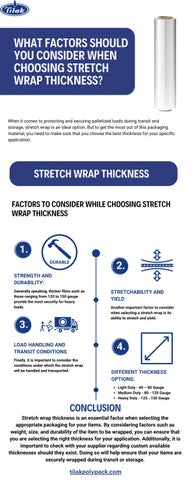

WHAT FACTORS SHOULD YOU CONSIDER WHEN CHOOSING STRETCH WRAP THICKNESS?

When it comes to protecting and securing palletized loads during transit and storage, stretch wrap is an ideal option But to get the most out of this packaging material, you need to make sure that you choose the best thickness for your specific application

STRETCH WRAP THICKNESS

FACTORS TO CONSIDER WHILE CHOOSING STRETCH WRAP THICKNESS

1.

STRENGTH AND DURABILITY:

Generally speaking, thicker films such as those ranging from 120 to 150 gauge provide the most security for heavy loads.

3.

LOAD HANDLING AND TRANSIT CONDITIONS

Finally, it is important to consider the conditions under which the stretch wrap will be handled and transported.

2.

STRETCHABILITY AND YIELD

Another important factor to consider when selecting a stretch wrap is its ability to stretch and yield.

4.

DIFFERENT THICKNESS OPTIONS:

Light Duty - 40 – 80 Gauge

Medium Duty - 80 - 120 Gauge

Heavy Duty - 125 - 150 Gauge

CONCLUSION

Stretch wrap thickness is an essential factor when selecting the appropriate packaging for your items By considering factors such as weight, size, and durability of the item to be wrapped, you can ensure that you are selecting the right thickness for your application Additionally, it is important to check with your supplier regarding custom available thicknesses should they exist Doing so will help ensure that your items are securely wrapped during transit or storage.

tilakpolypack.com