A BETTER GRIP

T-nut and insertion machines

T-nuts used to be inserted into a predrilled hole with a hammer and afterwards stapled to prevent the T-nut from being pushed out. It was a slow and physically demanding job, consisting of 3 steps: pre-drilling, hammering and stapling.

With the SIGMA inserting solution, the speed of insertion is up to 10 times higher, and furthermore, you avoid stapling the SIGMA T-nut.

In a few situations, the SIGMA T-nut machine can even do the pre-drilling, which means we are down to a 1-step working flow!

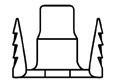

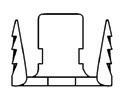

The T-nut rivet system ensures maximum push-out resistance. As illustrated below, the flaring pin (1) has a conical point for riveting the T-nuts (2).

SMALL

With the correct adjustment of the machine, all SIGMA T-nuts can be riveted for maximum push-out resistance. Moreover, the trumpet shape of the T-nut facilitates the positioning of the screw afterwards.

See the various SIGMA T-nut types below:

LARGE

*Type step

Please contact us for more information on the coil T-nuts, or if you need dimensions not listed above.

` Straight inserted T-nut

` Easier screw mounting

` Riveted T-nut

` Max push-out resistance

` No extra stapling

` Fast and easy insertion – up to 10 times faster

` Less manual handling – less physical strain

` High quality T-nut

We have used our TJEP Handtool LB-18 for almost 6 months now, and we are very happy with this inserting solution made by KYOCERA-UNIMERCO

We have obtained the following advantages with the tool:

` Faster insertion of T-nuts

` High quality of the insertion

` T-nuts always inserted straight

` Higher T-nut quality

` We can only recommend the use of the LB-18 inserting tool

Severine Roussel, Company de Trevillers Transformation, France

As user of the SIGMA insertion machines and T-nuts we hereby have the opportunity to thank the company KYOCERA- UNIMERCO for good service, delivery accuracy and fast response when needed.

With the SIGMA Machines, we have increased the insertion speed 10 times in comparison to earlier manual insertions.

Large T-nut range, high speed

We have one SIGMA machine for our SIGMA M6 × 12 mm Torqloc T-nuts. We found the SIGMA T-nuts to be of the best quality, and we could get this selflocking T-nut by KYOCERA-UNIMERCO which is important for us.

The speed of the insertion is a lot higher than manual insertion. Furthermore, we have the option to rivet the T-nuts for a higher push-out resistance; this means that the T-nut doesn’t have to be stabled to secure the T-nut from falling out. This saves us yet another working operation! The trumpet shape also navigates the screw easily in the thread.

I can’t see us returning to our old insertion methods again…

František Krošlák, Krošlák s.r.o., Slovakia

EUROLINE has 2 SIGMA machines in use:

We are very satisfied with the outcome of our investment. The SIGMA T-nut machine helped us increase the T-nut insertion speed by up to 5 times compared to manual insertion with hammer.

Jacek Kruk, EUROLINE Sp. z o.o., Poland

Type smallbase / M4, M5, M6(S)

Type largebase / M6(L), M8, M10

Type smallbase / M4, M5, M6(S)

Type largebase / M6(L), M8, M10

Hopper-fed machine for quick and accurate insertion of T-nuts

Machine features

▪ Hopper feeding system

▪ Pneumatic insertion

▪ Precision feed track

▪ Up to 2,000 insertions/hour

▪ Rivet option

▪ Dual safety system

▪ 100% straight insertion of T-nuts

▪ Customised machines available

Recommended T-nuts

▪ SIGMA Standard T-nuts

▪ SIGMA Torqloc T-nuts

▪ SIGMA Step Barrel T-nuts

▪ SIGMA Rivet square nut*

Coil-collated T-nut driving machine for quick and accurate insertion of coil-collated T-nuts

Machine features

▪ Simple feeding system

▪ Quick change to new T-nut dimension (ideal for smaller batches)

▪ Up to 2,000 insertions/hour

▪ Rivet option

▪ Dual safety system

▪ 100% straight insertion of T-nuts

▪ Customised machines available

Recommended T-nuts

▪ SIGMA coil-collated T-nuts

Type smallbase / M4, M5, M6(S)

Type largebase / M6(L), M8, M10

Type smallbase / M4, M5, M6(S)

Type largebase / M6(L), M8, M10

Machine features

▪ Manual feeding system

▪ Quick change to new T-nut dimension (ideal for smaller batches)

▪ Up to 1,000 insertions/hour

▪ Rivet option

▪ Dual safety system

▪ 100% straight insertion of T-nuts

▪ Customised machines available

Machine features

▪ Powerful drill and T-nut insertion in one operation

▪ Machine can be fitted for coil-collated T-nuts

▪ Dual safety system

▪ 100% straight insertion of T-nuts

▪ Rivet option

▪ Customised machines available

Recommended T-nuts

▪ SIGMA Standard T-nuts

Recommended T-nuts

▪ SIGMA strip T-nuts

▪ SIGMA Torqloc T-nuts

▪ SIGMA Step Barrel T-nuts

Customised solutions such as machines for robots, CNC-machines, production lines, etc. offer an opportunity to improve efficiency.

Customised machines can be tailored for special applications and integrated in other production processes.

Often, these solutions are developed in cooperation with your existing machine supplier to ensure the optimum interaction and production proces.

Compatible with these strip large base T-nuts

M6 × 12 mm strips of 13 pcs. (3,200 pcs. in a box)

M6 × 15 mm strips of 13 pcs. (2,700 pcs. in a box)

M8 × 12 mm strips of 13 pcs. (3,200 pcs. in a box)

M8 × 15 mm strips of 13 pcs. (2,700 pcs. in a box)

M10 × 12 mm strips of 13 pcs. (3,000 pcs. in a box)

Tool features

▪ Small investment

▪ Stable and easy to use

▪ Simple change to new T-nut dimensions

▪ 100% straight insertion of T-nuts

▪ Practical on large work pieces

▪ Flexible in production

▪ Angled track for working with curved products

▪ Ergonomically correct - with rubber handle

Recommended T-nuts

▪ SIGMA strip T-nuts

you know… …that at www.tjep.eu you will find a complete range of professional tools for fastening?

KYOCERA UNIMERCO Fastening supplies a wide range of fastening solutions for the construction industry, e.g. nailers, finish nailers, rebar tiers, T-nut solutions, compressors and accessories. For nearly 50 years, the company has been selecting and developing the most user-friendly and effective fastening tools. Close cooperation with the distributors and end-users ensures professional advice about the individual products and accessories, and about optimum use and maintenance. The Danish company was established in 1964 and is headquartered in Sunds.

The company is part of the KYOCERA UNIMERCO group, founded in Denmark in 1964 and then named UNIMERCO. In 2011, all activities were acquired by Japan-based KYOCERA. This has created an even stronger company with a larger range of products, a wide network of companies and distributors all over the world, and an ambitious growth plan. KYOCERA UNIMERCO Fastening A/S