Company Profile

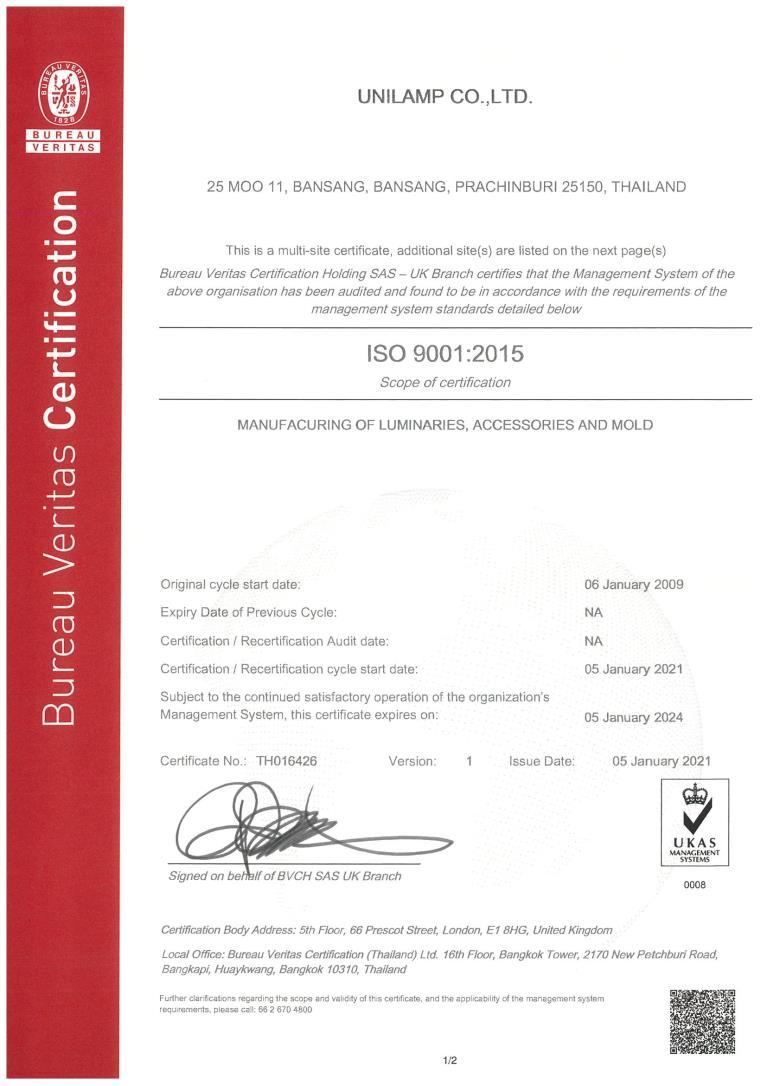

Founded in Thailand in 1993 Unilamp has become the leading manufacturer of outdoor lighting and indoor lighting applications.

To be recognized as a leading global and innovative lighting manufacturer.

To be acknowledge as an ethical and sustainable company by our customers.

Right in the Middle..... while at the forefront.

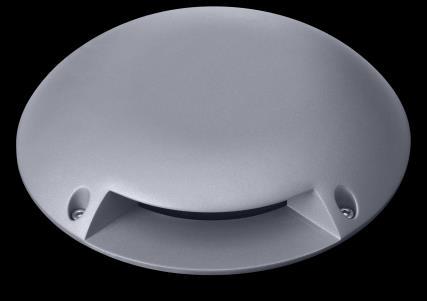

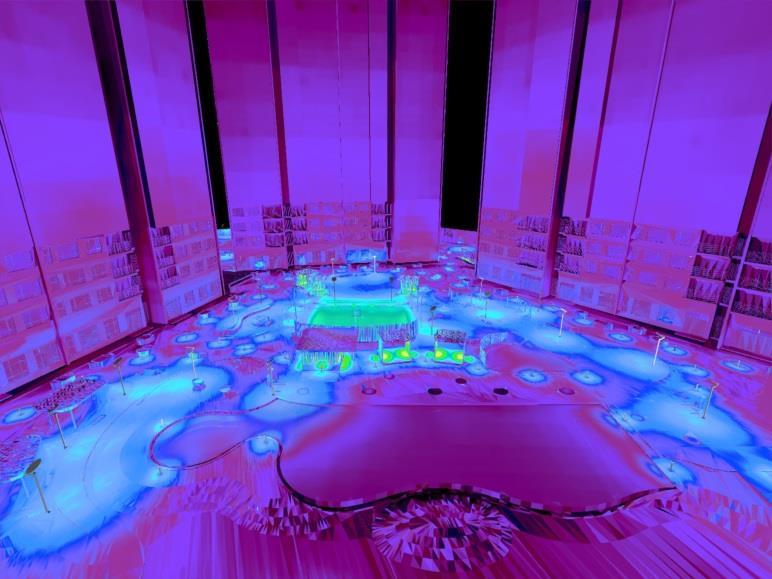

Unilamp is a B2B brand Focused on the high/ mid end Professional exterior luminaire market Sector.

Totally focused on producing quality, reliable, durable and functional luminaires.

A market leader in price/ Performance.

1993

• Established

1994 - 2000

• Export to Asian countries.

• Expanded export to include South America and Australia.

• Expanded export to include Europe.

2001 - 2010

• Exhibit at Light+Building in Frankfurt and Intel in Milan.

• Export to Europe/ Middle East/North America/Africa.

• Products approved by UL Demko

• Established in-house test lab.

• ISO 9001 / 14001 certified.

• Nano ceramic conversion implemented.

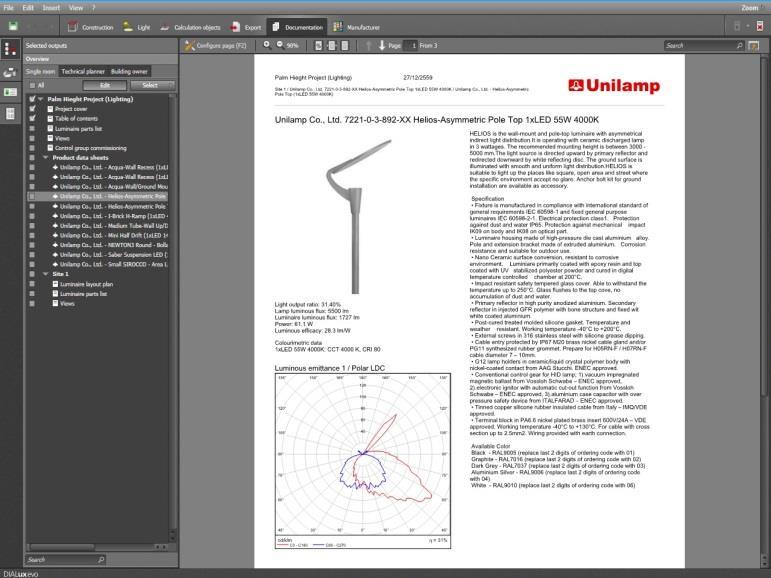

• Joined DIALux.

2011 – Present

• Products certified by VDE.

• Improved test facilities.

• Utilized Enhanced-LM6 alloy in high pressure die-casting process.

• Factory expansion.

• Unilamp Norden in Scandinavia.

• Established Sales support office in UAE. and India.

• Obtained ENEC certification issued by VDE.

• In-House testing lab has ISO/IEC 17025 accredited by NAC and ILAC.

• Open new business area in Indonesia.

• Renewal ISO/IEC 17025.

PRODUCT STANDARD WE FOLLOW

• IEC 60598-1 General Requirement and Test for Luminaires

• IEC 60598-2-1 Fixed Luminaires

• IEC 60598-2-2 Recessed Luminaires

• IEC 60598-2-3 Road and Street Lighting

• IEC 60598-2-5 Flood Light

• IEC 60598-2-6 Luminaires with Built-in Transformer

• IEC 60598-2-13 Ground Recessed Luminaires

• IEC 60598-2-18 Luminaires for Swimming Pools

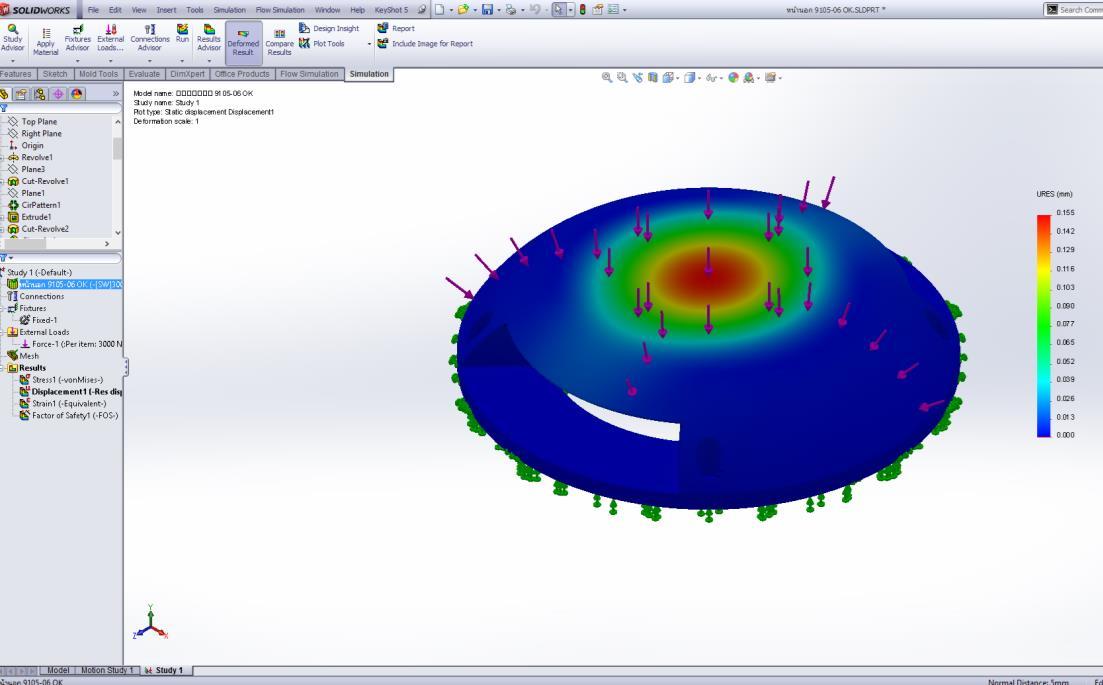

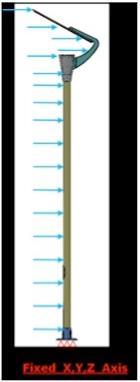

Boundary Condition

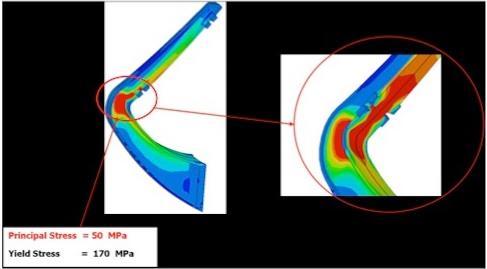

Principal Stress on arm

Wind Speed 150 km/hr

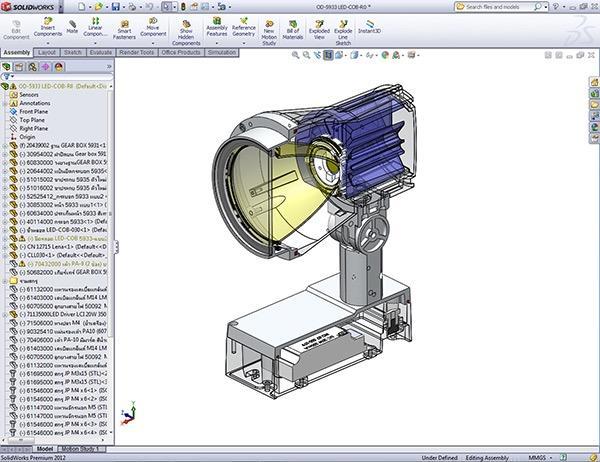

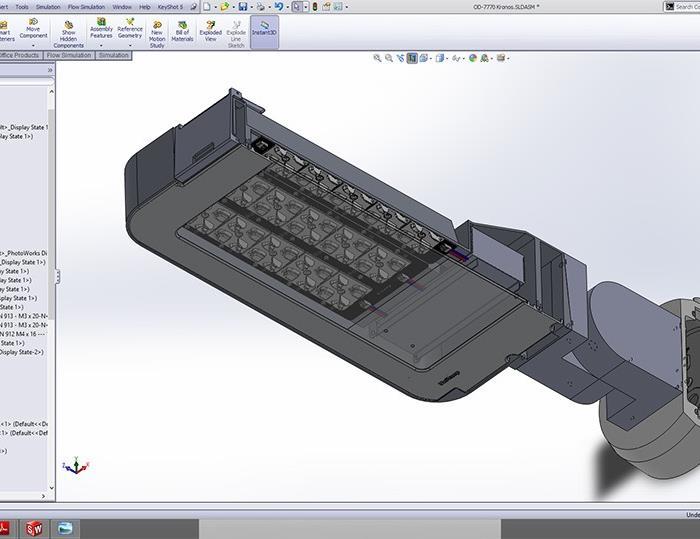

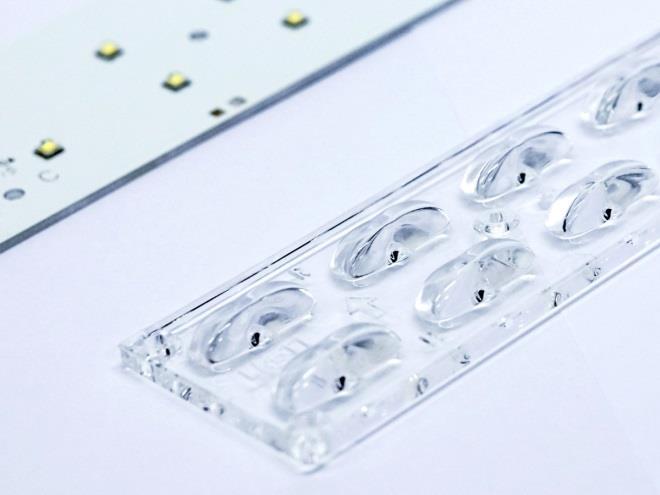

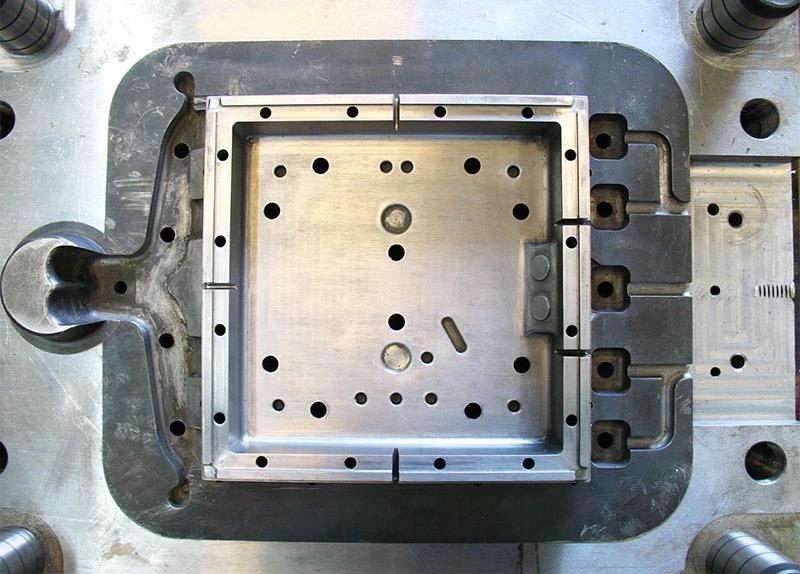

All Moulds and tools are made to exhaustive Unilamp procedures. Equipped with computerized CNC milling equipment for a precision moulding assists us to achieve high flexibility in mould manufacturing.

We utilize many CNC machines in this process to ensure that the highest quality of our materials and products are achieved. Health & Safety standards are our first priority and we strictly follow ISO 9001 and 14001 working procedures.

Unilamp complete coating process consists of 16 stages. Nano Ceramic surface conversion process optimizes the corrosion resistant property and increases powder coat adhesion.

1. Nano ceramic layer

2. Primer coating

1. Nano ceramic layer

2. Primer coating

Only well-trained work forces are allowed to work in the assembly unit. They perform the assembling works according to the illustrated manuals.

QC staffs regularly check the work-inprocess and finished goods in the assembling line.

At the final stage we carry 100% electrical check according to VDE requirement.

Raw materials, components and finished goods are kept in the warehouse in proper packaging with identification tags/numbers. FIFO system is in use in the warehouse.

Thanks to your commitment and strong work ethic, we know next year will be even better than the last.

We look forward to working together.