Material Reuse Handbook

Change begins here

Change begins here

Our industry is responsible for producing 62% of all non-hazardous waste in the UK.

According to the UN, material extraction is responsible for 80% of biodiversity loss worldwide.

91% of GHG emissions associated with fit-out projects are attributed to the sourcing and disposal of materials.

We are bored of hearing and repeating these statistics. We are acting now.

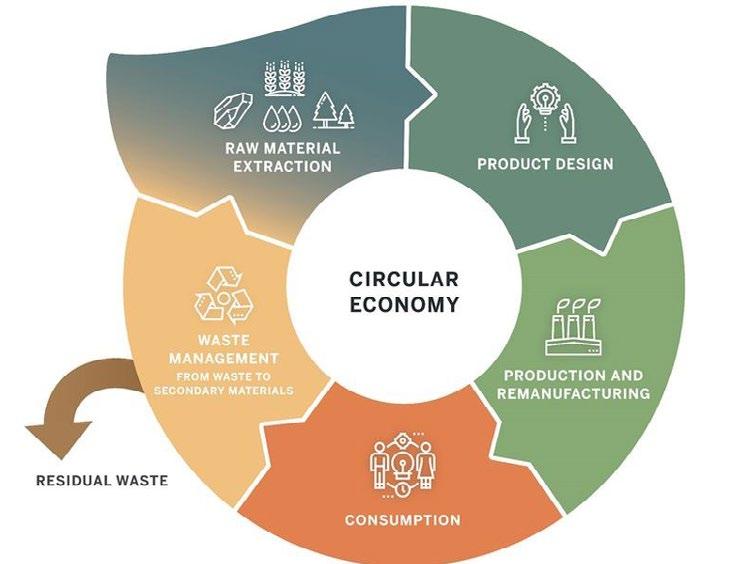

Our 2025 ESG strategy outlines our commitment to driving the circular economy within the built environment, contributing to the United Nations 12th sustainable Development GoalResponsible consumption and Production

““Circularity is the most effective singular focus we can have in the fit-out business if we want to drive real sustainability. With trends in more flexible, higher turnover commercial spaces, material wastage is a devastating result... I don’t just see circularity as a benefit for the environment, but also as a way to bring communities together and build relationships”

Poppy Cunningham, Head of ESG

Reduce our waste and resource consumption, encouraging reuse of materials where possible.

Virtus will report on all waste produced as part of its operations, both office and site based.

Virtus will maintain a 98% diversion form landfill rate, across all project waste.

Virtus will complete a pre-demolition audit on all projects including strip out and/or demolition woks and endeavour to retain and reuse items of quality.

Our first ever circular economy policy developed in 2025, sets out our objectives, targets and decision making processes to ensure material reuse is a priority across our projects. We have identified specific actions to drive this:

CE Action 1: Undertake material inventories during design - reviewing material make up, distance travelled and sustainable alternatives.

CE Action 2: Consider opportunities for retention and reuse of existing materials and items during each site set up, and where appropriate in a project’s design.

CE Action 3: Collaboration with the supply chain - aiming to discuss circular opportunities with manufacturers and clients as early as possible in a project's lifecycle.

CE Action 4: Work with circular economy experts - partnering with those who can identify real opportunities for use of quality reused materials and items.

CE Action 5: Upskilling of our workforce - providing continuous training opportunities and site Toolbox Talks.

CE Action 6: Ensure compliance - considering planning requirements, new legislation and industry best practice.

Circular economy in action - contractor side

We have recently transformed our storage unit into a fully functioning material reuse hub. Weekly material inventories are shared company- wide, with items up for grabs such as site welfare equipment, PPE, signage, consumables and temporary furniture.

Often, temporary materials used to keep our teams comfortable and safe during construction, can be overlooked.

With this storage unit we have a unique opportunity to drive circularity and material reuse through our site set up’s as standard.

This handbook can act as a cheat sheet for ensuring the success of reuse at early stages of a project. We have identified three key bits of information for each item that will be essential when completing a predemolition or refurbishment audit.

Gathering this key information will be help when sharing information with interested recipients.

We have identified some starter avenues to explore when considering items for reuse. The circular economy space is ever-evolving, and demand for items can shift at any moment.

See the key considerations section to get some tips on technical or logistical issues that may arise when dealing with specific items.

Materials included

Carpet tiles

Raised access floor

AC units & condensers

Kitchenware

White goods

Glazing/Glass partitions

Plasterboard partitions

Ceiling systems

Lighting

Key Information Needed

*50m2 = ~250 Carpet tile

Carpet Tiles can offer a great opportunity for reuse due to their easy removal and storage and generally a demand from both the commercial and charity sector.

Common Re-homing opportunities

Uplyfted

Salvation Army Flooring Reuse Programme

Forbo Takeback service

Key considerations

Carpet tiles should be removed prior to plasterboard partitions to avoid saturation with gypsum dust.

Carpet tiles often act as acoustic barriers especially during strip out works involving bins being wheeled around raised access flooring. Keep a key number of tiles in place of high traffic areas to stop disruption when working in occupied buildings.

Key Information Needed

Size m2

Grade (load)

Panel Type (e.g RG3)

Reuseability

High

Raised access flooring is high in embodied carbon due to the materials used. This means any avoidance of waste here can result in significant embodied carbon savings.

Common Re-homing opportunities

Tate - Kingspan’s reclaimed RAF scheme - will buy back medium grade tiles for £3.50 per tile Floorplan Systems - will offer a 1.25% MCD for reclaiming tiles of low grade.

Key considerations

Panels will be ‘graded’ high, medium or low, based on weight load they can take. The higher the grading, the more valuable

Typically, panels that have been cut to size will not be considered for takeback, so some waste is inevitable.

Underfloor services and pedestals need to be removed as part of strip out works, panels will need to be lifted and stacked early i.e if a third party reuse specialist has agreed to strip the panels out, they will need to do this in unison with the strip out contractor to avoid programme delays.

Key Information Needed

Age

F-Gas Type

Condenser loc.

Reuseability

Low

Much like all MEP equipment, AC units are full of many precious metals and materials, and the refrigerant gasses mean that disposal can be extremely harmful to our environment. complicated systems mean that reuse can be difficult.

Common Re-homing opportunities

Local community groups such as schools and social clubs

Key considerations

Units will need to be safely de-gassed, therefore the M&E subcontractor will need to be involved to carry this out. This cannot be done by a typical strip-out contractor due to safety.

AC units will only be operational when connected to a compatible condenser, which will typically be located externally. Access to the condenser may be a significant barrier when considering reuse.

Older more harmful F-gases will usually not be considered for use commercially

Key

Fixing Types

Condition

Measurements

Reuseability

Medium

Unhelpfully, every kitchen is fitted differently, if disassembly is not considered in design, often units will be glued together, preventing damage-free deconstruction.

Common Re-homing opportunities

Charities such as emergency housing providers.

Key considerations

How are units fixed together and to walls? Glue will prevent effective and damage-free disassembly.

If units are able to be disassembled, strip out contractors will need to bag and label fixings and small components so that they can be put back together. Imagine a reverse flat-pack.

Key Information Needed

Although used white good will not be attractive to commercial clients, these are often easy to remove and store, and are in demand from the charity sector.

Common Re-homing opportunities

Charities such as emergency housing providers.

Key considerations

Are items under warrantee? Have they been tested and are working?

It is important not to use charities as an alternative to waste disposal by handing them items of no good use. Ethics should be upheld.

Dont forget about the Zip-taps, these can be worth some money!

Key Information Needed

Size m2/lm

Acoustics

Fire rating

Reuseability

Low

Glazing is notoriously hard to successfully re-home, due to specific sizing and care it takes to dismantle and transport glass without damaging it.

Common Re-homing opportunities

Saint Gobain Takeback Scheme

Key considerations

Glazing is extremely difficult to remove without damaging panels. These are often too large be transported safely out of live tenanted buildings.

Usually glass is crushed and downcycled into fill products.

ASBP Glazing reuse guidance

Size m2/lm Acoustics Fire

Partitions pose a much larger opportunity for retention than complete re-homing.

Common Re-homing opportunities

Manufacturer take-back schemes are common.

It is often easier to identify where plasterboard can be retained rather than re-located, consider keeping the second internal skin during cosmetic works.

Key considerations

Storage on site can be difficult, some schemes will require panels to be stored in toas-rack style systems.

Designing out waste should be the first plan of action, ensuring that plasterboard ordered is to exact sizes to avoid off-cuts being produced.

Key Information Needed

Size m2/lm

Material

Access to MEP

Reuseability

Medium

Warrantee is a big issue for ceiling tile reuse. Most manufacturers only guarantee performance (e.g., fire resistance, acoustic properties, structural integrity) for first-time installation under specific conditions.

Common Re-homing opportunities

SAS takeback scheme

Key considerations

Panels are easy to remove, stack and pass on, however removal of the grid system will often need to be completed by specialist ceiling contractor due to its fixings, this therefore limits the reusability of full systems.

Sometimes ceiling systems will be sprayed with paint to brighten up a space, this may put potential buyers off, as the product is not original manufacturers standard.

Key Information Needed

Manufacturer Warranty Condition

Reuseability

Medium

As above, most manufacturers only guarantee performance for first-time installation under specific conditions.

Common Re-homing opportunities

Phillips (Signify) - Circular Lighting and take-back services for professional customers.

Key considerations

Broken lamps can be determined as Hazardous waste, therefore takeback schemes may require strict storage conditions.

Often manufacturers will be open to extending warrantees for lighting that has recently been purchased, it is always a good idea to contact the manufacturer to check.

£5.5m | CAT A | 24 Weeks | Marylebone

Working with reuse experts Material Index, with funding from the Mayor’s Circular Economy nonprofit ReLondon, carpet tiles, various light pendants, kitchenware, doors and door stoppers and a brand new dolphin toilet system were saved from the skip. In total 280 assets were reused, accounting for 6 tonnes of material. This has avoided an estimated 1709 kgCo2e and saved £400 on skip costs.

A shout out to demolition contractors Kendell who effectively dismantled and stored items at short notice, working this into their own programme.

£1.31m | CAT B | 8 Weeks | St James’s

Following on from lessons learnt with Material Index, Virtus went it alone on the 100 Pall Mall project and completed our first internal pre-refurbishment audit.

Opportunity was identified as the scope of works included the strip out of high quality, relatively new materials.

Barriers faced surrounded a limited network of third party organisations interested in buying items or receiving donations.

Success can be attributed to the help of our entire supply chain. MSK were able to carefully dismantle, stack and store items ready for collection. Whilst Gloster S-works carried out additional investigations into the safe re-usability of AC units and condensers.

Big ticket wins on this project was the reuse of 600m2 of light grade raised access flooring to industry partners with the help of Floor Plan Systems.

Sometimes reuse doesn’t work out. Measurements can be incorrect, storage is an issue and designs are changed. But we can still take away something valuable, whether that is a lesson learnt for the next project, or a new and beneficial relationship built.

Our Head of ESG tells a story that may be familiar to some - after misjudging some doorway measurements and navigating a hire car through the chaos of central London to pick up a free luxury sofa, she arrived home to find it wouldn’t fit through the doorway.

Despite best efforts, said sofa got stuck in the shared corridor, blocking her upstairs neighbours from reaching their front door. A Saturday wasted, a hallway blocked, and a lingering sense of frustration left her wondering whether the second-hand market was worth the trouble at all.

Several tense hours after re-listing the sofa, a local resident got in touch and arranged to collect it that same evening. When the doorbell rang, she was met by an unexpectedly kind and enthusiastic neighbour.

Together, with good humour and a bit of effort, they managed to pry the sofa from its awkward position. The neighbour explained it would be a gift for their daughter, a single parent in need of furniture. In that moment, frustration turned to fulfilment.

A new connection had been made, a deserving home found, and a valuable lesson learned about measurements and corridor angles. In the end, what started as a logistical nightmare became a heartening reminder of the power of community and circularity.

this interaction would not have happened without the second hand market.

We are so reliant on willingness of people

Unlike most other solutions within the built environment, the success of a circular economy in construction doesn’t rest solely on procedures, regulations or technology. It relies heavily on the willingness, goodwill, and engagement of individuals at every stage: from design and demolition to install and reuse.

Circularity in the built environment isn’t just about keeping materials in use longer- it’s about building a mindset where reuse is valued, repair is prioritized, and sharing becomes second nature. This mindset can’t be mandated through policy or engineered into a product. It develops in communities and cultures when more people choose to participate in a system that, while better for the planet, often demands more of them.

The reality is, the circular economy can involve more friction than traditional linear systems. It’s often less convenient, more time-consuming, and reliant on communication and coordination. But in that friction lies purpose and meaning - avoided waste, emissions reductions and a kinder industry for our natural world.

Policies and procedures can help, but the transition to a circular built environment requires a cultural shift, one where patience and collaboration are seen as strengths, not sacrifices.

To get there, we need:

Shared stories that highlight real-life experiences.

Supportive infrastructure - tools, storage, logistics & time.

Empathy and understanding when things don’t go or look perfect.

The built environment is made up of bricks, steel, and glass but it’s shaped by people. If the circular economy is going to succeed, it won’t be because it’s mandated or mechanised, but because people, like our ESG lead and her neighbour, choose to take part.

It is in these acts of willing and shared responsibility that a regenerative future is being built; sofa by sofa, story by story.

The circular economy can work—not because it is the easiest option, but because people will make it work.

Poppy has a passion for reducing our industry’s impact on the natural environment, and has identified material reuse as one way in which she can make a real difference at Virtus. Poppy enjoys collaborating with all of the different stakeholders involved in a project to make reuse a reality, bringing people along with her on the journey. Poppy is a big fan of bugs, nature and being active outdoors.

Michael ‘Micky P’ is the embodiment of what circular economy should be, and has been since way before those very buzzwords came about. Micky is passionate about saving materials from ending up in the skip, finding value in everything from from screws, to hoover parts to spare ceiling tiles. Micky spends his spare time exploring local flea markets.

Paul brings a key and balanced angle to all of our reuse projects, ensuring that cost savings from avoided waste are calculated and communicated with the team. Achieving cost neutrality or even cost savings means that project teams can benefit from all of the extra hard work put in to making reuse a possibility. In his spare time, Paul can be found appreciating the UK countryside in his campervan.