Tom Evans Product Design Portfolio

Tom Evans Product Design Portfolio

Tom Evans Product Design Portfolio

Tom Evans Product Design Portfolio

About Me

Education

• Nottingham Trent University 2022 - 2026 BSc (Hons) Product Design

• St Katherines Sixth Form 2020 - 2022

4 A-Levels and an EPQ - A* to A

• St Katherines School 2015 - 2020

11 GCSEs - 9 to 6

Skills

Hi, my name is

I am a creative designer with a passion for imaginative and playful products. I remain grounded with a technical and manufacturing focused design process.

I pride myself on my proficiency in CAD software. I use these CAD skills to design technically focused products with ergonomics at their core.

Contact Me

tom.evans2903@gmail.com

Certifications

www.linkedin.com/in/tom-m-evans/

tom.evans.designs

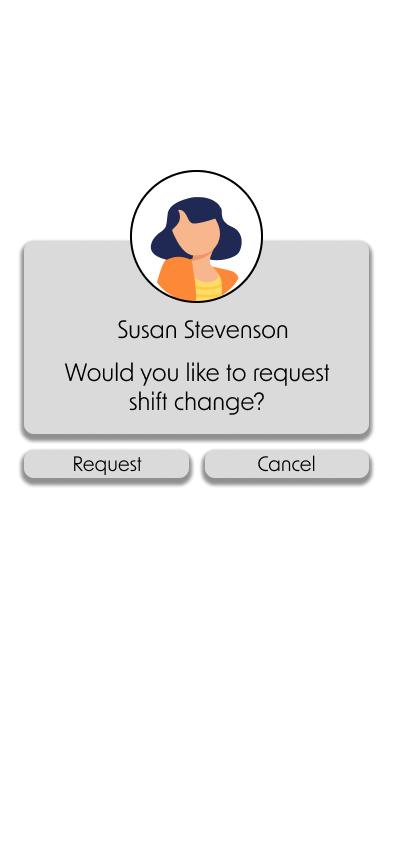

1 Learning Pool - 1 Week (Group)

Design Brief

Create a streamlined on-boarding solution for the hospitality industry that increases employee retention as well as making it easy for both managers and employee to monitor and manage shifts

Research

Selling Point

Hospitality

Within the on-boarding process the hospitality industry has to teach certain things such as food safety and handling as well as alcohol service.

These would be taught within the app and there would be an additional rota to help employees manage their time and schedule.

55% of companies do not measure how effective their on-boarding is

In the research we found the areas we wanted to add within our app these included a quick quiz for the on-board and training, a leader board to get employees excited about working and a rota so employees can easily see their schedule.

This would set it apart from others as it combines multiple apps employers use into one app.

50% of hourly workers quit within the first 120 days

On-boarding

New hires can be expensive as a new hire in the hospitality industry costs £50,000 including salary and training cost.

By shortening and streamlining the onboarding process it will decrease the cost to the company to hire new people.

An effective on-boarding process can increase retention by 84%.

Development

Initial --> Concept

Within the group I developed the rota viewer for both the manager and the employee.

Through my ideas a sleek and easy to use system was made with simple touch controls and swipes.

Final Product

Product Use

In order to make a high fidelity model we used Figma. This allowed me to make a full accurate model of the rota and implement the swipe and touch controls.

This created a working model for a presentation to the client.

2 Design Inovation Plastic - 4 Weeks

Design Brief

Design a product that will make bath time more fun and safer for young parents and their children.

Research

User Profile

The user persona I chose was new parents of young children. This is so I could incorporate new design that will both entice them and the children to use the product. They would be eco-conscious and shop at places like IKEA and John Lewis.

Mood Board

Before starting designing I collated a mood board of products with similar style and colours.

I used these to give a direction to the style and aesthetic of modern children’s products.

Development

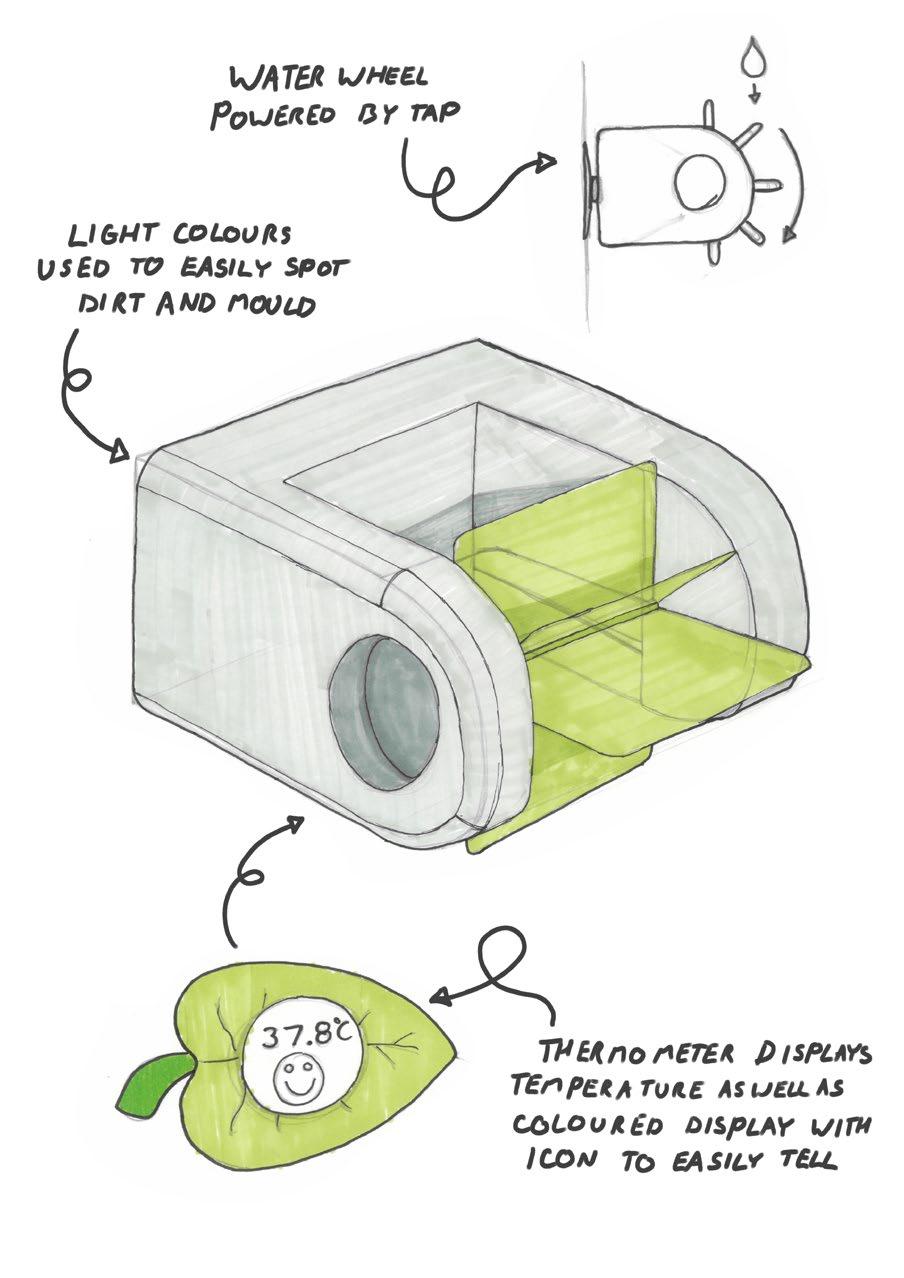

Ideation

Through my ideation I created the design for the water wheel. The product would turn the kinetic power of water into electricity to power the thermometer. However as development went on it no longer hung by the tap but stuck to the bath.

Modelling

In-Context Model

In order to have a better idea of size 1:1 scale models were made in order to check dimensions against the setting.

I took these models to some actual baths to see what it would look like in context with both size and aesthetics.

Technical

Manufacture Detail

The final parts were designed for injection moulding with ribs, bosses, lips and grooves.

The lip and grooves allow the parts to easily fit together. The ribs add support to the larger sections of the part. The bosses allow standard components to join parts together.

Suction Cups

Anti-microbial HDPE Casing

Wireless Charging Station

Removable Water Wheel

Thermometer Base with magnet

3 Starpack - 4 Weeks

Silver Award Winner

Starpack Students 2023

Design Brief

Design a bottle for Ribena that promotes the world cup as well as elevating Ribenas core values. This bottle must appeal to both adults and children.

Ribena

Ribena is a soft drink brand from England. Ribena sells millions of drinks a year with its ready to drink bottles being a large portion of their sales. Ribena’s core values are fun and giving consumers the “Ribenary feeling”.

Their new marketing campaign is aimed towards young adults and children by making light of awkward interaction we all experience.

World Cup 2022

The World Cup is watched by billions of people all over the globe. This huge viewer base is easily marketed to as 83% of viewers would consider buying something that they had seen advertised at the world cup.

Soft Drinks Market

The soft drinks market is a huge market valued at 434.50 Billion USD in 2022.

With this large of an industry there is a huge amount of waste that comes out of it with Billions of bottles a year not being recycled and sent to a land fill.

Development

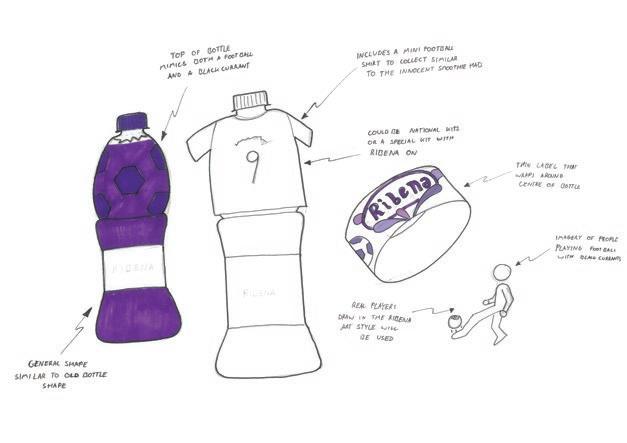

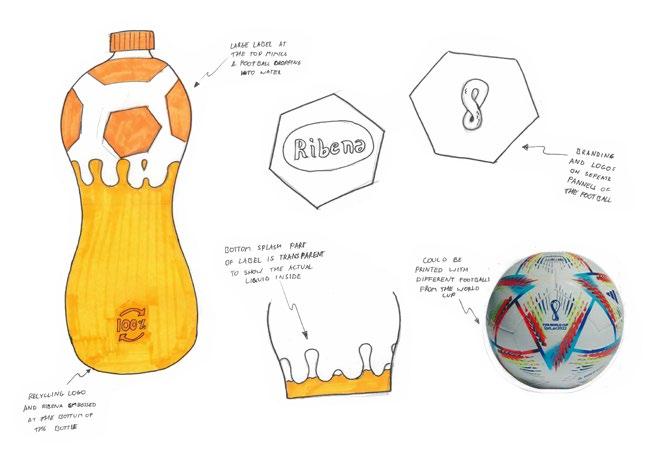

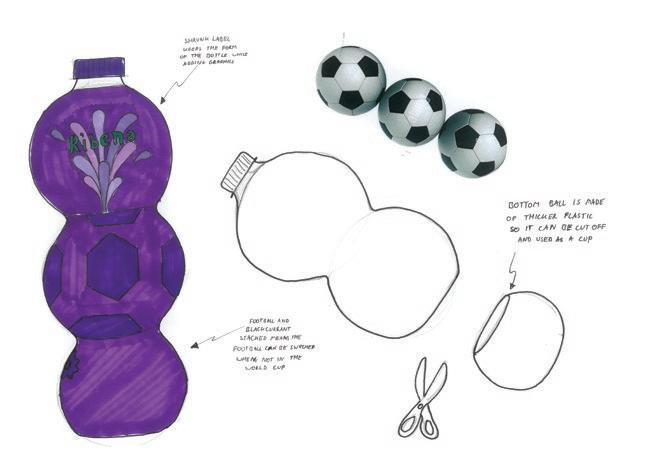

Concept --> Final Design

Each initial concept captured both Ribena in a different way. The design I chose to finalise is the bottle that would stand out the most on a shelf of other soft drinks by being a unique shape.

Final Product

Final Design --> CAD

After finalising the design I produced a high quality Solidworks model. This included small details such as the PET symbol and food safe symbol.

CAD --> Final Model

After the CAD model was finalised, I printed the bottle on an FDM 3D printer. I printed out the label on acetate and wrapped it around the bottle.

This model is a low fidelity model as the small details around the base are not as accurate as they should look.

Technical Drawings

After the final model was made I created tech drawings of the bottle that would allow manufacturers to prepare a mould for making it. These tech drawings give the overall dimensions for a 500ml bottle with the Ribena preform.

Manufacturing

Labelling

The new labels have an overall simpler style with simple vector graphics in line with their current marketing. This allows the label to be easily transfered to the other flavours.

Manufacturing

The bottle will be made via blow moulding. This is done with a mass manufactured PET preform from logoplaste. These are the same as the current Ribena preform that is made of 100% recycled plastic.

The label will be shrink wrapped to the bottle to only the top sphere in line with the current bottles.

4 Alpkit- 1 Week (Group)

Overall 1st Place

Design Brief

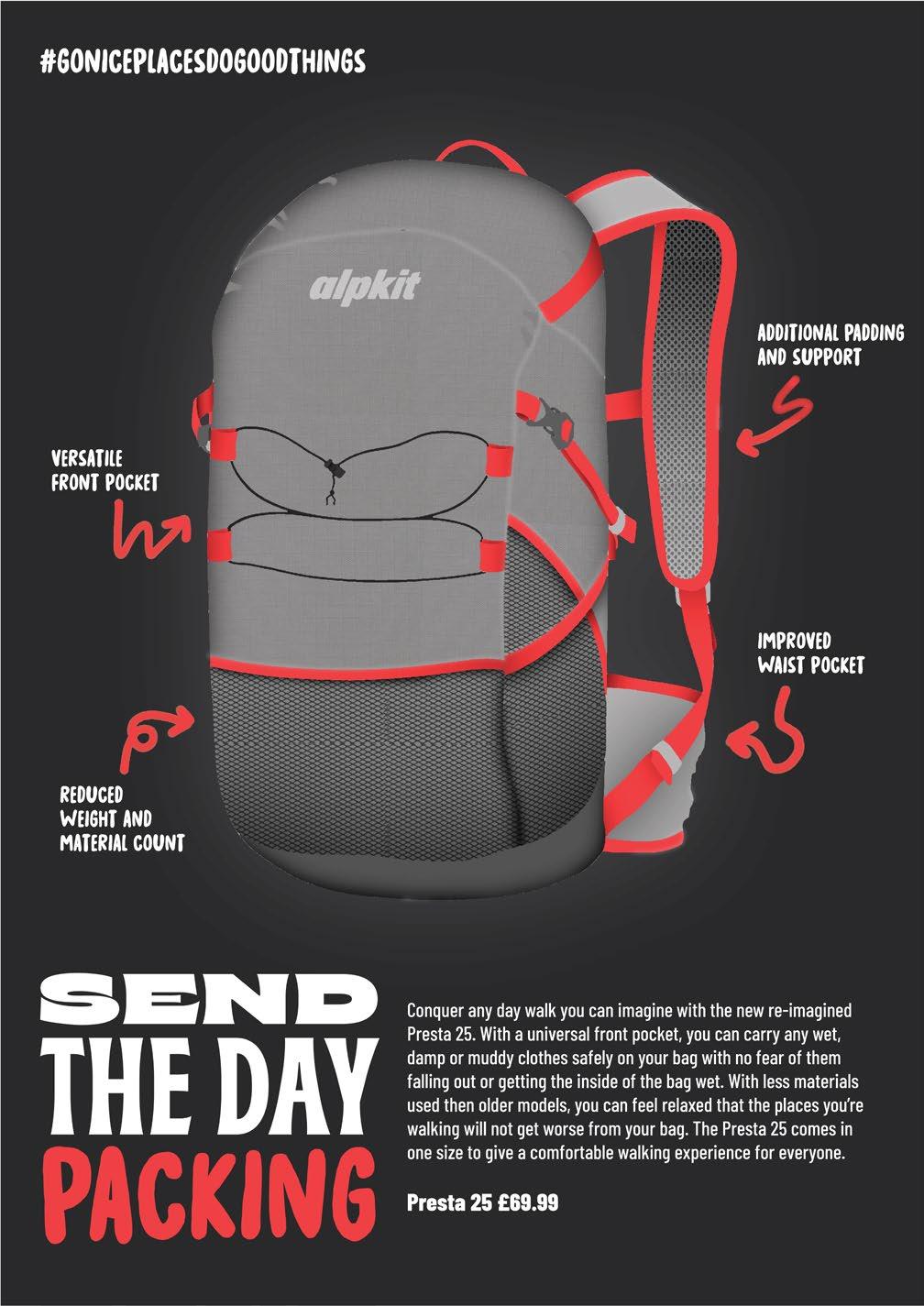

Redesign the Presta 25 rucksack to have a lower carbon footprint while increasing the functionality.

Research

Common Issues

To start designing we did some primary research of testing the bag in store and outside.

We then compared the problems we noticed with reviews and found that similar features were cropping up.

We then used these reviews to improve the overall design.

I find it a bit short in the back and so not hugely comfortable for me - I am just over 6ft.

the hip straps aren't the most supportive, not the comfiest to wear if the bag is heavily loaded.

it’s missing a key feature, namely no secure clip on outside of pack rear pocket

LCA and Tear-down

In order to measure the difference in carbon dioxide produced we used a life cycle analysis in order to get a rough number.

We did this by taking the bag apart and weighing each part. This allowed us to put it into a spreadsheet that calculated the carbon emitted by the fabrication of each part.

Development

Our Changes

From the user research and LCA we found what we wanted to change. This included reducing the number of materials used and to stop using the carbon heavy materials to save on cost and reduce the carbon footprint of the bag.

We also redesigned the front of the bag to fix the issues brought to us by the reviews.

Final Product

712g of CO equivalent saved on each bag 2

60g lighter than original

Materials

In order to both reduce the weight of the bag and the carbon dioxide produced during manufacture, new materials were chosen. Originally Nylon 140D twill spandex stretchy mesh was used for the front pocket. Not only is this material heavy but also very carbon intensive and expensive.

By changing this material to polyester mesh net we saved a large portion of carbon per bag. The overall change in carbon worked out to an 8% decrease from the original amount.

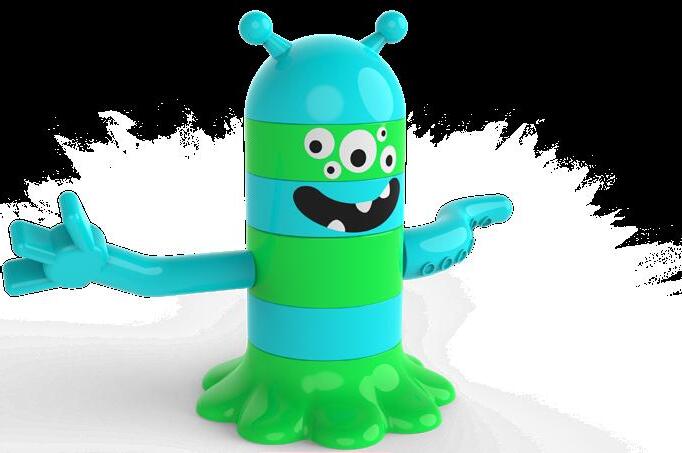

5 Clockwork Toy - 4 Weeks

Design Brief

Design a clockwork toy inspired by DUPLO for a young child of 3-5 that develops their curiosity for space while also giving a good play experience with parents.

Research

Clockwork Motor

The motor inside the toy is a wind up motor that I removed from a previous toy.

This motor spins after being wound up for a short amount of time. This works by a small coil of wire and holding energy and then being released.

DUPLO

User Profile

Thetoywasdesignedfor a young child of 3+ years old. They like space and undersea exploration similar to shows such as Octonauts.

DUPLO as a brand is the toddler friendly aspect of LEGO. This means the bricks are bigger and cannot be swallowed by young children. Their themes are also often based on more playful aspects of life with simple jobs and vehicles being a large portion of their library

Development

Initial --> CAD

The initial ideas from the brief transitioned into the concept below because of the minimum size for toys for toddlers.

Once the design had been finalised I took the parts into Solidworks to accurately plan and model them

Final Product

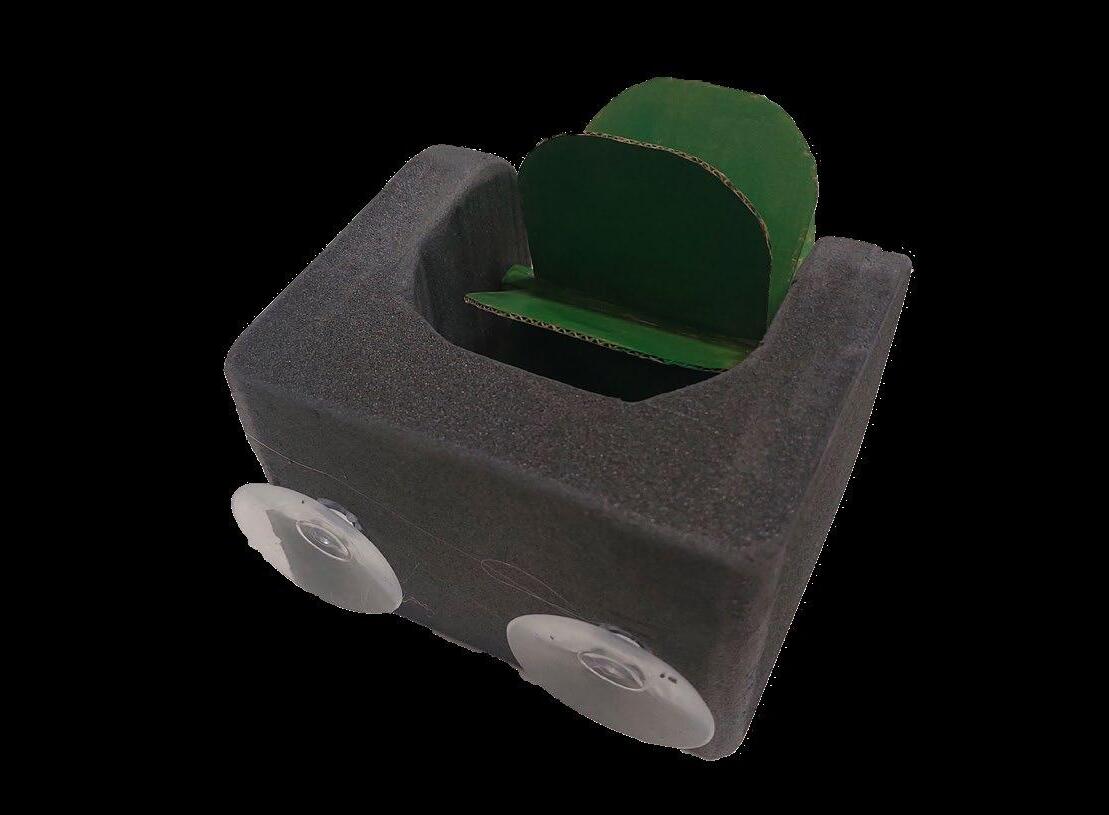

CAD --> Prototype

The final components had two versions one for 3D printing and one for injection moulding.

The printing models were then taken from Solidworks and sent to a 3D printer where they were used to create a prototype mock up of how it would function and fix together.

Technical Pack

The technical packconsists ofexploded views of the product and technical pages on each individual part.

The inclusion of a bill of materials as well as the technical drawings makes it easy to pass the technical pack to a manufacturer for them to produce.

Injection Moulding

As the product is injection moulded certain considerations need to be taken into account while designing parts. These include;

• Draft angles to ease removal

• Ribbing and bosses to make stronger

• Filleting edges to allow plastic to flow better