Studio 804

2024 // Personal Narrative

UNIVERSITY OF KANSAS // SPRING 2024

VED VARMA

The University of Kansas has several excellent five-year graduate programs, which include nationwide internships at various businesses. Although such alternatives are highly advantageous; they also give students the opportunity to enter the field and gain an understanding of what a normal day in an architectural business includes. Within the two semesters of a normal school year, students pursuing a Master of Architecture at the University of Kansas participate in a unique learning program called Studio 804. Students get to participate in every stage of the building process and learn via practical experience. Along with managing every aspect of the business, the students also obtain a deeper grasp of how a non-profit construction company handles its finances.

PROJECT DESCRIPTION

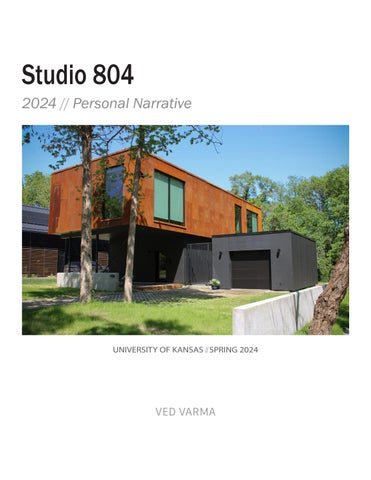

Our project this year is located at 436 Indiana street in the historical Pinckney neighborhood in Lawrence, KS. The project consists of two structures, the house and the garage. The house is comprised of 3 Bedrooms, 2.5 Bathrooms and a large living space with great views overlooking a tiny stream. The exterior facade of the house shows off a rustic Corten finish on the upper level and Richlite Panels (eco-friendly) on the lower level. A permeable driveway leads straight into the garage, which sits right next to the house. A Concrete paved pathway leads us through the two structures to the wooden deck that sits right behind the garage. The project is currently under development and striving to obtain LEED Platinum certification.

CONTRIBUTION

PRIMARY ROLE: INSULATION

At the start of the semester, each student got the opportunity to select an area of focus that they were meant to research on, in a way that works best with all the conditions set for the project.

The role I picked was Insulation. Initially, it took me a while to get used to the research requirements and how to present them since it was not like the ste-reotypical academic presentation that i was used to working on. But given time i started to grasp what was needed and focused on the task in collaboration with others who had adjacent tasks with respect to the building assembly.

My responsibilities were simple, the decipher the type of insulation the building requires as per the code, and calculating the amount and cost of insulation necessary. As the design of the building changed, the cal-culations for the insulation required changed as well and this was one of the things I tried toi stay on top of as the semester went by.

In addition to this, I alsocollaboratedwithseveralotherjobssuchassite, concrete,framingandroofassemblyasthesemesterwenton.

SITE/LANDSCAPE

As a part of the team, Myself along with the team were responsible for clear ing off all the unnecessary vegetation on site, whihc would have otherwise gotten in our way down the line. At that time, there were several trees that needed to be cut down andstumps dug out. In addition to the overgrown vines/ weeds that were penetrating the buildable space. All the waste from these materials were then taken to a composite facility. After removing all the obstacles, we then filled the holes and craters with engineered fill and clay.

CONCRETE

We finished with the site requirements and went guns blazing to tackle any problems we had for our concrete pour. Although the house was a suitable location to pour the footing, the garage, being placed closer to the drain provided us with unstable clay which would not have been able to support the structure of the garage. In order to tackle this problem, myself and adam started working on a formwork that we could use as a retaining wall on the south side to provide some support to the garage.

Soon after, we switched gears and concentrated on the main house, which was the easier part. When the day came to pour, i remember digging the trench for the concrete and rebarring the trench before the pour. Since we had our entire workforce on this objective, we breezed through it within a few hours and the end result looked fantastic.Currently, We are grinding the concrete floor to obtain a

FRAMING

While one team worked on site for concrete, i helped sam and the others frame walls back at the shop since i had an injured back. The process was a lot of fun and the way we made the walls was by placing the lumber into a jig after which all you needed to do was nailgun them together.

ROOF ASSEMBLY

The Roof assembly was a lot easier than any of the other jobs i worked on becasue a lot of it was provided to us in pieces that fit perfectly onto the OSB. I helped with every step of this process right to applying the TPO membrane which was the hardest part of the job.

SITE/LANDSCAPE; 2nd Semester

After the house’s structure finally sat completed on the site, we had to start planning to secure the dirt we had on the easement to safely construct the garage. To do this, we needed to place a retaining wall on the south most part of the site which spanned our southern perimeter. This meant digging more trenches for the concrete footing and retaining wall, along with several other trenches for electricals and sewer pipelines.

After standing up the garage, it was time to seed the site and tend to it, so it bloomed lush green by the time of our open house. I also used a power wash to clean up the concrete splatter for the driveway pour and dirt from the sidewalks to make the entrance to our site more presentable.

CONCRETE; 2nd Semester

This second semester, there were a lot of pours, but I was only able to be a part of a few since I aggravated my back injury which happened to be a slipped disc, which reduced my presence on site. The pours I was a part of were the Retaining wall footing and the retaining wall. This was probably the most crucial part of the project since our site had a steep dip into the storm drain south of the easement. To ensure the garage stayed put, the wall spanned over 90 feet covering the entire southern stretch of the site. We did the pours by digging a trench and then jumping jack the surface to compact it. The formwork for the foundation was then placed (I was a part of the formwork fabrication team) on the easement befo9re the pour.

The wall was done shortly after by placing the formwork on the foundation and then pouring. The wall not only supports the site, but also creates a separate field that separated the site from the storm drain, without obstructing the views.

For the other pours, due to my injury, I was asked by my PT not to participate to ensure I didn’t aggravate it. So, I documented all physically intensive laborious activities by taking photos and videos for LEED submissions and Project Video Documentation

.

INSTALLATIONS

INSULATION:

After we wrapped the walls with Intello, it was time to fill in the cavities with cellulose insulation. We did this by putting the blocks in the insulation grinder to break them and pump it into the walls. That worked for some time, but the machine broke and we had to break up the insulation and feed it into the walls by hand which was also a fun experience.

HVAC:

This was probably one of the most challenging tasks I did for Studio 804. It involved finesse and patience as it was an incredibly frustrating job. We assembled the pieces one by one connecting them between the studs and after that, secured gaps with aluminum tape before putting the insulating foil pads and then applying the sealant.

DRYWALL:

Drywall installation was also quite a hurdle because for starters, it’s incredibly fragile and can’t be handled by just two people since there would be a higher chance of us breaking them. So, we divided and conquered the walls but for the ceilings we had a drywall jack that helped get it to the top where we systematically screwed in the drywall to the studs.

CURTAIN WALL:

This was yet another extremely difficult task. There was only one way to do this with the equipment we had on hand. This was to forklift it between the scaffolding and building and pully it up by lining it perfectly before we place it on the gaskets and screw it in with the trim.

BASEBOARDS:

I shortly helped with applying baseboards as well which we did by taping the drywall before measuring, cutting and nailing it to the studs. Sometimes, certain spots seemed to be off and didn’t stay in place and we fixed that issue by putting cork shims in the back to give us the right plane to have it flush with the walls.

PAINTING

Painting was one of the more important tasks that I did this second semester. Right after we installed drywall and had the mudders finish their job, we got onto painting. It started off with us priming the walls first, which we applied evenly till the purple drywall was just barely visible. Our team of Cutters and Rollers worked efficiently to secure the entire house in less than a day. After that, we started applying 2 layers of paint. This job that seemed so easy proved to be quite difficult since it put a huge strain on my back. So, for the next two days we applied the two coats which was quite the shoulder and back workout. The most challenging room was the mechanical room since we had to dodge all the HVAC equipment without missing any spots.

It was after this that I had to check with an orthopedic specialist who told me that I had a slipped disc. Since then, I had been asked to take it easy on site to reduce damage to my spine. And so, I started focusing on smaller tasks like Gardening, Power washing and Cleaning which were mainly site related. I also documented videos and Photos of people doing their tasks for LEED and Studio 804 documentation.

MISC TASKS

This is a compilation of tasks that i worked on which were led by others throughout the construction process, namely; Sheathing, Grinding Concrete,puttingupthewalls,structuralframeworkofthebuildingandsome help with the Logistics to ensure that we were gliding comfortably on site without draining the efficiency of the workforce.

CONCLUDING REMARKS

Gaining insight into the many distinctive aspects of building construction and design has strengthened my overall grasp of what is possible with architecture and design, as well as my expectations for what can be accomplished in these fields. And that’s where Studio 804 really shines. Though they are significant in and of themselves, most of the other studios I’ve had up to this point have been more concerned with theoretical situations than with the actual building of the structure. I’ve been forced, along with the rest of the class, to delve deeper into the actual construction of the design we generated, and we’re proud of the results we achieved. I believe that after this experience, everyone in the class will understand how designs function better and I can think of no better course that would have offered this kind of exposure.