Breaking down the battery hierarchy

CALCIUM, EFB, AND AGM BATTERIES ALL HAVE THEIR PLACE IN THE MODERN AUTOMOTIVE ECOSYSTEM. HERE WE TAKE A LOOK AT THEIR SPECIFIC CHARACTERISTICS AND HOW THE KOBA BRAND DELIVERS ACROSS ALL THREE TYPES

The complex nature of the automotive industry is known to all. The aftermarket industry is just as complicated, leaving customers overwhelmed by the sheer number of options available. When it comes to the battery category alone, there are many types to choose from depending on power requirements, application, budget, and lifestyle needs.

The three types of automotive batteries predominately used today are calcium (maintenance free), EFB (Enhanced Flooded Battery) and AGM (Absorbent Glass Mat) batteries. The notable differences between each type of battery are best explained using the battery hierarchy.

Calcium batteries are positioned at the base of the hierarchy. These are the most commonly used batteries among the three battery types. Calcium batteries are lead acid batteries which

have small amounts of calcium added to both the positive and negative grids to improve durability and reduce water consumption. Calcium batteries are also maintenance free because the water in the electrolyte does not evaporate and therefore they do not require topping up with water. Despite these advantages, calcium batteries require charging if not used regularly to prevent sulfation, which will reduce the service life of a battery.

In the middle of the battery hierarchy are the EFBs. These are relatively new to the market as they were developed specifically to cater to modern Idle Stop Start (ISS) vehicle requirements. They are based on the calcium battery design which means that they can be manufactured in a calcium battery factory using the existing equipment. Enhancements to the base design

results in increased charge acceptance and cranking power, as well as the ability to constantly operate at partial State of Charge. Although EFBs are a step up from calcium batteries, they are considered an entry level option for vehicles that use ISS technology.

AGM batteries are the premium choice for highend and advanced ISS vehicles with recuperative braking. This is why they are positioned at the top of the hierarchy. AGM batteries are different to calcium batteries in a number of ways, however the chemical reaction is the same. AGM batteries use a compressible glass mat to separate the positive and negative plates in the battery. This mat also holds the electrolyte required for the battery to function. During assembly, the plate and mat assembly is compressed

CONTINUED ON PAGE 4

OUTSMART THE ELEMENTS™ Visit rainx.co.nz Available from leading automotive and hardware retailers. APPLY TO GLASS. DEFY

ISSUE 59 JULY 2023 THE VOICE OF THE NEW ZEALAND AUTOMOTIVE INDUSTRY

THE ELEMENTS.

to 1st June - 31st July 2023

$500 ON THESE SELECTED BRANDS TO GAIN ONE ENTRY INTO THE DRAW TO WIN ONE OF THREE SEMA IN LAS VEGAS. 1 OF 3 TRIPS AVAILABLE

& 7 NIGHTS

NHRA NEVADA NATIONALS

RACE 4 DAY PASS TO SEMA BROUGHT TO YOU BY THE BEST BRANDS! Open to NAPA Auto Parts trade account customers operating in New Zealand. Promotion starts 12.01 am on 1st June 2023 and ends 11.59pm on 31st July 2023. Spend $500 ex GST during the promotional period on any of the following brands and receive one entry into the prize draw. Qualifying brands: Projecta, NARVA, Century Batteries, RDA Brakes, Redarc, OEX, Ryco, Tridon, Penrite, Clutch Industries, Milwaukee, CRC, Gates, Donaldson, REMSA, NZ Gaskets and NAPA. Spend is cumulative across invoices and brands. Each subsequent cumulative purchase of $500 ex GST will accrue an additional entry. Promotion excludes Cash Sales account purchases. Customers must have a valid up-to-date Trading Account to claim their prize. Prize includes flights, 7-night accommodation, NHRA Nevada Nationals Drag Race ticket and 4-day pass to SEMA 2023. Travel dates 28 Oct - 4 Nov 2023. Trip details may change subject to availability. Limited to one prize per account. One winner will be picked from each of the geographical NAPA Auto Parts regions. North Region: Manukau to Kaitaia. Central Region: Pukekohe to Wellington. South Region: South Island.

WIN A TRIP SEMA

SPEND

PRIZE INCLUDES: FLIGHTS

ACCOMMODATION ATTEND

DRAG

15 Contents Breaking down the battery hierarchy Cover / 4 Speed up your wheel balancing 6 News in brief 8 Leverless: Innovation on tyre changers 10 Quality takes a back seat to innovation 11 Serious work to do? Bring in a Specialist 12 Ferraris forgotten in a barn 13 Let’s torque! 14 Turbos: Tackling oil contamination 15 Carbon footprint: All about teamwork 16 Making aftermarket towbars easy to install 18 Inner workings of a lead acid battery 19 Car news 20 Making car clips simple 22 Welding quality control 24 Braking power at your fingertips 26 Rare and wonderful Pontiac race car 29 Latest products Battle of the blands 29 21 24

ISSN 2816-0959 (Print)

ISSN 2816-0967 (Online)

AUTO CHANNEL IS DISTRIBUTED TO OVER 10,000

NEW ZEALAND BUSINESSES, AND AVAILABLE

FREE ONLINE

ONLINE autochannel.co.nz

EMAIL editor@autochannel.co.nz

MAIL PO Box 82045, Highland Park, Auckland 2143

DESIGNER

Deven Solanki

MEDIA SALES

Michael White, michael.white@viamedia.co.nz

Mark Everleigh, mark.everleigh@viamedia.co.nz

CAMPAIGN MANAGER

Nikola Tordeich

AUTO CHANNEL IS PUBLISHED BY

BUSINESS DIRECTOR

Michael White, michael.white@viamedia.co.nz

GENERAL MANAGER

Simon Holloway, simon.holloway@viamedia.co.nz

WORKFLOW MANAGER

Emily Khov

FINANCIAL CONTROLLER

Karen Grimmond

ACCOUNTS RECEIVABLE

Mel White

DIGITAL PLATFORMS MANAGER

Henry Khov

which enhances durability and vibration resistance. These factors mean that an AGM battery will last longer than a calcium or EFB in the same application.

AGM batteries are able to effortlessly cope with the high demands placed on the various accessories and technologies included in modern vehicles. In an ISS vehicle, the engine cuts off instead of idling to save fuel when the vehicle is stationary. It will rapidly restart when the vehicle is ready to drive off again. Despite these benefits, one of the biggest disadvantages of AGM batteries is that they are more expensive than calcium batteries and EFBs. When it comes to upgrading, there are a few things to note. While it is possible for many fitments to upgrade to a higher construction type, it is not recommended to downgrade. For example, a vehicle originally fitted with a calcium battery can often be upgraded to an EFB or even an AGM battery, provided that the case size is correct. If a vehicle originally fitted with an EFB battery was downgraded to a calcium battery, the battery will succumb to premature failure. The installation location also matters as it is important to consider how hot the battery will get. Flooded batteries shed heat more efficiently than AGM batteries as the electrolyte can transfer the heat to the outer surface case.

Among the many brands offering calcium, EFB and AGM batteries in New Zealand, Koba is a popular option. Koba has been in the New Zealand market for more than a decade, and the homegrown brand has a strong reputation for its range of high-quality batteries comprising over 40 different part numbers. The diverse range covers all major applications including automotive, commercial, marine, and industrial.

The maintenance-free Calcium range by Koba are suitable for both automotive and commercial applications such as trucks and buses, agricultural machinery, earthmoving machinery, and industrial equipment. These batteries are designed to provide safe and reliable starting power. They are built with low resistance envelope separators, maximising the battery’s electrical performance and minimising selfdischarge. Microfibre tissue increases plate durability, giving Koba Calcium batteries a greater life span.

Auto Channel is the best way to reach the wider automotive industry. The publication is direct mailed to over 10,000 New Zealand businesses in the following automotive sectors:

Automotive workshops, parts importers and distributors, transmission specialists, automotive recyclers, towing operators, panel beaters and painters, crash repairers, tyre dealers, suspension and underbody repairers, steering specialists, towing operators, auto-electrical repairers, newand used-car dealers, air-conditioning repairers, heavy-machinery dealers, trucking and transport.

ISS vehicles looking to upgrade from an EFB to an AGM battery may be able to do so as long as the battery is not subject to high heat. If the original battery has a heatshield fitted, it must be installed around the replacement battery. Seasonally used applications such as caravans and campers may also benefit from having a deep cycle AGM battery fitted as a deep cycle AGM battery will deliver more cycles compared to a flooded deep cycle battery.

Koba’s range of EFB and AGM batteries are designed to meet the evolving needs of modern vehicles. Koba EFB batteries can deliver up to two times the battery life compared to a calcium battery when fitted in a standard vehicle and have higher charge acceptance. Koba AGM batteries have the highest durability and cycle life when compared to calcium and EFB batteries, and offer excellent starting power which is important for modern battery management systems. They are also highly resistant to vibration due to their compressed internal construction.

Koba batteries are exclusively distributed by R&J Batteries. The battery distributor has branches in Wiri, Christchurch, Hamilton, Albany, Nelson and a strong distribution network across the two islands. To learn more about Koba batteries, please call 0800 546 000, or visit rjbatt.co.nz.

The winners are: Carol Bradley and Anthony Brown.

Congratulations from Auto Channel and FUCHS Lubricants.

4 Auto Channel Issue #59 July 2023

Via Media uses due care and diligence in the preparation of this magazine, but is not responsible or liable for any mistakes, misprints, omissions, or typographical errors. Via Media prints advertisements provided to the publisher but gives no warranty and makes no representation to the truth, accuracy, or sufficiency of any description, photograph, or statement. Via Media accepts no liability for any loss which may be suffered by any person who relies either wholly or in part upon any description, photograph, or statement contained herein. Via Media reserves the right to refuse any advertisement for any reason. The views expressed in this magazine are not necessarily those of Via Media, the publisher, or editor. All material published, gathered, or created for Auto Channel is copyright 2023 Via Media Limited. All rights reserved in all media. No part of this magazine may be reproduced in any form without the express written permission of the publisher.

NOTICE TO ADVERTISERS

THE WINNERS OF THE FUCHS LUBRICANTS AND MARK ‘FROSTY’ WINTERBOTTOM GIVEAWAY OF A DEWALT BLUETOOTH WORKSITE RADIO (VALUED AT $757) HAVE BEEN ANNOUNCED!

ACCELERATING YOUR POWER

KOBA AGM Batteries are manufactured in South Korea at one of the region’s most experienced calcium battery facilities. They are built with advanced technology to ensure reliable performance for Start Stop Vehicles.

• Sealed Spill-proof Design

• High Cranking Capacity

• High Reserve Capacity

• Carbon Plus Plate Technology

• Vibration Resistant Design

ACCELERATE YOUR POWER WITH KOBA 0800 546 000 rjbatt.co.nz RJBatteries

KOBA Batteries are exclusively distributed by R&J Batteries across New Zealand

Speed up your wheel balancing with the SpeedPlate EBA

THE POTENTIAL INACCURACIES THAT COME FROM TRADITIONAL WHEEL BALANCING USING A CONE ARE WELL KNOWN IN THE INDUSTRY. ONE PRODUCT MIGHT JUST HAVE THE SOLUTION

Many of you would be familiar with the problems that can arise from balancing a wheel on a balancer when using a traditional cone. While this method has been widely used, it presents challenges in achieving precise centring. The cone relies on friction to keep the wheel in place, making it susceptible to movement and misalignment. Factors such as imperfections in the wheel hub or cone, uneven pressure distribution, or even operator error can further complicate the centralisation process. The consequences can be costly and even dangerous.

Failure to achieve proper centring can result in imbalanced wheel rotation, leading to uneven weight distribution. This imbalance can cause vibrations, which are not only uncomfortable for passengers but also detrimental to other vehicle components. The uneven distribution of forces places excessive stress on the suspension system, wheel bearings, and tyre sidewalls, potentially shortening their lifespan and needing premature repairs or replacements often at a workshop’s expense.

The challenges in centralising a wheel using a traditional cone can go beyond inaccurate balancing. The cone’s reliance on friction can exert excessive pressure on specific areas of the wheel, potentially damaging the wheel surface or causing distortion. Over time, this can lead to weakened structural integrity and compromise the wheel’s overall performance and safety.

These issues arising from cone-driven balancing are not rare. Many of you would have suffered from the expense and reputational damages that this can cost a workshop when clients need to come back

for rebalance or to replace damaged wheels. There is also the fact that tyre techs can waste precious time chasing weights because they are not using the proper clamping tools and balancing properly.

So… how can the process be improved?

THE SPEEDPLATE SOLUTION

The SpeedPlate EBA System is the ultimate wheel balancing solution. This advanced system is designed to fit any wheel, with adaptors to fit 3-Lug, 4-Lug, 5-Lug, 6-Lug and 8-Lug wheels. The SpeedPlate EBA uses a bolt-type system, that can be easily configured for different bolt set ups, to centralise the wheel quickly, more accurately, and eliminate any damage that can be caused from trying to centralise.

When it comes to wheel balancing, accuracy, speed, and durability are paramount. It is here that the SpeedPlate EBA offers exceptional performance with its lightweight design, one-handed adjustability, and damage-prevention features. The SpeedPlate EBA stands out as the go-to solution for achieving precise balancing results while safeguarding expensive wheels.

The SpeedPlate EBA sets itself apart from the competition by providing effortless operation. Its unique gear system allows for one-handed adjustment, making it the only adjustable adaptor on the market that can be conveniently held and adjusted with a single hand. No pre-adjustment is required for the correct bolt pattern, saving valuable time during the balancing process and enhancing efficiency for tyre technicians.

Likewise, the SpeedPlate EBA excels at lug-

centric balancing, ensuring the most accurate results possible. By balancing the wheel precisely at the lug holes, it eliminates the risk of damage to costly custom wheels, cracks in plastic-clad wheels, and peeling of PVD-coated wheels. The innovative torque tips, which mirror the shape of lug nuts, are the only parts that touch the wheel during the balancing process, preventing any potential surface damage.

DURABILITY AND LONGEVITY

Built to withstand the demands of busy tyre shops, the SpeedPlate EBA is exceptionally durable. Its gears are designed to release from the plate when dropped on a concrete floor, preventing damage and ensuring continued accuracy. Simply snapping the gears back into place allows for immediate reuse without compromising balancing precision. With its longevity matching that of the balancer itself, the SpeedPlate EBA delivers exceptional durability and reliability.

COMPATIBILITY AND VERSATILITY

The SpeedPlate EBA is compatible with balancers featuring 40mm threaded shafts and power clamp shafts, making it a versatile solution for various machines. Additionally, reducing sleeves are available for smaller balancer shafts, expanding its compatibility even further. With the ability to accommodate bolt patterns ranging from 95mm to 180mm, the SpeedPlate EBA covers a wide range of wheel sizes and configurations, catering to diverse customer needs.

The SpeedPlate EBA is an exceptional solution for wheel balancing, offering unparalleled ease of use, accuracy, and durability. Its lightweight design, one-handed adjustability, and damage-prevention features make it a preferred choice for technicians. By investing in the SpeedPlate EBA, tyre shops can ensure optimal balancing results, prevent wheel damage, and eliminate customer dissatisfaction, ultimately enhancing customer satisfaction and boosting their own profitability.

SpeedPlate EBA is available from NAPA Auto Parts and Repco. Contact your local rep to find out more.

6 Auto Channel Issue #59 July 2023

News in brief

THE NUTS AND BOLTS OF WHAT’S HAPPENING AND COMING UP IN THE INDUSTRY EVS TO START PRICE BATTLE

So far seen as being luxury or at least expensive automobiles, EVs seem to now be entering a price battle in the Australasian market.

The introduction of two under $50K vehicles could be marking the beginning of price-based competition in the sector and giving access to the technology to a larger audience.

MG New Zealand recently announced a new variant to the upcoming fully electric MG4 range: the 51KWh Excite is expected to become the first EV in the country to be priced at under $40K (after the clean car rebate). Likewise, BYD’s new Dolphin — which recently launched in Australia, is expected to arrive in New Zealand soon and is, likewise, competing on price. This has had several industry experts there predicting an under AU$30,000 new EV price tag in the near future, as well as further changes and pressures on the maintenance and repairs sector.

EXECS ON THE MOVE

MG Motor New Zealand has appointed a new country manager. This appointment will see Arek Zywot step into the country manager position following Patrick Bourke’s return to headquarters in Australia after his secondment last year. Mr Zywot brings 11 years of automotive experience

and under his leadership, he has grown brands and successfully launched more than 20 models in the New Zealand market.

“I have spent my entire working life in the automotive industry locally, and to now be leading the New Zealand arm of MG Motor is an absolute privilege,” said Mr Zywot.

CHANGES OF LEADERSHIP AT EUROPCAR NZ

Europcar New Zealand has appointed Caddie Kerr as its new head of country and Claire Reynolds as its new national sales manager.

Kerr has been with Europcar for the past five years working across Australia and New Zealand in both national customer experience manager and network revenue manager roles.

Reynolds joins Europcar with a background in sales in the travel and tourism industry, across the UK, Australia, and New Zealand. As national sales manager, she will strategically develop business in the corporate, leasing, vehicle replacement,

Century Batteries extends warranty on Lithium Pro range

HAVING PUT THEIR BATTERIES THROUGH SOME OF THE MOST STRENUOUS TESTS IN THE INDUSTRY, CENTURY BATTERIES IS CONFIDENT THAT THEIR LITHIUM PRO BATTERY RANGE IS THE BEST IN THE BUSINESS

To reinforce their commitment to offering quality, class-leading products, Century has announced that the warranty on their Lithium Pro range is being extended from three to five years.

This new five-year warranty is the result of stringent performance testing and evaluation, which has demonstrated that Century’s Lithium Pro has what it takes to go the extra mile.

“Our Century Lithium Pro range incorporates advanced technology and state-of-the-art internal components to deliver longer life and exceptional performance in deep cycle applications,” explains Ward Lye, Century’s national sales manager. “The superior energy capacity, operating temperature range, and lightweight design makes Century Lithium Pro batteries ideal for use in a range of applications, where longer life, faster recharge, and dependable power is required.”

Century Lithium Pro’s new five-year warranty will also apply retrospectively to batteries that have been purchased previously, since they were introduced into the market in 2022.

What sets Century Lithium Pro batteries apart from other products on the market is the extensive

testing and certification processes they have been subjected to during development. Most other brands will carry certifications on the individual battery cells — but in many cases that’s where the promises end.

In comparison, Century has gone several steps further by subjecting their Lithium Pro batteries to additional rigorous testing considering the applications and conditions they will be subjected to. So not only are the battery cells certified, but they also have achieved certification on the BMS unit, and the battery assembly as a whole, and additional vibration testing has been performed to top it off.

The certifications cover performance tests — such as overcharge, thermal resistance, vibration resistance,

and SME sectors and ensure all operational elements of the New Zealand business are communicated and implemented.

WOMEN DRIVERS

June 24 marked International Women Drivers’ Day and several industry organisations marked the event in their own way. Founded in New Zealand, Women’s World Car of the Year celebrated International Women Drivers’ Day on 24 June by drawing attention to the role of women in motorsports. According to a recent survey, a total of 17.9% of those interviewed do not know any female drivers and 28.5% approve of separate categories based on gender. With this study, the Women’s World Car of the Year aims to promote the participation of female drivers in motorsports.

and more; plus a suite of safety tests which cover nail penetration, impact drop, and short circuit resistance, just to name a few. The extensive vibration testing ensures the batteries perform in harsh off road and marine conditions. A full list of certifications is available to view on their website.

The Century Lithium Pro range includes 100Ah, 200Ah, and Slimline Deep Cycle options, backed by a true national warranty and an industry leading support network ensuring customers are covered wherever their adventure takes them.

For more information on the Century Lithium Pro range, visit centurybatteries.co.nz.

8 Auto Channel Issue #59 July 2023

CHECK OUT OUR GREAT RANGE TO SUIT MOST MAKES AND MODELS Available from: Your local Holden & GM Trade Parts Outlet www.gmtradeparts.co.nz www.acdelco.co.nz

Ditch the lever: Innovation on tyre changers

NOT ALL LEVERLESS TYRE CHANGERS ARE THE SAME. WE EXPLORE CORGHI’S ARTIGLIO MASTER 28 TO FIND OUT WHAT MAKES IT SPECIAL AND IMPOSSIBLE TO IMITATE

In line with Corghi’s ethos and long history of innovation, product enhancement, and devising ways of bettering existing processes, in 2001, the Italian-born, world leader in the vehicle assistance equipment sector introduced ‘Leva la leva’. Italian for ‘without lever’, the concept was a game-changer for tyre changers and allowed these machines to get rid of the need for levers in order to eliminate contact with the rim and risk damage to tyres.

Using a combination of hydraulic power, pneumatics, and specialised mounting heads (among other innovations), these machines gently grasp the tyre and rim, applying equal pressure around the circumference to loosen and remove the tyre without exerting force on the sidewalls.

The almost robotic process has been perfected to the point that it requires minimal operator contact with the wheel and significantly speeds up the process while also improving operator safety.

Although many manufacturers immediately tried to imitate the technology, Corghi’s core mission of continuous innovation in products and technologies ensured that their offerings kept evolving, improving, and hence ensuring that imitators were always a few steps behind.

This ‘Smart Corghi System’ is now considered the only existing technology on the market that allows you to never touch the rim during any of the work phases and cancels any tension on the tyre during the demounting/mounting phases.

This technology is at the heart of the new Artiglio Master 28 and it is the perfect synthesis of the experiences gained over the past 22 years.

In a single tyre changer, tyre shops will find all of Corghi’s manufacturing and design experience, in a product that operates perfectly on every type of wheel, for an unrivalled technical and economic investment over time.

The Artiglio Master 28 includes:

• Consoles: Ergonomic and multifunctional consoles with a display that makes it possible to electronically set the rim diameter and automatically obtain the positioning of work tools in a quick, practical, and safe manner

• Dynamic bead breaking device with dual specular bead breaker disc — the radial positioning of the discs is made easier by an automatism that is able to prevent any manual positioning by the operator. This guarantees precision, rapidity, and repeatability by the patented bead

breaking system and by the perfectly synchronised and symmetrical motions of the two discs

• Clamping: Automatic wheel clamping

• Bead depressor with adjustable working height, This depressor shape is ideal for RFT tyres

• Ergonomics: Fixed work position, pedals, consoles, and wheel loading are all on the same side allowing for constant working height and less operator movement

• Wheel lifter: In order to achieve effortless wheel placement onto the centre mount turntable.

Today, leverless tyre changers have become a staple in many tyre shops and automotive service centres worldwide. They have significantly reduced the time and effort required for tyre changing, ensuring a safer and more efficient process. However, no one has been able to copy the patented Smart Touchless Corghi system and this is the difference between Corghi and all the others.

For more information on the Corghi Artiglio Master 28 or Automaster’s wide range of products, see automaster.co.nz, or call 0800 214 604.

AUTO EQUIPMENT BUILT TO PERFORM *Delivery, installation and GST not included AUCKLAND 87 Henderson Valley Rd, Henderson CHRISTCHURCH 6 Gerald Connolly Place, Hornby automaster.co.nz Single 4 xThree stage arms $ * $ *

Quality takes a back seat to innovation

ACCORDING TO A RECENT UNITED STATES STUDY, NEW CARS ARE EXPERIENCING A RECORD NUMBER OF QUALITY ISSUES ACROSS A NUMBER OF AREAS

New vehicles are becoming more problematic, evidenced by the number of problems per 100 vehicles (PP100) rising to a record 30 PP100 over the past two years. According to the J.D. Power 2023 US Initial Quality StudySM (IQS), released in late June of this year, the rise in problems is 12 PP100 greater than in 2022, which follows an increase of 18 PP100 in 2022 from 2021.

The continuing decline in quality can be attributed to multiple factors such as greater usage and penetration of technology; continued integration of known problematic audio systems into other new models; poor sounding horns; cupholders that don’t serve their purpose; and new models with 11 PP100 more than carryover models.

The US Initial Quality Study, now in its 37th year, is based this year on responses from 93,380 purchasers and lessees of new 2023 model-year vehicles who were surveyed early in the ownership period. The study is based on a 223-question battery organised into nine vehicle categories: infotainment; features, controls and displays; exterior; driving assistance; interior; powertrain; seats; driving experience; and climate. The study was fielded from February through to May 2023.

While problems with driving experience are

flat year over year, quality has declined in all other categories. The largest year-over-year increase in the number of problems is in the features, controls and displays category (+3.2 PP100), followed by infotainment (+2.3 PP100). Key findings of the 2023 study include:

• Vehicle basics — door handles— are increasingly problematic.

• Safety systems causing problems: More than three-fourths (80%) of owners say their new vehicle includes all four of the primary driver assistance features: forward collision warning; lane

keeping assistance; lane departure warning; and blind spot warning. However, problems owners encounter in the driver assistance category have increased 1.8 PP100 year over year. The most problematic areas are lane departure warning/lane keeping assistance and forward collision warning/ automatic emergency braking for those that have these features.

Smartphone charging becomes the most deteriorated problem: Across all 223 problems measured in the study, the wireless charging pad not working properly has increased by a sizeable 1.1 PP100 and is driven by both increased penetration and more usability issues with the technology. Users are experiencing several problems, including poor location; phone overheating; and intermittent charging, if at all. Biggest movers and shakers: Brands that show the largest year-over-year improvement are Maserati (73 PP100 improvement), Alfa Romeo (68 PP100 improvement) and Ram (45 PP100 improvement).

Finding the correct FUCHS Lubricants product for a vehicle has never been easier with FUCHS Rego Lookup! Simply scan the QR code, and follow the steps to easily get all the information you’ll need to choose the most suitable FUCHS Lubricant for the job! fuchs.com/au/en/product-search-aus-nz FUCHS Rego Lookup MOVING YOUR WORLD by finding the right oil EASIER! New bottle design with clearly structured labels Updated premium look and feel Images pictograms and lubricant quality categories The all new FUCHS Small Pack Range EASY TO CHOOSE

Serious work to do? Bring in a Specialist

THE WD-40 BRAND YOU HAVE COME TO KNOW AND TRUST HAS A NEW, EXCITING RANGE

The WD-40 Specialist line is an exciting range of products wearing the WD-40 shield you’ve come to rely on. These products have been designed for those demanding jobs that need to be done just right.

prefer a low-odour product that still delivers the same legendary performance you expect. Great for

cleaning greasy engines, corroded battery terminals (power off before applying), and also for getting grime off exhausts.

WD-40 Specialist Citrus Degreaser is a water-

for a clean finish. For heavy soiling, leave for a few seconds to penetrate through the dirt before wiping clean. Use it to clean workshop floor spills, rapidly clean your metal-finish alloy wheels, degrease your hoist and other uncoated steel, uncoated aluminium, or glass items that need it.

WD-40 Specialist Air Duster is fast and easy to use, producing continuous 70psi air pressure to get into tight spots and keep your workspaces clear. Deal with those metal scrapings, dust, wood shavings, dirt, crumbs, leaves, cobwebs, etc. Safe to use on electronics. Anywhere you need it — workshop, workbench, automobile including engine bay and window tracks, garage, household, shed, toolbox, storage units, and more. A versatile cleaner that leaves no residue.

These are only three products from a wider WD-40 Specialist product range. For more information check out wd40.co.nz/products/wd40-specialist-

SUPERIOR

• Ideal for use on workshops • 70 PSI continuous pressure • Safe to use on electronics WD-40 Specialist® Air Duster provides you with an anytime, anywhere solution for keeping your workshop, automobile, electronics and household clear of wood shavings, saw dust, metal scrapings, dust, dirt, crumbs, leaves, cobwebs and more! Fast and easy to use, this product produces continuous 70 PSI air pressure and can get into tight spots making it ideal for keeping your workspaces clear.

PERFORMANCE

Not your average lost & found

A HALF FORGOTTEN BARN FULL OF OLD CARS HAS BEEN PRIED OPEN AND ITS CONTENTS — 20 RARE VINTAGE FERRARIS — ARE SCHEDULED TO BE AUCTIONED IN CALIFORNIA

Nestled in downtown Speedway, Indiana, across the street from the legendary Indianapolis Motor Speedway, lies a treasure trove of dormant stallions that have remained untouched for decades, hidden away from Ferrari collectors, restorers, and the public at large, left to gather dust. Some of these lost vehicles have graced the world’s most famous races, such as Le Mans, the Targa Florio, and the Mille Miglia,

and one of them was once owned by royalty.

In 2004, Hurricane Charley wreaked havoc along the coast of Florida, causing widespread damage and exposing the forgotten Ferraris to the sunlight for the first time since 1990 when the barn they called home partially collapsed. Bearing the scars of debris from their dilapidated enclosure, the Ferraris were carefully relocated to a secure warehouse in Indianapolis,

Some of the highlights of the collection include a 1956 Ferrari 250 GT Coupe Speciale by Pinin Farina. This car was sold brand new by the factory to its first owner, King Mohamed V of Morocco and has an estimate of between US$1,700,000 – US$2,300,000. There’s also a 1965 Ferrari 275 GTB/6C Alloy by Scaglietti — the first ‘long-nose’ 275 GTB to be fitted with a low-weight alloy body and six carburetors. This remarkable discovery of 20 vintage Ferraris is destined to captivate the imaginations of enthusiasts and dreamers from all walks of life. The auction is scheduled to take place 17 August at the Monterey Car Week in California.

Finding the correct FUCHS Lubricants product for a vehicle has never been easier with FUCHS Rego Lookup! Simply scan the QR code, and follow the steps to easily get all the information you’ll need to choose the most suitable FUCHS Lubricant for the job! fuchs.com/au/en/product-search-aus-nz FUCHS Rego Lookup MOVING YOUR WORLD by finding the right oil EASIER! The all new FUCHS Small Pack Range EASY TO USE New tamper-resistant screw cap Improved ergonomics thanks to redesigned bottle Easier pouring: refined neck design, grip area and two handles

Let’s torque!

THE GEARBOX FACTORY DISCUSSES THE IMPORTANCE OF TORQUE CONVERTER LOCK-UPS, AND HOW TO KNOW IF A TORQUE CONVERTER NEEDS TO BE REPAIRED

All automatic transmissions require a torque converter — often one of the least understood components of an automatic vehicle. The torque converter was designed in the early 1900s to transfer power from the engine to the transmission’s input shaft. The impeller inside acts as a type of centrifugal pump. As it spins, fluid is flung to the outside — much as the spin cycle of a washing machine flings water and clothes to the outside of the wash tub. As fluid is flung to the outside, a vacuum is created that draws more fluid in at the centre. Added to the mix is a lock-up clutch, technology introduced in the mid 1900s which locks engine RPM and transmission so they are turning as one. By using a lock-up, overall fuel

efficiency was increased. By the 1970s demand for more efficient vehicles grew with manufacturers fitting lock-ups to most models of transmissions. In modern transmissions, the use of lockup is often applied between multiple gear shifts, almost feeling like an extra gear.

The most common fault with today’s torque converters is a lock-up shudder caused by poor-quality factory oil and oil deterioration. Much like a manual clutch shudder, this can often feel like running over road cat’s eyes while driving. One of the biggest fights against premature lock-up failure is servicing the transmission with specified oil. The Gearbox Factory can check, monitor, and diagnose any lock-up and torque converter faults with their state-of-the-art diagnostic tools and experienced technicians.

The Gearbox Factory’s dedicated in-house machine shop and fitting team have been overhauling and repairing converters for nearly 50 years. Their experienced engineers have rebuilt more than 30,000 units to date. They also stock high-quality replacement parts for most makes and

models of transmission.

As well as overhauling and repairing torque converters, The Gearbox Factory also repairs and replaces all types of automotive car transmissions, clutches, and differentials nationwide. They also service all passenger and light commercial vehicles with most oils, filters, and gaskets in stock readily available (servicing available within the Auckland area only).

For all torque converter, service, and repair enquiries, on all makes and models of automotive vehicles, and light trucks up to 5,000 kgs, call 09 274 8340 / 0800 4432 7269, visit them at 68D Greenmount Drive, East Tamaki, Auckland, or visit the website gearboxfactory.co.nz

WE ARE SPECIALISTS IN AUTOMATIC AND MANUAL TRANSMISSION SERVICES, REPAIRS (INCLUDING TRANSFER CASES, DIFFERENTIALS AND WHEEL BEARINGS)

DSGs & DCTs

We cover all repairs and servicing with the latest diagnostic equipment available.

CVTs

Continuously variable transmissions are a significant part of overall sales each month, therefore the equipment and knowledge that we have accumulated from years of experience repairing these complicated transmissions, has given us an unparalleled edge.

DIFF Audit

Often overlooked but not by us, the time to get your diff looked at is when you first hear a noise, to avoid more costly repairs down the track.

Torque Converters

The Gearbox Factory has been rebuilding torque converters for cash trade customers for over 48 years. With a significant increase in production capacity, The Gearbox Factory team is now able to offer a torque converter reconditioning and repair service to the motor industry.

AND

Dual clutch transmissions are hugely popular.

www.gearboxfactory.co.nz

ON ALL MAKES AND MODELS OF AUTOMOTIVE VEHICLES AND LIGHT TRUCKS enquiries@gearboxfactory.co.nz / (09) 274 8340 / 0800 443 272 68D GREENMOUNT DRIVE, EAST TAMAKI, AUCKLAND

OFFERING

NOW

TORQUE CONVERTER RECONDITIONING

REPAIR SERVICES DRIVETRAIN SPECIALISTS

Exchange stock rebuilt and ready for sale

Engineer using dedicated environmentally friendly parts wash

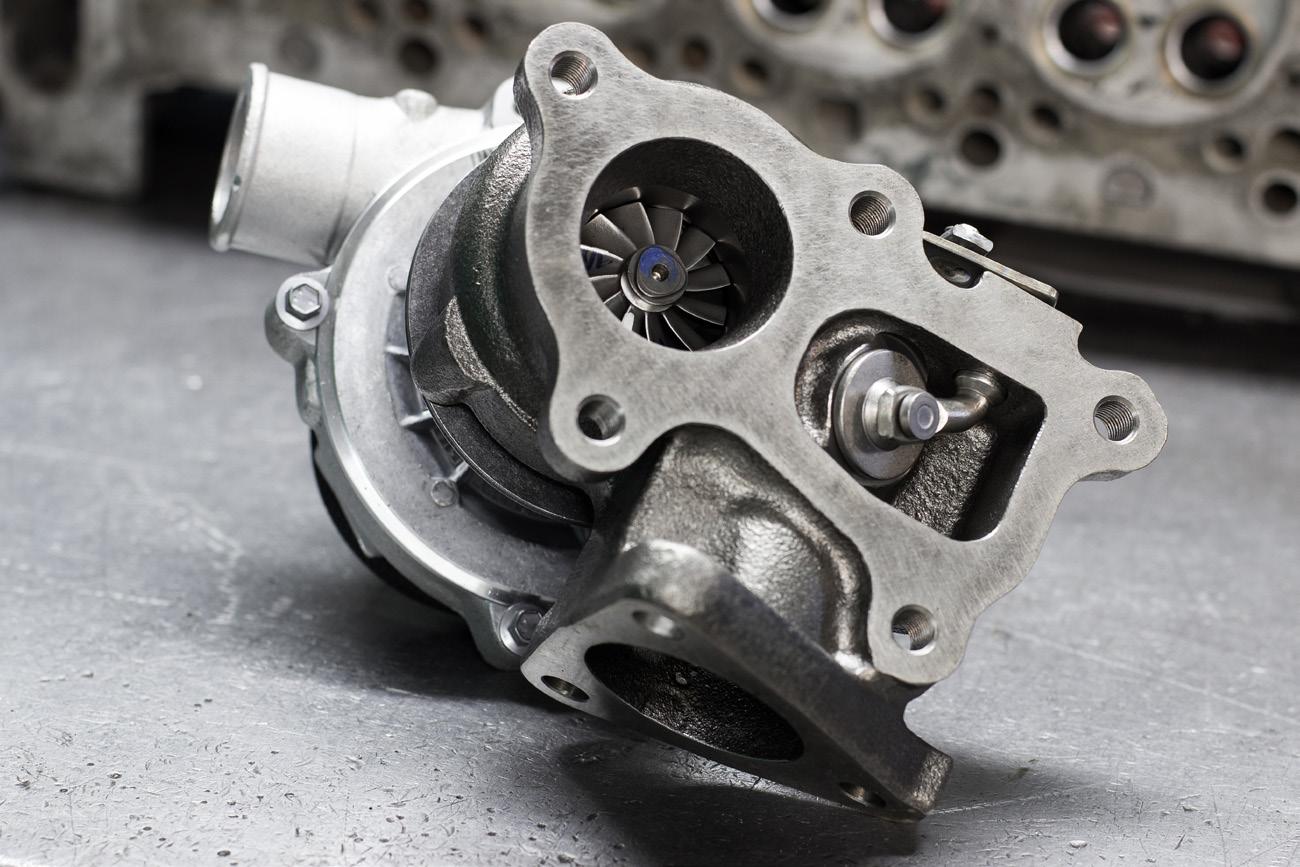

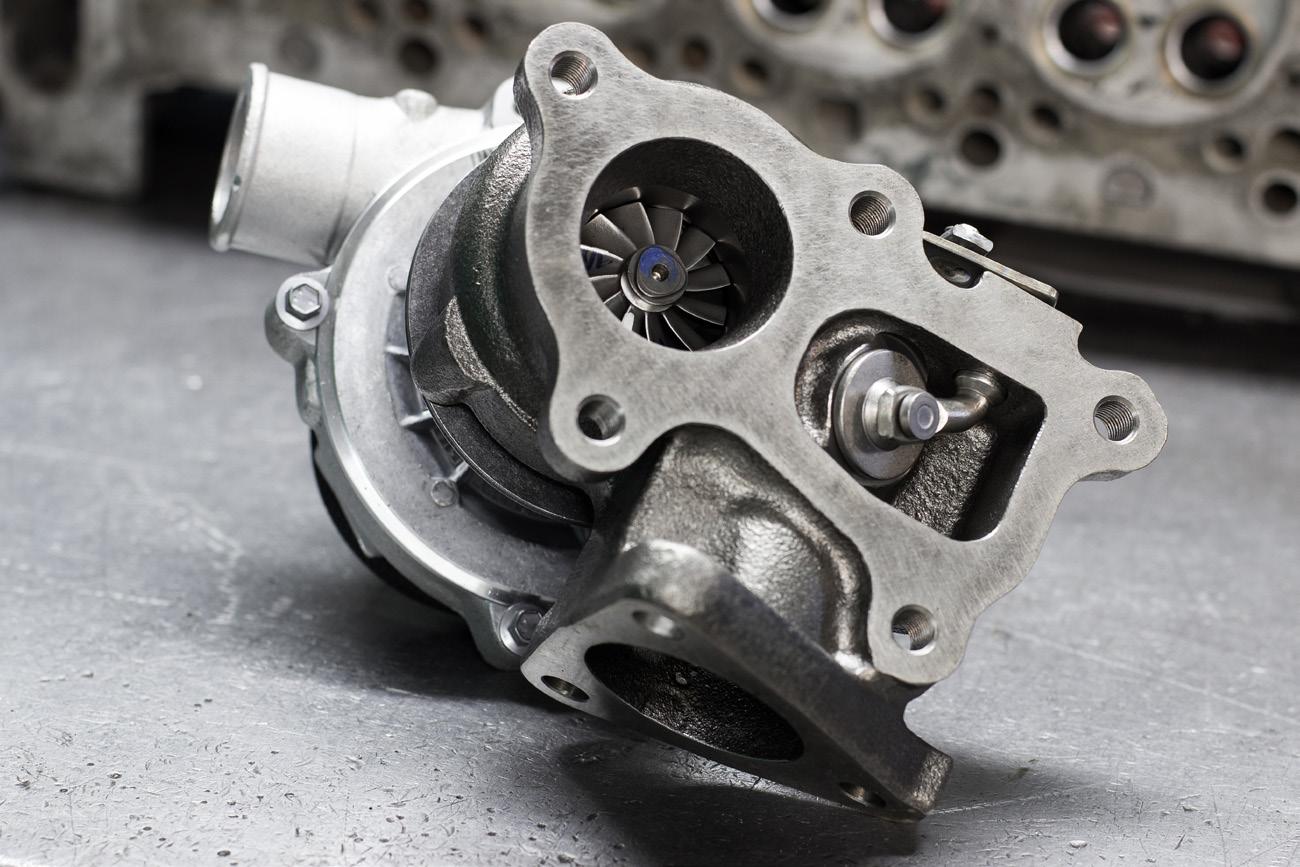

Turbos: Tackling oil contamination

The majority of turbo failures are caused by problems that have nothing to do with the turbo itself. That is why it is important to determine why it failed, and fix it, before simply fitting a new one, otherwise the replacement unit could fail too. Here we discuss one of the most common causes of turbo failure: oil contamination.

WHAT IS OIL CONTAMINATION?

With tolerances measured in microns, and operating speeds of over 300,000 revs per minute, turbochargers need a regular supply of good quality and clean oil to keep them churning over. Unfortunately, fuel, dirt, combustion residues, water, and other contaminants can easily contaminate the oil, and even the smallest particles can result in serious wear to crucial components, and potentially serious damage to the turbocharger, and even the engine.

WHAT CAUSES IT?

There are a myriad of possible causes of oil contamination. They include:

• Filter problems such as blockage, damage, or poor quality components

• Issues with the filter bypass valve

• Carbon build-up in engine or oil supply lines

• Poor quality engine oil due to either overly high temperatures and/or overdue servicing and maintenance

• Engine leaks that cause water, coolant or fuel to contaminate the oil

• Poor servicing techniques or engine wear and tear which introduce debris or dirt into the engine

WHAT ARE THE SYMPTOMS?

Performance issues and component wear could present themselves via:

• Warning lights (i.e. check engine light) and loss in vehicle power — limp home mode

• Scoring/grooves to either journal bearing, journal bearing diameters of shaft, wheel, and thrust components

• Larger particles can cause internal damage to the shaft and bearing

• Wear to oil flinger/flinger grooves which can lead to oil leaks

• Piston ring wear and tear that causes oil to enter the turbine side and increased oil usage

• Turbine and/or compressor wheel coming into contact with the housing bore due to excessive play in the shaft from worn bushings/bearings

• Blocked internal oil galleries restricting oil flow

• Smell of fuel in the oil

HOW TO FIX IT

Sure, preventing oil contamination via quality parts, servicing, and following manufacturer’s recommendations is better than having to fix it. However, if problems occur here is a quick guide that can help:

• Do an oil system flush and refill following manufacturer guidelines and using quality parts

• Clean the oil supply and return system (you might need to remove the sump, oil pump, and internal oil lines) — replace parts as needed

• When replacing the turbo, perform an oil pressure test to identify issues in the oil supply and return system.

This may add additional expense to your customer’s bill, but it is far more cost and timeeffective than having to fit another turbo, and potentially an engine, when they return with the same issue soon after.

Finding the correct FUCHS Lubricants product for a vehicle has never been easier with FUCHS Rego Lookup! Simply scan the QR code, and follow the steps to easily get all the information you’ll need to choose the most suitable FUCHS Lubricant for the job! fuchs.com/au/en/product-search-aus-nz FUCHS Rego Lookup MOVING YOUR WORLD by finding the right oil EASIER! The all new FUCHS Small Pack Range EASY ON THE ENVIRONMENT Recycled and recyclable packaging Improved residual emptying CO2-neutral production

Carbon footprint: it’s all about teamwork

FUCHS SELLS 10,000 PRODUCTS WORLDWIDE – AND 3000 SUPPLIERS ASSIST IN MAKING THEM. WITH THEIR HELP, THE COMPANY AIMS TO CALCULATE THE CARBON FOOTPRINT OF ITS PORTFOLIO, SETTING STANDARDS IN THE INDUSTRY. SOUNDS COMPLICATED? IT IS! BUT IT’S WORTH IT

Imagine the boss of a small, exclusive, Italian artisan pasta producer. And now, the CEO of a major Japanese automotive manufacturer. Perhaps add a German wind turbine builder, the operator of a huge cement works in China, and the management team of an American data centre. No matter how different their companies and sectors may be, they all require lubricant solutions in production, for logistics, or in administration. And you can be sure that they all share the same desire to operate efficiently and sustainably.

Fuchs has set out to support its customers with a specially developed method for calculating and transparently communicating the carbon footprint of these products (Product Carbon Footprint: PCF). Markus Garb, vice president global sustainability at Fuchs, explains how this major project came about and how it could help to develop standards for the entire lubricant sector. We chat to Markus Garb: Mr Garb, what were your maths grades like at school?

I was an average student — good, but not excellent. What I always liked about maths is the clarity with which you can describe and solve problems.

Fuchs supplies 100,000 customers worldwide with hugely different lubricants and performance fluids. The company has set out to calculate the carbon footprint of these products. That sounds like a very complicated arithmetic problem, but

preparatory work, establishing the boundaries of the system — which data do we need to include, which do we leave out? We gather only part of the data ourselves, such as the energy and water consumption, or the amount of waste generated in production. When it comes to raw materials that we buy in, then the data comes from our upstream suppliers. However, we have to tell them exactly how they need to calculate their values so that we can

16

Auto Channel Issue #59 July 2023

Fuchs wants to support its customers in operating more sustainably. Recording and transparently communicating the carbon footprint of its own products is an important prerequisite for this. How are you tackling this mammoth task?

First, we have defined which parts of the value chain that Fuchs contributes to should be included in the calculation of the Product Carbon Footprint (PCF). According to the ISO 14067 standard, a PCF must cover the entire value chain, from cradle to grave. This means from mining the raw materials to disposal. Now we offer 10,000 products to 100,000 customers worldwide. When a product is waiting to be sold from our warehouse, we don’t yet know which customer will use it for which application. That’s why we have decided to limit our PCF method: it covers the journey from cradle to the gate at Fuchs. This is called cradle-to-gate.

Cooperation with our upstream suppliers is incredibly important. They need to know exactly which data we need and how it needs to be defined. We’ve already come a long way with our internal data, as we’ve been calculating the company’s carbon footprint since 2011 and are continuously optimising our data collection.

Once all of that is defined, we look at the data structures. Fuchs has many sites, and many products are produced at multiple sites. That’s why some raw materials come from different sources. The data structures and calculation levels naturally have to fit with this multisourcing.

Where is Fuchs currently at in the process?

We’re in the middle of a pilot project for PCF calculation at regional level — that is to say European level. The first products could be ready by the end of the year. In order to cover all products, we’re largely dependent on the provision of data from our upstream suppliers. Some of them have already come a long way, others are still getting started.

In parallel to this, we are having our method checked by independent experts from Germany’s TÜV technical inspection board – that’s important for transparency and credibility.

What are the biggest challenges in PCF calculation?

Each result is only as good as the raw data that has been entered. As I mentioned, we’re already well on the way with our internal emissions calculations. Depending on the product, however, 80 to 90 per cent of the product-related emissions originate

Unfortunately, applicable standards like ISO 14067 don’t allow such ‘prevented emissions’ to be offset against ones that were previously amassed. This is intended to prevent greenwashing. What we can do, however, is to cleanly calculate and compare both areas of the value chain — this is called a lifecycle analysis (LCA). It’s a much more broadly applicable method that doesn’t just take emissions into account, but also looks at other environmental effects. We also plan to develop these LCAs and the necessary skills at Fuchs.

There are currently no sector-specific standards for PCF calculation. Fuchs is a true pioneer in this area. How is the sector responding to this?

from the upstream value chain, and many suppliers are not yet as far along. Luckily, we work closely in partnership with them. Several suppliers have already published PCF method documents and much seems to be going in the right direction. This is encouraging, because ultimately we need a standard for the entire industry, what we call sector-specific standards. After all, we can only compare results with one another if we make our calculations according to a standardised method.

Compared with other industries, your sector has somewhat lower emissions. Greater potential for climate protection lies with customers

Yes, that’s the ‘honey pot’ of the emissions calculation. When the products leave our factory, they’ve amassed a burden of emissions with us and our suppliers. In practical use, however, they are there to reduce friction and wear, increase efficiency, and extend the service life of machines.

The industry has recognised that it is no longer enough to sell a product based purely on its technical suitability. In the future, more detailed information on sustainability will be critical. We need sector-specific standards on how PCFs for lubricants and their upstream products need to be calculated, with a focus on data comparability. In European associations like UEIL and ATIEL, we are actively working on developing such standards and aim to contribute to standardisation with our method.

Due to the Covid pandemic and the many geopolitical challenges currently being faced, climate change is no longer as present in public debate. However, reports of extreme changes in the climate such as those being experienced in India, where temperatures sometimes reach 50 degrees Celsius, or the current unprecedented periods of drought in Europe, show how urgent this global crisis is.

That’s why we continue to work consistently on our products and processes at Fuchs. In many cases, lubricants are enablers for sustainable technical solutions. No company can stop this development alone; everyone needs to contribute. Climate change doesn’t rest — and neither do we.

FUCHS LUBRICANTS. MOVING YOUR WORLD

For more information visit fuchs.com

17

Fuch's Markus Garb

Making aftermarket towbars easy to install

HAYMAN REESE SIMPLIFIES AFTERMARKET TRAILER WIRING AND SUPPORTS TROUBLE-FREE TOWING FOR A VARIETY OF MARQUES

Equipping a vehicle with proper, aftermarket

trailer wiring to safely connect the turning signals, taillights, brake lights, and other electrical systems has not always been a straightforward process.

If the vehicle is not equipped with working trailer wiring, a number of different solutions exist to provide the perfect fit for the specific vehicle. Are you after custom wiring, splice-in wiring, or replacement wiring? Some require splicing and soldering while others only need specific connectors. For those cars without custom wiring, a more involved and customised taillight conversion process is required.

However, Hayman Reese — a prominent player in the field of towbar technology — is expanding its offerings in aftermarket towing solutions by introducing a smart and hassle-free alternative to these complex towbar wiring installations. Presenting SmartClick Intelligent wiring looms, Hayman Reese now provides tailored solutions for every vehicle, including the soon-to-be-released towbars to suit Tesla Model 3 and Model Y.

Each wiring loom has been meticulously engineered to fit the specific requirements of individual vehicles. The process is as simple as

connecting the smart plug to the vehicle nodes, and the wiring is seamlessly completed.

INTERFACING WITH CAN BUS

Traditional trailer wiring harnesses have the potential to trigger fault codes in vehicles managed by CAN bus and safety systems to fail to activate or deactivate when a trailer is connected.

Hayman Reese’s initial SmartClick systems included a base loom and ECU, with the tail chosen separately to complete the set up. The Hayman Reese SmartClick CAN bus system is a plug-and-play solution that eliminates the need for scotch locks or soldering into the vehicle’s wiring harness. Hayman Reese utilises factory plugs to enable this type of connectivity. The supplied ECU is designed to effectively communicate with the vehicle, replicating the functionality of the original equipment.

However, in 2019 this process was not as straightforward as anticipated and in many earlier versions of the SmartClick system the vehicle had to be taken back to the dealership for coding, which created resistance from dealers who were concerned about potential issues caused by aftermarket wiring looms.

SMARTCODE SOLUTION FOR INSTALLERS

This is where Hayman Reese’s Smartcode comes into play. Smartcode is a handheld device that connects to the vehicle’s OBD plug and programs the vehicle to recognise and accept a properly configured trailer wiring solution, thereby activating the appropriate parameters for safe towing. Since the installer can perform this programming, vehicle owners no longer need to contact dealerships.

The handheld device is exclusively designed for towing coding and lives up to its name by being highly intelligent. Within a matter of minutes, the vehicle is coded and ready to go. The Smartcode firmware is consistently updated, and a quick download ensures that the handheld device remains up to date.

Currently, the supported brands include Ford, VW, Audi, Skoda, and Mercedes. Tesla Model 3 and Model Y are soon to be released.

For more information, contact Hayman Reese on 0800 MY TBAR (0800 698 227).

Inner workings of a lead acid battery

ALTHOUGH A MYSTERY TO MANY, LEAD ACID BATTERIES ARE NOT AS COMPLICATED AS OFTEN THOUGHT. WE DELVE INTO HOW THIS WELL-ESTABLISHED TECHNOLOGY WORKS AND WHY IT HAS SURVIVED THE TEST OF TIME

The lead acid battery is the oldest form of rechargeable battery technology. They are used for a wide range of applications including cars, scooters, golf carts, UPS (Uninterruptible Power Supply), medical equipment, telecommunications, and even large grid-scale power systems. The inner workings of a lead acid battery are a mystery to many but here is a quick rundown by the battery experts at R&J Batteries.

The lead acid battery was invented in 1859 and despite being in use for over 160 years, the basic principles on which a lead acid battery works have not changed much. A lead acid battery consists of three major components — a positive plate (cathode) made of lead dioxide, a negative plate (anode) made of sponge lead, and an electrolyte solution of water and sulphuric acid. The positive and negative plates are submerged in an electrolyte solution to facilitate a controlled chemical reaction which allows the battery to store and supply electricity.

During charging, electrons are loaded onto the negative plates. As the quantity of electrons increases, the state of charge (SoC) and voltage of the battery increases. When the negative plates

cannot hold any more electrons, the battery is considered to be fully charged. At 100 per cent SoC, the electrolyte in the battery contains approximately 30 per cent sulphuric acid and 70 per cent water.

When a battery is connected to an electrical device, the electrons begin to flow through the device and do their work (i.e, producing light or motion).

As the battery discharges, electrons flow onto the positive plates and the resulting chemical reaction reduces the amount of sulphuric acid in the electrolyte, replacing it with water.

When a lead acid battery is being charged it will generate some bubbles, however if a battery is charged too aggressively, it will begin to gas excessively as the plates are unable to convert the energy fast enough.

Aggressive charging will also generate heat which will damage the plates by causing them to shed some of the active material, reducing the battery’s capacity. The plates can also warp or distort which can increase the chance of an internal short circuit.

There are a number of different types of lead acid batteries in the market. Calcium and EFB (Enhanced Flooded Battery) are

called flooded batteries because the plates are submerged in the electrolyte. AGM (Absorbent Glass Mat) batteries use the glass mats to separate the plates and also hold the electrolyte in suspension which makes the AGM battery non-spillable.

For those who prioritise quality and performance above all else, ACDelco batteries are an excellent choice. The global leader’s product portfolio consists of automotive, commercial, deep cycle, marine, and lawn mower batteries covering a wide range of applications.

ACDelco batteries are exclusively distributed by R&J Batteries in New Zealand through its branches in Wiri, Christchurch, Hamilton, Albany, Nelson, and an extensive network of stockists.

To learn more about ACDelco batteries, please call 0800 546 000, or visit rjbatt.co.nz.

BECOME AN ACDELCO BATTERY STOCKIST

A PROGRAM TAILORED TO YOUR BUSINESS

AUTHORISED

0800 546 000 rjbatt.co.nz RJBatteries

BECOME AN

STOCKIST

Towards carbon neutral motorsport

FOLLOWING A SUCCESSFUL DYNO TEST PROGRAMME WITH CARBON-NEUTRAL FUEL, TOYOTA GAZOO RACING NEW ZEALAND WILL CONTINUE ITS JOURNEY TOWARDS A MORE SUSTAINABLE MOTORSPORT FUTURE

Toyota Gazoo Racing New Zealand (TGRNZ) sourced a small supply of ground-breaking, Carbon Neutral Fuel (CNF) from P1 Fuels at the WRC Rally New Zealand event towards the end of 2022. They then began an engine dyno testing programme on the 2.0L turbocharged unit used in the Toyota FT-60 cars for its international single seater series.

The engine was developed locally in New Zealand for the annual international championship as part of Toyota New Zealand’s commitment to the future of NZ motorsport.

The dyno testing programme confirmed there was no loss in power or performance, reliability issues, or significant changes required in engine mapping. As a result, the motorsport operation of Toyota New Zealand confirmed in mid-June of this year that it will now integrate this fuel into its on-track testing programme for 2023.

If successful, CNF could be adopted as the official fuel for the championship as early as 2024 or 2025. That would make the Kiwi championship the first FIA Formula Regional series to genuinely use 100 per cent sustainable fuel.

TGRNZ would then look to introduce the fuel to its Toyota 86 Championship in New Zealand as soon as possible after that and is already looking at potential partners for the project.

P1 is the global leader in carbon-neutral fuels and has a growing presence in motorsport. It’s the exclusive supplier for the World Rally Championship and also powers the FIA Karting Championship, as well as having partnerships with other manufacturers apart from Toyota.

The P1 fuel shot to prominence when it was chosen by three-time F1 world champion Sebastian Vettel in his collection of historic F1 cars and was

What are carbon neutral fuels?

Carbon-Neutral Fuels (CNF) are part of a large family of partly or fully fossil-free synthetic fuels. They are blended from chemical components derived from either second-generation feedstock, such as bio-alcohols generated from agricultural and urban-waste biomass, or from the industrial catalytic conversion of syngas (CO + H2), generally known as e-Fuels or Power to Liquid (PtL). In both cases, every part of the fuel blend is of

non-fossil origin, so no new carbon dioxide is introduced into the atmosphere during its use. This is because the carbon atoms in the fuels are captured from CO2 already present in the atmosphere. The carbon capturing process can be achieved naturally, through the photosynthesis of plants or algae, or artificially, through processes such as direct air capture (DAC) where CO2 is taken directly from the atmosphere.

Kombi with a green twist

NEW ZEALAND’S VOLKSWAGEN COMMERCIAL VEHICLES ANNOUNCE FULLY ELECTRIC KOMBI

Volkswagen has recently revealed a fully electric 1966 Kombi along with an open source ‘greenprint’ for anyone looking to revolutionise their classic.

Once used by the Dunedin Health Board, KEV has been lovingly restored and repowered with a new heart, fuelled by clean energy.

The initiative seeks to ‘green up’ one of the brand’s most recognisable vehicles with an open source guide online to help Kombi owners revolutionise their iconic retro.

The guide, called the Greenprint, delivers a howto plan for passionate owners to convert their own Volkswagen vehicle to fully electric solution.

in cars across the globe.

“The dyno tests have been extremely productive and after a very short space of time we are more than ready to test the carbon-neutral fuel on track and take the process to the next step,” said TGRNZ motorsport manager Nicolas Caillol.

“Our goal, like our parent company Toyota New Zealand, is to reduce our greenhouse gas emissions by a minimum of 46 per cent by 2030. We will do this through carbon neutrality with both of our New Zealand racing championships and set new standards for sustainability in New Zealand motorsport.

“We believe that is a fantastic way forward for the sport here and in other official FIA Formula Regional series.”

says the change from classic to e-classic has been extraordinary. “I know Kombi owners are super passionate about their vehicles, so it’s great to share our journey and plans required to turn their classic into a full EV.

“When almost half [47%] of Kiwis are likely considering an EV for their next vehicle, we’re thrilled to offer a range of electric and PHEV vehicles along with one that’s slightly more unexpected.”

Car news

Auto Channel Issue #59 July 2023 20

The future is now

WE TAKE A LOOK AT SOME OF THE LATEST TECHNOLOGICAL ADVANCES, THAT’S TURNING HEADS IN THE AUTOMOTIVE WORLD

Imagine driving though the sky in a flying car that is as much a part of daily life as today’s automobiles.

Suzuki Motor Corporation has signed a basic agreement with SkyDrive regarding cooperation for the manufacturing of ‘flying cars’. The SkyDrive Flying Car is a lightweight eVTOL aircraft that can land at airports located almost anywhere. At a customer’s request, an autonomous flying car will pick you up and fly you straight to your destination in comfort as you enjoy the ride.

Suzuki and SkyDrive have agreed to use a plant owned by the Suzuki Group in Japan, and aim to start the manufacturing of these vehicles around spring of 2024, with a scheduled release of 2025.

SIX-MINUTE CHARGE?

Nyobolt, the UK-based developer of ultra fastcharging batteries, has recently revealed a vehicle that can charge fully and repeatedly in less than six minutes — a new record in automotive electrification. Seen by some as EV’s ‘holy grail’, the Nyobolt EV weighs close to one tonne — as opposed to two of most current EVs. It uses a

motorists to fuel their vintage vehicles with plantbased petrol, without any modifications to their engines, with three types of fuel initially available. Developed by fuel specialist Coryton, the fuel with the highest sustainable content promises a reduction of at least 65% in greenhouse gas emissions when compared to fossil fuels. The products use advanced second-generation biofuel manufactured from agricultural waste, such as straw, by-products or waste from crops which wouldn’t be used for consumption. By doing so, the fuel utilises the carbon that already exists in our atmosphere, which the plants absorb as they grow, recycling it, rather than releasing additional CO2 that is currently locked underground in fossil fuel.

distinctive car configurations: one inspired by the 1967 classy Maserati Ghibli coupé, and another by the 1986 Maserati Quattroporte Royale.

BENTLEY ENVIRONMENTAL FOUNDATION

Bentley Motors recently announced the launch of the Bentley Environmental Foundation, an organisation seeking to support a wide range of initiatives that create next-generation solutions to environmental challenges. The initial launch partners include Project Drawdown, The Biomimicry Institute, and Sustainable Surf.

DRIVE IT LIKE BECKHAM

For better or for worse, the world of celebrity owned and outrageously customised vehicles is nothing new (Justin Bieber’s gangster-like RollsRoyce Wraith anyone?)

35kWh battery and is capable of fully charging with up to 250km range in under six minutes with existing charging infrastructure. That’s the equivalent of charging at over 1600mph, more than double the fastest charging cars on the road today

TOMORROW’S CLASSICS

The first sustainable fuel specifically designed for classic vehicles has just been launched for public purchase in the UK.

However, Italian luxury vehicle manufacturer Maserati has taken this a little further in what could become the future of marque and pop icons collaborating with car brands. Maserati has launched the Fuoriserie Essentials collection: a series of cars “curated by select tastemakers and friends of the Trident”. The first collection has been designed by British footballer David Beckham who is passionate about classic cars and conceived this as an extension of his Savile Row sartorial wardrobe. His Fuoriserie DB Essentials collection includes two

Christoph Hohmann, head of global brand communications and responsible for the foundation, said: “We are very excited to launch the Foundation with these three partners. With Project Drawdown we aim to significantly increase the efficiency and effectiveness of billions of pounds worth of environmental donations and investments globally. With The Biomimicry Institute we’re supporting changemakers who are creating and scaling natureinspired solutions to address our most pressing environmental and social challenges. And with Sustainable Surf we’re helping to strengthen blue carbon ecosystems in Africa and Europe through the massive forestation of seagrass and mangrove trees.”

21

Aubit makes car clips simple

FOR MOST COMPANIES, CLIPS ARE MERELY AN ADD-ON TO THEIR GENERAL OFFER… IN CONTRAST, AUBIT HAS MADE THEM THE HEART AND SOUL OF THEIR SPECIALIST BUSINESS

Frustration used to be the most common feeling for anyone needing automotive clips and fasteners. Hard to find, long wait times, expensive pricing, and even cheap, dodgy clips from some suppliers were all persistent problems.

From humble beginnings in 2016, Aubit has stuck to its mission of taking this pain away for their customers and it has paid off as their products and services are now in demand across both New Zealand and Australia.

For most companies, clips are merely an add-on to their general offer, in contrast, Aubit is the only major supplier that is a dedicated specialist. This specialist focus allows them to deliver what people need and do so in a quick and efficient manner — as seen by the user friendliness and ultra-fast delivery provided via their website (aubit.co.nz).

Developed in 2020, the Clip Station was a real game-changer for the industry — a super simple and brilliant way of ensuring that mechanical, auto electrical workshops, or panel businesses always had the clips and fasteners they needed on hand.

The user-friendly Clip Station allows for the instant location of clips when you need them, and a simple scan of the drawer code makes re-ordering,

replenishment, and invoicing a breeze. What’s more, scanning the drawer code enables a business to invoice insurance companies for the precise number of clips used, resulting in full cost recovery for every job.

Initially Aubit was set up as the brainchild of Gary and Katie Senior in provincial Mosgiel as Carclips NZ. In July 2021, Carclips NZ acquired Autoclips NZ, and re-branded as Aubit Ltd.

This name change reflects the decision to expand the automotive product range offered. Customers can now also obtain quality auto bulbs and hose connectors from Aubit. The team at Aubit has grown to include Gary’s father, Derek Senior, who brings a vast knowledge of the industry, and also the addition of business development manager, Sophie Rendall, and Tara Senior as warehouse manager.

CASE STUDY: ALL CAR SERVICES

As Blackfern suppliers, Aubit looks after Kevin Offen, owner of All Car Services, Dunedin. Sophie explains: “Originally, Kevin started by purchasing a good number of our clip kits. These included specific kits for Toyota, Honda, as well as trim screws and bolts. Kevin wanted these as he had confidence that the

clip quality wouldn’t let him down when customers drove away, and it gave him a good choice on hand. Later, we introduced Kevin to the Clip Station as one central hub for all his clip and fastener needs. We cover quite a range with the Clip Station series, from the Clip Station mini, a smaller unit that houses eight different fasteners, to the Clip Station 96 — our largest option with 96 different fasteners, including bulbs, rivets, and bolts.

ON SPECIAL

Check out the special for Blackfern members of a 1000 clip bucket of various clips. This handy little bucket is only $89 and a great place for those one-off, hard-to-find clips. This bucket will save you time and money looking to quickly match that odd-looking clip.

Order this bucket anytime between June and August and go in the draw to win a $100 tool voucher from a listed Blackfern supplier, or get the value of your bucket credited back. Over to you!

On-demand bus service for Wellington

A PUBLIC TRANSPORT SERVICE FOR THE RIDE-HAILING ERA IS EXPANDING IN REACH

Metlink On Demand finished a successful 12-month trial on 16 May, having completed over 40,000 trips for the Wellington community. The trial will now be extended for another year, and the service will be expanded from Tawa and Grenada North to include Porirua CBD. As the trial continues, Metlink will also assess the viability of extending the service to Aotea and Cannons Creek.

Greater Wellington Transport Chair Thomas Nash is looking forward to the On Demand service becoming available to more passengers.

“Metlink On Demand is an accessible and flexible form of public transport that offers people a convenient, climate conscious alternative to personal vehicles. Passenger satisfaction with the

service has surpassed our target, averaging 96 per cent. We are delighted that Metlink’s commitment to modern, convenient transport is resonating with communities.”

To use the service, passengers request a vehicle with the Metlink On Demand app. A wheelchair accessible, 14-seater bus is allocated to the passenger, shared with others whose journeys are suitably similar. The bus picks up and drops off passengers at approximately 600 locations or ‘virtual stops’, mostly in areas without fixed route services.

A trip rate of $2.50 is paid through the app, making it a familiar – and cheaper – experience for anyone who uses ride-hailing apps such as Uber or Ola.

Fiona Abbott, acting Metlink group manager, says the on-demand service provides another path to mode shift, one of Greater Wellington’s targets in the Regional Public Transport Plan.

“Metlink On Demand connects commuters to the rail network, reducing their reliance on cars. It’s also proved popular with parents, children, and the elderly; passenger numbers continued to rise throughout the trial, connecting people to schools, shops, and social events.

“The extension of the Metlink On Demand trial

is a positive step towards reducing our region’s emissions. Greater Wellington is investing in modern transport solutions to ensure a sustainable future.”

Government is considering a bill which proposes to amend the definition of public transport to include on-demand public transport. This bill would make On Demand eligible for funding through the National Land Transport Fund, supporting Metlink’s ability to establish On Demand services in additional areas.

Apprenticeship Boost continues until 31 December 2024. Receive $500 per month to support each first-year and second-year apprentice. mito.nz/apprenticeshipboost

After detecting poor-quality plug welds on the right side, the repair process was temporarily halted. The technician received redirection and underwent off-vehicle training to improve their skills. Consequently, they were able to successfully execute quality plug welds, recognising the need to rectify previous subpar work

HOW

DO

WE ENSURE THE WORKSHOP IS UP TO SCRATCH WHEN IT COMES TO WELDING JOBS? WE EXPLORE SOME TECHNIQUES AND STEPS TO ENSURE PROPER QUALITY CONTROL

There are many different definitions of what quality control means. Whether it’s micromanaging someone by checking their work over their shoulder, or following long checklists on paper or software — all workshops must verify whatever standard they are trying to set to ensure safety. It is also often thought that quality control only means checking for the craftsmanship of a finished product. However, it can also mean better efficiency and nowhere is this more true in a workshop than in one of the more challenging technical processes there: welding.

When done properly, welding quality control may offer peace of mind that vehicles leaving your shop are safe and structurally sound.

YOU DON’T NEED TO SAY YES

One of the first questions of welding quality control must always be: Should I even be welding on this car? If the answer is positive, then follow that with the obvious: what types of weld and where should they be performed, as well as the types of processes that will be used. Car makers have very specific rules on how the vehicles they designed and manufactured need to be fixed. And although some people think weld-through primers must be used on every single repair that is not true unless the manufacturer calls for it and specifies which product is to be used. Another common mistake is the addition of extra welding

joints (i.e. backing sleeve), which might not actually be called for on some vehicles. Quality technicians can perform excellent welds, but we should always ask ourselves if we should do them in the first place and how (according to the OEM repair info for each specific vehicle).

ARE YOUR PROCESSES UP TO SCRATCH?

Any repair shop has to be set up properly before it even accepts a welding job. Failure to have the right processes in place means that, sometimes, complicated welding jobs are shoved down the line of repair and the workshop doesn’t catch it until it’s too late and realises that it shouldn’t have agreed to do it.

One of the biggest dangers is what happens when an unsafe repair gets done. By doing thorough training and having processes in place (i.e. in the check-in process, whether that’s front office estimators or back-of-house estimators) workshops should be able to determine if the shop is capable of the repair before tearing into any vehicle.

AREAS TO CONSIDER:

• Should you take on the job or not? Sometimes pride, sometimes lack of knowledge makes many a shop manager accept jobs they shouldn’t. It is hard to admit to not having the capacity for tough

worth it if doing a shoddy repair? It’s fine to admit your limitations and decline a job.

• Does your workshop have the OEM certifications that may be needed to perform the repair? Some manufacturers may not grant access to the welding procedures unless you are certified. It is worth double checking before accepting any job.

• Are the parts easily available? You can’t weld a new piece if you can’t buy it, and many manufacturers restrict purchase of structural parts to repairers who have the proper certification to install it.

• Does your shop have the approved tools for the job? Manufacturers may give repair shops permission to weld only on specify brands and models. Your workshop might have the newest, most expensive machine in town, but if it’s not approved for that repair, you might find yourself way over your head. Even the best welders with top-of-the-line equipment can find themselves in trouble trying to weld mismatched physical parts.

• Does the technician have the right skillset? Manufacturer specifications, materials and abilities all play a role. Ask yourself whether your staff is properly suited, trained, and certified for any specific job.

CONSTANT LEARNING

Making sure your technicians have the right training resources at hand is crucial. This could include classroom or hands-on shop training, virtual classes, and having the right training books. Resources include access to manufacturers’ and welding equipment

manufacturer

having

it is crucial to adhere to the specific guidelines

24

Auto Channel Issue #59 July 2023

These photographs serve as a prime example of deviating from the prescribed welding procedure specified by the original equipment

(OEM). Despite

access to advanced welding equipment technology, such as a silicon bronze welder or a squeeze-type resistance spot welder,

outlined by the manufacturer.

Initially, it was not immediately apparent that the corrosion present on the welding wire on the left side was causing issues for the technician until it was compared side by side with a brand-new roll. The corrosion had been impeding their progress

guidelines. Whether you use Lincoln or Miller MIG welders, you must provide continuing education specific to new materials and specific marque imperatives. Usually when a technician becomes quite senior in their workshop, there is a tendency to assume that he or she knows what they are doing. No one is usually checking their every move to see if there is room for improvement or additional skills, or even to see if they are doing things properly.

couple years or only getting a quick welding setup rundown every so often when a distributor drops off a new piece of equipment.

START WITH THE STAFF

Most technicians don’t want to do a bad job. It’s usually the exact opposite. They take pride in their work and want a quality and proper repair too. Poorquality welds can be due to shop infrastructure, the lack of knowledge of what makes a quality weld, or a mixture of the two. Giving the technicians the proper know-how and resources is the best bet to manage quality weld repairs, let alone the rest of the repairs we’re having them perform.

MICROMANAGING VS QUALITY CONTROL

While quality control primarily lies with the technicians, there have been numerous instances where individuals were aware of poorly performing welders, needing the involvement of the manager or workshop lead to ensure their work meets

Numerous options exist to practise and enhance hands-on welding skills. These options include training with metal coupons made from the same material as the vehicle or, as demonstrated by this technician, swiftly dialling in on a scrap part to ensure the welder is operating effectively and the technician feels comfortable with their technique

Quality control is also verifying skill sets and helping when needed. Continuing to practise and finding ways to do that in the shop is needed, whether it’s giving technicians the time to do so on their own or setting up instructions for them to practise their craft. It cannot only be when they’re sent to a welding test every

Quality control calls for honest dialogue, void of any attempts to conceal poor craftsmanship. Unfortunately, there have been cases where technicians concealed improper frame rail repairs, rendering them undetectable to an untrained eye once covered up