FRICTION FOCUS & FORWARD MOTION MOMENTUM

ALISON DUNN’S JOURNEY FROM TRIPLE GATOR TO PECASE RECIPIENT CHARTS A PATH OF CURIOSITY, MENTORSHIP, AND PURPOSE.

MAE Momentum is a publication of the Department of Mechanical and Aerospace Engineering at the University of Florida.

INTERIM DEPARTMENT CHAIR

Douglas Spearot, Ph.D.

EDITORS

Melanie DeProspero

Christi Swiers

GRAPHIC DESIGN

Christi Swiers

WRITERS

Katherine Canev

Gina Schoenfeld

Christi Swiers

EDITORIAL CONTRIBUTORS

Doug Bennett

Emily Hinds

Andrew Zuehl

WEBSITE

MAE.UFL.EDU

SOCIALS

facebook.com/UFMAE instagram.com/UFMAE linkedin.com/school/UFMAE linktr.ee/ufmae x.com/uflmae youtube.com/@UFMAE

From Our Interim Chair

It’s an exciting time for the Department of Mechanical and Aerospace Engineering. As I step into the role of Interim Department Chair, I’m honored to build on the strong foundation laid by Dr. Warren Dixon and to continue advancing the mission of our department with fresh focus and momentum.

This edition of MAE Momentum highlights just a few of the remarkable people and projects that make UF MAE a hub of innovation and excellence. From cutting-edge research in tribology to student-led engineering outreach across the globe, our community is tackling big challenges with creativity, skill, and purpose.

One of the strengths of this department is its scope — we’re not only educating future engineers, we’re shaping the technologies and systems that will define the next generation. That means investing in interdisciplinary research, supporting entrepreneurial thinking, and working together across fields and institutions. It also means ensuring that our department remains a welcoming and inclusive environment where all students, faculty, and staff can thrive.

As we look ahead, our priorities include expanding research capabilities, strengthening industry partnerships, and preparing our graduate and undergraduate programs to meet the evolving needs of the engineering profession. With your continued support, we are well-positioned to lead in areas ranging from aerospace systems to sustainable energy and autonomous technologies, just to name a few of our many strengths.

Thank you for being part of our journey. I hope this issue of MAE Momentum gives you a glimpse into the exceptional work being done here — and a sense of the exciting path ahead.

Douglas Spearot, Ph.D.

Newton C. Ebaugh Professor

Interim Chair

A CLOSER LOOK: FACTS & FIGURES

At the University of Florida Department of Mechanical & Aerospace Engineering, numbers tell a story of legacy, growth, and impact. As we approach the 120th anniversary of our mechanical engineering program and the 80th of aerospace engineering, we celebrate a tradition of excellence that continues to evolve. With nearly 60 faculty members and

190 Active Federal & Industry Grants

#

20

GRADUATE

28.8M Research Expenditures Active Grants Over $1M

over 3,000 students, MAE is one of the largest and most intellectually diverse departments in the Herbert Wertheim College of Engineering. Our research spans the fundamentals of force, energy, and motion—driving innovation in design, manufacturing, propulsion, and control systems. These numbers reflect more than scale; they represent a thriving community of thinkers, builders, and pioneers shaping the future of engineering.

14

GRADUATE AEROSPACE ENGINEERING PROGRAM RANKING #

Enrolled 3000+

40

Forbes ranks UF No. 5 public university in the Nation

5

25

MAE Faculty have won NSF CAREER or other Young Investigator Program Awards

FAST, BRIGHT, FEARLESS Solar Gators Electrify Collegiate Racing

1,550 Miles of Grit in Sunrider

The Department of Mechanical and Aerospace Engineering at the University of Florida is beaming with pride as the Solar Gators continue to make waves on the national solar car circuit. Over the past two years, this student-led team has demonstrated not only engineering excellence but also the power of teamwork, perseverance, and rapid innovation.

In 2024, the Solar Gators made their debut in the Electrek American Solar Challenge, driving 1,550 miles from Nashville, TN, to Casper, WY, in their solar-powered vehicle, Sunrider.

Along seven National Historic Trails, they faced intense conditions and technical demands, proving their grit and engineering skill at every turn.

460 miles in 3 days

1st Place MathWorks Presentation

Fastest Lap, 2025 FSGP

$10K, 2024 Altair Prize

That same year, they also took home the $10,000 grand prize in the Altair Challenge at the Formula Sun Grand Prix, where their optimized suspension component stood out among collegiate competitors nationwide.

But they didn’t stop there.

Flare Ignites a New Era

In 2025, the team returned to the Formula Sun Grand Prix with a new solar car, Flare—a complete redesign featuring a monocoque chassis, double wishbone suspension, and a custom battery management system. Flare didn’t just look good—it set the fastest lap of the competition and logged 460 miles over three days, the team’s second-longest total ever

and the best showing among teams debuting new cars.

Solar Gators also dominated offtrack challenges, taking first place in the MathWorks presentation competition and second in the Altair Challenge, earning a combined $1,200 in prizes and valuable tech tools. Their performance outpaced top-tier competitors like UC Berkeley and UT Austin, proving once again that Gator Engineering is built to lead.

With their eyes on the 2026 season, Solar Gators is committed to advancing Flare further and chasing an even stronger finish.

The team continues to represent UF with passion, pride, and technical prowess.

SUPERSTAR IGEM TEAM WINS IN PARIS

By Katherine Canev

The UF Chapter of iGEM dazzled 2024 Grand Jamboree judges, earning a gold medal for their research into sepsis, a life-threatening condition that results from the body’s dysregulated response

International Genetically Engineered Machine (iGEM) is a global competition

build genetically engineered systems to solve real-world problems using synthetic biology. Teams present their projects at the annual Grand Jamboree, competing for medals based on their ingenuity, technical achievements, and societal impact.

to hone their skills through

Under the guidance of Pan, team developed the procedures for their project and split into teams: Wet Lab, Dry Lab, and Human

“I’m

really proud of them, they put so much effort into this year’s competition, and receiving the gold medal is a huge accomplishment. It’s not just about the award—it’s about recognizing the impact of their work and the passion they brought to this project.”

-Jing Pan Ph.D.

The project had two key components: first, the team worked with induced pluripotent stem cells (iPSCs), which are reprogrammed body cells that act like versatile embryonic stem cells. By influencing iPSCs biochemically, they generated an organoid – a simple tissue culture that mimics the function and structure of a real organ – that simulates human bone marrow. These organoids can be utilized in preclinical studies in place of animal models, a major achievement for ethical testing.

Next, the team created a computational model for the

growth and behavior of different cell populations in bone marrow. The framework was based on a series of mathematical differential equations, highlighting the changes in the bone-marrow organoid at different stages of infection. The team faced many challenges due to the nature of their research, and they made an impression on both judges and participants with their creativity and success.

“You never really feel ready, no matter how much you prepare,” said Caleb Faison, captain of the Dry Lab team.

The iGEM competitions emphasize troubleshooting and flexibility, because the research is conducted under such tight time constraints. As a result, the team gained confidence as the competition progressed.

“At the Jamboree, we were able to connect with students and scientists from across the globe and learn from their unique work,” said Julia Jamieson, captain of the Human Practices team. “It was an amazing experience, and we are grateful for the support we have received from our sponsors throughout UF.”

IGEM Team at the 2024 Grand Jamboree in Paris, France

STUDENT GROUPS IN ACTION

These highlights showcase just a few of the exceptional groups whose dedication, creativity, and teamwork are shaping the future—one project at a time.

ASME supports UF mechanical engineering students through mentorship, networking, and hands-on events. The group earned the Student Section Achievement Award after a year of standout programming, including its first Design Team Showcase.

“It’s incredible to see our designs come to life. There’s no greater feeling than watching our airplane fly, knowing all our hard work paid off.”

– Isabel Stalcup, Project Manager

Gator Robotics builds combat robotics for competition, fabrication, and systems integration. This year, they completed their first 30lb battlebot, the highest weight class in their league, and qualified two 12lb bots for the NHRL Championship.

“MAE GSC has been a vital space for me to connect with fellow grad students who truly understand the ups and downs of graduate school.”

– Kaitlyn Downer, Social Chair

“ASME has connected me with friends, mentors, and the tools I need to succeed.”

– Eli Sacks, Secretary

Each year, UF’s Design/Build/Fly team designs and manufactures a custom aircraft for international competition against top engineering schools. This spring, they placed 33rd out of 112 teams at the AIAA DBF Competition in Tucson, Arizona.

Swamp Launch Rocket Team is a home for students with a passion for rocketry and a desire for greatness. Swamp Launch pushes the boundaries of rocketry by designing, building, and innovating on multiple rockets to foster teamwork and technical skills needed to ensure our student’s success in their future industry careers.

“Leading Gator VEX Robotics has been an incredible privilege—the dedication and skills gained here are truly unmatched.”

– Cannon Spencer, President

“I came into the club knowing absolutely nothing, and now I’m building some of the most competitive bots in the nation.”

– Adam Smith, Treasurer

MAE GSC fosters community through social and professional events. This spring’s students vs. faculty kickball game ended in a proud student win—proof that teamwork goes beyond the lab.

“Being able to collaborate on such a meaningful project with all kinds of other motivated engineers has been one of the most enriching experiences of my life.”

– Alejandro Izcaray, NASA USLI Project Manager

GATR VEX Robotics gives students hands-on experience in competitive robotics for the VEX U collegiate league. In the 2024–2025 season, both their teams qualified for the VEX U World Championship in Dallas, with GATR1 finishing in the top 30% worldwide. The team also earned the prestigious Design Award.

GRADUATE RESEARCH AND INNOVATION

MAE STUDENTS SUPPORTED BY NSF

The National Science Foundation (NSF) Graduate Research Fellowship Program supports outstanding students pursuing advanced degrees in science, technology, engineering, and mathematics. Recipients receive funding to conduct independent, high-impact research and develop professional skills. In 2025, UF mechanical and aerospace engineering graduates Taylor Johnson and Gabriella Peburn were named NSF fellows, joining a select group recognized for their potential to advance research and innovation.

Gabriella Peburn

Taylor Johnson

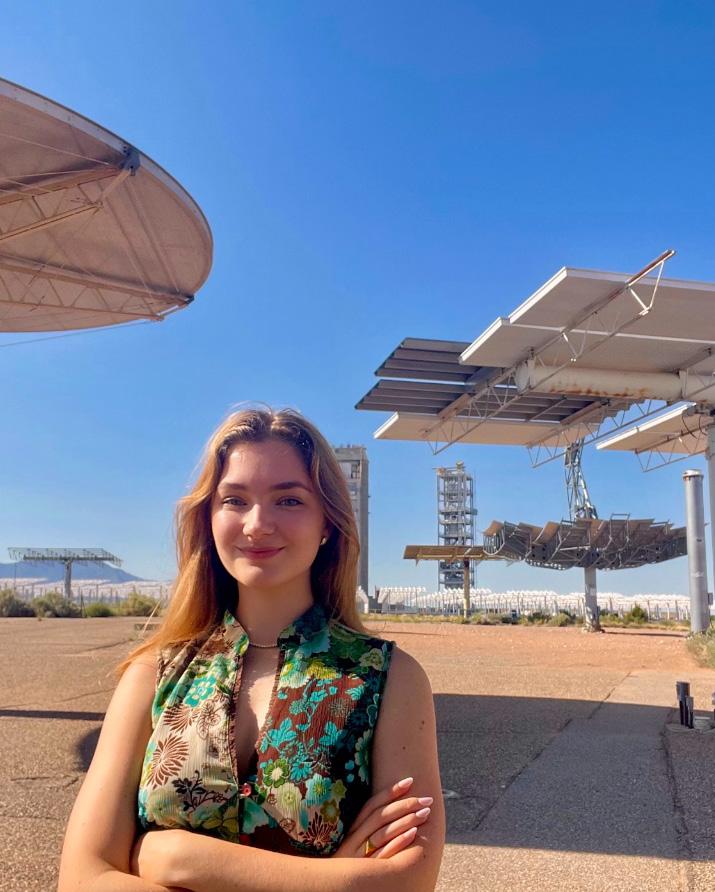

Taylor Johnson, a summa cum laude mechanical engineering graduate, has begun her Ph.D. in chemical engineering at the University of Colorado Boulder, where she continues her research on renewable energy and sustainable technologies. At UF, she worked in the Renewable Energy Conversion Laboratory under Johnathan Scheffe, Ph.D., developing a thermodynamic model for a solar thermochemical water-splitting cycle to produce hydrogen fuel. Her research journey has also included internships at MIT’s Electrochemical Energy Lab, the National Renewable Energy Laboratory, and Sandia National Laboratories’ National Solar Thermal Test Facility. Her fellowship provides the support to pursue long-term projects in solar energy and thermal storage, and she sees it as an opportunity to advocate for increased investment in clean energy research. Beyond the lab, Taylor demonstrated a commitment to global impact through Engineers Without Borders, leading the Peru design team in addressing critical energy challenges in underserved communities. She also served as a teaching assistant for courses including Solar Energy Utilization, Heat Transfer, Fluid Mechanics, Thermodynamics, and Computer-Aided Design.

Gabriella Peburn, an aerospace engineering graduate, has begun her Ph.D. in aerospace engineering at Georgia Tech. At UF, she conducted pioneering work in robotics and autonomous systems, including bridging communication over Starlink from Autonomy Park to the Research and Engineering Education Facility (REEF) at the Air Force Research Lab at Eglin Air Force Base and controlling dynamic quadruped robots using online deep learning. Her NSF fellowship supports research advancing spacecraft systems and fostering responsible innovation in collaboration with NASA.

Parallel to her technical work, Gabriella served as a Student Government senator, led a design team with the Swamp Launch Rocket Team, and completed internships with AFRL, Lockheed Martin Space, and Universal Studios Creative. Reflecting on her experiences, she said, “I hope my research will contribute to the pursuit of truth and justice in society by advancing technologies that promote safety and responsible innovation. My goal for the work I do is that it will serve others, and it will contribute to the good of humanity and the glory of God.”

MAE & ASTRAEUS

PARTNERSHIP

IN ACTION

At UF, the Astraeus Space Institute and the Department of Mechanical and Aerospace Engineering work side by side to push the boundaries of space research. Astraeus brings together experts from across disciplines, and MAE faculty and students are at the heart of many of its projects. By combining big-picture vision with hands-on engineering, the two strengthen each other—turning bold ideas into the experiments and technologies that will shape the future of space exploration.

That spirit of collaboration is clear in the work of MAE Associate Professor Amor Menezes and his SyBorgs Lab, where researchers are using synthetic biology to develop biomanufacturing solutions for space. Among them is Ph.D. student Hannah Roberts, whose recent experience training U.S. Air Force Academy cadets highlights the impact of this partnership in action.

Hannah Roberts Represents UF in Space Force Research Project

By Emily Hines for The Astraeus Space Institute

Roberts recently represented UF in a prestigious collaboration with the U.S. Air Force Academy and Space Force, where she trained cadets in synthetic biology techniques for spaceflight experiments.

As the only UF student selected for the project, Roberts traveled to the Air Force Academy in Colorado to support cadets in designing, launching, and analyzing biological experiments aboard zero-gravity parabolic flights. The work is part of a larger mission funded by the Air Force Office of Scientific Research. It also included academic partners at Washington University in St. Louis.

Roberts works under Amor Menezes, Ph.D., in UF’s SYstems/SYnthetic Biological Optimization, Regulation, or Generation Systems Laboratory, which engineers living cells for space and medical applications.

“This was such an exciting opportunity,” said Roberts, who is also president of the Astraeus Space Institute’s student organization at UF and a student in the College of Medicine. “I was the only UF student out there, helping teach cadets how to run spaceflight experiments using synthetic biology. It was hands-on and very collaborative. I feel incredibly lucky to represent UF in this way.”

In addition to assisting with experiment design and flight operations,

Roberts is now back in Gainesville analyzing samples and collecting data.

The goal of the experiment was to provide further insight into the “make it don’t take it” approach of using engineered microorganisms to produce useful compounds in space — known as biomanufacturing — rather than bringing all resources from Earth. For this experiment, Roberts and the cadets captured the genetic response of live, engineered and non-engineered cell cultures to real-time changes in gravity level aboard the parabolic flights.

The data will allow the research team to understand how microbes notice and respond to various gravity levels, and how that affects the ability of these microbes to produce various resources. In this case, the engineered microbes produced a precursor to vitamin A, which could be beneficial for supporting vision health in space.

“All the samples are back in our lab, and we’re processing them so we can learn from them,” Roberts said. “It’s great because we can compare these results with our previous missions to the International Space Station, where we studied the long duration effects of low gravity on these engineered microbes. It’s all connected and helps us move the science forward.”

“This isn’t just research — it’s training the next generation of scientists and engineers for space, and I get to be a part of that, as a student and as a Gator. That’s pretty amazing.” - Hannah Roberts

The research project reflects UF’s rising national profile in aerospace and biological science collaboration, especially in real-world space contexts.

Hannah Roberts

ENZYMES AS NANOSCALE MACHINES

The

Intersection

By Christi Swiers

of AI, Biochemistry, & Engineering

Enzymes are nature’s tiny machines, responsible for everything from digesting food to breaking down environmental pollutants. But what if we could design custom-made enzymes to tackle real-world challenges—like neutralizing harmful chemicals or detecting diseases—more efficiently than ever before?

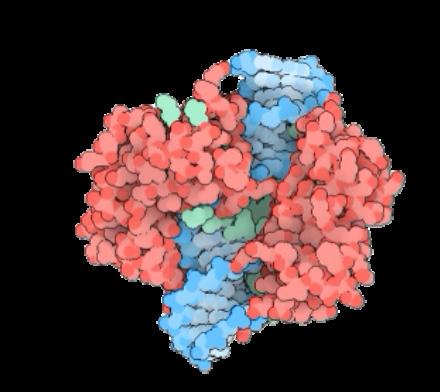

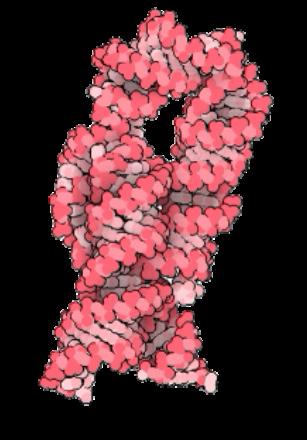

Jing Pan Ph.D., a faculty member in the Department of Mechanical and Aerospace Engineering at the University of Florida, is pioneering an innovative approach to enzyme engineering. By combining artificial intelligence (AI) with molecular simulations, his team is developing nanoscale enzyme machines with unprecedented precision and functionality.

Through a collaboration with Wenjun Xie Ph.D., from UF’s College of Pharmacy and funding from the Defense Advanced Research Projects Agency (DARPA), Pan’s research is pushing the boundaries of what’s possible in molecular design. By leveraging AI to predict protein structures and refine their performance through advanced simulations, this work has the potential to transform fields ranging from medicine to environmental protection to defense.

Engineering Next-Gen Biosensors

Pan’s lab specializes in biosensors capable of continuously monitoring human physiology. At the heart of these biosensors are specialized molecules, such as enzymes, that function as nanoscale machines, detecting and responding to biochemical changes within the body. However, designing artificial enzymes that rival natural ones in efficiency remains a major hurdle. Traditional protein design relies heavily on trial-and-error experimentation, but the vastness of the protein design space far exceeds what can be physically tested in the lab.

To address this challenge, Pan and Xie’s teams are developing an AI-driven engineering pipeline that automates and optimizes enzyme design. By leveraging AI to predict protein structures and using molecular simulations to refine functionality, they aim to significantly improve the success rate of enzyme development while reducing the need for extensive laboratory experimentation.

A Proof-of-Concept: Improving Dehalogenase for Industrial and Defense Applications

As an initial test case, the research team is focusing on haloalkane dehalogenase, an enzyme capable of breaking down harmful halogenated compounds. This enzyme has broad applications in industrial and defense settings, such as:

• Chemical Weapon Neutralization: Mustard gas, a toxic halogenated agent used in chemical warfare, could potentially be neutralized through enzymatic hydrolysis using optimized dehalogenase.

• Environmental Bioremediation: Many halogenated pollutants, including pesticides and industrial waste, persist in soil and water. Engineered dehalogenase could be deployed to detoxify groundwater and clean up industrial contamination sites.

While this project primarily serves as a proof-of-concept, the overarching goal is to establish a generalized AI-driven approach for enzyme engineering. By demonstrating the ability to create artificial enzymes with tailored properties, this research could open doors to a wide range of applications,

including therapeutic protein design and infectious disease control.

“AI gives us an unprecedented ability to explore the vast landscape of protein possibilities, but experimental validation is crucial to ensuring these designs function in realworld conditions. By combining computational power with biochemical expertise, we can engineer enzymes with properties previously thought unattainable.”

- Jing Pan Ph.D.

Interdisciplinary Collaboration: AI Meets Experimental Biochemistry

The success of this project is rooted in interdisciplinary collaboration. Xie, an expert in AI-driven enzyme design, generates candidate protein structures using generative AI. Pan’s lab then synthesizes and experimentally validates these proteins, to characterize their performance. This synergistic approach allows for iterative refinement of enzyme designs, ensuring that the final proteins meet the desired functional criteria.

Future Directions: Expanding the Scope of AI-Driven Molecular Engineering

Pan’s team is in the early stages of validating their technology, but they envision a future where AI-generated protein machines can perform a variety of critical tasks. Potential applications include:

• Custom-designed enzymes for targeted disease monitoring

• Therapeutic proteins optimized for human physiology control

• Enzymatic solutions for industrial and environmental challenges

While the current focus is on dehalogenase, the principles developed in this study could be adapted

to engineer a broad range of functional enzymes. By bridging the gap between AI-driven predictions and real-world biochemical functionality, this research marks an important step toward the future of molecular engineering.

Above: A look inside the lab spaces where AI-driven enzyme engineering takes shape

Left: Jing Pan, Ph.D. and Wenjun Xie, Ph.D. at AI BTO Pitch Day

Right: Prototype Microfluidic Chip for Biomolecular Analysis in Blood

Right: Single molecule characterization instrument in Pan’s lab

A HARSH ENVIRONMENT

Making space more hospitable for people and machines

by Doug Bennett

Excerpted from a full-length article originally published in Explore Magazine.

While people on Earth are thinking about self-driving cars, Christopher “Chrispy” Petersen is focused on self-driving satellites.

Petersen, an assistant professor of aerospace and mechanical engineering, loves pushing the limits of satellite capabilities.

“If we already have all this real-time data from sensors and fine manipulation via actuators, can we use them in a novel way? Can we chain together our algorithms to do the mission in a unique and unconventional way?” he asks.

That pioneering mindset comes naturally to Petersen and other UF space researchers. It’s led them to forge paths in brain research, muscle atrophy and space manufacturing. Persistence and bootstrapping also help. As a prime example, Petersen used Lego robots early in his career to do crucial satellite simulations on a shoestring budget.

Ask Petersen about controlling and optimizing satellites and he gives a simple but powerful example.

“You can’t put a laptop into space,” Petersen says.

For Petersen, a typical computer’s limitations reveal the many difficulties that come with keeping satellites

on track and bringing them into proximity. He ticks off some of the issues: Radiation in space would fry a laptop within six months. Computer processors on satellites are a decade behind the ones on Earth. Even simply having enough electrical power to complete complex, automated tasks in orbit is an issue.

To solve these challenges, his lab optimizes satellite operations, hardware and software amid extreme mission and safety constraints. That means docking a satellite while minimizing fuel use, coaxing a satellite into a particular orbit as quickly as possible or autonomously exploring unknown regions around the moon. Bringing multiple satellites close together to complete these goals is a big complication.

Ultimately, Petersen says, those solutions involve a mix of speed, safety and reliability — all of which needs to be optimized for peak performance. Much of the work in his Spacecraft Technology and Research Laboratory focuses on docking or operating satellites in close quarters — about 300 miles apart. To do that, he creates algorithms that let satellites produce safe, desired results within time frames needed to complete the mission.

Space flight control has long been a lure for Petersen, ramping up when he was a graduate student in flight dynamics at the University of Michigan in the mid2010s. Shortly after graduating, he was developing software and determining orbital plans for satellites from the operations floor at the Air Force Research Laboratory in Albuquerque, New Mexico. One of his favorite missions was developing advanced guidance

Christopher Petersen, Ph.D.

algorithms for Mycroft, an experimental spacecraft launched by the Air Force in 2018 to enhance space object understanding and navigation capabilities. The project also investigated automated control mechanisms used for flight safety and explored methods for enhancing space situational awareness.

Not all of his Air Force work involved fancy equipment and multimillion-dollar spacecraft. In 2013, Petersen was working on a new, efficient algorithm. It needed proving on a test harness but money was tight. Petersen and his co-workers turned to Lego Mindstorms, the small, programmable robotic kits for children. He used the Lego kits to emulate satellite motions — a simple proof of concept that actual satellites could avoid each other in space. That success led to better robots, larger test facilities and more definitive scientific validation.

“I got to say that I played with Legos for the Department of Defense. Who can say that?” Petersen says.

Petersen’s research carries big implications and even bigger goals: A nimble, carefully guided spacecraft that can fix or refuel satellites without humans. Space equipment that’s too large to launch intact can be built in orbit – but only if the satellites doing the assembly can work meters apart and in tandem. Satellites can also benefit from in-flight upgrades to graphics cards or rocket engines. Forty percent of satellites have a failure in their first year of operation. After that, problems become even more routine.

“If we can fix those failures in orbit, the life of a

spacecraft can be significantly extended,” Petersen says.

Petersen’s advances in precise guidance and satellite proximity are key to making that happen. That includes evolving robotic arms to better control what happens during satellite docking and repair missions. He’s also looking at ways to increase the life of spacecraft by designing modular “plug and play” components. With this comes another effort focused on making satellites less vulnerable to failure and hacking. That means satellites with multiple parts from different vendors can be operated with fewer concerns about unexpected events.

As satellites get more autonomous, mission-control workers can focus on interpreting incoming data, giving higher-order directives and other human-oriented tasks, Petersen says.

“What I get out of my work is a sense of relief that the overall mission has been accomplished,” he says. “I’m not the most important thing on a satellite team. It’s the science. It’s the mission. If I can make that happen, then that’s the best feeling.”

-Christopher Petersen

FRICTION FOCUS & FORWARD MOTION

Alison Dunn’s journey from triple Gator to PECASE recipient charts a path of curiosity, mentorship, and purpose.

By Christi Swiers

Engineering For The Body:

Biomedical research that bridges surfaces, sensation, and human-centered design.

Alison Dunn Ph.D. makes surfaces behave. It’s not magic—it’s mechanics. Through her work in tribology, she explores friction, wear, and lubrication to better understand how materials move and interact. Her ultimate goal? To define the design rules for soft materials, especially those used in biomedical devices like contact lenses and artificial joints—materials that need to feel like they belong in the body.

Dunn describes her research in simple terms: “I make surfaces behave the way we want them to.” Her lab focuses on soft, water-based gels, called hydrogels, that can be engineered to feel right when in contact with the human body. That “feel” isn’t just about comfort; it’s a critical aspect of biomedical compatibility. Her team studies how to tune properties like water content, surface structure, porosity, and deformation to control how a surface feels when something slides against it.

This work holds promise for a wide range of applications— from soft contact lenses to heart valves, artificial joints and other devices that interface directly with human tissue. Dunn sees the broader purpose in all of it: building the knowledge that will allow others to design safer, more effective technologies.

One of her current projects, in collaboration with Shelby Hutchens at UIUC, explores the mechanical experience of inserting a needle through layered materials—an everyday but complex task in medical procedures. To better understand this interaction, Dunn’s team uses soft synthetic models that mimic the behavior of biological tissues. They measure how much effort is needed to advance a needle through these materials and how surface interactions influence that motion. By studying both the resistance to entry and the friction along the surface, they’re building a more complete picture of how tools interact with soft matter.

The next phase of the project involves using microscopy to observe these interactions at a fine scale, helping the team understand how material structure and movement influence one another. The goal is to develop predictive models that can anticipate the tactile feedback a practitioner or robotic system might encounter—turning a traditionally intuitive process into one grounded in measurable mechanics.

This research could enhance medical training by helping clinicians understand what to expect when navigating complex tissue environments. It also holds promise for improving robotic needle systems, allowing them to respond more intelligently to subtle changes in material

properties. Instead of relying solely on force sensors, these systems could be guided by a mechanical “map” of expected feedback, improving precision and safety.

“I want to create new fundamental design rules,” she explains. “We don’t yet have a handbook for soft materials the way we do for engineering materials. I’m hoping to help write that someday.”

A hydrogel sample from Dr. Alison Dunn’s lab. These soft, waterrich materials hold the key to biomedical devices that feel like they belong in the body.

Beyond The Body

While much of Dunn’s work focuses on biomedical applications, her passion for tribology extends far beyond the human body. At its core, her research explores how surfaces move and interact, a question that spans biology, robotics, and even mechanisms in space.

“Once you start thinking about friction, you see it everywhere. It’s in how we move, how machines operate, how animals jump, grip, or glide.”

That curiosity led her lab to draw inspiration from an unexpected source: the click beetle. Led by her first Ph.D. student, Nabin Bastola, the project investigates how these small insects use a latching mechanism to store and explosively release energy, propelling themselves into the air.

The team studies how friction governs the motion of the latch, with an eye toward replicating the mechanism in robotics or space systems that require rapid mechanical motion without complex power sources.

A click beetle, known for its signature spring-loaded jump.

“It’s a great example of how biology can inspire better engineering. We’re imagining uses

in deserts or space, anywhere you need fast deployment without a lot of machinery.”

This work could inform low-power, highefficiency systems for planetary exploration, disaster response, or remote sensing. Bastola has already built a latching friction tester to study the mechanics in detail and is leading the experimental work as part of his doctoral research. Bastola’s work reflects the kind of curiosity Dunn has nurtured throughout her career—one that began with a promise, a pivot, and a mentor who saw her potential early on.

The Click Beetle (Family: Elateridae)

Species: 10,000+ globally

Size: up to 1 inch

Common Names: click beetle, snapping beetles, spring beetles, or skipjacks

Click beetles can right themselves from a flat position without using their

A Promise & A Pivot:

“You’ll be back.” Dunn didn’t believe Dr. Greg Sawyer, her undergraduate research advisor and longtime mentor, when he said those words years ago. She was finishing her bachelor’s and master’s degrees in mechanical engineering at UF and preparing to leave for a Peace Corps assignment in China. “I swore I wouldn’t,” she remembers. “But he knew.”

Two years later, while teaching English overseas, Dunn realized just how much she missed research, and how much she loved teaching. She emailed Sawyer: “You were right.” He welcomed her back into his lab, and she began her Ph.D. in 2008. Her research flourished, spanning hydrogels for soft contact lenses, friction in bulk polymers, and even lubrication of living tissues. Along the way, she navigated the dual challenges of graduate school and new motherhood with Sawyer’s encouragement helping her find her stride.

“I aimed for academia,” Dunn says. “Not with a rigid goal, but with the intention to give it my all.”

Palm & Pine vs.

Corn & Soybeans

After completing her doctorate in 2013, Dunn taught at UF as a teaching fellow, then landed a faculty position at the University of Illinois Urbana-Champaign. She spent nearly a decade there, launching her own research program and mentoring students. But she never lost her Gator spirit.

“We grew deep roots at Illinois, but UF remained dear to us. We watched every

legs by rapidly releasing a latch-like joint between the thorax and abdomen. The sudden, powerful release produces the “click” sound and enough energy to launch the insect into the air. Alison Dunn’s work investigates this extreme energy release in biological systems to better understand power amplification, material limits, and potential applications in engineered structures and robotics.

football game from Illinois and stayed connected to Gainesville from afar.”

Even miles away, she and her husband maintained a special connection to Gainesville, signing up for the SEC Network, tuning into games, and holding on to fond memories of the South and the swamp.

When she heard that Sawyer was stepping away from UF, she reached out—curious whether the department was looking for someone to build on the work they had shared. That led to a conversation with Dr. Warren Dixon and, eventually, an opportunity she couldn’t pass up. Dunn returned to UF MAE in 2024.

Mentorship & Motivation

Dunn’s lab is growing quickly, with students from diverse technical backgrounds and academic levels. Many presented at the Society of Tribologists and Lubrication Engineers (STLE) annual meeting in 2025, an event Dunn has attended since 2005.

She’s committed to teaching as much as research. “I love helping students build their engineering intuition,” she

Below: An imagined landscape of Gainesville, Florida.

says. “Not just solving problems, but understanding how to think like engineers.”

Her Ph.D. student Nabin Bastola, originally from Nepal, says working with Dunn has been both technically enriching and personally meaningful.

“Dr. Dunn has played a pivotal role in my growth as a researcher by encouraging me to be open and communicative. Last semester, she motivated me to participate in the STLE Tribology Conference, where I was able to share my research ideas effectively and learn from the work of others. She is always willing to provide resources and opportunities that foster my development, while also emphasizing the importance of interdisciplinary collaboration and critical thinking.”

- Nabin Bastola

Leading with Purpose

This year, Dunn received one of the most prestigious honors in the country for early-career researchers: the Presidential Early Career Award for Scientists and Engineers (PECASE). Presented by the White House, the award recognizes scientists and engineers at the frontiers of innovation and community impact. Dunn was nominated by the National Science Foundation for her pioneering work in tribology and her deep commitment to mentoring students.

The award affirms the significance of her research on surfaces and materials, which directly impacts technologies ranging from biomedical devices to robotics. It also connects her to a national network of scientists working to advance both science and society.

For Dunn, the recognition brings renewed energy and a sense of responsibility to continue mentoring, asking bold questions, and contributing to the field. It marks a milestone in a journey that began in Gainesville, stretched around the globe, and ultimately led her back to UF.

In addition to receiving the PECASE in 2025, Dunn has earned several other prestigious recognitions for her contributions to tribology and engineering education. She was awarded the NSF CAREER Award in 2018, the ASME Burt L. Newkirk Award in 2019, and was named a 2024 Rising Star by the Academy of Science, Engineering, and Medicine of Florida (ASEM-FL). She also holds the Robert and Jill Peterson Professorship, a position that supports the continued growth of her research program at UF.

At home in Gainesville, Dunn and her family live close to

campus and enjoy being part of the local culture. They recently added a black lab puppy to the mix and spend their free time visiting coffee shops, attending UF events, and riding bicycles around town. She is grateful to be rooted in the place where it all began, a place that continues to inspire her work and her outlook.

“I try to focus on what I can do,” Dunn says. “There are always challenges: funding, tenure pressures, the unknowns. But I believe in the work, and in the good it can do.”

Triple Gator to PECASE

2006

2007

2009

2013

2014

2018

Graduates from UF with a dual BS/MS in Mechanical Engineering

Begins teaching English in China with the U.S. Peace Corps

Returns to UF to begin Ph.D. in Mechanical Engineering

Earns Ph.D. from UF

Joins University of Illinois UrbanaChampaign as faculty

2019 Receives the NSF Career Award

Receives the ASME Burt L. Newkirk Award

2022

Spends sabbatical semester at Imperial College London

2024 Returns to UF, is honored with the Robert & Jill Peterson Professorship, & receives the ASME Rising Star Award

Is honored as a PECASE Receipent

Nabin Bastola

2025 DISTINGUISHED ALUMNI

The Department of Mechanical and Aerospace Engineering at the University of Florida proudly welcomes its 2025 Distinguished Alumni inductees. These exceptional engineers have demonstrated remarkable achievement, leadership, and innovation throughout their careers. Their achievements highlight the lasting influence of Gator Engineers around the world.

Carlos Fernandez

B.S. 2005

Analyst, Upstream Acquisitions and Divestments

EXXONMOBIL

Carlos Fernandez has spent the past two decades at ExxonMobil, supporting global operations, projects and strategic initiatives, including establishing technical support centers in Malaysia and India. He continues to drive innovation and leadership within the company. Outside of work, Fernandez enjoys marathon and ultrarunning, traveling, and spending time outdoors with his wife Molly, also a Gator alum, and their two children.

Benjamin Griffin

Ph.D. 2009, M.S. 2006, B.S. 2003

Senior Vice President of Research Partnerships

APPLIED RESEARCH INSTITUTE

Benjamin Griffin is Senior Vice President of Research Partnerships at the Applied Research Institute and Senior Advisor for Strategic Research Development at Purdue University’s College of Engineering. Previously, he served six years at DARPA’s Microsystems Technology Office, including five as Program Manager, advancing innovations in microsystems. He began his engineering journey at UF, earning his BS and MS in aerospace engineering and PhD in mechanical engineering.

Above: MAE Distinguished Alumni in attendance at the 2025 MAE Annual Celebration of Distinguished Alumni & Awards Banquet

Baron Johnson

Ph.D. 2011, M.S. 2009, B.S. 2007

Chief Engineer AEROVIRONMENT, INC.

Barron Johnson is Chief Engineer at AeroVironment in the MacCready Works Advanced Solutions segment, where he develops advanced uncrewed aircraft systems (UAS). Previously, he spent 12 years at Dynetics working on experimental UAS projects. Johnson began his passion for aviation and engineering at UF, contributing to the Micro Air Vehicle and Flight Control Labs, and today he also inspires future engineers as an Adjunct Faculty member at Embry-Riddle Aeronautical University. He lives in Huntsville, AL with his wife Brekke and their two children.

Brandon Krick

Ph.D. 2012, M.S. 2011, B.S. 2007

Associate Professor

FLORIDA STATE UNIVERSITY

Brandon Krick is a faculty member at Florida State University, where he explores friction, wear, materials deformation, and adhesion across scales, from cells to nanocomposites, and in environments ranging from space to deep underwater. A proud Gator, he earned his BS, MS, and PhD in mechanical engineering at the University of Florida and also served as a postdoctoral associate here. Krick has conducted experiments on the International Space Station, studied wear in dinosaur dental fossils published in Science, developed ultra-low wear polymer nanocomposites, and collaborated internationally on soft matter research.

Oscar Martinez

Ph.D. 2007, M.S. 2004, B.S. 2003

Senior Research & Development Staff

Nuclear Materials Packaging, Transportation, and Systems Analysis Group Leader Program Manager for Package Testing Program

OAK RIDGE NATIONAL LABORATORY

Oscar Martinez is Program Manager for Oak Ridge National Laboratory’s Package Testing Program, leading critical regulatory testing of radioactive material transportation packages. He earned his PhD in mechanical engineering from UF and contributed to major NASA projects, including the James Webb Space Telescope and Orion crew capsule. Honored with the Great Minds in STEM Luminary Award, Martnez is also dedicated to mentoring and expanding STEM opportunities for underrepresented groups.

Tom Singer B.S. 2002

Senior Vice President of Research Partnerships

APPLIED RESEARCH INSTITUTE

Tom Singer earned his BS and MS in aerospace engineering from UF and has built a career in structural analysis and defense aeronautics, developing launch risk analysis software for the FAA and Air Force/Space Force and now managing a team of analysts. He remains connected to UF MAE through capstone courses and as chair of the Education Committee on the External Advisory Board. Singer lives with his wife Ruth, also a Gator, and their daughter Adelyn. Outside of work, he enjoys mountain biking, restoring a classic Mustang, and competing in regional curling championships.

Scan to view the full list of MAE Distinguished Alumni or to nominate someone for next year’s awards:

JOHN SULLIVAN INSPIRING ENGINEER AND CHAIR OF THE MAE EAB

By Gina Schoenfeld

John Sullivan, chair of the University of Florida Department of Mechanical and Aerospace Engineering’s External Advisory Board (EAB), has devoted his career to advancing aerospace engineering. The EAB is a group of industry and academic leaders who advise the department on curriculum, strategic initiatives, and student engagement to ensure graduates are careerready.

“As chair of the External Advisory Board, I believe it is our responsibility to support the university in shaping curriculum and fostering student engagement to help instill these skills before students graduate.”

-John Sullivan

After earning his bachelor’s degree from UF, Sullivan began working at Pratt & Whitney as an analytical engineer. During his time there, he developed expertise in subsonic, transonic and supersonic aerodynamics while also gaining practical skills such as effective communication, focus and planning. He identifies these qualities as critical for a successful engineering career.

Throughout his career, Sullivan continued his education by completing graduate coursework and writing a technical paper on axial compressor design. This would be followed by his master’s degree in aerospace from MIT, which he completed from 1997 to 1999.

certification of all major jet engines and components.

In the early 2000s, Sullivan returned to the United States and joined Hamilton Sundstrand as vice president of engineering for engine and control systems. In this role, he was appointed chief engineer of the Boeing 787 for Collins content.

“My work on this project was the most challenging and rewarding accomplishment of my professional career.”

The project involved more than five major aircraft systems, all of which were newly developed. As chief engineer, he was responsible for all technical matters, budget management, scheduling and certification of both individual components and the complete aircraft system.

“I was put on the program T-minus three years until certification, and I think I aged 10 years on it,” Sullivan said.

He later expanded his turbine design expertise internationally, working for Pratt & Whitney Canada as director of component engineering. There, he was responsible for the analytical design, development and

In retirement, Sullivan enjoys giving back through volunteer work. In addition to his role on the MAE External Advisory Board, he volunteers for Meals on Wheels and spent the past six months providing relief for victims of Hurricane Helene in North Carolina.

Sullivan’s advice to current MAE students is to “learn how to learn.”

“Expertise is fleeting, technologies are constantly changing, and learning how to learn will help you in the long run,” he said.

Sullivan’s lifelong commitment to service, growth and adaptability continues to inspire the next generation of engineers.

Left: John Sullivan at Hume Hall, 1978

John Sullivan

by Katherine Canev and Christi Swiers

Pictured: Boxerman with the Liquid Robotics Waveglider in the Pacific Ocean.

Rebecca Boxerman, Master of Mechanical Engineering and proud UF MAE alum, is soaring to new heights. From her early days as a driven student at the University of Florida to her leadership role within the Navy’s cutting-edge technology programs, Boxerman’s career reflects a rare blend of technical expertise, creative problem-solving, and dedicated mentorship. With a passion for aerospace and mechanical engineering, she has continuously pushed boundaries—whether mastering complex computational analyses, pioneering unmanned naval systems, or guiding the next generation of engineers. Her journey is marked not only by impressive achievements but also by the meaningful relationships and challenges that shaped her along the way.

Boxerman launched her career at General Electric Aviation in Massachusetts after graduating from the University of Florida. For two years, she specialized in finite element analysis for military turbine engines, using advanced computational models to predict how components would withstand real-world forces. Although the work was technically challenging and rewarding, Boxerman soon realized she was craving more—more creative control, more hands-on design, and more opportunities to think beyond conventional boundaries.

During her time in the Mechanical and Aerospace Engineering program at the University of Florida, Boxerman found herself truly challenged by both professors and peers. “UF MAE is an outstanding program because it commits completely to its students, constantly pushing them to learn, innovate, and develop their creativity and entrepreneurial spirit,” she said.

In particular, Boxerman credited her mentor Anil Rao, Ph.D. and University Term Professor at MAE, for his devotion to his students.

After leaving General Electric Aviation, Boxerman took a role with Naval Surface Warfare Center Panama City Division (NSWC PCD), contributing to the development of advanced helicopter systems designed to detect and neutralize mines. With a dual degree in mechanical and aerospace engineering, Boxerman continued her education during her time at NSWC PCD, earning her Master’s of Science in Systems Engineering at the Naval Postgraduate School in 2014.

In this post, Boxerman felt right at home. “It was satisfying to use my engineering degree to design systems that went directly to the Naval fleet for use,” she recalled.

After several years supporting the airborne mission, Boxerman moved on to be the Lead Systems Engineer for the first Unmanned Surface Vessel (USV) delivered to the Fleet. Shortly after this, she then embraced a new challenge through the Office of Naval Research’s Global Science Advisors Program, embarking on a “tour” structured like a field assignment to serve as the Science Advisor to the Commander of Naval Surface Forces. This program enables civilian scientists to engage directly with the Navy by rotating through various high-priority scientific projects, immersing themselves in Navy operations while contributing their expertise. As science advisors, participants act as trusted consultants to senior officers, guiding decisions on research investments, resources, and project execution—all while working alongside the operational staff. This unique role positions advisors as vital bridges between the Fleet and the Research Enterprise, providing crucial insight into gaps between command intent and capability delivery.

In her role as the Surface Force Science Advisor, Boxerman led the execution of over $35 million in experimentation that resulted in accelerated delivery of systems and capabilities to the Surface Force. She provided critical guidance on allocating resources to weapons development, unmanned systems, and autonomous technologies. Today, she serves as the Acting Director of the Science Advisors Program—a meaningful

“The Science Advisors Program accelerates the delivery of capabilities to the Naval fleet by leveraging expertise from diverse engineers and scientists and enabling them to apply their knowledge across all warfighting domains. In these roles, every door, window, nook, and cranny opens, exposing you to a wide spectrum of engineering challenges and career opportunities.”

Keith Hines, Rebecca Boxerman, CAPT Eric Hutter, and Brian VisserUnmanned Surface Vessel Squadron THREE (USVRON3)

Left: Boxerman boarding a helicopter flight to an expeditionary island base.

full-circle moment in her career.

Above all her professional accomplishments, Boxerman is most proud to be the wife of Jason and the mother of two imaginative children, who often dream up their own engineering projects at home—like designing fixed-wing modifications for UAVs just for fun. Together, the family lives in San Diego, California, where curiosity and creativity are part of everyday life.

LOGAN HICKOX

Stepping into Innovation at Nike

What do robotics and basketball shoes have in common? For UF mechanical and aerospace engineering (MAE) alum Logan Hickox, the answer is simple: engineering. Hickox, now a mechanical engineer at Nike’s Bowerman Footwear Lab, is at the forefront of blending cutting-edge technology with athletic performance. His journey, which began at P.K. Yonge and the University of Florida, is a testament to the transformative power of engineering education and the importance of exploring diverse paths.

In his three years at Nike, Hickox has worked on projects that bring together his passion for engineering and athletics. From collaborating with sports icons to designing performance-enhancing footwear, his work is a full-circle moment, blending his background as an athlete with his expertise as an engineer. “It’s incredible to see how engineering can impact people’s lives in ways you wouldn’t expect,” Hickox shared. His journey to this role, however, began long before Nike, starting with his formative years at the University of Florida and P.K. Yonge.

Hickox’s engineering journey began in high school at P.K. Yonge, where he joined the robotics team through

By Katherine Canev

the For Inspiration and Recognition of Science and Technology (FIRST Robotics) program. What began as a way to fill time after an injury sidelined his athletic pursuits quickly grew into a passion for hands-on problem-solving. His dedication earned him the prestigious FIRST Dean’s List Award in 2015, solidifying his decision to pursue mechanical engineering at UF.

At UF, Hickox explored various engineering disciplines before finding his niche in mechanical engineering. He credits UF MAE with equipping him with theoretical knowledge and practical skills, particularly in courses like dynamics and materials laboratory (DML) and mechanics of materials (MOM). He cited Peter Ifju, Ph.D., as a major influence in his mechanical engineering journey at UF, saying, “He always makes himself available to students so that we can really understand what he is teaching, and why. His support goes a long way.”

Ifju’s mentorship and the Integrated Product and Process Design (IPPD) program, where he worked on an autonomous robotic dog, further honed his ability to innovate and practice skills that go beyond mechanical engineering into civil engineering, computer science, and more. Beyond that, he reflected on how the IPPD program furthered his interpersonal skills, allowing him to understand different perspectives and different approaches from the various disciplines represented by the students in the program.

Hickox’s growth at UF went beyond academics. Leadership roles in the National Society of Black Engineers (NSBE) and participation in Theta Tau, a professional engineering fraternity, provided him with valuable professional skills and a supportive community. Through NSBE and the Society of Hispanic Professional Engineers (SHPE), Hickox secured an internship at Nike that sparked his passion for footwear engineering. “Although I initially went for the free T-shirt, I was hooked when I learned about the airbag technology in shoes,” Hickox shared. After completing the internship, he joined Nike full-time in 2021, where he now blends his love of athletics and innovation to create products that make a tangible impact.

Logan Hickox, Nike Bowerman Footwear Lab

HELLOS & GOODBYES

As we begin a new academic year, the Department of Mechanical and Aerospace Engineering celebrates both new beginnings and lasting legacies. We warmly welcome our new faculty, whose expertise and passion will enrich our community, and we honor our retiring faculty for their years of dedication and impact.

Exciting New Additions

Jack Famiglietti

Dr. Jack Famiglietti returns to UF MAE as a Lecturer after several years immersed in Gainesville’s thriving biotech startup scene. A triple Gator, Famiglietti earned his B.S., M.S., and Ph.D. in Mechanical Engineering from the University of Florida, completing his doctoral work in 2022. His teaching interests span engineering design, design for manufacturing, mechanics, and measurement and analysis techniques—areas where he brings both academic depth and real-world insight. With a passion for hands-on learning and innovation, Famiglietti is excited to help shape the next generation of engineers through dynamic, design-driven education.

Claire Grégoire

Dr. Claire Grégoire will join UF MAE as an Assistant Professor in January 2026, bringing deep expertise in combustion science and chemical kinetics. She earned her Ph.D. in Mechanical Engineering from Texas A&M University, where she developed advanced laser absorption diagnostics to study combustion processes—including solid rocket propellants— and contributed significantly to the safety of lithium-ion batteries and sustainable energy systems. With 22 peer-reviewed publications and a strong foundation in optical diagnostics and shock tube experiments, Grégoire is committed to advancing chemical kinetics research and mentoring future engineers at UF.

Chase Hartquist

Dr. Chase Hartquist joins UF MAE as an Assistant Professor, bringing a rich background in the mechanics of soft materials. He earned his Ph.D. in Mechanical Engineering from MIT, where he explored fracture mechanics in soft network materials. Prior to that, he completed his B.S. and M.S. at Washington University in St. Louis, focusing on biomedical materials and vascular surgery mechanics. Hartquist’s research investigates the mechanical and failure behaviors of soft structures, networks, and polymers—work that informs the design of nextgeneration materials for medical technology and clean energy. We’re excited to have him on board as he helps shape the future of soft material innovation at UF.

Piran Kidambi

Dr. Piran R. Kidambi joins UF MAE as an Associate Professor, following faculty appointments at UT Austin and Vanderbilt University in Chemical and Mechanical Engineering. He earned his Ph.D. from the University of Cambridge and completed postdoctoral research at MIT through a Lindemann Trust Fellowship. His work integrates nanomaterial synthesis, process engineering, and in situ metrology to drive innovation in hydrogen energy, separations, national security, and healthcare. Recognized with honors including the DOE Early Career Award, NSF CAREER, and ASME Rising Star, Kidambi brings a deep commitment to advancing materials design and mentoring scholars across all levels.

Sunjae Kim

Dr. Sunjae Kim joins UF MAE as an Assistant Professor, bringing expertise in two-phase flow and heat transfer for advanced thermal systems. He leads the KIMS LAB, which focuses on applying fundamental thermal science to real-world challenges in space exploration and high-performance cooling. His research spans in-space fluid and cryogenic propulsion systems, HVAC and refrigeration for space habitats, ultra high heat flux cooling, and cryogenic bio-preservation. Kim earned his Ph.D. in Mechanical Engineering from Purdue University, where he conducted microgravity experiments and CFD modeling, and holds B.S. and M.S. degrees from Korea University.

Jaeyun Moon

Dr. Jaeyun Moon joins UF MAE as an Assistant Professor and leads the Complex Materials Group, where he investigates the microscopic properties of complex materials like liquids and glasses. His research aims to uncover fundamental behaviors that inform the design of advanced systems for batteries, nuclear reactors, and thermoelectrics. Moon earned his B.S. from Georgia Tech and M.S. and Ph.D. from Caltech, with visiting research at Stanford and SLAC. He completed postdoctoral training at Cornell and Oak Ridge National Laboratory and is a recipient of the IUCr Young Scientist Award for his work on thermal properties of glasses.

Legacies to Celebrate

John D. Abbitt III

Dr. Abbitt made lasting contributions to aerospace engineering through his teaching, research, and service at UF. A former Navy pilot and expert in propulsion systems, Abbitt was instrumental in developing hands-on labs and expanding student access to wind tunnel and engine technologies. His commitment to education and leadership on university committees earned him the Morton Wolfson Service Award and the respect of students and colleagues alike.

James A. Trainham

Dr. Trainham served as Professor and Associate Chair for Industry Relations at UF’s Herbert Wertheim College of Engineering, where he advanced renewable energy research and strengthened academic-industry partnerships. With leadership experience at DuPont, PPG Industries, and Sundrop Fuels, he brought a wealth of perspective to UF MAE. An elected member of the National Academy of Engineering, Trainham leaves a legacy of innovation, mentorship, and excellence.

Ren Wei Mei

Dr. Mei distinguished himself as a leading scholar in fluid mechanics and computational modeling. His work in multiphase flows and turbulence advanced the field and enriched the academic environment at UF MAE. A sought-after collaborator and thought leader, he also helped shape research directions at national and international levels. Known for his rigorous research and dedication to student success, Mei’s influence continues through the many engineers he inspired.

FACULTY ROSTER

Behind every discovery and every classroom breakthrough is a team of faculty committed to excellence. Their work spans cutting-edge research, innovative teaching, and mentoring students who will shape the future of engineering. From developing new technologies to exploring the frontiers of aerospace and mechanical systems, these educators inspire innovation, foster collaboration, and contribute to the department’s mission of advancing knowledge. The following roster lists the faculty whose expertise and dedication make these achievements possible.

Aifantis, Katerina E. Allen, Jessica Balachandar, Sivaramakrishnan Barke, Simon Brooks, Jonathan T. Cardenas-Lailhacar, Cristian

Carroll, Bruce F. Chen, Youping Chung, Jacob Conklin, John Costello, Kerry

Crane, Carl D., III

Dickrell, Daniel Dickrell, Pamela Dixon, Warren Dong, Ting Dunn, Alison Fairbanks, James Famiglietti, Jack Fan, Zhonghui Hugh Fitz-Coy, Norman Greene, Max

Greenslet, Hitomi

Grégoire, Claire

Griffis, Mike Hartquist, Chase

Huang, Yong

Ifju, Peter G. Kamalapurkar, Rushikesh Kidambi, Piran

Kim, Nam Ho

Kim, Sunjae Kumar, Ashok

Lind, Richard C. Menezes, Amor Moghaddam, Saeed Mohseni, Kamran Moon, Jaeyun Musgrave, Patrick Niemi, Sean R. Pan, Jing Persad, Umesh Petersen, Alicia Petersen, Chrispy

Rao, Anil Ridgeway, Shannon

Roy, Subrata Sarntinoranont, Malisa

Scheffe, Jonathan Schueller, John Kenneth Schulze, Kurt

Segal, Corin Sheplak, Mark Sherif, SA

Shi, Jingjing

Shin, Jane Song, Youngsup Spearot, Douglas E. Subhash, Ghatu Tang, Xin Taylor, Curtis Traum, Matthew Ukeiley, Lawrence Walker, Benjamin Wang, Yu Wass, Peter

YONG HUANG, PH.D. FACULTY HIGHLIGHT

Dr. Yong Huang is a professor in the departments of mechanical and aerospace engineering, biomedical engineering, materials science and engineering, chemical engineering, and electrical and computer Engineering at the University of Florida. A passionate researcher and mentor, Huang focuses on advanced manufacturing, particularly how materials behave during processing and how innovative manufacturing methods can be used to tackle realworld problems in health care and energy.

At the core of his work is a deep curiosity about how materials, both solid and liquid, respond to manufacturing-induced deformation. He’s especially known for his contributions to additive manufacturing, including inkjet- and laser-based bioprinting, where his team explores how to precisely and reliably dispense inks and print complex structures at the microscale. It’s work that blends the rigor of physical and biological sciences with a creative, problemsolving, enigneering mindset.

As director of UF’s Advanced Manufacturing and System Integration Lab within the Center for Manufacturing Innovation, Huang leads a diverse and dynamic team. Together, they’ve developed techniques for scaffold-free bioprinting of tissue constructs, room-temperature metal printing, and even additive manufacturing in space, to name a few. The group also designs and prints microphysiological systems, such as human respiratory models and brain simulants—for use in disease research and medical education.

Over the past five years, Huang has authored papers in top-tier journals such as Nature Communications, Nature Reviews Method Primers, Advanced Materials, and Advanced Science. He holds 15 additive manufacturing-related patents (with one licensed technology) and has secured various research funding as principal investigator, with major support from the U.S. Department of Energy, National Science Foundation, and National Institutes of Health.

In addition to his Research Foundation Professorship recognition at UF, his contributions have earned national recognition, including the 2024 Society of Manufacturing Engineers Sargent Progress Award and the 2025 American Society of Mechanical Engineers Milton C. Shaw Manufacturing Research Medal. He has served in leadership roles with the American Society of Mechanical Engineers and provided expert service as a reviewer and editor for top journals in the field.

Huang is equally committed to education and mentorship. He was recently honored with the the college-level Faculty Doctoral Mentoring Award. Many of his Ph.D. students have earned departmental research and teaching honors, a reflection of his hands-on, studentcentered approach to training the next generation of researchers.

Huang earned his Ph.D. in mechanical engineering from Georgia Tech and is a fellow of the American Society of Mechanical Engineers. Through his work, he continues to push the boundaries of what’s possible in manufacturing— and inspire numerous young minds who will carry that work forward together.

“I focus on nurturing curiosity, critical thinking, and creativity by offering personalized mentorship and encouraging students to take ownership of their projects.”

-Yong Huang, Ph.D.

EARLY CAREER HIGHLIGHT

PATRICK MUSGRAVE PH.D. HONORED WITH AIR FORCE YOUNG INVESTIGATOR

AWARD AND NSF CAREER AWARD

By Christi Swiers

The Air Force Office of Scientific Research (AFOSR) Young Investigator Program (YIP) is a highly competitive and prestigious award granted to early-career scientists and engineers who show exceptional promise. It provides three years of research funding totaling $450,000. Beyond the monetary support, being selected is a significant professional honor.

Patrick Musgrave, mechanical and aerospace engineer at the University of Florida, knows the feeling firsthand. As a Gator engineer, an assistant professor, and director of the Fluids and Adaptive Structures Laboratory in UF MAE, Musgrave was selected for the 2025 AFOSR YIP for his bold and innovative approach to a fundamental aerospace challenge: unsteady airflow.

Imagine flying an aircraft through the clouds. The very act of flying generates turbulence, shock waves, and vortices that constantly affect the aircraft, either from the surrounding environment or shed from its own surfaces. Every movement, whether a change in speed, angle, or altitude, alters these airflows. These shifting forces create unsteady conditions that make lift unpredictable and reduce the effectiveness of the aircraft’s wings. Musgrave’s research aims to help aircrafts respond to these unpredictable forces in real time, using the structure of the aircraft itself.

Traditionally, sensing and responding to airflow involves outfitting aircraft with numerous sensors and running the data through powerful onboard computers, but this method is heavy in hardware and computations. Musgrave is developing materials

that can sense, process, and act all on their own. His approach uses the natural vibrations within the aircraft’s body instead of relying solely on electronics. The way the structures in the body of the vessel are vibrated by wind flow can be analyzed to tell the system how to respond and adapt to changes in airflow. The structure effectively becomes its own sensor and decision maker.

This vibration-based method could reduce the need for external sensors and complex computation. In turn, this would lead to aircraft that are lighter, faster, more energy-efficient, and better able to respond to their environment without added complexity.

redefine how aircraft are designed to handle the unpredictable skies.

“The YIP is a great opportunity to strengthen my ties with the Air Force Research Labs—both by building new relationships and expanding on the ones I already have at Wright-Patterson and Eglin Air Force Bases,” Musgrave said. “I’m really grateful for the chance to take part in something that supports both my research and these important collaborations.”

“I’m fascinated by how things move, bend, flex, and contain information,” Musgrave says. “To me, it’s amazing that a dynamically moving structure can act like a computer. It can make decisions, even replace electronics. It could be as simple as a piece of plastic doing incredible things.” - Patrick Musgrave, Ph.D.

By the end of the three-year award period, Musgrave hopes to demonstrate working physical prototypes operating in realistic aerodynamic conditions. His vision could help

In addition to the YIP award, Musgrave also secured a FY2025 NSF CAREER award for his groundbreaking work in underwater robotics. His project focuses on developing soft-bodied robotic swimmers that mimic the efficient, adaptive motions of fish, allowing these vehicles to navigate extreme environments with minimal computing power. Scan the QR code at the bottom of this page to read more about this incredible research and see how Musgrave is pushing the boundaries of air and sea.

Right: Patrick Musgrave, Ph.D., and Ph.D. student Brandon Giompalo.

TEACHING CAPSTONE TEACHING CAPSTONE MECHANICAL ENGINEERS’ RITE OF PASSAGE

By Katherine Canev

The Capstone Experience

If you are an engineer, there is a good chance that you still remember your Capstone project. Capstone is the culminating experience of an undergraduate engineer’s time in MAE – it is an opportunity for students to combine all of the practical and theoretical knowledge that they have accumulated to create a prototype product. Working in teams, senior engineering students are paired with a client and presented with a customer needs statement, which outlines all features their design must include. Beyond those guidelines, students have the freedom to innovate, choosing features that enhance and refine their creations.

The Capstone courses are not mere classes. In senior design, each individual advances from an apprentice to a practicing engineer; this transformation happens under the supervision of expert faculty who bring real-world industry experience. Students face common obstacles in applying theoretical concepts, particularly when translating digital models into physical, functional hardware. By the end of the sequence, they have demonstrated tangible examples of their expertise. This evidence can be leveraged in interviews with potential employers, or as the seed of a student-founded startup company - ME Capstone has produced four such startups in the past three years.

Inside EML4501

The ME Capstone sequence begins with EML4501 –Mechanical Engineering Design 2, led by Dr. Umesh Persad. Each section of the class is paired with a client who presents a real, unsolved engineering problem. Students

work in teams to create a conceptual design using computer-aided design (CAD) software and 3D-print key mechanisms to test that their ideas work.

By the end of the semester, student teams aim for a proposed design that reaches Technology Readiness Level (TRL) 3. The TRL scale, used by NASA, the U.S. Military, and companies, measures how developed a technology is, from 1 (just an idea) to 9 (a fully built, commercial-ready product).

Reaching TRL 3 means the students’ designs are functional on paper and in early testing. Teams present their work to the client and a panel of experts through design reviews and a written report.

In the following semester, students take EML4502 – Mechanical Engineering Design 3. This course is the final step in the Capstone sequence before graduation, and for many, it is the launchpad for their career. Taught by Dr. Matthew J. Traum, EML4502 takes students through the technical aspects of engineering product design – how to translate drawings and theory to a functional prototype on the lab bench. Students select groups based on project preference; some continue with their EML4501 projects from the previous semester while others undertake projects new to them.

Capstone students refine their designs, translating complex engineering concepts into functional prototypes.

Matthew Traum, Ph.D.

Umesh Persad, Ph.D.

A Partnership with IFAS

One such project in the ongoing pipeline is an interdisciplinary collaboration between UF MAE and IFAS. In EML4501, student teams worked to design an automated soil sampling system for Dr. Franta Majs. Majs is the Director of the IFAS Analytical Services Laboratories (ANSERV Labs), an agricultural science research group that serves the entire state of Florida.

The territory of Florida, though seemingly flat and plain, is geologically diverse. This variability presents a challenge to soil scientists at UF IFAS, who are responsible for gathering data on the characteristics and quality of soil from across the state – amassing and testing more than 300,000 samples per year. Moreover, the soil must be retested annually, as changing climate conditions impact soil quality. These measurements are crucial to Florida’s agricultural industry.

Currently, these samples are manually collected, measured, and tested; an expensive and laborintensive process. The samples must be weighed to very precise masses to ensure uniformity and accuracy in the subsequent quality evaluations. In addition, the complex soil makeup of Florida requires careful differentiation between soil classes to ensure proper tests are assigned to the samples. Due to the large volume of samples processed every year, it is easy to get lost between bags of dirt – therefore, soil samples must be labeled and stored carefully.

Designing Smart Soil Systems

Last spring, EML4501 students designed robots capable of taking samples of accurate mass, categorizing them, and transporting them between test vessels. Such a machine will vastly reduce the labor required for this procedure and improve accuracy by automating repetitive steps. The machines were required to separate mineralbased from organic-rich soil samples and to transfer precise masses of material from sample bags into extraction vessels. On top of these requirements,

students were challenged to stay within a strict budget to ensure their machines were a reasonable investment for IFAS and other agricultural research institutions. Two teams carried their designs forward to EML4502. Having previously printed the critical components of their machines to verify functionality, these students must now produce the entire machine. However, integrating all parts into a complete assembly affects the performance of each individual component, as everything must fit and work together seamlessly. Students are refining their designs to optimize the machine and collaborating closely as they navigate the challenges that arise throughout the process. They are also preparing to present their fleshedout designs in front of the client, industry sponsors, faculty, and stakeholders. The audience will have varying degrees of engineering background, requiring students to communicate technical information in a digestible way. By the end of the sequence, students demonstrate mastery of the broad range of competencies required in a professional engineering design environment.

Capstone As a Career Catalyst

Capstone is more than a class project — it represents the culmination of the knowledge, collaboration, and problem-solving skills that engineering students have developed throughout their undergraduate studies. By addressing real-world challenges, students strengthen their technical expertise as well as their capacity for communication, project management, and teamwork — all essential for success in a professional environment. ME Capstone students emerge not just as graduates, but as engineers ready to tackle the complex problems of tomorrow.

CAD image of soil sampler.

Print farm featuring Bambu 3D printers. Students working on the soil sampler project will use these extensively for prototying.

MAE STAFF LEAD THE WAY AWARD WINNING IMPACT

By Katherine Canev

This year, our exceptional MAE staff received recognition through the Division Three Superior Accomplishment Awards! These prestigious University-wide honors highlight their outstanding contributions and collaboration efforts.

MAE Facilties Team Team Collaboration

The MAE facilities team plays an essential role in running department activities and troubleshooting on the go. The team includes Melanie DeProspero, Daniel Preston, Steven Davis, and Andrew Evans, each of whom has demonstrated remarkable teamwork and dedication.