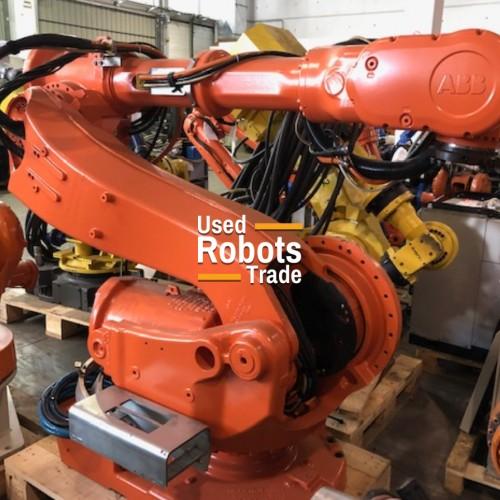

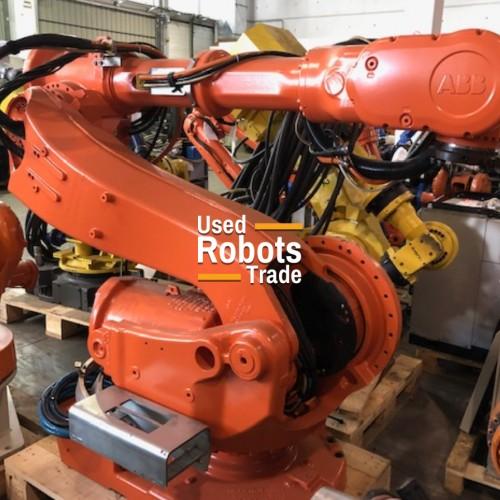

ABB Robotics is a global leader in industrial automation. ABB robots are used in a wide range of industries, including manufacturing, automotive, and food and beverage.

Reliability

ABB robots are known for their reliability and durability. They are designed to operate for years with minimal downtime.

3 Safety

ABB robots are designed with safety features that protect workers and equipment.

2

Flexibility

ABB robots can be easily reprogrammed to perform different tasks, making them adaptable to changing production needs.

4 Efficiency

ABB robots can increase production efficiency by performing tasks faster and more accurately than humans.

Small Robots

Ideal for tasks requiring precision and dexterity, such as assembly and handling small parts.

• IRB 120

• IRB 140

• IRB 1600

Medium Robots Suitable for a wide range of applications, including welding, painting, and material handling.

• IRB 2400

• IRB 2600

• IRB 4600

Large Robots Designed for heavy-duty applications, such as palletizing and machine tending.

• IRB 6700

• IRB 7600

• IRB 8700

ABB robots can work tirelessly without breaks, increasing overall production output.

Robots provide consistent accuracy and precision, leading to fewer defects and higher quality products.

Automation can reduce labor costs, material waste, and production downtime.

By automating dangerous or repetitive tasks, robots help create a safer working environment for employees.

ABB robots are used in a variety of welding applications, including arc welding, spot welding, and laser welding. 2

3

ABB robots are ideal for assembling products with high precision and speed, particularly in industries like electronics and automotive. 4

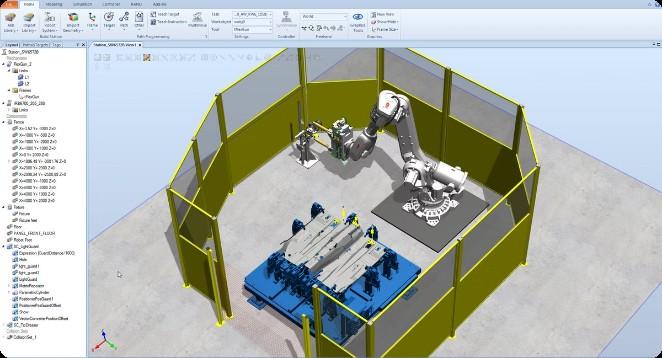

ABB robots can be programmed to operate machinery, such as CNC machines, injection molding machines, and presses, enhancing efficiency and reducing manual labor.

ABB robots can be used for both liquid and powder painting applications, offering precise and consistent results.

ABB robots handle a wide range of materials, from heavy parts to delicate components, in tasks like palletizing, packaging, and loading/unloading. 5

ABB experts can assist in designing a complete robotic system tailored to your specific requirements.

ABB provides intuitive software and programming tools to easily configure and operate your robots.

ABB offers installation and commissioning services to ensure seamless integration of your robots into your production environment.

ABB provides comprehensive maintenance and support services to keep your robots running smoothly and efficiently.

Buy abb robots offers a comprehensive solution for businesses looking to automate their operations. Contact ABB today to discuss your specific needs and explore how robotics can enhance your productivity and profitability.