Building Progress with Responsibility

Sustainability Report 2024

Sustainability Report 2024

At VCON, we believe that true progress means leaving no one behind, not our people, not our communities, and certainly not our planet. Sustainability has been more than a goal for us, it has been a fundamental part of who we are for over 50 years. It shapes how we build, how we innovate, and how we care.

This year, we are proud to share the progress of our Environment, Social, and Governance (ESG) journey. Guided by a long-term vision and grounded in daily action, our sustainability strategy is built on three core pillars: People, Planet, and Progress.

Our commitment to people begins with education, equality, and wellbeing. We partner with universities across Thailand to educate civil engineering students on sustainable design principles and material selection. Through our VCON Seminar Program, we offer real-world exposure to green construction practices, nurturing the next generation of builders.

At the same time, we remain deeply invested in our own employees. From promoting health and safety on-site to offering long-standing scholarship programs for employees’ children, we continue to create opportunities for families to grow and thrive.

Our efforts to protect the planet are visible in the everyday decisions we make. We’ve launched reforestation projects to restore biodiversity and absorb carbon emissions around our facilities. Our wastewater treatment systems help conserve millions of gallons of water, while our recycling and waste separation programs support a circular economy across our operations.

At employee residences, we’ve created sustainable food systems including vegetable gardens and fishponds that reduce both commuting emissions and food expenses, empowering our people to live more self-sufficiently.

And in the name of Progress, we continue to lead through innovation. VCON’s precast products are designed to reduce the use of concrete, steel, and gasoline while maintaining industry-leading performance and durability. We’ve embraced low-carbon cement and are actively working toward a clean energy transition. These innovations are not just technical upgrades, they are strategic choices aligned with our net-zero vision.

Together, these actions form a sustainability framework rooted in purpose, responsibility, and innovation. They reflect our belief that construction can be both strong and sustainable and that every beam, every slab, and every structure can help shape a more equitable and resilient world.

Thank you for joining us on this journey as we continue to build tomorrow, sustainably.

Ken Chaichanavong Managing Director, VCON Group

At VCON, we believe that the strength of our company lies in the health and wellbeing of our people. We are proud to share our progress in building a safer, healthier, and more equitable future for our workforce.

Our commitment begins with creating a physically safe environment for all employees. We work hand-in-hand with our team members to plan tasks carefully and ensure they are equipped with the tools and knowledge necessary to return home safely to their families each day. Recognizing the inherent risks in factory settings, we’ve taken proactive steps to reduce the likelihood of injuries and workplace accidents through rigorous safety protocols, ongoing training, and comprehensive risk assessments.

We understand that true health goes beyond physical safety. Our wellness initiatives are designed to support the whole person, addressing both physical and mental wellbeing. Employees have access to health and wellness professionals and programs that promote work-life balance, mental resilience, and long-term vitality.

To maintain a healthy work environment, we continuously monitor key environmental indicators across all our business units, including temperature, air quality, and water quality. In particular, we take extra measures to protect our team from exposure to harmful substances such as cement dust and airborne particulates associated with concrete manufacturing.

We have installed industrial dust collection systems and localized ventilation units at high-exposure points throughout our factories. Regular maintenance of machinery and real-time monitoring help ensure airborne particle levels remain well below occupational safety thresholds.

Given the nature of our industry, exposure to cement dust is one of the most significant occupational health risks. VCON has invested heavily in engineering controls to reduce airborne contaminants, including enclosed mixing stations, sealed conveyor systems, and negative-pressure zones in high-risk areas. Employees working in these zones are provided with personal protective equipment, including respirators and protective eyewear, and undergo mandatory safety training sessions focused on dust exposure prevention.

We also conduct regular air quality audits and employee health screenings to detect early signs of respiratory conditions, ensuring swift medical intervention if needed. Our approach is preventive, systematic, and based on international occupational health standards.

VCON has implemented annual health check-up programs for all employees to detect and address potential health issues early. In parallel, we have put in place a comprehensive system of risk assessments, preventative controls, and transparent reporting to ensure continuous improvement in workplace health and safety. We also maintain detailed incident logs and use them as learning tools to refine our safety protocols each year.

100% of employees and subcontractors receive annual health check-ups

Quarterly safety training and risk assessments across all sites

Dust control systems installed at all high-risk production points

NIOSH-certified PPE provided for respiratory protection

Onsite and referral access to mental wellness professionals

Ongoing goal: Zero serious workplace accidents by 2030

SDG Alignment: United Nations

Sustainable Development Goal 3 –Ensure healthy lives and promote wellbeing for all at all ages

At VCON, we believe that shaping the future of sustainable construction starts in the classroom. Through active engagement with local universities and the next generation of civil engineers, we’re helping future professionals build the skills, confidence, and values needed to lead the industry forward.

Throughout 2024, VCON organized over 14 VCON’s NextGen Engineering Program Seminars at 11 leading universities

Chulalongkorn University

Thammasat University

King Mongkut’s Institute of Technology

Srinakharinwirot University

Mahidol University

Naresuan University

Pibulsongkram Rajabhat University

Rajamangala University of Technology

International Partners

National Polytechnic Institute of Cambodia

INSA Toulouse, France

The University of California, San Diego, USA

Where our engineering team introduced civil engineering students to innovative low-carbon construction materials and sustainable design principles. These interactive sessions focused on practical applications from low-carbon cement, materials optimization and precast innovation to energy-efficient systems and climate-resilient infrastructure tailored to the challenges of urban development in Southeast Asia.

As part of our long-term investment in education, VCON has also hosted the VCON Externship Summer Program for the past 10 consecutive years, providing over 350 students with firsthand experience in real-world construction environments.

Externs work alongside our engineering teams on major infrastructure and commercial projects in Bangkok, learning about project planning, green building standards, and digital tools like Building Information Modeling (BIM).

10 Consecutive Years of Hosting Excellence

Externs work alongside our engineering teams on major infrastructure and commercial projects in Bangkok. Green building standards

This year, we were especially proud to welcome a record number of female civil engineering students into the externship program, a 24% increase from previous years. Many expressed a strong interest in pursuing full-time careers with VCON. By encouraging and supporting gender diversity, we aim to dismantle the misconception that construction and site-based roles are only for men. At VCON, we believe civil engineering is for everyone and we’re committed to creating opportunities where all individuals can thrive.

To deliver these programs, VCON’s engineers took on roles as mentors, discussion leaders, and event organizers. From guiding students through hands-on learning zones to sharing peer-to-peer career insights, our team provided students with a comprehensive, industry-informed learning experience that bridged the gap between classroom theory and field application.

These initiatives reflect VCON’s broader ESG mission under the pillars of People, Planet, and Industry:

Educational Initiative Highlights Empowering Future Builders: Key Achievements

People: Promoting diversity, education, and future employment pathways

Planet: Advocating for lowcarbon materials and sustainable design Industry: Developing the skills and knowledge needed to transform how we build

Aligned with the UN Sustainable Development Goals particularly SDG 4 (Quality Education) and SDG 5 (Gender Equality) VCON is committed to nurturing the next generation of builders who will lead the way in sustainable, inclusive construction.

Together, we are building more than structures ,we are building futures.

14+ Seminars Organized 11 Universities Engaged 10 Years of Externships

350+ Students Hosted 24% Increase in Female Externs

the

Education

At VCON, we believe in building a stronger future not only through sustainable construction but also by investing in the education of our people’s families. For over 35 years, the VCON Scholarship Program has supported the children of our employees in achieving their academic goals and unlocking new opportunities.

Every quarter, scholarships are awarded to children of VCON employees regardless of whether their parents work in blue-collar or white-collar positions who maintain a minimum GPA of 3.0 or a “B” average. This commitment to educational equity ensures that all qualifying children are given the same opportunity to thrive, regardless of their family’s position within the company.

The scholarship supports academic expenses at any accredited school or university of the student’s choice, helping to ease the financial burden of higher education. Applications are made available through our Human Resources Department, and our team ensures fair and transparent administration of the program.

Over 1,500 scholarships awarded to employees’ children 98% of recipients have earned a bachelor’s degree 62% of graduates pursued degrees in engineering and related fields Many alumni have returned to work at VCON, while others have joined multinational corporations, contributing to society and industry on a global scale.

This long-standing initiative is more than just financial aid, it’s a symbol of VCON’s commitment to uplifting families and breaking the cycle of poverty through education. By helping employees' children access quality education, we are not only changing individual lives but also strengthening communities.

Many scholarship recipients are now the first in their families to graduate from university, an achievement that inspires younger siblings and neighbors to follow in their footsteps.

Through this program, VCON continues to promote social mobility, equal opportunity, and a culture that values education as a cornerstone of sustainable development.

At VCON, our employees are at the heart of everything we do. We believe that a diverse and inclusive workplace fosters innovation, collaboration, and sustainable growth. Our commitment is to ensure every employee feels supported, included, and empowered to thrive in a culture that values difference and provides equitable opportunities for advancement.

Since the launch of our inclusion efforts in 2021, we have remained focused on creating a work environment where equity and representation are integral to our operations. Our Inclusion Action Committee, established in 2021, comprises leaders from across the country and drives our strategic initiatives. The committee has set forth a 2032 Vision to achieve diversity and equitable representation at all organizational levels

To support this mission, we created the Diversity Advocate Network, which champions inclusive principles and helps challenge unconscious bias. These advocates lead diversity action plans and participate directly in recruitment and talent development processes to ensure fair and equitable outcomes for all employees

We are committed to eliminating bias in every stage of the employee lifecycle from recruiting and hiring to promotion and compensation. Our non-discrimination policy applies across procurement, staffing, advancement, and remuneration. All employees are evaluated based solely on performance and merit.

To ensure transparency and accountability, we offer a confidential reporting channel that connects directly to the Managing Director and Board, allowing employees to safely report any misconduct or concerns.

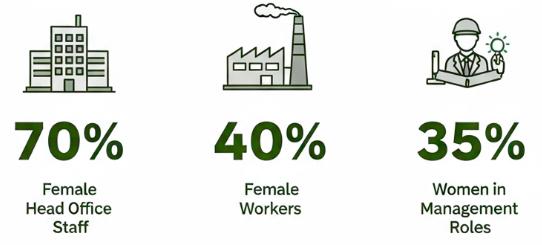

70% of head office staff and 40% of factory workers are female an average increase of 10% annually since 2021.

35% of management roles are held by women, significantly surpassing the construction industry average. Our goal is to reach over 40% female representation in management by 2032.

We actively promote LGBTQIA+ recruitment and foster an inclusive culture.

We host two LGBTQIA+ awareness events annually, with a 90% employee participation rate.

We have maintained a record of zero complaints related to sexual harassment or discrimination based on sexuality.

VCON Talk Panels feature speakers and discussions centered on diversity and inclusion.

We offer special leave policies for pre and post maternity to support employees' family needs.

We will continue to expand our workforce while maintaining a strong focus on inclusive hiring, particularly among recent college graduates. Our goal is to foster an inclusive culture where diverse perspectives are represented and valued at every level.

Our DEI efforts align with the United Nations Sustainable Development Goal 5: Gender Equality. By promoting female leadership, protecting gender and sexual identity rights, and embedding fairness into every policy, we are proud to contribute to a more equitable and just global workforce.

At VCON, we are committed to building an inclusive and equitable workplace by actively hiring individuals with disabilities Our hiring policy ensures equal access to employment opportunities, and we thoughtfully assign work that matches each person's unique abilities and strengths. By tailoring roles to fit individual capabilities, we create a supportive environment where everyone can contribute meaningfully and thrive.

Mr. Piya Chatwattananon

Having a company that understands my abilities instead of focusing on my limitations has made a big difference in my confidence and motivation."

Mr. Narean PHEA TRA

From the moment I joined, I’ve felt welcomed and supported. The team has gone above and beyond to make sure I have everything I need to succeed."

At VCON, we are committed to reducing our environmental impact by minimizing water usage and protecting biodiversity and ecosystems. Clean, accessible water is essential not only for human health but also for building a sustainable future. However, water resources are increasingly under threat due to unsustainable management practices and climate change.

This issue is especially important to VCON, as our precast concrete production process consumes a significant amount of water at every stage of its lifecycle. Preparing for a future of potential water scarcity is critical to our long-term success and our positive impact on surrounding communities.

VCON is committed to reducing freshwater consumption by an average of 5% per year across all operations, starting from our 2022 baseline. By 2030, our goal is to achieve a cumulative 25% reduction in water use and maintain a water recycling rate of at least 75% at all production facilities. This target aligns with UN Sustainable Development Goal 6 (Clean Water and Sanitation) and reflects our commitment to sustainable manufacturing and resource efficiency.

Beyond factory operations, our approach includes testing and piloting water and waste reduction strategies across VCON offices and staff residences. We are actively identifying opportunities to convert wastewater into clean water. Recently, we installed water meters on job sites to measure and monitor consumption, which represents our first step toward establishing a data baseline and evaluating future water conservation strategies.

To address this challenge, we have implemented a closed-loop water recycling system at our production facilities. This system captures wastewater generated from our manufacturing processes and treats it through sedimentation, filtration, and purification. The result is clean, reusable water that is reintegrated into our operations for concrete mixing, equipment washing, and dust suppression dramatically reducing our reliance on freshwater and minimizing environmental discharge. This initiative reflects our commitment to circular economy principles and sustainable factory operations.

Since the launch of our recycling system, VCON has reduced its annual water usage by 3–5%, based on a baseline of 6,340,128 US gallons per year. Over the past three years, this has resulted in an estimated total savings of over 760,000 US gallons. These results demonstrate measurable, ongoing progress in water efficiency and sustainability.

This figure represents the average annual water consumption across VCON’s four factories, based on operations running at approximately 80% production capacity and reflecting reductions achieved through our closed-loop recycling systems.

While carbon emissions have historically been the central environmental focus in the construction industry, we recognize that water use, recycling, and biodiversity are equally critical. At VCON, we are proactively expanding our environmental strategy to address these interrelated challenges and drive meaningful change across the industry.

Reduction Rate -

Number of Sites with Meters Installed

per year Consistent yearly improvement

This figure represents the average annual water consumption across VCON’s four factories, based on operations running at approximately 80% production capacity and reflecting reductions achieved through our closed-loop recycling systems.

As a recognized leader in construction innovation, VCON is deeply committed to sustainability and environmental responsibility. In alignment with global climate goals and OECD policy frameworks on green growth and the circular economy, VCON launched the “VCON Eco-Friendly Structures: Transforming the Construction Industry” seminar series. Held every two months, this recurring event brings together thought leaders to explore solutions for reducing the industry’s carbon footprint while maintaining structural performance and economic viability.

The most recent seminar was successfully hosted at The Renaissance Bangkok Hotel on February 28, 2025. The event convened a distinguished group of architects, project developers, and structural engineers to share knowledge and best practices. This initiative is part of VCON’s broader mission to promote resource-efficient, low-carbon construction aligned with international sustainability standards.

February 28, 2025

Advance green and low-carbon construction practices through consistent knowledge exchange and technical dialogue.

Showcase sustainable precast concrete innovations that reduce material usage while preserving durability. Support OECD-aligned policies on circular economy, infrastructure resilience, and lifecycle design

Facilitate cross-industry collaboration to accelerate the adoption of environmentally responsible construction methods

Attendees explored how advancements in precast concrete technology can lower the environmental impact of construction. VCON shared its approach to reducing cement and steel usage, two major contributors to embodied carbon without compromising structural integrity or building longevity.

VCON experts emphasized design strategies that minimize material consumption while optimizing strength and performance. Lifecycle assessment methodologies were highlighted as essential tools for understanding long-term environmental impacts, in line with OECD recommendations.

The seminar highlighted strategies to reduce construction waste and promote reuse. Techniques such as reusable precast concrete and light weight structures were presented as effective methods to reduce excess material and improve sustainability outcomes.

Sessions addressed construction waste separation, digital tracking systems, and on-site recycling processes. Presenters shared datadriven insights into how waste diversion strategies can dramatically reduce landfill contributions and support circular economy objectives.

To reinforce the urgency of sustainable construction, VCON presented industryspecific carbon emissions data that highlighted the sector’s contribution to global greenhouse gas outputs Statistics on the embodied carbon in cement, steel, and construction processes were shared to contextualize the impact of building material choices and design strategies.

By providing clear, visualized emissions figures, the seminar empowered participants, particularly project owners and designers, with a deeper understanding of their role in climate change mitigation The data-driven presentation helped stakeholders recognize how practical changes in material selection, structural systems, and waste handling can result in substantial carbon reductions across a building's lifecycle.

This evidence-based approach reinforced the importance of proactive decisionmaking and the tangible environmental benefits of adopting green construction principles

By hosting this seminar series every two months, VCON fosters continuous engagement, encourages iteration on sustainable practices, and provides a platform for emerging technologies and pilot project outcomes. This frequency ensures the initiative remains dynamic, relevant, and responsive to industry challenges.

By hosting this seminar series every two months, VCON fosters continuous engagement, encourages iteration on sustainable practices, and provides a platform for emerging technologies and pilot project outcomes. This frequency ensures the initiative remains dynamic, relevant, and responsive to industry challenges.

The “VCON Eco-Friendly Structures” seminar series is a cornerstone of VCON’s corporate social responsibility strategy. By driving innovation in green construction and aligning with both OECD principles and the United Nations Sustainable Development Goals, VCON is actively shaping a more sustainable future for the construction industry. Through recurring knowledge-sharing, cross-sector collaboration, and a clear focus on climate impact, VCON continues to lead the way in responsible, forward-thinking infrastructure development

This seminar series directly supports the following UN Sustainable Development Goals:

SDG 9: Industry, Innovation and Infrastructure – Encouraging sustainable industrial development through advanced construction technologies.

SDG 11: Sustainable Cities and Communities – Supporting the development of inclusive, resilient, and low-impact urban environments

SDG 12: Responsible Consumption and Production – Promoting efficient resource use and minimizing construction waste.

SDG 13: Climate Action – Driving carbon reduction across the built environment.

SDG 17: Partnerships for the Goals – Building collaborative networks across disciplines to scale sustainable solutions.

SDG 11: Sustainable Cities and Communities

SDG 12: Responsible Consumption and Production

The United Nations Sustainable Development Goals (UN SDGs) offer a universal framework for addressing global challenges, including poverty, inequality, environmental degradation, and climate change.

The following section explores how innovative approaches in green precast concrete support and advance a selection of these goals. Through the application of resource-efficient technologies, low-carbon practices, local economic development, and strategic partnerships, these initiatives not only enhance ASEAN’s infrastructure but also contribute to the global movement toward sustainable development.

As the global construction industry continues to grapple with its environmental impact, companies are increasingly under pressure to adopt sustainable practices

Accounting for over 39% of carbon dioxide emissions worldwide, the building and construction sector is both a major contributor to climate change and a key driver of potential solutions.

VCON’s sustainability efforts center on advanced green precast concrete technologies designed to significantly reduce carbon emissions at every stage of the product lifecycle. By combining innovations in material science, precision manufacturing, and energy efficiency, VCON has emerged as a regional leader in low-carbon construction materials.

A landmark achievement was realized in 2024 when VCON’s Hollow Core Slabs were recognized as Thailand’s lowest carbon emissions concrete flooring system These slabs use 40% less cement and raw materials while maintaining superior structural performance. VCON incorporates low-carbon cement in their production, further reducing emissions by minimizing traditional clinker use and replacing it with more sustainable alternatives. Remarkably, if reused, these slabs can reduce carbon emissions by up to 80% compared to conventional cast-inplace, post-tensioned, or solid precast floor systems.

VCON’s manufacturing process is highly automated and optimized to minimize waste, water usage, and energy consumption. By replacing traditional castin-place methods, the Hollow Core Slabs allow for faster installation, lower transportation emissions due to their lighter weight, and reduced on-site disruption.

Over the past 50 years, VCON’s introduction of hollow-core technology has had a significant environmental impact. If conventional solid concrete slabs had been used instead, carbon emissions would have totaled approximately 4.2 million tons of CO₂. Thanks to our innovative approach, emissions were limited to just 1.9 million tons, preventing over 2.3 million tons of CO₂ from entering the atmosphere.

That’s equivalent to the carbon absorption capacity of 150 million trees or about 60,000 hectares of forested land, an area roughly the size of Nonthaburi Province in Thailand or the city of Portland, Oregon.

These estimates are based on VCON’s production and distribution data in Thailand and were calculated using industry-aligned carbon accounting practices.

Beyond product design, VCON applies industrial symbiosis principles by recycling concrete slurry, reusing water in production, and sourcing supplementary cementitious materials to replace clinker in cement. These measures help decrease embodied carbon and align with life-cycle thinking, in support of SDG 12 (Responsible Consumption and Production) and SDG 13 (Climate Action)

VCON also invests in green cement technologies and collaborates with cement suppliers and academic institutions to improve mix designs for maximum sustainability.

By emphasizing innovation over mere compliance, VCON actively contributes to SDG 9 (Industry, Innovation, and Infrastructure). These efforts not only lead to more sustainable construction practices but also demonstrate the business case for green building throughout Southeast Asia.

Looking ahead, VCON aims to scale its impact further by exploring carbon capture integration, transitioning to renewable power sources, and expanding the application of its low-carbon precast solutions across residential, commercial, and infrastructure projects throughout the ASEAN region.

VCON’s dedication to low-carbon innovation in the precast concrete industry exemplifies how sustainable industrial practices can be embedded into modern construction. With internationally recognized products like its awardwinning Hollow Core Slabs, the company has set a regional benchmark for carbon-efficient flooring systems.

By aligning its business strategy with key UN SDGs particularly those addressing innovation, climate action, responsible production, and infrastructure VCON has created a replicable model of success for other manufacturers aiming to decarbonize their supply chains. As global climate commitments tighten, VCON is positioned to be a key enabler of the transition to a more resilient, low-carbon built environment.

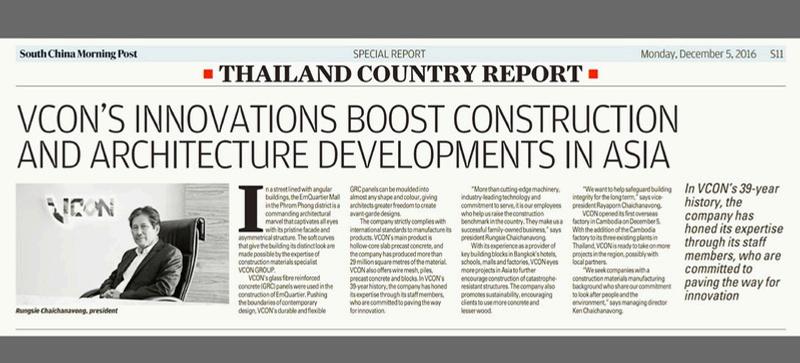

Hong Kong, showcasing our pioneering role in transforming the construction and architecture industries across Asia The article highlights VCON’s commitment to sustainable innovation developing advanced construction solutions that significantly reduce the use of traditional materials like concrete and steel.

impact while maintaining structural integrity and performance. This recognition in SCMP reinforces our leadership in sustainable construction technology and our vision for a more responsible future in urban development.

VCON was honored to be invited to the Road to Net Zero 2024: The Extraordinary Green event, hosted by Thansettakij, Thailand’s leading economic newspaper. At this major sustainability forum, VCON showcased its latest green precast concrete innovations designed to reduce PM2.5 pollution and tackle the challenges of climate change. Highlighting the company’s leadership in sustainable construction, VCON’s Managing Director also spoke at the event, sharing insights on how the company is driving innovation to help build a greener future for Thailand.

In 2024, VCON was proudly recognized by the Thailand Greenhouse Gas Management Organization (TGO) for producing the lowest carbon emission precast concrete slabs in the country. This prestigious award highlights VCON’s commitment to sustainability and innovation in construction materials, setting a new standard for eco-friendly building solutions in Thailand.

VCON’s Vice President was honored to speak at the Innovator X Festival 2024, where she shared valuable insights on low-carbon precast concrete and its role in advancing sustainable construction. Her presentation highlighted VCON’s commitment to innovation and environmental responsibility, inspiring professionals across the industry to adopt greener building practices. The session sparked engaging conversations and positioned VCON as a leader in the push toward a more sustainable future in construction.

Architects from the Association of Siamese Architects visited VCON to learn more about our innovative low-carbon precast concrete solutions. The visit highlighted VCON’s commitment to sustainable construction technology and fostered valuable knowledge exchange

Among the distinguished guests was Patikorn Na Songkhla, Senior Architect at Architects 49 Limited and board member of the Association, whose presence underscored the importance of this collaboration.

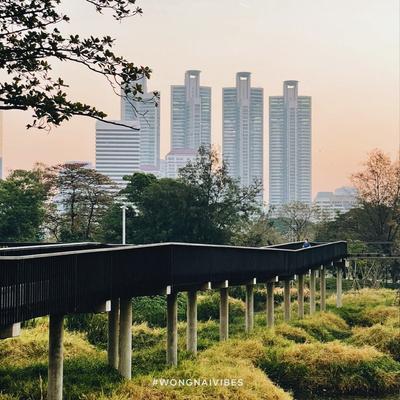

In the heart of Bangkok’s green oasis, Benjakitti Park, VCON’s low-carbon precast concrete slabs were used to create an elevated skywalk that seamlessly blends with the natural surroundings. Designed for sustainability, these eco-friendly slabs offer durability and strength while reducing environmental impact. The skywalk enhances the park’s role as the “lung of Bangkok,” giving visitors a unique view of the landscape and promoting green urban development through smart, responsible construction.

VCON's Green Concrete Wall Technology Leads to Over 937 Tons in Carbon Savings for New Toyobo Indorama Facility.

In 2022, VCON proudly supported Toyobo Indorama in their mission to produce sustainable, high-performance nylon yarn for automobile airbags by supplying over 198,917 square feet of green precast concrete wall for their new yarn manufacturing facility in Rayong, Thailand.

Built on IPI factory site, the project utilized VCON’s innovative 6-inch thick green hollow core wall system, significantly reducing the environmental impact of construction. This eco-friendly approach resulted in a carbon savings of more than 937 tons equivalent to preserving over 56,672 trees demonstrating VCON’s commitment to advancing sustainable building solutions in the industrial and automotive textile sectors.

VCON’s green precast concrete innovation is featured in Southeast Asia Building magazine, Singapore edition. The article highlights a strong commitment to sustainable construction, showcasing how eco-friendly precast solutions are contributing to the future of urban development in the region.

This recognition underscores VCON’s role as a leader in environmentally conscious innovation across Southeast Asia.

In 2024, VCON was honored with the prestigious BCI Asia Award for Sustainability in Design, presented by Ms. Pailin Teansuwan, Advisor to the Minister of Industry. The award recognizes VCON’s groundbreaking work in low-carbon construction, particularly its Hollow Core Slabs Thailand’s lowest carbon-emission concrete flooring system.

By incorporating low-carbon cement and significantly reducing raw material usage, these slabs offer substantial environmental benefits through reuse. VCON’s innovations set a new benchmark for sustainable building practices across Southeast Asia.

At VCON, we understand the profound impact that waste has on both society and the environment. As part of our long-term commitment to sustainable operations, we have taken proactive steps to reduce our environmental footprint. Since 2018, VCON has implemented a robust waste reduction strategy focused on effective waste management and trash separation across all production facilities.

Our program centers on the systematic separation of waste into categories such as recyclable, organic, hazardous, and general waste. This process improves recycling efficiency, minimizes landfill contributions, and reduces the risk of environmental contamination.

Color-coded bins, clear signage, and operational protocols are in place at all factory sites to ensure proper waste handling. Regular internal audits and process reviews help us continually improve the system.

We believe our employees are critical to the success of our sustainability initiatives. All team members receive training on waste separation practices, with updated materials provided regularly to align with evolving environmental standards.

In addition, we host an annual Waste Separation Week, a company-wide event designed to reinforce sustainable habits through hands-on activities, interactive workshops, and team-based challenges. This initiative helps embed a culture of environmental awareness throughout the organization

Our impact extends beyond the workplace VCON actively engages with nearby residential communities through educational outreach, encouraging responsible waste practices at home. By empowering individuals with practical knowledge, we foster a broader culture of environmental stewardship.

Community outreach educates and promotes ecofriendly habits.

Engagement fosters adoption of better waste management practices.

Collaboration builds trust, enhancing program effectiveness.

Through these efforts, VCON has achieved measurable reductions in waste sent to landfills, increased recycling rates, and enhanced awareness among employees and residents.

Additional benefits include improved cleanliness in factory environments, fewer pest-related issues, and safer, more sustainable workspaces.

Together, we are transforming waste into opportunity for our business, our communities, and our planet.“

VCON’s waste reduction program aligns with UN Sustainable Development Goal 12: Responsible Consumption and Production. Our initiatives directly support the goal’s targets to reduce waste generation through prevention, reduction, recycling, and reuse.

By integrating sustainability into our daily operations, VCON is helping to advance a circular economy and ensure more responsible use of natural resources.

�� Green Bars (left side of each year):

Waste per Employee (kg)

This metric shows the annual amount of waste generated by each employee. From 2018 to 2024, this value dropped from 250 kg to 120 kg per employee a 52% reduction, highlighting significant progress in waste management efficiency.

�� Grey Bars (right side of each year):

% Reduction from 2018

This indicates the percentage decrease in waste generated per employee, relative to the 2018 baseline. The reduction has grown steadily from 0% in 2018 to 52% in 2024, demonstrating continuous improvement in waste efficiency over the seven-year span.

VCON achieved a 52% reduction in waste from 2018–2024.

This was through employee engagement and behavior shifts. The target of 120 kg/employee was reached in 2024.

For over four decades, VCON has maintained a unique initiative that supports both employee welfare and environmental sustainability across all our factory locations. By regularly releasing fish into the ponds located in front of employee housing and allocating space for vegetable gardens behind the apartments, VCON empower its workforce to access fresh, sustainable food sources directly on-site.

This initiative not only reduces the financial burden of food expenses but also minimizes the environmental impact associated with frequent travel to external markets.

Internal surveys indicate that employees who utilize the fishponds and cultivate vegetables are able to save up to 20% of their monthly income on food.

This program has become a cornerstone of VCON’s commitment to improving the quality of life for its employees while encouraging sustainable practices.

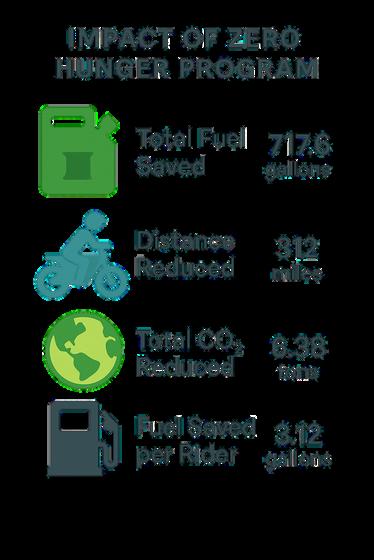

Out of all VCON employees, approximately 230 individuals regularly commute by motorbike. As a direct result of access to on-site food, these employees have reduced their trips to local markets from three times per week to twice. This behavioral shift has led to measurable environmental benefits.

Based on data collected before and after we implemented the Zero Hunger Program

Round-trip distance to market: 6 miles

Reduction in weekly trips per rider: 1

Annual distance reduction per rider: 312 miles

Average motorbike fuel efficiency (small commuter bikes): 100 miles per gallon

Annual fuel saved per rider: 3.12 gallons

Total annual fuel savings across 230 riders: 717.6 gallons which translates to a reduction of about 6.38 metric tons of CO₂ emissions annually.

TotalAnnualFuelConsumptionBeforeAnd AfterZeroHungerProgram(230Riders)

These savings contribute directly to a lower carbon footprint and reflect our broader commitment to reducing Scope 3 emissions within our operations.

This initiative illustrates how VCON integrates environmental, social, and economic considerations into its operations. By supporting on-site food production and reducing the need for motorized travel, we not only improve the lives of our employees but also advance our environmental sustainability goals. These efforts align with our broader ESG strategy and Thailand’s national objectives for sustainable development.

Social

Support on-site food production

Reduce motorized travel

Align with national sustainability goals

Environmental & Governance

Conduct business responsibly

Enhance efficiency

Support Thailand’s development objectives

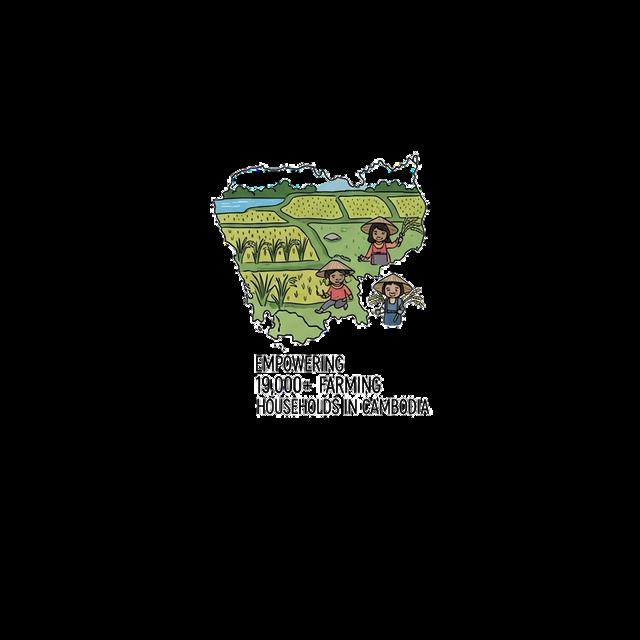

As part of our commitment to sustainable development and regional progress, VCON proudly supported the Cambodia Agricultural Value Chain Program (CAVAC) , an initiative funded by the Australian Government. CAVAC’s mission is to boost incomes for Cambodian farmers involved in rice-based farming systems by accelerating growth across the agricultural value chain.

To contribute to this critical program, VCON supplied precast concrete gutters manufactured with American prestressed concrete technology. This advanced engineering method delivers exceptional strength, durability, and efficiency key features required for high-performance agricultural infrastructure.

VCON’s involvement included:

Producing modular precast concrete gutter units tailored for efficient water flow. Using prestressing techniques to increase load capacity and extend service life. Coordinating with local contractors to ensure smooth installation within the irrigation system.

CAVAC recognizes that improving irrigation is essential to increasing agricultural productivity. To help farmers grow more high quality rice and vegetables, they must have dependable access to water and strong market links.

VCON’s precast gutter systems helped advance these goals by Accelerating construction through off-site fabrication. Enhancing water distribution by improving canal stability and flow efficiency. Reducing maintenance needs, thanks to high-quality, durable materials.

Our work supported the construction and rehabilitation of vital irrigation infrastructure, enabling better water management and long-term agricultural benefits.

of June 2015)

By mid-2015, the CAVAC program had achieved significant milestones

Approximately 19,000 farming households directly benefited.

Over 20,000 hectares of farmland received year-round access to water. Farmers were able to produce an additional 218,000 tons of rice annually, valued at roughly USD 43 million.

VCON’s innovative infrastructure solutions were instrumental in making these outcomes possible, helping farmers raise their productivity and income levels.

19,000+

Farming households directly benefited from improved irrigation infrastructure and water management systems implemented through the CAVAC program.

20,000+

Hectares of farmland now have year-round access to water through the advanced precast concrete gutter systems, enabling consistent crop production regardless of seasonal variations.

218,000+

Additional tons of rice produced annually by participating farmers, valued at approximately USD 43 million, demonstrating the significant economic impact of the program.

Our Ongoing Commitment to Sustainability

This project reflects VCON’s broader commitment to:

Empowering rural communities through smart, sustainable infrastructure. Reducing environmental impact with modern construction technologies. Partnering with government and development organizations to foster inclusive growth.

VCON continues to align its Corporate Social Responsibility (CSR) efforts with the United Nations Sustainable Development Goals (SDGs), especially

SDG 2: Zero Hunger

SDG 6: Clean Water and Sanitation

SDG 8: Decent Work and Economic Growth

At VCON, we recognize that preserving biodiversity is essential to maintaining the health and resilience of our natural environment. As part of our Environmental, Social, and Governance (ESG) strategy, we are committed to understanding our impact on ecosystems and implementing meaningful mitigation and restoration efforts.

"ENHANCING BIODIVERSITY THROUGH RESEARCH AND RESPONSIBLE PRACTICES”

Our project teams are actively studying the environmental impact of our operations to better understand how we can protect and enhance biodiversity. These assessments inform our approach to site development, construction, and land use, ensuring that we prioritize ecological balance alongside industrial progress.

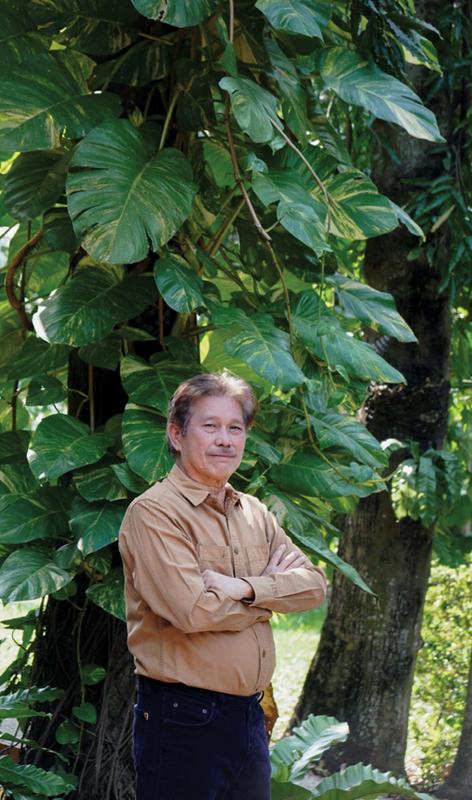

We will enhance our culture of sustainability, invest in learning opportunities for our people, expand our green network across the company, and continue to achieve the evolving green building goals of clients.

Rungsie Chaichanavong Chairman VCON

VCON fosters a culture of environmental stewardship. Through employee-led volunteer initiatives such as reforestation programs, we contribute directly to biodiversity conservation. Since 1972, VCON employees have planted more than 100,000 trees in local communities supporting habitat restoration,

Trees provide numerous benefits to society. They filter pollutants, produce oxygen, store carbon, protect watersheds, and serve as critical habitats for countless species. Our tree planting initiatives not only benefit the environment but also strengthen the well-being of the communities in which we operate.

VCON has established a long-term reforestation goal of planting at least 2,000 teak trees annually on unused company land, in local forests, and within public green spaces. Teak trees, a native and long-lived species, play a significant role in carbon sequestration. A mature teak tree can absorb more than 20 kilograms of carbon dioxide each year, helping mitigate the effects of climate change.

To ensure lasting impact and accountability, we have implemented a comprehensive monitoring system to track the condition and growth of all planted trees. This data-driven approach enables us to evaluate tree health, survival rates, and environmental outcomes over time.

To date, the 100,000 teak trees planted by VCON employees since 1972 have collectively sequestered an estimated 80,000 metric tons of CO₂.

Each mature tree can absorb up to 20 kilograms of carbon dioxide per year. It’s important to note that this rate applies only to fully grown, healthy trees, young or newly planted trees absorb significantly less during their early years.

Looking ahead, our continued commitment to planting 2,000 teak trees each year is expected to generate even greater environmental returns. Over the next 40 years, this initiative is projected to remove an additional 32,800 metric tons of CO₂ from the atmosphere, further reinforcing our contribution to climate action and biodiversity restoration. This reforestation program directly supports the United Nations Sustainable Development Goals, particularly SDG 13: Climate Action, SDG 15: Life on Land, and SDG 11: Sustainable Cities and Communities, as we work to build greener, more resilient ecosystems for future generations.

We believe biodiversity conservation must be a collaborative effort. VCON actively engages with local communities to identify opportunities for habitat restoration and environmental education. These partnerships allow us to maximize our positive impact and foster shared responsibility for the ecosystems we rely upon.

Looking Forward

VCON’s commitment to biodiversity is a core element of our broader sustainability vision.

We will continue to expand our conservation programs, invest in ecological research, and engage our workforce and partners in protecting the natural world. Through these actions, we aim to create lasting value for both the environment and the communities we serve.

Strengthen Climate Action

Supporting global and local climate goals through significant carbon sequestration.

Restore Biodiversity

Increasing the diversity of life and enhancing local ecosystems.

Build Resilient Ecosystems

Preparing robust natural environments for future generations.

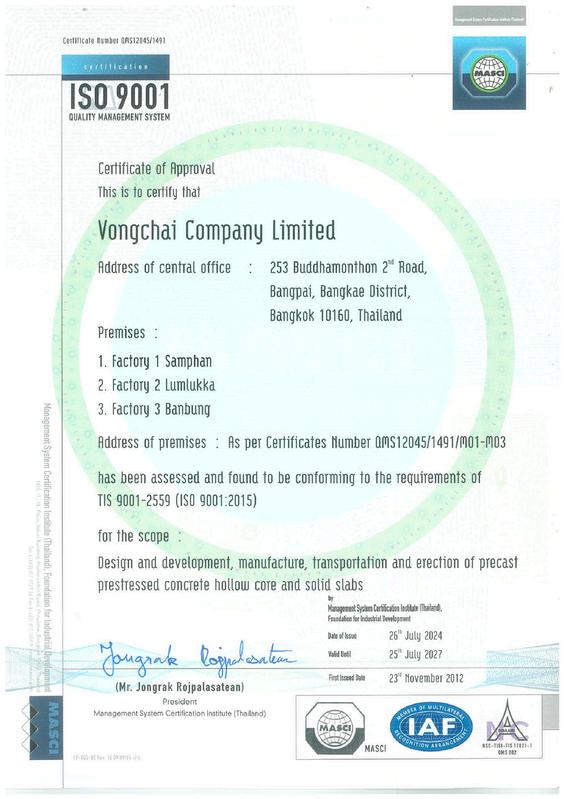

At VCON, we are committed to maintaining the highest standards of operational excellence, integrity, and accountability. Central to this commitment is our dedication to standardized, secure, and transparent processes that support sustainable and responsible growth. To achieve this, we align our operations with internationally recognized ISO certifications, which serve as benchmarks for quality, safety, efficiency, and environmental responsibility.

These certifications provide a robust framework that enables VCON to demonstrate our adherence to global best practices across various aspects of our business. By integrating ISO standards into our core operations, we ensure consistency, reliability, and accountability in everything we do.

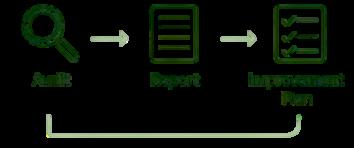

To ensure our processes remain effective and aligned with international standards, VCON undergoes regular audits conducted by independent third-party organizations. These audits are essential to verifying our compliance and assessing the performance of our internal systems.

This external validation not only reinforces trust with our stakeholders but also helps us identify opportunities for improvement. Through these regular assessments, we cultivate a culture of continuous improvement, ensuring that our operations evolve in step with industry advancements and regulatory expectations.

A proactive approach to risk management is a cornerstone of our operational strategy. VCON regularly conducts comprehensive risk assessments to identify, evaluate, and address potential threats that could impact our employees, clients, partners, or business continuity.

Based on these assessments, we implement targeted mitigation measures designed to reduce exposure and enhance resilience.

Whether through improved workplace safety enhancements, or process safeguards, we prioritize risk reduction to protect our stakeholders and maintain operational excellence.

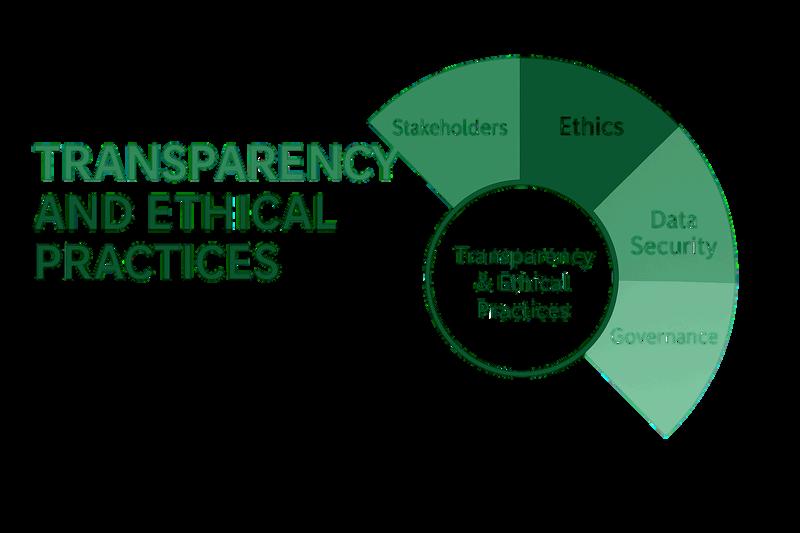

Transparency, ethical conduct, and data security are fundamental principles that guide VCON’s operations. We have established strong internal controls and governance structures to ensure that our business practices are both accountable and aligned with our values.

providing regular updates on our performance, compliance efforts, and CSR initiatives.

This transparent approach builds trust and demonstrates our integrity as a responsible business leader.

Through our commitment to ISO standards, independent audits, robust risk management, and transparent operations, VCON continues to uphold the highest levels of professionalism and responsibility.

These efforts are not only a reflection of our core values but also a strategic foundation for long-term success and stakeholder confidence.

Since its founding, VCON has been a proud member of the American Concrete Institute (ACI) and the Precast/Prestressed Concrete Institute (PCI), based in Illinois, USA. This long-standing affiliation has enabled us to set a new world-class standard for precast concrete construction in Southeast Asia.

We design and manufacture our green precast concrete products in full compliance with ACI and PCI standards, ensuring they meet the highest levels of performance, safety, and sustainability. These American codes guide our innovations and are deeply embedded in our design processes, manufacturing systems, and construction methodologies.

By integrating these globally respected standards, VCON not only elevates the quality and efficiency of construction in Thailand but also acts as a catalyst for the wider adoption of sustainable, high-performance building practices across the region.

VCON plays an active role in strengthening Thailand’s labor force by sharing U.S.-based civil engineering knowledge and practices. Our internal training programs and technical workshops are built around ACI and PCI principles, providing construction professionals with the expertise to apply world-class methods in their daily work.

We also organize seminars and technical sessions at Thai and Cambodian universities, as well as with professional bodies such as the Association of Siamese Architects, the Thailand Structural Engineers Association, and the Thai Concrete Association. At these events, our engineering team shares practical insights into American precast concrete technology. They serve as platforms for knowledge transfer, helping students, educators, and professionals understand how U.S. standards can support more sustainable and efficient construction in Thailand.

Through our internship program, VCON provides university students with first-hand experience working in a professional environment that applies ACI and PCI codes at every stage from design to production to installation.

These students are mentored by experienced engineers, enabling them to apply theoretical knowledge in a hands-on, real-world context. This not only enhances their skills but also positions them as future leaders in Thailand’s construction industry.

At VCON, we are committed to bringing U.S. green precast concrete innovations to Southeast Asia. Our mission is to not only implement these technologies, but to actively promote their benefits through education, collaboration, and outreach.

We partner with universities, industry stakeholders, and public agencies to demonstrate how ACI and PCI-based systems can support Thailand’s infrastructure and climate goals.

By localizing and sharing U.S. precast concrete standards, VCON helps unlock new opportunities for Thai workers, students, and communities. From upskilling the workforce to inspiring sustainable construction careers, our initiatives ensure that the benefits of American engineering excellence are felt across generations and geographies.

At VCON, we are dedicated to advancing the United Nations Sustainable Development Goals (UNSDGs) a global framework of 17 goals aimed at ending poverty, protecting the planet, and improving the quality of life for people around the world.

We actively incorporate the UNSDGs into our business operations and strategic planning, using them as a foundation to measure and track our social, environmental, and economic impact. By aligning our initiatives with these global objectives, we partner with governments, businesses, and organizations to help create a more sustainable and inclusive future.

This commitment reflects VCON’s mission to drive responsible innovation, support the communities we serve, and contribute meaningfully to long-term global progress.

At VCON, sustainability has never been a solo endeavor. From the beginning, we understood that our vision to build in ways that are environmentally responsible, socially conscious, and economically viable could only be realized through strong, intentional partnerships.

It started with a simple question: What more could we achieve if we aligned our values across the entire ecosystem of clients, suppliers, government, and industry leaders alike?

The answer led us down a path of collaboration.

With our clients, we moved beyond transactional relationships to form sustainability alliances. In project planning meetings, we found common ground not just in cost or timelines, but in shared environmental aspirations. Whether we were working on green certifications or carbon reduction targets, we co-created strategies that embedded ESG principles at the core of design and construction. These conversations helped us reframe success not only by what we built, but by how responsibly we built it.

Our suppliers and trade partners became another pillar of this effort. We recognized that the choices made upstream how raw materials were sourced, how labor was treated, how emissions were managed had a direct impact on our projects.

So we began asking deeper questions, conducting social impact reviews, and engaging our partners in sustainability workshops. We didn’t just ask for greener materials, we shared why it mattered and worked with them to find better solutions.

Through open dialogue and shared learning, we elevated awareness and fostered accountability throughout our supply chain.

But it wasn’t enough to look inward we also needed to look outward, to the public sector and regulators. Our collaboration with government organizations helped us navigate emerging sustainability frameworks and align with national climate goals. These partnerships provided access to renewable energy incentives, innovation pilots, and critical insights into future policy shifts. More importantly, they reminded us that sustainability is a societal challenge and that our role as builders carries real responsibility.

VCON has built a powerful partnership with Shimizu Corporation Japan, driving innovation in sustainable construction across Thailand and Southeast Asia. United by a commitment to decarbonization, the two companies are working together to bring Shimizu’s “Beyond Zero 2050” Environmental Vision to life on every project site through the use of VCON’s advanced green precast concrete technologies.

Shimizu Corporation brings its worldclass expertise to a wide range of complex and cutting-edge construction projects throughout Thailand. As part of their commitment to environmental responsibility, Shimizu has chosen to incorporate VCON’s Hollow Core Slabs across their ongoing projects in the country.

These precast concrete systems support sustainable construction by using less concrete and steel, generating minimal on-site waste, and eliminating the need for temporary supports. This results in faster build times and greater resource efficiency key advantages that contribute to green building certifications such as LEED, and reinforce Thailand’s broader push toward net zero by 2050

Through it all, we remained active in industry groups, learning from peers, sharing our progress, and contributing to the collective advancement of ESG practices in construction. We spoke on panels, contributed to task forces, and opened our doors to discussions that helped push the entire industry forward.

Looking back, our sustainability milestones didn’t happen in isolation. They were the result of many voices: clients with vision, suppliers with integrity, governments with purpose, and teams with passion coming together with a shared commitment.

And that’s how we continue to build: not just with steel and concrete, but with connection, collaboration, and a belief that we rise by lifting each other and the planet higher.

Shimizu’s “Beyond Zero 2050” strategy is more than just about reducing impact, it’s about creating positive environmental value. With VCON’s support, Shimizu is deploying decarbonized building methods, constructing renewable energy facilities, and advancing zero-waste and biodiversity-focused practices. Together, they are helping redefine what sustainable construction looks like in the region.

The collaboration between VCON and Shimizu represents a strategic alliance grounded in shared values, mutual respect, and a long-term vision for sustainable construction. By working together, both companies are able to integrate innovative green building solutions with a commitment to environmental responsibility and construction excellence.

This partnership reflects a joint pursuit of higher standards in speed, quality, and sustainability, contributing to more efficient project delivery and meaningful progress toward net zero goals. It is not just a collaboration; it is a model for how global and regional leaders in construction can shape a greener future through collective action and innovation.

As part of VCON’s ongoing commitment to responsible industrial development, we partnered with Cheer You Construction Co., Ltd. (CYC) a leading Taiwanese contractor to deliver the Quanta Electronics semiconductor manufacturing facility in Chonburi, Thailand. This collaboration showcases how environmentally conscious engineering and sustainable construction practices can be effectively applied to large-scale, high-specification infrastructure.

Cheer You Construction’s emphasis on circular resource use and carbon footprint reduction aligns with VCON’s own approach to sustainable building. As one of Southeast Asia’s leading precast concrete producers, VCON delivers low-carbon solutions that minimize material consumption, reduce construction waste, and accelerate build times. For this project, VCON supplied hollow core slabs, precast walls, and staircases, all selected for their structural efficiency and environmental performance. These components significantly reduced the use of cement and steel, eliminated the need for temporary formwork, and enabled faster, cleaner installation.

The successful completion of the Quanta facility delivered on time and to international quality standards demonstrates how shared sustainability values can lead to measurable outcomes. The use of precast systems helped lower emissions, reduce noise and site waste, and improve overall safety and cleanliness during construction.

Beyond the technical execution, this project reflects a strategic alignment between VCON and Cheer You Construction. Both organizations regard sustainability not as a peripheral commitment, but as a guiding principle that informs long-term decisionmaking. By bringing together Cheer You’s leadership in environmentally responsible construction and VCON’s expertise in precast innovation, the partnership resulted in a high-performance facility that meets both commercial objectives and environmental benchmarks.

This case serves as a replicable model for sustainable industrial development in Southeast Asia. It directly supports Thailand’s national carbon neutrality roadmap and reflects broader alignment with international ESG frameworks. VCON remains committed to delivering future-ready infrastructure solutions that enable industrial progress while advancing a more resilient and sustainable future.

As Thailand accelerates its shift toward innovation-driven and environmentally responsible development, VCON has taken an active role in forging partnerships that support this national agenda. Our collaboration with the National Innovation Agency (NIA) reflects a shared belief in the power of technological advancement to address environmental challenges and drive systemic change. As a government agency under the Ministry of Higher Education, Science, Research and Innovation, NIA serves as a catalyst for public–private cooperation, policy alignment, and the promotion of forward-thinking solutions that benefit both industry and society. Through this partnership, VCON is proud to contribute to the advancement of lowcarbon construction technologies as part of a broader innovation ecosystem.

This partnership was further strengthened during VCON’s flagship seminar, “Sustainable Concrete Structures” where Dr. Nimit Suksutdhi, Director of the Social Innovation and Entrepreneurship Division at NIA, served as a featured speaker. In his address, Dr. Nimit highlighted the critical role of industry-led innovation in addressing environmental challenges, citing VCON’s green precast concrete systems as a model for low-carbon, highperformance industrial solutions.

Dr. Nimit emphasized that innovations such as VCON’s hollow core precast systems have the potential to support multiple national priorities including the reduction of construction-related carbon emissions and the development of resilient infrastructure in seismic zones. His remarks underscored NIA’s belief that cross-sector collaboration is essential for scaling impactful technologies that contribute to Thailand’s long-term innovation strategy and its transition toward a carbon-neutral future.

This collaboration reflects more than a shared stage; it represents a strategic convergence of values. VCON’s engineering leadership and commitment to climateconscious construction complement NIA’s national mission to foster innovation with social and environmental impact. Together, both organizations are advancing a future where sustainable infrastructure is not just an aspiration, but an achievable standard.

By partnering with NIA, VCON affirms its position not only as a provider of building solutions but as a driver of innovation actively shaping the future of construction through collaboration, technological advancement, and measurable ESG performance.

VCON has partnered with Sansiri Public Company Limited, one of Thailand’s leading real estate developers, to introduce hollow core precast slab systems into Sansiri’s residential construction operations. This collaboration directly supports Sansiri’s “Green Mission” , a bold commitment to achieving net-zero greenhouse gas emissions by 2050, with interim targets of a 20% reduction by 2025 and 50% by 2033. A key pillar of this strategy is reducing construction waste, lowering embodied carbon, and embedding sustainability into core building practices.

Historically, Sansiri utilized traditional solid slab flooring systems in its development methods known to be labor-intensive, waste-generating, and carbon-intensive. Through ongoing technical engagement, engineering demonstrations, and a proven track record of performance, VCON successfully persuaded Sansiri to transition to a more sustainable alternative: the hollow core precast concrete system. By demonstrating the system’s environmental benefits particularly its ability to reduce material consumption, eliminate temporary formwork, and significantly cut CO₂ emissions, VCON positioned its solution as a natural fit for Sansiri’s sustainability goals. This marked a pivotal shift in Sansiri’s approach to residential construction.

Today, Sansiri plans to increase the use of precast systems from approximately 50% to 80%, a move expected to reduce concrete waste by more than 1,600 tons per year and avoid over 48 tons of greenhouse gas emissions annually.

VCON’s hollow core system continues to deliver tangible benefits across Sansiri projects: improved construction speed, reduced on-site waste, and enhanced environmental performance. The system’s structural efficiency has enabled Sansiri to streamline construction without compromising quality directly supporting its lowcarbon, high-efficiency building targets.

This partnership demonstrates how innovation in construction materials can catalyze meaningful change. By integrating VCON’s precast solutions, Sansiri is not only building more efficiently but also advancing its long-term environmental commitments from vision to execution.

Together, VCON and Sansiri are setting a benchmark for sustainable residential construction in Thailand aligning private-sector leadership with national and global climate objectives. VCON remains a trusted partner in delivering scalable, low-carbon building solutions that support a more resilient built environment for future generations.

In its pursuit of environmentally responsible construction, VCON has taken a decisive step toward decarbonizing its building materials by integrating low-carbon cement from Siam City Cement Public Company Limited (SCCC)into its precast production. This collaboration reflects VCON’s material-driven approach to sustainability, where innovation at the raw input level is critical to reducing emissions throughout the entire construction process. By embedding SCCC’s advanced cement technology into its core product lines, VCON is actively transforming how structural systems are designed, produced, and delivered with climate performance in mind from the start.

Siam City Cement is widely recognized as an industry pioneer in low-carbon cement development. Its INSEE Low-Carbon Cement reduces carbon emissions through clinker reduction and the incorporation of supplementary cementitious materials such as fly ash and slag. For every ton of cement used, approximately 50 kilograms of CO₂ emissions are avoided compared to traditional cement yielding measurable, scalable carbon savings, particularly across large precast volumes.

At VCON, this low-carbon cement has been fully adopted across its portfolio of hollow core slabs, precast walls, and stair units, reinforcing the company’s ability to offer structural products that combine high performance with reduced environmental impact. The resulting precast systems retain their strength and durability while delivering significantly lower embodied emissions, an outcome that supports both VCON’s internal carbon goals and its clients’ sustainability commitments.

The use of low-carbon cement has also improved the environmental performance of VCON’s manufacturing operations. With precast production taking place in controlled factory settings, the integration of greener cement contributes to lower energy demand, minimized material waste, and more efficient curing and handling processes. These benefits compound across the construction cycle, reducing overall site emissions and helping to accelerate clean, precise installation at the project level.

This collaboration also reflects a shared commitment to long-term sustainability. Siam City Cement’s Sustainability Ambition 2030 outlines a bold framework focused on climate action, circular resource use, and environmental stewardship values that strongly align with VCON’s own sustainability roadmap. By working together, the two companies are advancing Thailand’s climate goals while setting a new benchmark for carbon-conscious construction across the region.

In today’s rapidly evolving construction landscape, VCON’s partnership with Siam City Cement demonstrates how deep, technical collaboration can lead to real environmental impact. Through this integration of low-carbon cement into precast systems, VCON is delivering not only efficient and reliable building solutions, but also contributing meaningfully to the future of sustainable infrastructure in Southeast Asia.

As we wrap up this year’s ESG report, we want to extend our heartfelt thanks to everyone who played a role in its creation and in driving our ESG strategy forward. Your dedication, hard work, and commitment to sustainability have been key to advancing our shared mission. Every effort from careful data collection to the innovative initiatives highlighted in this report demonstrates our collective drive to build a better, more sustainable future.

The progress we've made together reflects the strength of the VCON community and the power of collaboration. Your contributions have not only helped us reach important ESG goals but have also raised the bar for excellence in our industry. We’re incredibly proud of what we’ve accomplished so far, and with your continued support, we’re confident that even greater milestones lie ahead.

Thank you again for your invaluable contributions and for being an essential part of our journey. Together, we’re making a real difference and setting the foundation for a more responsible and brighter future.

Best,

Rungsie,

Rayaporn, Ken, Udomsak

Rungsie Chaichanavong Chairman

Rayaporn Siribunyawat Vice President

Ken Chaich Managing

ESG

ESG Leadership Team

Rungsie Chaichanavong - Chairman

Rayaporn Siribunyawat - Vice President

Udomsak Markjuy - Director of ESG

Ken Chaichanavong - Managing Director

Working Group Leaders

Jiraporn Lekngam – General Manager

Nattapong Panadit – Assistant Managing Director

Waranya Chanwitthayanuchit – Head of Accounting

Phongphrom Phongnurak – Engineering Manager

Suchin Thonnon Daeng – Installation Manager

Amporn Morarak – Head of Finance

Waraporn Srikot – Head of Purchasing

Buswarin Buranasakun Chai – Head of Audit

Parinya Junthawornpreecha – Head of Human Resources

Thanaporn Suttichai

Monthira Wangboon

Pornphan Thamwattanakul

Kamonchanok Sueatae

Orawan Nimsanga

Kanchanaporn Raksathale

Wanida Palasu

Apichat Paothong

Monthip Kosinanon

Phatthanit Wannawan

Natthawatt Khongkhorat

Sutathip Onkhong

Sukanya Rattannoi

Phisan Sangkaphinyo

Maliwan Nammoon

Chayan Charoenwong

Nattapong Nattapong

Wittaya Khampaktra

Somyot Sawangsi

Thongphim Sringam

Srinuan Kaewkrasae

Chanphen Panyajirawut

Cheewawat Prakhongsin

Kanyarath Saengnak

Napaporn Sombat

Prathumporn Kalampakorn

Sonthaya Saiai

Phichet Siriphot

Phunsap Yuchaem

Manoch Meepansri

Sutath Khamthoonsri

Narongrat Thanasarn

Amarin Ubonhom

Oi Kroppaen

Nanthawan Paechan

Nareerat Meemuk

Ishaya Thanachantaporn

Phit Sisuhong

Panchaphon Sisuhong

Phon Phrommanat

ESG Report Team

Ken Chaichanavong

Udomsak Markjuy

Sirichot Vipharat

Parinya Junthawornpreecha

Waraporn Srikot

This vibrant, sketched graphic represents VCON’s deep-rooted approach to sustainability, a commitment that has been a fundamental part of our identity for over 50 years. It captures our belief that strong, resilient construction can and must be sustainable.

facebook.com/vcongroup

instagram.com/vcongroup

youtube.com/@vcongroup

linkedin.com/company/vcon-group

vconthai.com

lin.ee/3YwiviOg Driven

For information regarding this report, please contact our ESG Department at vcon@vconthai.com

Report Published: July 2025 VCON

253 Buddhamonthon 2nd RD

Bangpai Bangkhae Bangkok 10160

Thailand

Tel: +662-455-0151

© 2025 VCON All Rights Reserved