2025-2026 PRODUCTION GUIDE

Editors: L.M. Diepenbrock, M.M. Dewdney, and T. Vashisth

Ute Albrecht, Fernando Alferez, Ozgur Batuman, Brian Boman, Ronald H. Brlansky, Brett W. Bultemeier, Jamie D. Burrow, Liliana M. Cano, John M. Chater, Michelle D. Danyluk, William O. Dawson, Megan M. Dewdney, Lauren M. Diepenbrock, Larry W. Duncan, Jason A. Ferrell, Frederick M. Fishel, Renée M. Goodrich-Schneider, Sandra Guzmán, Alissa Hevesh, Mark E. Hilf, Renato N. Inserra, Davie M. Kadyampakeni, Ramdas Kanissery, Amit Levy, Xavier Martini, Kelly T. Morgan, Joe W. Noling, Taylor O’Bannon, Thomas A. Obreza, Chris Oswalt, Natalia A. Peres, Jawwad Qureshi, Mark A. Ritenour, Pamela D. Roberts, Masoud Salyani, Keith R. Schneider, Arnold W. Schumann, Brent A. Sellers, Muhammad A. Shahid, Peggy J. Sieburth, Ariel Singerman, Matthew Smith, Lukasz Stelinski, Sarah Strauss, Tripti Vashisth, Christopher Vincent, Callie Walker, Mongi Zekri, and Jiuxu “John” Zhang

Florida Citrus

2025–26 Florida Citrus Production Guide

EFFECTIVE AND SAFE CITRUS PRODUCTION STRATEGIES FOR USE IN COMMERCIAL GROVES ONLY

Before using any pesticide: Read the complete label and the general instructions in this guide.

A contribution of the University of Florida Institute of Food and Agricultural Sciences citrus faculty located at the Citrus Research and Education Center–Lake Alfred, Southwest Florida REC–Immokalee, Indian River REC–Ft. Pierce, UF main campus–Gainesville, and researchers from the Florida Department of Citrus–Lake Alfred.

Lauren M. Diepenbrock, Megan M. Dewdney, and Tripti Vashisth.

The printing of this guide was made possible through funding provided by the State Legislative Funding for the UF/IFAS Citrus Initiative.

UF/IFAS Citrus Research and Education Center – Lake Alfred 700 Experiment Station Road Lake Alfred, FL 33850-2299 Institute of Food and Agricultural Sciences

UF/IFAS Extension University of Florida, Gainesville Andra Johnson, Dean

© 2025 by the University of Florida Institute of Food and Agricultural Sciences (UF/IFAS). All rights reserved.

Material from this book may be used for educational purposes if full credit is given. Please refer to the EDIS website at https://edis.ifas.ufl.edu for the currently supported versions of these publications. © 2025 UF/IFAS. This publication is licensed under CC BY-NC-ND 4.0.

An Equal Opportunity Institution. UF/IFAS Extension, University of Florida, Institute of Food and Agricultural Sciences, Andra Johnson, Dean. Information on copies for purchase is available from UF/IFAS Extension Bookstore, University of Florida, PO Box 110011, Gainesville, FL 32611-0011 (visit our website at: ifasbooks.ufl.edu). Information about alternate formats is available from UF/IFAS Communications, University of Florida, PO Box 110810, Gainesville, FL 32611-0810.

DISEASES

WEEDS

PESTICIDES

doi.org/10.32473/edis-cg033-2023

2025–2026 Florida Citrus Production Guide: Introduction1

Lauren M. Diepenbrock, Megan M. Dewdney, and Tripti Vashisth2

Over the past decade, Florida citrus production practices have changed dramatically due to the challenges presented by huanglongbing (HLB). As we have learned more about this disease, how it is spread by the Asian citrus psyllid, and the overall effects on citrus tree health, it is increasingly evident that management of this disease requires changes to all aspects of citrus production. Several factors must all be considered together when developing a site-specific management plan for citrus production in the presence of HLB. The Florida Citrus Production Guide will continue to be updated annually with the latest information to help growers refine their production practices using the latest research-based findings proven to be effective for Florida citrus production.

For example, in this edition, Citrus Fix (2,4-D), along with Progibb (gibberellic acid), have been added strategies to reduce HLB-associated preharvest fruit drop. Please refer to chapter 19, “Plant Growth Regulators,” for details.

In addition to changes in production practices needed to manage emerging pest problems in Florida, the regulatory environment is also constantly changing. New rules for Worker Protection Standards (WPS) were fully implemented in January 2018, including important changes to worker training, reporting, and posting of pesticide applications. Likewise, compliance with the Food Safety

Modernization Act (FSMA) Produce Safety Rule (PSR) was required by January of 2020 for all farm sizes. This rule established minimum food safety standards to be implemented by growers, packers, and harvesters of fresh produce. Compliance with these rules directly impacts day-to-day production practices and costs to Florida citrus growers. The requirements of these rules are explained in the chapters on WPS and food safety. Because changes in these rules are likely to occur, the guide will be updated to reflect the latest information growers need to know to ensure compliance, so please continue to review these chapters in the coming years.

Overall, the goal of the Florida Citrus Production Guide is to serve as a reference for information needed to guide decision-making in Florida citrus-growing operations. It is not intended to replace agricultural product labels that contain important usage information and should be immediately accessible for reference. Violations of directions for use printed on the label are against state and federal laws. Always read and follow label instructions! Likewise, state and federal regulations on topics such as WPS are constantly changing, and not all the information needed to ensure compliance can be covered in this guide. The WPS chapter in this guide covers some of the important highlights of these rules. It is imperative that growers

1. This document is CPMG01, one of a series of the Department of Plant Pathology, UF/IFAS Extension. Original publication date December 1999. Revised annually. Most recent revision August 2025. Visit the EDIS website at https://edis.ifas.ufl.edu for the currently supported version of this publication. © 2025 UF/IFAS. This publication is licensed under CC BY-NC-ND 4.0

2. Lauren M. Diepenbrock, assistant professor, Integrated Pest Management and Insect Ecology, Department of Entomology and Nematology, UF/ IFAS Citrus Research and Education Center; Megan M. Dewdney, associate professor and Extension specialist, Department of Plant Pathology, UF/ IFAS CREC; Tripti Vashisth, citrus Extension specialist and associate professor, Department of Horticultural Sciences, UF/IFAS CREC; UF/IFAS Extension, Gainesville, FL 32611.

The Institute of Food and Agricultural Sciences (IFAS) is an Equal Opportunity Institution authorized to provide research, educational information and other services only to individuals and institutions that function with non-discrimination with respect to race, creed, color, religion, age, disability, sex, sexual orientation, marital status, national origin, political opinions or affiliations. For more information on obtaining other UF/IFAS Extension publications, contact your county’s UF/IFAS Extension office. U.S. Department of Agriculture, UF/IFAS Extension Service, University of Florida, IFAS, Florida A & M University Cooperative Extension Program, and Boards of County Commissioners Cooperating. Andra Johnson, dean for UF/IFAS Extension.

obtain copies of and follow the detailed rules outlined in the regulatory documents referenced in this guide. The Florida Citrus Production Guide provides general guidance and is NOT the final regulatory document that should be followed!

For specific information on pest identification, biology, damage, or nonchemical management techniques, refer to Ask IFAS/EDIS and other UF/IFAS, USDA, and Florida Department of Agriculture and Consumer Services (FDACS) publications. In addition to the authors listed throughout the Florida Citrus Production Guide, the citrus Extension specialists, faculty, and Extension agents listed below can provide assistance with citrus production practices.

UF/IFAS Research and Education Centers

UF/IFAS Citrus REC

700 Experiment Station Road Lake Alfred, FL 33850-2299 http://crec.ifas.ufl.edu (863) 956-1151

Dr. Michael E. Rogers, Center Director/Entomology

Dr. John M. Chater, Horticulture

Dr. Michelle D. Danyluk, Food Safety

Dr. Megan M. Dewdney, Plant Pathology

Dr. Lauren M. Diepenbrock, Entomology

Dr. Larry W. Duncan, Nematology

Dr. Manjul Dutt, Horticulture

Dr. Choaa El-Mohtar, Plant Pathology

Dr. Fred G. Gmitter, Horticulture

Dr. Jude W. Grosser, Horticulture

Dr. Davie M. Kadyampakeni, Soil, Water, and Ecosystem Sciences

Dr. Nabil Killiny, Plant Pathology

Dr. Amit Levy, Plant Pathology

Ms. Taylor O’Bannon, Food Safety

Dr. Ahmad Omar, Horticulture

Dr. Arnold W. Schumann, Soil, Water, and Ecosystem Sciences

Dr. Ariel Singerman, Economics

Dr. Lukasz L. Stelinski, Entomology

Dr. Tripti Vashisth, Horticulture

Dr. Christopher I. Vincent, Horticulture

Dr. Nian Wang, Microbiology and Cell Science

Dr. Yu Wang, Food Science

UF/IFAS Indian River REC

2199 South Rock Road

Ft. Pierce, FL 34945-3138 https://irrec.ifas.ufl.edu/ (772) 468-3922

Dr. Mark Kistler, Center Director/Agricultural Education

Dr. Liliana Cano, Plant Pathology

Dr. Sandra Guzmán, Agricultural Engineering

Dr. Mark A. Ritenour, Associate Center Director/Postharvest Physiology

Dr. Alan Wright, Soil, Water, and Ecosystem Sciences

Dr. Flavia Zambon, Horticulture

UF/IFAS Mid Florida REC

2757 S. Binion Road Apopka, FL 32703 https://mrec.ifas.ufl.edu (407) 884-2034

Dr. Kirsten Pelz-Stelinski, Center Director/Entomology

UF/IFAS North Florida REC

155 Research Road Quincy, FL 32351 http://nfrec.ifas.ufl.edu (850) 875-7100

Dr. Dean Pringle, Center Director/Animal Science

Dr. Xavier Martini, Entomology

Dr. Muhammad A. Shahid, Horticulture

UF/IFAS Range Cattle REC

3401 Experiment Station

Ona, FL 33865

http://rcrec-ona.ifas.ufl.edu/ (863) 735-1314

Dr. Brent Sellers, Center Director/Weed Science

UF/IFAS Southwest Florida REC

2686 State Road 29 N Immokalee, FL 34142-9515

https://swfrec.ifas.ufl.edu/ (239) 658-3400

Dr. Michael Burton, Center Director/Agronomy

Dr. Ute Albrecht, Horticulture/Plant Physiology

Dr. Fernando Alferez, Horticulture

Dr. Ioannis Ampatzidis, Agricultural and Biological Engineering

Dr. Ozgur Batuman, Plant Pathology

Ms. Stephanie Brown, Food Science

Dr. Ramdas Kanissery, Weed Science

Dr. Kimberly Morgan, Economics

Dr. Jawwad Qureshi, Entomology

Dr. Sarah Strauss, Soil, Water, and Ecosystem Sciences/Soil Microbiology

Dr. Nicolaos Tziolas, Soil, Water, and Ecosystem Sciences

Dr. Tara Wade, Economics

UF/IFAS Tropical REC

18905 SW 280 Street Homestead, FL 33031-3314

https://trec.ifas.ufl.edu/ (305) 246-7000

Dr. Edward “Gilly” Evans, Center Director/Economics

Dr. Jonathan H. Crane, Associate Center Director/ Horticulture

Dr. Daniel Carillo, Entomology

Dr. Romina Gazis, Plant Pathology

UF/IFAS Extension Agents—Citrus

Alissa Hevesh

Extension Agent I, Highlands County, Agriculture and Natural Resources UF/IFAS Extension Highlands County 4509 George Blvd. Sebring, FL 33875 (863) 402-6540

Email: ahevesh@ufl.edu

TBD

Extension Agent I, Multi-County, Citrus DeSoto, Hardee, and Manatee Counties

UF/IFAS Extension DeSoto County 2150 NE Roan St Arcadia, FL 34266 (863) 993-4846

Madelyn Greathouse

Extension Agent I, Multi-County, Commercial Horticulture Sumter, Pasco, and Hernando Counties

UF/IFAS Extension Sumter County 7620 SR 41 Suite 2 Bushnell, FL 33513 (352) 569-6872

Email: mgreathouse@ufl.edu

Mr. W. Chris Oswalt

Extension Agent IV, Multi-County, Citrus Hillsborough and Polk Counties

UF/IFAS Extension Polk County PO Box 9005, Drawer HS03 Bartow, FL 33831-9005 (863) 519-8677

Email: wcoswalt@ufl.edu

Dr. Amir Rezazadeh

Extension Agent II, Multi-County, Fruit/Field Crops

UF/IFAS Extension St. Lucie County 8400 Picos Rd., Suite 101 Ft. Pierce, FL 34945 (772) 462-1660

Email: amir2558@ufl.edu

Mr. Matt T. Smith

Extension Agent II, Multi-County, Commercial Crop

Production & Food Systems

UF/IFAS Extension Lake County and Orange Counties

1951 Woodlea Rd. Taveres, FL 32778 (352) 343-4101

Email: smith197@ufl.edu

Mrs. Danielle Williams

Extension Agent II, Multi-County, Commercial Horticulture

UF/IFAS Extension Gadsden County 2140 W. Jefferson St. Quincy, FL 32351 (850) 875-7255

Email: dsprague@ufl.edu

Dr. Mongi Zekri

Extension Agent IV, Multi-County, Citrus

UF/IFAS Extension Charlotte, Collier, Glades, Hendry, and Lee Counties

PO Box 68 LaBelle, FL 33975-0068 (863) 674-4092

Email: maz@ufl.edu

doi.org/10.32473/edis-cg030-2023

2025–2026 Florida Citrus Production Guide: Useful Telephone Numbers1

Jason A. Ferrell and Frederick M. Fishel2

National Pesticide Information Center (NPIC)

1-800-858-7378, 11 a.m.–3 p.m. Eastern time, Monday–Friday. Provides general information on pesticide products, recognition and management of pesticide poisoning, toxicology, and environmental chemistry.

CHEMTREC®

CHEMTREC® is the Chemical Transportation Emergency Center. It is operated by the Chemical Manufacturers Association to assist people in handling chemical emergencies, such as large chemical spills or leaks.

Register at their website: https://www.chemtrec. com/our-services/emergency-response/ chemical-response-call-center

Then, call their telephone number during chemical emergencies: 1-800-424-9300

UF/IFAS

Pesticide Information Office: 352-392-4721

UF/IFAS Citrus Research and Education Center: 863-956-1151

Florida Department of Agriculture and Consumer Services

Division of Plant Industry: 352-395-4700

Pesticide Certification/Licensing Office: 850-617-7870

Florida’s Poison Control Centers

1-800-222-1222

1. This document is PI-15, one of a series of the Department of Agronomy, UF/IFAS Extension. Original publication date December 1995. Revised annually. Most recent revision August 2025. Visit the EDIS website at https://edis.ifas.ufl.edu for the currently supported version of this publication. © 2025 UF/IFAS. This publication is licensed under CC BY-NC-ND 4.0

2. Jason A. Ferrell, professor, weed science and invasive plants, and chair, Department of Agronomy; and director, UF/IFAS Center for Aquatic and Invasive Plants; Frederick M. Fishel, professor (retired), Department of Agronomy, and former director, UF/IFAS Pesticide Information Office; UF/IFAS Extension, Gainesville, FL 32611.

The Institute of Food and Agricultural Sciences (IFAS) is an Equal Opportunity Institution authorized to provide research, educational information and other services only to individuals and institutions that function with non-discrimination with respect to race, creed, color, religion, age, disability, sex, sexual orientation, marital status, national origin, political opinions or affiliations. For more information on obtaining other UF/IFAS Extension publications, contact your county’s UF/IFAS Extension office. U.S. Department of Agriculture, UF/IFAS Extension Service, University of Florida, IFAS, Florida A & M University Cooperative Extension Program, and Boards of County Commissioners Cooperating. Andra Johnson, dean for UF/IFAS Extension.

HS1301

https://doi.org/10.32473/edis-hs1301-2023

2025–2026 Florida Citrus Production Guide: Fresh Fruit Pesticide Residue Limits1

Mark A. Ritenour2

Current production practices often include the use of various pre- and postharvest chemicals, many of which are pesticides. To be used, these materials must be labeled for use on citrus (see chapter 44, “Pesticides Registered for Use on Florida Citrus”) and used only according to label instructions. Chemical residues on the fruit after harvest are a concern to regulators and the public alike because of their potential negative health effects. Therefore, the United States and other countries set maximum residue limits (MRLs) on fresh produce for various chemicals. By US law, such materials must be applied according to label instructions, but doing so also means it is unlikely for US MRLs to be exceeded. However, when exporting product to a country that has lower MRLs than the United States, the use of these pesticides usually must be modified or discontinued to keep from exceeding the other country’s tolerances. When no MRL or default tolerances are stated, any detectable residue will constitute a violation. The limit of detection for chemical residues on citrus fruit is often between 0.01 and 0.05 ppm, depending on the testing laboratory and chemical of interest. Violations may lead to rejected loads of product, restrictions on future shipments, and even increased scrutiny or requirements for the entire industry.

Because MRLs change frequently, see the UF/IFAS Postharvest Resources website for the most current list of MRLs (in parts per million) for various chemicals used on fresh

Florida citrus destined for the United States and important export countries. This information is intended as an initial reference source, and no guarantee is made of its accuracy. Always verify these values with other knowledgeable sources within specific markets of interest. This website includes links to specific MRL databases for select countries and to a BCGlobal MRL database for the most comprehensive list of MRLs for all commodities and markets.

Web Addresses for Links

BCGlobal MRL Database: https://bcglobal.bryantchristie. com/

UF/IFAS Postharvest Resources: https://irrec.ifas.ufl.edu/ postharvest/index/pesticides.shtml

1. This document is HS1301, one of a series of the Department of Horticultural Sciences, UF/IFAS Extension. Original publication date July 2017. Revised annually. Most recent revision August 2025. Visit the EDIS website at https://edis.ifas.ufl.edu for the currently supported version of this publication. © 2025 UF/IFAS. This publication is licensed under CC BY-NC-ND 4.0

2. Mark A. Ritenour, professor, postharvest physiology & handling, Department of Horticultural Sciences; and associate center director, UF/IFAS Indian River Research and Education Center, Fort Pierce, FL 34945.; UF/IFAS Extension, Gainesville, FL 32611.

The Institute of Food and Agricultural Sciences (IFAS) is an Equal Opportunity Institution authorized to provide research, educational information and other services only to individuals and institutions that function with non-discrimination with respect to race, creed, color, religion, age, disability, sex, sexual orientation, marital status, national origin, political opinions or affiliations. For more information on obtaining other UF/IFAS Extension publications, contact your county’s UF/IFAS Extension office. U.S. Department of Agriculture, UF/IFAS Extension Service, University of Florida, IFAS, Florida A & M University Cooperative Extension Program, and Boards of County Commissioners Cooperating. Andra Johnson, dean for UF/IFAS Extension.

doi.org/10.32473/edis-cg026-2023

2025–2026 Florida Citrus Production Guide: Pesticide Resistance and Resistance Management1

Lauren M. Diepenbrock, Megan M. Dewdney, and Ramdas Kanissery2

Populations of animals, fungi, bacteria, and plants possess the ability to respond to sustained changes or stresses in their environment in ways that enable the continued survival of the species. Such environmental stresses include physical factors (e.g., temperature or humidity), biological factors (e.g., predators, parasites, or pathogens), and environmental contaminants. In any population, a small percentage of individuals will be better able to respond to new stresses because of unique traits or characteristics that they possess. Consequently, those individuals will survive, reproduce, and become more common in a population. This phenomenon is commonly referred to as “survival of the fittest.”

Many pest species, such as the citrus rust mite, are exceptionally well equipped to respond to environmental stresses because of their short generation time and large reproductive potential. The use of chemical sprays to control insects, mites, bacterial and fungal diseases, and weeds of citrus creates a potent environmental stress. There are now many examples of pests, pathogens, and weeds that have responded by developing resistance to one or more

pesticides. Pesticide-resistant individuals are those that have developed the ability to tolerate doses of a toxicant that would be lethal to the majority of individuals. The resistance mechanisms can vary according to pest species and/or the class of chemical to which the pest is exposed. Resistance mechanisms for insects include an increased capacity to detoxify the pesticide once it has entered the pest’s body, a decreased sensitivity of the target site that the pesticide acts upon, a decreased penetration of the pesticide through the cuticle, or sequestration of the pesticide within the organism. The main resistance mechanism for fungal pathogens is a change in the target site so that the pathogen is less susceptible or fully resistant. With repeated or intense exposure to herbicides, some weeds develop resistance because only individuals that are capable of detoxifying the chemical persist over time. A single resistance mechanism can sometimes provide defense against different classes of chemicals; this is known as cross-resistance. When more than one resistance mechanism is expressed in the same individual, this individual is said to show multiple resistance

1. This document is ENY-624, one of a series of the Department of Entomology and Nematology, UF/IFAS Extension. Original publication date December 1995. Revised annually. Most recent revision August 2025. Visit the EDIS website at https://edis.ifas.ufl.edu for the currently supported version of this publication. © 2025 UF/IFAS. This publication is licensed under CC BY-NC-ND 4.0

2. Lauren M. Diepenbrock, assistant professor, Integrated Pest Management and Insect Ecology, Department of Entomology and Nematology, UF/IFAS Citrus Research and Education Center; Megan M. Dewdney, associate professor and Extension specialist, Department of Plant Pathology, UF/IFAS CREC; Ramdas Kanissery, associate professor, weed science, Department of Horticultural Sciences, UF/IFAS Southwest Florida REC; UF/IFAS Extension, Gainesville, FL 32611.

The use of trade names in this publication is solely for the purpose of providing specific information. UF/IFAS does not guarantee or warranty the products named, and references to them in this publication do not signify our approval to the exclusion of other products of suitable composition.

Use pesticides safely. Read and follow directions on the manufacturer’s label.

The Institute of Food and Agricultural Sciences (IFAS) is an Equal Opportunity Institution authorized to provide research, educational information and other services only to individuals and institutions that function with non-discrimination with respect to race, creed, color, religion, age, disability, sex, sexual orientation, marital status, national origin, political opinions or affiliations. For more information on obtaining other UF/IFAS Extension publications, contact your county’s UF/IFAS Extension office. U.S. Department of Agriculture, UF/IFAS Extension Service, University of Florida, IFAS, Florida A & M University Cooperative Extension Program, and Boards of County Commissioners Cooperating. Andra Johnson, dean for UF/IFAS Extension.

Of the factors that affect the development of resistance, including the pest’s or pathogen’s biology, ecology, and genetics, only the operational factors can be manipulated by the grower. The key operational factor that will delay the onset of pesticidal resistance and prolong the effective life of a compound is assuring the survival of some susceptible individuals to dilute the population of resistant individuals. The following operational procedures should be on a grower’s checklist to steward sound pesticidal resistance management for acaricides, insecticides, fungicides, antibiotics, and herbicides:

1. Never rely on a single pesticide class.

2. Integrate chemical control with effective and complementary cultural and biological control practices.

3. Always use pesticides at recommended rates and strive for thorough coverage.

4. When there is more than one generation of pest, alternate different pesticide classes.

5. Do not use tank mixtures of products that have the same mode of action.

6. If control with a pesticide fails, do not re-treat with a chemical that has the same mode of action.

Reports of resistance have been documented for certain acaricides used to control citrus rust mite and fungicides used to combat diseases in Florida. Resistance is also likely to be found in weeds with repeated exposure to certain herbicides. Resistance to Benlate developed in the greasy spot fungus shortly after the product was introduced about 30 years ago and is still widespread. Benlate resistance also occurs in the scab fungus in isolated situations and is stable. In tangerine groves with Alternaria brown spot, resistance has been detected to strobilurin fungicides (Gem, Headline, and Quadris [formerly Abound] and contained in the mixtures Pristine, Priaxor, and Amistar Top), but no resistance has developed to ferbam. Dicofol resistance in citrus rust mite was detected throughout the citrus industry about 10 years ago, but resistance proved to be unstable, and usage of dicofol has continued. Agri-mek tolerance in citrus rust mite is of concern, and growers should follow sound resistance management practices when using this product. Recent studies have shown reduced susceptibility to several insecticides in populations of Asian citrus psyllid after repeated exposure to similar materials, but that susceptibility can be restored by rotating modes of action used in management programs. Resistance management

is crucial to the management of this insect. Glyphosateresistant weeds are becoming commonplace in many production systems with the repeated use of this popular preemergence herbicide, highlighting the need to rotate materials for weed management.

The following tables are provided to aid in the rotation of pesticides with different modes of action within a season or from year to year. There are separate tables for insecticides/ acaricides, fungicides/antibiotics, and herbicides. The information in these tables was derived from information produced by the Insecticide Resistance Action Committee (IRAC), the Fungicide Resistance Action Committee (FRAC), and the Herbicide Resistance Action Committee (HRAC). Each table lists the number (or letter in the case of herbicides) of the group code for each pesticide class, the group name or general description of that group of pesticides, the common name of pesticides used in citrus production that belong to each group, and examples of trade names of pesticides for each common name listed. When using the table to rotate between using products with different modes of action, choose products with a different group code than previously used in the grove during the current growing season. In the case of insecticides/acaricides, many of these pesticides are broken into subgroups. It is unclear whether cross-resistance will occur between these subgroups. When possible, it is recommended to rotate with an entirely different group. (Note: The IRAC and FRAC mode of action systems both use a similar numbering system. There is no cross-resistance potential between the insecticides and fungicides.) Products with broad-based activity such as sulfur and oil are not included in this list because the development of resistance to them is not likely.

Web Addresses for Links

FRAC: https://www.frac.info/

HRAC: https://hracglobal.com/tools/classification-lookup

IRAC: http://www.irac-online.org/

Table 1. Insecticides and miticides used in Florida citrus grouped by mode of action. IRAC Group1

1 1A Carbamates carbaryl oxamyl Sevin Vydate, ReTurn 1B Organophosphates acephate dimethoate malathion naled phosmet

3 3A Pyrethroids bifenthrin fenpropathrin zeta-cypermethrin

4 4A Neonicotinoids acetamiprid clothianidin imidacloprid thiamethoxam

Orthene, Acenthrin, Avatar PLX, Bracket Dimethoate

Malathion

Dibrom

Imidan

Brigade Danitol Mustang

Actara, Admire Pro, Advise, Alias, Assail, Belay, Couraze, Imida E-Ag, Impulse, Macho, Montana, Nuprid, Pasada, Platinum, Prey, Torrent, Widow 4D Butenolides flupyradifurone Sivanto, Altus

5 Spinosyns spinosad spinetoram Spintor Delegate

6 Avermectins abamectin Abacus, Abba, Agri-mek, Clinch, Epi-mek, Reaper, Zoro

7 7A

Hormone Analogues

11 11A Bacillus thuringiensis (Bt) Bt var. aizawai Bt var. kurstaki

Various Various

12 12B Organotin miticides fenbutatin oxide Vendex 12C Propargite propargite Comite

15 Benzoylureas diflubenzuron Micromite

Ant Bait

16 Buprofezin buprofezin Applaud, Centaur

18 Diacylhydrazines methoxyfenozide Intrepid

21 21A METI acaricides pyridaben fenpyroximate

23 Tetronic/Tetramic acid derivatives spirodiclofen spirotetramat

28 Diamides chlorantraniliprole, cyantraniliprole

UN Unknown MOA bifenazate

Nexter Portal, Apta

Envidor Movento, Senstar

Exirel, Verimark, Voliam Flexi (one component)

Acramite cryolite Kryocide dicofol Kelthane

1 Mode of action based on the Insecticide Resistance Action Committee (IRAC) Mode of Action Classification v. 11.4 (2025).

Table 2. Fungicides and antibiotics used in Florida citrus grouped by mode of action.

FRAC Group1 Group Name

1 MBC—fungicides (Methyl benzimidazole carbamates)

3 DMI—fungicides (Demethylation inhibitors)

Common Name

thiabendazole Many (TBZ)

difenoconazole fenbuconazole imazalil

mefentrifluconazole propiconazole

4 PA—fungicides (Phenylamides) metalaxyl mefenoxam

7 SDHI—fungicides (Succinate-dehydrogenase inhibitors)

boscalid fluopyram fluxapyroxad pydiflumetofen

11 QoI—fungicides (Quinone outside inhibitors) azoxystrobin trifloxystrobin pyraclostrobin

Amistar Top, Miravis Top, Acadia ESQ, Luna Flex Enable Many Cevya, Provysol, Veltyma

Many

Ridomil, ReCon, Regulate, MetaStar, Xyler Ultra Flourish, Ridomil Gold, Subdue, Mefenoxam 2 AQ, ReCon Bold, Stergo MX

Pristine, Endura

Luna Sensation, Luna Flex, Broadform, Velum

Priaxor Xemium

Miravis Top

Quadris (formerly Abound) and others, Graduate A+, Amistar Top Gem, Broadform, Compass, Luna Sensation

Headline and others, Pristine, Priaxor Xemium, Veltyma

12 PP—fungicides (Phenylpyrroles) fludioxonil Graduate, Graduate A+, Pilato PacRite FDL

19 Polyoxin Polyoxin D zinc salt OSO 5% SC, Ph-D

40 CAA—fungicide (Carboxylic acid amides) mandipropamid Revus Orondis Ultra

41 tetracycline antibiotic oxytetracycline Fireline, Mycosheild ReMedium TI, Rectify

43 Benzamides fluopicolide Adorn, Presidio

48 Polyene natamycin BioSpectra 100SC

49 OSBPI—oxysterol binding protein homologue inhibition oxathiapiprolin Orondis Orondis Ultra

M 03 Dithiocarbamates ferbam Ferbam Granuflo

M 01 Inorganic copper Many

P 01 Benzo-thiadiazole (BTH) acibenzolar-S-methyl Actigard

P 07 Phosphonates fosetyl-Al phosphorous acid and salts Aliette, Linebacker Many

1 Mode of action based on the 2024 Fungicide Resistance Action Committee (FRAC) Mode of Action Classification.

Table 3. Herbicides used in Florida citrus grouped by mode of action.

HRAC

Group1

Group Name/Chemical Family Common Name

A (1) Aryloxyphenoxy-propionates

Cyclohexanediones

fluazifop-p-butyl sethoxydim

C1 (5) Triazines Uracils simazine bromacil

C2 (5) Ureas diuron

D (22) Pyridiniums paraquat

E (14) N-Phenyl-triazolinones N-Phenyl-imides

carfentrazone-ethyl flumioxazin saflufenacil

F1 (12) N-Phenyl heterocycles norflurazon

F2 (27) Triketones mesotrione

Trade Name(s)

Fusilade Poast

Caliber, Princep, Simazine Hyvar, Krovar

Direx, Karmex, Krovar

Gramoxone

Aim Chateau EZ

Treevix

Solicam

Broadworks

G (9) Glycine glyphosate (Various) e.g., Roundup, Gly Star

H (10) Phosphinic acids glufosinate-ammonium

K1 (3) Dinitroanilines oryzalin pendimethalin

Rely 280, Scout

Surflan Prowl

L (29) Alkylazines indaziflam Alion

O (4) Phenoxy-carboxylates 2,4-D

Embed Extra

1 Mode of action based on the 2024 Herbicide Resistance Action Committee (HRAC) Mode of Action Classification. HRAC/Weed Science Society of America (WSSA) numerical codes for this classification are provided in parentheses.

2025–2026 Florida Citrus Production Guide: Pesticide Application Technology1

Masoud Salyani2

Spraying Trees

Sprayer Selection

Most Florida citrus applications are made with aircarrier ground sprayers. These sprayers may be truck/ tractor-mounted, tractor-drawn (p.t.o./engine-driven), or self-propelled. They may be equipped with a positive or nonpositive displacement pump to pressurize the spray liquid and generate spray droplets by hydraulic nozzles, air-shear nozzles, or rotary atomizers. Spray droplets are normally transported by sprayer airflow, generated with one or more axial-, centrifugal-, or cross-flow fans. The air is directed toward the canopy by a series of fixed, adjustable, or moving deflectors (oscillators). Some sprayers use a short or tall tower attachment to discharge a portion of the spray-laden air close to the upper parts of the tree canopy. Sprayers may use mechanical and/or hydraulic agitation systems.

The differences in size, shape, design features, and construction material of the sprayers could result in substantial variation in the price of the spray equipment. Nevertheless, a higher price does not necessarily mean a better sprayer or guarantee more satisfactory spray coverage. A pesticide can be expected to be effective if the right material is applied, at

the right amount, on the right target, at the right time, with the right sprayer, and under the right weather conditions. A cheap sprayer, adjusted and operated properly, may result in better pest control than a sophisticated sprayer used improperly under adverse weather conditions.

Sprayer Air Capacity

Because air-blast applications depend on the sprayer air stream to deposit the spray on the tree, the air volume and velocity must be sufficient for efficient droplet transport, acceptable penetration inside the canopy, and satisfactory spray coverage. However, air-carrier sprayers have a wide range in air capacities (5,000–100,000 cfm). While larger sprayers generate much more air volume than smaller ones, they may not provide any improvement in spray coverage, and in some cases, too much air may adversely affect spray deposition by increasing spray runoff from the leaf surface.

As the fan power requirement changes with the cubic factor of the airflow rate (fan speed), excessive air capacities dramatically increase the needed horsepower for fan operation. A 10%–20% increase in fan speed increases the fan power demand by 33.1%–72.3%, respectively. On the other hand, a 10%–20% decrease of the speed reduces the power

1. This document is ABE-356, one of a series of the Department of Agricultural and Biological Engineering, UF/IFAS Extension. Original publication date December 1995. Revised annually. Most recent revision August 2025. Visit the EDIS website at https://edis.ifas.ufl.edu for the currently supported version of this publication. © 2025 UF/IFAS. This publication is licensed under CC BY-NC-ND 4.0.

2. Masoud Salyani, emeritus professor, UF/IFAS Citrus Research and Education Center, Lake Alfred, FL; UF/IFAS Extension, Gainesville, FL 32611.

The use of trade names in this publication is solely for the purpose of providing specific information. UF/IFAS does not guarantee or warranty the products named, and references to them in this publication do not signify our approval to the exclusion of other products of suitable composition.

Use pesticides safely. Read and follow directions on the manufacturer’s label.

The Institute of Food and Agricultural Sciences (IFAS) is an Equal Opportunity Institution authorized to provide research, educational information and other services only to individuals and institutions that function with non-discrimination with respect to race, creed, color, religion, age, disability, sex, sexual orientation, marital status, national origin, political opinions or affiliations. For more information on obtaining other UF/IFAS Extension publications, contact your county’s UF/IFAS Extension office. U.S. Department of Agriculture, UF/IFAS Extension Service, University of Florida, IFAS, Florida A & M University Cooperative Extension Program, and Boards of County Commissioners Cooperating. Andra Johnson, dean for UF/IFAS Extension.

requirement by 27.1%–48.8%, respectively. Higher energy demand of the fan requires purchasing a larger sprayer or operating the fan at higher rotational speeds. These practices would increase capital investment, fuel consumption, and operating costs. Therefore, smaller fans or lower rotational speeds should be used as much as possible. Using lower air volumes could offer substantial savings in energy expenditure and cost of spray applications. Certainly, small trees and lightly foliated canopies do not require large sprayers. Reduction of fan speed is a practical method for decreasing pesticide waste and application cost in spraying small and low-density trees. It should be noted that sprayers must be recalibrated if they are used at lower fan speeds.

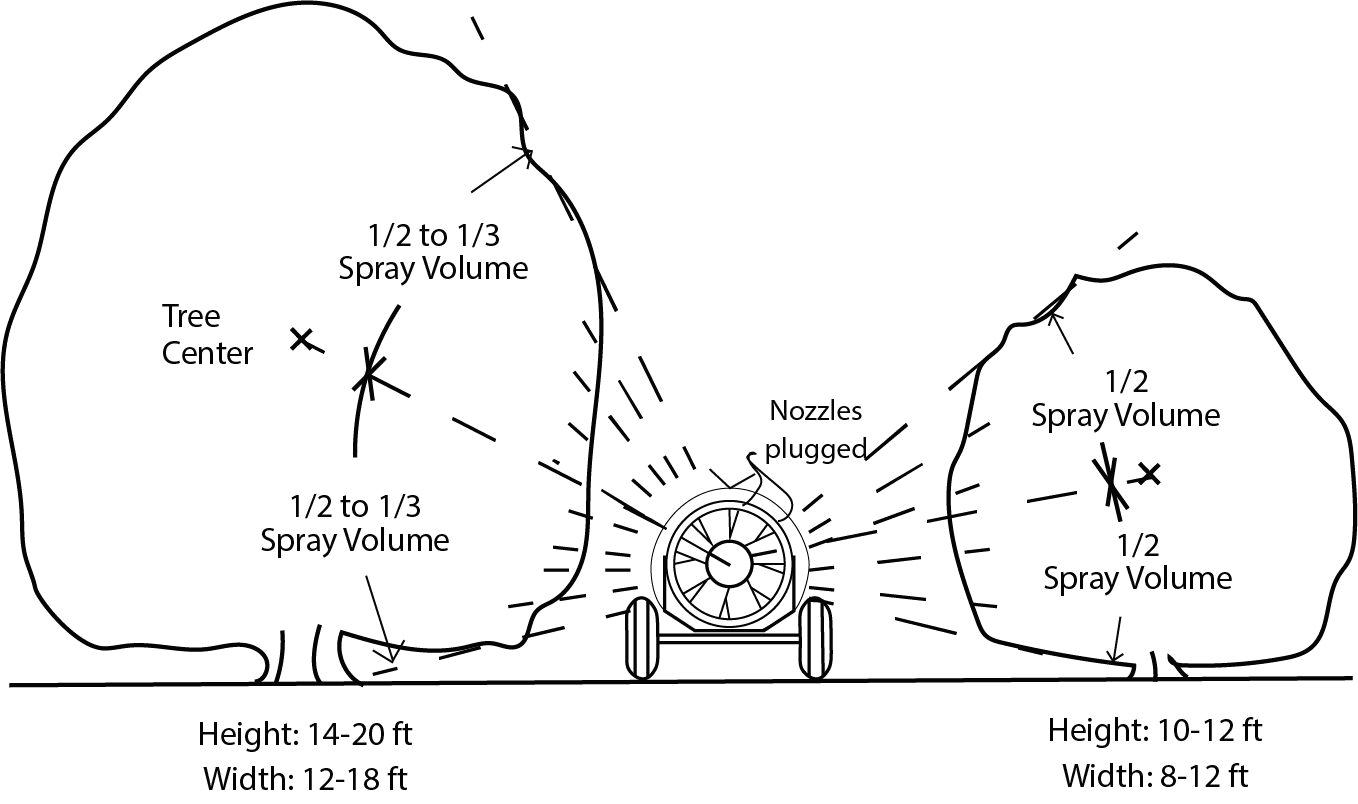

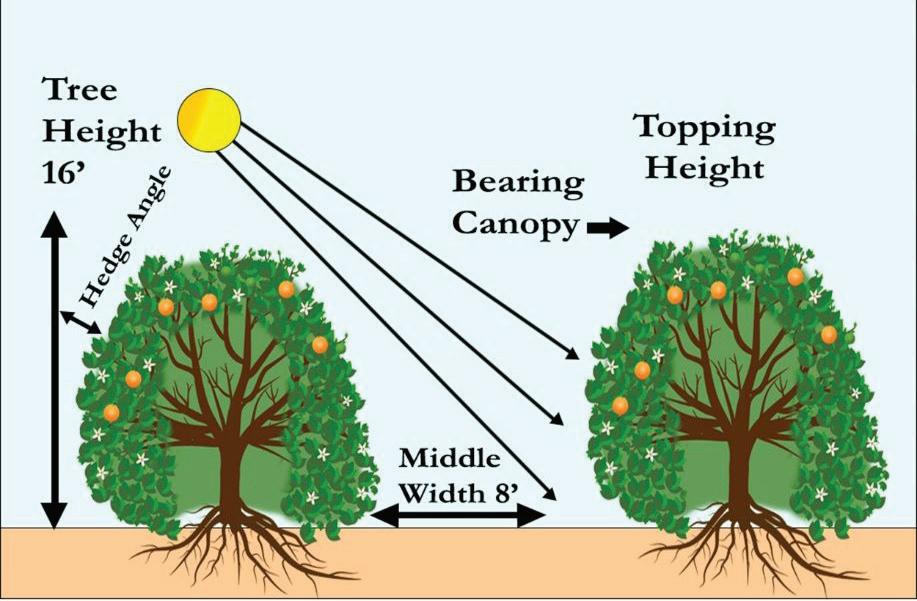

Nozzle Arrangement

In Florida citrus applications, it has been a common practice to direct 2/3 of the spray volume to the upper half of the tree and 1/3 to the lower half. However, this practice is no longer recommended when spraying small trees or using large airblast sprayers. The 2/3–1/3 nozzle arrangement has shown no significant improvement in overall spray deposition or pest control as compared to 1/2–1/2 (uniform) nozzle arrangement. The latter may also minimize errors in nozzle selection. Sprayer air deflectors, nozzle orientation and number of nozzles should be adjusted to match the size and shape of the canopy and minimize spray wastage (see Figure 1).

Figure 1. Recommended nozzle arrangement and spray volume distribution.

Credits: UF/IFAS

For low-volume rates (less than 100 gal/acre), reducing the number of nozzles and using smaller disc and core sizes rather than spraying at higher ground speeds may improve spray deposition. For high-volume rates (greater than 250 gal/acre), increasing the number of nozzles and spraying at higher ground speeds, instead of using fewer large disc and core sizes, may give higher deposition efficiency. Deposition efficiency of mid-volume rates (100–250 gal/acre) is less sensitive to these application variables.

Sprayer Calibration

Application errors can originate from either incorrect tank concentration of the pesticides (mixing error) or incorrect sprayer output per unit area (calibration error). The latter may be due to travel speed, nozzle pressure, or the use of improper, defective, and worn nozzles. However, by proper matching of the sprayer discharge rate, swath width, and travel speed, calibration errors can be mitigated. Sprayer calibration can be carried out by (a) determining the amount of the tank mix used to spray a known area; (b) operating the sprayer in a fixed place and measuring the amount of discharged liquid (water) for a specified time; or (c) collecting the nozzle discharge and determining the output for a time period. Application rate is then determined by calculations. If the rate is not acceptable, then sprayer and/or application parameters need adjustment. See UF/IFAS Circular 1435, “Calibration of Airblast Sprayers”, for details. The use of high-capacity nozzles at low pressures to achieve low-volume application rates, one-sided calibration of the sprayer for two-sided operations and vice versa, calibration at closed pressure settings, and intermittent operation of the nozzles can introduce errors in application rates. Sprayers using positive displacement pumps (diaphragm, piston, etc.) have more potential for application error compared to sprayers using centrifugal pumps, particularly at high-volume rates.

Application Rate Adjustment

The maximum per-acre rate of pesticides given in this publication is based on applications to mature citrus trees that have reached containment size (hedgerow status). Smaller trees can be sprayed with the same concentration of agrichemical, but using fewer nozzles (see Figure 1). This should provide spray deposition approximately comparable to that of mature trees, with lower spray volume and active ingredient per acre.

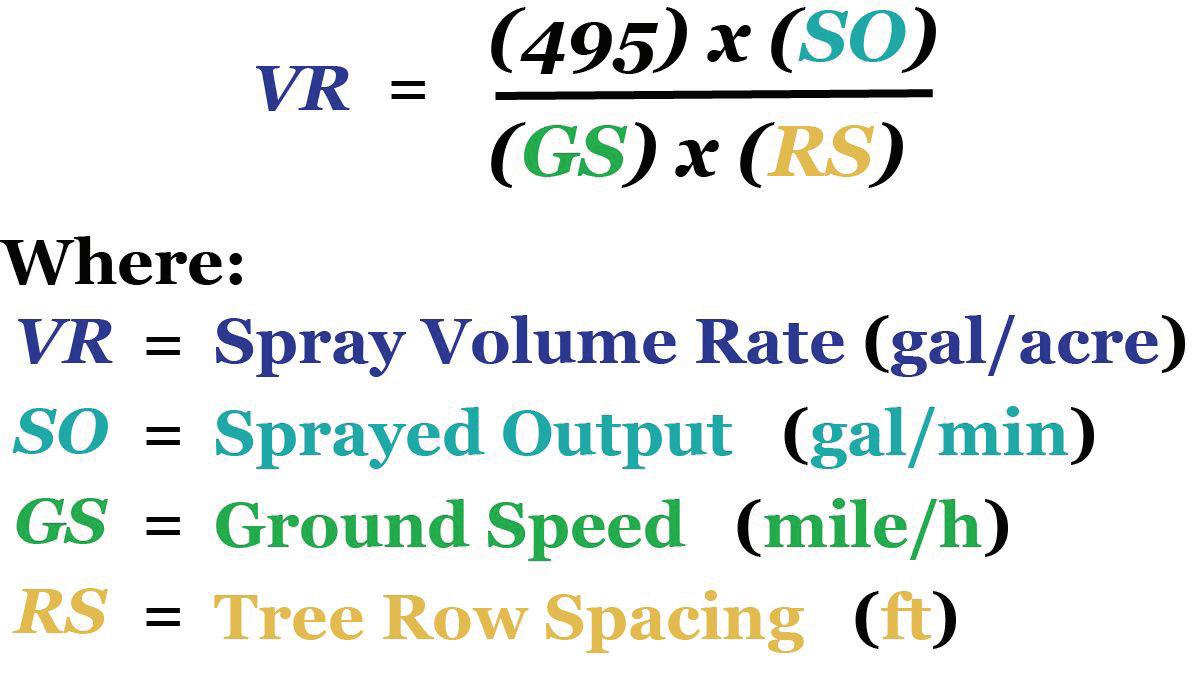

The spray volume rate can be calculated from Equation 1:

Equation 1.

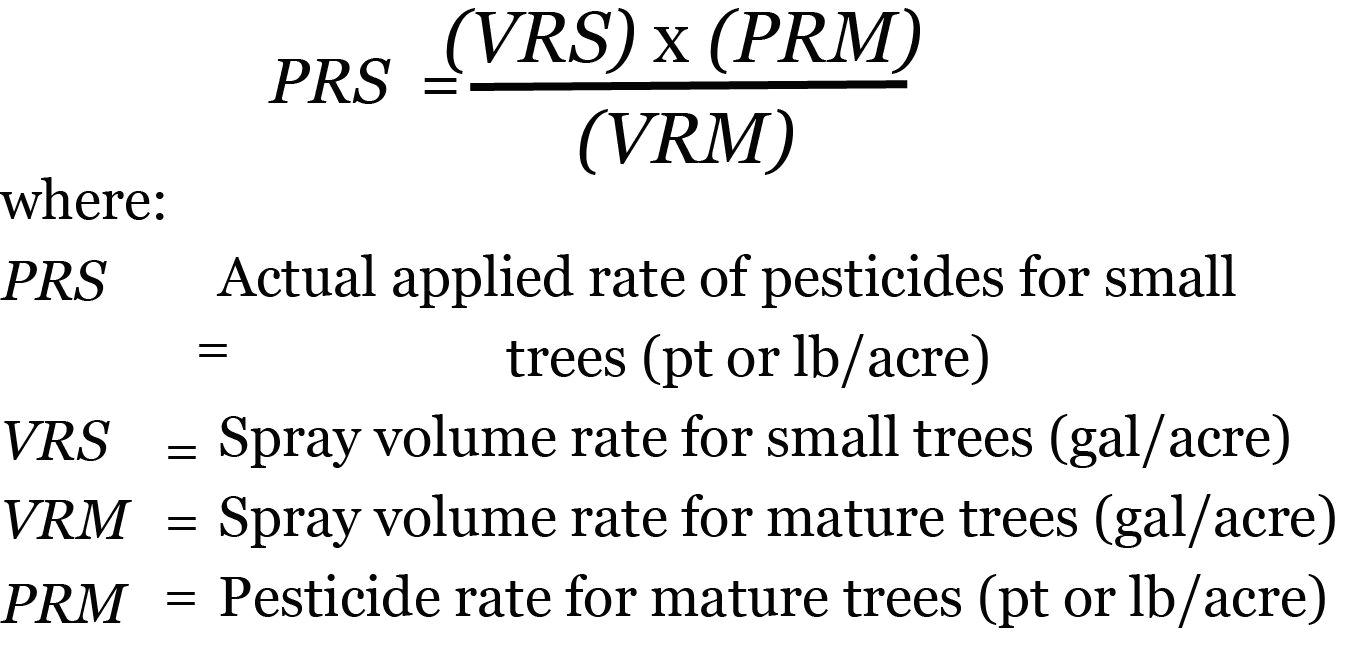

The actual applied rate of pesticides for small trees would be a fraction of the maximum rate per acre, as shown in Equation 2.

Further reduction in spray usage may be obtained by shutting the nozzles (manually or automatically) when passing by the gaps between adjacent trees. The above adjustments match the sprayer output with the tree size while providing adequate spray coverage and lowered off-target spray movement.

Spray Volume and Ground Speed

Lower spray volumes can deposit as much or more pesticide on the canopy than dilute rates. This is because spray runoff from leaf surface decreases and more material remains on the canopy. Lower volumes involve the use of smaller-orifice nozzles that provide smaller droplet sizes and more uniform spray distribution on the leaf surface. However, variability of spray distribution within the canopy and drift potential increase as spray volume decreases. With existing spray equipment and for average-size trees, a volume rate of about 250 gal/acre may be a good compromise for controlling most pests of economic importance, except some scale insects. The volume rate may be reduced further if higher pesticide concentration is more important than thorough wetting for controlling certain pests (see the label for limitations).

Increasing the ground speed can reduce the runoff from leaf surfaces in locations close to the sprayer. This effect can result in increased spray deposition and may be more pronounced with high-volume rates and large-orifice nozzles. On the other hand, hard-to-reach areas of the canopy may not have enough exposure for adequate spray penetration and deposition. The higher the sprayer air volume, the more potential it may have for high-speed applications. However, because variability of deposition increases at higher speeds, a ground speed of about 2.5 mph may be a reasonable speed for most citrus sprayers operating under average grove conditions.

Weather Conditions

The effectiveness and safety of spray applications largely depend on weather conditions during the application. High wind velocities can decrease spray coverage while increasing the variability of deposition and off-target drift. Pesticides should not be applied when wind velocity exceeds 10 mph or when it blows toward an adjacent residential area or susceptible crop. While calm conditions are desirable for spray deposition, temperature inversion may create severe drift problems. Vertical movement of the air during unstable weather conditions can increase the chance of spray drift, but dilution of the drift cloud makes it less serious than concentrated drift clouds generated under inversion conditions.

The size of the water-based droplets reduces constantly as they move from the sprayer. The evaporation becomes faster under hot and dry conditions and may become critical for low-volume applications. By using larger-orifice nozzles and/or lower spray pressures, droplet size can be increased and spray drift decreased.

LV/ULV Spray Guidance

The US Environmental Protection Agency and the Florida Department of Agriculture and Consumer Services allow the use of a pesticide on an agricultural site in a manner that results in the application of the same or less amount of active ingredient(s) to the site as specified on the product label but with less diluent than is specified on the product label if certain conditions are met:

1. The use of less diluent is not specifically prohibited on the product label; and

2. All other precautionary statements regarding product mixing, loading, and preparation, application methods, rates, frequency, preharvest intervals, tolerances, field reentry intervals, protective clothing or equipment requirements, product packaging and transportation requirements, and storage and disposal practices are complied with.

Typically, pesticide product labels include advisory language encouraging the user to apply the product in a solution of sufficient volume to achieve complete coverage of foliage. Coupled with this language, manufacturers suggest a range of spray volumes necessary to achieve adequate foliage coverage. However, unless the label contains language such as “do not use less than x gallons of water volume per acre,” it is acceptable for the grove manager to use less volume than suggested by the range on

the label. Growers should be cautious, however, and recognize the fact that crop damage occurring as a result of the use of less diluent than recommended on the label is solely their responsibility. Therefore, it is strongly recommended that this use pattern be tested on a small crop area before implementing widespread application.

Spraying Weeds

Herbicide Applicators

Herbicides are mostly applied with boom sprayers. These sprayers work on the same principles as tree sprayers and consist of a tank, pump, flow (pressure) regulator, agitation system (hydraulic or mechanical), nozzle manifold (boom), and a set of nozzles. However, compared to tree sprayers, herbicide applicators normally are equipped with smaller PTO-driven pumps (centrifugal, roller, or piston) and lower hydraulic pressures (10–50 psi).

The pump should be resistant to wear and corrosion. It must have enough capacity (gal/min) and pressure (psi) for both nozzle output and hydraulic agitation. This requires at least 20% greater capacity beyond the combined nozzle demand. Most pump manufacturers recommend not exceeding 70%–80% of the pump’s capacity for continuous operations. Agitation is more critical for wettable powders and water-dispersible formulations. Inadequate mixing of these products could result in nonuniform concentration of the herbicide in the tank, nozzle clogging problems, and over- or underdose output from nozzles. Overdosing of blocks with young trees can result in severe stunting and/ or phytotoxicity. Tanks without sharp corners minimize the chance for product settlement. Herbicide applicators equipped with mechanical agitation systems perform better than those with hydraulic agitation, but they are more expensive.

Regardless of differences in the design and price of the sprayers, the success of weed control largely depends on the choice of herbicide, timing of the application, and proper maintenance, calibration, and use of the equipment. More information on the selection and timing of herbicide application can be found in HS-107,Weeds (Chapter 43 of this guide). The following sections provide information on proper nozzle selection and calibration of herbicide applicators.

Nozzle Selection

In Florida, nearly all boom sprayers are equipped with hydraulic pressure nozzles. These nozzles are available in many sizes, shapes, and materials and may be color-coded

or identified by a number. A typical nozzle assembly consists of nozzle body, strainer (screen), tip (orifice), and cap (tip holder). Strainers vary in mesh size based on the size of the nozzle orifice (opening). Smaller openings (lower capacities) require finer mesh to minimize nozzle clogging.

Nozzles differ significantly in durability, flow rate, droplet spectrum, and distribution pattern. Brass and nylon nozzle tips are the least expensive but are relatively soft and wear rapidly; therefore, they are not suitable for spraying abrasive tank mixes such as wettable powders. On the other hand, ceramic and hardened stainless steel tips are more expensive but have excellent wear life and are very resistant to abrasive and corrosive chemicals.

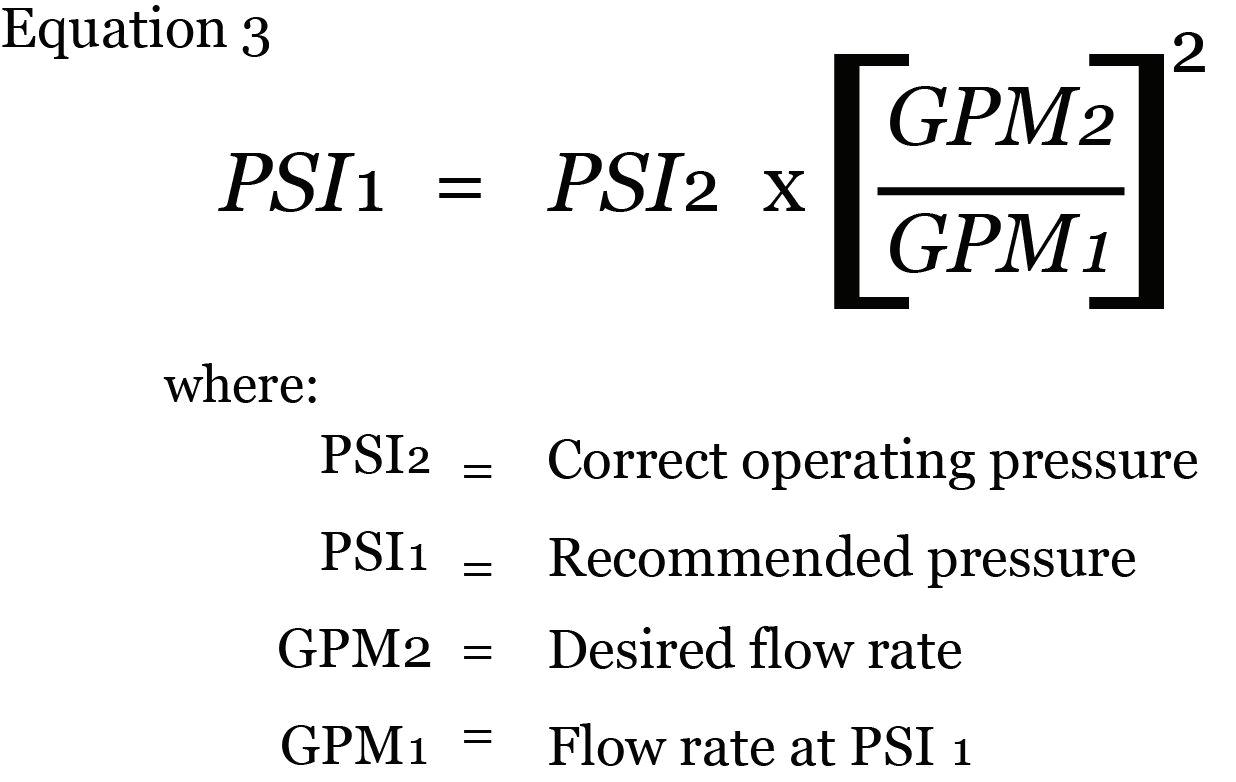

For a given nozzle type, flow rate (capacity) depends on the tip orifice size and operating pressure. In nozzle manufacturers’ catalogs, nozzle flow rates (GPM) are usually listed for a few selected pressures (PSI). It should be noted that all the tabulations are based on spraying water. When calibrations are based on water, the equivalent GPM of the heavier or lighter solutions should be calculated from Equation 3.

GPMw = GPMs × CF

where:

GPMw = Equivalent nozzle capacity for water

GPMs = Desired nozzle capacity of heavier or lighter solution

CF = Correction factor for solution density = square root of specific gravity (SG)

Equation 3.

Most nozzles perform satisfactorily around 30 PSI; however, recommended pressure of each specific nozzle should be determined from its manufacturer’s catalog. If the desired GPM could not be obtained at the recommended pressure, then the pressure should be adjusted. Because nozzle flow rate varies in proportion to the square root of the pressure (Equation 4), only minor adjustment could be achieved by changing pressure. Major adjustments require the use of smaller or larger nozzles.

It is normally mounted on a swivel body, a few inches beyond the last main nozzle.

Nozzles that generate tapered-edge patterns (e.g., flat fan) need some pattern overlap in order to obtain a reasonably uniform distribution across the spray swath. The amount of pattern overlap depends on nozzle spacing, boom height, and spray angle. Nozzles used on citrus herbicide applicators are normally mounted on 10–12 inch centers and operated at a height of 12–14 inches. Smaller spray angles require higher nozzle (boom) height in order to achieve acceptable pattern overlap (usually 30%–50%). Some nozzles may require 50%–100% pattern overlap. Nozzle catalogs normally specify optimum spacing, height, and overlap for each nozzle type. For a given nozzle flow rate, an improper boom height setting or vertical movement of the boom will result in uneven distribution (untreated bands or larger-than-desired treatment areas) across the spray swath.

Herbicide Sprayer Calibration

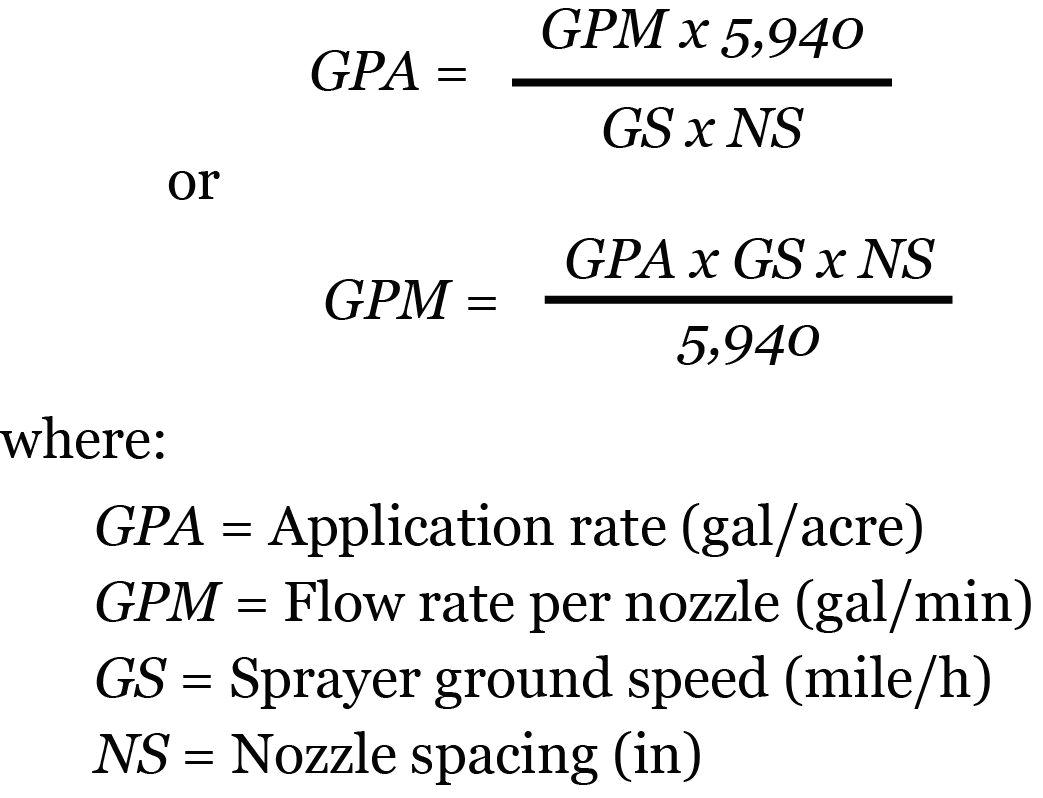

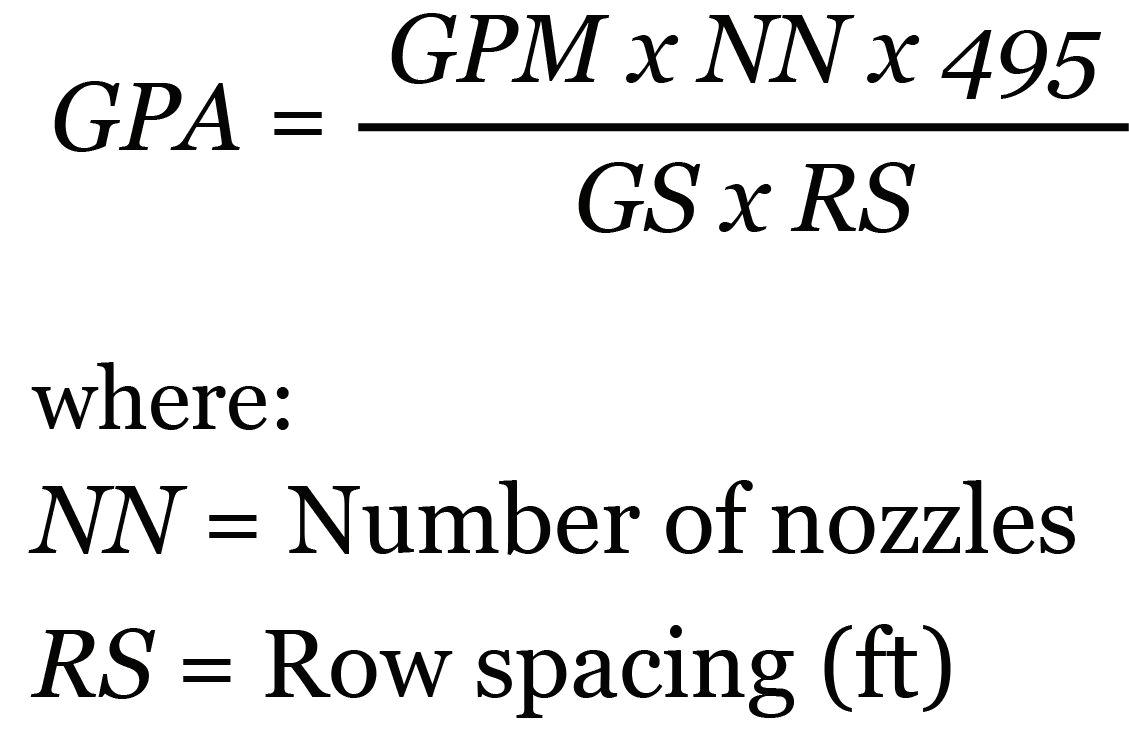

Application rate depends on nozzle flow rate (function of orifice size and operating pressure), number of nozzles, row spacing, and ground speed. Equations 5 and 6 show the relationships among these factors for broadcast and directed sprays, respectively. Equation 4.

Droplet size spectra and distribution patterns of nozzles vary substantially and largely depend on nozzle type, flow rate, operating pressure, and spray angle. Flat fan nozzles generate relatively smaller droplets, whereas drift-reducing nozzles produce larger droplets. Extended-range nozzles adjust the droplet size over a wide range of nozzle pressures. Flooding nozzles produce a wide spray angle and flat pattern. Nozzles with solid or hollow cone spray patterns may also be used in some postemergence herbicide applications.

Most of the available nozzles have spray angles ranging from 65° to 140°. The nozzle’s designated angle corresponds to the rated pressure. Spray angle increases or decreases at higher or lower pressures, respectively. Nozzle wear not only increases the angle and output, but it also distorts spray distribution pattern to some extent.

Spray Distribution

Unlike tree sprayers, nozzles used on herbicide equipment should be uniform (same type, material, capacity, and spray angle). Using a variety of nozzles on a boom results in uneven distribution patterns. However, herbicide applicators used in citrus may include an off-center nozzle tip (at the end of the boom) to extend the coverage beyond the end of the boom and cover the area around the tree trunk.

The quality of calibration depends on accuracies of the nozzle flow rate and ground speed measurements. To ensure accurate nozzle flow rate, flow regulator(s) and pressure gauge(s) must be in working order. The latter should have a reasonable range in order to provide accurate reading of the system pressure.

Because nozzle capacity tabulations (in catalogs) are based on pressure at the nozzles, the gauge closer to the nozzles should be used in calibration. In-line strainers and nozzle filters (screens) should be clean in order to avoid any restriction in the nozzle flow. Calibration procedures are similar to those mentioned for tree sprayers. They include (a) determining the amount of the tank mix (gallons) used to spray a known area (acres), (b) operating the sprayer in a fixed position and measuring the amount of discharged water (tank refill gallons) for a given time (minutes), or (c) determining the nozzle discharge rate (gal/min). If the calculated GPA was not the same as the desired GPA, then ground speed and/or nozzle pressure should be changed. The latter could only be used for minor adjustments. See UF/IFAS Factsheet HS-1012, “Citrus Herbicide Boom Sprayer Calibration”, for more information.

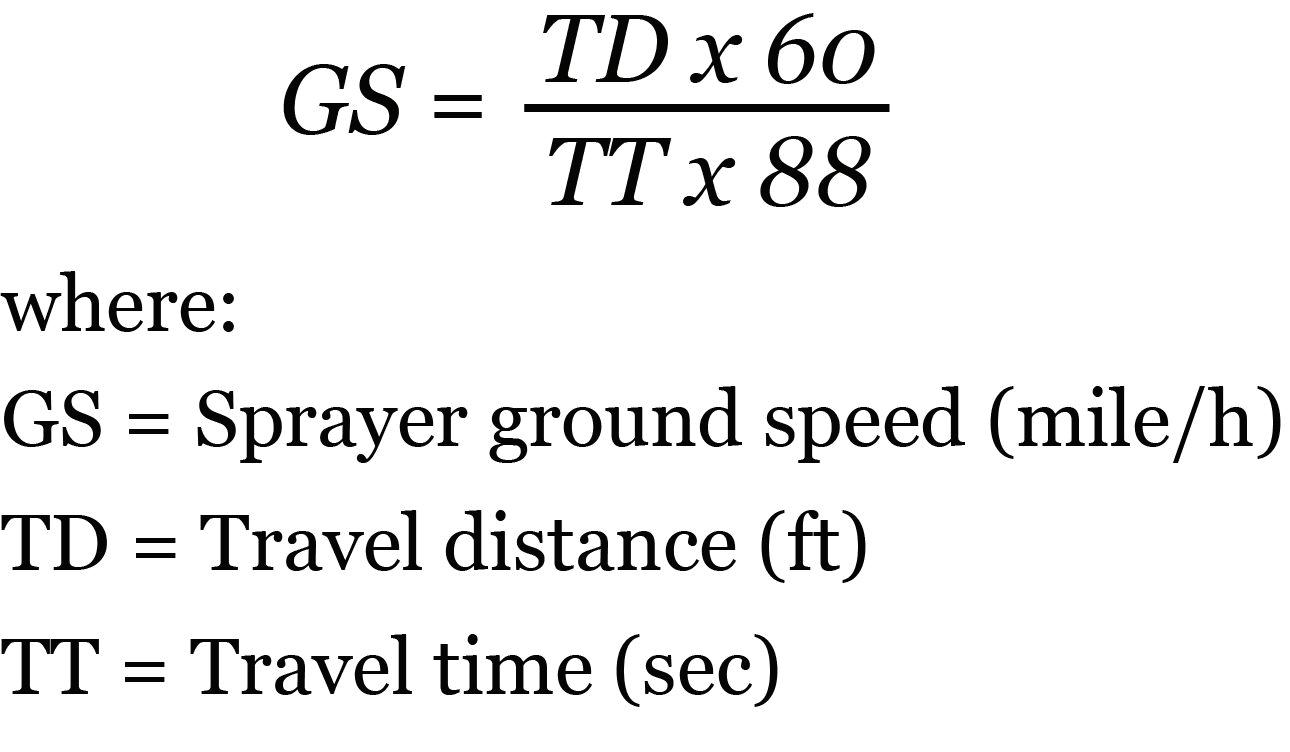

Equation 7 determines the ground speed. See UF/IFAS Circular 1435, “Calibration of Airblast Sprayers”, for detail of procedures for ground speed measurement.

Best Management Practices (BMPs) for Pesticide Applications

As mentioned earlier, pesticides can be expected to be effective if the right material is applied at the right amount, on the right target, at the right time, with the right sprayer, and under the right weather conditions. Read the product label for specific information, pertinent regulations, and safety recommendations. Follow the federal, state, and local government laws and regulations carefully. The following general BMP guidelines apply to most spraying practices.

1. Identify the nature of the pest that is causing the problem (consult with an Extension agent, plant pathologist, entomologist, etc.).

• Determine whether it is located on the canopy or in the root system, outside or inside the canopy, and on the upper or lower leaf surface.

• In case of weeds, identify their types and whether they are spread under trees or in the row middle.

• Learn about pest biology and its interaction with trees and fruit growth stage.

• Find out if the pest could be controlled by cultural practices and/or nonchemical methods.

• If chemical control is the preferred method, what category of pesticides may provide the desired solution?

2. Find out about the timing of the application.

• Scout the grove/field to establish the pest threshold level.

• Determine the optimum application window for effective control of the pest.

• Try to apply the pesticide when the pest is most vulnerable. It is very important to deal with pests at the most vulnerable biological or growth stages in their life cycles. Pesticide applications beyond the optimum window are likely to result in less efficacious pest control.

• Make sure the application will be completed several hours before a rain shower.

3. Select an appropriate pesticide (insecticide, fungicide, herbicide, etc.).

• Make sure the selected pesticide has been proven effective against the specific pest and registered for the intended use.

• Choose the least persistent and lowest toxicity pesticide.

• Make sure it will not generate phytotoxicity or pest resistance under intended use conditions.

• Check its compatibility with other products that will be included in the tank mixture.

• Learn about proper storage of the material to prevent chemical breakdown and fire hazards (read the label).

• Some pesticides specify the use of specific adjuvants to improve physical and/or chemical properties of the product. Select the right adjuvant and use it at the right rate in order to achieve the desired objective.

4. Determine the right amount (application rate) for the intended application.

• This information could be found on the label. It is usually specified as gallons, pints, pounds, or ounces of the product per grove or treated acre.

• Consider the application time and the target growth stage for suggested dose transfer.

• Adjust the rate according to the tree size, row spacing, pest pressure, and other pertinent factors.

5. Use properly calibrated equipment.

• Make sure the sprayer is in good working condition. Examine the pump, nozzles, manifolds, hoses, regulators, pressure gauges, etc. Clean all nozzle screens and inline strainers.

• Read the label for limitations on spray droplet size (spray classification category) and suggestions for drift mitigation near the sensitive areas. Select the right nozzle type, size, and pressure for the job. Make sure the selected nozzles are consistent with the label’s spray quality recommendation (i.e., very fine, fine, medium, coarse, very coarse, or extremely coarse). Use nozzles that generate a minimal percentage of smaller drift-prone droplets at the specified operating pressure. Consider using “low-drift” nozzles when available.

• Check nozzle spacing, nozzle angle, and boom height to make sure there is sufficient pattern overlap for uniform spray coverage.

• In airblast applications, adjust the orientations of nozzles and air deflectors to direct the spray cloud onto the tree canopy only.

• Check the functionality of the sprayer agitation system (mechanical or hydraulic). Some formulations have specific mixing requirements.

• Be careful about the order of material addition into the tank. Usually, adjuvants are added before pesticides. Refer to the product label for recommended mixing order.

• Use only clean water free from dirt, sand, algae, etc. Algae quickly clog the strainers and nozzles. Sand and other abrasive particles expedite pump and nozzle wear. Other contaminants may react with the pesticide and reduce its effectiveness. Water pumped from ditches or ponds should be filtered before filling the tank.

• Examine the uniformity of the tank mixture. This is more critical when using wettable powder or dry formulations, particularly with irregularly shaped tanks featuring sharp corners. Premixing the chemicals in a small container could help uniform mixing in the sprayer tank.

• Follow the label recommendations for avoiding drift from highly volatile formulations.

• Use an appropriate ground speed based on the tractor/ sprayer capabilities, terrain conditions, boom stability requirements, etc. Make sure the intended ground speed will be achieved during the application. Check the tire pressure.

• Monitor the operation of the nozzles during the application. Observe the output pattern of nozzles periodically. Nozzle clogging and changes in nozzle pressure and ground speed will affect the actual application rate.

• Carry spare nozzles, screens, washers, etc. for quick adjustments/repairs in the field.

6. Apply pesticide under the right weather conditions.

• If possible, avoid spraying during hot, dry, or windy weather conditions. Nighttime applications could increase spray deposition and reduce drift.

• Avoid spraying during stable (inversion) conditions (early morning and early evening) when there is little or no vertical mixing of the air. These conditions generate concentrated drift clouds and increase the chance of drift fallout.

• Stop spraying a few hours before rain showers. Allow sufficient time for sprays to dry and form reasonably durable deposits.

• Monitor wind direction and do not spray when there are sensitive crops/areas immediately downwind.

• Keep records of air temperature, relative humidity, wind speed, and wind direction. These records as well as equipment and application information may be very helpful in dealing with drift-related litigation.

7. Follow the safety instructions.

• Read the most recent product label. Look at the signal word (Danger, Warning, Caution). It gives an indication of the pesticide toxicity level.

• Learn about the environmental hazards (effects on wildlife, water resources, etc.) associated with using the product.

• Read the label for recommended personal protective equipment (coveralls, boots, gloves, goggles, respirators, etc.). Wear protective clothing during equipment calibration, loading, mixing, spraying, and cleanup.

• Before mixing and applying the pesticide, learn about using the first aid and medical treatment in an accident.

• Minimize the spray mixture leftover and rinsate (mix right amount as needed).

• If possible, use formulations that are packaged in returnable or refillable containers.

• Clean the sprayer shortly after task completion. This practice not only increases equipment life but also reduces the chance of pesticide cross contamination.

• Rinse and dispose the pesticide containers properly as directed by the label.

• Follow all safety guidelines related to the operation of the equipment (tractor, sprayer, nurse tank, etc.).

• If available, use sprayers equipped with a canopy sensing system (UF/IFAS Factsheet HS-872, “Sensor-Controlled Spray Systems for Florida Citrus”. The system helps to direct the pesticide to the intended target more precisely, thereby reducing pesticide wastage and environmental contamination.

8. Prevent point-source pollution of pesticides.

• Store your pesticides in a properly constructed and secured storage room. The storage area should have a smooth floor with no connection to a drainage system. It should be equipped with nonabsorbent sturdy shelves, a first aid kit, a fire extinguisher, measuring cups/jugs, and absorbent inert material (to confine spillage). It should display hazard classification symbols, clear instructions for dealing with spillage, and emergency phone numbers. Note that the locker containing personal protective equipment should not be located inside the storage area.

• Store the empty packages/containers of solid/liquid pesticides inside the storage room and dispose of them in a legal way (never burn or bury in the field).

• Use a lockable and securely fixed box to transport the pesticides to the field safely. Do not leave pesticides in a place that is accessible to unauthorized users or children. In case of accident, contact emergency phone numbers.

• Make sure the sprayer tank lid is closed tightly and the tank, pump, strainers, manifolds, and nozzles do not leak. Use antidrip nozzles.

• Fill the tank in a bounded filling station or in the field (away from surface water). If filling in the field, use a tray to collect any accidental spill. Do not overfill the tank and do not insert the water pipe/hose inside the tank (avoid tank mix contact with water supply). Load powder formulations through induction hopper, if available.

• Rinse empty containers during filling, using the rinsing nozzle or a water hose. Pour the rinsate in the tank.

• Clean the sprayer in a bounded area (with collection system) or in a grassy field (away from surface water). Never drain undiluted spray liquid in the field.

• Do not spray in the buffer zones around lakes, water wells, or along streams and drainage ditches.

• Do not use an airblast sprayer for spraying small trees or bushes. Use a recirculating tunnel sprayer or similar equipment to minimize spray losses to the environment.

Web Addresses for Links

UF/IFAS Circular 1435, “Calibration of Airblast Sprayers”: https://doi.org/10.32473/edis-ae238-2003

UF/IFAS Factsheet HS-872, “Sensor-Controlled Spray Systems for Florida Citrus”: http://ufdc.ufl.edu/ IR00002701/00001

UF/IFAS Factsheet HS-1012, “Citrus Herbicide Boom Sprayer Calibration”: https://doi.org/10.32473/ edis-hs252-2005

doi.org/10.32473/edis-cg027-2023

2025–2026 Florida Citrus Production Guide: Best Management Practices for Soil-Applied Agricultural Chemicals1

Davie M. Kadyampakeni and Larry W. Duncan2

Over the past few decades, certain pesticides and nitrates have been detected in some shallow groundwater locations on the sandy ridge soils of central Florida. Federal and state regulatory agencies emphasize the need to protect groundwater and all drinking water supplies and, in turn, have restricted the timing and use of certain widely used agricultural chemicals. As a result of these concerns and more stringent regulatory policies and best management practices (BMPs), growers will have to assume increasingly more responsibility for the crop management practices they choose: The fate of the environment depends, in part, on the agricultural chemicals they use. Specific BMPs are currently being implemented to optimize crop production and environmental protection for both ridge and flatwoods citrus production; this state-sponsored, voluntary program encourages citrus growers to develop and adopt site-specific BMP plans for controlling agrichemical contamination of state water resources. Growers who formally adopt BMPs and can produce a documented plan will receive a waiver of liability from the state for any inadvertent environmental contamination events. Many different environmental factors and management components can be involved in the BMP plan.

To prevent or reduce the movement of chemicals to groundwater, users must consider many different site-specific BMPs, including the following: integration of crop and pest management strategies, product selection, application rates, timing, placement in relation to the root system, weed cover, soil properties, and irrigation management strategies.

Application Rates, Frequency, Timing, Placement, and Other Considerations

Integrated pest management (IPM) requires one to (1) monitor activities for the presence and abundance of pests within the grove, (2) determine whether pest population densities are high enough to cause economic loss, and (3) select a profitable, worker-safe, and environmentally compatible management option. Pesticide application should only be considered after the results of monitoring activities have been completed and other potential causes of tree or grove decline are evaluated and corrected. In addition, a truly integrated strategy requires consideration of pesticide selection, when the choice exists, prior to application.

1. This document is HS-185, one of a series of the Department of Horticultural Sciences, UF/IFAS Extension. Original publication date December 1995. Revised annually. Most recent revision August 2025. Visit the EDIS website at https://edis.ifas.ufl.edu for the currently supported version of this publication. © 2025 UF/IFAS. This publication is licensed under CC BY-NC-ND 4.0

2. Davie M. Kadyampakeni, associate professor, Department of Soil, Water, and Ecosystem Sciences, UF/IFAS Citrus Research and Education Center; Larry W. Duncan, professor, nematology, Department of Entomology and Nematology, UF/IFAS Citrus Research and Education Center; UF/IFAS Extension, Gainesville, FL 32611.

The Institute of Food and Agricultural Sciences (IFAS) is an Equal Opportunity Institution authorized to provide research, educational information and other services only to individuals and institutions that function with non-discrimination with respect to race, creed, color, religion, age, disability, sex, sexual orientation, marital status, national origin, political opinions or affiliations. For more information on obtaining other UF/IFAS Extension publications, contact your county’s UF/IFAS Extension office. U.S. Department of Agriculture, UF/IFAS Extension Service, University of Florida, IFAS, Florida A & M University Cooperative Extension Program, and Boards of County Commissioners Cooperating. Andra Johnson, dean for UF/IFAS Extension.

Pesticide selection should be based not only on costeffectiveness but also on mode of action rotation; consideration of the latter helps avoid resistance buildup, toxicity to nontarget species, and product solubility, persistence, and leaching potential of the pesticide in question. This consideration also requires regulating the irrigation schedule based on soil type, and other site characteristics. Various sources of information are available for identifying specific soil types and ideal irrigation schedules to help in predicting and minimizing movement and leaching potential of most citrus agrochemicals.

Once a need for pest control has been established and a chemical has been selected, the grower must decide on rate and timing of application. Agricultural chemicals should be applied only at the labeled or recommended rates. Lower rates applied more frequently combined with sound irrigation management practices can significantly reduce chemical movement beyond the root zone. Split applications of pesticides or fertilizers will reduce the amount applied at any one time, thereby reducing the amount that might be leached at a given time.

Controlled release (encapsulated) formulations, when available, also provide the advantage of reduced leachability.

The timing for application of most pest management/crop production chemicals should not be based on the calendar but on pest population biology, abundance, and tree growth periods. Applications during the summer rainy season should be avoided whenever possible. In some instances, pests may require treatment during times when rainfall can be expected, but if heavy rainfall is imminent, application should be delayed and subsequent irrigations adjusted to account for rainfall amounts.

Most soilborne pests are associated with citrus roots. For pesticide applications targeting soilborne pests and diseases, pesticide efficacy occurs primarily within the zone of application and, to a much lesser degree—due to the systemic activity of these pesticides—within and around roots outside of the zone of application. Because a large majority of fibrous roots grow within the top 24–30 inches of soil and decrease in abundance from the tree trunk to the row middle, pesticide placement to maximize under-canopy coverage is of critical importance. Pesticide placement under the tree canopy targets the areas of highest fibrous root and pest density; by doing so, this placement can significantly improve overall pest control and minimize leaching. Tree skirts may need to be raised by pruning to improve application equipment access under the tree canopy.

Cultural practices that promote excessive vegetative growth, such as overwatering and excessive nitrogen fertilization, can intensify some pest problems and should be avoided in the control of some plant diseases (e.g., Alternaria brown spot). Under-canopy weed growth may reduce pesticide effectiveness by interception or absorption of pesticide residues targeted for citrus roots or pests in the soil. Undercanopy weeds also interfere with microsprinkler operation and prevent uniform coverage of chemigated compounds. At the individual tree level, excessive irrigation, when coupled with unmanaged weed growth, can promote localized deep soil penetration of soil-applied pesticides or fertilizers, resulting in groundwater contamination.

Soil and Chemical Properties

The potential for leaching of agricultural chemicals below the root zone depends on both soil and chemical characteristics. Persistence, sorption, and water solubility are the primary characteristics of chemicals that determine leaching potential. Organic matter is one of the most important soil characteristics in determining the leaching potentials of many agricultural chemicals. Rates of leaching are lower for soils with high organic matter content. Deep Ridge sands, low in organic matter (typically less than 1%), are particularly vulnerable to leaching. A list of vulnerable soils that allow chemicals to be easily leached may be obtained from the Natural Resources Conservation Service (NRCS, formerly Soil Conservation Service).

Chemical persistence is the length of time required for a material to break down and is often expressed in terms of half-life. Half-life is the amount of time required for onehalf of the applied pesticide to be broken down in the soil. Pesticides in the soil are bound to soil particles, particularly organic matter, through a process called sorption. This binding retards their movement through the soil. A useful means of quantifying pesticide sorption on soils is the partition coefficient (Koc): the relative affinity or attraction of a pesticide to soil materials. Pesticides with a high Koc are strongly adsorbed and thus less subject to leaching.

Chemicals with shorter half-lives and higher Koc values are less likely to contribute to groundwater contamination. If possible, more leachable products should be used during the drier seasons. Products with short half-lives and high K oc values should be reserved for periods of high rainfall, if needed.

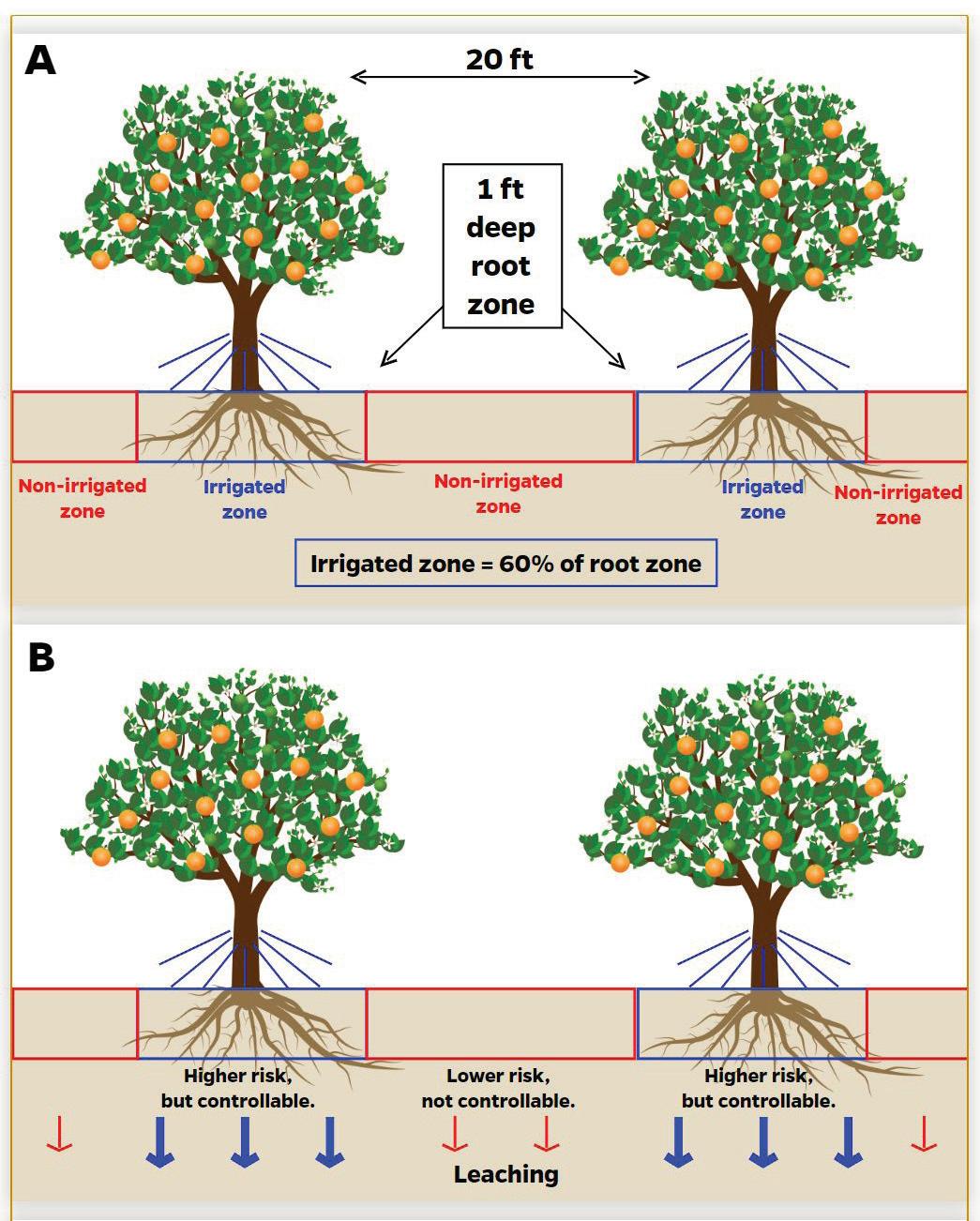

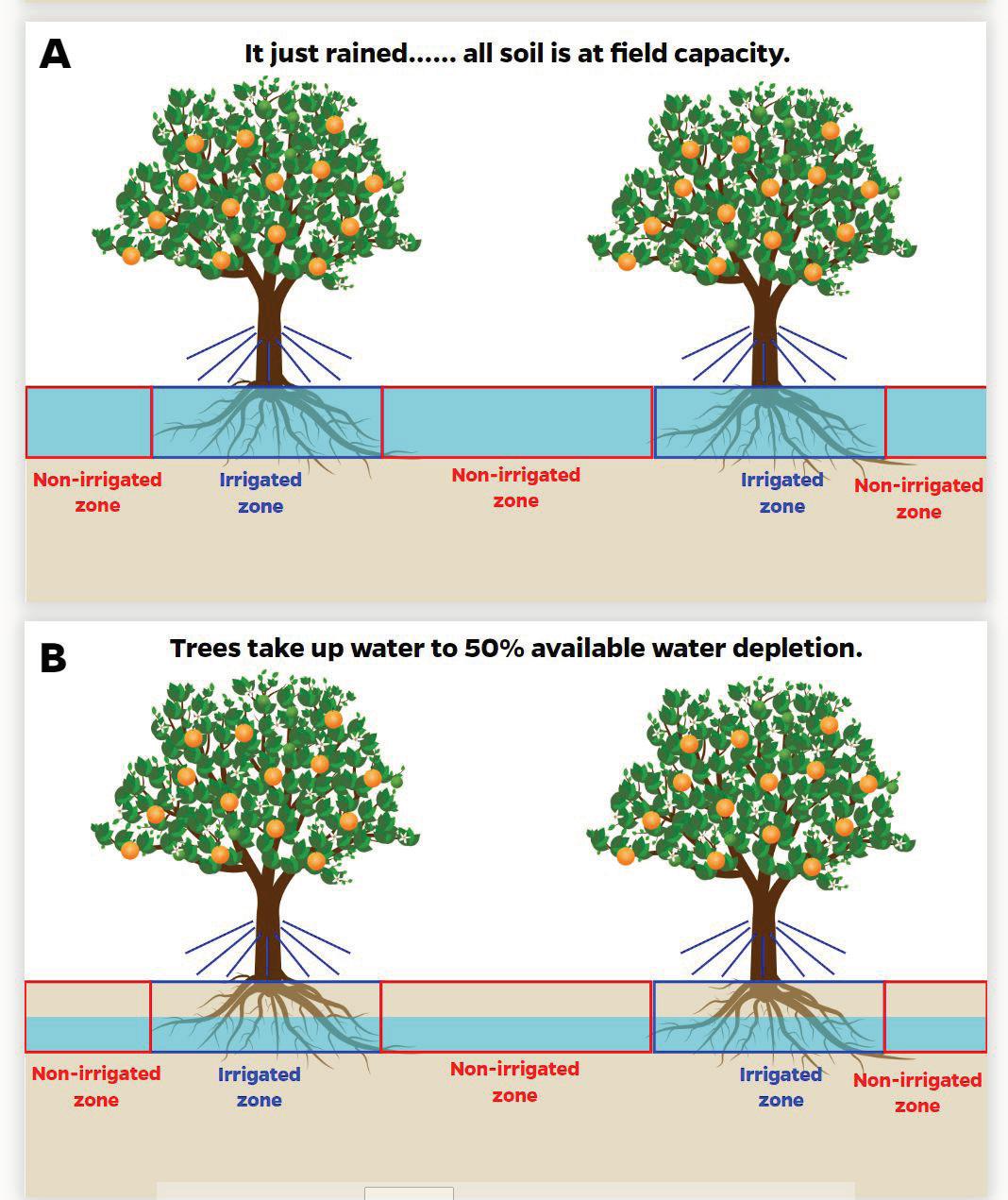

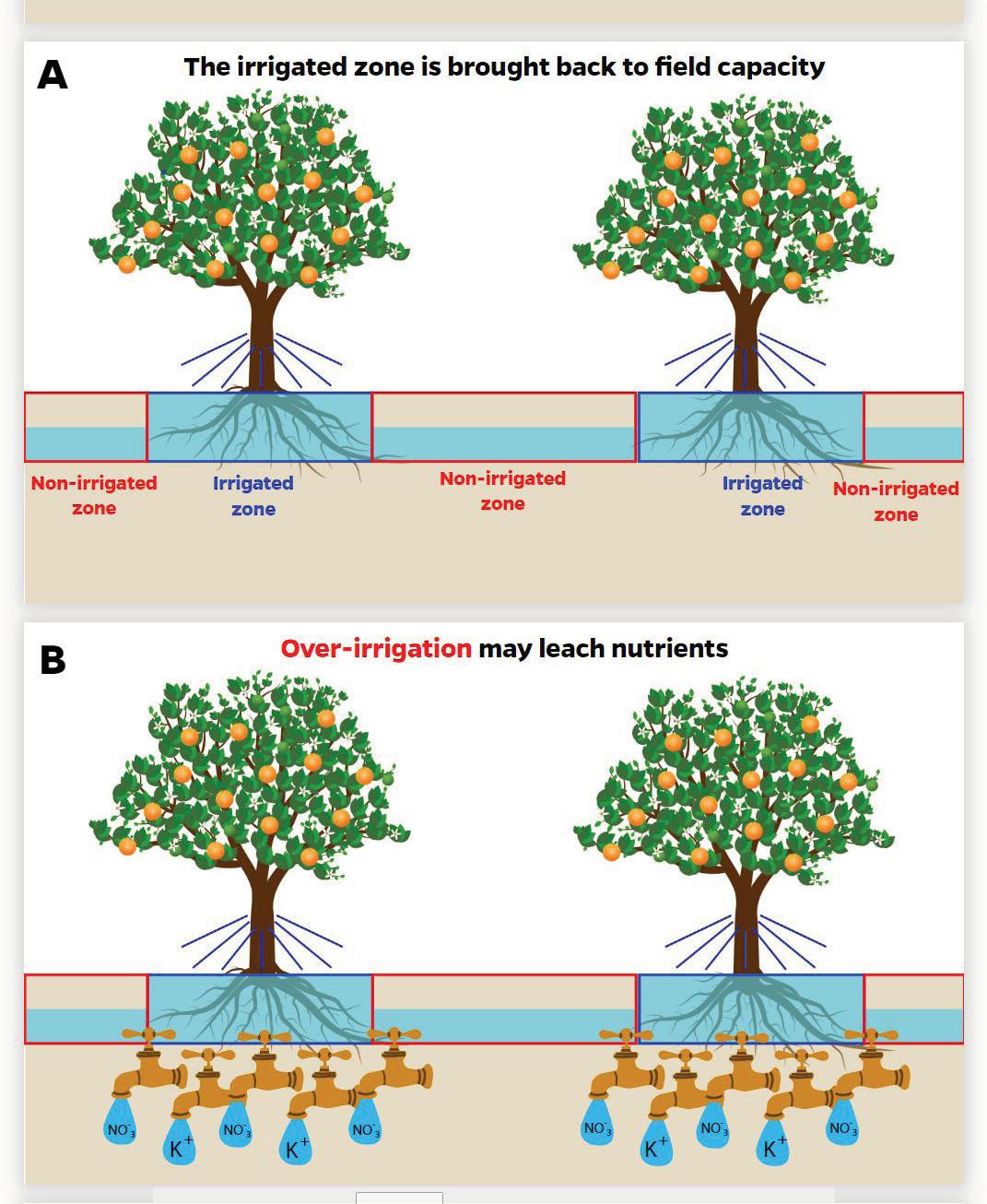

Irrigation

Both rain and irrigation water move agricultural chemicals through the soil. Hence, it is important to consider best irrigation management practices that minimize water movement below the root zone. Failure to irrigate properly may jeopardize the future use of some important soilapplied chemicals. The ability of soils to hold water affects their ability to retain pesticides and nutrients. Many Ridge soils have a low water-holding capacity and a high hydraulic conductivity, which allows water to easily percolate through the soil. These soils require frequent irrigation. If more water is applied than is used by the tree, water will move below the root zone. Repeated irrigation or rainfall events will leach soluble nutrients and pesticides below the root zone where they become both economic losses and potential pollutants of groundwater.

Excessive irrigation and rainfall can also promote population buildup of some pests such as Phytophthora spp., Alternaria spp., and various weeds. Reduced residence time of pesticide compounds in shallow soil horizons contributes to losses in production efficiencies and pest control efficacy. To avoid premature leaching from the root zone, soilapplied fungicides, nematicides, insecticides, herbicides, and fertilizers should be targeted to under-canopy areas of highest fibrous root density and should not be followed by excessive irrigation. Given the sandy, permeable nature of citrus soils and their low soil organic matter content, irrigation schedules based on soil moisture deficits are likely both to improve pest control and grove response to treatment by maximizing retention of toxic concentrations in the citrus tree root zone as well as to prevent problems of environmental contamination.

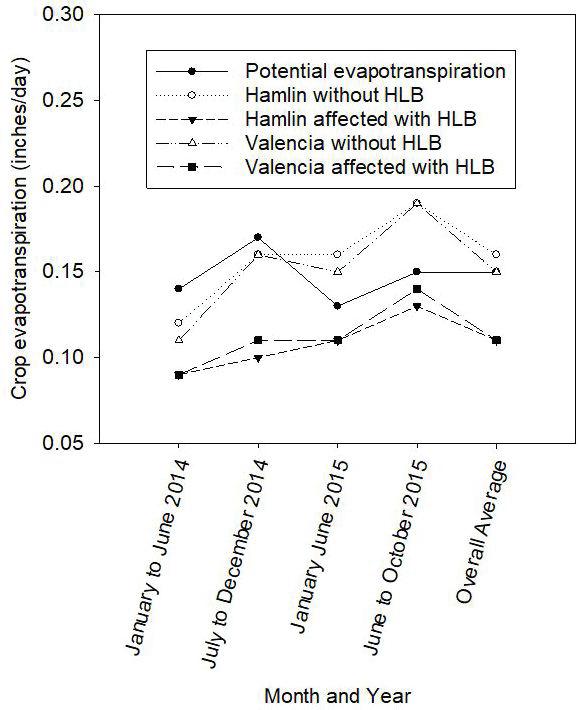

Best water-use management practices currently rely upon the use of accounting methods or the use of soil water sensors (e.g., tensiometers, capacitance probes, or other sensors) and irrigation apps to determine how much irrigation water to apply per irrigation event and when to apply it. Irrigation based on tensiometers will likely require the instruments to be installed at two depths in the well-drained soils of the central ridge. Irrigation will be scheduled when either tensiometer reaches a specified set point of soil water depletion. The deeper tensiometer can be monitored to ensure that no water moves below the root zone. To irrigate on a budget, one needs a computer on which to input daily rainfall, irrigation, and evapotranspiration data. The set points for irrigation are based on accumulated daily depletion of available soil water throughout the profile and on tree growth stage. The irrigation app provides the guideline for when water content in the root zone reaches a critical

point, e.g., below 25% to 33% of available water, thereby prompting an irrigation event to occur.

The water-holding capacity of the soil and the diameter and application rate to the wetted under-canopy area are necessary data to determine the duration of irrigation that would wet to only the appropriate root zone depth. Data on the water-holding capacity of citrus soils can be found in UF/IFAS publications SL456, “Nutrition of Florida Citrus Trees, 3rd Edition: Chapter 2. Production Areas, Soils, and Land Preparation”; Circular 1127, “Citrus Fertilizer Management on Calcareous Soils”; HS1306, “Fertigation for Citrus Trees”; or in the soil survey report for each county.

Total volume of irrigation water—not necessarily duration (irrigation run time) of the sprinklers—is important in driving the movement of chemicals through the soil profile. Careful planning and management of irrigation can improve pesticide and fertilizer efficacy and reduce the potential for groundwater contamination. For more information on microirrigation management, see Circular 1413, “Control and Automation in Citrus Microirrigation Systems”; Bulletin 265, “Field Evaluation of Microirrigation Water Application Uniformity”; and HS958, “Management of Microsprinkler Systems for Florida Citrus.”

Web Addresses for Links

EDIS Publication Bulletin 265, “Field Evaluation of Microirrigation Water Application Uniformity”: https://edis. ifas.ufl.edu/publication/AE094

EDIS Publication Circular 1127, “Citrus Fertilizer Management on Calcareous Soils”: https://edis.ifas.ufl.edu/ publication/CH086

EDIS Publication Circular 1413, “Control and Automation in Citrus Microirrigation Systems”: https://doi. org/10.32473/edis-ch194-2002

EDIS Publication HS958, “Management of Microsprinkler Systems for Florida Citrus”: https://doi.org/10.32473/ edis-hs204-2004

EDIS Publication HS1306, “Fertigation for Citrus Trees”: https://edis.ifas.ufl.edu/publication/HS1306

EDIS Publication SL456, “Nutrition of Florida Citrus Trees, 3rd Edition: Chapter 2. Production Areas, Soils, and Land Preparation”: https://edis.ifas.ufl.edu/publication/SS669

doi.org/10.32473/edis-cg031-2023

2025–2026 Florida Citrus Production Guide: Interpreting PPE Statements on Pesticide Labels1

Jason A. Ferrell and Frederick M. Fishel2

This document helps you understand the revised PPE statements now part of labels on pesticide products used on farms, forests, nurseries, and greenhouses.

Background