Official Magazine & Media Partner: Official Publication of the International Society for Trenchless Technology M ay 2024 | I ssue 213

voice of the trenchless

TRENCHLESS

BKP & ProKASRO deliver first-class lining support in

The

community

Works

Guadeloupe

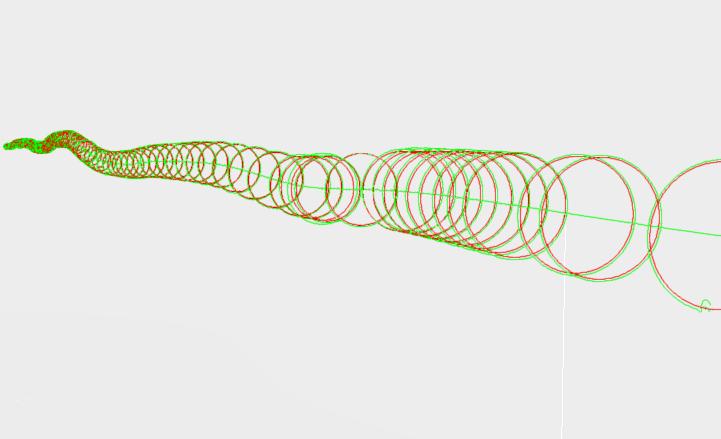

The Dancutter Superflex is suitable for use on straight runs & bends up to 90°.

The head has 360° continuous rotation with a working range of 70 - 150mm, whilst the 12” screen and self-cleaning camera lens allow for easy visibility.

Scan here to find out more!

2 TRENCHLESS WORKS | MAY 2024

+44 (0)330 043 9604 sales@rsm-web.com www.rsm-web.com

Editor’s Welcome

Austen Lees

PUBLISHER

Paul Harwood pharwood@westrade.co.uk

EDITOR

Austen Lees editorial@trenchless-works.com

MANAGING EDITOR

Leigh Abbott labbott@westrade.co.uk

SALES DIRECTOR

Trevor Dorrell tdorrell@westrade.co.uk

DESIGN & PRODUCTION

Ioan Lucian Sculeac lucian@westrade.co.uk

CHINESE AGENT

Lexi Di lexi.di@bestexpo.cn

COPYRIGHT

Trenchless Works is published 12 times a year by Westrade Group Ltd I Carotino House| Bury Lane I Rickmansworth I WD3 1ED I UK

Contributions: Contributions are invited and articles should be emailed to editorial@trenchless-works.com. No responsibility can be taken for drawings, photographs or written contributions during delivery, transmission or when with the magazine. In the absence of an agreement, the copyright of all contributions, regardless of format, belongs to the publisher. The publishers accept no responsibility in respect of advertisements appearing in the magazine and the opinions expressed in editorial material or otherwise do not necessarily represent the views of the publishers. The publishers accept no responsibility for actions taken on the basis of any information contained within this magazine. The publishers cannot accept liability for any loss arising from the late appearance or non-publication of any advertisement for any reason whatsoever. ISSN 2049-3401

Firstly, thanks for all the positive feedback relating to the new look magazine –we’re glad you love it as much as us!

There’s loads to look out for in this edition of Trenchless Works including world records in India, the opening of a new oil pipeline in Canada, and our cover feature from BKP and ProKASRO which provides a fascinating insight into their lining work in Guadeloupe – I am available for site visits to the Caribbean if anyone has an interesting project out there!

We are also starting to gear up for a busy summer of events kicking off with the No-Dig Roadshow in Reading supported by Thames Water, Wessex Water and SES Water. From there we head to the capital of the Philippines and Manila for the

ever-popular Trenchless Asia. We’re then back to the UK for our flagship No-Dig Live event at Stoneleigh in the first week of October.

Thank you to everyone who contributed to the magazine this month, if you’ve got some exciting news or opinion that that you want to share, please drop me a line editorial@trenchlessworks.com.

Enjoy the magazine and hopefully I’ll see some of you in Reading in a couple of weeks.

Austen

Subscribe for free: www.trenchless-works.com

ARTICLE

Editor’s Welcome

NEWS

TRACTO gives insight into the future of pipeline construction

Connections made in Glastonbury

Danaher & Walsh continues to demonstrate pipelining prowess

Trenchless Solutions leader promoted

Barhale to upgrade water delivery capacity for Corby

PE100+ announces new President & Chairman

PIPELINE REHABILITATION

BKP & ProKASRO deliver first-class lining support in Guadeloupe

Precision redefined

JBP patching system - fast and reliable solution for pipeline repair

Quick-Lock BIG system used for challenging underwater project

HDD

World record for HDD pipeline in India

Pipe pullback in British Columbia

TUNNELLING

Herrenknecht AG TBM launched for HS2

ASSET MANAGEMENT

Saudi Aramco approves Electro Scan for leak detection of buried non-metallic piping

FOCUS ON TRENCHLESS TRAINING

Identifying your training needs

EVENT NEWS

UK trenchless sector hits the road to Reading

Trenchless sector set to shine in Philippines’ capital

UKSTT SOCIETY NEWS

A message from the Chair

Entries are open for UKSTT awards

support at UKSTT Gala Dinner & Awards Ceremony

& education report

NASTT SOCIETY NEWS

A message from the Chair

Technical

Council member

Technical enquiries ISTT SOCIETY NEWS

message from the Chair ITTC 2024

great success

Charity

report

A

- A

EVENTS

To submit editorial for Trenchless Works next issue please email copy and images to: editorial@trenchless-works.com by the 12th of the month. Submissions arriving after this date cannot be guaranteed inclusion in that month’s issue. For

Works sponsorship and advertising rates

PAGE 3 6 11 12 14 16 18 20 26 30 34 37 38 40 42 44 46 48 53 54 54 55 56 57 59 60 67 69 6 20 37 CONTENTS 4 TRENCHLESS WORKS | MAY 2024

AND MEETINGS

Trenchless

please email: tdorrell@westrade.co.uk

Any shape Any size

GRP structural lining systems

For over four decades, Channeline has been a global leader in the custom design and manufacture of high-quality, fully structural glass reinforced plastic (GRP) lining systems in any shape, and any size, for the trenchless rehabilitation of existing sewers, tunnels, culverts, stormwater, and other buried structures. With a worldwide presence in over 30 countries, we offer turnkey, innovative, and sustainable solutions with a design life of 150 years, for our clients, consultants, and contractors from design to installation.

Channeline International Fiber Glass Manufacturing L.L.C.

E-mail: info@channeline.com

Wastewater

Stormwater

Rail and road culverts

Tunnels

Seawater cooling network

Custom

t h e Beyondordinar y

Applications

www.channeline.com

Follow us on

TRACTO gives insight into the future of pipeline construction

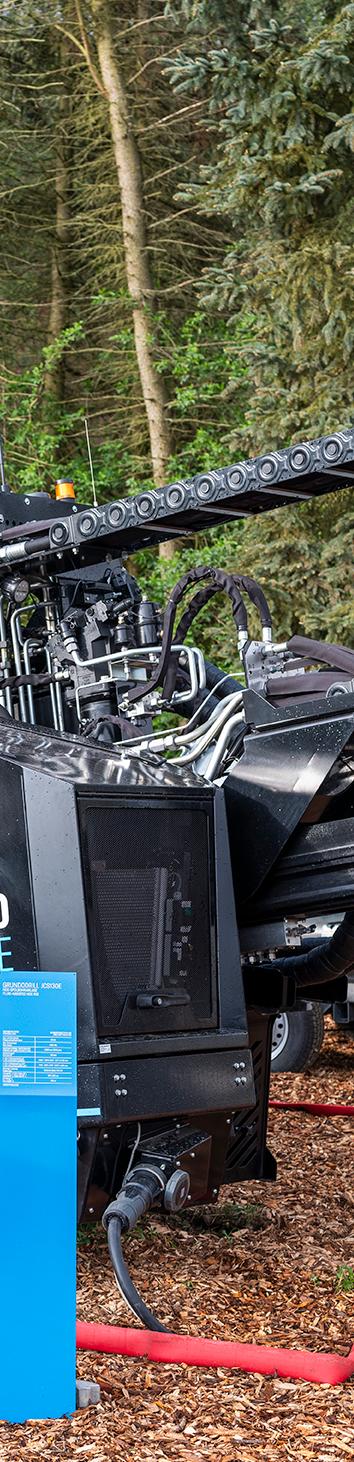

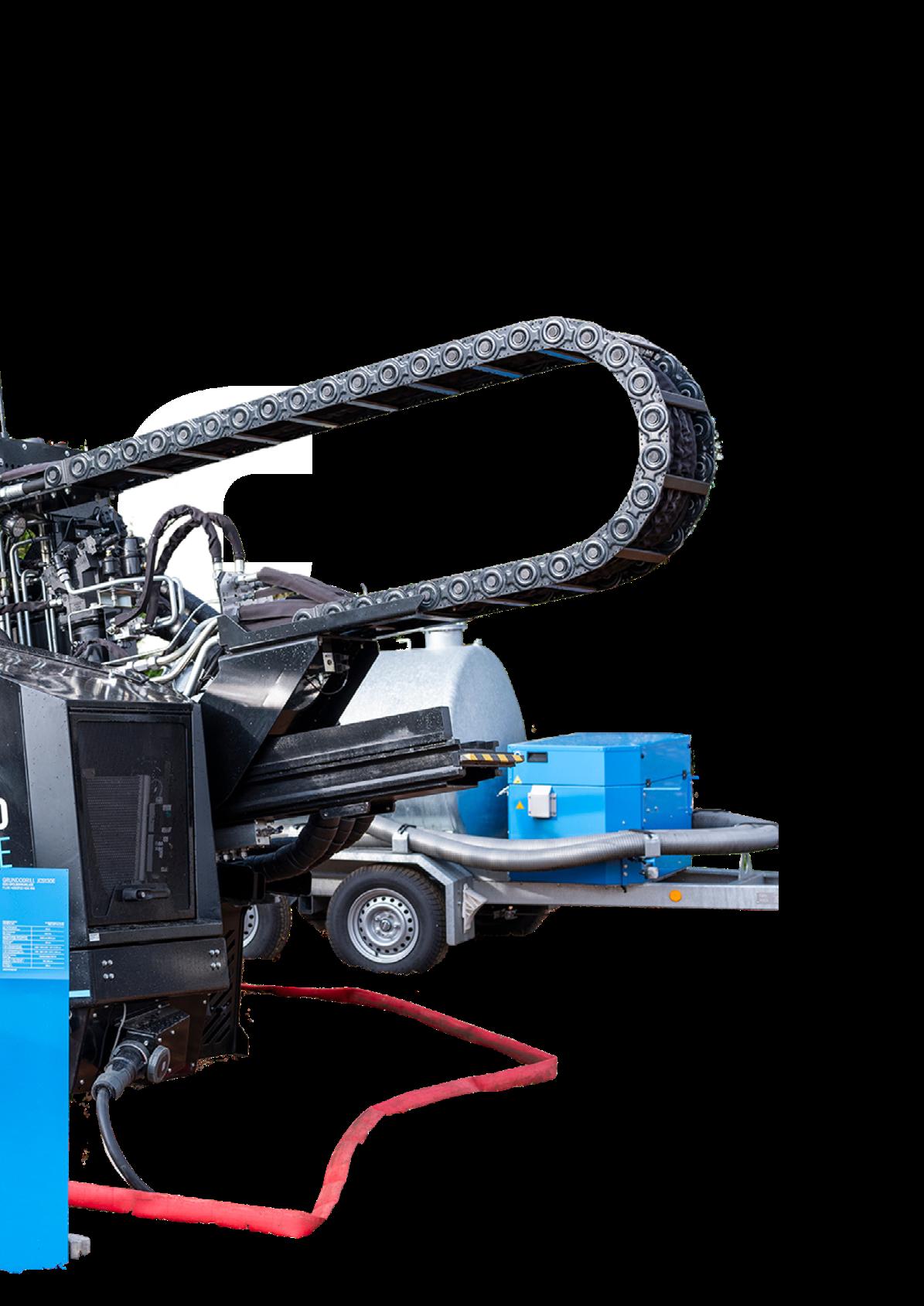

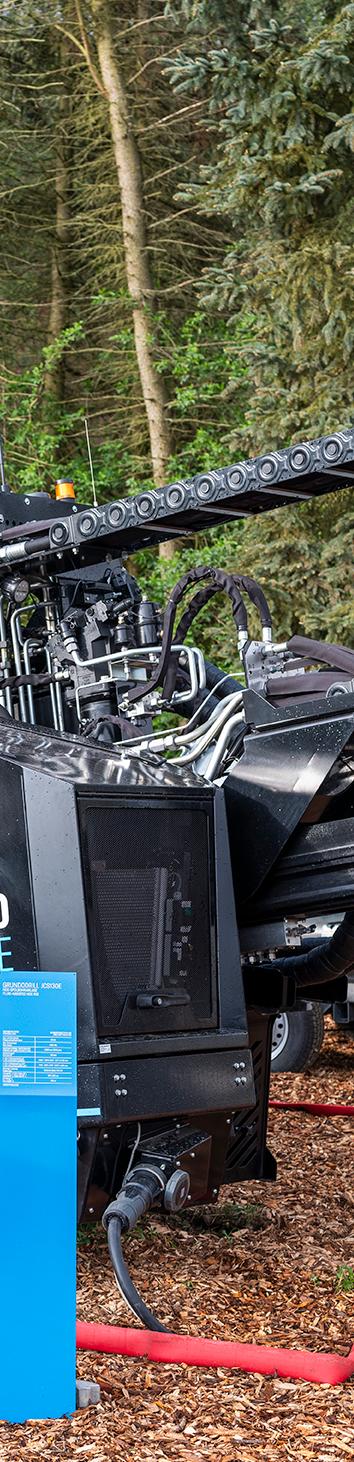

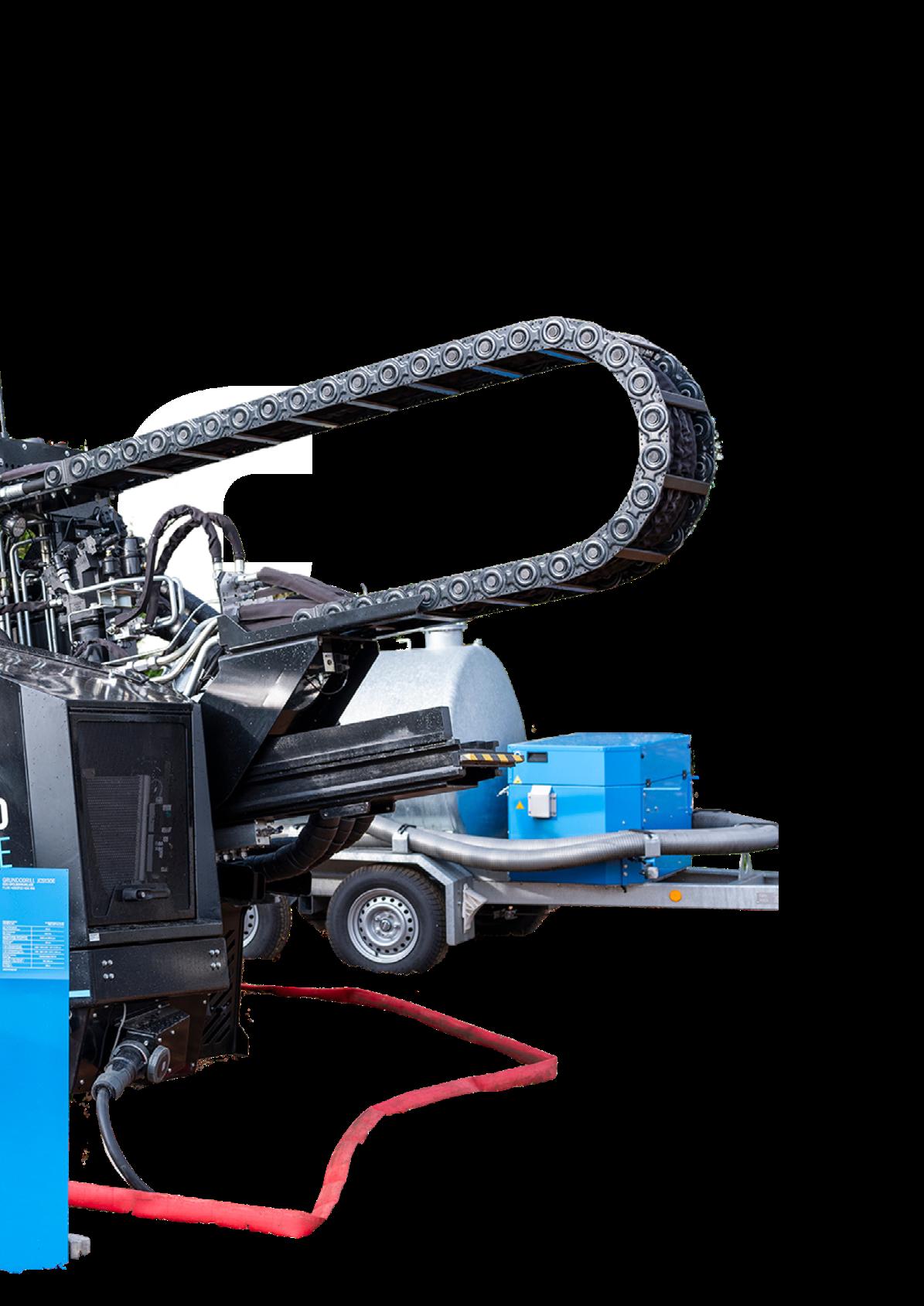

TRACTO’s popular “Hands on Days” took place for the 12th time at the company’s headquarters in Lennestadt-Saalhausen on 15 - 19 April, offering their customers and partners the opportunity to look behind the scenes of their innovations, and provide unique insight into the world of trenchless technology.

6 TRENCHLESS WORKS | MAY 2024 NEWS

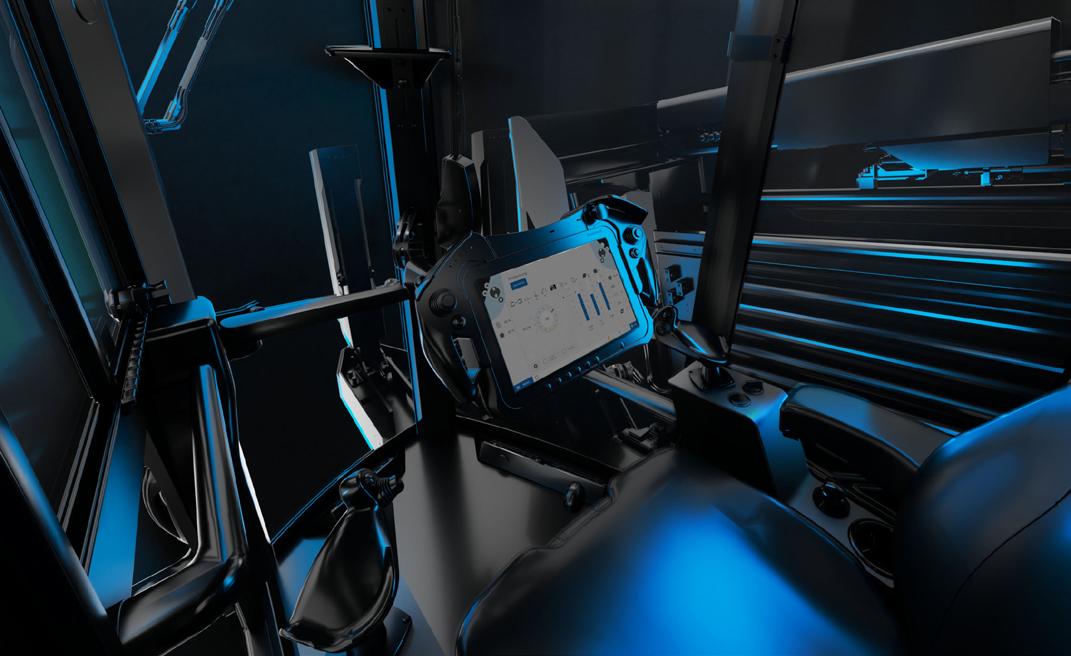

Modern HDD drill rig GRUNDODRILL JCSE with electric drive for low-emission construction sites

World first ORFEUS: Schematic illustration of the HDD ground penetrating radar for automatic detection of obstacles in the bore path

TRACTO-CITY” was set up especially for the event in the form of a tent city where the whole world of trenchless technology and its applications were clearly presented with 20 machines on display. Around 1,000 visitors from 30 countries were able to obtain comprehensive information on products and

tailor-made services from experts in individual themed tents. More than 30 factory tours gave interested visitors an additional insight into TRACTO’s production and quality management, and the No-Dig systems could be seen in action in more than 100 live demonstrations. >

MAY 2024 | TRENCHLESS WORKS 7 NEWS

Technology and knowledge for the future

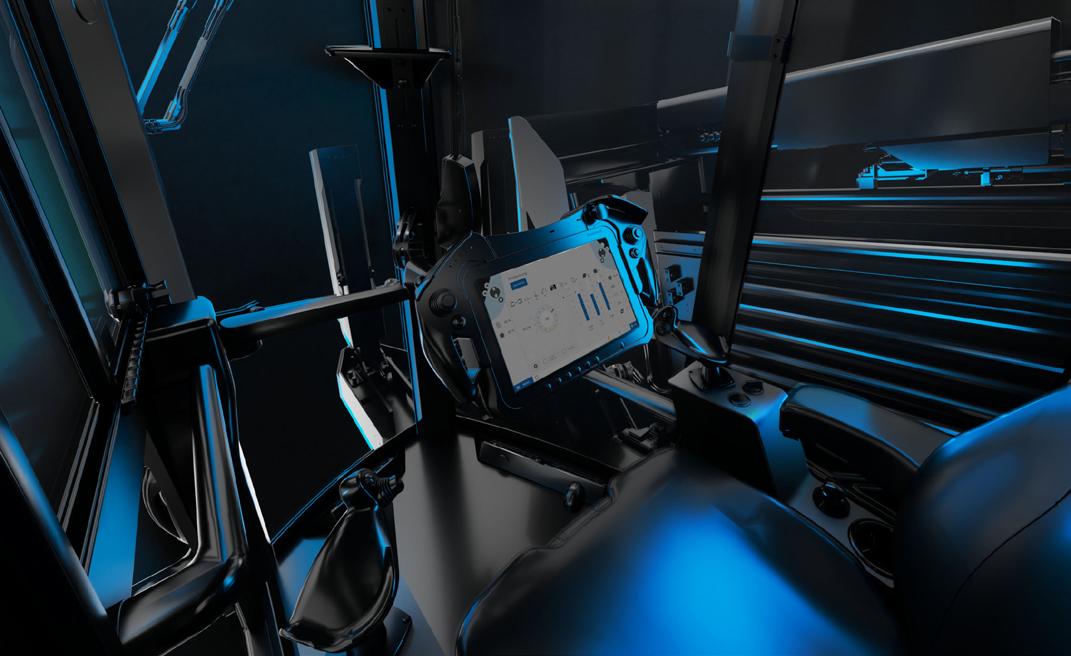

TRACTO is playing a major role in shaping the future of trenchless construction. The first HDD drilling rig with an electric motor, the GRUNDODRILL JCS 130E, could also be seen at work on the demonstration site. A broad programme of 15 presentations in four blocks covering markets, applications and technology trends focused on current topics in pipeline construction, namely fibre optics, power lines, pipe rehabilitation and future topics.

The future of drilling technology and its continued automation, as well as environmental and sustainability issues, were also explored in depth in the presentations, as was

advancing digitalisation. The presentations were dedicated to these areas, but there were also separate information tents where these important topics could be explored in greater depth in personal dialogue with the experts. Further evidence of TRACTO’s innovative strength was provided by the presentation of an interactive network called the “Trenchless Platform”, which allows users to participate in digital development initiatives for the drilling rig of the future.

TRACTO’s head of R&D, Elmar Koch, states “The longterm goal is to achieve fully autonomous drilling, their HDD rigs already use a variety of support systems, for example, cameras already monitor the drilling process, GPS is used to digitally document the drilling,

sensors on the drill head provide information on ground conditions, and other sensors measure distances around the machine and detect hazards” Comprehensive data is also analysed and evaluated to help the operator assess and react to unexpected events during the drilling process.

“Cameras already monitor the drilling process, GPS is used to digitally document the drilling, sensors on the drill head provide information on ground conditions, and other sensors measure distances around the machine and detect hazards.

8 TRENCHLESS WORKS | MAY 2024 NEWS

The international guests experienced trenchless technology up close in the demonstration area

ORFEUS

With the world innovation ORFEUS, which is still under development, it will soon be possible to use radar antennas to detect unexpected obstacles in the drilling process at about 0.5m from the drill head, such as incorrectly mapped supply lines. The hardware evaluates the detected obstacles and

triggers a warning if necessary. All obstacles are shown in real time on the drill’s display using traffic light colours. The drill stops automatically when the colour changes to red. The ORFEUS ground-penetrating radar makes the HDD process even safer and is an important step towards autonomous drilling. It will be ready for the market by bauma 2025.

Minimally invasive: compact pit drilling rig with a very small footprint

Minimally invasive: compact pit drilling rig with a very small footprint

MAY 2024 | TRENCHLESS WORKS 9 NEWS

The streams of visitors at TRACTO’s Hands on Days in Lennestadt-Saalhausen

The GRUNDODRILL JCS/ACS rigs by TRACTO are setting standards in HDD, combining premium quality and state-ofthe-art technology: - Intuitive operating concept - Maximum automation - Remote-controlled drilling - Peak power & performance for jet and rock bores To discover the future of HDD, please get in touch: T +49 2723 8080-0 M info@tracto.com THE FUTURE OF HDD GRUNDODRILL JCS / ACS TRACTO.COM/GRUNDODRILL

Connections made in Glastonbury

Difficult ground conditions called for a specialist solution when new PE pipes for potable water services had to be installed underneath two, 10m road crossings in the grounds of the UK’s ultimate music festival at Worthy Farm

The geology of the bore was a mixture of rocks and boulders, with only a small layer of clay and the added issue of very wet ground conditions. The project screamed out for a mole and the GRUNDOMAT 145 was identified to supply sufficient power and thrust to bore under an inner road on the farm. After the initial bore, the GRUNDOMAT was reversed back to the start pit towing a 32mm and 90mm PE pipe and a 63mm and 32mm on the 2nd to install new water pipes for the extended camp site.

The bores were undertaken by experienced GRUNDOMAT and HDD operator, Arnie Bailey, and were very successful - coming out at the correct depth and right in the centre of the pits.

Both Arnie, who runs Arnie Bailey Enterprises Ltd offering drilling consultancy and NoDig operations, and the client were delighted at the accuracy achieved and the ease with which the GRUNDOMAT towed the pipes through the bore.

Arnie Bailey said “We managed a very precise and accurate bore even though we couldn’t see the reception pit from the start pit due to the overgrowth of hedges on either side of the road. The GRUNDOMAT tackled the whole job with ease, as usual and the customer was over the moon with completion of the project, which has ensured services can be connected to the existing mains over a mile away and in good time for the festival.”

MAY 2024 | TRENCHLESS WORKS 11 NEWS

Danaher & Walsh continues to demonstrate pipelining prowess

Danaher & Walsh Civil Engineering has claimed top spot in Anglian Water’s Alliance delivery performance table for the second year running.

The civil engineering company, which operates throughout the Midlands and the East of England, has a dedicated pipeline rehabilitation and repairs division, and has worked with Anglian Water for almost 20 years. In doing so, they have become an integral part of a team of delivery partners known as the Integrated Maintenance and Repair Water Recycling (IMRWR) Alliance.

Commenting on the achievement Danaher & Walsh’s Commercial Director, Ian Gilbert, said: “A massive well done to everybody involved – the IMRWR Alliance has smashed it yet again and finished top of the Capitol Delivery Index (CDI) table for Alliance delivery performance throughout the whole of Anglian Water, for the second year running. The (CDI) metric measures all alliances and internal departments for expenditure, delivery on time and efficiency and as such is a recognised measurement of overall performance across the water industry. This accolade

cannot be over-stated and is a testament to everyone’s commitment and hard work.”

Working with their IMRWR Alliance partners Danaher & Walsh has helped to achieve some impressive results over the last twelve months. This has included the use of its innovative No-Dig technology to save many hundreds of thousands of pounds while also reducing health and safety risks and disruption for Anglian Water customers.

UKSTT Member 12 TRENCHLESS WORKS | MAY 2024 NEWS

Anglian Water DW sign van

INNOVATION MEETS INNOVATION MEETS OPPORTUNITY OPPORTUNITY

Multi-platform content

Tailored advertising solutions

Amplify your brand

Get global exposure! Reach 55,000+ industry professionals through our worldwide distribution, including online subscribers and event readership. Maximise your brand's visibility today!

Cutting-edge equipment to groundbreaking techniques, our pages are where industry leaders turn to stay ahead of the curve.

(0)1923 723990 tdorrell@westrade co uk For more details regarding advertising and sponsorship opportunities please contact: Trevor Dorrell: CONTACT US

Trenchless Solutions leader promoted

Vortex Companies, LLC (Vortex), a global provider of trenchless infrastructure rehabilitation products and services, is pleased to announce the promotion of Ryan Graham to Chief Operating Officer. In this role, Graham will be responsible for ensuring strategic collaboration across company divisions to strengthen customer relationships, increase sales, and improve overall service and product quality.

“Bringing Ryan in as chief operating officer will help increase efficiency across the organisation, resulting in tangible benefits for Vortex customers and the communities

they serve,” stated Mike Vellano, CEO of the Vortex Companies. “Ryan is a trusted and seasoned leader, and I’m excited to see his impact on the company expand in this capacity.”

As one of Vortex’s first employees when the company opened its doors in 2015. Graham has steadily risen through the ranks, most recently serving as Senior Vice President for Vortex Services. “Ryan has been in the trenches since the beginning. He understands our culture and the high standards we hold ourselves to,” added Vellano. “His calm leadership and open communication management style have earned him the respect of everyone from the executive management team to our crews in the field.”

In his new role, Graham will oversee the day-to-day operations of the company’s Products and Service divisions, an effort that will include driving strategic initiatives, managing cross-functional collaboration, ensuring quality and compliance, and mitigating risks to support the company’s success and growth. “He has one ear to the ground at all times, and a proven track record of strategic planning and execution,” said Vellano. “I trust him to make sure we exceed operational expectations on all levels.”

Graham is taking over as COO during a crucial period of change for Vortex, which has grown both organically and through a series of strategic acquisitions in recent years. “It’s been a great journey and I believe that my prior responsibilities within the company have prepared me well for this new role,” said Graham. “I look forward to being a part of Vortex’s continued growth and helping the company meet the growing demands of the industry and our customers.”

“ Bringing Ryan in as Chief Operating Officer will help increase efficiency across the organisation, resulting in tangible benefits for

Vortex customers and the communities they serve.

Ryan Graham promoted to COO at Vortex Companies

14 TRENCHLESS WORKS | MAY 2024 NEWS

Ryan Graham, one of Vortex Companies’ first employees, promoted to Chief Operating Officer

JACK TALBOTT, Technical Sales

phone +44 7740 197127 e-mail jtalbott@impreg.com

BEN CARTER, Warehouse Manager

phone +44 7546 869289 e-mail bcarter@impreg.com

The UV-Liner for DN 150 – DN 2000. We set standards in trenchless sewer rehabilitation. Being the Best in whatever we do. ANY SIZE. ANY SHAPE. ANY PIPE. IMPREG UK Ltd • 9 Doman Road • Camberley Surrey, GU15 3DF • www.impreg.de/en

IMPREGLiner

Barhale to upgrade water delivery capacity for Corby

The upgrade of a key Anglian Water asset in Corby will pave the way for future residential development in the Northamptonshire town where the population is expected to double over the next 30 years.

“ It looks like Corby is going to see dramatic growth over the next few decades and that inevitably means there will be real pressure on utilities.

16 TRENCHLESS WORKS | MAY 2024 NEWS

As part of the IOS Alliance, Barhale is leading works to enhance service capacity at the well-known Beanfield water towers and reservoir on the eastern edge of the existing settlement. The key focus is the installation of new pumps to transfer potable water from the reservoir into the two towers which between them hold more than 4.54 million litres of water (Number 1 holds 1.14 million litres, Number 2 holds 3.41 million litres) and supply the town. Built in the 1960s and 1970s, the distinctive water towers on Uppingham Road are part of an Anglian Water network which links Rutland Water to the Beanfield Reservoir and Water Towers via the Morcott and Wing Water Treatment Works.

Civil engineering, infrastructure, and tunnelling specialist, Barhale will install two new 259

kW water pumps to provide the capacity to generate additional flow through the system. The new pumps will require works to install an additional 800 kVA mains power supply. To mitigate the event of mains power failure, Barhale will install a 550kVA generator with a 24,000-litre fuel tank alongside the construction of a bund and a 7,000- litre fuel oil separator to prevent the possibility of a pollution event.

Although the existing water pumps will be replaced, the work programme has been designed to ensure that there are no interruptions in supply to customers. Barhale’s project manager Jedi Sznajder underlined the importance of the works to meet Corby’s anticipated future development.

“It looks like Corby is going to see dramatic growth over the

CUT OUT THE CRANE

next few decades and that inevitably means there will be real pressure on utilities,” he said. “The work we are carrying out at the Beanfield site is an important strategic intervention which will significantly increase the capacity of the water supply infrastructure and ensure Anglian Water is able to meet future demand.”

The IOS Alliance was set up in 2015 as a partnership within Anglian Water to concentrate on capital maintenance across the Anglian Water asset portfolio. It comprises Anglian Water, Barhale, Morrison Water Services and Kier. Together they ensure the infrastructure’s longevity and effectiveness.

Adding Atlas to your project means you can cut out unnecessary and expensive logistics. Our new Hammar self-loading cable drum trailers make handling and transporting large cable drums easier than ever. With only one driver/operator required to handle drums of up to 35tonnes, your cable drum logistics have never been simpler.

Add Atlas expertise to your project, give us a call today.

T: +44 (0)1899 221 577 (Scotland) T: +44 (0)1371 859 555 (Essex) E: info@winchhire.com W: winchhire.co.uk

UKSTT Member MAY 2024 | TRENCHLESS WORKS 17 NEWS

PE100+ announces new President & Chairman

The PE100+ Association has announced that Andrew Wedgner has been appointed as the new President & Chairman of the Association from 3 June 2024.

Andrew is a chartered civil and environmental engineer who spent the first 22 years of his career in the infrastructure and environmental engineering industry, working for utilities and engineering companies. He moved into the polyolefin industry in 2010 and since then has held pipe related technical, marketing, and commercial management positions, all of which have given him a strong overview of the PE100 pipe value chain.

The association thanked Robin Bresser (Borealis) for his contribution as President of the Association during the last years, which have seen 2 new member companies join the association, PE100-RC grades added to the quality list of materials and the association hold its first member meeting in Asia.

Andrew thanked the members and followers of the association for their congratulations “After 31 years of working with PE pipe systems in one way or another, I hope that I can put my knowledge and experience to good use. My aim is to continue the work of Robin Bresser in developing the association, to better serve our members and the PE pipe community.”

18 TRENCHLESS WORKS | MAY 2024 NEWS

Andrew Wedgner UKSTT Member

26 June 2024

Hilton Reading, Drake Way, Reading RG2 0GQ www.nodigroadshows.co.uk

TRENCHLESS ASIA 2024

16-17 July 2024

World Trade Center Metro Manila, www.trenchlessasia.comPhilippines

www.nodiglive.co.ukWarwickshire

5-6 November 2024

Jumeirah Beach Hotel, Dubai www.trenchlessmiddleeast.com

TRENCHLESS

21-22 May 2025

KL Convention Centre, Kuala Lumpur, Malaysia

t: +44 (0)1923 723990 e: trenchless@westrade.co.uk w: www.westrade.co.uk instagram: @trenchlessworks International No-Dig events brought to you by the industry's world experts NO-DIG EVENTS NO-DIG

READING

ROADSHOW

NO-DIG

2024 Featuring the UKSTT Annual Dinner

Awards Ceremony

2024 NAEC

LIVE

&

1-3 October

Stoneleigh Park,

TRENCHLESS MIDDLE EAST 2024

ASIA 2025

NO-DIG ROADSHOW SERIES 2025 TRENCHLESS MIDDLE EAST 2025

of

EUROPEAN NO-DIG 2025 TRENCHLESS MIDDLE EAST 2026 Dubai 2026 EUROPEAN NO-DIG 2026 NO-DIG LIVE

NAEC

TRENCHLESS

NO-DIG ROADSHOW SERIES 2026 FUTURE EVENTS TRENCHLESS THAILAND | TRENCHLESS VIETNAM | TRENCHLESS KSA NO-DIG SOUTH AFRICA | TRENCHLESS GERMANY

Kingdom

Saudi Arabia 2025

2026 29th September – 1st October 2026

Stoneleigh Park, Warwickshire

ASIA 2026

BKP & ProKASRO deliver first-class lining support in Guadeloupe

As paradisiacal as Caribbean Guadeloupe may appear with its picture postcard images of white beaches and palm trees, it also has a very real need for more functional and sustainable wastewater infrastructure.

By Teresa Jahn (ProKASRO) and Max Gottschalk (BKP Berolina)

Teams from ProKASRO

Mechatronik GmbH and BKP

Berolina Polyester GmbH & Co. KG, recently travelled to the French overseas territory to train and support their new customer, Grands Travaux Caribéens SAS (GTC), in installing three UV light-curing Berolina-HF-Liners. After three hot and humid days, the DN 1,200 hoses with a wall thickness of 11mm and a total length of 95m were successfully installed.

Working in a holiday paradise is a welcome change in any technician’s everyday life, but it does come with some unique challenges. During the monsoon season (between June and October) tropical storms and hurricanes bring torrential rain and flooding. In recent years this has been particularly extreme and has even cost human lives. Guadeloupe is responding to these changing weather patterns with a major investment programme to renovate

and expand its dilapidated wastewater infrastructure. An important element of this work is the renovation of sewers and storm drains with UV light-curing pipe liners.

ProKASRO delivers flexible curing solutions and know-how

The starting signal for the renovation work on Guadeloupe was given in Germany late last year when a small delegation from GTC was presented with

20 TRENCHLESS WORKS | MAY 2024 PIPELINE REHABILITATION

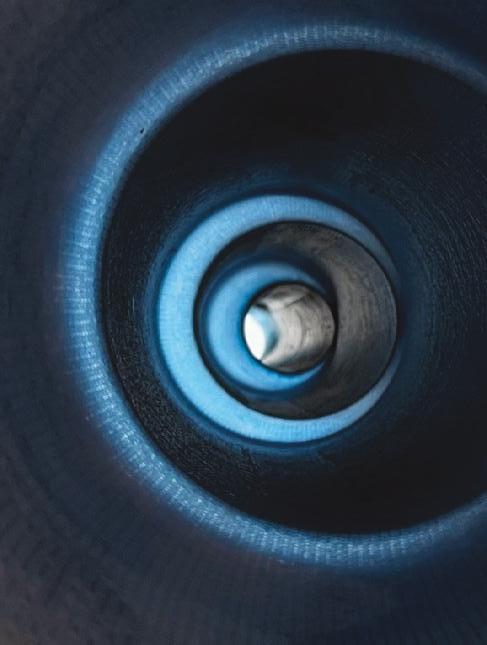

their new KASRO UV-CCU system, including the KASRO UV double core 2 x 4 x 1000W. A specially designed container made island hopping through the archipelago of the French Antilles with this flexible solution designed for use on construction sites much more comfortable.

Importantly however this project was far more than the supply of a high-quality lining product. Applications Technician Richard Plank and Service Engineer Nicolas Kempf trained the GTC team in Guadeloupe on how to properly use the KASRO UV system. Imparting this knowledge

and experience enabled the GTC team to flawlessly complete the work and set them up to successfully deliver future projects in the region.

BKP Berolina impresses with its liner characteristics and support

The project took a major step forward when close discussions between BKP’s Sales Manager Antoine Noirtin and GTC engineer Gregory Renaison resulted in the decision to utilise the Berolina-HF-Liner to renovate the culverts in Guadeloupe. The GTC team was particularly

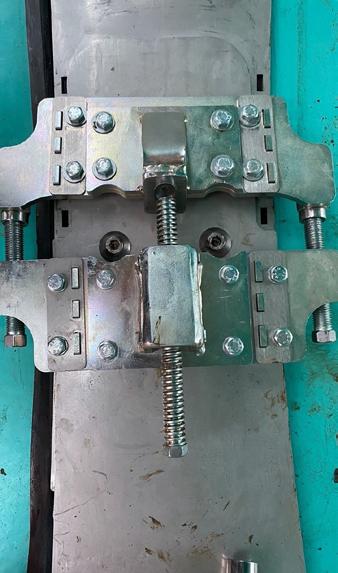

Curing passages MAY 2024 | TRENCHLESS WORKS 21 PIPELINE REHABILITATION

The highly motivated GTC team pulling in the liner

22 TRENCHLESS WORKS | MAY 2024 PIPELINE REHABILITATION

impressed by the product’s unique extension and adapting behaviour, as well as its 50-year minimum expected lifespan.

Commenting on GTC’s decision Noirtin said: “The HF-Liner’s high mechanical properties also make it an ideal solution in regions where earthquakes occur frequently.” On the ground in Guadeloupe, Noirtin and Application Technician David Kijewski then trained and supported the inexperienced installation team, working in partnership with BKP employees from France and Germany.

Elaborate construction site preparation and a tight schedule

The two construction sites with stormwater drains running under busy streets required thorough preparation. This included pumping out the backwater basins and the construction of a concrete platform in order to reach the pipes that needed to be renovated. In addition, 80 tons of gravel were delivered for a construction road, so that the liner boxes could be transported to the installation site using an excavator.

Incredibly, it only took three days to install the DN 1,200 liners including the training. This is even more impressive given the local team had no practical installation experience and were immediately confronted with such a large diameter liner. The BKP technicians however were always on hand to support the GTC team with all the necessary fine tuning.

Learning by doing

After the first site visit, and a final equipment check, the first installation under a country road was successfully completed. The impressive learning curve of the GTC crew was already evident during the second renovation project which took place in a busy inner-city environment. This stage of the work was undertaken while

Double core in tube MAY 2024 | TRENCHLESS WORKS 23 PIPELINE REHABILITATION

24 TRENCHLESS WORKS | MAY 2024 PIPELINE REHABILITATION

Power Handler

A safer and more compliant way of handling large diameter GRE, HDPE pipe, Ducting’s, Carbon Steel/Ductile Iron and Concrete Pipes.

With the UIS Power Handler™ excavator attachment, you are selecting the powerful all-in-one solution for pipe handling on a large scale like no other.

Control of the pipe from the comfort of the excavator cab. With the capability to rotate the pipe 360° the UIS Power Handler™ offers control to the operator like no other product when handling and lowering pipes safely into open trenches.

Available in 3 sizes (Handler)

6

(Pusher)

Power Push.

The UIS Power Push™ excavator attachment offers a faster, safer and more compliant way of inserting new PE pipe and cable & is fully approved for operation on both live and dead insertions.

Power Push™ is easily attached to the excavator arm with minimal operator contact, removing the risk of injuries which may occur during manual projects. Once attached, Power Push is fully operated and controlled from the safety of the excavator cab.

The Power Push™ excavator attachment is compatible for use with the majority of excavators from 1.5T up to 25T and can also be used for slip lining / manoeuvring & rerounding PE pipe of diameters up to 900mm.

the

Innovative

Faster,

Simple to use & Low maintenance Cost Efficient Safer than previous methods

sizes

Robust and Effiicient Removes Operator Risk

Machinery

Safer & more compliant

Scan

QR code to learn more about UIS Tooling Learn More.

Precision redefined

By incorporating LiDAR Survey data into our PE 100 load calculations, Die Draw LTD can now produce the most advanced and accurate analysis ever seen in the industry.

By Dr Steve Brogden, MD, Die Draw Ltd

Dr Steve Brogden

Dr Steve Brogden

We have been developing advanced calculation methods for accurately determining the insertion loads on PE 100 liner pipes for pipeline rehabilitation, and as a result we have seen a step change in the level of accuracy.

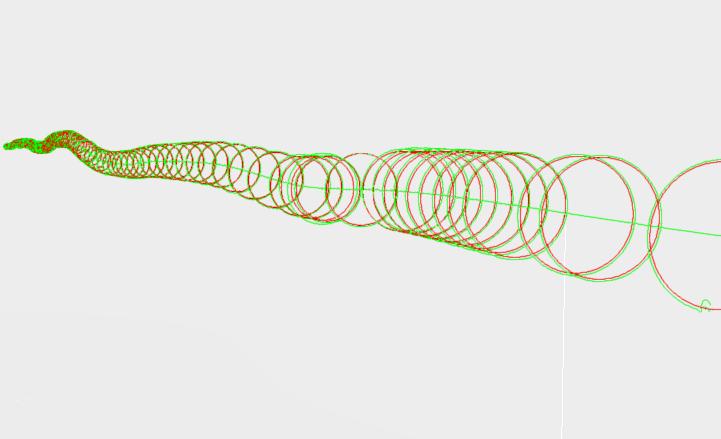

LiDAR survey data

By incorporating LiDAR survey data into our design process, we can now precisely predict installation loads, ensuring optimal equipment specification and temporary works design. This innovative approach represents a new standard in

liner installation design, offering unmatched predictability, control, and safety for thermoplastic lining solutions.

Since the 1980s, the use of thermoplastic liners has been a popular option for the in-situ rehabilitation of deteriorating pipelines. There are several techniques available but for pipelines where maintaining flow capacity is critical then a tight fit lining solution such as Die Draw can be used to retain or even increase flow capacity.

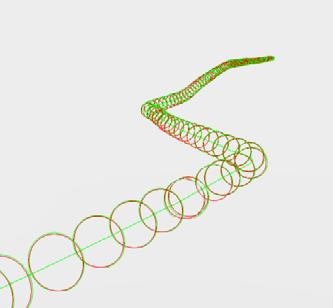

A Die Draw liner is pulled into the host pipe and understanding the loads involved is essential to ensuring a successful installation. Calculating the load for a straight pipeline is relatively simple, however accurately predicting load distribution around bends has always been a challenge. The viscoelastic nature of PE 100 alters material properties with “time under load” and ambient temperature.

Bending moments

The bending moment changes as the liner negotiates a bend, depending on factors like bend radius, liner insertion diameter, and host pipe’s internal diameter.

26 TRENCHLESS WORKS | MAY 2024 PIPELINE REHABILITATION

LiDAR Scan of bend in host pipe

Current industry practice of increasing friction factor to account for bends often leads to inaccurate force predictions and poses challenges in equipment specification and temporary works design.

PE 100 liners from Die Draw can negotiate bends of up to 22.5° and have even been successfully installed in 45° bends. However, each bend affects the overall

installation force, and the number of bends a liner can negotiate depends on their orientation, radius, and location within the pipe section. Each pipeline section is unique and will result in different loadings, which is further complicated by the change in stiffness and strength of the liner at different ambient installation temperatures. >

MAY 2024 | TRENCHLESS WORKS 27 PIPELINE REHABILITATION

LiDAR data used to understand pipe geometry

Developing and refining

For the last five years Die Draw has been developing and refining our own calculation methods. Die Draw is now able to accurately predict the loads around bends as part of our design process, determining the optimum liner insertion size to negotiate the bends in the host.

A recent refinement of our process has been to incorporate LiDAR survey information

into our design. Using this data rich technology enables very accurate prediction of installation loads accounting for every minor deflection within the host pipe and all variations in internal diameter. This enables us to precisely predict installation loads enabling optimum equipment specification and temporary works design.

The implications are that the Die Draw design process can be

used for successful installation of all thermoplastic liners including those by Die Draw and slip-lining too.

We believe our design process for installing liners is the most sophisticated method yet developed, and we are not aware that anyone else in the industry has achieved this.

LiDAR crawler selfie

3D model bend analysis

LiDAR crawler selfie

3D model bend analysis

UKSTT Member 28 TRENCHLESS WORKS | MAY 2024 PIPELINE REHABILITATION

Vertical and horizontal bends affect total loads

•

•

Connection

MIDI STEAMER • Quickly set temp & pressure • Automatically mix steam & air • Compact, portable & efficient • For CIPP, Patches & Lining PRESSURE GUARD

Monitor air pressure, power & temperature. View on monitor

Send alerts to up to 10 contacts

Smart device based on LTE-M tech

Comes with 2yr data subscription

Dual function: Control pressure & vacuum

•

•

•

•

•

Switch easily between functions with lever

Great addition to Picote

Collar System SMART CONTROL UNIT picotegroup.com | picoteinstitute.com NEW Contact your Picote Reseller or call us on 07771 872106

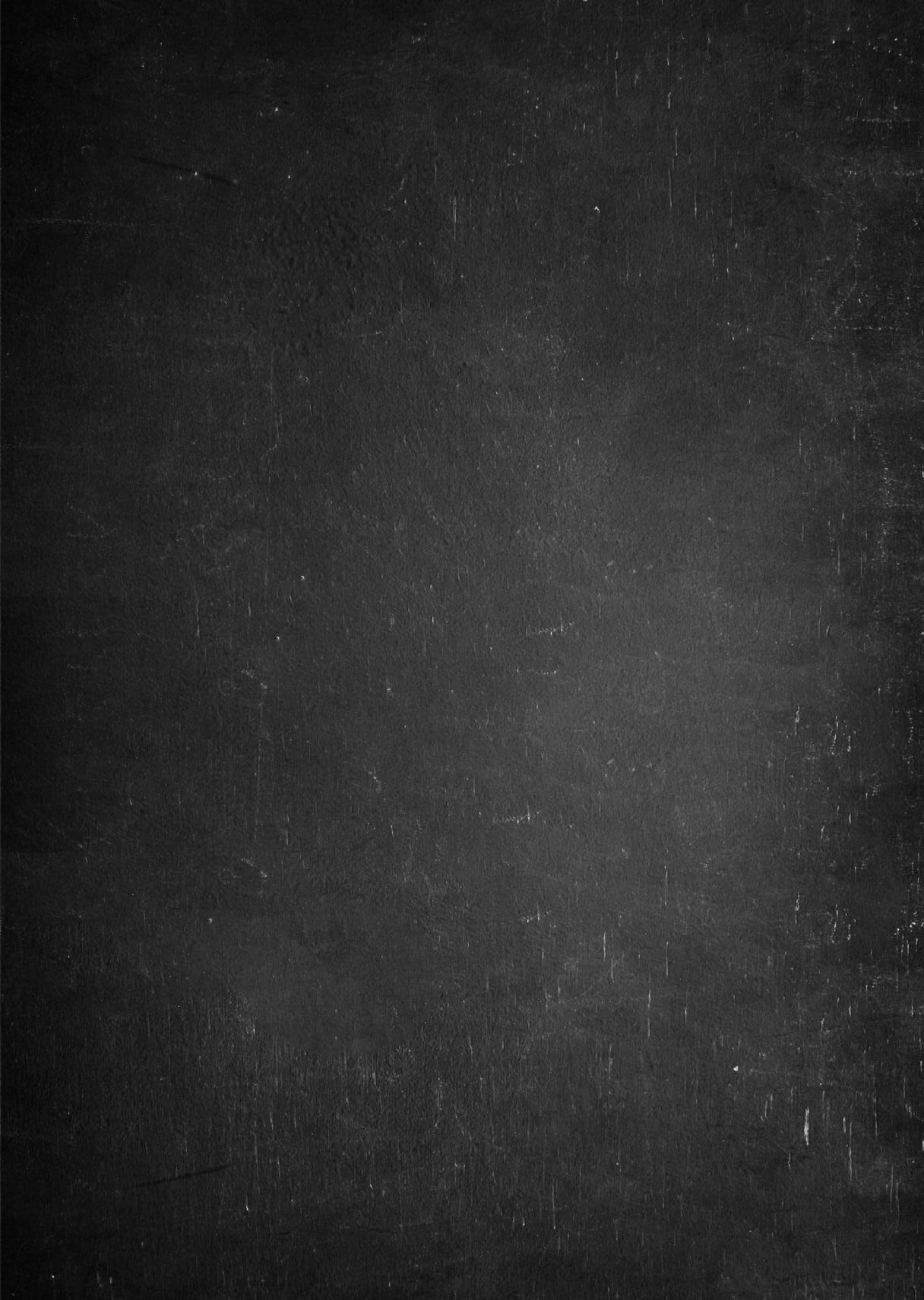

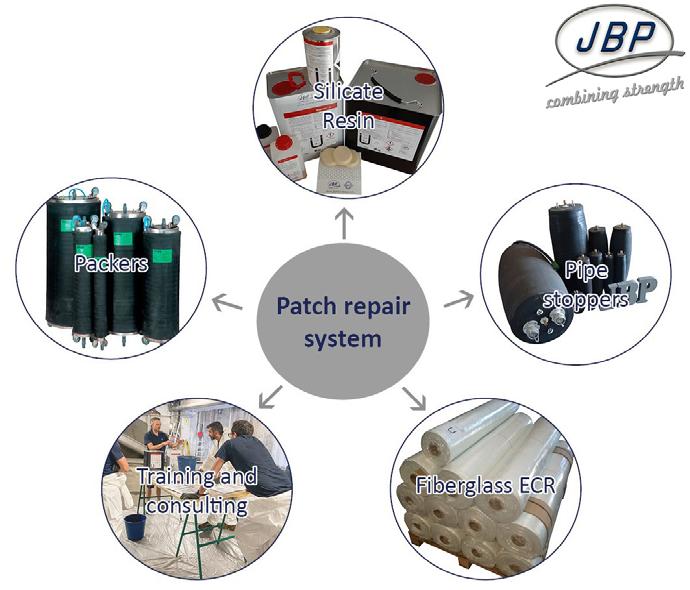

JBP patching system - fast and reliable solution for pipeline repair

In our modern cities, pipe networks are the invisible backbone that supports our daily lives, carrying drinking water, wastewater, gas and waste from our homes and businesses. Over time, however, these pipes inevitably deteriorate and face challenges such as corrosion, collapse, and leakage.

Repairing this infrastructure is vital and, faced with this challenge, there is an urgent need for solutions that are not only efficient in terms of time and cost, but also less invasive to the urban and natural environment.

JBP Patching System

There are many solutions using trenchless technologies, but this focus is on pipe repair using the Packer System, commonly known as Patch Repair. This technique is particularly useful for repairing underground water and sewer pipes. It is versatile and suitable

for a wide range of situations, particularly in contexts where traditional excavation would be disruptive, costly, or impractical. Some of the ideal situations for the use of this technology include:

1. Leak and seepage repair: To repair specific sections of leaking or seeping pipe without replacing entire pipe segments.

2. Emergency situations: In cases where a quick repair is critical to avoid major damage or service interruption, packers can be deployed quickly.

3. Dense urban areas: In cities where pipelines are located under busy roads, buildings or critical infrastructure.

4. Landscape and ecosystem conservation: In areas where excavation could damage the environment, such as wetlands, parks, or nature reserves.

A method with a simple process and great benefits

The packer system involves the insertion of an inflatable packer coated with silicate resin and ECR-Fibreglass into the damaged

30 TRENCHLESS WORKS | MAY 2024 PIPELINE REHABILITATION

pipe. This packer is strategically placed in the area to be repaired and inflated with air to ensure a tight and close fit conexion to the old pipe. The time required for the resin to cure and harden can vary between 45 and 180 minutes depending on the type of resin used.

Installation is simple and JBP offers free training with the first order, along with certification to install packers. The training includes both theoretical and practical sessions. Along with the training, a user manual and all the necessary information about the material used, such as technical data sheets and quality certificates, are provided. >

MAY 2024 | TRENCHLESS WORKS 31 PIPELINE REHABILITATION

32 TRENCHLESS WORKS | MAY 2024 PIPELINE REHABILITATION

Installing the packer system has several important benefits:

• Speeds up pipe repairs

• Suitable for a wide range of pipe diameters, from DN 50 to DN 1200

• Resins suitable for harsh chemical environments

• Suitable for waste water and sewer pipes

• Cost effective

• Permanent repair solution

It is important to remember that this method of repair is not suitable for all types of damage; for example, it cannot be used for complete collapses or very extensive damage. Other trenchless technologies are available for these situations.

JBP Patching System in the Middle East

The situation and conditions of the pipes in need of

rehabilitation or repair in the Middle East are very different from conditions we encounter across European networks. JBP’s business model as a solutions provider offering training, supply of materials and applications technologies has proven successful for local contractors working to address specific conditions found in the Middle East. This combination has established JBP as the market leader for patching solutions in the region.

As an Associate Partner of the Trenchless Middle East

International Exhibition in Dubai in November 2024, JBP will be showcasing its packer system, trenchless technologies, and other key aspects of the solutions it provides.

Low-maintenance

Long-lasting Sewer Management

• Superior pipes challenging today’s market

• Safe storage systems for storm- and wastewater

• Amiscreen – stormwater attenuation with built-in coarse material retention

• Amiblu NC Line – non circular pipes in all shapes

• Corrosion free and low carbon footprint

Amiblu Pipe Systems Designed for generations T +44 7786013574 | united.kingdom@amiblu.com | www.amiblu.com Call to book a meeting or Lunch & Learn Presentation! MAY 2024 | TRENCHLESS WORKS 33 PIPELINE REHABILITATION

Quick-Lock BIG system used for challenging underwater project

S1E Ltd supplied 11 Quick-Lock BIG mechanical seals for JIFMAR SCOTLAND who has been supporting an installation project on Gouthwaite Reservoir alongside Yorkshire Water and local subcontractors.

The project that started in July 2023, which has included creating a bypass of a dam by installing 80m of DN2000 pipe under water that initially was installed via excavation and float and sink methods, however, issues arose during a failed pressure test. During the installation the team found issues with leaking joints as water was coming through the flanges on the pipeline, because of the intense weight and pressure. Due to the timescales, the expense of labour and equipment, and the difficult access outside of the pipe, continuing to excavate on site was not an option as this project needed to be completed quickly and with minimal disruption – resulting in the need for a trenchless method to be used.

S1E Ltd were recommended to JIFMAR SCOTLAND, as a certified Quick-Lock partner, and they are the only UK official stockist and reseller. S1E Ltd worked with JIFMAR SCOTLAND so they had all the support, technical data, and equipment they needed for the repair, as they helped supply and deliver eleven of the new designed Quick-Lock BIG systems to site. The Quick-Lock systems are globally proven solutions to seal pipes and its design and trenchless installation methods made it compliant with the water authority’s requirements for an ecofriendly solution.

The installation of the QuickLock BIG systems was under

challenging conditions due to there being little to no more than 20cm of visibility when under water and inside the pipeline. Each mechanical seal needed two divers as they placed one mechanical seal on each flanged connection. Prior to installation, training with the divers took place above ground, which included blindfolds to try and replicate the unfamiliar working conditions, as well as preparing the seals with buoyancy aids to help with transportation in the water and inside the pipe.

“

It’s been great to work with both S1E and JIFMAR on this very unconventional project, and see its success. Our new designed QuickLock BIG system is far easier to install and has shown to be more efficient in this instance when working in such challenging conditions.

34 TRENCHLESS WORKS | MAY 2024 PIPELINE REHABILITATION

JIFMAR - QLBIG

The Project Manager at JIFMAR SCOTLAND, commented: “We were up against timescales, and needed to find a resolution that didn’t require anymore further work outside of the pipe. It’s fantastic we were able to find a simple solution in Quick-Lock so we could complete this project on schedule. The Quick-Lock BIG’s swift installation process enabled our team to create a watertight seal on the leaking joints easily.”

He continued, “S1E not only helped supply the solution but supported us throughout the process, both in the initial scoping phase and installation, with good communication, advice and of course, fast delivery.”

Quick-Lock mechanical point repair systems are made from high-quality and long-lasting materials, such as EPDM rubber and stainless steel. Their install requires no curing time and releases no emissions or foul smells and doesn’t involve excavation which helps reduce disruption and avoids additional equipment rental charges.

The systems are an efficient method of sealing pipes that are damaged due to corrosion, displaced joints, tree roots and ground movement, and are manufactured to suit an array of pipe materials including concrete, steel, cast iron, plastic, and glass-fibre.

Christopher Rings, Sales & Customer Service Europe at UHRIG Kanaltechnik GmbH, said, “It’s been great to work with both S1E and JIFMAR on this very unconventional project, and see its success. Our new designed Quick-Lock BIG system is far easier to install and has shown to be more efficient in this instance when working in such challenging conditions. We are looking forward to continuing to support our users and work in partnership with S1E and their customers.”

Quick-Lock BIG was designed for the renovation of individual damages in walkable and large diameter pipe systems up to DN 3000 and includes a reliable EPDM rubber seal with sealing technology that has a longlife expectancy and very high resistance.

Mechanical point repair systems have been used thousands of times globally, however it continues to be unknown to some contractors in the industry as a trenchless solution. Trenchless systems can reduce costs by 40%-60% and result in fewer disturbances to the public and the environment when compared to excavation methods.

Inversionstrommel

Inversionstrommel

UKSTT Member MAY 2024 | TRENCHLESS WORKS 35 PIPELINE REHABILITATION

Impregnation of the 70 metres of BRAWOLINER®

World record for HDD pipeline in India

Numaligarh Refinery Limited (NRL) completes Ganga River crossing as part of its mega crude oil pipeline project.

NRL is continuing to execute its ‘Numaligarh Refinery Expansion Project (NREP) which includes laying a 1635km cross country pipeline from Paradip Port in Odisha to Numaligarh alongside a significant expansion of the refinery itself.

As part of the project, a team comprising NRL, Engineers India Limited (EIL), and Trenchless Engineering Services Pvt. Ltd has achieved a major milestone with the safe and successful pullback of a 26” diameter pipeline section across the Ganga River in the East Indian state of Bihar.

The project utilised Horizontal Directional Drilling (HDD) and adopted the Intersection Technique to achieve the crossing length of 4027m. In doing so, it set a new world record as this is the longest distance ever achieved for a 26” diameter pipe. The whole

operation was completed in just 76 days, some 15 days ahead of schedule.

The work follows the successful completion of a 3510m HDD project across the Subansiri River, which connects Lakhimpur in the North and Majuli on the South side. To deliver this project, two giant 500mt rigs were positioned on both side of the river and used for the drilling, reaming, and pulling activities. The site’s remote nature made it even

more challenging, together with the fact that it remains flooded most of the year leaving a working window of only 4-5 months.

On completion of a final HDD project at the Brahmaputra River all the major HDD crossings for the Paradip Numaligarh Crude Oil Pipeline (PNCPL) will be complete. NRL plans to accomplish construction and commissioning of the PNCPL Project by mid 2025.

MAY 2024 | TRENCHLESS WORKS 37 HDD

Pipe pullback in British Columbia

Trans Mountain has successfully completed the pipe pullback for the Mountain 3 Horizontal Directional Drill (HDD) in the Fraser Valley between Hope and Chilliwack, British Columbia.

The work marks an important milestone in the Trans Mountain Expansion Project which will provide increased capacity to support Canadian crude oil production growth and ensure access to global energy markets. The largest project in the pipeline’s history, it involves installing approximately 992km of new pipeline, new and modified facilities including pump stations and terminals, and a new dock complex at the Westridge Marine Terminal in Burnaby, British Columbia.

The 4 May, 2024, marked the commercial commencement date for the Expanded System as all deliveries for shippers become subject to the Expanded System tariff and tolls. Tankers will be able to receive oil from line two by midMay.

Line fill on the Expanded System continues and is expected to be completed by mid-May. Both the existing and expanded pipelines are now able to transport crude oil and Trans

Mountain can load cargoes from all three berths. As of April 30, 2024, the expanded pipeline was 70% full by volume, and 69% complete by distance.

“Trans Mountain has demonstrated that challenging, long linear infrastructure can be built in Canada,” said Dawn Farrell, President and CEO, Trans Mountain Corporation. “With our project management team and contractors, we were able to build 988km of new pipeline, 193km of reactivated pipeline, 12 new pump stations, 19 new storage tanks, and three new berths at Westridge Marine Terminal in Burnaby. We did this while adhering to the highest environmental, safety and social standards including respecting and working with local First Nations and Métis communities throughout the entire process.”

After commencement of operation of the Expansion Project, Trans Mountain will continue cleanup, reclamation, road and civil work.

“With our project management team and contractors, we were able to build 988km of new pipeline, 193km of reactivated pipeline, 12 new pump stations, 19 new storage tanks, and three new berths at Westridge Marine Terminal in Burnaby.

38 TRENCHLESS WORKS | MAY 2024 HDD

2 Mountain 3 Horizontal Directional Drill pullback in the Fraser Valley between Hope and Chilliwack, BC.

Game changer! New era for pipe jacking and direct pipe projects with small and even non-accessible diameter: new planning possibilities, reduction in cost and construction time, increased daily output, maximum safety, ... ... and much more that TUnIS.pipelight, our new assistance system for automated control measurement has to offer. Find out! vmt-microtunnelling.com • Ability to transition liners to multiple sizes • Multiple bends up to 90 degrees • Increased consistency for calculating stretch and drawback WovoX: The Next Generation addition to the WovoLiner suite of products. No question, a GAME CHANGER! WORLD CLASS CIPP LINERS appliedfelts.com | 276.656.1904 | +44(0)1924 200535 A B C

Herrenknecht AG TBM launched for HS2

The fourth, and final, Tunnel Boring Machine (TBM) for HS2’s 13.5km Northolt tunnel beneath London, has now been launched.

40 TRENCHLESS WORKS | MAY 2024 TUNNELLING

TBM Anne, an Earth Pressure Balance Machine (EPBM) manufactured by Herrenknecht AG, weighs in at 1,700 tonnes and is 170m long with a 9.11m diameter cutterhead. This impressive machine was lowered in parts into the 25m deep crossover box at the end of last year and will now bore 5.5km from Victoria Road in Ealing, near HS2’s Old Oak Common station, to Greenpark Way in Greenford, alongside TBM Emily which was launched in February.

As it progresses, TBM Anne will install concrete tunnel rings with an external diameter of 8.78m and an internal

diameter of 8.10m, each made up of seven segments weighing approximately 7 tonnes. The ring segments are manufactured in Hartlepool and transported to London by train, following the reopening of a freight line at the town’s Dock.

TBM Anne is the eighth TBM to be launched across the HS2 project with almost half of the 105km of twin-bored tunnels has now having been excavated. London tunnels contractor, Skanska Costain STRABAG Joint Venture, delivered an extensive programme of work in order for the TBM to launch at the Victoria Road Crossover Box, excavating the caterpillar-

shaped box where eventually the trains will cross tracks on their way in and out of Old Oak Common station.

The other 8km of the twinbored Northolt tunnel has been under construction since 2022, with TBMs Sushila and Caroline both over halfway through their journey between West Ruislip, on the outskirts of London, and Greenpark Way. The four TBMs are all set to complete their journeys in 2025.

MAY 2024 | TRENCHLESS WORKS 41 TUNNELLING

UKSTT Member

Saudi Aramco approves Electro Scan for leak detection of buried non-metallic piping

Saudi Aramco (Aramco) has approved the use of Electro Scan Inc.’s electrical resistance technology for leak detection in buried non-metallic piping, in accordance with the company’s engineering requirements (SAER-12366).

The approval follows a benchmark challenge testing exercise on nonmetallic lines which was led by Electro Scan’s Managing Director, Brad Weston, and supported by members of UK team including Chris Fisher (Head of Sewer Projects) and Gwyn Jenkins (Head of Clean Water Projects).

Commenting on the successful approval Brad Weston said: “We are delighted to achieve this prestigious engineering designation after a successful field benchmark challenge that was held in Saudi Arabia by our hosts Aramco. A great team effort from the UK crews on the ground in Saudi with US staff providing online support.”

By measuring the change in electrical resistance of a pipe wall, Electro Scan is unique in its ability to precisely locate leaks, including the assessment of pipe wall integrity, and estimated leakage rates in gallons per minute or litres per second. Electro Scan’s use of low voltage, high frequencybased sensors automatically locates and maps each defect opening, thereby helping to better locate pipe defects.

Brad Weston went on to say: “This is just another example of Electro Scan’s FELL (Focused Electrode Leak Location) technology being benchmarked to locate those hard-to-find leaks in non-metallic pipe. It is a great tick in the box for an

organisation such as Aramco to back our claim and I would like to thank our hosts for all their hospitality while we were there.”

FELL has also been benchmarked in mapping pipe wall conditions of cement-based pipelines, including asbestos cement pipes and cement mortar-lined steel pipes, in addition to certifying new pipe installations as watertight.

Unaffected by ambient noise, flow velocities, groundwater levels, pipe pressures, or soil types, Electro Scan has re-purposed the use of highresolution underwater CCTV cameras to first identify defective pipe locations using Electro Scan FELL technology; then reposition in-pipe cameras at Electro Scan defect locations to conduct AI particulate tracing to confirm exit locations by clock position of a pipe.

“

This is just another example of Electro Scan’s FELL (Focused Electrode Leak Location) technology being benchmarked to locate those hard-to-find leaks in non-metallic pipe. It is a great tick in the box for an organisation such as Aramco to back our claim.

42 TRENCHLESS WORKS | MAY 2024 ASSET MANAGEMENT

High quality material, stainless steel From DN 100 up to DN 2000 JBP, your solution supplier for pipe rehabilitation MORE INFORMATION www.jbptrenchless.com | info@jbpcomposites.com Quick-Lock Liner-End, a perfect solution for sealing CIPP lined pipe ends

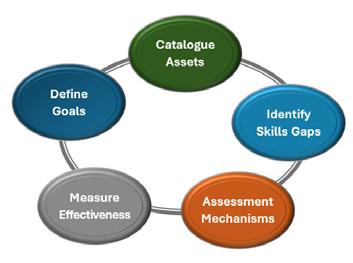

Identifying your training needs

“Probably the greatest challenge facing the water industry and our society today is making the most effective use of our workforce. Our most important resources are not our wealth and our machines, but our human resources. Equipment, capital, and methods are important, but human resources are the vital heart that makes our system work.”

By Frank Reilly - JBP Trenchless Training Director

Frank Reilly Director JBP’s Trenchless, Training Programme

Frank Reilly Director JBP’s Trenchless, Training Programme

This is a direct quote, slightly modified to bring it up to date, from a paper on Financing Water Utility Training by Donald D. Heffelfinger, published in the AWWA Journal back in 1969. It was tempting to give over this space to the whole of Mr. Heffelfinger’s paper, as much of what he described back in 1969 is as relevant today as it was then. Perhaps the main difference is that we now have a more complex and sophisticated mix of tools and technologies at our disposal and are at a point of inflexion with the advent of AI, where rapid change is inevitable.

I would suggest that it has never been more important to invest in training to make sure our ‘human capital’ is fit for purpose and prepared for the changes and challenges that lie ahead!

Precise figures are hard to come by for average spend on training in the trenchless sector, but a quick Google search of general spend on training reveals an average per employee of $1,200 in the U.S., between $1,400 and $930 across several European markets, and $650 in India. If one considers the contribution to a company’s activities, the value attributable

44 TRENCHLESS WORKS | MAY 2024 FOCUS ON TRENCHLESS TRAINING

to areas of responsibility, and the consequences of poor performance or error of judgement by an employee, then some may consider these averages to be on the low side.

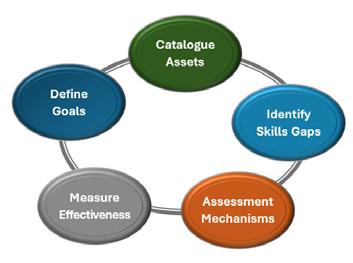

Training is indeed an investment, both in terms of direct costs and indirect costs through time committed. It may also not be immediately evident what the short-term benefits are, but, with the right metrics in place, it is possible to measure the benefits of good training programmes. Before committing to any training, a good starting point is to carry out a training audit. This process is scalable and can and should be carried out on a regular basis by all organisations, irrespective

of size. Not only will this ensure the right type of training at all levels, but it will also provide the framework through which to measure benefits for the individual and the company, making sense of the investment.

An effective training audit should include at least these five general areas: define the goals of the training; assess current knowledge and skills assets; identify knowledge or skills gaps to inform training needs going forward; develop mechanisms for assessments; measure the effectiveness of any training matched against identified goals.

One of the more impressive processes I have come across was where a company established an in-house continuous professional development (CPD) scheme, asking all employees to keep an individual training log, noting all aspects of training they had engaged with, whether it was a 15-minute YouTube video on Patch Repair, or a full threeday course in Sewer Condition Assessment and Coding. Training comes in all shapes

and sizes and at all levels. One of the benefits of this company’s in-house CPD scheme was to create a knowledge-hungry culture for continuous learning.

Targeted and well-delivered training does have a positive impact on the bottom line.

Next issue: Sources of training beyond the classroom

www.trenchless.training

MAY 2024 | TRENCHLESS WORKS 45 FOCUS ON TRENCHLESS TRAINING

READING

Hilton Reading, Drake Way, Reading RG2 0GQ

Wednesday 26 June 2024

UK trenchless sector hits the road to Reading

Westrade’s Managing Director, Paul Harwood, gives readers an update on the No-Dig Reading Roadshow.

We are now just weeks away from our No-Dig Roadshow of the year and excitement is really starting to build here at Westrade HQ as we launch yet another stellar conference programme.

The conference programme includes:

• Thames Water - Progress on the Thames Tideway Tunnel

• Wessex Water – Sewer rehabilitation - achievements in AMP 7, expectations for AMP 8

• SES Water - Resilience - water mains connectivity programme

Sessions are also being held on:

• Asset Management Plan 8 arriving April 2025

• Trenchless Knowledge Sharing supported by the UKSTT and ISTT

• Standards and Regulations for Trenchless – what’s happening and why?

J Join the conversation with UK thought leaders in trenchless technology.

Register for free at: www.nodigroadshows.co.uk

Our Roadshows are always tremendously well attended and this event, which is taking place at the Hilton in Reading on the 26 June, is no exception. I am also delighted to be able to confirm that the Roadshow is once again being held in association with UKSTT and that we are fortunate to be supported by no less than three major UK water companies

(SES Water, Thames Water and Wessex Water) all of whom will feature on the conference programme.

The success of these events is founded on the provision of unique, relevant, high-quality content and the Reading conference programme includes some of the UK’s leading authorities on underground utilities. Over the course of the day, delegates will hear about some the UK’s largest water projects together with the latest product updates and techniques for the installation, repair and rehabilitation of our underground utilities.

REGISTER NOW Sponsored by Organised by Official Media Partner Supported by www.nodigroadshows.co.uk

46 TRENCHLESS WORKS | MAY 2024 EVENT NEWS

Some of the conference highlights this time look set to include Francielli Thums, Programme Manager - Sewer Rehabilitation, at Wessex Water discussing ‘Sewer rehabilitation - What’s been achieved in AMP 7 & what to expect in AMP 8’ and an update on ‘Progress on the Thames Tideway Tunnel’ from John Sullivan, Head of Tideway Integration Group at Thames Water. We can also look forward to Jenny Rhodes, Head of Supply, Sutton and East Surrey Water presenting on ‘Resilience at SES Water’ and their water mains connectivity programme.

As always, the event will also host a fantastic exhibition

area with over 25 exhibitors including Vac-Ex, Quick-Pig, and the PE100+ Association which is currently celebrating its 25th year. Before, during and after the event, visitors will be able to see the sector’s innovation firsthand, while enjoying the Hilton’s excellent catering!

No-Dig Roadshow Reading is free to attend and registration is via the website.

For more information visit www.nodigroadshows.co.uk.

Hilton Reading, Drake Way, Reading RG2 0GQ

Wednesday 26 June 2024

Sign up for the next roadshow of 2024 in Reading supported by Thames Water, Wessex Water and SES Water.

AMIBLU NORWAY AS

BLUELIGHT LINING LTD

CHANNELINE INTERNATIONAL FIBER GLASS

MANUFACTURING LLC

CIPP SUPPLIES LTD

DCR INSPECTION SYSTEMS

DIE DRAW LIMITED

HY-RAM ENGINEERING CO LTD

IMS ROBOTICS UK LTD

MAMMOTH-MTS

MCALLISTER BROS LIMITED

PE100+ ASSOCIATION

PEARPOINT

PICOTE SOLUTIONS

PRO-LINING SOLUTIONS LTD

PUBLIC SEWER SERVICES LTD

RADIUS SUBTERRA

REINERT-RITZ GMBH

RELINEEUROPE GMBH

RSM LINING SUPPLIES GLOBAL LTD

STEVE VICK INTERNATIONAL

SYNTHOTECH LIMITED

TRACTO TECHNIK UK LTD

UIS LIMITED - TOOLING & TECHNOLOGIES

VAC-EX LIMITED

VIVAX-METROTECH LTD

READING

REGISTER NOW

Sponsored by Organised by Official Media Partner Supported by www.nodigroadshows.co.uk

Exhibitor List

MAY 2024 | TRENCHLESS WORKS 47 EVENT NEWS

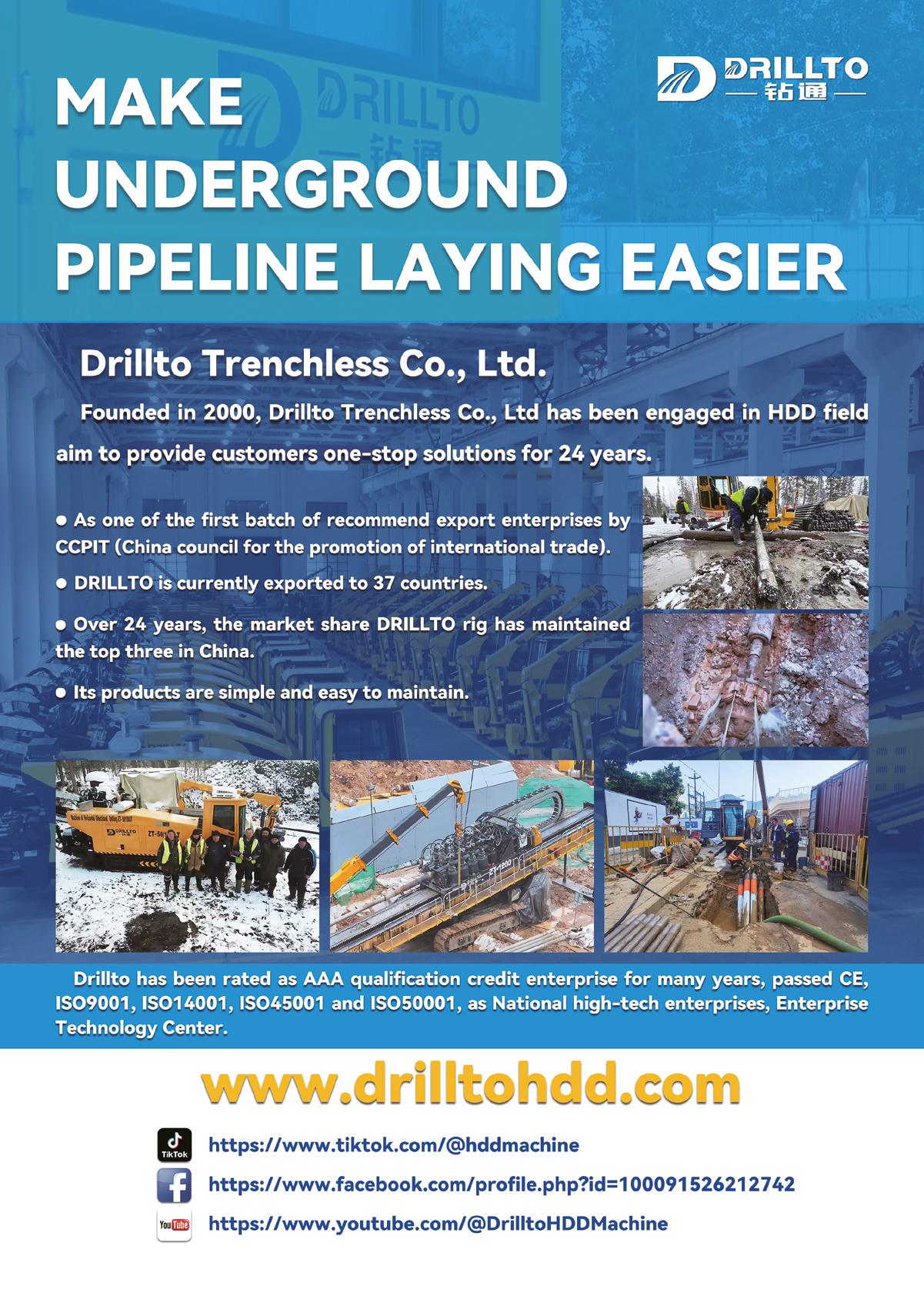

Trenchless sector set to shine in Philippines’ capital

Trenchless Asia heads to the World Trade Center Metro in Manila on 16 & 17 July, 2024.

Trenchless Works is delighted to reveal that Manila Water, Maynilad Water, Metropolitan Waterworks and Sewerage System, Philippine Tunnelling Society and the Hong Kong Tunnelling Society will all feature as part of the Trenchless Asia conference programme sponsored by the PE100+ Association and Herrenknecht.

Visitors to Manila will hear from the sector’s key innovators discussing the latest installation,

repair and rehabilitation techniques and bringing them to life with case studies from around the world. There will also be updates on some of Asia’s biggest underground utilities projects with CPD points available for all conference attendees. An exciting addition to Trenchless Asia 2024 will be a bespoke training programme delivered by Westrade’s training partner JBP Group. We look forward to sharing more details on this in next month’s edition.

Trenchless Asia continues to cement its position as the leading trenchless technology exhibition and conference for the Asia-Pacific region, a fact that is reflected in its impressive line-up of Platinum Sponsors which includes PipeSolution Inc, Vermeer, XCMG, USAE, Drillto and DCI. Over the course of the two days the event provides a unique platform for professionals from across the trenchless and underground utilities sectors to exchange knowledge, share experiences,

TRENCHLESS ASIA 2024

16-17 July

World Trade Center Metro Manila, Philippines

www.trenchlessasia.com

Experience the Future of Underground Infrastructure: Trenchless Asia 2024 Platinum Sponsors Chinese Partner Conference & Drinks Sponsor Conference Sponsor Supported by Organised by Official Media Partner Chinese Partner Training Partner Catering Sponsor

EVENT NEWS

and explore the latest innovations and best practices in trenchless technology.

Alongside the world leading conference programme

Trenchless Asia’s packed exhibition hall will provide a unique opportunity for visitors to access over 80 of the sector’s leading product and service providers. There are also numerous informal networking opportunities including a drinks reception kindly sponsored by Herrenknecht and a magnificent lunch courtesy of Rockpecker.

For further information please visit the Trenchless Asia website www.trenchlessasia.com.

Register now for Trenchless Asia 2024 and secure your place in shaping the future of trenchless technology!

Discover cutting-edge technologies, network with industry leaders, and gain invaluable insights into the world of trenchless construction.

We’re delighted to confirm speakers from the following organisations:

• Metropolitan Water Works and Sewerage System

• Maynilad Water

• Manila Water

• Philippine Tunneling Society

• Hong Kong Tunnelling Society

• Malaysia Association for Trenchless Technology

And many more industry experts including Prof Sam Ariaratnam from Arizona State University

Your FREE ticket includes:

• Two-day access to the conference

• Access to the exhibitors specialising in the most innovative trenchless techniques

• Certificate of attendance and CPD and CCD points

• Networking drinks reception on day one

• Free catering with lunch and refreshments

Register to attend via: www.trenchlessasia.com and look out for updates on the conference programme.

www.trenchlessasia.com

FREE TO ATTEND

EVENT NEWS Success in Trenchless Asia

A message from the Chair

Well at last we are seeing some good weather and summer looks like it’s not far away. Of course, the trenchless industry has its own issues and challenges. I often talk about the issue surrounding “sewer spills and discharges” due to excess rainfall entering the network, this is well publicised and gets a lot of media coverage. However, an area that is also very concerning is the capture of rainwater and its use. I was in California recently and they have had an unusually wet winter. Their biggest issue is with water capture. Around 90-95% of the rainwater that hits the ground ends up in the sea. Their infrastructure is just not set up to environmentally capture and utilise the excess water.

Similarly, I am coming back from meetings in Spain, and the discussion there is similar to California. The rain in Spain does not just fall mainly on the plain, but falls on the cities too. The major authorities are looking into improved methods of capturing the rainwater, primarily for farming but also to save costs and improve the environmental factor.

Interestingly, United Utilities in the UK have a pilot scheme for rainwater capture that they recently promoted and the results are looking promising. The whole

concept of hose pipe bans and water restrictions seems far away from the flooding in winter. However surprisingly to go from one extreme to the other does not take long depending on the geography and where people live in the UK. A prolonged period of dry weather really starts to cause issues on water and water retention. Springs dry up, reservoirs are depleted and issues start again. 2 years ago the heat wave above 40 degrees is a good example.

So, in a nut shell, the infrastructure needs to be drastically reviewed. We can turn to other countries, experts, etc but fundamentally it can’t cope in the long term. Lateral thinking as well as investment is key.

On 11 June UKSTT is holding its first National Trenchless Conference where we will be discussing future opportunities and the regulations that inhibit trenchless innovations. We will also have some interesting seminars highlighting these issues at No-Dig Live in October. If you would like more information on either of these events please email admin@ukstt.org.uk

Ian Ramsay, Chair, UKSTT

MAY 2024 | TRENCHLESS WORKS 53 UKSTT NEWS ukstt.org.uk Society News brought to members by Trenchless Works SOCIETY NEWS

Ian Ramsay, Chair, UKSTT

Entries are open for UKSTT awards

Each year the UKSTT has annual awards to promote excellence in trenchless technology and this year the awards will be made at the Society’s Annual Dinner & Awards Ceremony that will be held during No-Dig Live at Stoneleigh Park on the 2 October 2024.

The awards recognise the outstanding contributions made by organisations and individuals to the promotion, use, and development of Trenchless Technology in the previous calendar year. The awards themselves are open to all aspects of Trenchless activity. Entries for overseas projects will be accepted provided they are submitted by UK companies who either did the work or

supplied the equipment as well as entries submitted by overseas companies for work carried out in the UK.

For each of the categories a panel of independent judges, many of whom are not necessarily members of the society, are carefully selected to be representative from a broad cross-section of the relevant

industries. For further category information and criteria or to access the online application form please visit the UKSTT website. The call for entries closing date is Sunday 7 July.

https://www.ukstt.org.uk/ ukstt-annual-dinner-awardsceremony/

Charity support at UKSTT Gala Dinner & Awards Ceremony

UKSTT are proud to be supporting two charities at this year’s Gala Dinner & Awards Ceremony

Motor Neurone Disease Association – MND affects the nerves known as motor neurones. These nerves are found in the brain and spinal cord and they help tell your muscles what to do. With MND the messages gradually stop reaching the muscles which leads the muscles to weaken, stiffen and waste, which can

affect how people walk, talk eat, drink and breathe. The MND Association focuses on improving access to care, research and campaigning for those people living with or affected by MND in England, Wales and Northern Ireland. https://www.mndassociation. org

The Christie Charity – The Christ Charity provides enhanced services over and above what the NHS funds. As one of the largest hospital charities in the

UK, they promise to ensure that they are spending your donations as cost-effectively as possible, with 82p of every £1 raised going directly to their cancer patients.

https://www.christie.nhs.uk/ the-christie-charity

54 TRENCHLESS WORKS | MAY 2024 UKSTT NEWS

Technical & education report

Final preparations are being made to the line-up of speakers for the National Trenchless Conference with an overarching theme around driving greater use of trenchless. There will be five one-hour sessions and three coffee breaks/lunch between them, giving 2 hours of networking opportunity during the day, not including networking before and after. The topics will coverdemonstrating the benefits of trenchless; standards and regulations – help or hinderance; recruitment to trenchless; increasing awareness of trenchless among customers; and future opportunities – new networks needing trenchless.

No-Dig Roadshow Reading, 26 June

The programme for the Reading No-Dig Roadshow is being developed. A reminder that No-Dig Live in October (1 to 3) at its new venue Stoneleigh Park offers an exciting new opportunity to re-vamp UKSTT events during the show because the conference area will be within the exhibition hall next to the UKSTT stand, not in a building outside the hall, as it was in Peterborough.

Standards, Research & Awards Chair: Richard Swan

The awards process for 2024 is progressing, the categories are the same as last year, following feedback there are some changes to the submission form. The pop-up banners

detailing the winners and shortlisted from 2023 will be used at the conference and at Reading No-Dig Live in June.

Regulations and standards – help or hinderance will be one of the sessions at the conference in June and we are looking forward to interesting presentations and discussion on them.

Education, Client Organisations & Patrons Chair: Tim Sargent

Our primary focus is switched to encouraging Patrons and Education establishments to be more actively engaged in the society. This is being demonstrated through the speaker line up and attendance at No Dig Live events and Masterclasses. Tim will be chairing a session raising awareness of Trenchless at the UKSTT National Conference on 11 June.

Richard Swan

Tim Sargent

Iain Naismith

Richard Swan

Tim Sargent

Iain Naismith

MAY 2024 | TRENCHLESS WORKS 55 UKSTT NEWS

Council member report

On 25 April, members of the UKSTT Council met at Camden House in Warwickshire to discuss the society’s plans. There is a busy year planned so there was a lot to discuss.

Highlights

CIPP Masterclass Update - In total 71 attendees registered and attended the UKSTT masterclass on the 20 March at the Woodland Grange making for a very successful event with lively discussions thanks to the organisers, speakers, and delegates.

The first UKSTT Trenchless Conference - all exhibitor places have been sold and the programme will be released very soon.

No-Dig Live 2024 - we are all looking forward to No-Dig Live this year and we are in constant discussions with Westrade to make sure we support it as best as we can.

Annual Dinner & Awards Ceremony - Awards are now open for entries. Supported charities will be the MNDA & The Christie Charity. Discussions on how we can best support these charities took place and sponsorship packages were agreed and will be available to purchase soon. A co-host was agreed upon and as soon as their availability has been confirmed we will update everyone.

Plans are being taken to ensure the continuity of the council and smooth transition between Chairs.

A Chairman’s advisory panel has been approved. This panel will consist of all past chairs who wish to be involved with the Society and provide valuable insight into past and future actions.

56 TRENCHLESS WORKS | MAY 2024 UKSTT NEWS

Technical enquiries

The UKSTT website has a dedicated link for visitors to raise any technical enquiries you may have concerning trenchless technology and whether it may be applicable to any specific project: https://www.ukstt.org.uk/ technical-enquiry/

We have had a variety of interesting enquiries recently, ranging from invitations to tender in various locations of the UK & Europe, to requests for advice and proposed solutions for projects currently on-going. All of these enquiries are circulated to our Corporate Members, and if more detailed advice is required UKSTT have

a dedicated team who will advise separately. All technical enquiries are stored on the members only area of the UKSTT website.

For all your trenchless solutions and latest news, visit the UKSTT website. https//www.ukstt.org. uk/

UKSTT Council has a dedicated technical subcommittee to offer advice, support and guidance.

We have an extensive list of members experienced in all aspects of trenchless technology, who want to help you!

For all your trenchless solutions and latest news, visit the UKSTT website: https//www.ukstt.org. uk/

Email us: admin@ukstt.org.uk

MAY 2024 | TRENCHLESS WORKS 57 UKSTT NEWS

SOCIETY NEWS

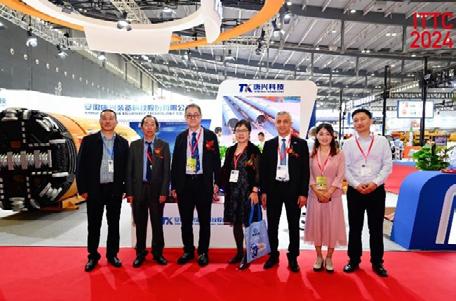

A message from the Chair

Dear ISTT members

As you may know that we have been having many national and regional No-Dig events in 2024. I believe the events in the following few months will be more active and prosperous, so please do not forget to check the event calendar in the ISTT website. As you may remember, I have attended the No-Dig events in many countries, and will continue to do it in Latin America, France, Hong Kong, Japan, Malaysia, Middle East, Turkey, etc. The ITTC 2024, the 27th annual meeting of CSTT, accommodated more than 120 exhibitors and 4000 registered attendees. It also set up a good example for the national event being more international.

In addition to the intercontinental ChinaEurope TT Conf., the cooperation between Asian societies, the bi-lateral and multi-lateral cooperation also help in developing new technologies and good business. Through the regional events, like 2023 Trenchless Latin America, 2023/2024 No-Dig Turkey, and the 2024 ITTC, the organising societies

successfully attracted the spotlight by integrating the governing sector, consultants, contractors, suppliers in trenchless business, also created more cooperation between the affiliated societies in their region. I strongly believe the regional No-Dig conferences will be the major trend in the next few years. Obviously, the demands and challenges in different regions also create different good opportunities.

I would like to remind you that we will soon have 2 more new ISTT educational webinars, please do not forget to check the notice and register in ISTT website. On the other hand, please kindly be patient about our website as it is now under an overhaul process. Again, ISTT will try to provide more services to our affiliated societies. Please do not hesitate to let us know should you have any suggestions.

All The Best!

Keh-Jian (Albert) Shou Chair, ISTT

Keh-Jian (Albert) Shou, Chairman, ISTT

MAY 2024 | TRENCHLESS WORKS 59 ISTT NEWS

ITTC 2024, Changsha, China

ISTT News brought to members by Trenchless Works

ITTC 2024 - A great success

As a poet once said: Changsha, China is such a place where talented people come from, and will be a gathering place for more talented people. The annual event of the “Trenchless Community” - the 27th China International Trenchless Technology Conference and Exhibition was successfully held in the city from 24 to 26, April 2024 at Changsha International Convention and Exhibition Center.

With an exhibition area of nearly 20,000 square meters, the exhibition brought together more than 120 companies worldwide to showcase their latest products and technologies. A total of 8,080 visitors attended the exhibition during the three day

exhibition. Among which, 3,718 professional visitors from 19 overseas countries and regions and 32 provinces, municipalities, autonomous regions and special administrative regions across the country registered to visit the exhibition, and 172 people registered to participate in the seminars.

Among the exhibitors, 24 companies made their debut, accounting for 20% of the total exhibitors. 90% of the exhibitors brought dozens of physical exhibits to showcase the latest technologies, products and solutions, and comprehensively demonstrated the new pipeline construction and aged pipeline rehabilitation of trenchless technology in municipal,

petroleum, electric power, communications, gas and other fields. Cutting-edge development trends and innovative technologies. ITTC2024 provided a learning and communication platform for professionals in the industry.