me tell you a story about the 90s...”

In college (1993-1998) I enjoyed a Tuesday special at a well-known fast-food joint. Three cheeseburgers for $1.00. ONE. DOLLAR. You can barely purchase a stamp for $1.00 today (although, why are you still mailing things?). Even as a broke college kid, I thought three burgers for $1.00 was an unsustainable offer. I recall thinking, “I should write a Vital essay about this in 30 years.”

I frequented a movie theater in the early 90s where I could purchase a ticket, pop, and popcorn and get change back from a five-dollar bill. These movies weren’t the streaming garbage we have today. I’m talking about the finest films the entertainment industry has ever created: Dances with Wolves, Forrest Gump, and Teenage Mutant Ninja Turtles III. It was the golden age of affordable cinema.

But not everything was a bargain “back in my day.”

In 1992, I invested in a half-dozen roses for a girlfriend-to-be that turned out not to be. The cost: $27.30. Perhaps there was a nationwide rose shortage or an unfortunate floral billing error. The exorbitant cost stung almost as much as the rejection itself. Had I saved that money a few years, it could have yielded 81+ Tuesday hamburgers.

Technology cost trends defy the typical inflationary behavior of other goods. Early adopters find high costs despite low functionality. My first computer (1996) barely met the threshold of “low functionality.” It cost $2,200. No, it wasn’t dipped in gold. My coffee pot has more computing power than that first PC.

Inflation and purchasing volatility are not a new phenomenon. Whether the economy was better or worse is irrelevant. Yes, most items were much less expensive, but some were shockingly more.

The important thing is that we remember the minutiae of our own experiences so we can share those excruciatingly mundane details with future generations. Will our stories teach them valuable lessons? Will they appreciate our personal history with market fluctuations? Will they savor our insights when we regurgitate the same tales over and over again? No. But we must tell them anyway. Reminiscing about the price of things “back in my day” is a time-honored tradition as vital as the Consumer Price Index itself.

poet.com/feed