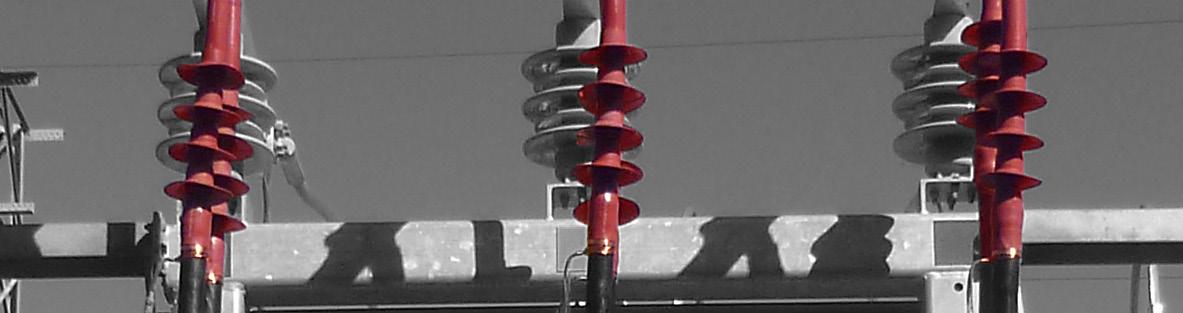

Raychem first came to NZ in the 1970s. As the country moved away from lead covered cables new joint closures were required for the new PVC telecom cables being installed. Heatshrink LV and HV terminations and joints were introduced and proved to be an excellent solution as they were able to be adapted locally for the many varied applications of the 40+ utilities at that stage.

Even as cable designs, switchgear designs, and the workforce itself has changed, these factors continue to be important and still provide the key reason for the continued success of the product as TE keeps evolving heatshrink and other technologies. TE's products suit the NZ market well because they can focus on customer requirements locally, which enables them to customise their cable accessories to suit customer-specific requirements.

As a material science company TE develops high quality materials suited to a wide variety of applications. TE has now expanded their Raychem range of capabilities from heatshrink to cold shrink, cold applied, and resin encapsulation materials, with an eye towards introducing solar connectors and smart technologies in the future.

The days are getting shorter and cooler and it's time for a bit of a glucose hit to get us through the long night shifts, so this month we've returned to our friends at the LollyShop in Christchurch for this month's locally made giveaway from

a family run business. This time we've selected a good old fashioned jelly mix full of all the classic Kiwi favourites. Do you fancy a snake or are you more of a strawberries and cream person? Do

https://lollyshop.co.nz/

you have strong opinions about the tastiest colour? We reckon there's a bit of something special in there for all our customers.

"The success and fast adoption was driven by local technical expertise backed up by overseas resources, the ability to develop and build products to suit local applications, an emphasis on training, and field support."

- TransNet General Manager Ed Cheeseman

Designing TE Raychem kits to suit a wide variety of applications makes Technical Support very rewarding and at times challenging. TE has special kits specifically tailored for most of our customers as requested, with over 2500 kits already in a database that is still increasing year on year. Some of the new product introductions driven by NZ are the Rayvolve Roll on 11kV Bushing Insulation Sleeve used on Magnefix and SD Switchgear, as well as more recently 2W and 4W Screened Elbow Bushing assemblies for 1000mm2 33kV cables.

TE has been involved is many major projects over the years, including submarine joint applications, wildlife asset protection projects, cable jointing projects involving 12, 24, 36, & 72kV throughout NZ, and the Christchurch Earthquake response. Each one had its challenges but with ongoing technical back up, training, onsite supervision, worldwide technical expertise, a large stock holding at

TransNet, and technical internal staff members, TE is able to get each job done well.

Over the last two decades TE's close relationship with TransNet has been an asset to both, and

today TE is TransNet's biggest supply partner in addition to TransNet being the sole New Zealand distributor with the only independent TE approved Raychem kitting room outside of Europe. TransNet's specialist Raychem staff work closely with both local and international TE technical experts to provide a level of service that is backed by global knowledge but also refined to suit our specific needs here in New Zealand. We look forward to another 50 years of getting the job done right.

"Coming up with designs to suit small niche applications is rewarding once the product has been type tested and used in the local market."

TE Connectivity Technical Sales Manager Paul Godfrey

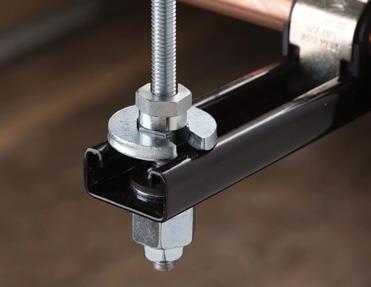

This innovative slotted design allows side mounting of the nut to threaded rod. Ideal for retrofit projects.

Use as a stopper when installing Rod Lock assemblies

Ready to use out of the box and eliminates multiple pieces of standard hardware

Functions as a hex nut and flat washer combined

Washer is wide enough to work with standard strut channel profiles

Allows side mounting of nut to threaded rod

Reduces the need for threading compared to standard nuts and washers

Ideal for retrofit projects, such as trapeze installations, where disassembly of the support system is not desired

Works with slightly damaged threads and minor burrs on the threaded rod

Reduces installation time up to 50%

A combination of a slotted channel washer and nut that can be easily installed, removed, and repositioned at any location along a threaded rod. Ideal for retrofit projects where disassembly of the existing trapeze is not desired.

More and more contractors are leveraging the efficiencies provided by prefabrication, including:

• Cost savings

• Better time management

• Safer installations

With prefabrication, assembly is completed in a space devoted to the production and storage of components. By completing these tasks off-site, contractors can mass-produce assemblies used in similar projects, and on-site installers can focus exclusively on mounting the finished product.

Rod Lock “Push-to-Install” technology allows prefabrication of complex assemblies off-site or on the ground. Large assemblies can simply then be lifted and locked into place.

The process requires less time on the job site, allowing for more tasks to be completed in a controlled off-site facility. As a result, prefabrication reduces installation costs, enables schedule flexibility and improves safety. While results may vary based on specific product and application, studies have shown the unique features of the Rod Lock system help reduce the installation time of threaded rod by up to 52 percent compared to conventional fasteners.

“Push-to-install” Technology

• 145lm/W using Luxeon

• Capacity to add motion and/or daylight sensor

• Programmable motion sensor using optional remote control

• Switchable power output and colour temperature (at time of installation)

• All units are supplied standard at 5000K and 200W from the factory

• Power adjustable: 100W, 150W and 200W

• Colour Temperature: 4000K, 5000K and 5700K

SENSOR OPTIONS HIGH PERFORMANCE

• 3 seconds easy plug-in scalability

• No re-circuiting or new control wiring

• Provide interfaces for follow-up system expansion

LEDIL58-REMOTE (sold separately)

VIEW SPECS

FB145SS19R1STDO

Recessed Steel Lid Outlet Box 2x Power

POWDER COATED ZINC

ANNEALED STEEL BODY

STAINLESS STEEL LID & FRAME

RECESSED LID FOR FLEXIBLE FLOORING OPTIONS

SINGLE CABLE EXIT FLAP

25MM KNOCKOUTS

PROVIDED FOR EASY

CONDUIT ENTRY

TWO AUTO SWITCHED POWER OUTLETS SUPPLIED

available with 2 usb ports

FB145SSF1STDOUSB Flush Steel Lid Outlet Box 2x Power 2x USB Charge

FB145SSF1STDO

Flush Steel Lid Outlet Box 2x Power

POWDER COATED ZINC

ANNEALED STEEL BODY

STAINLESS STEEL LID & FRAME

DOUBLE CABLE EXIT FLAP

25MM KNOCKOUTS

PROVIDED FOR EASY

CONDUIT ENTRY

TWO AUTO SWITCHED POWER OUTLETS SUPPLIED

Carcass dimensions WxLxD 125x125x105mm (130mm D including lid), 150x150x22mm lidOur onsite Auckland test lab checks all brands of test & measurement equipment quickly and expertly. All checks and calibrations are traceable as our instruments are calibrated by IANZ Accredited or equivalent labs.

Most suitable for Digital Multimeters, Clamp Meters, Voltage Testers (e.g., Duspols) and similar lower cost instruments.

This procedure is most suitable for mid-range, multifunctional instruments like Electrical Installation Testers, Appliance Testers, Micro-Ohm Testers and Insulation Resistance Testers (up to 10kV) - or similar.

This procedure is recommended for highly accurate and complex instruments like Power Quality Analysers, top range Installation Testers, Process Meters etc.

We can do an inspection when you’re not 100% sure what the problem is. We’ll do a detailed check and confirm any out-of-range readings, or tests that it is unable to perform.

If you already know where the issue lies, then your instrument is due for a repair. Usually, but not always, this means your instrument will have go back to the manufacturer. This may take several weeks before you get it back, but it will return completely checked and up to manufacturer’s original specifications.

testlab@transnet.co.nz