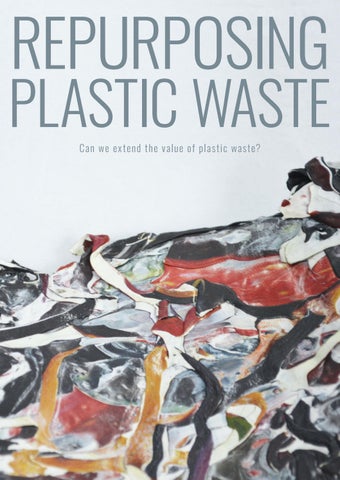

REPURPOSING PLASTIC WASTE

Can we extend the value of plastic waste?

How might plastic waste be reused for a longer life?

‘Around 70 percent of all the litter in the ocean is made of plastic’ and this ongoing issue needs to be improved for the future of our planet. Plastic pollution is a worldwide issue, with rubbish littering the oceans causing detrimental effects to marine life, the oceans eco-system and eventually to us. Even though there are schemes to try and reduce the plastic nightmare such as The Ocean Clean Up, the problem still needs assistance to try and decrease the amount of pollution.

Multiple plastic items end up in our oceans for example, plastic bottles, sachets and carrier bags due to people not recycling efficiently. Plastic bags we use daily can take anywhere from 10 to 1,000 years to decompose. Even though they can be reused their physical makeup and relatively low cost make them appear disposal.

The purpose of this project is to create a new material from carrier bags which can then be applied to create a product. The objective is to help reduce the amount of plastic waste that is littering oceans and landfills by providing a solution for what to do with the waste. Hopefully people’s perception of carrier bags will be altered but also, they will see a value in their discarded waste.

Figure One: Carrier Bags

RECYCLE.REPURPOSE

CARRIER BAGS

On average we only recycle one plastic bag in every 200 we use -

Carrier bags are created by using different combinations of heat and pressure, as this produces different densities of plastic. Thicker bags (bags for life) are typically formed from High Density Polyethylene (HDPE) whereas thinner bags are made from Low Density Polyethylene (LDPE) 3

According to Waste Management, only 1 percent of plastic bags are returned for recycling. Therefore, the average family only recycles 15 bags a year4 the rest end up in landfill or as litter.

Worldwide, around two million plastic bags are used every minute5 and on average a plastic bag is only used for twelve minutes6 . It can take anywhere from 10 to a 1000 years for a plastic bag to degrade in landfill7 Furthermore, it either ends its days in landfill or accumulates in the ocean, as up to 80 percent of ocean plastic pollution enters from land8

Supermarkets offer carrier bag recycling drop of points. The majority of the United Kingdom’s waste is shipped abroad. Since 2012 more than 2.7 million tons of plastic waste has been sent to China and Hong Kong 9 . But why does our waste need to take the long trip be recycled? It would be more appropriate if there was a process to help reuse waste and create it into something new.

REUSING PROCESSES

MELTING HDPE

“Using carrier bags to create a solid block of material.”

1. Cut the plastic into long strips. 2. Lay a piece of greaseproof onto the panini press, then lay the plastic and finally another piece of greaseproof.

3. Heat the plastic until it becomes malleable and using gloves twist the material (this creates the marble effect).

4. Repeat this step 2-3 times to ensure the material has bonded.

5. Place into a mould and clamp to press the material. Leave for 20 minutes then release.

SHEET FORMING

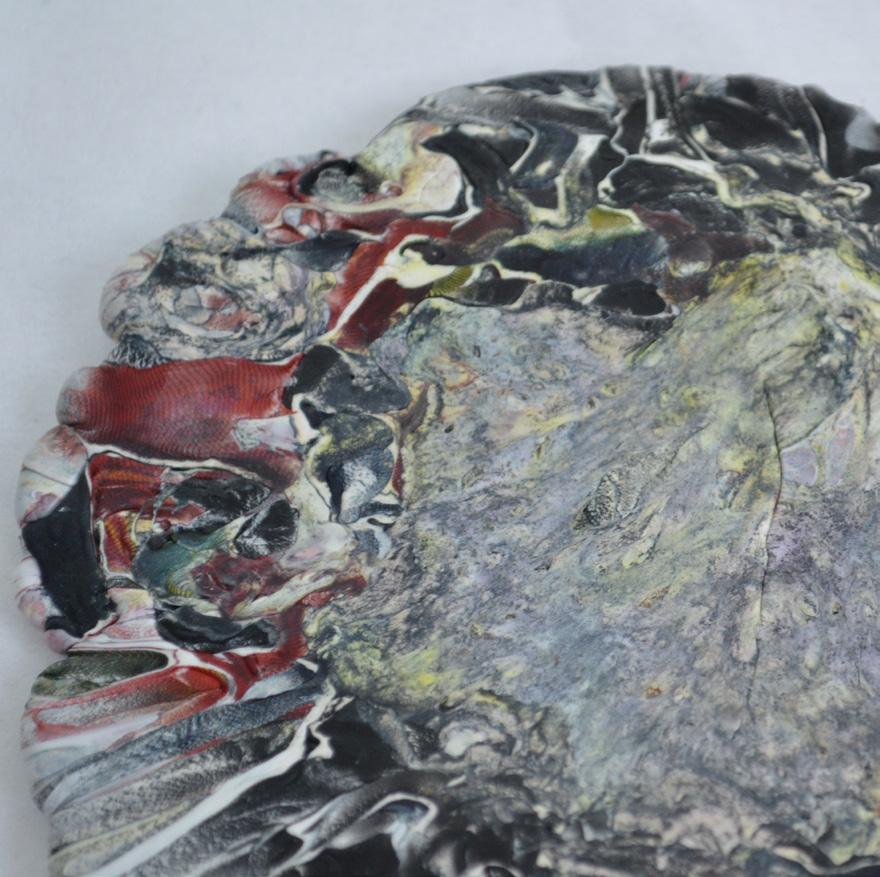

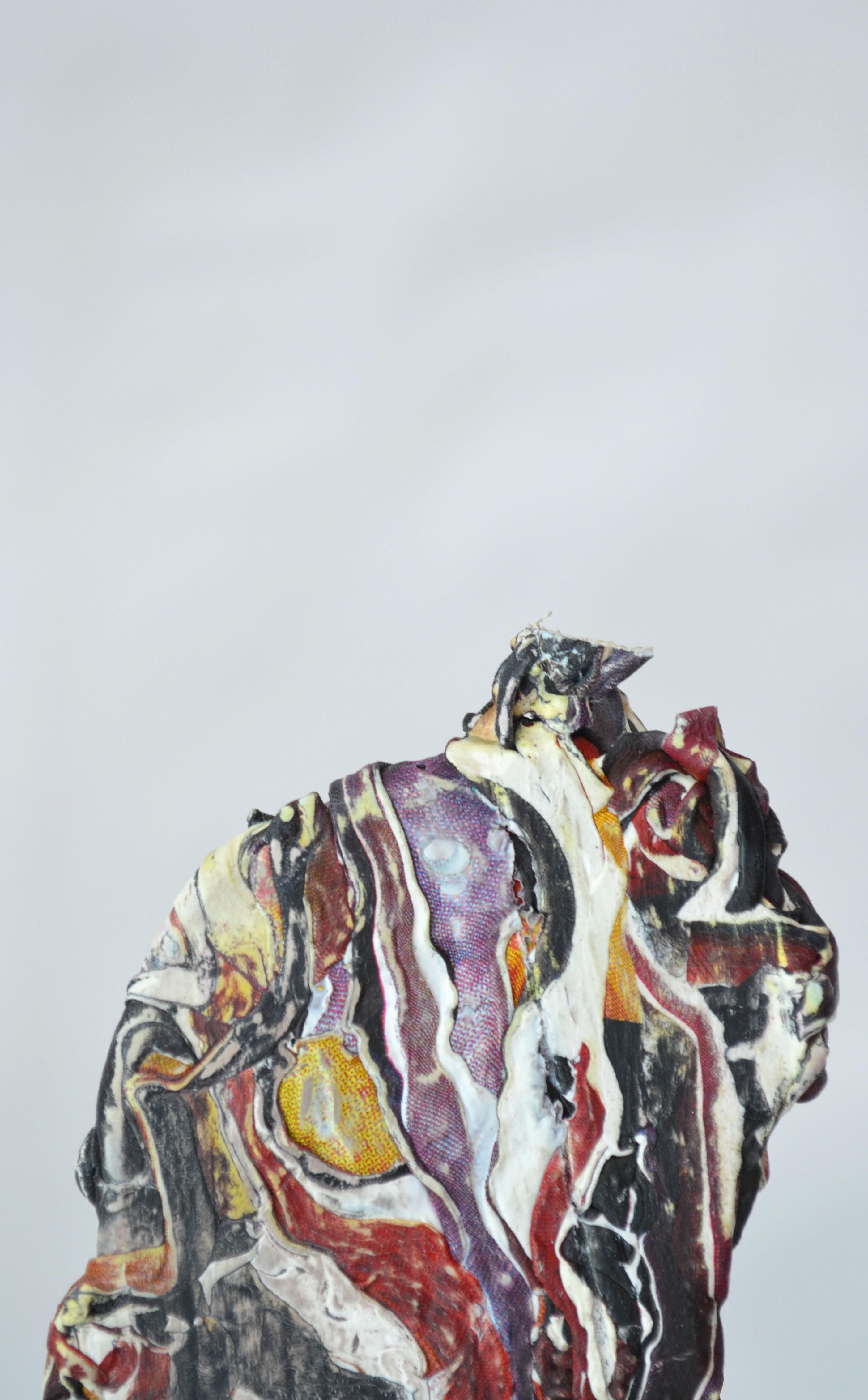

MARBLE BLOCK

“Fusing old plastic bags together to create thick sheets”

1. Cut the plastic bags into sheets by removing the handles and the end seems.

2. Place a piece of greaseproof paper onto a hard heat resistance surface.

3. Layer two of the plastic sheets together and finish with another piece of greaseproof.

4. Iron on top of the greaseproof paper for around 15 seconds (or until the sheets are bonded)

5. Keep repeating the process until the desired thickness.

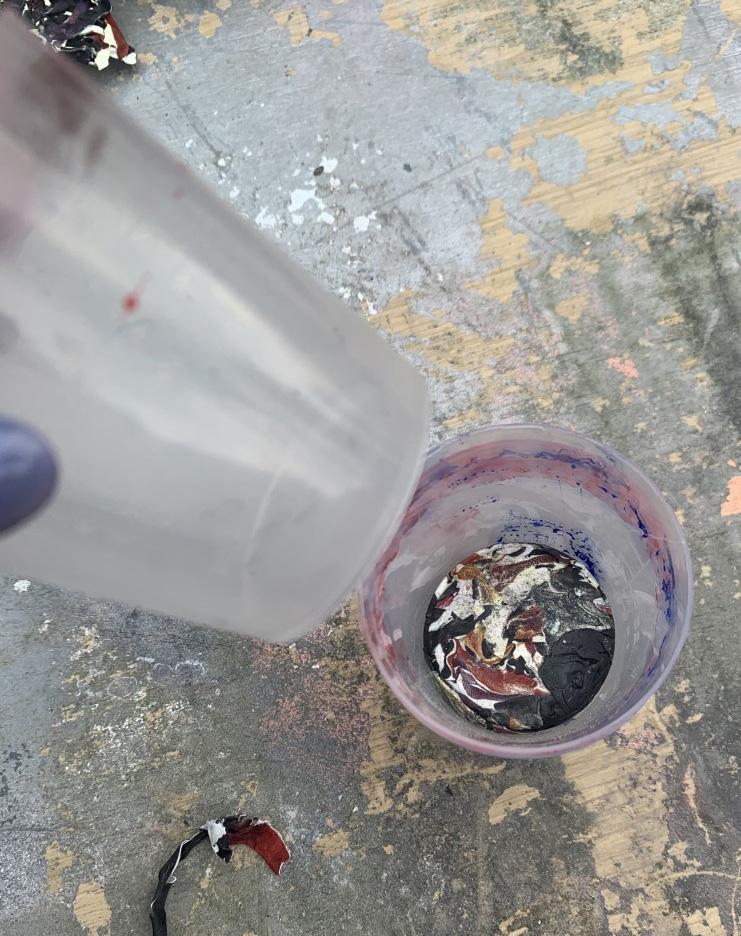

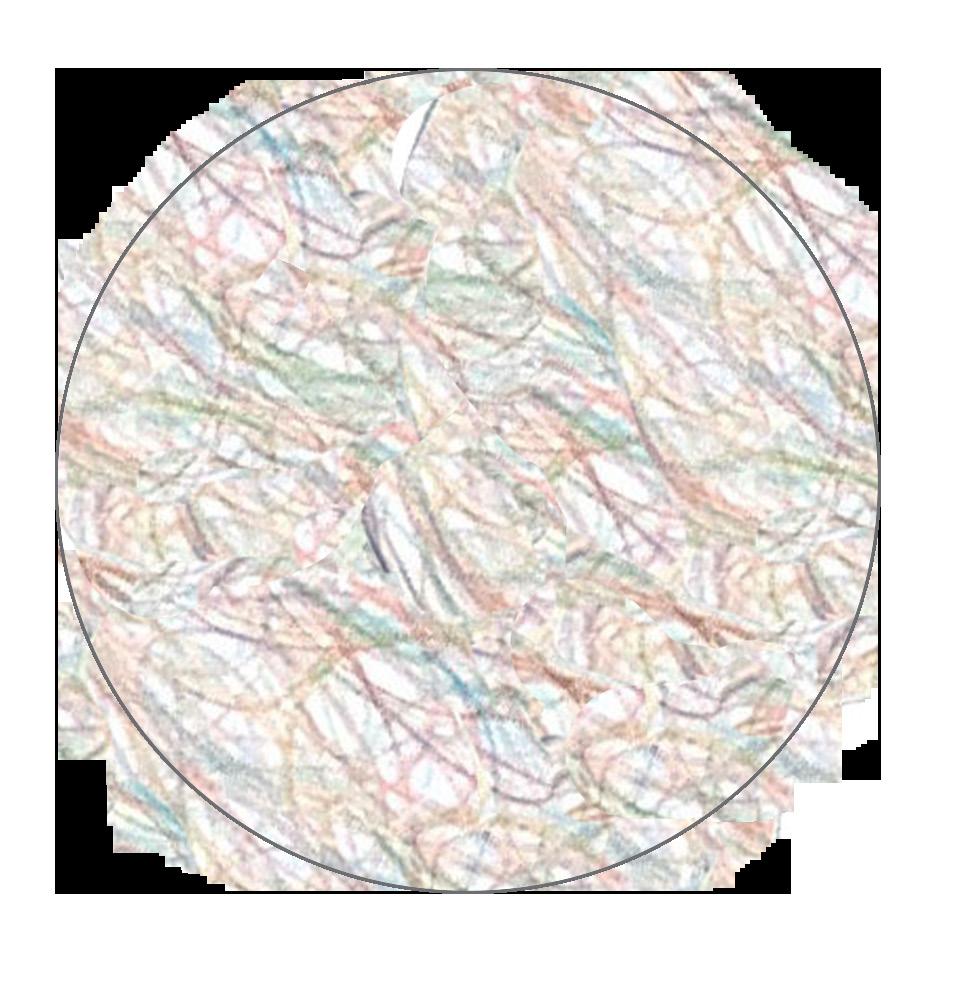

“Creating marbled blocks from recycled bags .”

1. Prepare the plastic bags by shredding them or cutting by hand however leave some uncut.

2. Preheat the oven to 200 degrees.

3. Put the uncut plastic bags into a large bowl and place into the oven for 5 minutes.

4. Remove the bowl and mix. Add in the plastic bag strips, mix and place back into the oven.

5. Repeat this step until there is a large enough quantity.

6. Place the dough inside of the mould and press for 1-2 hours.

7. Once cooled, remove from the mould. Cut off edges and buff to reveal the marble design.

TIPS AND TRICKS

- Ensure the plastic is washed and dried to guarantee a good bond.

- Large strips or shredded pieces help to ensure there are no air bubbles which can make the material weak.

- Measure the material used as this helps to reduce waste.

- Melt at a low temperature to avoid toxic fumes.

- Ensure the room is well ventilated and the correct protective equipment is always being worn.

Figure Two: Carrier bag recycling diagram

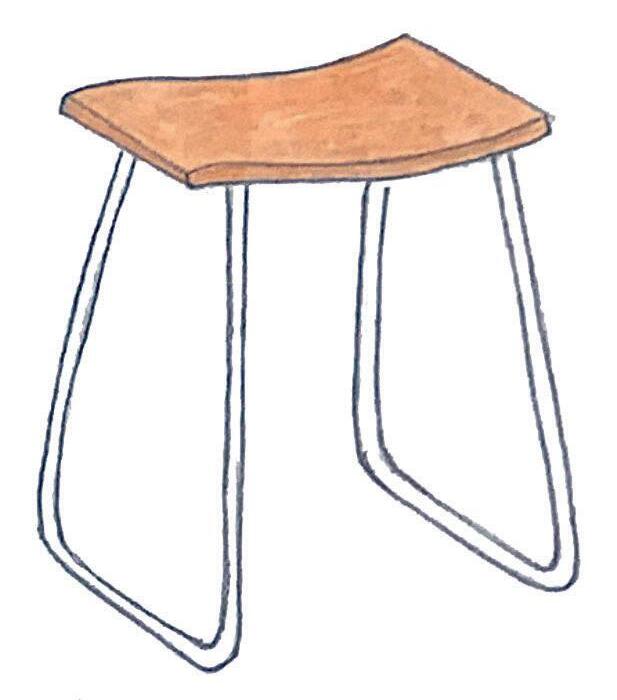

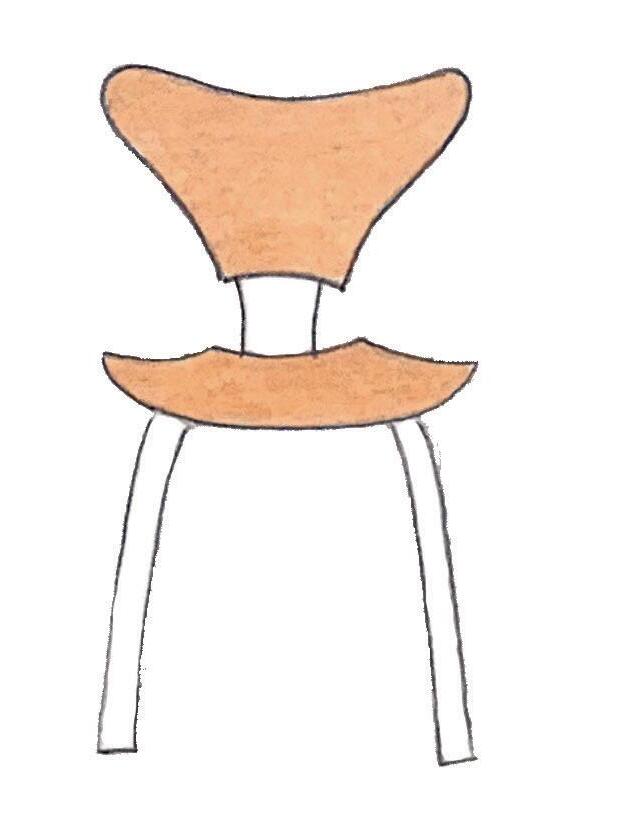

Figure Three: Chair from waste material

REUSE.REDUCE

PLASTIC PANDEMIC

PRECIOUS PLASTIC

Instagram: @realpreciousplastic

Precious Plastic’s aim is to reduce plastic waste. They achieve this by advertising the benefits of recycling, experimenting with new technologies and even trying to adopt a zero-waste lifestyle. Their solutions see people as the key element to fix the plastic mess.

Precious Plastic is a combination of people, machines, platforms and knowledge to create an alternative global recycling system.

Precious Plastic is an open source project, they share knowledge and resources to help people contribute towards recycling plastic. Their website contains various resources that people can access which can contribute towards the process.

They create simple yet elegant products that have value. This is something that needs to be replicated in this project. Showing the user that their discarded plastic waste has been repurposed into something that has a value and that people would want in their homes. However, Precious Plastic is a process that people would struggle to recreate at home due to the equipment needed, so this project could give the opportunity for people to try it themselves.

THE SCALE OF THE POLLUTION

WHY IS WASTE A PROBLEM?

Currently there are no corners of the world that are free from plastic waste10. Plastic pollution can be found on every beach worldwide11 from busy tourist beaches to uninhabited tropical islands, nowhere is safe. Furthermore, it has been predicted that by 2050 there will be more plastic than fish in the ocean12 if nothing changes. More than 300 million tons of plastic are produced annually, yet more than 90% of all plastic is not recycled13 and less than 1% of carrier bags are not recycled14

Plastic becomes a problem if it is not disposed of correctly. Plastic can have detrimental effects on the oceans eco system as it decomposes slowly and breaks down into microplastics which are extremely damaging to sea life. Microplastics make their way into the food chain as they can be eaten by fish which are then eaten by larger animals and even us.

Plastic waste is an issue due to people not recycling efficiently. Plastic waste that can be recycled but is not, remains in landfill where it takes years to decompose. Furthermore, the waste does not make it to landfill as it gets blown away due to being so light. From there it can clutter drains, enter rivers and then pollute the ocean.

Low income countries also have insufficient or no recycling facilities. For example, in Indonesia, they pile rubbish onto the riverbanks which is subsequently burnt. The rubbish on the banks can collapse which enters the rivers and offers the plastic a gateway into the ocean.

In 2017 the Ocean Conservancy conducted the international costal clean up to help reduce the plastic waste littering the worlds eco system. Plastic carrier bags came 4th in the list of most common items found, as sadly 520,900 plastic bags were recovered during the clean-up15

Figure Four: Precious Plastic Product Examples

Figure Five: Plastic in the ocean

TURNING TRASH INTO TREASURE

Supermarkets encourage customers to use reusable bags in order to reduce the consumption of plastic. Marks and Spencer’s offer a bag replacement scheme after a bag for life has been purchased. The scheme aims to reduce the number of bags placed into landfill by giving the consumer a new bag once theirs is damaged. Then Marks and Spencer’s can dispose of the bag correctly.

However, the bag for life design changes seasonally. This can produce waste if a store has received more bags for a previous season than needed, these are not placed for sale with the new seasons design. Instead they are stored backstage and not used.

Marks and Spencer’s could create products using the recycled bags. These products would be used in store, in the café or food hall. Furthermore, it would show customers how their damaged carrier bags can be turned into a valuable item. It would be the perfect platform to spread awareness of plastic pollution as well as showing that carrier bags are not single use item and how important it is to dispose of them correctly. Carrier bags should be recognised as a material that can be used efficiently and effectively for multiple applications.

PROJECT FOCUS

These aims are guidelines which ensure that the project remains consistent and is focused on achieving the end goal of repurposing plastic waste for a longer life. There are three key sections that are vital for this project to be successful, these are experimentation, the design and the story. Below are the key aims for each category.

EXPERIMENTATION

Develop a technique that can be controlled in order to produce a professional material.

Ensure that the process produces a consistent output.

The process must be a batch production process.

The material that has been created should be tested to have a good understanding of the properties and boundaries.

Creating a process that doesn’t create a great deal of waste

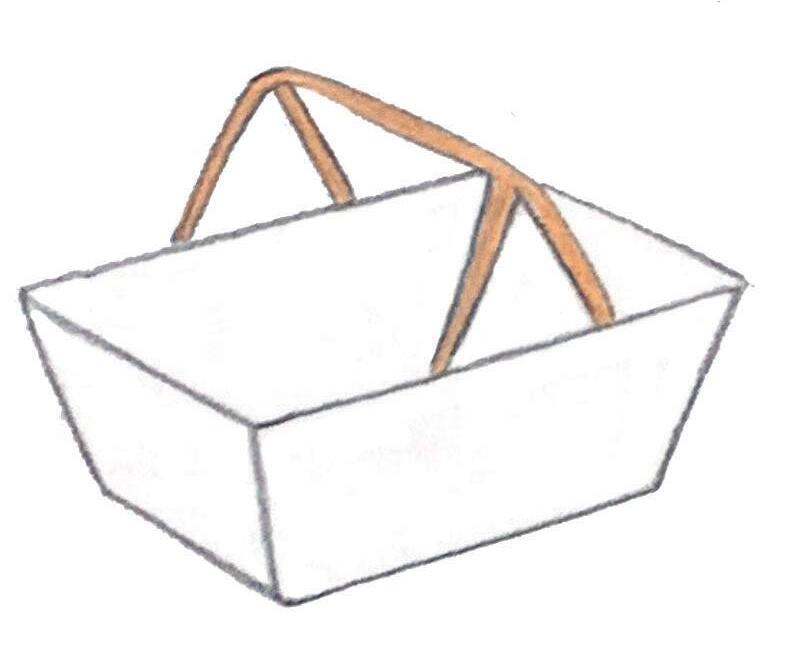

THE DESIGN

Ensure that the design of the product enhances the material created. Using the properties to improve the product (for example the material could be waterproof so used for outdoor applications).

To create a product or a range that are suitable for Marks and Spencer’s.

The design must be able to be manufactured by the process.

Other materials can be used if they are repurposed or sustainable.

TELLING THE STORY

Explore ways to show that the material can have a value.

To show how plastic waste can be used to recreate aesthetically pleasing products.

Ensure that there is a visual element to help explain the process e.g. a diagram.

Explore ways to promote the products.

R I S K

RISKY BUSINESS

Due to this idea being a relatively new prospect, it was not certain that it would be possible to create a suitable material with the resources available. This was a huge risk to take, as there was not a definitive answer whether this material would be useable to take forward and if a suitable process would be discovered. The question is, was it worth the risk?

TRIALS AND TESTING

Left to right shows the order of the experimentation.

THE PROCESS

Testing the initial proces and changing aspects to improve it.

STEP ONE preparing the carrier bags

Remove any contaminants for example receipts. Removing the black handles from the bags (set these aside as there could be a future use for these). Cut the bag into 25mm strips (vertically). Each strip should then be cut into 60mm sections (one vertical strip should produce 5 pieces).

POSITIVES TO KEEP

Size of the pieces remove the black handles remove contaminants

ASPECTS TO CHANGE

Wipe the bags with an antibacterial substance to remove bacteria

STEP TWO melting the bags

Place 20g of the cut bags into the heat proof bowl and melt using the heat gun. Use a metal rod to help combine the material together. Apply heat depending on the state of the material (stop if burning occurs).

STEP THREE additional material

Once the material in the pan is combined, add another 20g of strips. Ensure it is bonding to the pervious material. Keep adding additional strips until enough material is created.

STEP FOUR using a mould

Take the material and place it into a heat proof mould. Apply force to the mould in order to ensure that the material is taking the shape of the mould. Leave until cooled.

POSITIVES TO KEEP

The method

ASPECTS TO CHANGE

Add more material

Try a different heat source as the heat gun is too powerful

POSITIVES TO KEEP

The method

Adding more material once combined

ASPECTS TO CHANGE

The time this step takes as after too long the material doesn’t seem to bond

POSITIVES TO KEEP

A variety of moulds

The method

ASPECTS TO CHANGE

Find a better way of applying the pressure consistently Knowing when the material is cool.

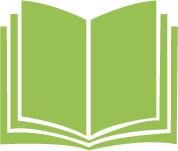

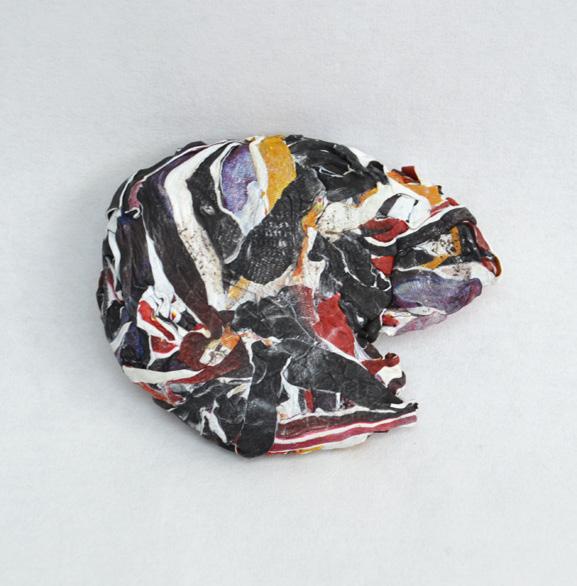

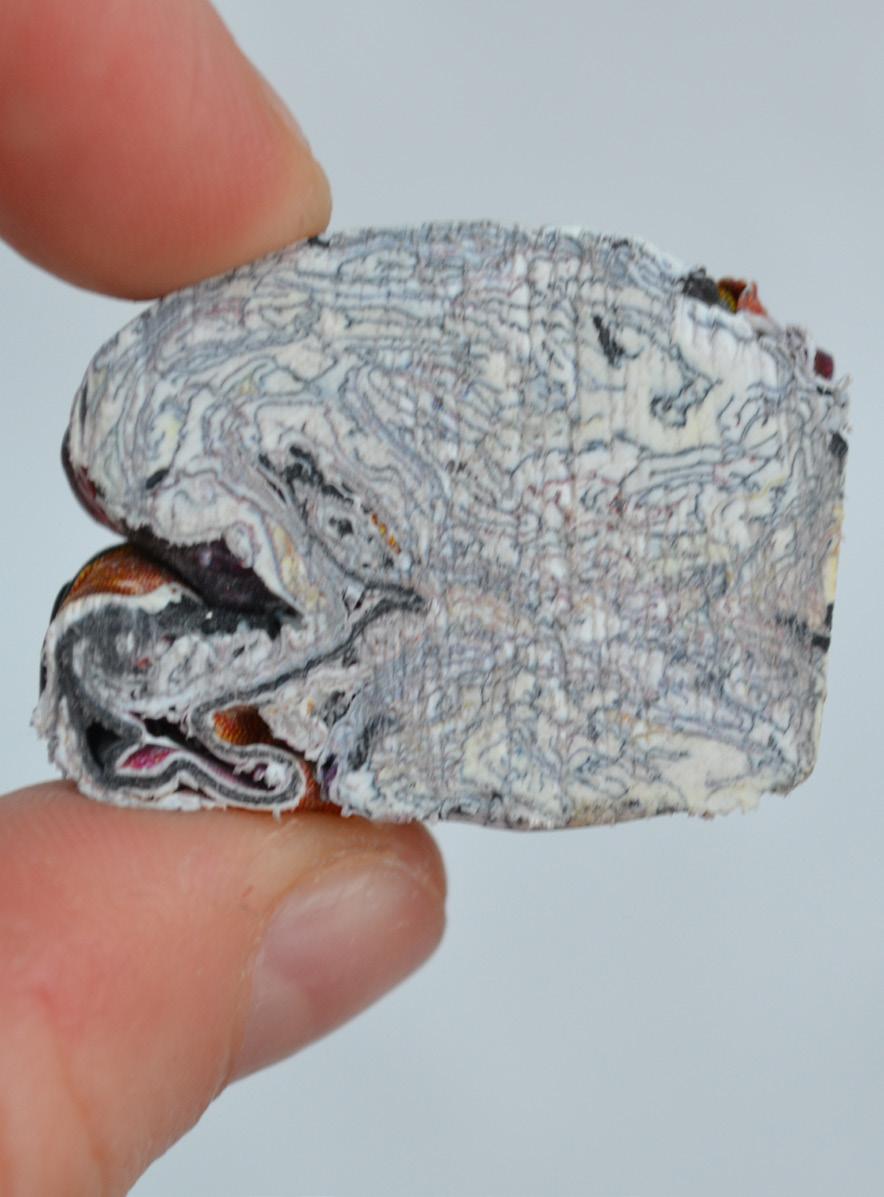

POSITIVE DISASTERS

Throughout the experimentation process there were times when experiments didn’t turn out as expected. However, even these turned out to become positive disasters.

(Image order left to right)

Image One: Experiment Sixteen. During the melting process the heat was too high which turned the dough extremely sticky and hard to handle. However, this test was proof of how versatile this material is. The process that I attempted would work well for low income countries. They could melt the plastic and place it into basic moulds to create bricks that could be used for houses. It also could be used for curb stones due to how tough it is.

Image Two: This experiment showed how texture can be held by the material. After accidently placing a textured item onto the warm material, it was apparent that the material could be embossed.

Image Three: Understanding the structure of the material was crucial in knowing the melting point of the material. Inside of the test, there are areas where the material has bonded well and other sections where it has not. At the points where the material is not compressed, it is not as strong or durable.

These positive disasters gave crucial information and insights into the material and its properties. They allowed the material to be improved and provided a structure to ensure the material is created to the best of its ability.

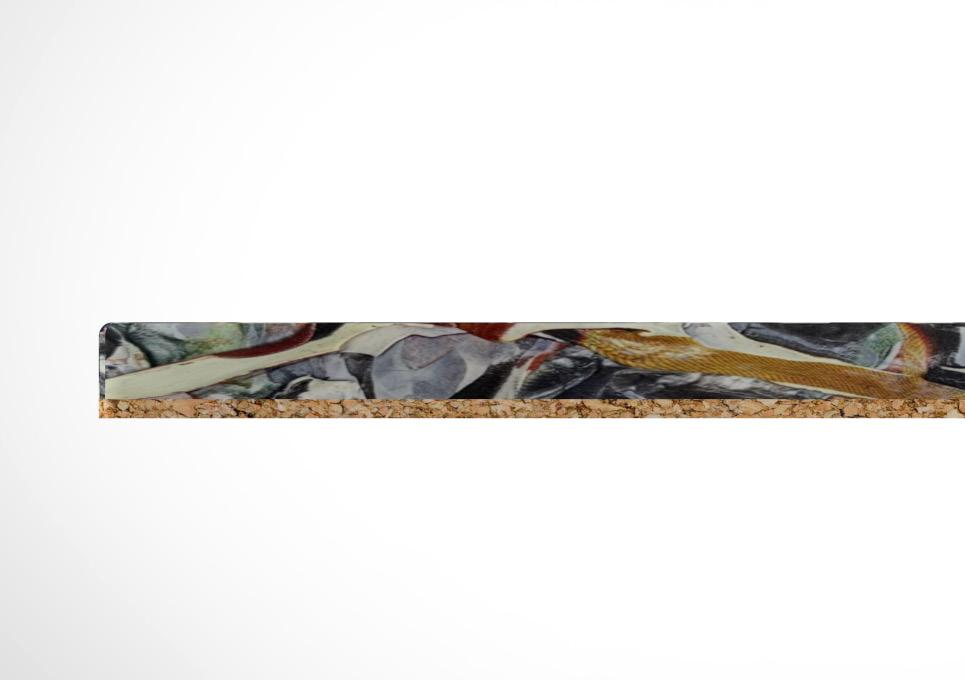

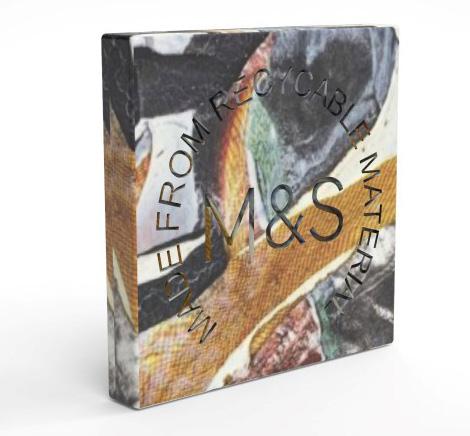

THE REPURPOSE PLASTIC PROCESS

THE PROCESS

The repurpose plastic process (RPP) consists of five stages. Before the process the carrier bags are cleaned from contaminants and cut into pieces that are approximately 80mm x 20mm (length, width). The process is as followed:

1. Strips of carrier bags are melted at 200 degrees to form a dough. Initially, a large quantity of the strips are placed into the bowl while being heated. More strips are added to achieve a better quality marbled appearance.

2. The hot dough is placed inside of a mould.

3. The moving pattern is placed on top of the static platen, where heat and pressure are applied. This forces the material to spread into the mould.

4. The material is left in the mould for fifteen minutes. The ensures that the material is keeping the desired shape when cooling.

5. The moving pattern is raised, and the part is removed from the mould.

THE MATERIAL

The carrier bag material is known as PCM (Plastic carrier material). PCM is created from only one source, Carrier bags. The properties of PCM are as followed:

- Durable: PCM can withstand wear, pressure and damage. It is a hardwearing material.

- Waterproof: PCM is impervious to water as it does not affect the aesthetics.

- Dense: The structure of PCM is closely compacted making it dense.

- Hard: PCM can withstand large forces due to its solid structure. It does not scratch easily or show indentations after manufacture.

- Not Ductile: PCM does not deform by bending, twisting or stretching as it is solid.

PCM can be machine cut, filed, sanded and drilled. Once sanded PCM can be left unfinished or a gloss can be applied. PCM can be embossed while in the mould.

Melted

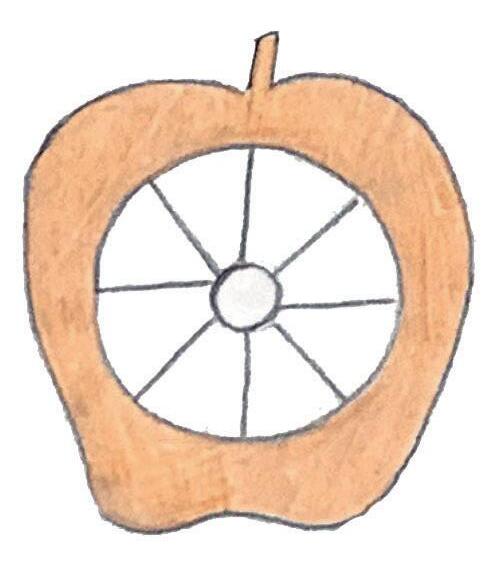

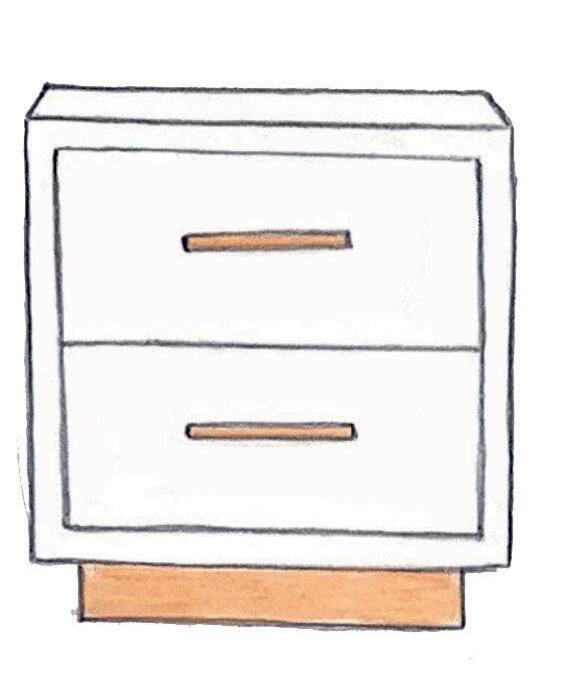

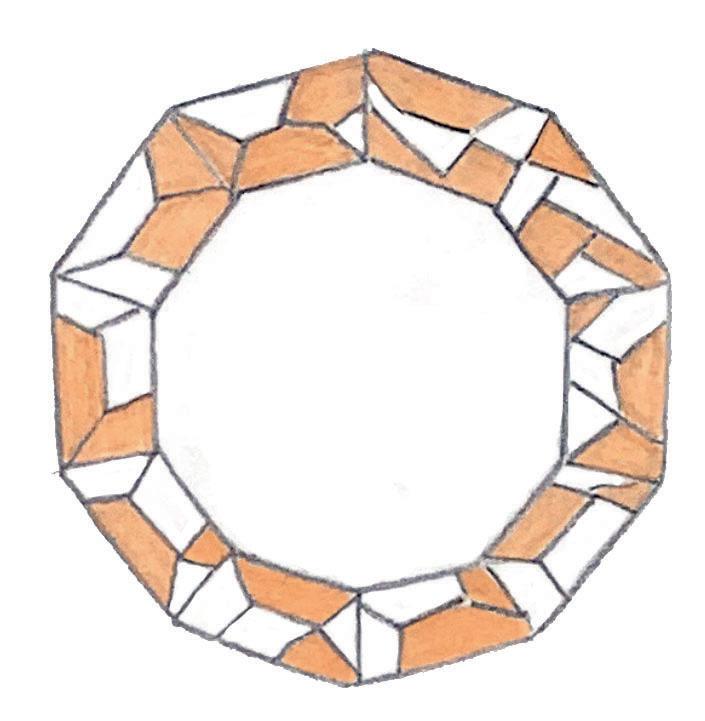

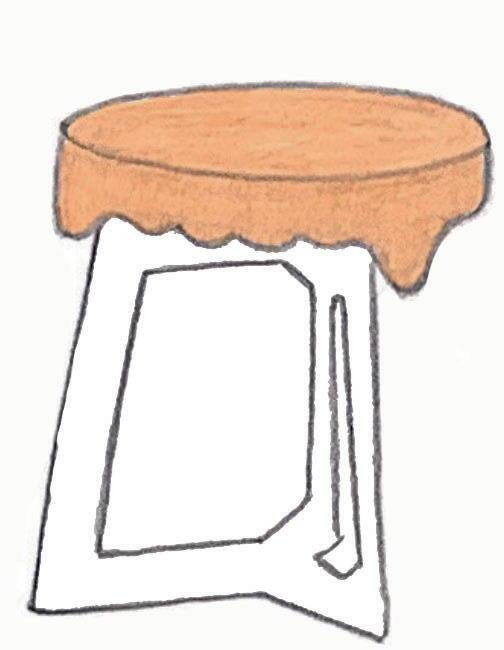

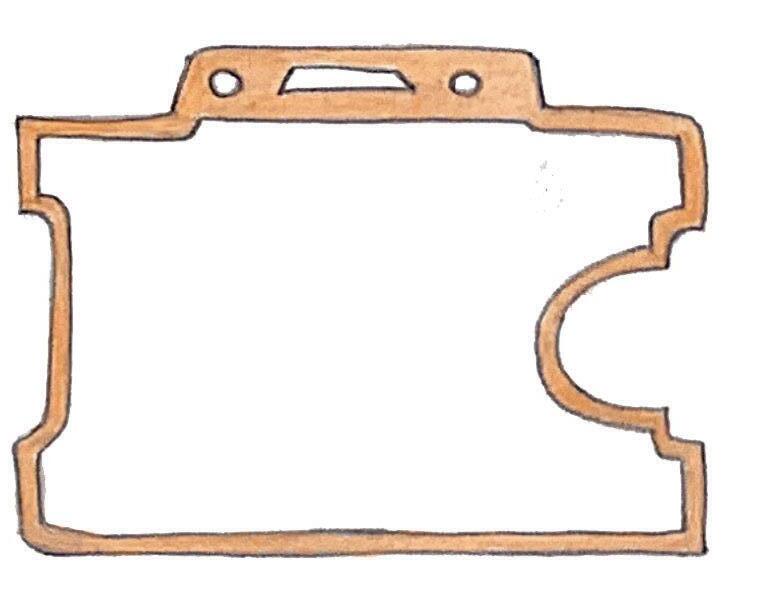

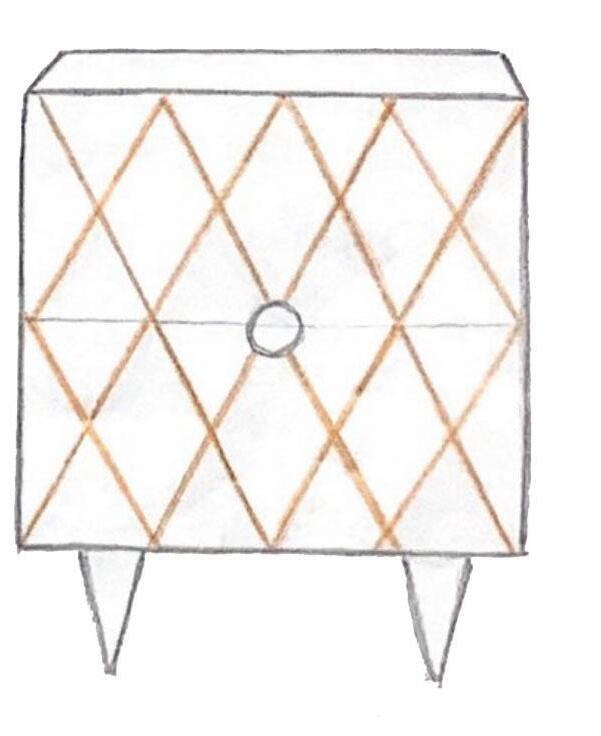

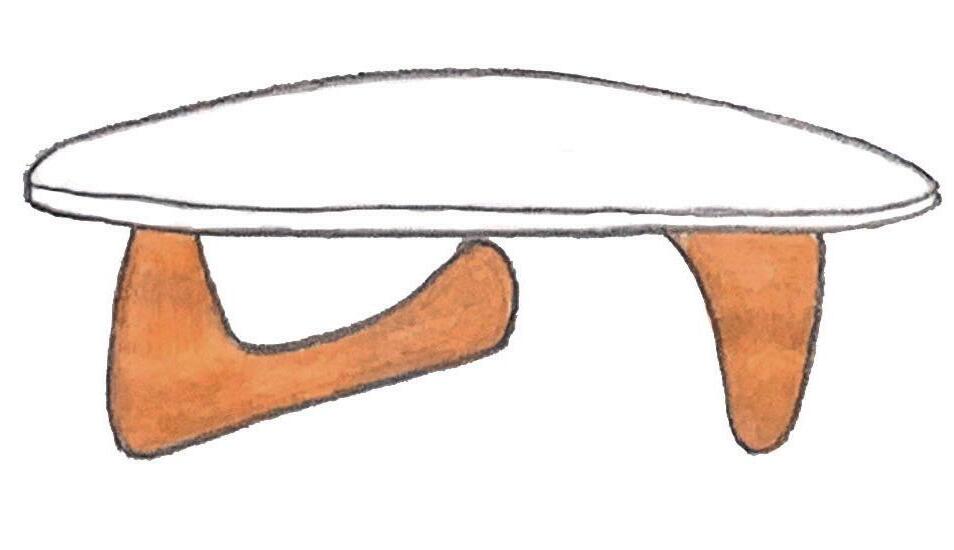

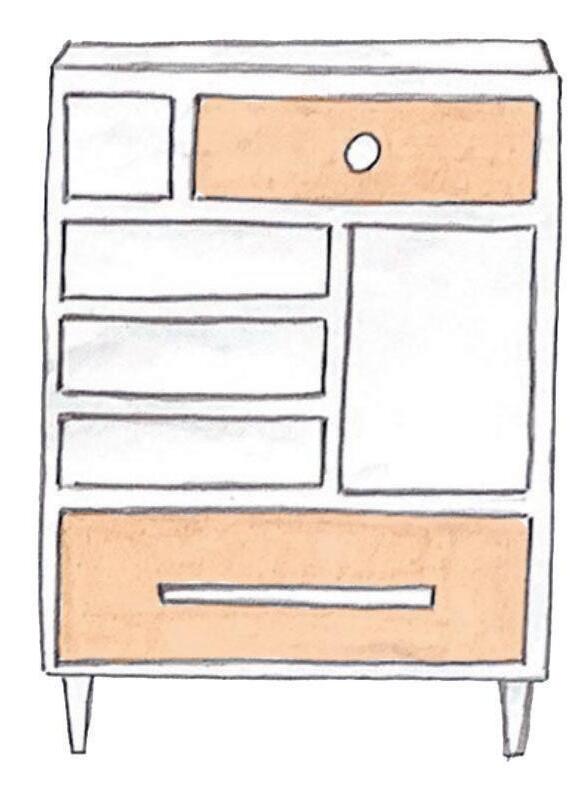

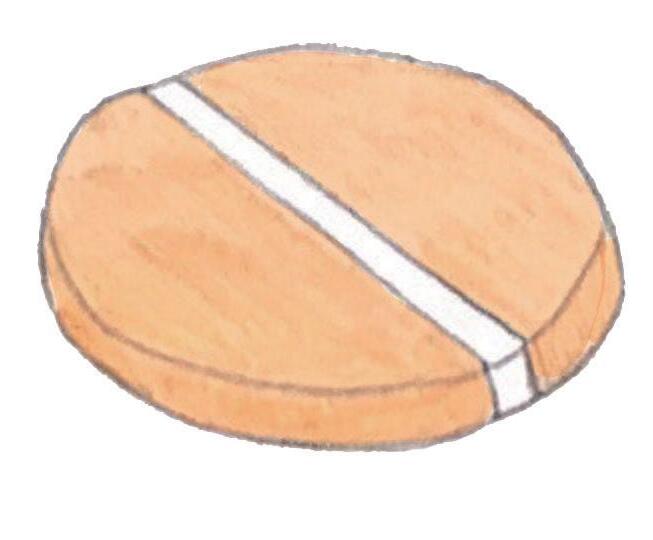

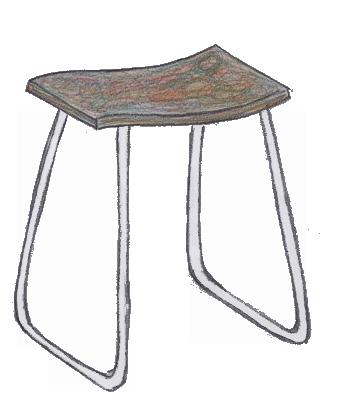

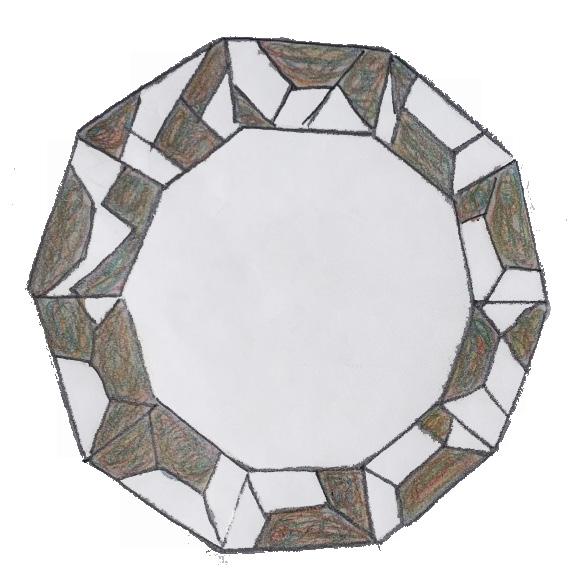

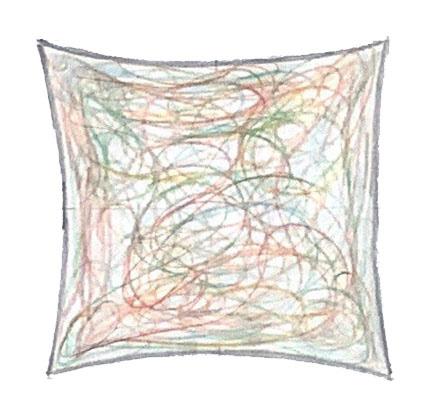

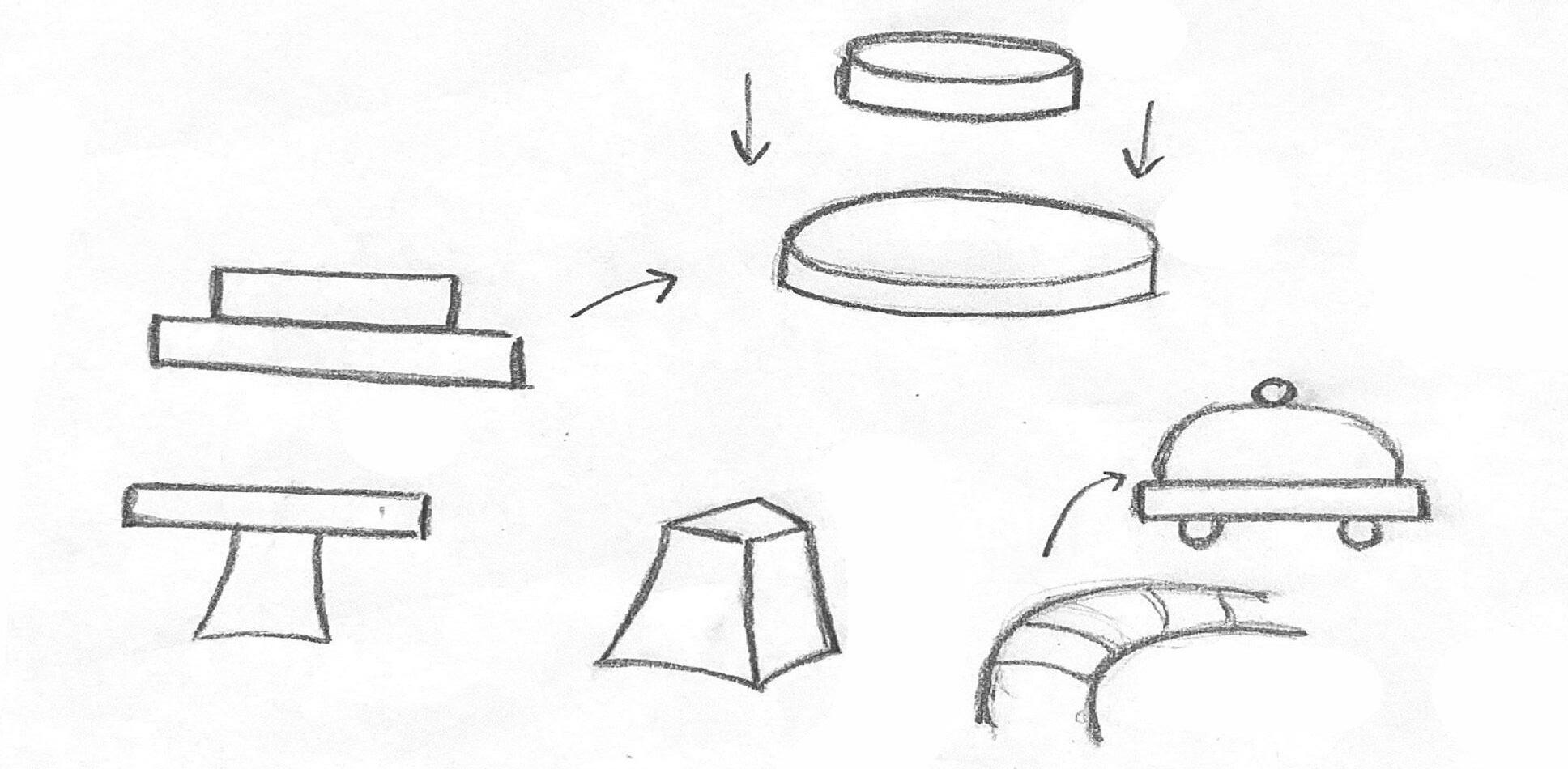

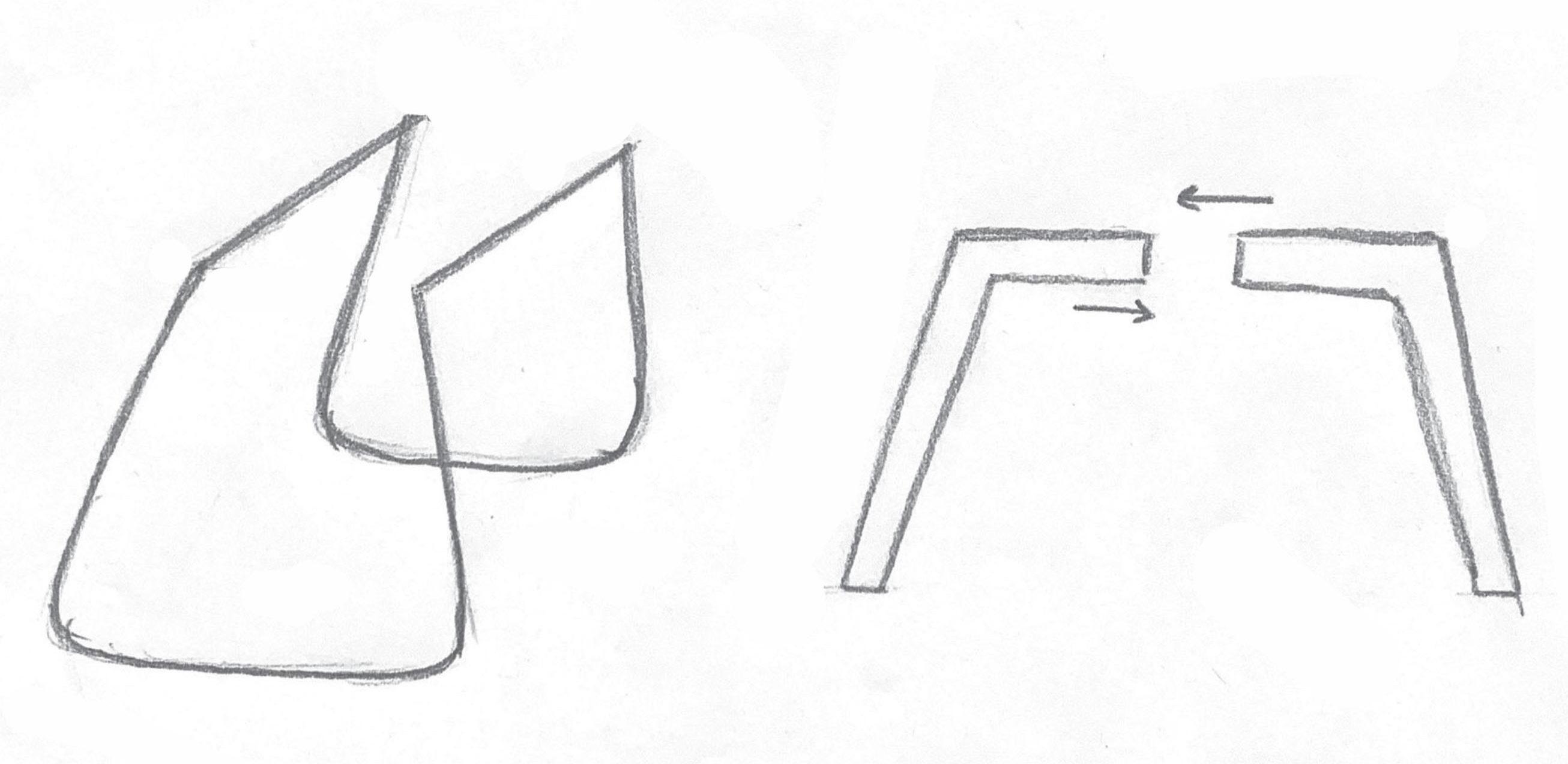

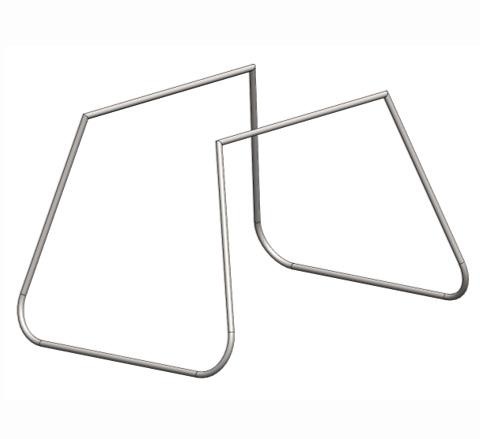

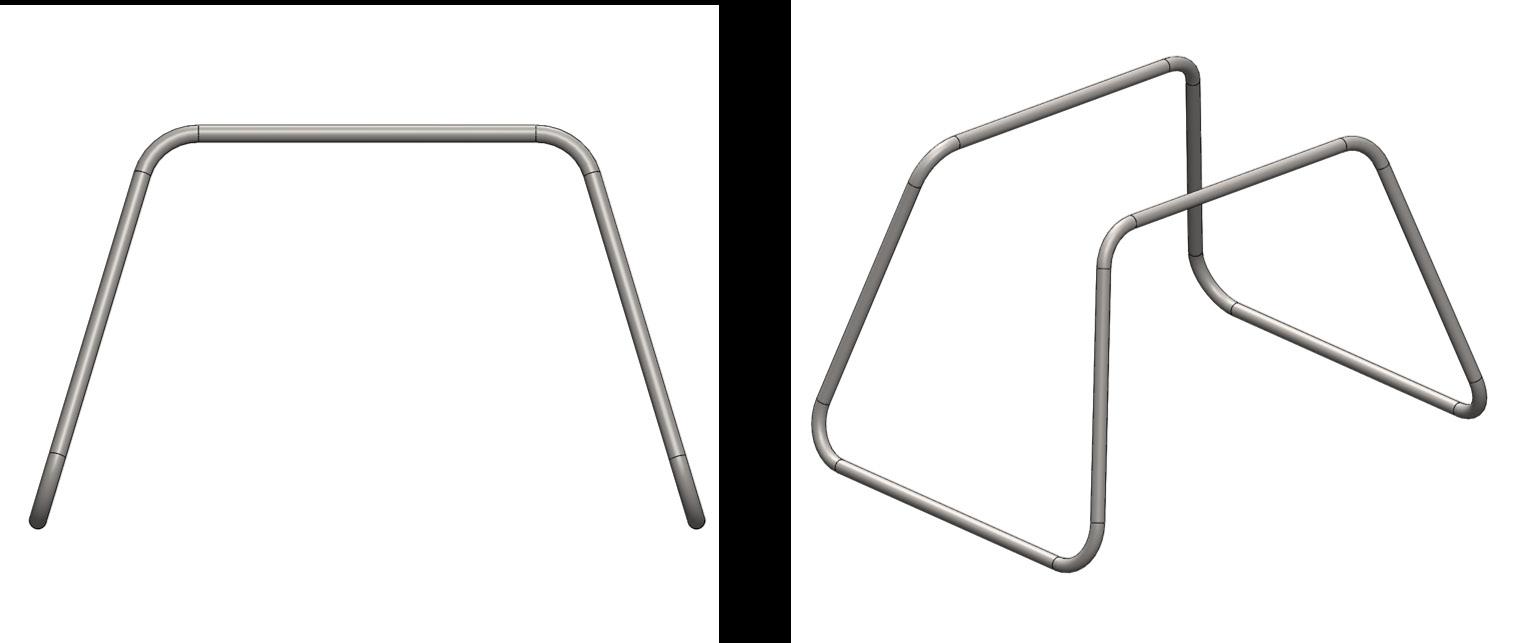

The orange on the sketches indicates where the PCM would be used.

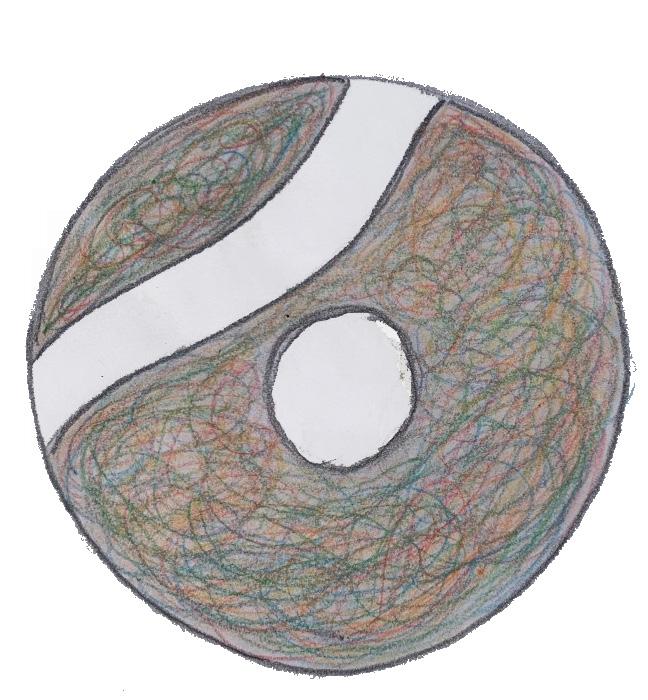

ADAPT

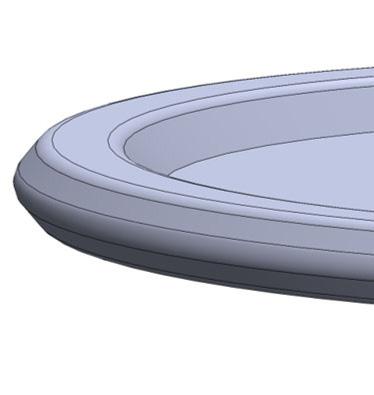

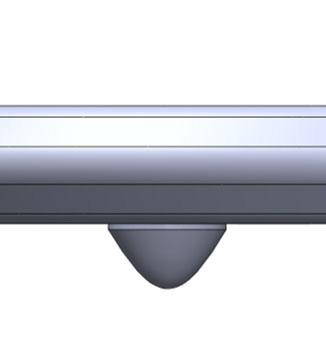

THE TURNING POINT

Due to the current climate (Covid-19), there was no access to the facilities needed to continue with the physical making aspect of the project. Instead CAD has been used to create mock-ups of what the products could have been.

The change of the form. (Image order left to right).

Stay in place. The cork bottom ensures that the coaster will not slide while being used.

A simple yet effective design that could be seen in any home.

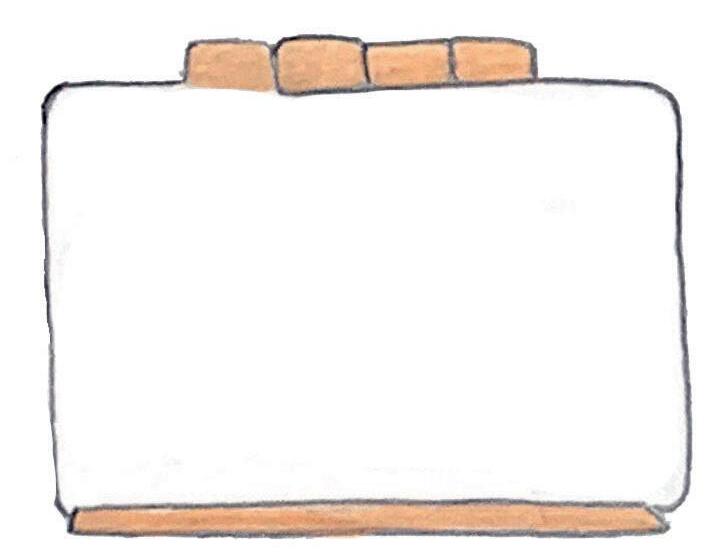

The development of the base form. (Image order is left to right).

Fresher for longer.

The lid ensures that’s the goods inside stay fresh as well as protecting them from any bacteria.

Rubber

at the

the stand ensure that it stays secure and will not slide.

Reusable

The card can be easily changed whenever needed. The displayer holder is wipe clean.

Embossed detail

The makers mark on the back of the display holder informs that it is made from 100% recyclable material.

No movement

stoppers

bottom of

The improvements to the stools structure. (Image order left to right).

User friendly

The form of the seat allows it to be easily moved around the café. The seat is slightly curved for added comfort.

Curves in all the right places

The frames radiused edges have seen specifically placed to ensure that the stool is rigid and secure.

Seamlessly attached

The seat and legs are attached by screwing into the seat via the bracket.

Safe and secure

The additional grip on the legs ensures the stool will not slide, providing a safe seat for all ages.

6. BACK TO STORE

The items for the store or to be sold in store are packaged and transported back to be used or sold.

5. MANUFACTURING

The moulded or pressed PCM will then be used to create various products needed for the store e.g. Stools. Or it will be used for products for the store to sell.

4. REPURPOSE THE PLASTIC

Using the Repurposing Plastic Process (RPP) the melted PCM will be pressed into flat sheets or placed into moulds to create forms.

INSTORE PROCESS

1. COLLECTING THE BAGS

The bags are collected from the store. Used bags are brought to the store by customers.

The bags are disinfected to remove bacteria and any contaminants such as receipts.

2.

TO THE WORKSHOP

The bags are transported to the workshop where they will be made into valuable products.

3. DEEP CLEAN

INSTORE DISPLAY

To promote the product to the customers a display (as seen above) would be used in stores. This would educate the individual about the product explaining it is made from used carrier bags from the bag for life scheme. The product would be placed here available to purchase.

Product in use example

Each batch of coasters would be different and unique

The black handles from the bags could be used to package the product. This would make use of every part of the bag meaning no waste.

FUTURE

WHERE NEXT?

The possibilities seem endless with this project. There are various options on what to do next but the plan for the next few months is:

- To physically make a product. The process has been proven and a suitable material can be created, now it is time to make prototypes and refine the design until a suitable product has been produced. The first product I am aiming to make is the coaster.

- Sell the products. Over the next few months when multiple products have been made these could be sold on sites such as Etsy.

- To keep documenting the process on Instagram as it is a platform to present the idea.

- As a member of staff at Marks and Spencer’s I have applied for my work to be shown in the monthly staff magazine.

I am also in the process of arranging a meeting with management about my idea for them to pass forward. Hopefully, will be able to achieve this and push my idea to the next step. Who knows one day people might be using this process themselves and see that their used carrier bags still have a value.

Plastic Waste by Esther Peacey

Any further information on the project can be found at my website: https://estpeacey.wixsite.com/estherpeacey

Further development work and an additional explanation of each element can be found at this site.

Email: estpeacey@hotmail.com

Instagram: @productdesign.est

Repurposing

REFERENCES

All photographs or illustrations in this book have been taken or created by the author unless stated otherwise.

1: BBC. (2019). Drowning in Plastic. Retrieved from: https://www.bbc.co.uk/programmes/b0bmbn47

2: Leblance. R. (2019). The decomposition of waste in landfills. Retrieved from: https://www. thebalancesmb.com/how-long-does-it-take-garbageto-decompose-2878033

3: Environment Agency. (2011). Life cycle assessment of supermarket carrier bags: a review of the bags. Report retrieved from: https://assets.publishing. service.gov.uk/government/uploads/system/uploads/ attachment_data/file/291023/scho0711buan-e-e.pdf

4: Centre for Biological Diversity. (undated). The problem with plastic bags. Retrieved from: https:// www.biologicaldiversity.org/programs/population_ and_sustainability/sustainability/plastic_bag_facts. html

5: Earth Policy Institute, (undated). Plastic Bag Fact Sheet. Retrieved from: http://www.earth-policy.org/ images/uploads/press_room/Plastic_Bags.pdf

6: The world counts. (2020). How many plastic bags are used each year? Retrieved dorm: https://www. theworldcounts.com/challenges/planet-earth/waste/ plastic-bags-used-per-year

7: Leblanc, R. (2019). The decomposition of waste in landfills. Retrieved from: https://www. thebalancesmb.com/how-long-does-it-take-garbageto-decompose-2878033

8: . Ritchie, H. Roser,M. (2018). Plastic Pollution. Retrieved from: https://ourworldindata.org/plasticpollution

9: The Independent. (2017). Impending crisis for UK waste recycling. Retrieved from: https://www. independent.co.uk/environment/china-plasticimport-ban-uk-recycling-landfill-options-waste-crisisdisposal-a8097166.html

Page 6 Quote: Conserving now. (undated). Plastic bag consumption facts. Retrieved from: https:// conservingnow.com/plastic-bag-consumption-facts/

10: Greenpeace, (2020). Plastic Pollution. Retrieved from: https://www.greenpeace.org.uk/challenges/ plastic-pollution/

11: Surfers against sewage. (undated). Plastic Pollution facts and figures. Retrieved from: https://www.sas. org.uk/our-work/plastic-pollution/plastic-pollutionfacts-figures/

12: Hornak, L. (2016). Will there be more fish or plastic in the sea in 2050?. Retrieved from: https://www.bbc. co.uk/news/magazine-35562253

13: Plastic Oceans, (2020). Who we are. Retrieved from: https://plasticoceans.org/who-we-are/

14: The world counts. (2020). How many plastic bags are used each year?. Retrieved dorm: https://www. theworldcounts.com/challenges/planet-earth/waste/ plastic-bags-used-per-year

15: Ocean conservancy, (2017). International Costal Clean up. Retrieved from: https://oceanconservancy. org/trash-free-seas/international-coastal-cleanup/ volunteer/

Photographs

Figure One: Carrier bags

Social Change UK. (undated). Carrier bags [Photograph]. Retrieved from: https://social-change. co.uk/images/made/images/uploads/One-year-on--did-the-plastic-carrier-bag-charge-impact-on-ourbehaviour-_860_540_80_s_c1.jpg

Figure Two: Carrier bag recycling diagram

Peacey, E. (2020). The lifecycle of a carrier bag [Illustration]. Created by the Author

Figure Three: Chair from waste material

Precious Plastic. (2019). Repurpose Plastic Chair [Photograph]. Retrieved from: https://preciousplastic. com/

Figure Four: Precious Plastic Product Examples

Real Precious Plastic. (2017, December 31st). Multiple examples of Precious Plastic products [Photograph]. Retrieved from @realpreciousplastic (Instagram).

Figure Five: Plastic in the ocean

The Hans India. (2018). Plastic in the ocean [Photograph]. Retrieved from: https://www. thehansindia.com/posts/index/NewsAnalysis/2018-06-08/Ocean-pollution-makingwaves/387427