3D printing is revolutionizing the oil and gas industry, particularly with recent advancements in metal additive manufacturing. This technology is predicted to enhance efficiency, reduce costs, and transform component production and repair processes.

Vexma is the leading Rapid Prototyping & Industry 4.0 Manufacturing Service Provider. We provide vivid services including 3d printing, 3d modeling, 3d design, vacuum casting, product design, new product development, low batch manufacturing, and On-demand manufacturing.

3D printing benefits in the oil and gas industr y

Faster product development and design flexibility It offers faster product development and design flexibility, enabling better response to market opportunities and identification of design flaws before production.

Economic low-volume productio

3D printing holds promise for economic low-volume production in the oil and gas industry, although its adoption has been slower in this area compared to other sectors

Faster repair of high-value components The technology also facilitates faster repair of high-value components in the oil and gas industry, presenting significant potential for the sector.

Reduced costs

Reduced costs are a crucial driver for the adoption of 3D printing in the oil and gas industry. Companies in this sector are exerting pressure on component manufacturers to reduce manufacturing costs and lead times.

3D Printing Applications in the Oil & Gas Sector

D Metalforge and Shell Collaborate to Make Heat Exchanger Parts

At the end of 2021, 3D Metalforge announced that it had collaborated with Shell Jurong Island, a dedicated chemical manufacturing site based in Singapore and owned by Shell, to provide 3D printed heat exchanger parts

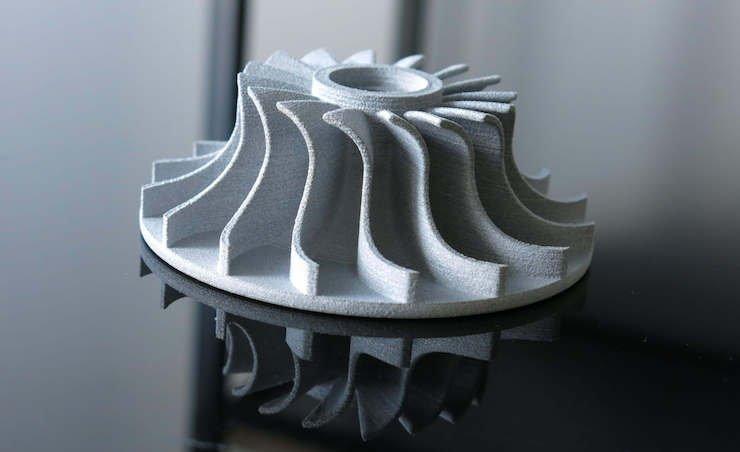

A 3D Printed Pressure Vessel from AML3D

The project involves the design of a metal pressure vessel, 8 meters long and 1.5 meters in diameter, with a total weight of 2000 lbs, using 3D printing. It is believed to be the largest commercially available 3D printed vessel on the market.

with its Wire Additive Manufacturing (WAM®) process, which is derived from DED and combines an electric arc with certified welding wire.

In case of any queries, feel free to mail us info@vexmatech.com