SPECIFICATION Magazine

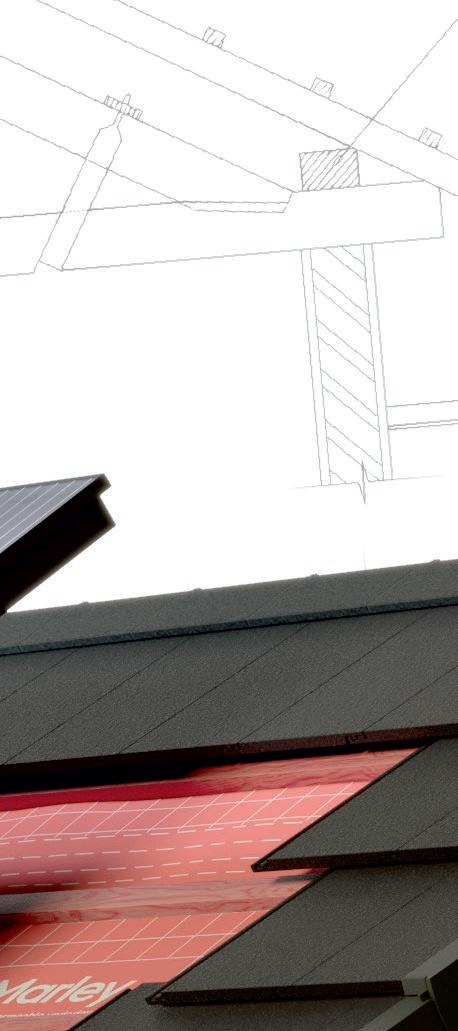

Fassacouche launches the first-ever KIWA-accredited 'Very Severe' wind-driven rain category in BRE Report 262. rt

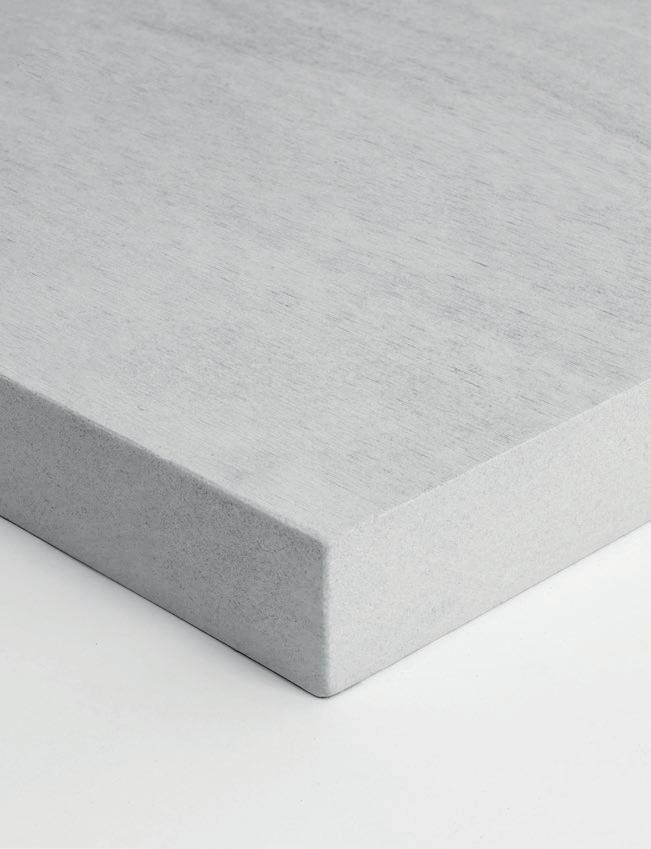

Our long-awaited KIWA-certified, class OC W2 through-coloured render delivers superior protection at 15mm thickness. Proving that superior protection doesn't have to come at the expense of compromise. Tried. Tested. Certified. Fassa strong.

KIWA BDA Certified for 'Very Severe' wind-driven rain conditions

15 mm render thicknessminimal, efficient protection

23 stunning shades

Multiple finishes: scratched, floated, sponge-floated & smooth

The Royal Institute of British Architects (RIBA) has published its annual Business Benchmarking 2025 report.

Using data submitted by UK-based RIBA Chartered Practices, the report tracks business trends in the twelve months to 1 May 2025, including revenue, expenditure, profitability, salaries, work types, and international activity. The full report is available exclusively to RIBA Chartered Practices.

This year’s findings show a profession delivering its strongest financial performance since before the pandemic, marked by strong revenue growth, rising profitability, and renewed confidence across much of the sector. While growth has been broad-based, much of the international expansion is driven by larger practices – with 83% of overseas revenue generated by those with 100 or more staff – while the smallest practices continue to face tougher trading conditions.

RIBA President Chris Williamson said: “This year’s critical research paints an encouraging picture of a profession regaining strength, confidence and international reach. The record £5 billion in revenue – and the first meaningful rise in profits for some years– reflect architects’ adaptability and resilience in the face of persistent economic uncertainty and regulatory pressures.

“It’s particularly encouraging to see renewed global momentum, with international work up by an unprecedented 67%, much of it from the EU. UK architecture continues to be a world-leading export and a vital part of our creative economy. But despite signalling the sector is on the right trajectory, there are also significant areas of concern. I know from speaking to many colleagues that some aspects of this survey will come as overly optimistic given current circumstances. Small practices especially, continue to work in a challenging market. Stagnant revenue and falling profit reflect the challenge of winning residential work with adequate fees.

“There’s more work to do to close the gender and ethnicity pay gaps and I will work to ensure all RIBA members adhere to our pay policies. Thank you to every Chartered Practice that contributed their data. Together, we’re building an essential evidence base to help us champion and support the profession through both its continued growth and ongoing challenges.”

Fassa Bortolo’s FassaLime range embodies the

between tradition and

Featuring the Ex Novo line, these lime-based solutions are designed for restoration, conservation, and ecoconscious construction. Rooted in Bio Architecture, FassaLime promotes natural breathability, durability, and respect for the environment – creating buildings that stand the test of time, beautifully and responsibly.

See pages 16-17 for the details.

Enquiry - 10

TSP Media Ltd, Grosvenor House, Central Park, Telford, TF2 9TW

T: 01952 234000

E: info@tspmedia.co.uk www.tspmedia.co.uk

The Housing Commission of the Radix Big Tent think-tank have issued a warning to the government that without changes to the existing housing stock, the UK is risking a ‘health emergency’ as the climate becomes more unpredictable.

Climate-related health factors are becoming more prevalent in the UK as, according to climate-management firm Tado, the country has the worst-insulated housing in Europe and leak heat three times faster than some European neighbours.

But cold and the resulting damp is not the only factor raised as a threat - during the scorching heatwave of 2022, Britain saw nearly 3,500 excess deaths linked to high temperatures.

The main risk factors here were age and house quality, with The Centre for Ageing Better predicting death counts will only rise.

The Housing Commission noted in its 2024 report, Beyond the Permacrisis’, that poor housing costs society £18.5bn per year, with the NHS spending £1.4bn a year to treat the health-related effects of housing that is damp, too cold or too hot.

The think-tank’s new Homes without Harm report points out that nearly 9 out of the 10 homes we’ll be living in by 2050 have

already been built and it is with these in mind that Radix Big Tent’s Housing Commission sets out a number of policy shifts required by the government in order to allow the housing sector to address issues with ‘retrofitting’ existing buildings.

Radix Big Tent’s Housing Commission Chair, Alex Notay Hon MRTPI, said: “The government’s direction of travel - publishing the Healthy Homes Standard and enacting Awaab’s Law - has been broadly positive in ensuring residents do not suffer because of the places they live in.

“However, the continued delays around the Future Homes Standard, Minimum Energy Efficiency Standards and revised EPCs are making the already complex challenge of ensuring homes are sustainable and affordable even more difficult when balancing the challenge of retrofitting and decarbonising existing homes with futureproofing new housing.

“Our latest report suggests some key nudges to ensure progress towards net zero is maintained but not at the cost of quality homes for our citizens.

“We strongly encourage the government to listen to the cross-sectoral voices we are providing here and take the steps needed to address homes that are causing harm.”

Hartwell Plc, the automotive and property development company, has received planning approval for its masterplan to deliver new carbon efficient laboratory and workspace buildings for small and medium sized science and technology companies and amenities at Wootton Science Park to the south-west of Oxford.

Hartwell has owned the park since 1975 and built the first office building in 2005. The £44 million Scott Brownrigg-designed masterplan was submitted to Vale of White Horse District Council in May 2024.

The approved masterplan will deliver circa 106,233 sq ft (9,869 sq m) across five new commercial buildings and connected amenities and facilities for future employees and the surrounding community, which will include high quality landscaped areas, secure bike storage, a bistro and gym.

The new Rob Burrow Centre for Motor Neurone Disease at Seacroft Hospital in Leeds will become the first of its kind to offer specialist services for MND patients under one roof.

Constructed by Yorkshire-based firm, I&G, part of the wider Sewell Group, the centre which is run by Leeds Teaching Hospitals NHS Trust provides a calm and peaceful environment for patients and was designed in partnership with the hospital’s clinical staff, patients, their families and the wider MND community.

Named after rugby league legend, Rob Burrow CBE, who campaigned for MND after being diagnosed with the condition in 2019, the new centre is a fitting tribute to his memory.

The Future Homes Hub has released its Whole Life Carbon (WLC) Benchmarking Study for 2025, a landmark report addressing a critical knowledge gap in the UK homebuilding industry.

For the first time, this study provides a vital, empirically grounded evidence base on the embodied carbon performance of new lowrise housing, guiding the sector’s collective transition to net zero.

The study’s core purpose is to create a robust snapshot of current carbon performance by analysing 48 detailed Whole Life Carbon assessments submitted by 17 industry partners.

To ensure consistency, credibility, and comparability across the dataset, all assessments adhere to the rigorous standards outlined in the WLC Conventions for New Homes and RICS Professional Standard 2nd edition.

This study is a testament to the power of industry collaboration. Its findings were made possible by the homebuilders and consultants who contributed their detailed project data and expert insights, demonstrating a shared commitment to transparency and progress.

Adam Graveley, Head of Technical and Innovation, Future Homes Hub, said:

Downing has submitted a planning permission application to redevelop 40 Anderston Quay, situated along the River Clyde in Glasgow.

The project is designed to meet the growing need for high-quality student accommodation and co-living residential units in the local area.

Formerly the headquarters for the Daily Record and Sunday Mail newspaper, the brownfield regeneration site is planned to include three blocks with a total of 1,135 bedrooms, alongside a 3,700 sq. ft commercial unit. Two of the blocks will accommodate Purpose-Built Student Accommodation (PBSA) units, whilst the third will be allocated for co-living use. All three blocks will have their own management suites, ancillary and amenity features, landscaping and extensive public realm.

"This benchmark is a pivotal moment for the homebuilding sector. For the first time, we have a clear, data-driven picture of our collective starting point on whole life carbon.

“This isn't just about numbers; it's about providing the tools and transparency our industry needs to set ambitious targets, make smarter design choices, and track meaningful progress. We are immensely grateful to our members who contributed data, and we urge the entire sector to join us in building this evidence base for our shared net-zero future.

“This collaborative effort provides the essential foundation for the targeted actions needed to accelerate the sector's decarbonisation journey.”

This inaugural benchmark is not an endpoint but a critical foundation for future work. The Future Homes Hub will continue to gather data to refine these benchmarks and has identified several key opportunities for the sector to pursue collectively.

To spearhead this agenda, the forthcoming Embodied Carbon Implementation Board will convene stakeholders from across industry and government, providing the leadership needed to dismantle strategic barriers and capitalize on these opportunities.

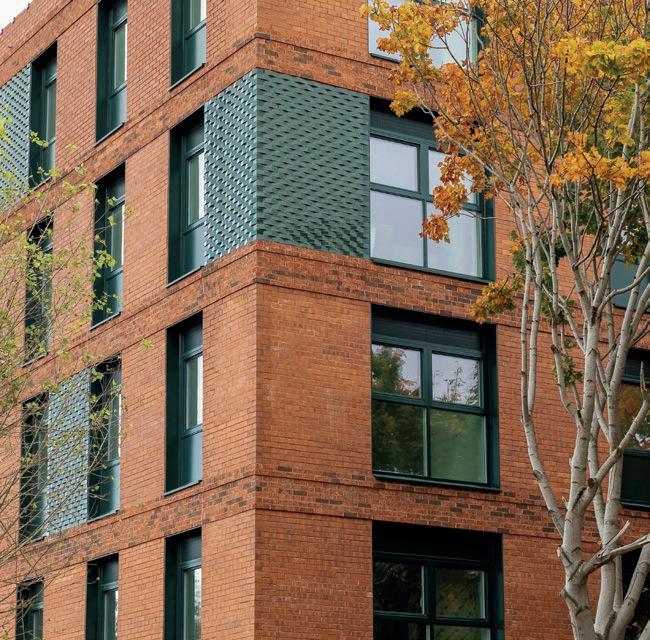

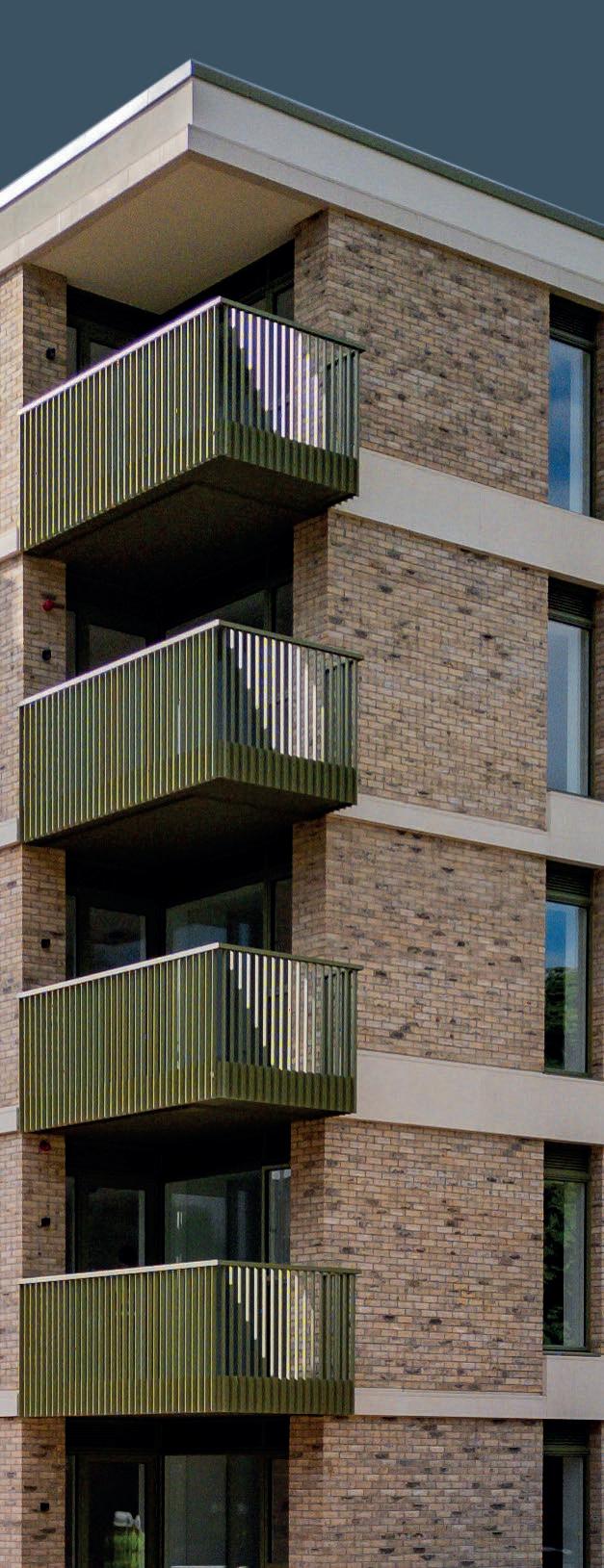

Major milestones have been reached at Willohaus, 100 affordable, Passivhaus homes on Peru Street in Salford, with the completion of the brick exterior and the first apartment.

The homes form the first part of Adelphi Village, a main residential zone of the £2.5bn, 240-acre Crescent Salford masterplan being delivered by Salford City Council, the University of Salford and ECF – a joint partnership between Homes England, L&G and Muse. The new community will deliver a diverse range of housing to create a sustainable, inclusive neighbourhood, with plans recently submitted for 263 homes at Old Adelphi and 42 townhouses and 185 apartments at Farmer Norton.

Salix Homes is the housing association partner for Willohaus, which has been designed by Buttress Architects and built by Eric Wright Construction. The one and two-bedroom apartments will be available for affordable rent, reflecting Salix Homes’ ongoing commitment to delivering muchneeded, high-quality, affordable housing.

Better communications and more consistent enforcement are needed to improve compliance with the Building Safety Act, according to speakers at the recent London Build Expo.

A lively panel session informed by new research from the Building Engineering Services Association (BESA) debated the need for more targeted information about the Building Regulations, stronger enforcement, and sector specific training to overcome the barriers to compliance reported by the SMEs and micro-businesses that make up 99% of the construction sector and its related professions.

BESA’s director of specialist knowledge Rachel Davidson told the busy event at the

Olympia exhibition centre in London that 88% of the industry’s professionals were aware of the Act but most SMEs found the legislation “overwhelming and daunting” and felt “left behind”.

“This is critical because those companies are the lifeblood of the industry,” said Davidson. “There are also a lot of people who still think the legislation only applies to HRBs (higher risk buildings).”

BESA’s second annual survey of the sector’s response to the legislation also showed that many clients were carrying on with “business as usual” meaning they continue to prioritise cost and speed over safety. “A lot of this comes back to leadership and culture,” said Davidson.

The first life-changing homes land at Harriet Gardens, the newest purposebuilt supported accommodation village by Social Bite, in partnership with South Lanarkshire Council and Salvation Army.

The arrival of the modular Nest Houses marks the next stage of construction as the project progresses towards an opening date in early 2026. Upon completion, the £3m village

will have 15 modular Nest Houses and a community hub with shared cooking facilities, spaces for group activities, therapeutic support, and areas for social connection.

Day-to-day running of the village will be supported by financial contributions from South Lanarkshire Council and Social Bite and managed by the Salvation Army, who will deliver specialist, round-the-clock support.

“78% of companies tell us that this is important to them but fewer than half report having taken enough action.”

She said that building engineering contractors were increasingly calling for clear and consistent enforcement of the legislation because “unless there are consequences, clients will continue to think compliance is optional”.

Davidson added that BESA was delivering more guidance to help firms see “what good looks like” in their sector. “It is also important to reassure people that they don’t need to know or understand everything about the Act – they should focus on the parts they can control and their specific roles and responsibilities.”

The Hill Group is starting construction work on Little Chalfont Park, a landmark new residential development that will deliver up to 380 high-quality new homes and a wealth of green open space in the sought-after village of Little Chalfont, Buckinghamshire.

This key milestone follows the recent approval of the first Reserved Matters Application, covering the Western Parcel of the site accessed from Burtons Lane. This first phase includes 74 new homes, extensive green spaces, infrastructure works and the start of construction of the pedestrian and cycle bridge providing direct access to Chalfont and Latimer station.

The homes in the first phase, with a development value of £78.5 million, include a collection of three, four, and fivebedroom houses for private sale and shared ownership, all designed in a traditional style that blends seamlessly with the local setting.

Project: The Northcliffe

Architects: John Robertson Architects

Suppliers: ASWS; Optima; OAG; Granada; Tyrell; Sortfords; Kone

The Northcliffe is the Grade II listed former Daily Mail headquarters in London’s Whitefriars Conservation Area which has been reimagined by John Robertson Architects.

The Northcliffe is a historically sensitive reimagining of the former headquarters and print works of the Daily Mail newspaper in Tudor Street, close to Fleet Street, in the City of London.

JRA’s redesign incorporates the Grade II Listed façade of the original 1920s building, and extends the building across two floors to offer 17,344 m2 of office space centred around a spectacular reimagined atrium. The Northcliffe is WELL Ready and offers extensive amenities, including three new landscaped roof terraces, lounge spaces, a library area, a quiet room, end-of-trip facilities, a café and a retail unit, all unified by references to the building’s post-industrial heritage.

JRA’s design achieved BREEAM ‘Outstanding,’ which less than 1% of refurbished buildings have achieved to date, and is certified EPC B. The project saved 53% of global warming potential versus demolition by retaining the superstructure and building fabric, and exceeds RIBA’s 2030 embodied energy emissions targets. The practice’s sustainable approach has been informed by a Life Cycle Assessment (LCA) commissioned by the Client.

The extensions at the upper two levels step back from the Daily Mail façade, allowing for three new south facing ‘green’ roof terraces to be formed at levels 5, 6 and 7. These new ‘green’ terraces link with the existing terrace on Bouverie Street and Whitefriars Street and

are wide enough to provide usable external landscaped terraces for occupiers.

The main entrance of the building has been relocated, placed centrally on Tudor Street and within the original Daily Mail façade. It marks a new era for the building and draws users and visitors alike into the heart of the revitalised, hospitality style reception. The interior design is inspired by the rich history of the 1920s, focusing on strong geometries, bold use of colour and

pattern, and high quality, crafted finishes. The atrium is the central feature of the building, around which the office floors and key circulation routes are organised. It provides natural daylighting for the office spaces and visual interest at the heart of the workplace. It is an integral part of the user and visitor experience, with a feature stair located at ground floor level connecting the lower ground floor to the main entrance hall.

The Grade II listed façade was designed by Ellis and Clarke in 1925, with the addition of the recessed façade and turret at level four in 1929. The building was constructed using a cast steel frame with the external elements encased in concrete to support the walls and ties for the precast cladding of ‘Atlas White’ Portland cement stone and the fashionable neo-Egyptian style decorative features such as the fluted coved cornice above the third floor. It made liberal use of Crittall’s minimalist W20 section galvanised steel windows with copper-lite glazing, giving the first and second floors an almost fully glazed appearance. >>

We’re huge stockists of fire and safety glass, offering fast delivery from local branches. Our team provides technical help and specification support, with options for supply-only or supply-and-fit to suit your project and budget needs.

Enquiry 8

>> Levels five, six and seven feature landscaped terraces that utilised 8,163 plants made up of over 55 species to create a country garden experience, enclosed by glass balustrading and perimeter planting. The terraces have been designed to provide a variety of spaces in which to work, relax and ‘to do more’. The terraces at level five and six have been demised to the adjacent office tenant and the level seven terrace is an amenity for the whole building.

Responding to the climate crisis was a priority at The Northcliffe. A Life Cycle Assessment was conducted to ensure the client’s sustainability goals were met. The LCA confirmed the benefit of retaining the superstructure and building fabric, saving 53% of global warming potential versus demolition.

The building possesses 40m2 of solar panels, 910m2 of landscaped terraces with biodiverse planting, 345 cycle spaces and extensive premium end of trip facilities.

In use, all waste is diverted from landfill, the building is powered by 100% renewable electric energy and has greater than 55% more efficient water consumption. In addition to BREEAM ‘Outstanding,’ the building is certified EPC B and the design exceeds RIBA 2030 targets for sustainability.

ASWS conducted a full condition survey across the building’s complex elevations, internal doors, and screens – covering steel, aluminium, and curtain walling.

This detailed report formed a key part of the tender process and set the foundation for the restoration strategy.

ASWS Operations Director, Kris Bennell, described the scope: “For the steel windows, we carried out full servicing and detailed cleaning of the original copper light glazing, along with redecoration and overhaul of all ironmongery. On-site, we completed extensive mastic work and redecoration across the remaining windows which included timber sashes.”

JRA Associate Andy Thomas highlighted the architectural significance of the copperlight windows, which were retained as a key interior feature. He praised ASWS’ role in restoring these elements and managing the sequencing of works with precision.

ASWS’ contribution was instrumental in helping the project team meet its sustainability goals.

By restoring and reusing original components wherever possible, The Northcliffe is now on track to achieve a BREEAM Outstanding rating – placing it among the top 1% of commercial refurbishments in the UK.

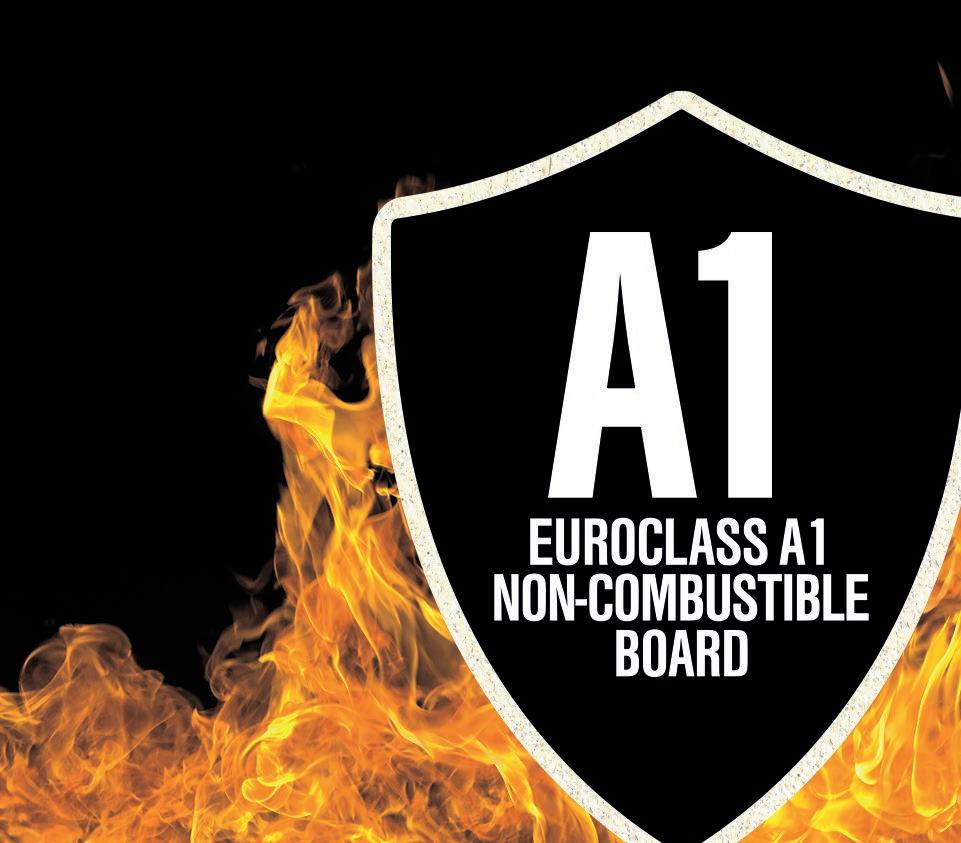

When it comes to balcony safety, there’s no room for compromise.

The Building Safety Regulator (BSR) is setting a new benchmark for accountability, compliance, and long-term performanceand AliDeck is leading the way.

We’re proud to be the only UK balcony manufacturer with QUALICOAT accreditation, the global quality mark for aluminium powder coating. This certification confirms that our in-house finishes meet the highest international standards for durability, corrosion resistance, and weather protection.

It’s proof of our commitment to quality — not just in words, but in verified performance.

✔ Only balcony manufacturer with QUALICOAT accreditation

✔ BSR-compliant non-combustible systems

✔ Made in Britain certified

✔ 30-year product warranty

AliDeck - where compliance meets quality. LEARN MORE about our Qualicoat process - SCAN HERE!

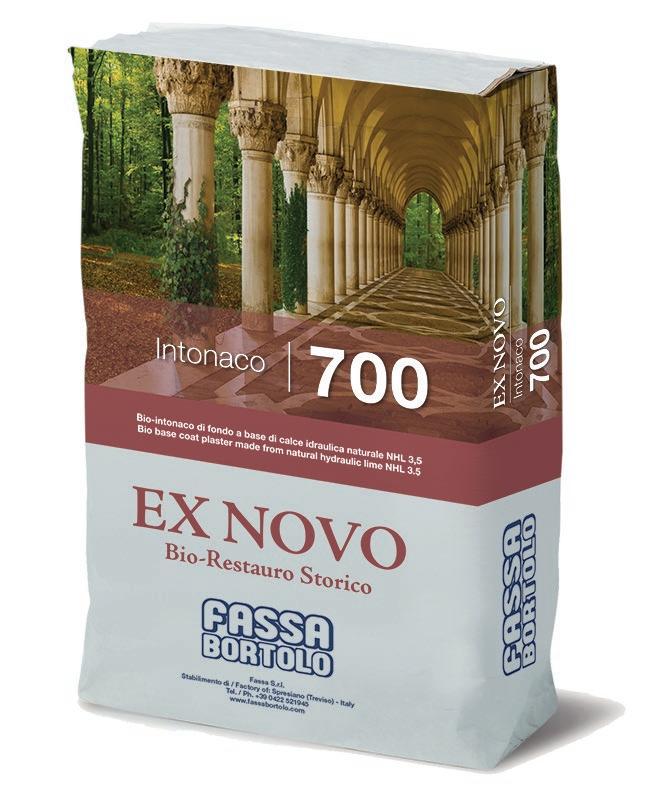

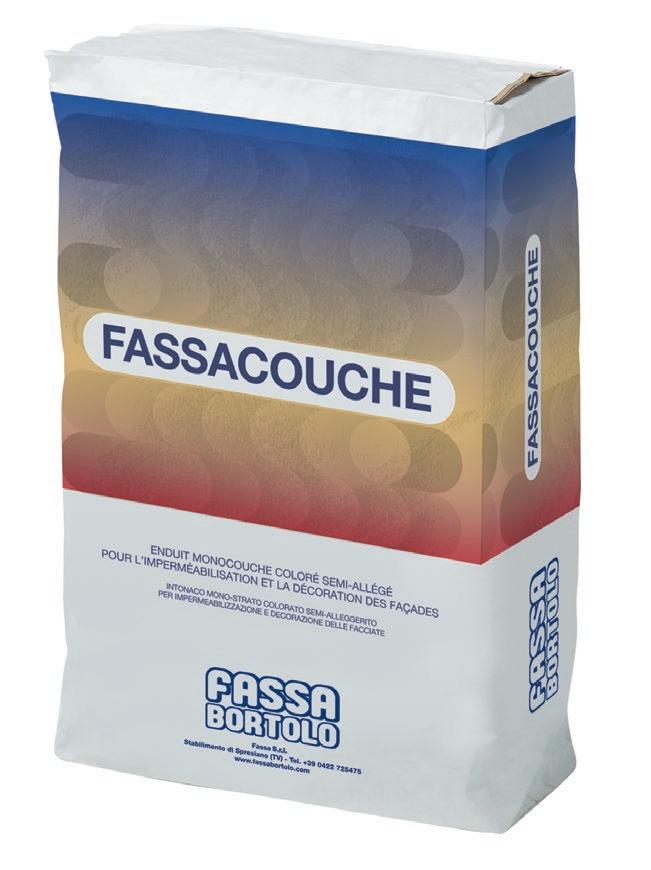

In a world increasingly focused on sustainable development, Fassa Bortolo continues to lead the conversation with its FassaLime range. A collection of lime-based systems designed to respect the environment, preserve architectural heritage, and deliver exceptional building performance. Rooted in centuries-old craftsmanship yet guided by modern science, FassaLime embodies the company’s philosophy of creating harmony between tradition, innovation, and the natural world.

At the heart of the FassaLime line are its carefully developed cycles, each tailored to meet the needs of restoration, conservation, and ecoconscious construction. These lime-based solutions are not simply products, but complete systems that work in synergy - from mortars and renders to finishing coats, to ensure durability, breathability, and authenticity. Each cycle within the FassaLime portfolio is designed to enhance the natural performance of historic structures while providing sustainable alternatives for modern builds.

Among these, the Ex Novo range stands out as a perfect example of Fassa Bortolo’s dedication to both preservation and progress. Ex Novo is a specialist line developed to restore, conserve, and protect historic buildings, allowing their beauty and integrity to endure for generations to come.

Using natural hydraulic lime (NHL) and selected raw materials, the products in the Ex Novo range mirror the original materials used in traditional architecture while offering the consistency, reliability, and technical performance expected of modern formulations.

The genius of Ex Novo lies in its ability to balance authenticity with innovation. Its products allow buildings to ‘breathe’, facilitating the natural movement of moisture through the walls; a critical factor in maintaining structural health and avoiding the trapped dampness that can result from cement-based materials. In doing so, Ex Novo supports the intrinsic sustainability of traditional construction, reducing the need for frequent repair and minimising environmental impact over the building’s lifetime.

This focus on Bio Architecture, an approach that places the health of people and the planet at the core of design and material choice, defines the ethos of Fassa Bortolo.

Every FassaLime product is created with full respect for natural cycles, utilising lime sourced and processed through low-impact methods that reduce carbon emissions and energy consumption. The brand’s research and innovation teams continue to refine these formulations to align with global environmental standards and sustainable building certifications.

Beyond material performance, Fassa Bortolo’s vision extends to the cultural and ecological value of construction. The company recognises that architecture is more than the sum of its materials; it reflects the communities and landscapes that surround it.

By combining ancient knowledge with modern expertise, FassaLime allows architects, designers, and conservation specialists to work in harmony with nature - preserving the past while building responsibly for the future.

With FassaLime and Ex Novo, Fassa Bortolo reaffirms its position as a pioneer in sustainable building technology. Proving that when innovation is guided by respect for history and the environment, truly timeless architecture can be achieved.

To find out more on our FassaLime cycles and Ex Novo products, please call 01684 218305 or email info.fassauk@fassabortolo.com

Fassa Bortolo – Enquiry 10

Recycling and recovery of materials waste management

Sustainable architecture and environmental issues have become rooted in popular culture and the work of building professionals.

Sustainable building means promoting ecological awareness through the image of the building, with its features being related to its relationship with the environment.

Sustainable building means reducing environmental impact and setting energy efficiency as design goals, improving the health, comfort and quality of life of inhabitants, objectives that can be achieved by incorporating appropriate structures and technologies into the building.

TO FIND OUT MORE about Fassa Bortolo and its range of render systems and building products. Visit www.fassabortolo.co.uk or call 01684 218 305

product environmental Footprint assessment

Sustainable building means managing a building that satisfies the needs and demands of its owner, taking into account natural rhythms and resources right from the initial stages of the project, without causing damage or inconvenience to others and the environment, striving to fit harmoniously into the context and thus also thinking about the ability to totally reuse spaces and materials.

Efficiency and circularity are key issues when it comes to sustainability. At Fassa Bortolo we are committed to optimising the use of resources, reducing waste and promoting a circular economy in the building industry. Only through responsible business practices can we create a better future.

City Campus is a vibrant new hub in the heart of Gloucester. The former Debenhams site has been transformed into a state-of-the art centre for teaching, learning and community services.

Howells Patent Glazing was tasked with supplying five bespoke rooflights and two areas of mono pitch glazing for this iconic building.

University of Gloucestershire purchased the site in 2021 and has subsequently been working with main contractor, Morgan Sindall and project architect, ADP Architecture to create a home for the University’s Education, Psychology and Social Work programmes and shared public access facilities.

The site includes a Victorian wing and sections dating back to the 1930s and 1950s, meaning the transformation has been complex – combining heritage preservation and progressive development.

For Howells, City Campus is the largest and one of the most challenging projects in the company’s 50+ years history, as business development manager, Tracey Jackson

explains: “This was an incredibly complex yet rewarding project. The biggest challenge was the size and weight of the glass combined with the building’s city centre location which created access, material handling and storage issues.”

“The existing building had a floor plate that was too deep for an educational environment, making it difficult to bring daylight into the centre,” comments Natalia Lopez, Associate Director, ADP Architecture Ltd. “With only a few existing rooflights located above the third floor, natural light was unable to reach the lower levels effectively. To address this, new rooflights and openings were introduced across all floor plates, enabling daylight to penetrate the central social learning spaces and classrooms, and even extend down into the basement.”

Howells advised ADP Architecture and Morgan Sindall on the most appropriate rooflighting solution. Following a site survey, Howells confirmed design and installation of two hip-ended rooflights, two self-supporting octagon rooflights, two areas of mono pitch glazing and one tapered ridge rooflight.

Due to their size, Howells appointed a structural engineer to complete structural calculations for each rooflight to ensure the aluminium bars could withstand the weight of the glass plus any imposed loadings, such as wind and snow.

The fabrication team strengthened the glazing bars based on these calculations adding steel inserts. This also increased their span capabilities. One of the hipended rooflights measures 3.2 metres

long by 6.3 metres wide and is the largest rooflight manufactured by the Black Country-based specialist. To guarantee a precise installation, this rooflight and a slightly smaller version were built-up in the factory before being dismantled and sent to site.

The tapered ridge rooflight proved very interesting. The ridge went from 5.1 metres to 4.3 metres wide along its 12.5+ metre length and dropped by around 24.5 centimetres. This presented all sorts of challenges many of which had to be addressed at both the design and fabrication stages. Shaped glass is used throughout.

The two self-supporting octagonal rooflights replaced one smaller rooflight which had sat above the former Debenhams central atrium and two new areas of mono pitch glazing were added.

Each bespoke aluminium rooflight is powder coated in Black Grey RAL 7021 in a matt finish, both inside and out.

“Daylight is fundamental to the success of the building, shaping not only its environmental performance but also the quality of its internal spaces,” concludes Natalia Lopez, Associate Director, ADP Architecture. “Ultimately, it is the presence of daylight that enables the building to feel open, connected, and alive.”

In the spring of 2022, the new Dutch Galapagos headquarters opened its doors at the Leiden Bio Science Park (NL). The impressive 17,000 m² building, combining office and laboratory spaces, owes much of its architectural character to the plinth and rooftop structure clad in Linius, Renson’s horizontal façade cladding system.

The brushed and anodized finish of the aluminum blades brings vibrancy to the façade. Special laser-cut combs integrated into the carrier profiles add an extra layer of functionality: fall protection for visitors in the parking garage. This clever solution eliminated the need for traditional, visually intrusive fencing and guardrails.

Both the client and the architect deliberately opted for anodized blades. “Purely for aesthetic reasons,” explains Koos Zwitser, Project Manager at OZ Architects. “We wanted to create liveliness in the façade. Powder-coated cladding tends to look too uniform and sterile.

“The final result with brushed, anodized blades has received unanimous positive feedback. Mission accomplished. And

The design of the façade plays a central role in architecture, as it not only shapes the external appearance of a building but also fulfils functional, cultural, and communicative roles.

With the Kalzip FlexForm® façade, Kalzip is launching a new generation of meander façades that offer architects and planners maximum creative freedom. This innovative system is a logical further development of the proven TF800R façade. The folded aluminium profiles enable relief-like structures, clean lines, and rhythmic façade compositions— from serial grid solutions to individually modelled surfaces.

With the new Kalzip FlexForm® façade, the Koblenz-based company provides a selection of technically tested profile shapes for efficient planning and reliable execution. For bespoke design requirements, the Kalzip FlexForm® Ultra façade offers a solution in which architects can define their own profile shapes with variable angles, depths, and pitches. Kalzip supports this process with technical consulting, feasibility studies, sampling, and project-specific manufacturing.

The new system is also available in a wide range of high-quality surfaces and colours. These include the AluPlusPatina surface finish, which provides an elegant, matte metallic appearance in bronze, copper, and gold tones. A high-performance coating (HPC) option is also available, allowing colours and gloss levels to be freely selected. The HPC coating provides excellent UV and weather resistance.

the fact that the anodizing process is less harmful to the environment than powder coating was a welcome bonus.” Façade contractor Storax brushed and anodized the Linius blades and installed the entire system, including the integration of around fifteen door constructions.

Find out more at www.renson.net

Renson – Enquiry 12

This ensures that every façade can express material culture, value, and identity. As with every Kalzip product, the new façade solution stands for responsible construction: the profiles are made from up to 95 per cent recycled aluminium of European origin and can be completely recycled back into the material cycle.

Kalzip – Enquiry 13

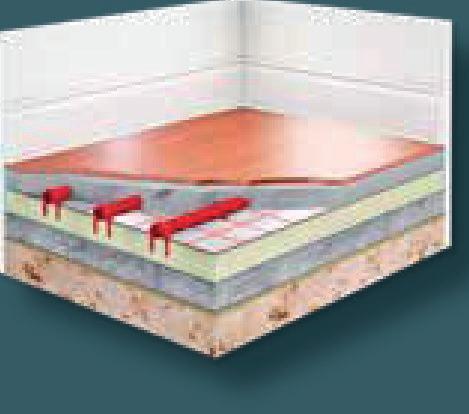

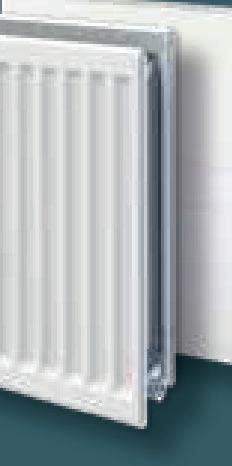

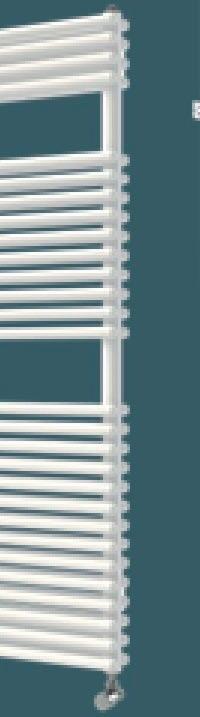

Heating systems are increasingly being designed with lower flow temperatures to help decarbonise buildings. To maximize impact, it‘s crucial to choose the right heat emitters and user-friendly controls for precise temperature management.

As a total solutions provider, Myson has carefully created a complete range that caters to all needs. Ranging from hydronic and electric radiators to underfloor heating, heating valves and electronic controls, all products are designed to offer the highest levels of comfort and efficiency.

Low Temperature Heating Solutions, it has to be MYSON range of

Explore our solutions

A quarter of a century of innovation and collaboration

Tracing the history of Specification Magazine has been an illuminating experience and unsurprisingly it runs parallel with the development of the industry as a whole.

As a flagship, product-based publication of TSP Media’s portfolio of titles, Specification has accurately traced the significant changes that have shaped the industry in the last 25 years and also previewed many of the innovations that have taken it in new and exciting directions.

The team at TSP Media is delighted to welcome you to our special anniversary supplement, which highlights many of the companies who have spearheaded change and innovation over the last two decades and more, as well as many of the industries bodies and trade organisations which have played an active role in improving the built environment in the UK and beyond.

We will highlight how product development has played a crucial role in making the industry leaner, more efficient, sustainable, futureproofed and above all better equipped to provide the developments and schemes the country needs.

Specification has played its part in that progress. As a dynamic, multi-media and multi-channel publisher we have developed a set of information resources that still has the printed magazine at its heart but also offers a wide variety of professional and industryleading options to do what we have always done best – get the right information to the right audience.

A week remains a long time in politics, but arguably with the advent of new technology literally changing the way we access information on a daily basis then 24-hours can often be a lifetime in publishing. But TSP Media and Specification continue to evolve and adapt, which is why celebrating 25 years at the leading edge of the industry is such a landmark worth celebrating.

The industry has undergone seismic change in recent years and we continue to reflect that every month in the magazine and every day through our website.

We will continue to act as a vital information resource for the industry and are already making plans for the next 25 years.

Paul Groves || Group Editor

Build UK Chief Executive Suzannah Nichol MBE has stressed that construction remains central to the government’s economic plans.

While ambitions such as building 1.5 million homes may seem unrealistic to many, she explained that the ambitious goal puts construction “at the heart of government.”

The NFRC continues to underline roofing’s critical role in the wider construction landscape. Whether it is providing skilled contractors for housing delivery, expertise for retrofitting the UK’s draughty housing stock, or trusted products and installation in the push for energy efficiency, NFRC Trade and Supplier Members are uniquely placed to deliver.

As the UK navigates political change, economic uncertainty, and urgent environmental goals, NFRC will continue to champion Members, push for fair and consistent standards, and ensure the roofing sector has a strong and united voice at the table.

This years has seen CIOB, in collaboration with NFRC, launch a brand-new Roofing Chartered Membership Programme (CMP) – a dedicated route for experienced roofing professionals to achieve Chartered status (MCIOB).

The Roofing CMP marks an exciting milestone for the roofing sector, providing a tailored pathway to professional recognition through the CIOB. The programme is designed for individuals with at least five years' experience in roofing who manage people, processes, or projects, offering the opportunity to gain professional accreditation that their skills knowledge and leadership within the industry.

"It’s a significant step forward in recognising roofing as a professional discipline in its own right."

James

Talman, CEO, NFRC

Programmes such as the new Roofing CMP are becoming increasingly important as proof of competency requirements under the Building Safety Act 2022 (BSA) come into force.

James Talman, CEO of NFRC, added: “This collaboration with CIOB gives our members a unique opportunity to gain Chartered status through a programme designed specifically for their expertise. It’s a significant step forward in recognising roofing as a professional discipline in its own right.”

Looking back at the last 25 years, we can trace many changes to energy efficiency regulations. We can highlight the evolution of important standards like BS 5250. Above all, we can see how our climate has changed in that time.

We also understand how the climate is likely to continue changing. That means we can, and should, be creating products capable of dealing with the increased frequency and intensity of extreme weather.

In other words, innovation is vital to futureproofing buildings.

As a 4th generation family business, Proctor Group has a history of technical innovation, promoting good practice, and developing products that roofing contractors want to use. We applied this wealth of experience to creating our air permeable and vapour permeable (APLR) underlay, Proctor Air®

Hidden from view, pitched roof underlays usually warrant little attention from building users. Yet they play a vital role in protecting those users from the elements, and from unhealthy indoor climates.

By choosing and installing Proctor Air, specifiers, contractors and building owners can enjoy the confidence that comes from a high-performance product doing its job without intervention.

Proctor Air’s water resistance has been tested and, having a water hold out performance of more than a 1m head of water, meets the guidance of the NFRC’s Technical Bulletin TB06.

While stopping external moisture getting in, a low resistance underlay must also allow water vapour out. Since Proctor Air permits the passage of both air and moisture vapour through the roof construction, no VCL is

required in the ceiling and no ventilation measures are required in the cold roof space.

Avoiding the need for ventilation –particularly at the eaves – helps when it comes to installing the substantial thicknesses of insulation required in lofts. With the impending introduction of new energy efficiency regulations,

those thicknesses may well increase. Rooftop solar is also expected to be made compulsory as part of the Future Homes Standard in England.

We have recently published industry-leading research demonstrating the compatibility of Proctor Air with integrated PV panels. Confusing technical guidance made specifiers and housebuilders unwilling to use the two together. Our recommendation gives the roofing sector the confidence it needs to fully embrace new solutions.

There has never been a more important time to deliver innovation, and Proctor Air is an underlay that makes pitched roof constructions simpler while delivering performance ready for the future.

Find out more: https://proctorgroup.com/ products/proctor-air

A clear indication of the strength of an industry and product market is often seen in the success of related trade events.

LIFTEX, the triennial trade show run by the Lift & Escalator Industry Association (LEIA), attracted record attendance when it took place at London’s ExCeL this year, bringing together 4,400 industry professionals from more than 40 different countries.

Now in its 37th year, LIFTEX is the UK’s dedicated exhibition for the lift, escalator and access industry and welcomed visitors from as far afield as Hong Kong, the UAE, India, South Korea, Japan, China and the USA. The show also featured exhibitors from 12 different countries. Attendees ranged from lift consultants and specifiers to property owners, facilities managers, and building designers and many from the industry – all with a common goal of making vertical transportation safer, smarter and more efficient.

LIFTEX Show Director Oliver Greening commented: “The atmosphere at this year’s show was incredible. We saw engagement across the board from both visitors and exhibitors. What sets LIFTEX apart is its ability to unite the entire industry, not just to conduct business, but to share knowledge and actively shape the sector’s future. This year’s record-breaking

"What sets LIFTEX apart is its ability to unite the entire industry, not just to conduct business, but to share knowledge and actively shape the sector’s future."

Oliver Greening, LIFTEX Show Director

turnout confirms how vital the show is to the market. While the show’s international participation grows, LIFTEX still retains a strong UK focus.”

This year LEIA embarked on “Recalibration 2025”, a year-long initiative to shape the support and services provided by their association.

Recalibration 2025 was launched at the LEIA Council meeting in London in February where significant time was set aside for focus group discussion. Representatives from the LEIA management board, member companies and association staff engaged in deep conversation on topics including, business needs, association services and members’ relationships with the association.

Nick Mellor, LEIA’s managing director said “It’s important to ensure the association is delivering the leadership, support and guidance members need to prosper in uncertain times. We can only achieve this by actively engaging with all our members to better understand their current concerns, needs and ideas – it’s time to recalibrate.”

From revitalising step free access in heritage spaces to improving safety and accessibility in some of the UK’s most iconic locations, Stannah Lifts has played a key role in a range of prestigious projects.

Whether balancing old and new at the Creamery, delivering a seamless multi-lift solution at Welcome Break’s latest service station, or improving engineer access inside Big Ben, Stannah Lifts continues to showcase its vast expertise.

Once a dairy processing local farmers’ milk into cheese for transport to London in 1912, the Creamery has been reconstructed by Ken Biggs Contractors as a vibrant hub with a restaurant and shop celebrating its past.

A standout feature is the bespoke all-glass lift installed by Stannah Lifts with Stonewood Design, using bespoke German glass from Gemtec. Handrails were discreetly integrated into the glass panels without corner trims, and the keyhole for operating the lift doors was repositioned to align with the minimalist aesthetic, all contributing to a seamless and elegant design.

Signal issues inside the lift shaft were resolved with a GSM package and antenna, ensuring reliable operation. This project stands out for its careful balance between heritage preservation and modern functionality, allowing all visitors to experience a piece of local history.

Welcome Break

Welcome Break’s 60th Yorkshire village inspired service station features a multi-lift solution from Stannah Lifts ensuring smooth movement of visitors and goods.

Stannah Lifts installed a 13-person MRL traction passenger lift to improve accessibility for wheelchair users, families with prams and those with reduced mobility. It provides energy-efficient travel with VVVF drives, LED lighting and remote monitoring. The A2C escalator supports visitor flow with a wide step, durable glass balustrade and energy-saving slow-down mode. Back of house, Stannah Lifts proposed a 1,000kg Goodsmaster goods lift to ensure safe transport of goods between floors, improving workflow and reducing manual handling risks.

This coordinated approach delivered all three lift solutions seamlessly ahead of schedule, ensuring reliable and efficient movement throughout Welcome Break’s first new service station in two decades.

Big Ben

Built in 1859, Big Ben has faced more than 160 years of wear. During its first full restoration, Stannah Lifts was tasked with creating safe lift access for engineers without disturbing the tower’s historic fabric. Previously, the only route up was a narrow 334-step spiral staircase, posing safety risks and making transporting equipment difficult.

Working with Sir Robert McAlpine Special Projects and SVM Associates, Stannah Lifts designed two bespoke lifts to install inside the tower’s unused 11.7m² ventilation shaft, overcoming tight space and the 0.23-degree lean with a compact 500kg hydraulic lift for the final ascent.

Winners of the RIBA London Award and Elevator World’s Project of the Year Award, Big Ben was also shortlisted for RIBA’s 2025 Stirling Prize. For more information on lift solutions, visit: www.stannahlifts.co.uk

Stannah Lifts – Enquiry 16

The Door & Hardware Federation (DHF) is a not-for-profit trade association for over 500 members and is the ‘go to’ place for technical advice and training which lends itself to raising the standards of the industry.

It is regarded as the ‘Centre of Excellence’, with a network of professional staff members as well as external consultants that can provide support in all sectors, making us a single source for technical expertise, information, knowledge, advice, and practical help.

As a federation, it supports various industry sectors by representing them on BSI standards committees, liaising with compliance authorities such as the Health & Safety Executive

"We will continue to raise awareness of the crucial role that fire doors play in saving lives and protecting property"

Patricia Sowsbery-Stevens, Director of Commercial Operations, DHF

(HSE) and Trading Standards as well as fire safety organisations across the UK and Europe.

DHF once again endorsed its commitment to fire safety by supporting Fire Door Safety Week, the national awareness campaign first launched in 2013 in response to widespread neglect of fire doors.

For a fire door to perform effectively, every stage must be right. From correct product manufacture and quality standards to proper installation and ongoing maintenance, the detail matters. How fire doors are specified, managed and used can quite literally mean the difference between life and death for building occupants. Something as simple as propping a fire door open can prevent it from doing its job in the event of a fire.

Responsibility does not lie with one group alone, however. Manufacturers, installers, building owners and users all share the duty of ensuring fire doors remain fit for purpose. This principle of shared responsibility is the driving force behind Fire Door Safety Week.

DHF has also partnered with BRE to deliver a series of one-day training courses on fire door safety, inspection and ongoing maintenance. DHF’s Director of Commercial Operations, Patricia Sowsbery-Stevens, said: “Through our guidance work, industry partnerships and training initiatives, we will continue to raise awareness of the crucial role that fire doors play in saving lives and protecting property.”

Having partnered with Specification Magazine for many years, GEZE UK is proud to celebrate with them on their 25th anniversary.

During the last 25 years, we’ve witnessed first-hand the rapid transformation of the door, window and access control sectors, to which GEZE UK has constantly evolved. From humble beginnings supplying door closers to becoming a leading provider of integrated door, window and safety systems, our journey has been defined by innovation, quality and partnership.

When GEZE UK was first established back in 1988, the focus was on durable mechanical products. Today, our solutions connect doors and windows into intelligent building systems, balancing accessibility, safety and energy efficiency. Automatic sliding, swing and revolving doors, access control integration and window automation are now part of complete smart-building solutions that help architects, contractors and facility managers deliver safer, more efficient environments.

Since our inception, GEZE UK has grown from a small team to a national operation with regional offices, a dedicated service division and expert specification support. This expansion reflects our commitment to being more than a supplier - we’re a consultative partner throughout the entire building lifecycle, from design to aftercare. Andy Howland, Sales & Marketing Director, said: “GEZE UK’s success has always been about people — our team, our customers, and the long-term relationships we’ve built. From those early days to the intelligent

systems we deliver today, we’ve grown together with the industry and stayed true to our values of quality, service and partnership.”

GEZE UK is proud to have supplied products for many prestigious global projects, across multiple sectors, including; healthcare, education, hospitality, retail and commercial; helping our clients navigate evolving regulations on fire safety, accessibility and sustainability.

Excellence and responsibility have always been at our core. GEZE UK was among the first in the industry to achieve ISO 45001:2018 for Health & Safety, alongside ISO 9001 and ISO 14001.

Sustainability is embedded in everything we do – from product design to operations. Our parent company’s EcoVadis “Committed” sustainability rating underlines our dedication to responsible innovation and continuous improvement.

We also recently won ‘Fire Door Product of the Year’ at the National Fenestration Awards for our ‘Slimdrive EMD-F Powered Swing Door Drive System’, highlighting our commitment to quality, performance, and innovation that underpin all GEZE products.

Even the smartest technology needs the right support behind it. GEZE UK’s service division ensures that every system, new or old, continues to perform safely and reliably long after installation.

Our engineers work across the UK to keep doors, windows and access systems operating smoothly, helping clients meet compliance requirements and maintain safe, accessible environments. For us, great service isn’t just about fixing problems, it’s about giving customers confidence that their buildings work exactly as they should, every day.

With GEZE recently celebrating more than 160 years globally, GEZE UK remains focused on shaping the future of building automation. From cloud-connected control platforms like myGEZE Connectivity to energy-efficient systems that support smart building management, our vision is to create safer, healthier and more liveable spaces.

Andy Howland, Sales & Marketing Director, added: “We’re proud of what we’ve achieved in the past 25 years – but we’re even more excited about what’s next. Together with our partners, we’ll continue to open doors to innovation, sustainability and smarter buildings for generations to come”.

To learn more about GEZE UK: Website: www.geze.co.uk Email: info.uk@geze.com

GEZE UK – Enquiry 17

As part of its mission to ensure consumer safety and product compliance across various industries, the Office for Product Safety and Standards (OPSS) plays a critical role in regulating products within the UK market.

Operating under the Department for Business and Trade (DBT), the OPSS oversees a wide range of sectors, from construction products to consumer goods and environmental regulations.

Recently, the OPSS has ramped up its inspections in the glass and glazing sector, with a specific focus on heat soaked thermally toughened glass. This increased level of scrutiny represents a significant development for the industry.

In this context, the Glass and Glazing Federation (GGF) has been instrumental in supporting the OPSS’s efforts. The GGF has worked closely with the regulatory body to communicate critical industry issues and ensure that its members stay informed about the importance of compliance. Through this collaboration, the GGF raises awareness within the industry, encouraging members to

meet regulatory standards and continuously improve their product offerings. The GGF fully supports the OPSS inspections, as they present an essential opportunity to strengthen compliance and promote higher standards in the sector.

We are aware that several of our members have already been inspected and we’ve also received inquiries from non-members about these inspections. This shows that the message is reaching a broad audience and that the industry is taking compliance seriously.

As the GGF continues to work with the OPSS to raise the bar on product safety, the GGF is committed to supporting its members in navigating the regulatory landscape and ensuring their continued success in the market. By maintaining the highest standards of compliance, we can all contribute to a safer and more reliable glass and glazing industry.

Senior Architectural Systems has marked 2025 with a series of transformative milestones, reinforcing its reputation as one of the UK’s most forwardthinking manufacturers of aluminium windows, doors and curtain walling solutions.

From product innovation to championing best practice in communicating technical information, and even a touch of beekeeping, Senior has had quite a year!

SF52 curtain wall system gains EPD certification

Senior’s commitment to transparency and sustainability has been further demonstrated with the launch of a new Environmental Product Declaration (EPD) for its SF52 mullion-drained aluminium curtain wall system. Independently verified and developed in accordance with EN 15804+A2 and ISO 14025:2011, the SF52 EPD provides detailed insights into the system’s environmental impact across its full lifecycle. Unlike many EPDs that include insulated glass units, which are typically not supplied by system houses, Senior has chosen to omit glazing from its calculations on the environmental credentials of its SF52 aluminium system.

This is because the heavy weight of glass, combined with its relatively low carbon per kg, can make the overall figures for the aluminium system look lower than they really are after conversion. By omitting the glazing from its EPD, Senior ensures that the carbon figure per square metre reflects only the aluminium system itself, giving a more accurate and honest assessment.

This bold approach sets a new benchmark for product transparency in the fenestration

industry and provides a solid foundation for the publication of further EPDs for Senior’s doors and windows.

This year also marks ten years of Senior’s pioneering PURe® aluminium window and door system. Launched in 2015, PURe® was the first UK aluminium system to incorporate a thermal barrier made from expanded polyurethane foam, delivering exceptional thermal performance. To celebrate this milestone, Senior also unveiled a new closed-loop recycling process for its PURe®

systems. This initiative ensures that endof-life PURe® products can be fully recycled and reintroduced into the manufacturing cycle, reducing waste and supporting a circular economy.

Senior’s product portfolio also continued its evolution with the development of the new SPD 150 aluminium commercial door. Designed to meet the demands of high-traffic environments, the SPD 150 offers enhanced durability, security, and ease of operation. With its robust construction and sleek design, the SPD 150 is set to become a go-to solution for commercial projects requiring reliable and stylish entrance systems.

Away from the factory floor, Senior has embraced a sweeter kind of sustainability with the installation of its very own beehive. Located at the company’s dedicated Thermal Improvement Facility in Rotherham, the hive supports local biodiversity and reflects Senior’s holistic approach to environmental responsibility. This year saw the harvesting of the first batch of honey, another milestone that was celebrated by staff and shared with customers.

For more information on Senior’s products and initiatives, please visit www.seniorarchitectural.co.uk or search for Senior Architectural Systems on LinkedIn, Instagram and Facebook. Senior Architectural Systems – Enquiry 18

One of the key improvements the industry has seen in the last two decades and more is the implementation of tighter guidelines on product information and marketing.

Along with stricter rules on testing and certification, the advent of the Code for Construction Product Information has been universally welcomed across the industry as a significant step forward.

The Tile Association has become a Trade Associate of the Code (CCPI). This means that it has pledged support for CCPI’s goal to raise standards in construction product information and marketing and will encourage TTA members to register.

There are two separate Codes provided by CCPI, one for manufacturers and one for merchants and distributors:

• For manufacturers – including responsibility for product information, clarity of performance claims made, general information and competency

• For merchants and distributors – including requirements to have audit trails for all product information, documented sign-off process, and have a company policy in place to promote the Manufacturers’ CCPI to its suppliers

CCPI aims to aid participating companies from organising their systems to marketing their products – supporting compliance with anticipated new regulatory requirements and helping to give specifiers, clients, and others confidence regarding the information provided on the construction products they select.

It is also working proactively on another significant issue impacting the industry – sustainability.

To help reduce carbon emissions and prepare your business for future Government rules and regulations, The Tile Association’s Sustainability Working Group is available to answer your sustainability questions. Through regular meetings, it continues to steer the industry’s efforts to improve its environmental impact, helping TTA members and the wider industry play their part in achieving Net Zero by 2050.

Large organisations with turnovers of £10 million+ are already preparing or working to these rules, however we believe small businesses will need to be prepared too. Getting to grips with sustainability helps you safeguard not only people and the planet, but your business. The following advice is designed to help you start or advance your sustainability journey to protect your interests.

In collaboration with some of its members, TTA has produced a series of case studies now available on its Ways to Be More Sustainable website page to help inspire sustainable action.

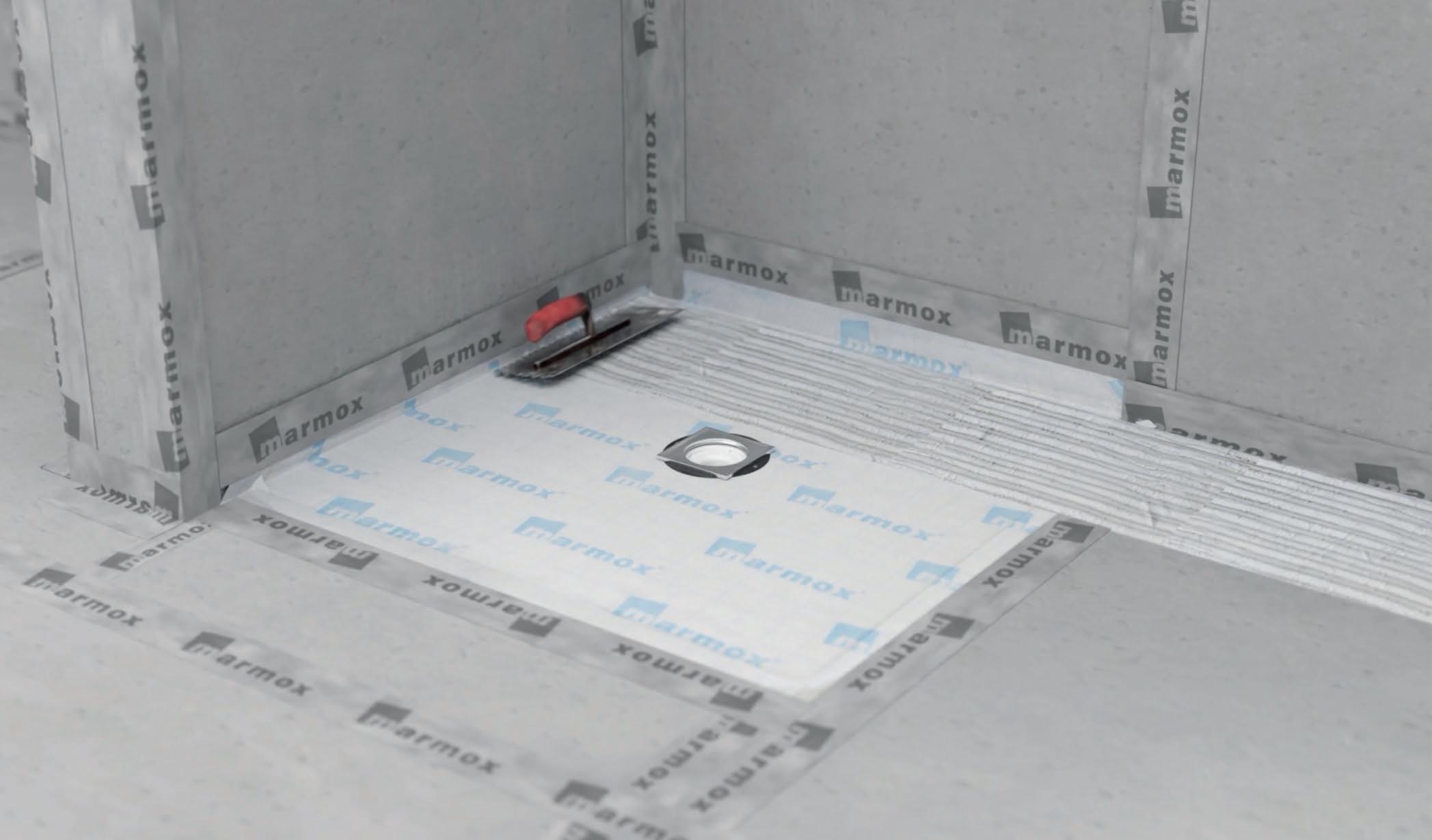

This year, Marmox celebrated a major milestone: 25 years of delivering high-performance building solutions. Earlier in the year, to mark the occasion, the Marmox team gathered at the Big Cat Sanctuary in Headcorn, Kent, for a Silver Jubilee event full of reflection, recognition – and a few surprises.

ACelebration to Remember

Around 50 team members and their families enjoyed guided tours of the sanctuary, coming face to face with lions, tigers, cheetahs, jaguars, and leopards. A special cake, decorated with the Marmox logo, was cut by founder Harry Parsons, who shared the story of how the company began and how it has grown over the past quarter-century.

Certificates were presented to long-serving employees by Managing Director Sarah Viney, Business Development Director Johnathan Parsons, and Finance Director Richard Kent-Smith, recognising their dedication. And adding a playful touch, lottery tickets under dining glasses gave three lucky guests the extraordinary opportunity to feed the tigers.

Looking Back – and Forward

“Over the past 25 years, we’ve introduced a range of solutions that respond to changing building needs,” says Sarah Viney. “From Marmox Thermoblock for cold bridging, to Fireboard for non-combustible compliance, and of course our original Multiboard –which remains a tiling favourite – we’ve always focused on practical, reliable solutions. And our wetroom range continues to grow with installer-friendly innovations.”

December 2025

Marmox is set to launch an updated wetroom range this December, expanding the popular Multiboard Showerlay collection.

Redesigned with installer feedback, the new range includes centre and offset drains, linear drain options, and additional tray sizes. A brand-new drain is easier to clean, with choices in stainless steel, white, black as well as gold finishes.

Each Showerlay now features a 100mm surplus waterproof fleece for seamless integration with Marmox Multiboards and S/A Waterproof Tape. Built from high-density extruded polystyrene, the trays combine strength, insulation, and lightweight handling, with pre-formed falls directing water efficiently to the new drain. Fibreglass mesh and cement-polymer mortar coatings ensure long-term durability in both domestic and commercial settings.

The updated wetroom range also introduces stylish new accessories: wall-mounted tileable vanity basins with point or linear traps, a floating shelf for traditional basins or as an extension to the new tileable basins, and two new niche sizes – 600mm x 300mm and 1200mm x 400mm – offering more design freedom.

Grant Terry, Marmox Marketing Manager, comments: “Customer feedback has directly shaped these improvements,

resulting in a more versatile and userfriendly wetroom offering. We’re excited to see how these products will enhance bathroom spaces across the UK.”

A Quarter-Century of Success

Marmox’s 25-year journey reflects a commitment to quality, reliability, and customer-focused innovation.

With a dedicated team, expanding product ranges, and a clear vision for the future, Marmox is ready for the next 25 years – continuing to deliver solutions that installers and specifiers can trust.

Marmox – Enquiry 19

Encouraging and promoting the next generation of professionals is always a key priority and the kitchen and bathroom sector is working hard to developing training and mentoring programmes.

For a product sector where innovation has consistently been a key characteristic, this has taken on an added impetus with a new award scheme.

The Bathroom Association, the leading voice for the UK bathroom industry, unveiled the winners of its prestigious Thirty-underThirty Awards at the Association’s Gala Dinner.

Now in its second year, the Thirty-under-Thirty Awards recognise and honour the next generation of bathroom industry talent. The initiative showcases individuals who are already making waves across the sector—whether through commercial leadership, innovative design, operations, marketing, sales, or technical excellence.

Association Chief Executive Daphne Doody-Green praised the awardees for their “unmatched enthusiasm and commitment to shaping the bathroom industry of tomorrow.” She added, “These winners exemplify what it means to lead with purpose, innovate with intention, and elevate our industry through fresh thinking. It’s not just about age—it’s about impact, and every one of these individuals is delivering it in spades.

“The result is a list of thirty outstanding individuals whose work is already driving positive change—and whose future contributions promise even more. The winners represent a wide range of companies, specialisms, and career paths—from design studios and engineering teams to marketing departments and finance roles—each of them united by their passion for excellence and dedication to the bathroom manufacturing sector.”

The awards are part of the Association’s broader strategy to foster skills development, support career progression, and ensure a robust talent pipeline for the UK bathroom industry.

“These young professionals aren’t just the future—they are the now,” said Lisa Carnwell, Policy Manager at the Bathroom Association. “Recognising them publicly not only celebrates their hard work, but sends a clear message: this is an industry where talent is seen, valued, and supported.

"These young professionals aren’t just the future—they are the now"

Lisa Carnwell, Policy Manager, Bathroom Association

Over the past quarter of a century, Kinedo –the sister brand to SFA Saniflo – has evolved from pioneering prefabricated cubicles to manufacturing a design-led range of modern, inclusive cubicles, enclosures, trays, and wall panels that combine elegance, simplicity, and performance.

Since launching in the UK in 2000, Kinedo has led the way in transforming shower spaces. From the groundbreaking all-in-one cubicles — still the first choice for rapid, mess-free refurbishment — to the sophisticated new Solo Design + walkins and cuttable shower trays, the brand’s products have redefined what modern showering can look and feel like.

Kinedo cubicle arrive as a complete package — including tray, internal and external panels, door, thermostatic valves and shower head, plus a handheld shower and all fixtures and fittings. With no need for tiles, grout, or silicone, installation is fast, clean, and reliable, whilst specification is simple. The result? A watertight shower that is ready for use after installation, no follow-on trades and a space that is high quality, low maintenance and long lasting.

In 2017 enclosures and cuttable trays were added to the Kinedo portfolio in the UK and these have evolved over time to today’s collection of design-led products. This was complemented by a stunning range of slim, but strong lightweight shower wall panels in over 70 designs in 2023.

Inclusive design is central to the Kinedo philosophy. The Kinemagic Serenity cubicle features a levelaccess tray, fold-down seat and grab rails as standard offering the same level of modern design, safety and independence for all users. Kinedo trays feature anti-slip surfaces, and the latest Kinediva model, uniquely offers a lateral water-flow design to facilitate the swift egress of water.

Kinewall panels aren’t just for showers –they are designed to offer a robust wall covering that can be used above sinks, in cloakrooms and utility rooms to offer a scuff free, easy clean and attractive wall covering. With designs that replicate the beauty of stone, tile, wood, marble and nature, the fully waterproof panels can be cut to size on site and fit directly over existing surfaces for a seamless finish in hours, not days.

Designed and manufactured in Europe by the SFA Group, every Kinedo product is engineered for performance and backed by robust warranties. Combining aesthetic appeal with practicality and ease of maintenance, Kinedo continues to deliver style, speed and simplicity to homes, hotels, gyms and commercial projects across the UK.

Saniflo – Enquiry 20

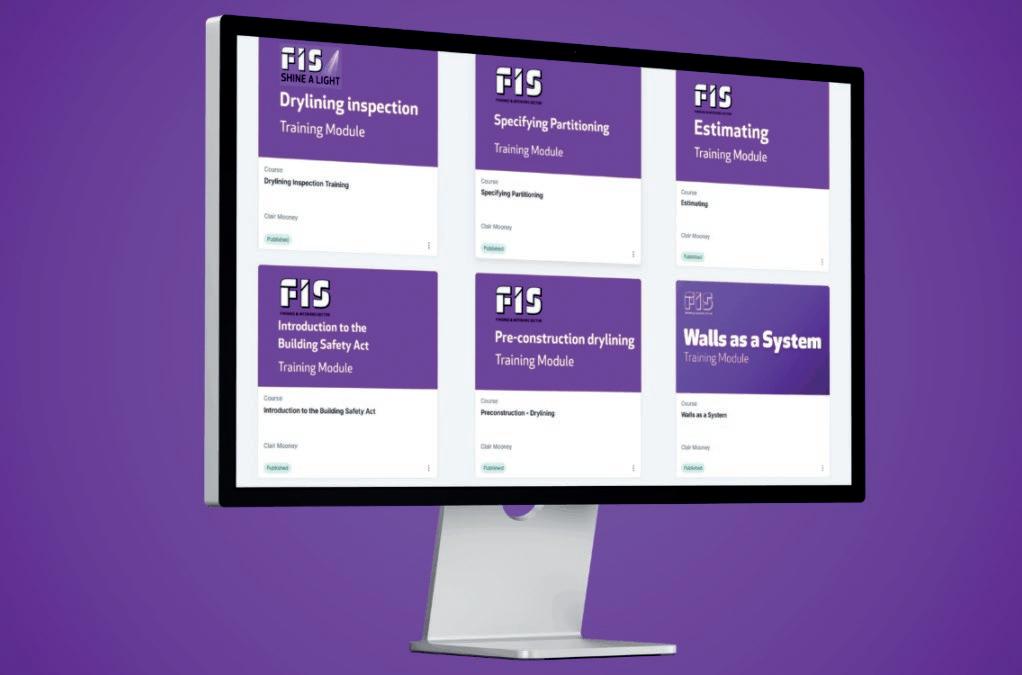

The industry is investing heavily in developing the workforce of the future and the FIS has been instrumental in spearheading initiatives and programmes for this sector.

FIS has continued the expansion of its e-learning offering with the introduction of three new training courses. Tailored to meet the evolving needs of those working in the sector industry, these courses are a valuable resource for those working in the sector to enhance their skills and knowledge.

These development of these new courses reflect FIS’s commitment to fostering professional growth and supporting the continuous development of its members and the wider community.

FIS President Ian Strangward said: “FIS is focussed on building skills and competence and key to this is the development of e-learning to support our members and the wider community. Since we launched our e-learning platform in 2024 we have developed seven new courses.

“The bank of knowledge which FIS has built is impressive, and the transition of this content into e-learning puts guidance into people’s heads. Hundreds of people have accessed our courses so far and we will continue to develop more courses targeting vital interventions, job titles and knowledge gaps.”

Meanwhile, the Industry Task and Finish Group on the management of competence in organisations (ITFG) launched its short consultation on its draft guidance Managing Competence in the Built Environment: A Guide.

The ITFG was pulled together in June 2025, to collaborate on guidance that will support organisations across the sector to manage competence of individuals, engaging with the Industry Competence Committee (ICC).

The resulting output is a consensus document that follows the principles in the recently published ICC Consultation document.

While the ICC principles document is pitched at a high level of ‘what’ is expected of organisations in this area, the ITFG document follows these principles and seeks to help organisations understand in detail ‘how’ to put in place approaches and processes to meet the ICC principles.

The broad representation in the ITFG aims to ensure that the wide-ranging needs of all types and size of organisations are met.

Innovation has always been at the forefront of Hunter Douglas Architectural's ethos – and the past 25 years of investment in research and development has enabled the global company to create an impressive ceilings portfolio that has sustainability at its heart.

It now offers more than 70 different types of ceilings in a wide range of materials and finishes that are suitable for exterior and interior applications.

In a world where design and quality are uncompromising, Hunter Douglas has undertaken more design partner roles. The development of Heartfelt®, which won the Red Dot Award in 2017, is just one example of how engineers and designers can collaborate to create a striking, sustainable ceiling system.

Improving integrated high-performance acoustic backers and micro-perforation technologies has also enabled Hunter Douglas ceilings to play a key role in comfort and environmental quality.

David Harris, general manager of Hunter Douglas Architectural UK, says: “Over the past 25 years, there have been significant changes in the specification of ceiling and wall systems from architects and designers.

“There has also been a been a considerable change in product requirements, specifically related to the acoustic and fire performance, together with recyclability and the importance of ethical and environmental sourcing of raw materials.

“We have expanded our popular Luxalon metal ceiling systems, specifically the linear aluminium ceilings that are suitable for

external, swimming pool and applications where high levels of acoustic absorption are required.”

Sustainability has also become a defining force, with ongoing efforts to address environmental concerns. Hunter Douglas’s aluminium systems contain up to 86% recycled material, with the linear and wide panel metal ceilings, as well as felt

programmes, being C2C level bronze certified. Some of the wood systems are C2C level silver certified. This assists in the design of buildings when working towards BREEAM or LEED certification.

David adds there has been a significant growth in over the past two and a half decades in the Derako solid and veneered wood range and HeartFelt® felt product range, as well as a marked rise in the number of custom projects it delivers.

A desire for the highest level of technical performance and design solutions, as more designers demand a wall solution to match the ceiling system, has led the technical team to adapt several of its products for use in vertical wall applications.

“More recently we have begun to work more closely with several lighting manufacturers, to offer fully integrated lighting solutions for most of our linear ceiling systems,” explains David.

“We have witnessed the transitioning from standardised ceiling products to delivering architectural systems that carefully balance design, sustainable practice and rigorous performance standards – and this will only grow.”

Hunter Douglas Architectural – Enquiry 21

The wider construction and architectural products industry has never stepped away from the challenges posed by future growth and progression and the flooring sector has been instrumental in shaping best practice.

Whether it is the growing importance of the sustainability agenda or the significant challenges faced in developing the next generation of industry professionals, the Contract Flooring Association has been at the forefront of pushing for positive change.

The CFA’s latest Sustainability Guide, an annual publication that highlights key information, products, services and case studies, is fast becoming more and more important as a reference document for our sector. It aims to help anyone with a current flooring project (with sustainability at its heart) to deliver best practice. At the same time, it provides some thought leadership pieces around the future of sustainability in the commercial flooring sector.

Returning to its roots as a guide, there is a very practical article on ways that contractors can improve their green credentials outside of installing sustainable products. A whole list of accessible actions and improvements that make both environmental and business sense. Doing the right thing, whilst at the same time making a flooring contractor more attractive as a supply chain partner to work with.

The CFA has also formally added its support to an industry initiative opposing the recently proposed apprenticeship reforms by Skills England and the UK Government.

These reforms include a significant reduction in the minimum apprenticeship duration period in England and removal of key elements of the End Point Assessments (EPA), including external verification.

Whilst CFA supports ongoing efforts to modernise apprenticeship pathways, it believes the proposed changes pose real risks to the quality, competence and safety of the construction sector and the commercial flooring sector in the future.

CFA will continue to work with member companies, training providers, awarding organisations and industry bodies to ensure that the commercial flooring sector remains underpinned by robust, employer-led training and assessment pathways.

Proposed changes pose real risks to the quality, competence and safety of the construction sector and the commercial flooring sector in the future

For more than 80 years, Gerflor has been synonymous with resilient flooring innovation. Its world-class, design-led, and sustainable solutions have earned the brand a global reputation across healthcare, education, sport, offices, retail, industry and housing. Gerflor’s success is rooted in a rich history defined by continuous progress and a commitment to shaping the future of flooring.

Gerflor’s journey began in 1937, when the company launched its first homogeneous flooring product in Troisdorf, Germany. This early innovation laid the foundation for what would become one of its most iconic ranges. Mipolam has evolved into a benchmark solution for healthcare, education, and industrial markets. Recognised for its benefits in delivering durability, stain resistance, easy cleaning and maintenance and suitability for high traffic environments.

In 1947, Gerflor introduced another breakthrough: the first foam-backed vinyl sports flooring. Taraflex was designed as a technically advanced synthetic floor that enhanced performance, safety, and durability for sports facilities, offering a point-elastic solution to minimise injuries. Today, Taraflex continues to be a popular choice in the Education, Leisure, and Fitness sectors, and has been used in the Olympics since 1976.

In 1985, responding to a growing need for quicker, more flexible installation methods, Gerflor launched its self-adhesive tiles, a precursor to today’s fast-track systems. This spirit of problem-solving paved the way for one of its most significant technical achievements: the GTI interlocking tile. Designed for industrial, retail, warehousing, and even cleanroom settings, GTI offered a durable, fast, easy-to-install solution that addressed the practical challenges of busy, high-impact environments.

A major chapter in Gerflor’s history unfolded in 2015, when the group expanded its interior finishing capabilities by acquiring Gradus. A UK-based manufacturer specialising in contract interior solutions, stair-edgings, floor trims, barrier matting, wall protection, entrance matting, lighting and more. This brought a complementary suite of products that allowed Gerflor to broaden its offering beyond flooring alone.