2 minute read

12 Cleaning and work facilities

12.1 Hygiene and cleaning

Use only cleaning materials that have been certified for use in food processing.

Corian materials in doors: Clean with Corian cleaner. Plastic material: Clean with a mild soap and high-pressure spray. Stainless steel: Clean with a mild soap and high-pressure spray.

NOTE! Do not use strong soaps containing caustic soda or other corrosive chemicals. High-pressure wash: Do not spray the screen / screen frame, laser housing or power cables with the highpressure spray.

For processing interruption

Spray the machine with machine protection oil, preferably twice a month and also every time the ship docks or if processing stops for shorter or longer periods. This may be water-miscible oil from Olís, Finlube from Kemi, or similar. Although the machine is made from corrosion-free materials, the oil sinks into joints and into the surface of the material and makes it easier to clean the machine and prevents fish oils and bacteria from getting into the machine assembly.

Cleaning belt housings

Clean the belt housings and grease with food-certified, water-miscible oil cleaners.

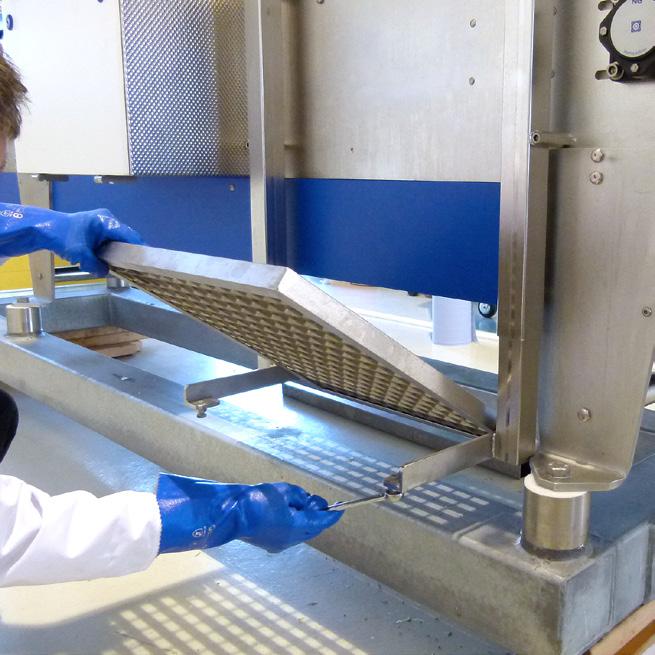

12.2 Guards removed before cleaning

Supply belt in primary position

6 15

UserUser

Press ‘Up’ for supply belt

Guard opened and unattached

UserUser

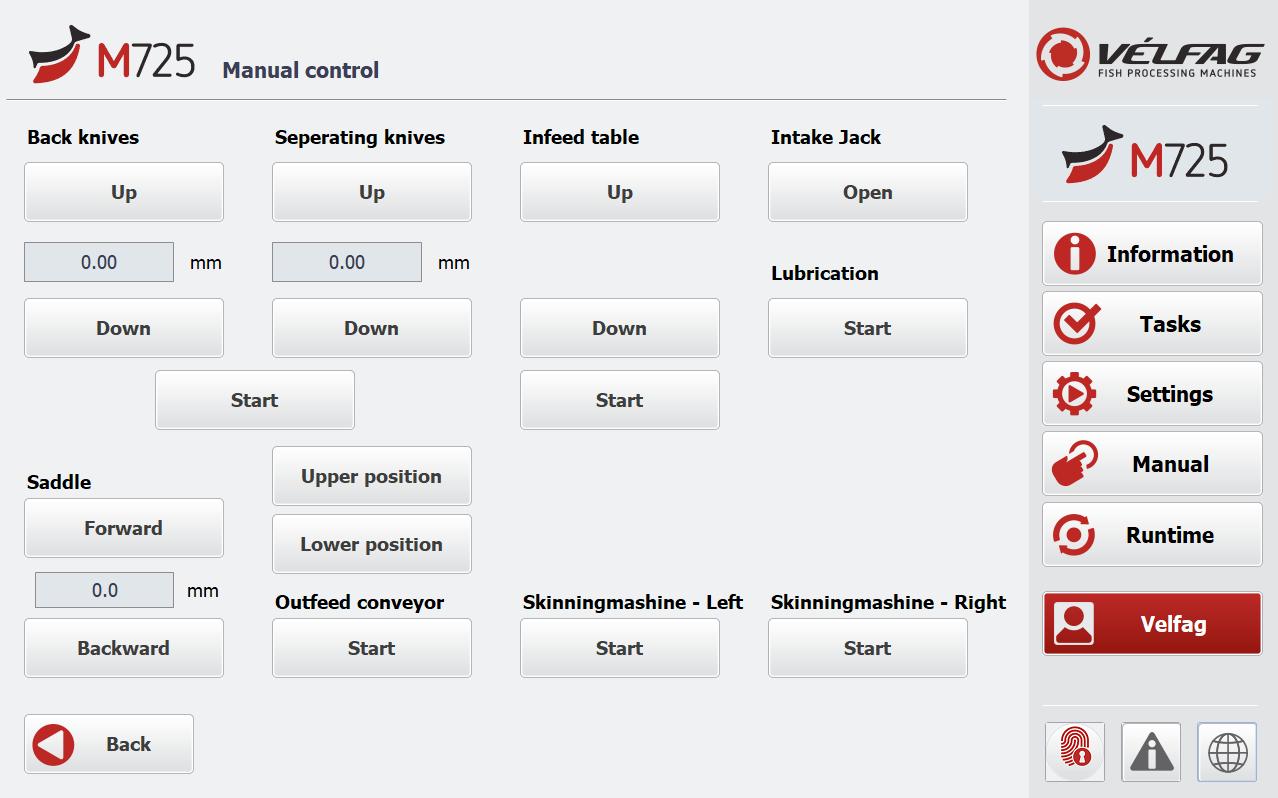

Press ‘Manual control’

Supply belt open

Saddle area open and ready for cleaning

DANGER! It is forbidden to open the machine’s safety guards or work on the machine whilst the safety guards are open, unless the machine has first been stopped using the emergency button/bar and all power to the machine has been disconnected at the circuit breaker in the fuse box.

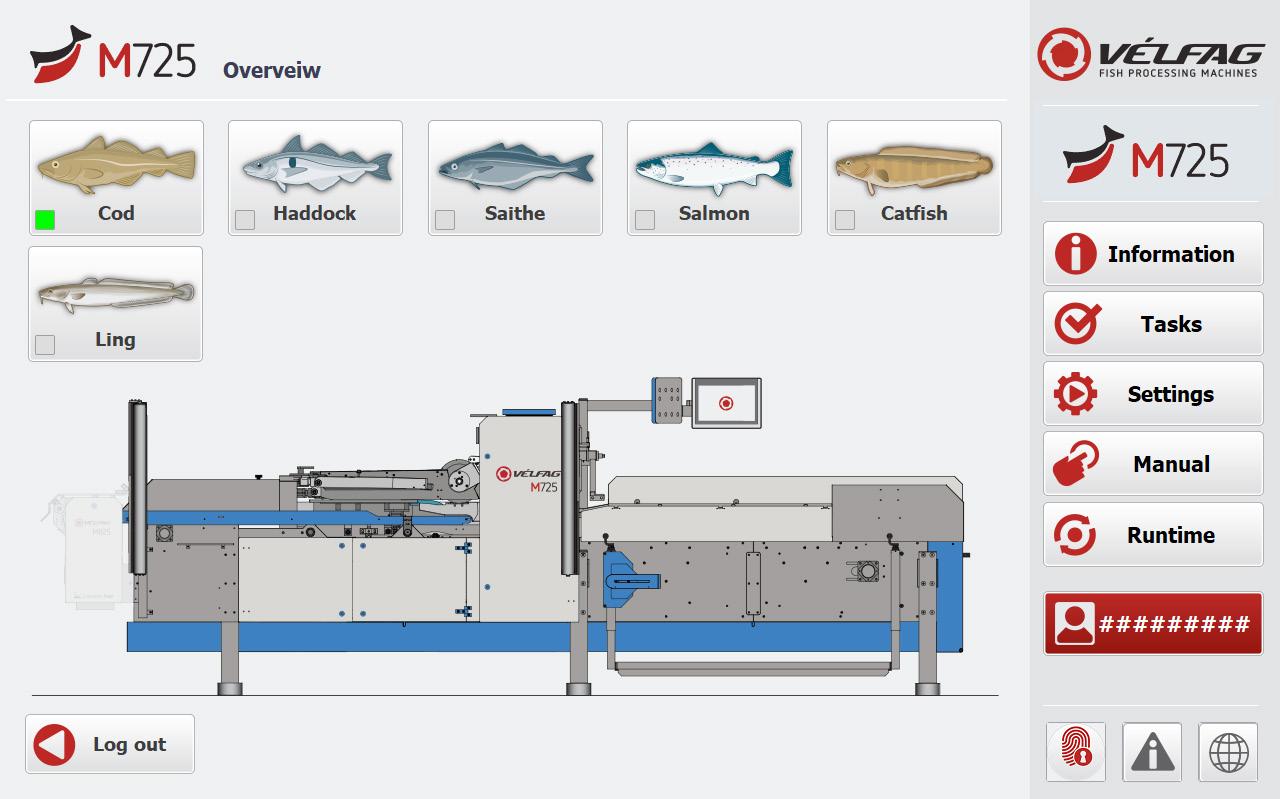

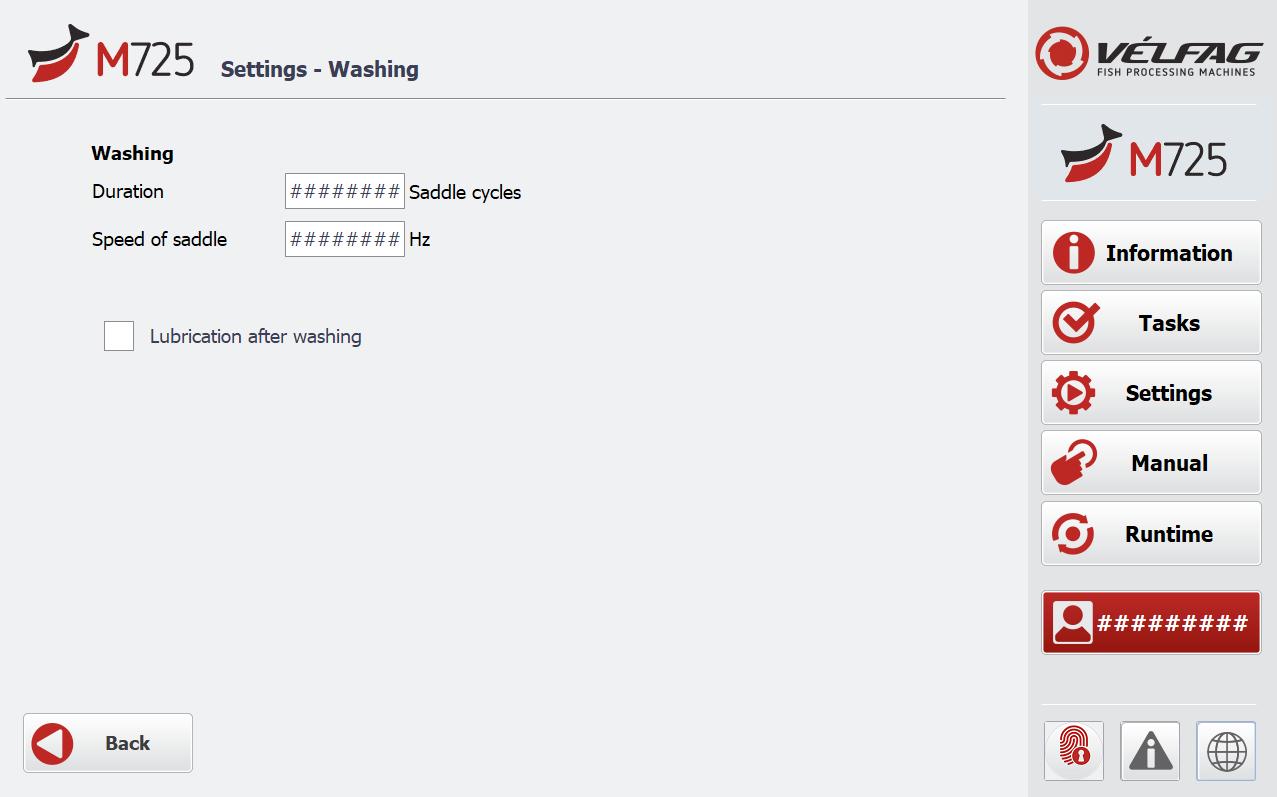

12.3 Automatic rinsing system

20

30

User

Figure 12.1

The machine has its own built-in automatic rinsing system. This enables the user to have the machine clean itself inside without the need to open the machine’s guards and clean it manually.

Despite this automatic system, it is still necessary to thoroughly clean the machine manually inside and outside at regular intervals if the machine is in full use. This is to meet hygiene and food production requirements.

12.4 Work platform

17 mm

Set the working platform to a comfortable working height to reduce stress on the back and shoulders of the person working at the machine.

Figure 12.2 49

Tilt of the work platform adjusted with 17 mm wrench Working height is adjusted by the handles (49)