Vinyl Floors for Social Housing Projects

Here at IVC, we are focused on vinyl flooring solutions that respond to the needs of all people in social housing. By supporting wellbeing through comfort, design and practicality; our floors exceed the requirements of modern social and affordable housing.

The ability of our floors to improve social housing environments is matched by our attention to your needs. With IVC, you have a trusted partner that will help you exceed quality and design expectations.

“By supporting well-being through comfort, design and practicality; our floors exceed the requirements of modern social and affordable housing.”

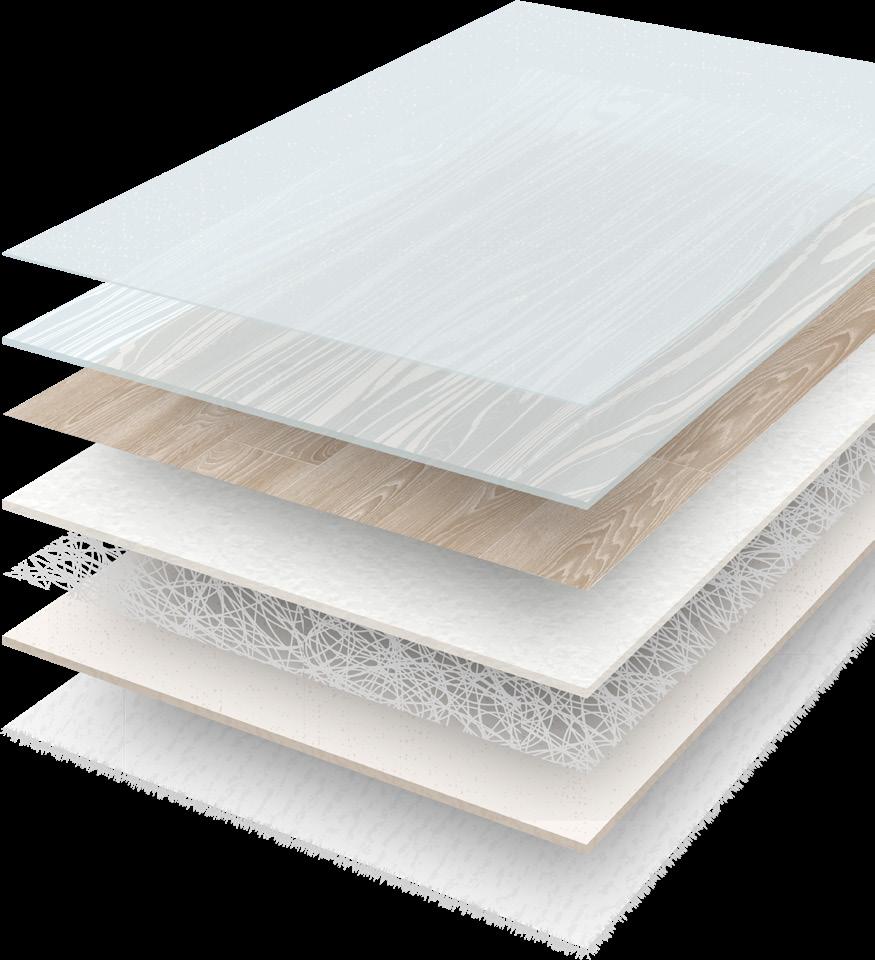

With comfort, acoustics, hygiene, safety and design in mind, our sheet vinyl floors support the well-being of all those that live upon them. What’s more, functional features also enhance the everyday experience, for a floor with the ability to improve lives.

Improved comfort Quieter spaces Safer homes

With cushion-back vinyl floors, you can improve comfort while walking and standing.

Reducing the noise of footsteps and to rooms below, our sheet vinyl floors make homes quieter.

With extra slip-resistance that reduces the chances of slips and trips, our floors are safer for all.

More hygienic Easier cleaning Durability

Sanitec® protection on selected ranges improves hygiene with a surface that inhibits bacteria.

Hyperguard+ layer resist scratches and dirt for a floor that’s easier to clean.

A high-quality wear layer provides durability for a long lasting finish that holds its appearance.

An easy way to quieter homes

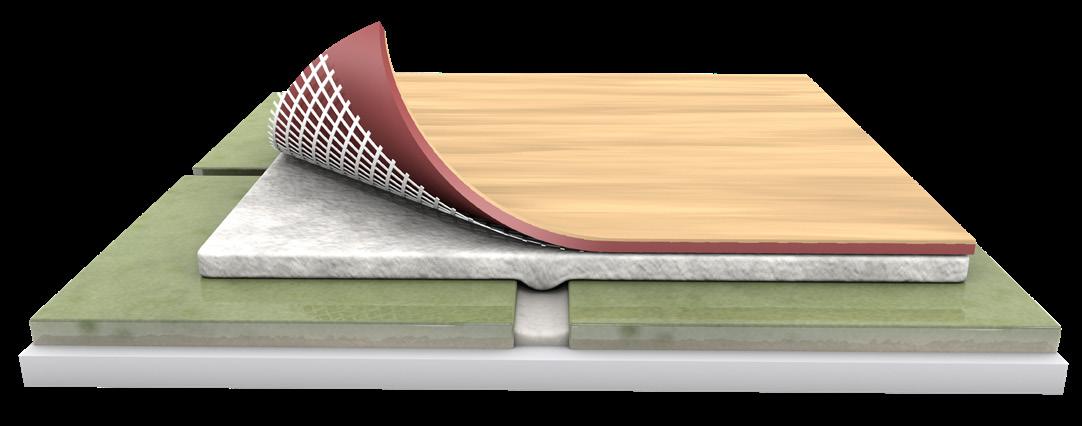

Our textile backed floors can be fitted straight on top of old finishes and can be laid without glue in most room sizes. Plus, they are also brilliant at reducing impact noise, giving you an easy way to make homes quieter and more comfortable for tenants.

Through loose lay installation and our Recover programme, choosing IVC floors for your social housing project can help you to cut down on waste and contributes to the sustainability of your project.

Our Recover programme takes a regional approach to ensure efficient recycling with minimal transportation impact.

In the UK, a local programme collects vinyl installation waste at projects and from contractors and sends it to a recycling partner, where it is downcycled into plastic products. While this approach doesn’t maintain the same material quality as floor-to-floor recycling, it’s a great step forward compared to landfill or incineration. It is also impressively flexible.

Install without glue for easier refurbishment and recovery

Our textile backed floors for private areas can be installed in most rooms without glue*. Thanks to impressive stability and the ability to absorb minor subfloor imperfections, they can simply be cut to fit over existing floors and will stay in place under use.

*Up to XXm2 depending on specification and use

With no glue needed, they can also be lifted and replaced quickly and easily at change of tenancies without any remedial work needed.

What’s more, old floors can easily be downcycled through our Recover programme.

Our floors are expertly designed and made in Belgium to bring social housing projects a high quality floorcovering. But you don’t have to just take our word for it, as our floors are certified by leading independent bodies to deliver you sustainability, performance and quality in every corner.

As a leader in flooring, we belong to a wide range of organisations that represent the industry. We are a member of ERFMI (EU), FEB (DE), DGNB (DE) and Kaléi (FR). With both ERFMI and Kaléi we are working together to provide our customers with collective Environmental Product Declarations (EPD) and Fiches de Déclaration Environnementale et Sanitaire (FDES), showing our industry efforts towards greener products. In Belgium, we are a member of the Fedustria and Voka employer organisations. As part of these organisations, we consider it important to work together for a green industry.

Since 1997 IVC has made substantial efforts towards a precisely tailored, fully integrated environmental management system. In 2012 we were awarded ISO 14001 certification, showcasing our commitment to environmental responsibility. This certification for ecological performance is a good reflection of our past efforts and current compliance with environmental rules and regulations.

Additionally we only purchase and process raw materials that are in line with the REACH regulations and only work with suppliers who comply with these regulations. In this way we are able to guarantee the integrity and quality of the end product that we deliver to the end user.

As part of our ISO 9001 certification, we have implemented a quality management system that enables us to comply with the strictest regulations. This demonstrates our ability to consistently provide products that meet customer and regulatory requirements.

Together with temperature and humidity, air quality is one of the most important factors in interior environments. We want to make sure that our vinyl flooring – often a central part of people’s living spaces – contributes to healthy and safe living spaces, and to ensure that they don’t pose any health risks to our end users. To do so, we make sure that our finished products intended for interior use comply with some of the strictest indoor emission labels.

Even the gentlest of playtimes can send noise to floors below, disturbing other tenants and impacting their well-being. Our vinyl flooring for social housing includes collections that can reduce impact sound by up to 19dB, absorbing noise transferred to rooms below and delivering a better living experience.

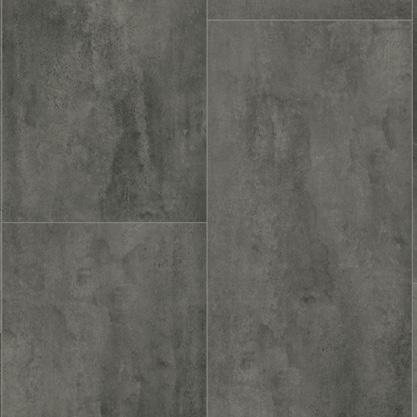

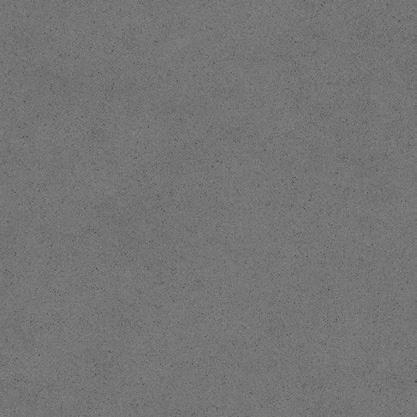

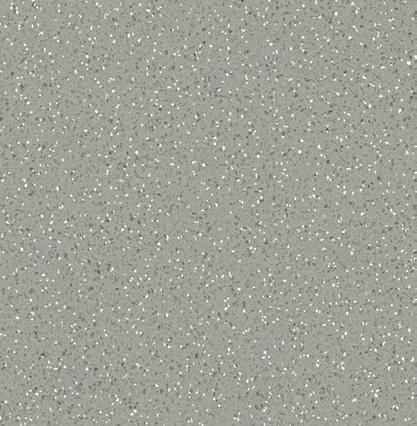

When the comfort of tenants is paramount, our cushion and textile backed sheet vinyl floors are the solution. Durable, simple to maintain and comfortable to walk on, they provide an ideal floor finish in all domestic areas of social housing. Not just kitchens and bathrooms, but living spaces, bedrooms and corridors too.

When durability, safety and ease of maintenance are demanded, our high-performance compact backed sheet vinyl floors are suitable. Available in a range of welcoming residential designs, they offer a heavy duty solution capable of withstanding extreme levels of foot traffic.

Providing 18dB of impact sound reduction in heavy duty environments, Pionieer 70 can withstand busy areas. Equipped with Invertech and PUR Shield for improved appearance and easier maintenance.

Invisiweld uses a chemical bond that’s simple to apply, less messy and less hazardous than hot welding.

Invisiweld can be used on all of our floors for social housing and eliminates a common failure point in installations.

For public areas where floors may need joining at the seams, our Invisiweld is cleaner and less hazardous than using a hot weld gun and weld rods. What’s more, it leaves an almost invisible seam that’s less prone to wear. With Invisiweld, our floors our even stronger and better to look at.

Unlike domestic carpet which may make using wheelchairs and walking aids difficult, our vinyl floors make it easy to move around for physically impaired tenants. What’s more, they offer good underfoot comfort and come with up to R11 slip-resistance in our flooring options for private areas. Our Isafe 70 range for public areas performs even better, delivering R12 slip restraint.

In 2022, Unilin launched One Home, a group-wide sustainability strategy with ambitious targets in several domains. This means that at IVC, we look into the environmental impact of our products and production processes, but also at how we live at home, at work and on our planet.

Even before the group-wide One Home strategy was established, we’ve been thinking about how the manufacturing of our products impacts the planet. In fact, as far back as 2013, when the Scheldt cooling project was completed, we’ve been harnessing natural resources to reduce the fossil-fuel energy we need to make our floors.

We use solar energy to make our fleet greener, in every sense of the word. For instance, we use the power from our solar panels to charge our employees’ electric cars and e-bikes. Furthermore, even the forklifts in our warehouses are charged with solar energy. The result is a great amount of kilometres with zero emissions.

Photovoltaic panels Sunny Side Up Luminosity 3,846 x 1,026 Watts IVC forklifts

energy pumps (makes less noise)

Charging stations for e-carpark Encouraging the use of e-bikes

In 2014, three wind turbines were installed on the Avelgem production site. The turbines produce around 11,000 MWh of renewable energy each year. That’s about as much as the yearly electricity consumption of 3,000 Flemish households. With this clean energy we power our own production facilities.

11 GWh/year = equivalent of 947 tonnes of oil (toe) annual electricity consumption of 3,000 households

The manufacturing of vinyl flooring requires cooling water to absorb heat in the different stages of production. IVC has invested in a bold experiment that uses surface water from the nearby river Scheldt as a secondary coolant Using only a minimal amount of energy, river water is pumped up and sent along the closed loop flow of our

Avelgem plant’s process cooling water. The exchange of thermal energy (up to 4,000 kw) is achieved through state-of-the-art heat exchangers, so there is no direct contact between the river water and the process water en route.

Using minimal electricity compared to other cooling systems, these innovations have resulted in a 30% increase of energy efficiency in the overall production of vinyl flooring. By eliminating the need for machine-driven refrigeration, we’ve also significantly reduced on-site noise and created better working conditions. Heat exchangers

The warranty covers manufacturing defects and premature wear in the event of normal

Abrasion resistance test

RRL Pendulum test (Wet Test) RRL 36+ low slip risk potential

Furniture leg resistance EN ISO 16581 Very good Pass Pass

Throughout technical specifications in this brochure, you’ll find mention of Class 23, Class 33 and more. But, what do these classes mean?

The class relates to a standard that aims to ensure the quality of vinyl flooring and sets out minimum requirements for each class. This means you know they will provide satisfactory service to the level of use specified.

www.ivc-commercial.com