Thomas Brennan

Chicago, IL | thomasjbrennan9720@gmail.com | (708) 465-9213

Professional Experience

Assured Corporation, Mokena, IL.

Project Coordinator

June 2024 - Present

Acting as regional contact for technical support and design assistance for architects, glaziers and owners working with NanaWall Movable Glass Wall Systems. Responsible for understanding and sharing product knowledge, quoting, and assisting the sales team with AIA presentations, project communication, and site visits.

Also providing in-house design and drafting work for the Mokena Location’s Product Showroom.

BE

Architects, Chicago, IL.

Architectural Associate

May 2023 - March 2024

Performed field measurements, created finish palettes and specifications, verified code compliance, and produced full construction drawing sets for permit. Focused on corporate interior and residential projects in the City of Chicago and surrounding suburbs.

Carnegie Mellon University

Teaching Assistant / dFab Monitor

June 2021 – May 2023

Taught students the required software and techniques for laser cutting, 3D printing, and CNC routing. Supported student information gathering and construction detailing production, and assisted instructors with grading and research collection.

Margittai Architects, Pittsburgh, PA.

Architectural Internship

May 2022 - May 2023

Performed field measurements, building code reviews, and drafted construction documents primarily for residential projects. Functioned as the spearhead of a Change of Occupancy permit submission and adaptive reuse project for Refuge for Women.

Education

Carnegie Mellon University

Masters of Architecture May 2023

University of Wisconsin - Milwaukee

Bachelors of Science in Architectural Study

Dec. 2019

Skills

Software

Rhino, Grasshopper, Revit, AutoCAD, V-ray, Enscape, Adobe / Affinity Suite, Bluebeam Revu, Microsoft Office Suite

Model Making / Fabrication

Wood Working Tools, Laser Cutting, CNC Milling and 3D Printing

Technical Experience

Code Review, Drafting, Detailing, Finish Palette Selection, Field Measuring, Space Planning, Specifications, Submittals and RFI’s, File Management, Construction Observation, Building Envelope Testing

Recognition / Publications

“Small Town Big Future” Exhibiting Designer

Featured work from the Farm and Forest studio presented to the residents of Orfordville, Wisconsin.

“Pull and Push” Prototyping Project

Worked collaboratively to produce hardware designs iteratively through a variety of physical and digital modeling methods.

UWM Commencement Honors 2019

SARUP SUPERjury Nomination

2019 Orfordville Farmers Market

2018 UWM Student Housing

2017 Milwaukee Street Car Depot

Table of Contents

Orfordville Farmers Market and CSA

Aperture Mixed Use Building

Pull and Push

Tessellated Facade

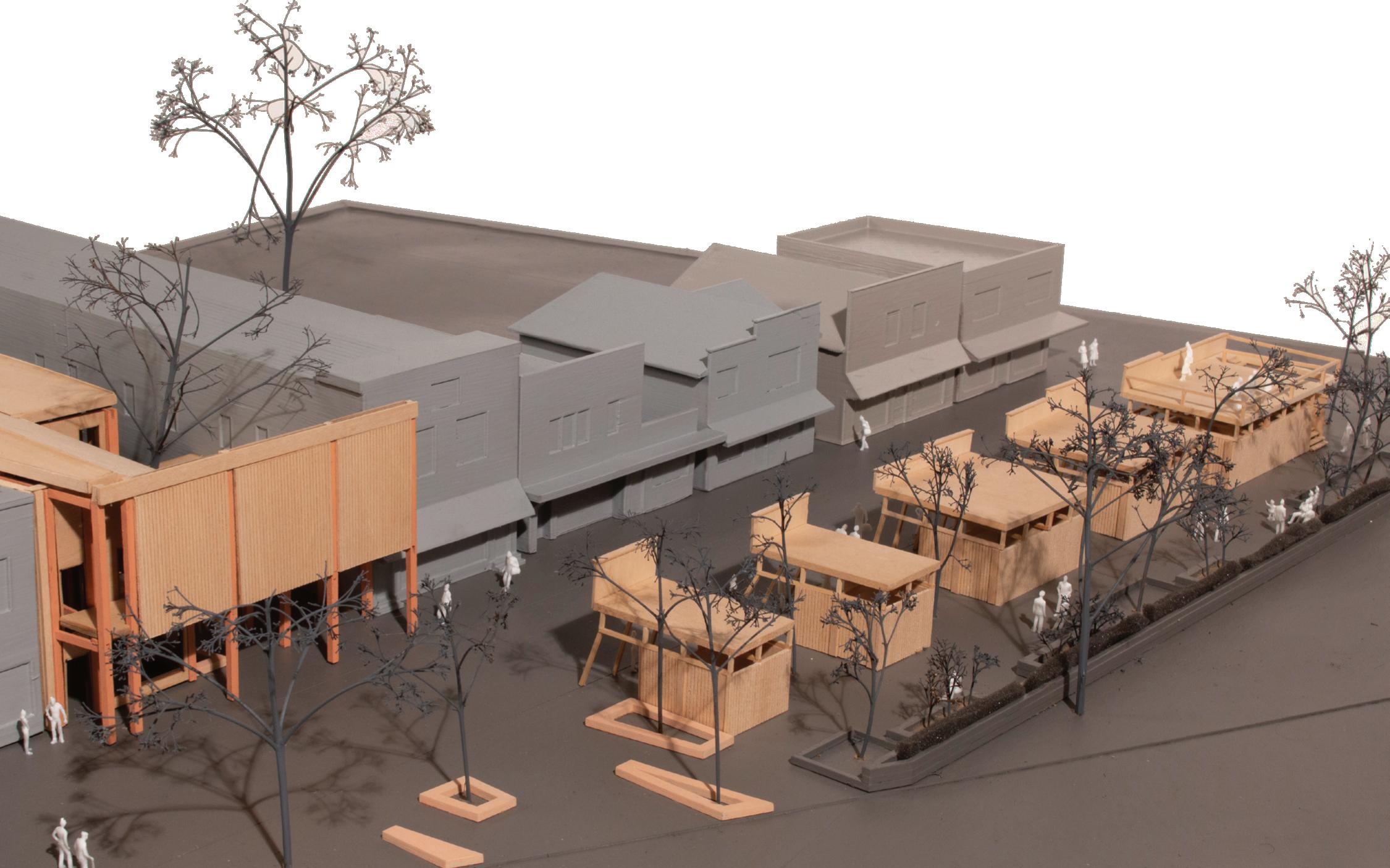

Orfordville Farmers Market and CSA

This project is located in the growing downtown strip of Orfordville, Wisconsin. It focuses on improving the walkability of this downtown area. It accomplishes this by creating a pedestrian street to alleviate traffic issues caused by the existing five-point intersection. The structures are placed to create a continuity of the street front that is familiar in the downtown vernacular. The structures themselves use prefabrication methods and only require pin connections in the event that they need to be relocated.

This project was an individual academic work.

Course: Farm and Forest Studio

Instructor: Kyle Talbott

Tools and Methods: Physical Modeling, Rhino 3D, Lumion, Adobe Illustrator, Adobe Photoshop

Sectional Site Axon

Structure Component Assembly

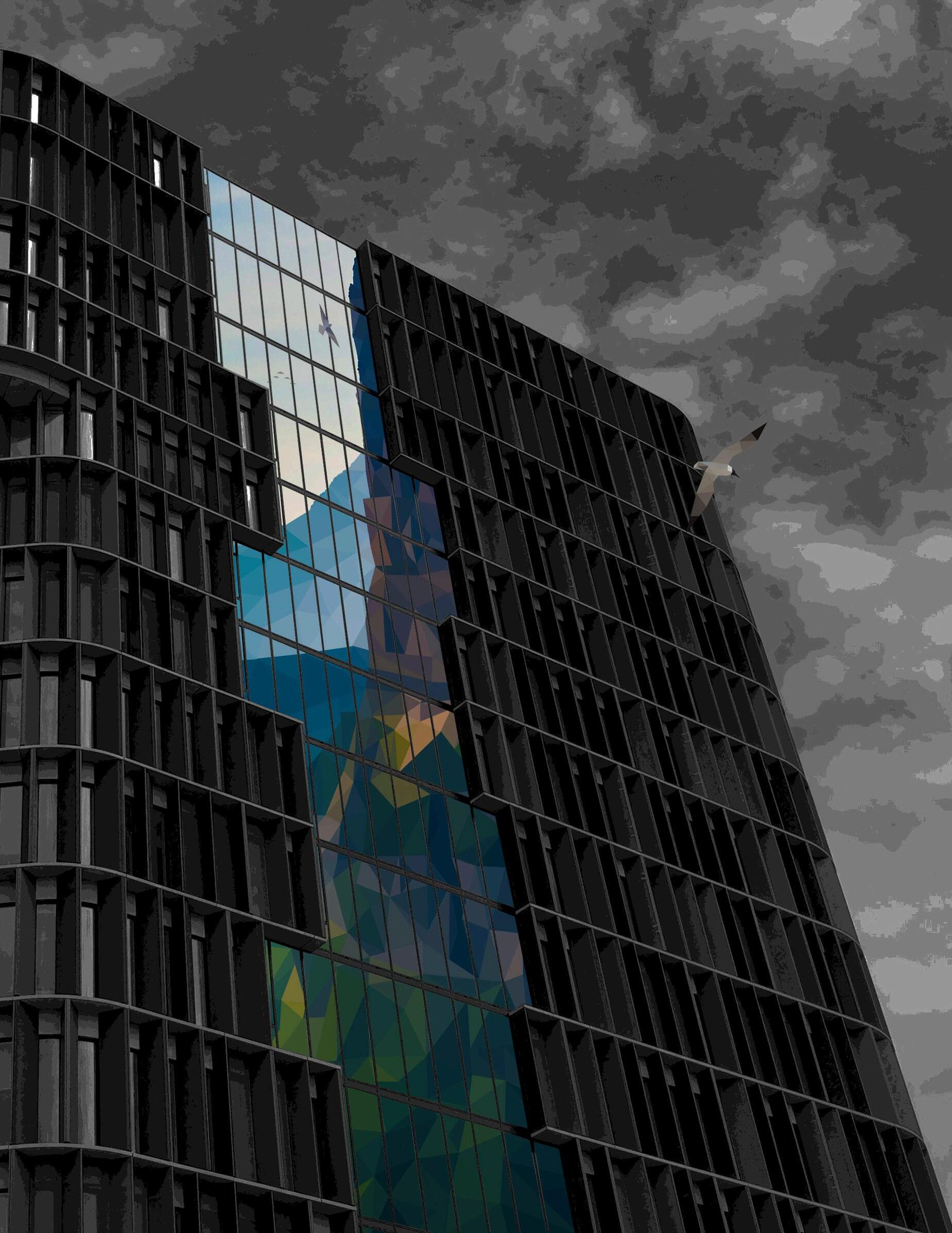

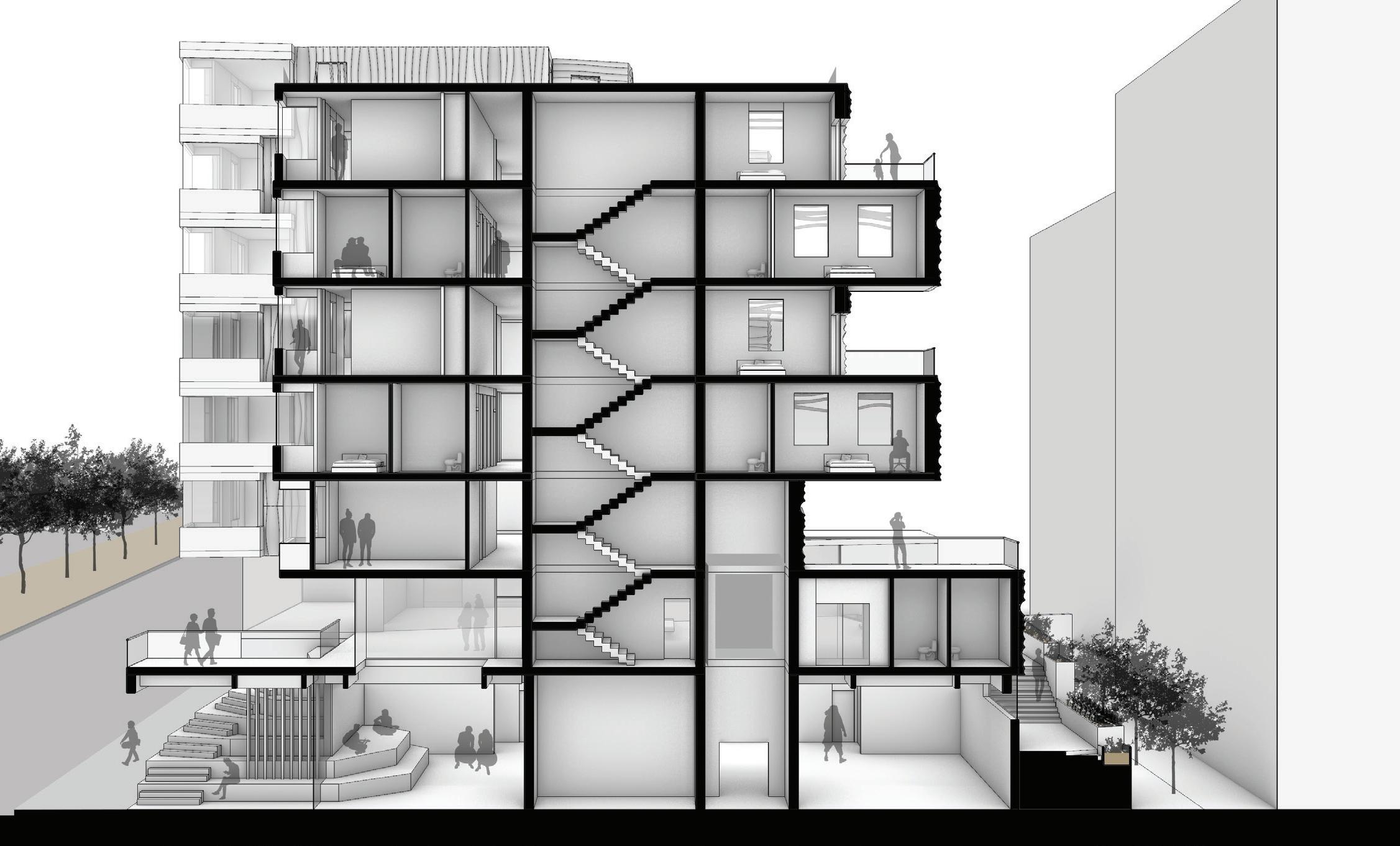

Aperture Mixed Use Building

This project is located in the cultural district of downtown Pittsburgh, PA. The building was to act as a mixed use residential tower focusing on providing programmatic needs for a specific art form to be cultivated and supported in the district. Aperture seeks to provide proper live-work spaces for photographers and videographers. Using a CLT mass timber construction, the structure reveals itself in the framing of the views in and through the building.

This project was a collaborative academic work completed with partners: Gavin Hurley and Kushal Shah.

Course: Praxis II Studio

Instructors: Azadeh Sawyer, Mathew Huber, Jeff Davis

Tools and Methods: Rhino 3D, Grasshopper, Enscape, Adobe Illustrator, Adobe Photoshop

Andy Warhol Bridge

FortDuquesneBlvd.

FortDuquesneBlvd.

7thSt

Sectional Axon Diagram

Typical Residential Floor Plan

PrimaryLoadDirectionforUpperFloors

C.L.T. Structural Plate

Secondary Load Bearing

C.L.T. Walls

Steel Beams for Cantilever Support

Primary Load Bearing

C.L.T. Walls

Site Cast Concrete Core

Embedded Steel Beams for Cantilever Support

PrimaryLoadDirectionforGroundFloor CLT Structural Diagram

Glulam Beams

Treated Timber Columns

Concrete Foundation walls and Footings

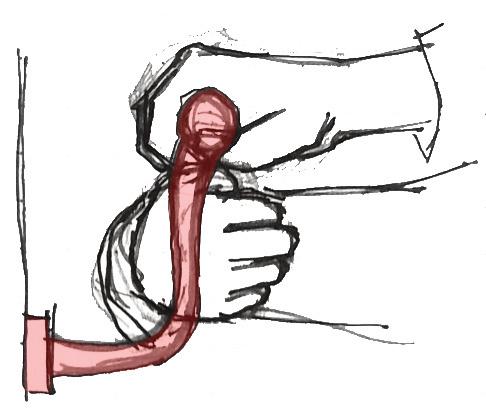

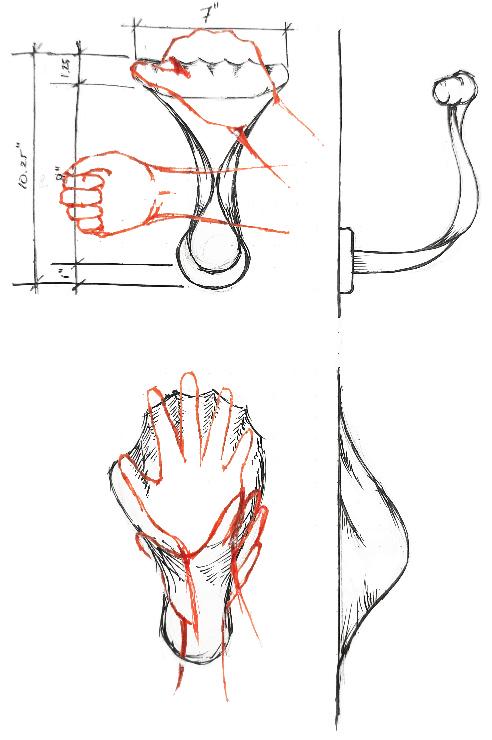

Pull and Push

The focus of this project was to utilize multiple digital fabrication methods in the design and prototyping of two full-scale door handle designs. In collaboration with a partner, one handle was created through subtractive fabrication methods through CNC 4-axis milling, while another was created through additive fabrication via plaster casting and 3D printing.

This project was a collaborative academic work completed with partner: Samantha Su.

Course: Fabricating Customization Prototyping Instructor: Jeremy Ficca Tools and Methods: Physical Modeling, Rhino 3D, RhinoCAM, 3D Printing, CNC 4-Axis Routing, CNC Milling, Plaster Casting, Woodshop finishing

Concept Sketches

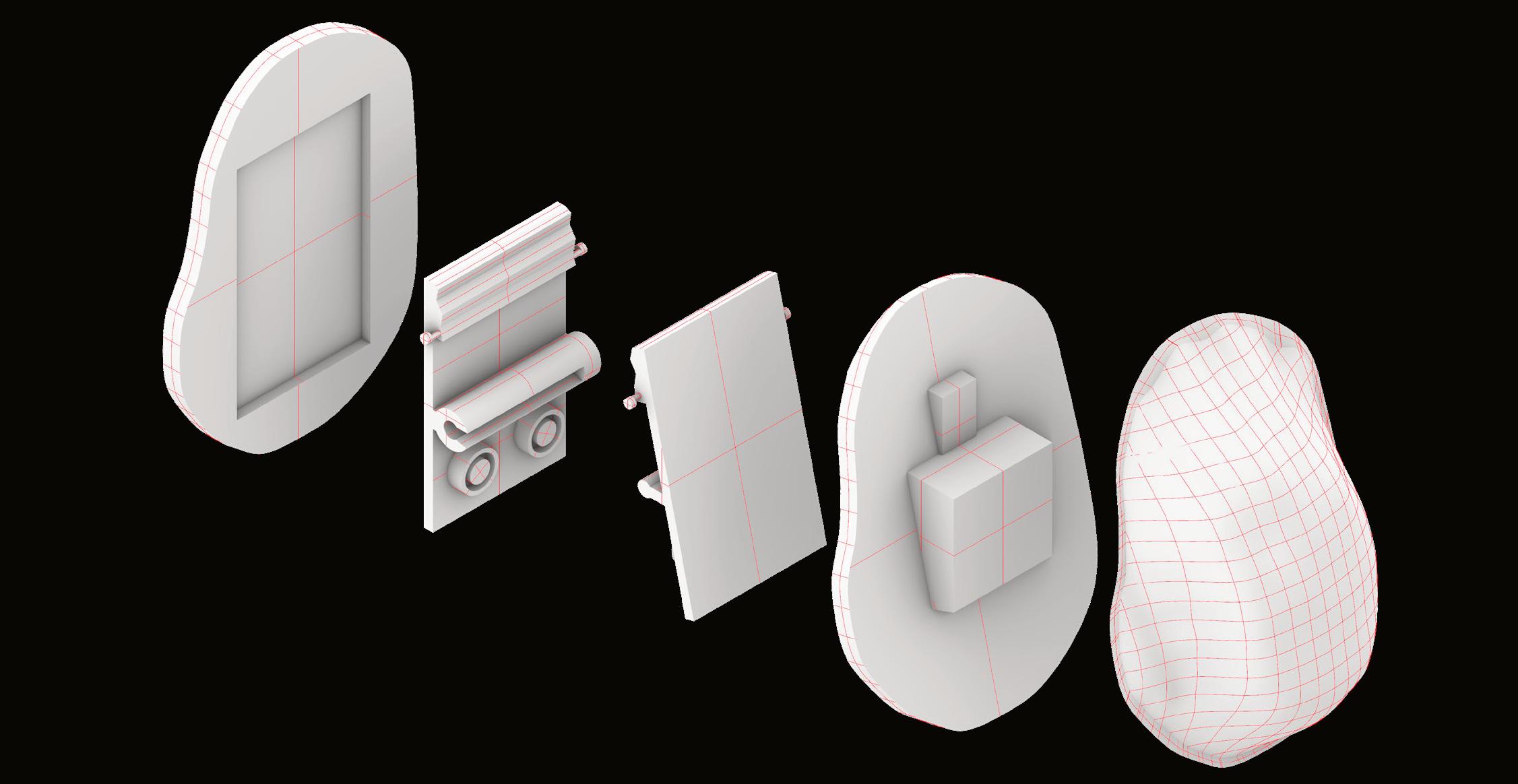

Exploded Push Handle

Pull Handle Versions

Push Handle Assembly with Plaster Hand Piece and 3D Printed Compression Mechanism

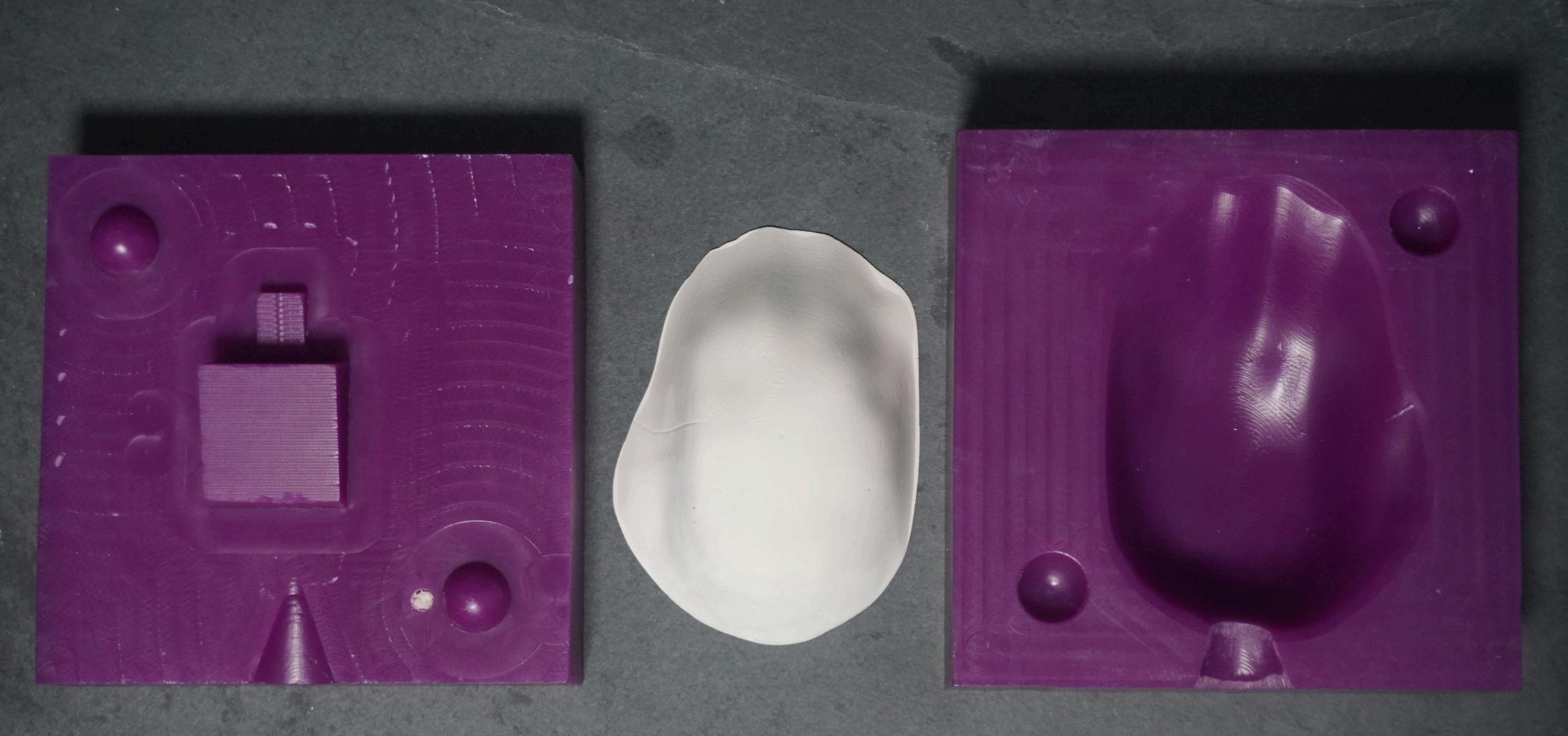

2 Part Wax Mold for Push Handle

Final Pull Handle Approaches

Final Push Handle Approach

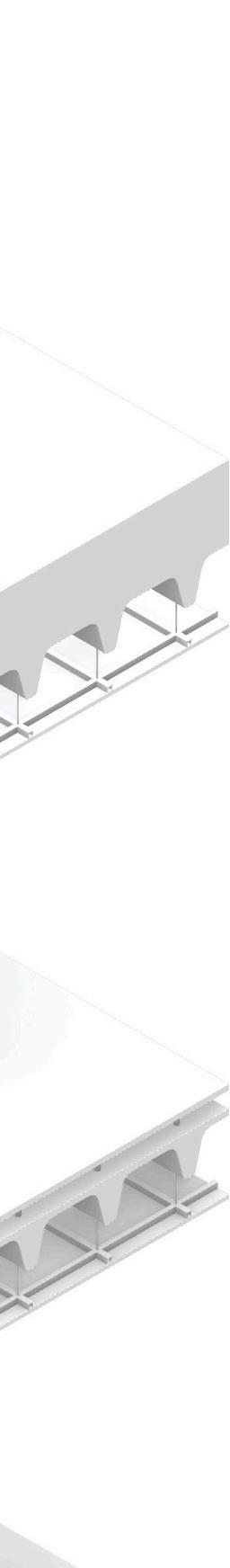

Tessellated Facade

Tasked with designing the facade of a standard Pittsburgh building, this project utilizes tessellation and gradation to achieve unique lighting conditions inside the space. The unit changes in the protruding direction based on focal points which increase the viewing area. The facade is transformed by these different scaled protrusions resulting in peaks and valleys along the otherwise flat surface.

This project was a collaborative academic work completed with partners: Cunxiong Bi and Samantha Su.

Course: Fabricating Customization Prototyping Instructor: Jeremy Ficca

Tools and Methods: Physical Modeling, Rhino 3D, Grasshopper, Enscape, Adobe Illustrator, Adobe Photoshop, 3D Printing, Laser Cutting

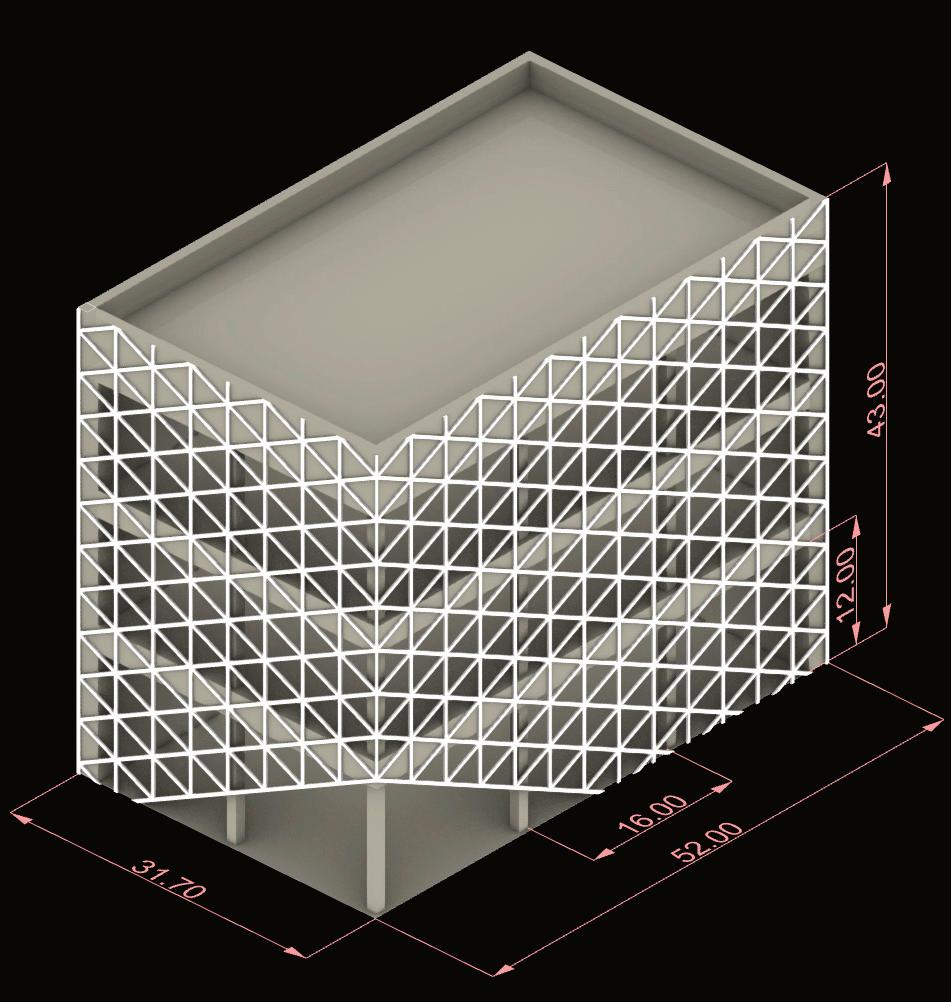

Base Building With Triangulated Grid

Tessellation and Gradient Concept Sketch

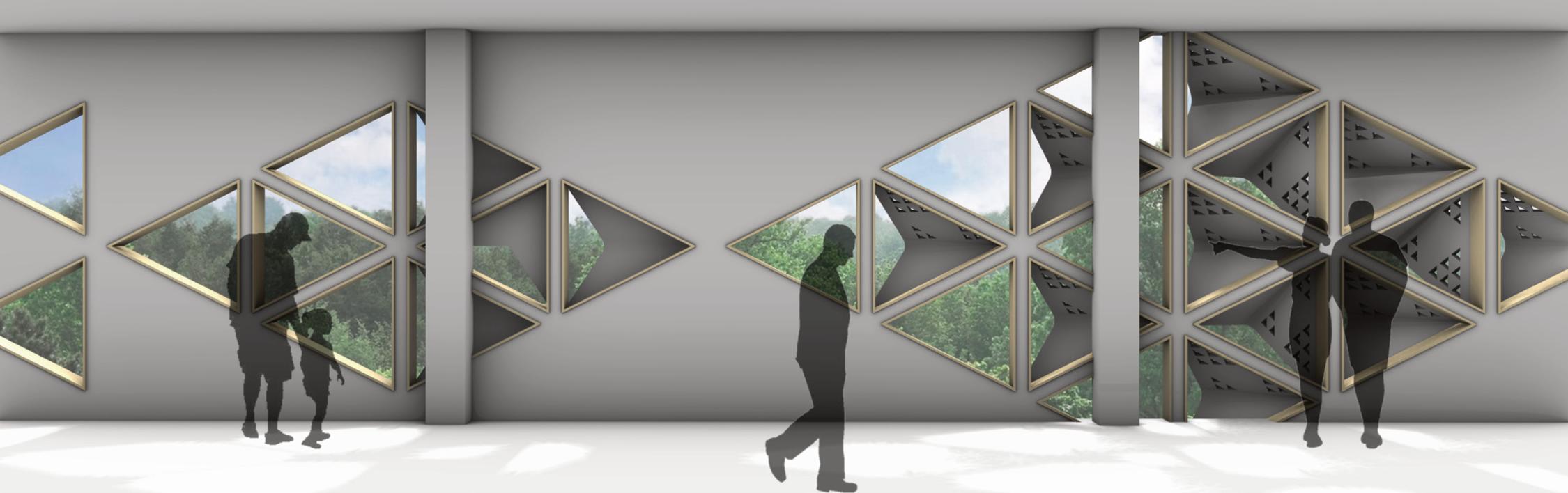

West and South Facade Highlighting Gradient

ParapetFlashing

VerticalAluminumClip

PrecastGlassFiber

Reinforcement

ConcretePanel

PerforatedPrecast

GlassFiber

Reinforcement

ConcreteCladding

WallAssembly

• RigidInsulation

• ExteriorSheathing

• Stud

• Insulation

• InteriorSheathing

• GypsumBoard

Exploded Section