Wood Products

Enviva, Chesapeake

Virginia Tech

American Woodmark, Frederick County

Speyside Bourbon Cooperage, Inc., Washington County

Trex Company, Frederick County

Enviva, Chesapeake

Virginia Tech

American Woodmark, Frederick County

Speyside Bourbon Cooperage, Inc., Washington County

Trex Company, Frederick County

Forestry has long been a vital part of Virginia’s economy. Since timber was first shipped to England 400 years ago, the industry has grown to contribute more than $21 billion per year in industrial output. In the past decade, wood products companies have announced 129 location or expansion projects in Virginia, representing more than 5,600 jobs and over $2.2 billion in investment. Companies continue to choose Virginia for its thriving industry ecosystem, outstanding logistical advantages, access to quality talent, and top-ranked business climate. Among the companies that have recently announced projects are Woodgrain, the Teal-Jones Group, Laminate Technologies, Speyside Bourbon Cooperage, and TemperPack.

5 Thriving Wood Products Industry Ecosystem Why Virginia? 1 Strategic Mid-Atlantic Location 3 World-Class Logistics Infrastructure 15 Robust Portfolio of Project-Ready Sites 17 Attractive, Stable, and Predictable Operating Environment 19 Exceptional Quality of Life 13 America’s Top State for Talent 11 Dynamic Centers of Innovation

Strategic Location that Enables Global Connectivity

Virginia’s location offers major advantages for the wood products and related industries. Virginia is located within the Southeastern “wood basket” region, which supplies over 60% of the total volume of timber harvested in the U.S. The Commonwealth’s central position on the East Coast is ideal for import and export of wood products through The Port of Virginia and provides ready access to suppliers and to major hubs of economic activity along the Northeast corridor, across the Southeast, and throughout the Midwest.

Logistically, the access that Virginia has fits our business model, and from a resource standpoint, Virginia cannot be beat. All of these factors have played an important part in leading us to Virginia, and we look forward to a long and prosperous future here.

DARREN WHITMER President and General Manager, Speyside Bourbon Cooperage, Inc.

Strategic Mid-Atlantic Location

1

Virginia’s Access to Markets Serves Speyside Bourbon Cooperage

Speyside Bourbon Cooperage, Inc. is an offspring of Speyside Cooperage Ltd., founded in Scotland in 1947. In 2008 Speyside Cooperage was sold to the Tonnellerie François Frères, a global cooperage company founded in 1906 and headquartered in Saint-Romain, France. As of 2015, the company maintained two cooperages in Scotland and two in the United States in Kentucky and Ohio. When Speyside Bourbon Cooperage began the search for its first U.S. stave mill manufacturing location in 2016, Bath County provided the best business scenario for the company’s ‘flagship facility’ to thrive. Officially opened in spring 2018, Speyside’s state-of-the-art stave mill manufactures white oak staves and headers used in the production of bourbon barrels, using only the finest white oak sourced from Virginia.

As Speyside considered locations in Virginia, West Virginia, and Pennsylvania for its newest cooperage and stave mill, accessibility to white oak for bourbon barrel production was a key focus. Fortunately, Virginia’s 16 million acres of forestland (Virginia Department of Forestry, 2018) would allow the stave mill to procure approximately 80% of its white oak logs from Virginia growers.

Just two years after the decision to open its first U.S. stave mill operation in Bath County, Speyside announced a $26 million investment to establish a new cooperage in Smyth County, which became operational in February 2020. At the same time, the company also invested $9 million in a new stave mill facility in Washington County, which started production in March 2020.

Speyside’s continued investment and expansion in three regions of Virginia is a powerful testament to the Commonwealth’s plentiful resources, access to markets, and commitment to partnership.

2

Speyside Bourbon Cooperage, Inc., Smyth County

World-Class Logistics Infrastructure

In Virginia, a modern and expanding network of roads, railways, ports, and airports allows for efficient operational logistics — domestically and internationally — and a consistent flow of cargo. Virginia’s transportation system is integrated with the Eastern United States’ vast network of highways, interstates, and double-stack freight rail. This transportation system connects several important manufacturing and population centers across the Southeast, Northeast, and nation’s Heartland with The Port of Virginia’s three deepwater marine terminals in Norfolk Harbor and two inland port locations. The port, through its $1.4 billion Gateway Investment Project, is expanding its assets, capabilities, and reach and creating one of the most advanced ports in the Western Hemisphere.

2 nd densest roadway and railway networks in the Southeast

6 major interstates, including major North-South and East-West trucking routes

3,000 miles of railways (anchored by Class I railroads CSX and Norfolk Southern)

300 k + tons

of air cargo handled annually by Washington Dulles International Airport

28 8 1 3 1 7 3 6 0 5 8 5 8 2 9 3 3 ¡ 2 3 1 9 30 1 25 0 2 1 1 50 1 22 0 22 1 1 5 6 0 7 7 7 5 2 6 8 5 9 5 6 4 7 7 9 5 7 1 7 0 6 8 7 9 6 4 4 0 4 0 4 0 6 6 6 4 8 1 8 1 95 85 95 6 4 2 9 77 77 TENNESSE E KE N TUCK Y OHI O WES T VIRGIN I A NO R TH CAROLI N A M A R Y L AN D DE L A W AR E NEW JERSEY BWI CHO DCA GSO IAD LWB LYH ORF PHF RDU RIC ROA SHD TRI TYS SBY Bristol Charlottesville Nor folk Richmond Roanoke Danville Winchester Kn oxvill e Charles to n Baltimo re G reensbo ro Raleig h Washington, D.C Commercial Airpor t The Por t of Virginia 6 4 Interstate 5 8 U.S. Highway 288 State Route Railroad

One of the Most Advanced Ports in the U.S.

5 terminals comprise The Port of Virginia and operate on a combined 1,577 acres, including three deepwater terminals

41 minutes

average turn time for motor carriers in 2022, significantly below the industry standard of 60 minutes

180 k teu s

of paperboard, paper, and wood pulp moved through The Port of Virginia in 2022

$1.4 billion modernization and expansion project on track to create the deepest, widest, and safest commercial shipping channels and harbor on the East Coast

Decarbonizing

The port is committed to decarbonizing its entire operation and becoming a net-zero carbon emissions port by 2040

Source: The Port of Virginia

Virginia International Gateway, Portsmouth

Thriving Wood Products Industry Ecosystem

Illustrative Examples

Virginia’s thriving wood products ecosystem provides companies with access to the suppliers, partners, and customers they need to prosper. Sustained by Virginia’s abundant, renewable timber resources, this industry ecosystem spans the entire value chain, from forestry to primary wood processing, manufacturing of engineered and finished wood products and paper and packaging, and a growing wood byproducts industry.

Wood Products Value Chain in Virginia

Virginia’s wood products industry spans the entire value chain, from a thriving forestry sector to primary wood processing, engineered wood products, finished wood products manufacturing, paper and packaging manufacturing, and a growing wood byproducts industry. In this thriving ecosystem, companies have access to the suppliers, partners, and customers they need to prosper.

Sawmills

Virginia’s 150+ sawmills, which employ more than 4,100 people, produce primarily hardwood (72% in 2016). In 2019, Virginia had a total production of over a half million MCF of timber production resulting in nearly 7 billion board feet. ArborTech in Blackstone is the largest producer of southern yellow pine board footage. Virginia is the northernmost state with access to yellow pine.

Engineered wood products (mass timber)

Virginia is home to 99 companies, employing over 5,700 people, that manufacture a wide range of traditional and innovative wood products — veneer, plywood, engineered wood products, and similar products.

Finished wood products (furniture, cabinets, etc.)

Virginia is home to 450+ companies that produce finished wood products like furniture and cabinets, and employ almost 10,000 people. Historically, Virginia was part of an industry cluster that constituted a third of furniture manufacturing in the U.S. Finished wood products remain a thriving industry subsector in Virginia, as furniture companies have moved toward higher-end manufacturing.

Paper and packaging

Virginia’s 120+ paper and packaging companies, which employ almost 8,000 people, include major Fortune 500 companies like WestRock and International Paper. Several regions across Virginia have paper packaging clusters such as the Roanoke Region, Greater Richmond, and the Shenandoah Valley due to their strategic proximity to major interstates and customers.

7

WestRock Company Produces Sustainable, Innovative Packaging in Virginia

WestRock Company, headquartered in Norcross, Ga., was formed in 2015 by a merger of MeadWestvaco and RockTenn, creating what is now the second-largest American packaging company and one of the largest paper and packaging companies in the world. WestRock employs approximately 3,500 workers across its nine Virginia facilities, primarily manufacturing paperboard and container board products. The company’s locations throughout the Greater Richmond region remain the center of its consumer packaging business, which represents about half of its $14.5 billion annual revenue. In 2018, WestRock announced plans to invest $248.4 million over a five-year period in its manufacturing operations in the city of Covington, the company’s largest facility in Virginia manufacturing cardboard packaging, and in Alleghany County. These investments will be used to purchase new equipment designed to improve productivity at the paper mill and extruding facility, as well as to increase employee training.

WestRock has built a strong reputation for sustainable forestry and positive environmental practices. The company focuses on partnering with local landowners to source its fiber and is committed to responsible procurement and maintaining certifications to the Sustainable Forestry Initiative® (SFI®), Forest Stewardship Council® (FSC®), Programme for the Endorsement of Forest Certification (PEFC™), Brazilian Forest Certification Program (CERFLOR®) standards, and the American Tree Farm System® Group Certification process. WestRock is also a member of the Recycling Partnership, based in Falls Church, which focuses on building stronger recycling systems. The company’s commitment to improving sustainable environmental practices goes far beyond recycling — WestRock advocates for responsible consumption of resources and has set sustainability goals for water use, recycling, and energy efficiency. To better pursue these endeavors, the company sits on the Board of Forestry in Virginia and has closely partnered with the U.S. Department of Forestry (DOF) to ensure the sustainable consumption and care of forest lands.

WestRock, Richmond

WestRock, West Point

WestRock, Richmond

WestRock, West Point

8

Because healthy, sustainable forests are essential to Virginia’s economy, the Virginia Department of Forestry (VDOF) works to support forests through an array of programs. Through a statewide network of professional foresters and technicians, VDOF helps forest landowners by providing timber harvest inspections and technical assistance on forest management, harvesting, water compliance, reforestation, sustainable practices, and wildfire protection.

Virginia’s 68,000 acres of state forests are managed by VDOF and certified to the standards of both the Sustainable Forestry Initiative and the American Tree Farm System. The Reforestation of Timberlands (RT) program, managed by VDOF and funded by the forest industry and the state, has been helping Virginia landowners grow pines for more than 40 years. For owners of non-productive, cutover, or worn-out agricultural lands, an investment in pine trees can yield many benefits. RT reimburses landowners for a portion of the total costs (typically $70 to $200 per acre) to successfully grow a crop of pines.

9

The Turman Group, Bedford

The Virginia Department of Agriculture and Consumer Services (VDACS) supports the state’s robust agricultural and forestry industries by helping producers and processors grow their business, build their brands, and locate the best markets for their products, both domestically and abroad.

In 2012, Virginia established an economic development incentive program created specifically to suit the unique aspects of forestry. Administered by VDACS, the Governor’s Agriculture and Forestry Industries Development (AFID) Fund is used by the Commonwealth in partnership with local governments to support new and expanding forestry businesses that are committed to sourcing wood products from Virginia landowners, loggers, and sawmills. Past recipients of AFID funding include sawmills, kiln operators, mulch and soil companies, and manufacturers of varied wood products including millwork, trailer bed flooring, and miscellaneous building components.

A third-generation family business established in 1954, Woodgrain Inc. is one of the largest millwork operations in the world, with 25 locations and approximately 3,000 employees across the United States and Chile. With more than 65 years of quality craftsmanship and service, the company produces the highest quality wood moldings, doors, and windows. Woodgrain, Inc. is vertically integrated, which allows the company to oversee every step of the supply chain, from owning forests and cutting timber at state-of-the-art sawmills to final millwork production in a network of manufacturing facilities nationwide.

Woodgrain operates one of its six U.S. millwork manufacturing facilities in Smyth County, employing over 175 Virginians and sourcing 100% of its timber from Virginia forests. Over the past 20 years, Woodgrain has expanded this facility several times with support from the Commonwealth. In 2016, Virginia partnered with Woodgrain through the Governor’s AFID program to incentivize the creation of 17 new jobs and increased production at the facility. When the company decided to expand further in 2021, Woodgrain again received AFID funding to not only create 80 new jobs at this facility, but also purchase, improve, and expand an existing sawmill in Grayson County, retaining 80 jobs and creating 20 new jobs.

10

Dynamic Centers of Innovation

Virginia ranks 11th nationwide and 2nd in the Southeast in research spending in areas relevant to wood products manufacturing. Virginia’s university-based research activity encompasses a wide array of disciplines relevant to the wood products sector — industrial and manufacturing engineering, geological and earth sciences, and natural resources and conservation, among others. The Virginia Tech Center for Forest Products Business has been a national leader in research on and promotion of cross-laminated timber for over a decade.

Department of Forest Resources and Environmental Conservation, Virginia Tech

Virginia Tech’s Department of Forest Resources and Environmental Conservation is one of the top programs in natural resource management in the U.S., including majors such as forest management and urban forestry.

Department of Forest Resources and Environmental Conservation, Virginia Tech

Virginia Tech’s Department of Forest Resources and Environmental Conservation is one of the top programs in natural resource management in the U.S., including majors such as forest management and urban forestry.

11

The Southern Virginia Higher Education Center (SVHEC) has distinguished itself through cutting-edge research, including in the area of wood products. In 2020, marking its tenth anniversary, SVHEC’s R&D Center for Advanced Manufacturing & Energy Efficiency rebranded as ProductWorks@SVHEC. ProductWorks provides small and medium-size businesses with three core services: technology adoption, applied research, and short-production runs. From design planning and prototyping to testing and small production runs, ProductWorks is a one-stop shop where technology, creativity, and industry insight connect.

Virginia Tech Department of Sustainable Biomaterials and SVHEC’s R&D Center collaborated to produce and press cross-laminated timbers (CLT) using southern yellow poplar, a hardwood species abundant in the southeastern United States. Historically, hardwoods have been used very little in CLT production, but the SVHEC staff helped attract market awareness to CLT as suitable for a wide range of building applications. Through this project, ProductWorks connected with Virginia Tech’s College of Architecture and Urban Studies to design and build a train-viewing platform for the City of Radford. Plans are to continue additional research on other hardwood species such as soft maple, oak, and sweetgum. SVHEC R&D is also working with advanced manufacturing in training on CNC routers that can be used to customize CLT panels.

Mountain Gateway Community College, formerly Dabney S. Lancaster Community College, is one of only 24 colleges and universities across the country and the only one in the state of Virginia to offer a Society of American Foresters — accredited Associate of Applied Science degree in Forest Management Technology.

Mountain Gateway Community College’s Forest Management Technology Associate of Applied Science degree program trains individuals planning to enter forestry and forestry-related technical positions. This program is designed with the fundamental philosophy of delivering classroom instruction with hands-on experience. Students use industry-standard equipment and gain practical experience through summer internships regionally and across the country with organizations such as the U.S. Forest Service, Virginia Department of Forestry, and private sector forestry employers. Coursework includes Forest and Wildlife Ecology, Dendrology, Forest Mensuration, Forest Management, Forest Mapping, Applied Silviculture, Forest Protection, Timber Harvesting, Sawmilling, and Forest Products.

Mountain Gateway Community College

Mountain Gateway Community College

America’s Top State for Talent

Ranked No. 1 in the U.S. for education by CNBC, Virginia is home to more than 225,000 workers in the wood products industry and related occupations. Employers can draw from the tens of thousands of skilled manufacturing workers in Virginia and from the thousands of service members who exit the armed services in the Commonwealth each year. Virginia is home to excellent K-12 schools — No. 1 in the South and No. 5 in the U.S. according to WalletHub — and the No. 2 higher education system in the U.S. according to SmartAsset, ensuring a steady flow of new talent every year.

The Virginia Talent Accelerator Program — VEDP’s world-class customized talent acquisition and training solution — is available to new and expanding companies to ensure they can quickly attract and onboard high-quality employees. The program is offered at no cost to qualified companies as an incentive for job creation. As an alternative, Virginia Jobs Investment Program (VJIP) grants are available for companies that prefer to manage their own recruitment and training.

13

A Search for Talent Leads England Furniture to Virginia

England Furniture has crafted quality upholstered furniture since 1964 and offers customers a competitive selection of over 500 fabrics and leathers from which to choose. With its efficient manufacturing capabilities and customizable products, England attracted the attention of La-Z-Boy Incorporated in 1995 and has operated as an independent division ever since.

The company had several potential expansion locations to choose from at the start of its search; however,

Southwest Virginia presented a unique opportunity to secure a large, infrastructure-ready facility in proximity to its existing headquarters less than 60 miles away.

England Furniture has maintained a commitment to employing the hardworking people of Appalachia since its founding. By exploring sites near its Tennessee headquarters, the company was able to access the new talent it needed for growth in Virginia while staying true to its target workforce.

14

England Furniture, Lee County

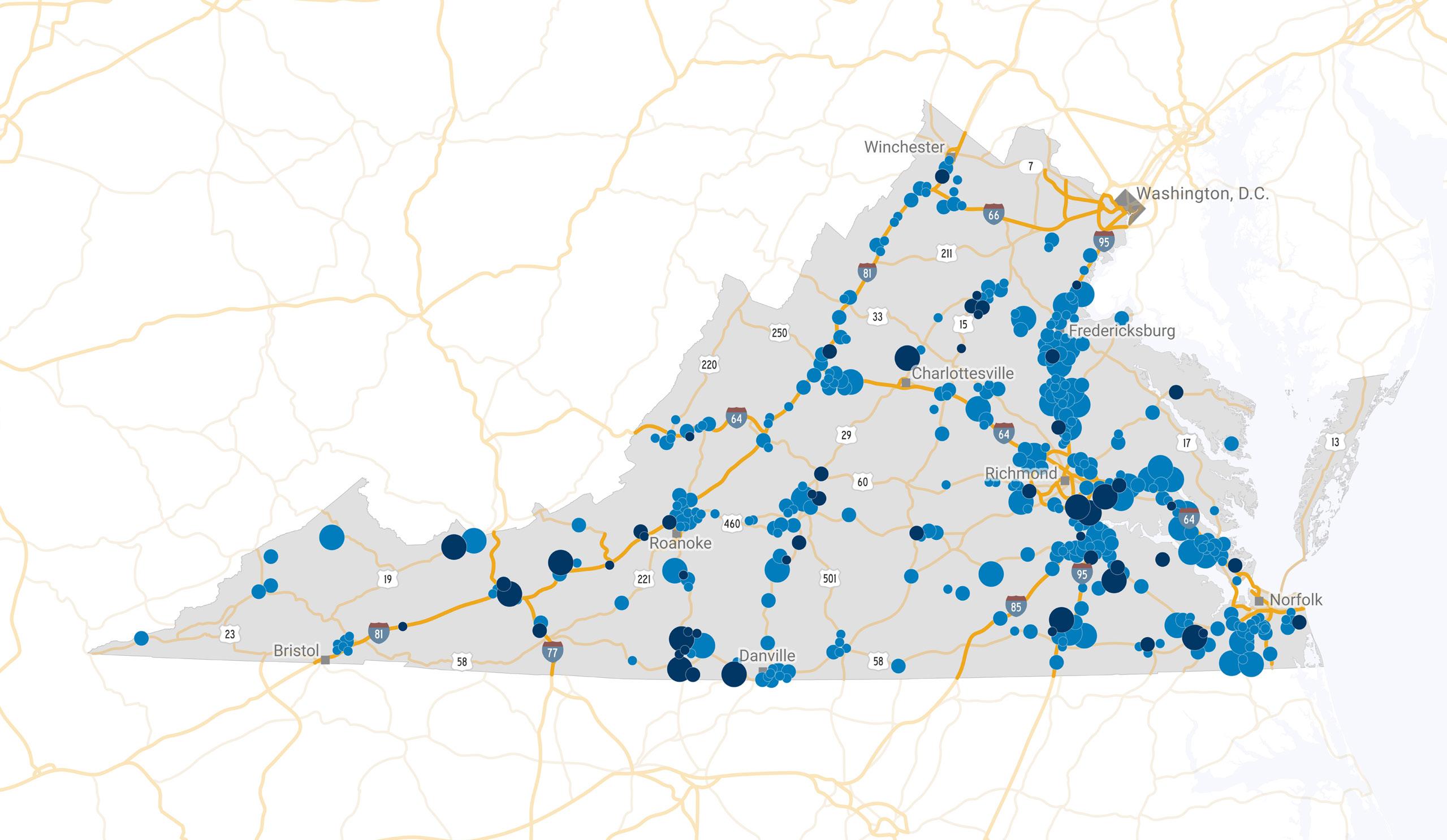

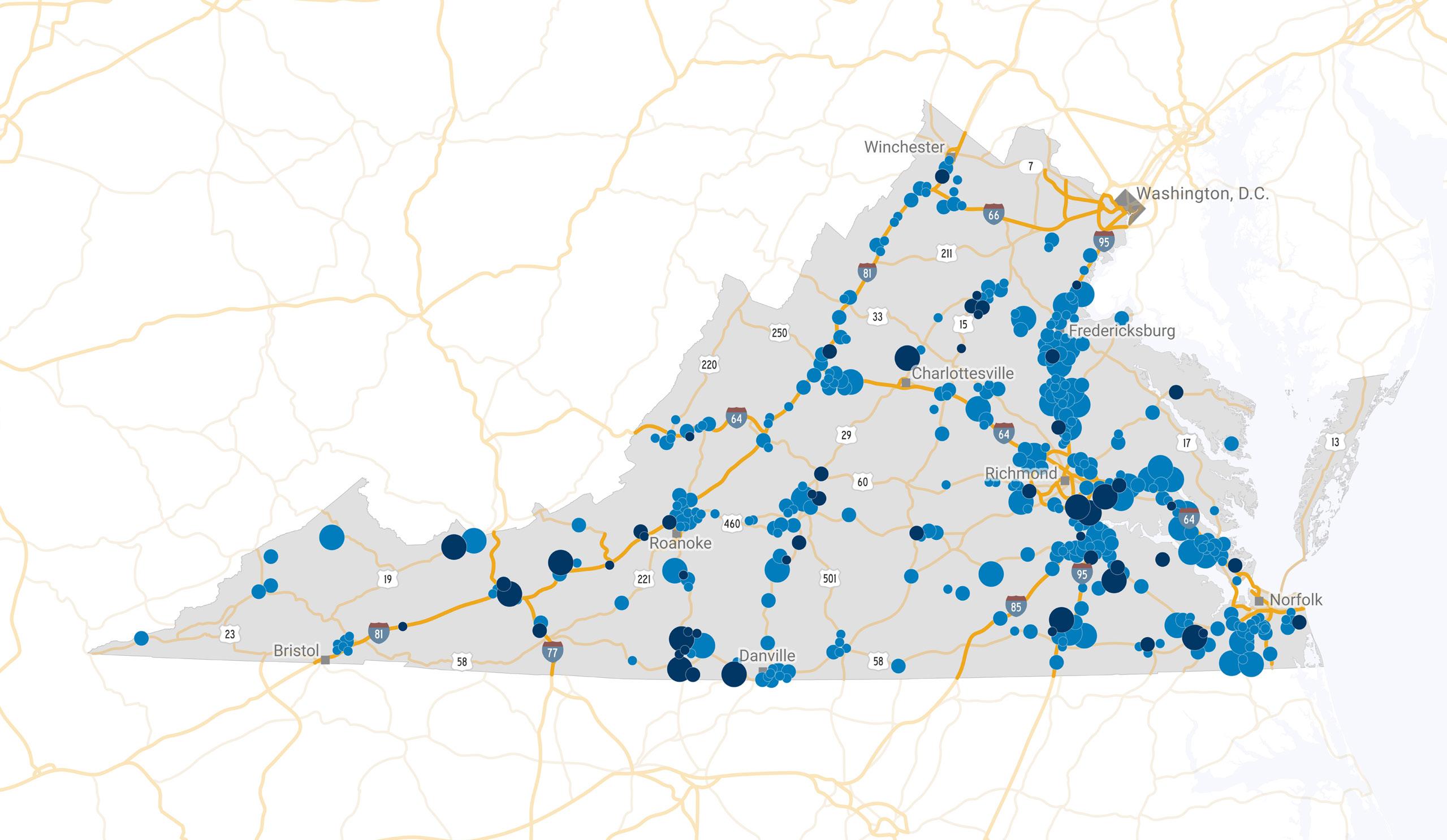

Robust Portfolio of Project-Ready Sites

With 300+ fully characterized sites of 25 acres or larger, dozens of certified sites, and a growing inventory of spec buildings and virtual buildings, Virginia is continuously expanding its portfolio of real estate options for the wood products industry. Companies looking for ready-built options have ample choices among the thousands of existing buildings with space for lease, representing over 20 million square feet of industrial space for lease, including more than 440 industrial buildings with 10,000 or more square feet available. Construction is underway on an additional 14.6 million square feet of industrial space.

and certification status of sites across Virginia

40+ sites are certified as project-ready under the Virginia Business Ready Sites Program

12 of Virginia’s certified parks have graded pad sites available for construction

12-18 mos. for project-ready sites to have utilities on-site and all infrastructure in place

Size

15

We have absolutely amazing crews down here in Virginia, and the community support and welcome from Henry County and Westmoreland County during the transition has been incredible. Every step of the way, the folks at VEDP, VDACS, and the local economic development arms have been looking for ways to help us build a stronger foundation for our mills and employees. We plan on putting down deep roots here in Virginia.

DICK JONES President, Teal-Jones Group

We studied several of our East Coast production facilities for expansion but selected our Ridgeway, Virginia, location for multiple reasons, including the solid workforce, proximity to customers, and supply chain logistics. Adding hardwood plywood production to our current lamination and fabrication capabilities provides a great product synergy. This, coupled with our neighboring supply partner, Southern Finishing in Martinsville, enables us to bring a lot of value to the market.

CEO

CEO

President,

Bassett Furniture Industries, Inc., Henry County

RANDY JOSEPH

&

Laminate Technologies, Inc.

President,

Bassett Furniture Industries, Inc., Henry County

RANDY JOSEPH

&

Laminate Technologies, Inc.

16

LL Flooring (Formerly Lumber Liquidators), Henrico County

Franklin Lumber, Isle of Wight County

Trex Company, Frederick County

LL Flooring (Formerly Lumber Liquidators), Henrico County

Franklin Lumber, Isle of Wight County

Trex Company, Frederick County

Attractive, Stable, and Predictable Operating Environment

Ranked as a Top State for Business by CNBC, Virginia is frequently recognized for its favorable regulatory climate and consistently rated one of the best-run states in the country. Having maintained an AAA bond rating since 1938, longer than any other state, Virginia offers a stable tax environment and competitive wages, construction costs, and industrial lease rates. Virginia also has one of the oldest right-to-work laws and the 5th-lowest private-sector unionization rate in the country at 2.4%.

Virginia is the northernmost right-to-work state along the I-95 Corridor.

Virginia has had a stable 6% corporate income tax rate, one of the lowest in the nation, since 1972. Sound economic policy and prudent financial management has earned Virginia an AAA credit rating since 1938 — longer than any other state.

18

Exceptional Quality of Life

With a competitive cost of living, a mild four-season climate, and a diverse range of natural and cultural attractions, Virginia offers an exceptional quality of life. Vibrant urban centers and picturesque small towns are alive with arts, culture, history, and stunning landscapes. Outdoor enthusiasts are within easy driving distance to the scenic shorelines of Virginia’s beaches and rivers as well as hiking trails and mountain vistas. For these reasons and many others, Forbes ranked Virginia No. 1 in the U.S. for Quality of Life.

Tinker Cliffs, Botetourt County

Virginia Creeper Trail, Washington County

Tinker Cliffs, Botetourt County

Virginia Creeper Trail, Washington County

19

The Omni Homestead Resort, Bath County

Smith Mountain Lake, Bedford County

Old Town Winchester

Sandbridge, Virginia Beach

Smith Mountain Lake, Bedford County

Old Town Winchester

Sandbridge, Virginia Beach

20

Carpenter Theatre, Richmond

Expertise • Collaboration

Solutions

The Virginia Economic Development Partnership’s team of dedicated and knowledgeable professionals is committed to Virginia’s economic success, and connects industry-leading businesses to the resources they need to make relocations and expansions successful. From site selection, customized research, cost analysis, and coordination with public and private partners, to discretionary incentives and workforce solutions, VEDP’s services are tailored to companies’ unique requirements.

To learn more about VEDP’s expertise and resources, visit VEDP.org.

© August 2023

The Spearhead Trails in Southwest Virginia’s Appalachian Mountains boast more than 500 miles of ATV, bike, and hiking trails of varying difficulties convenient to the towns of Coeburn and St. Paul.

The Spearhead Trails in Southwest Virginia’s Appalachian Mountains boast more than 500 miles of ATV, bike, and hiking trails of varying difficulties convenient to the towns of Coeburn and St. Paul.

• Innovation •

Enviva, Chesapeake

Virginia Tech

American Woodmark, Frederick County

Speyside Bourbon Cooperage, Inc., Washington County

Trex Company, Frederick County

Enviva, Chesapeake

Virginia Tech

American Woodmark, Frederick County

Speyside Bourbon Cooperage, Inc., Washington County

Trex Company, Frederick County

WestRock, Richmond

WestRock, West Point

WestRock, Richmond

WestRock, West Point

Department of Forest Resources and Environmental Conservation, Virginia Tech

Virginia Tech’s Department of Forest Resources and Environmental Conservation is one of the top programs in natural resource management in the U.S., including majors such as forest management and urban forestry.

Department of Forest Resources and Environmental Conservation, Virginia Tech

Virginia Tech’s Department of Forest Resources and Environmental Conservation is one of the top programs in natural resource management in the U.S., including majors such as forest management and urban forestry.

Mountain Gateway Community College

Mountain Gateway Community College

CEO

CEO

President,

Bassett Furniture Industries, Inc., Henry County

RANDY JOSEPH

&

Laminate Technologies, Inc.

President,

Bassett Furniture Industries, Inc., Henry County

RANDY JOSEPH

&

Laminate Technologies, Inc.

LL Flooring (Formerly Lumber Liquidators), Henrico County

Franklin Lumber, Isle of Wight County

Trex Company, Frederick County

LL Flooring (Formerly Lumber Liquidators), Henrico County

Franklin Lumber, Isle of Wight County

Trex Company, Frederick County

Tinker Cliffs, Botetourt County

Virginia Creeper Trail, Washington County

Tinker Cliffs, Botetourt County

Virginia Creeper Trail, Washington County

Smith Mountain Lake, Bedford County

Old Town Winchester

Sandbridge, Virginia Beach

Smith Mountain Lake, Bedford County

Old Town Winchester

Sandbridge, Virginia Beach

The Spearhead Trails in Southwest Virginia’s Appalachian Mountains boast more than 500 miles of ATV, bike, and hiking trails of varying difficulties convenient to the towns of Coeburn and St. Paul.

The Spearhead Trails in Southwest Virginia’s Appalachian Mountains boast more than 500 miles of ATV, bike, and hiking trails of varying difficulties convenient to the towns of Coeburn and St. Paul.