Introductiontopressurecastinganddiecastingmoldstructure

1.Definitionandcharacteristicsofpressurecasting

Die-casting:pourmoltenorsemi-moltenmetalintopressurechamberofdie-castingmachine,fill itincavityofdie-castingmold(die-castingtype)ataveryhighspeedunderactionofhigh pressure,meltitunderhighpressureorsemi-moltenmetalcoolingandsolidificationtoobtain castings.

Advantagesofdiecasting:

1.Highdimensionalaccuracyandlowsurfaceroughness

2Highutilizationrateofmaterials

3.Itcanformcomplexstructure,thin-walledanddeep-cavityparts

4Die-castingpartshavecompactstructure,highstrengthandhardness

5Highproductionefficiency,suitableformassproduction

6Partsofothermaterialscanbeembedded

Diecastingdisadvantages:

1.Diecastingsarepronetopores,andexpansionofgasinporesathightemperaturewillcause bubblingonthesurfaceofdiecastings

2.Moldcostishigh,notsuitableforsmallbatchproduction

3Sizeofdie-castingmachineislimited,anditisdifficulttodie-castlargedie-castingpartsdueto limitationofclampingforceofmachineandsizeofmold.Forcastingswithcomplexconcaves, die-castingproductionisalsodifficult

4.Typesofdie-castingalloysarelimited.Duetouseoftemperaturerestrictions,lifeofdie-casting diesforhigh-meltingpointalloys(suchasferrousmetals)islow

Diecastingalloymaterialselectionprinciples:

1Canmeetperformancerequirementsofproductusescenarios

2.Ithassufficienthightemperaturestrengthandplasticity,andthermalbrittlenessissmall

3Crystallizationtemperaturerangeissmall,fluidityisgood,tendencytoproduceporesand shrinkagecavitiesissmall

4Shrinkagerateisassmallaspossible,tendencyofhotcracking,coldcrackinganddeformation issmall

5Tendencyofphysical-chemicalinteractionwithcavitywallissmall

6Goodprocessingperformanceandcertaincorrosionresistance

Currentlycommonlyuseddie-castingalloysarezincalloy,aluminumalloy,magnesiumalloy, copperalloy,tinalloy,leadalloy

2.Structuralrequirementsofdiecastings

Whendesigningstructureofdiecastings,followingpointsshouldbeconsidered:

1.Compactnessofthin-walledcastingsisbetter

Aswallthicknessincreases,defectssuchasinternalporesandshrinkagecavitieswillalsoincrease

Underpremiseofensuringsufficientstrengthandrigidityofcasting,thicknessshouldbereduced asmuchaspossibleanduniformthicknessshouldbeensured

Recommendedwallthicknessdesignvaluesfordiecastingsareasfollows:

Zincalloy AluminumalloyMagnesiumalloyCopperalloy Wallthicknessh(mm)

smallestnormalsmallestnormalsmallestnormalsmallestnormal

2.Forconnectionpositionofwallsurface,roundedcornerconnectionshouldbedesignedas muchaspossibletoavoidstressconcentrationRecommendeddesignvaluesareasfollows:

2DemouldingangleshouldbeaslargeaspossibleRecommendeddemouldingangleisas followsSomezincalloyplaneswithsmallareascanachievezero-degreedraft

3Avoiddeepandsmallholes,narrowanddeepgroovesinstructuraldesignSeetablebelowfor relatedprocesscapabilities.

Alloy Minimumholediameterd(mm)Depthisamultipleofapertured

Followingprinciplesshouldbeconsideredwhenselectingproductpartingsurface:

1Apartingschemethatiseasytoprocesscavityshouldbeselected,andcore-pullingmechanism shouldbeminimized.

2Inordertomakedie-castingpartstayinmovablemoldaftermoldisopened,duringdesign, tightnessofdiecastingonmovingmoldcoreisgreaterthanthatoffixedmodelcore,and tightnessofcastingoncoreisgreaterthanthatofshrinkageofcastingonthecore

3.Sidecorepullingshouldbesetonmovablemoldasfaraspossible,sothatwhenmoldis opened,corepullingandleavingfixedmoldcanbecarriedoutatthesametime,whichsimplifies moldstructureOtherwise,corepullingactionmustbecompletedbeforemainpartingsurface canbeparted

4Topreventpartingsurfacefromaffectingdimensionalaccuracyofcasting,keysizepartsand partswithhighshapeandpositiontolerancerequirementsshouldbesetinsamehalfmold.

5Partingsurfaceshouldavoidcoincidencewithmachiningreferenceplaneofcasting

6.Considerappearancerequirementsofcastingtoselectpartingsurface

7PartingsurfaceshouldchooseapositionthatisconducivetofillingandformingAtthesame time,itisrecommendedtosetitatlastfillingpartofmoltenmetal,soastofacilitateexhaustand slagdischargeofproduct

8.Choiceofpartingsurfaceshouldfacilitateinstallationofinsertsandmovablecores.

3Diecastingmachinestructure

Die-castingmachinesaremainlydividedintohot-chamberdie-castingmachinesand cold-chamberdie-castingmachinesHot-chamberdie-castingmachinesbasicallyonlyhave horizontalstyles,whilecold-chamberdie-castingmachinesaredividedintohorizontal,vertical, andfull-verticalEquipmentfeaturesandapplicationscenariosareasfollows:

Diecastingmachineclassification

EquipmentFeatures

Cold Chamber Die Casting Machine

1.Pressurechamberandheat preservationcrucibleareseparated Duringdiecasting,itisnecessaryto takeoutmetalliquidfromheat preservationfurnaceandpouritinto pressurechamberbeforediecasting Heatlossislarge,operationis cumbersome,andproduction efficiencyisnotasgoodasthatofhot chamberdiecastingmachine.

2Workingenvironmentofpressure chamberofcoldchamberdie-casting machineisbetter,andalarge-pressure horizontalinjectioncylindercanbe used,whichissuitableformedium andlargedie-castingmachines.Itis mostlyusedfordie-castinghigh meltingpointalloys,andcanbeused fordie-castinglarge-scalecastings

Aluminum alloy Magnesiu malloy Copper alloy Black metal

pressure

Hot Chamber

Die Casting Machine

pressurechamberandinjection mechanismarehorizontal,pressure chamberisparalleltodirectionof moldmovement.;

Verticalpressurechamberis perpendiculartoinjectionmechanism, andpressurechamberisperpendicular tomovementdirectionofmold; Fullyverticalinjectionmechanismand moldclampingmechanismareina verticalposition,andpressure chamberisparalleltomovement directionofmold.

Advantagesofhorizontaldiecasting machinearehighpressure,convenient maintenanceandhighefficiency Disadvantageisthatsurfaceareaof moltenmetalexposedtoatmosphere islarge.Whenprocessparametersare notselectedproperly,itiseasytoget involvedinair,oxidesorother impurities,itisnotconvenientfor insertdie-casting.

Advantageofverticaldie-casting machineisthatitoccupiesasmall area,butstructureisrelatively complicated,operationand maintenanceareinconvenient,which affectsproductionefficiency

Advantageoffull-verticaldie-casting machineisthatmoldisplaced horizontally,soitisconvenientto installinsertsDisadvantageisthat structureiscomplicated,partsare morecomplicated,andproduction efficiencyisnothigh.

1.Pressurechamberisimmersedin liquidmetalinheatpreservation

crucible,andinjectionpartsare installedoncrucible

2Simplestructure,convenient operation,simpleproductionprocess, noneedforseparatefeeding,high efficiency,easytorealizeautomatic

production,butitisinconvenientto replacepressurechamber,and injectionspecificpressureissmallItis mostlyusedfordie-casting low-meltingpointalloysand miniaturizedcastings.

3Die-castingmoltenmetalenters moldcavitydirectlyfrompressure chamber,temperaturefluctuation rangeofmoltenmetalissmall,heat lossissmall,airorimpuritiesarenot easilybroughtin,purityofmolten metalishigh,die-castingprocessis stable,andcastingqualityisgood

4.Comparedwithcoldchamberdie castingmachine,pouringsystem consumeslessrawmaterialsandsaves costs

5.Pressurechamberandotherparts areimmersedinmoltenalloyliquidfor alongtime,whichiseasilycorroded, affectsservicelife,andmayincrease ironcontentofcasting.

Workingprincipleofhotchamberdie-castingmachineandcoldchamberdie-castingmachine (horizontal,vertical,fullvertical)isshownbelow:

Workingprincipleofhotchamberdiecastingmachine

Workingprincipleofhorizontalcoldchamberdiecastingmachine

Workingprincipleofverticalcoldchamberdiecastingmachine

Workingprincipleoffullyverticalcoldchamberdiecastingmachine 4Die-castingmoldstructure

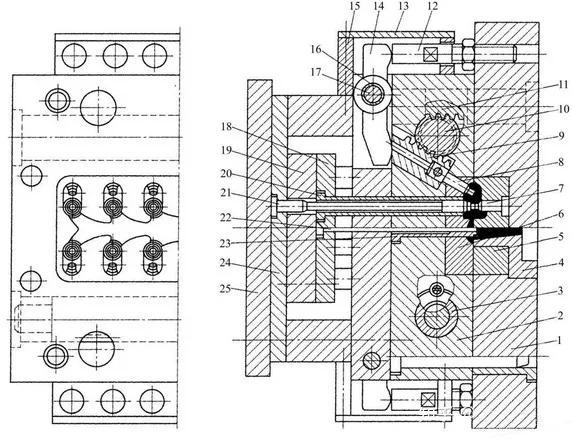

Asetofdie-castingmoldsgenerallyconsistsoffollowingparts:

Structuralcompositionofdie-castingmold

1pushplate;2pushrodfixedplate;3pad;4limitstop;5pullrod;6gasket;7nut;8 spring;9sideslider;10wedgeTighteningblock;11-obliquepin;12,27-cylindricalpin; 13-movablemoldinsert;14-sidecore;15fixedmoldinsert;16-fixedmoldseatplate;17,26, 30-hexagonsocketscrews;18-spruesleeve;19-guidepost;20-guidesleeve;21-core;22fixedmoldcoverplate;23-movablemoldcoverplate;24-supportplate;25,28,31-pushrod: 29limitingnail:32resetrod;33pushplateguidesleeve;34pushplateguidepost;35 movingmoldbaseplate

SystemArchitectureofDieCastingMold

1Moldingsystem

Itconsistsofacavity,afixedcore,amovablecore,etc

2Gatingsystem

Itconsistsofsprue,horizontalsprue,innergate,etc

3.Overflowsystem

Consistsofoverflowtank,exhausttank,etc

4.Demouldingsystem

Itconsistsofpush-outelements(pushrods,pushtubes,unloadingplates,etc),resetelements (resetrods,inclinedsliders,etc.),limitelements(limitblocks,limitnails,etc.),guideelements (guidepillars,guidesleeves,etc),structuralelements(pushplate,pushrodfixingplate,etc)

5.Corepullingsystem

Itconsistsofformingelements(sidecores,inserts,etc),movingelements(sidesliders,inclined sliders,etc.),transmissionelements(obliquepins,racks,hydrauliccorepullers,etc.),locking elements(lockingblocks,Wedgeblocks,etc),limitcomponents(limitblocks,limitnails,etc)

6.Supportsystem

Itiscomposedoffixedmoldbaseplate,fixedmoldplate,movablemoldplate,movablemold

supportplate,moldbase,ejectionplate,guideparts,etc.

7Heating/coolingsystem

Composedofheatingandcoolingoil/watercircuits

Followingisabriefintroductiontoeachpart:

1.Formingsystem

Moldingsystem:Partsthatformformingcavitytoformgeometricshapeofdie-castingarecalled formingparts,whichdeterminequalityandprecisionofdie-casting,andalsodetermineservice lifeofdie-castingmoldFormingsystemincludescavity,fixedcore,movablecore,etc

Formingsystemisdividedintointegraltypeandmosaic(combined)structure

Integraltype,thatis,coreandcavityaredirectlyprocessedonmoldplate

Inmosaictype,cavityandcorearemadeofasinglepieceofmaterial,thenloadedintomold sleeveofmoldbase,thenfixedwithshouldersorbolts

Monolithicstructure

1-fixedmoldcoverplate;2-fixedmoldbaseplate;3-guidebush;4-gatesleeve;5-combinedinsert; 6-integralinsert;7-castinsert

Mosaicstructure

Duetolargeamountofstructuralprocessing,integraltypeisnoteasytomaintain,difficultto heattreatmentandsurfacetreatment,soitisonlysuitableformoldsortestmoldswithsmall batches,shallowcavities,lowprecisionrequirements,andlowalloymeltingpoints

Mosaicmoldingstructureiswidelyusedindie-castingmolds

Designprinciplesofmosaicmoldingsystem:

1Formedpartsshouldbeeasytoprocessandensuredimensionalaccuracy,fitaccuracyand structuralstrength.

2Avoidsharpedgesandthinwalls

3.Directionofinlaidgapshouldbeconsistentwithdirectionofmoldrelease

4Itshouldbeeasytomaintainandreplace

5.Doesnothinderappearanceofcastings,andisconducivetoremovalofflash 2Gatingsystem

Gatingsystemismainlycomposedofsprue,runnerandinnergate.Differenttypesofdie-casting machineshavedifferentgatingsystemsDifferencesareasfollows:

Verticalcoldchamberdiecasting machine Horizontal cold Hotchamber diecasting

Fullverticaldiecasting machine

Diecasting machinetype

Hotroom

Structurediagram

chamber

diecasting machine

machine

Verticalcold room

Illustrate

Itconsistsofsprue,inner gate,lateralrunner, diverterconeandoverflow tank(notshowninfigure).

Sincepressurechamberis placedincrucible,after injectioniscompleted, injectionpunchmoves upwardtoformanegative pressureinpressureair, whichsucksuninjected moltenmetalbackinto gooseneck channel, resultinginlesspouring residue

Itissomewhatsimilarto pouringsystemofhot chamberdie-castingmold, exceptthatmaterialcake isproduced

1-straightflowchannel;2-crossflowchannel;3-innergate;4-remainingmaterial;5-splittingcone nestHorizontal coldroom

Fullvertical coldroom

Sprue:directpassagefrommoldgatingsysteminlettorunner

Thisisthemostcommonly usedforminpractice, consistingofsprue, runner,ingate,overflow troughandexhaust channel.

Sinceitisfedfrombelow, thecakeappearsinthe lowerpartofthepouring systemandthediverter coneisintheupperpart

Forcoldchamberdie-castingmachine,sprueismainlycomposedofpressurechamberof die-castingmachineandspruesleeveondie-castingmold,andalloycondensateonsprueis calledremainingmaterial

1-Nozzle;2-Spruesleeve;3-Diverter;4-Remainingmaterial

Forhotchamberdie-castingmachines,sprueisgenerallycomposedofnozzlesondie-casting machine,spruesleevesandsplitterconesondie-castingmold

1-nozzle;2-gatesleeve;3-runner

Spruesleeve(nozzle):Aroundsleeve-shapedpartformingasprue,generallyembeddedinfixed moldseatplate,oneendisconnectedtonozzle,andtheotherendisconnectedtofixedmold

insert.Useofspruesleevecansavemoldsteelandeasytoprocess.

Splittercone:aconicalpartthatisassembleddirectlyagainstspruetodivertmoltenmetaland changeflowdirectionsmoothly.Itisusedtoadjustcross-sectionalareaofrunnerandchange flowdirectionofmoltenmetalForasplitterconewitharelativelylargediameter,pushrodscan besetatthecenterorsymmetricallyalongcenter.

Runner(runner):passagefromtheendofspruetothefrontofingate

Itsfunctionistointroducemoltenmetalfromsprueintoingate,andpreheatmoldwiththehelp oflargevolumeofmoltenmetalinrunnerWhencastingcoolsandshrinks,itisusedtofeed shrinkageandtransmitstaticpressureSometimesrunnercanbedividedintomainrunnerand transitionrunner

Mainrunnerandtransitionrunner

1-Mainrunner;2-Transitionrunner

Keypointsofrunnerdesign:

1.Cross-sectionalareaofrunnershouldbekeptuniformorgraduallyreducedfromsprueto ingate,andshouldnotchangerapidlyItisrecommendedthatcross-sectionalareaofexitbe reducedby10%-30%comparedtoentrance.

2Forexpansionfan-shapedrunner,ratioofentrancetoexitgenerallydoesnotexceed1:15,and openinganglemustbe<90°

3Runnershouldbestraightorhaveaslightreversebeveltoavoidairentrainmentorunstable flow.

4Forsmallandthincastings,methodofusingrunnersorexpandingrunnerscanbeusedto

makemoldreachthermalbalance,andblindrunnerscanbeaddedtoaccommodatecolddirty metalliquid,paintresiduesandgases

5.Cross-sectionalareaofrunnershouldnotbesmallerthancross-sectionalareaofinnergate underanycircumstances

6.Whentherearemultiplecavities,trytoadoptasymmetricallayout,makefillingprocess conditionsofeachcavityasconsistentaspossible,andfilleachcavityatthesametimeasmuch aspossible.Whentypesofdie-castingpartsineachcavityaredifferent,cross-sectionalareaof eachingateshouldbecalculatedanddeterminedseparately,andinitialsizeofcross-sectional areashouldbeselectedtobesmaller,soastofacilitateadjustmentandcorrectionofsubsequent moldtrial

Ingate:Asectionofrunnerfromtheendofrunnertocavity

Therearemainlyfollowingcategoriesofgates:

1Sidegate

Openonpartingsurfaceofmold,feedingfromoutsideorinsideofthelargestcontour

Itisgenerallysuitableforplatedie-castingpartsorcoverandshellpartswithnottoodeepcavity

Productswithacertaindepthgenerallyadoptendfacelapjointfeeding

Advantages:simplemolddesignandstructure,easygateremoval,widelyusedindie-casting products

Disadvantages:Whenfeedingdirectlyfromoutside,moltenmetalislikelytosealpartingsurface first,whichmakesitdifficulttodischargegasincavityandformpores

2Directgate(topgate)

Atypeofgatingsysteminwhichsprueisdirectlysetatoutercenterofbottomofshellorcylinder diecastingConnectionwithcastingisingate,whichisalsoplacewiththelargestcross-sectional areaingatingsystem,whichisconvenientforfeedingattheendofdie-castingandholding pressure

Advantages:goodflowstateofmoltenmetal,shortprocess,smoothexhaust,andsumof projectedareaofgatingsystem,overflowgrooveanddiecastingonpartingsurfaceisthe smallest,moldstructureiscompact,nozzleslagisless,andforceisuniform.

Disadvantages:heatjointsareformedatjunctionofdiecastingandsprue(nodeorlocalareain castingthatsolidifiesslowerthansurroundingmetalcanalsobesaidtobetheplacewiththe highesttemperatureandlastcoolingplace,whichispronetoshrinkage,shrinkagecavitiesand

shrinkagestressconcentration)

Gateresidueislarge,anditisdifficulttoremoveGenerally,mechanicalprocessingisusedto removeit.

Sincemoltenmetalenterscavityfromlargeendofsprueandthenrushesstraightintocavity,itis easytocausestickingofmoldandaffectlifeofmold

3Centergate

Itisaspecialformofdirectgate.Whenthereisasmallthroughholenearcenterofproduct, ingateislocatedatthroughhole,andasplitterconeissetinthemiddleMoltenmetalenters cavityinaringshapeatthebottomofdiecasting

Advantages:Ithassameadvantagesastopgate,andatthesametime,therewillbenoshrinkage cavityduetothermaljointsatdirectgatefeed

Disadvantages:Itisdifficulttoremovegate

4Pointgate

Aspecialform,forsomedie-castingpartsthatarebasicallysymmetricalorcenter-symmetricalin shape,uniformandthininwallthickness,smallinsize,smallinheightandhavenoholeinthe centeroftop,pointgatescanbeused

Advantages:Ithasthesameadvantagesastopgate,andatthesametime,therewillbeno shrinkagecavityduetothermaljointsatdirectgatefeed

Disadvantages:Cross-sectionalareaofgateissmall,flowrateofmoltenmetalislarge,itiseasy tocausesplashing,andmoldstickingoccursnearinnergate

Atthesametime,inordertotakeoutcondensateofgatingsystem,apartingsurfaceneedstobe addedtofixedmold,fixed-distancesequentialpartingmechanismisadopted,andmoldstructure isrelativelycomplicated.

5.Ringgate

Mainlyusedincylindricaldiecastings,aisringgateofdirectfeeding,bisringgateoftangential feeding,lessused.

Advantages:Ithasaveryidealfillingstate,smoothexhaust,pushrodscanbesetatringgateand overflowgroove,sothatnothimblemarksareleftonproduct

Disadvantages:Consumptionofmetalrawmaterialsislarge,itisdifficulttoremovegate,moldis oftendesignedasasplittype,andmoldstructureiscomplicated.

6Slotgate

Similartosidegate,differenceisthatdimensionofdepthdirectionofinnergategreatlyexceeds dimensionofwidthdirection,andgateisshapedlikealongstripgap

Advantages:fillingstateisbetter,whichisconducivetopressuretransmission

Disadvantages:Inordertofacilitateprocessing,moldgenerallyalsoneedstobesplitlaterally

Ingatelocationdesignprinciples:

1Importedmoltenmetalshouldfirstfilldeeppartofcavitythatisdifficulttovent,anditisnot

suitabletoimmediatelysealpartingsurfacetocausepoorventing

2Moltenmetalflowingintocavityshouldminimizetwistsandturns,avoidexcessiveeddy currents,andreducewrappinggas

3Positionofinnergateshouldmakeflowofmoltenmetalasshortaspossibletoreduceenergy lossandtemperaturedropofmoltenmetalduringfillingprocess.

4Positionofgateshouldmakedistancebetweenmoltenmetalflowtoeachpartofcavityas equalaspossible,soastoachievesimultaneousfillingandsolidificationofeachdividedpart 5Itisgenerallyinstalledatthickwallofdiecasting,whichisbeneficialtopressuretransmission offeedingflowaftermoltenmetalfillscavity

6Trytouseasingleinnergateanduselessbranchgatestoavoidmutualimpactwhenmultiple channelsofmoltenmetalconverge.Whenmultiplebranchgatesmustbeused,careshouldbe takentopreventmultiplechannelsofmoltenmetalfromcollidingwitheachothertoformeddy currents,resultingindie-castingdefectssuchasairentrainment,oxideinclusions,andcoldshuts

7Considerationshouldbetakentoreducediversionofmoltenmetalincavity,preventdiverted moltenmetalfromcausingcoldjointmarksorcoldshutsattheconfluence

8.Trytoavoidmetalliquidrushingdirectlyintocavity,reducekineticenergyloss,preventerosion andmoldsticking,especiallyavoidimpactingsmallcoresorthreadedcorestopreventbending anddeformation.

9Ingeneral,whencastingisthinandrequiresaclearoutline,athinneringateshouldbeusedto ensuresufficientfillingspeed,buttoothinaningatewillleadtoseriousinjectionofmoltenmetal andbeeasilyblockedbyimpuritiesAtthesametime,moltenmetalenteringcavityisproneto atomization,whichblocksexhaustchannelandcausespittingandporesonthesurfaceofcasting. Forpartswithgeneralshapes,itisrecommendedtouseathickeringate,whichisbeneficialto reducefillingspeedandtransferfeedingpressure.However,ifingateistoothick,fillingspeedwill betoolowandcoolingwillbelarge,whichmayleadtounclearcontoursofcasting,anditwillbe troublesometoremoveingate.

10Itisnotadvisabletoarrangeingateswhereprecisionrequirementsarehigh,surface roughnessvalueislow,andpartsthatarenotprocessedshouldbearrangedtopreventleaving tracesafterremovinggates

11Settingofingateshouldconsiderdistributionoftemperaturefieldofmoldsothatfarendof cavitycanbefilledwell

Commonempiricalformulaforingatesizedesign:

Ringparts,cylindrical

Framepieces

3Overflowsystem

Overflowsystemismainlycomposedofoverflowgroove,exhaustgroove,togetherwithgating system,itisaninseparablewholeincavityfillingprocess

Overflowgroove(slaggingbag):itisusedtopushcondensedmetalliquid,gas,oxidationresidue andotherimpuritiesatthefrontendtogrooveoutsidemoldcavity,soastoincreaselocal temperatureofmoldandachieveagoodandorderlyfillingprocess.Whenoverflowgrooveis openedonmovablemoldside,pushrod(thimble)canbeplacedonoverflowgroove

1-overflowport;2-overflowgroove;3-pushrod;4-exhaustgroove

Principlesforsettinglocationofoverflowtank:

1Setanoverflowtankonlastfillingpartofalloyliquid

2.Whenalloyliquidisdividedintotwostrands(ormorethantwostrands)duetoobstructionof core,anoverflowtankshouldbeprovidednearcavity

3.Anoverflowgrooveshouldbeprovidedforcavityoflocalthickboss

4Whenthereisapartofcavitythatislocallythin,inordertoincreaseheatofcavityatthat place,anoverflowgrooveshouldbeprovidednearplace.

5Overflowgrooveshouldbesetonbothsidesofingateorindeadangleareawheremolten metalcannotbefilledsmoothly,soastoplayroleofdrainageandfilling

6Trytoavoidopeningmultipleoverflowportsononeoverflowtanktoavoidbackflowofmolten metal.

7Whendesigningoverflowtank,payattentiontoconvenienceofpost-processingremoval,and trynottoplaceitonappearancesurface,soastoavoidpost-processingaffectingproduct appearanceInprinciple,underproductperformancerequirements,overflowtankshouldbe addedaslittleaspossibleConsiderincreasingandreducingpost-processingworkload

Suggestedoverflowtankvolumesize:

ConditionsofUse Volumerange Illustrate

Eliminateshrinkage cavitiesatlocalhot spotsindiecastings

Thetotalvolumeof overflowtank

Itis3-4timesofhotspot,or 2-25timesofvolumeof defectivepart.

Notlessthan20%ofdie castings

Ifitisusedasaheatsourcefor equilibriumtemperatureorusedto improvefillingflowpatternofmolten metal,itsvolumeshouldbeincreased

Smalldiecastingshavealargerratio

Therearemainlythreetypesofcross-sectionalshapesofoverflowtanks:

Exhaustgroove:Itisusedtopushgasincavitytoairflowgrooveoutsidemoldcavity,whichis convenientforproductfilling.Itusuallycooperateswithoverflowgrooveandisarrangedatthe backendofoverflowgroovetoenhanceeffectofslagdischargeandexhaust Mainpointsofexhaustgroovedesignareasfollows:

1Locationofexhaustgrooveisbasicallysameasthatofoverflowgroove,anditshouldbeseton partingsurfaceasmuchaspossibletofacilitatedemoulding

2Exhaustgrooveshouldbesetonsamemoldhalfasmuchaspossibletofacilitateprocessing 3Whenexhaustvolumeislarge,numberorwidthofexhaustslotscanbeincreased,and thicknessshouldnotbeincreasedtopreventmoltenmetalfromcloggingorsplashingoutwards 4Exhaustslotsshouldbeopenedattheendofoverflowtank

5.Thetotalcross-sectionalareaofexhaustgrooveisgenerallynotlessthan50%ofthetotal cross-sectionalareaofingate,butmustnotexceedthetotalcross-sectionalareaofingate

6.Whenusingzigzagexhaustgrooves,inordertoreduceexhaustresistance,turningwidthcan betwicethewidthofnormalexhaustgrooves,andlengthofnormalexhaustgroovesshouldnot belessthan15-25mm.

7.Straight-throughexhaustgroovecanbemadeintoasteppedshape,deepenedto1.5times thickness,ormadewithaslopeof15',orprojectionshapeonpartingsurfacecanbemadeinto anenlargedhornshape

Recommendedventsize:

Exhaustslotsize

Alloytype

Leadalloy 005-0108-25

Zincalloy 005-012

Aluminumalloy0.10-0.15

Magnesium alloy 0.10-0.15

Copperalloy 015-020

Blackmetal 020-030

4Ejectionsystem

1Afterexhaustgrooveleavesmoldcavity 20-30mm,itsdepthcanbeincreasedto 03-04mmtoimproveitsexhausteffect;

2Whenitisnecessarytoincreaseareaof exhaustgrooves,itisadvisabletoincrease widthandnumberofexhaustgroovesItisnot advisabletoincreasetheirdepthexcessivelyto preventleakageofmoltenmetal

Ejectionsystemismainlycomposedofejectionelements(pushrod,pushtube,dischargeplate, etc),resetelements(resetrod,inclinedslider,etc),limitelements(limitblocks,limitnails,etc), guideelements(guidecolumn,guidesleeve,etc.),structuralelements(pushplate,pushrod fixingplate,etc),functionistoreleasecastingfromformedpart

Compositionoflaunchorganization

1-Limitnail;2-Resetrod;3-Pushrod;4-Pushtube;5-Pushplateguidesleeve;6-Pushrodfixed plate;7-Pushplate;8-Pushrodguidepost

Push-outdistanceisgenerallydeterminedaccordingtoheightofprotrudingpartingsurfaceof movablemold,asshowninfigurebelow

WhenH≤20mm,St≥H+K

WhenH>20mm,1/3H≤St≤H

Kissafetyfactor,take3-5mm

Formoldswithsplittercones,ifheightofsplitterconeprotrudingfrompartingsurfaceisgreater thanheightofmoldingpart,push-outdistanceshouldbeconsideredaccordingtoheightof

splittercone.

Keypointsforsettingpushrodpushingposition:

1Pushrodsshouldbedistributedreasonablysothatallpartsofcastingareevenlystressed

2.Castinghasadeepcavityandapartwithalargetighteningforce.Diameterandquantityof pushrodshouldbeselectedAtthesametime,pushrodalsohasfunctionsofexhaustand overflow

3Avoidsettingpushrodonimportantsurfaceordatumsurfaceofcasting,andsetpushrodon overflowtank.

4Whennecessary,pushrodshouldbearrangedreasonablyonrunnerWhenthereisasplitter cone,pushrodshouldbesetatthepositionofsplittercone

5Pushrodshouldbesetatpartwithgreaterdemouldingresistance,suchasedgeofsidewallof moldedpart,aroundcoreordeephole,butitshouldbeatleast3mmawayfromsideofcoreto avoidweakeningstrengthofcoreduetotoothinawall

6Pushrodshouldbesetinapartwithalargerthrustbearingcapacity

7PushrodshouldnotbetoothinWhendiameterislessthan8mm,asteppedpushrodshould beused

8.Ingeneral,inordertoensureflatnessofdiecasting,assemblyheightofpushingendsurfaceof pushrodshouldbehigherthanformedparth,buthshouldnotbetoolarge,otherwisedie castingmayadheretopushrod,hisgenerallytakenas0.05-0.1mm,nomorethan0.4mm.

Forthin-walleddie-castingparts,withoutaffectingassembly,thicknessofpush-outpartcanbe appropriatelyincreased,orendfaceofpushrodislowerthancoreh1=0.05-0.1mm,not exceeding02mm,soastoincreasestrengthofdie-castingpart

9.Trytoavoidsettingpushrodattheplacewhereinsertormovablecoreisplaced,otherwise pre-resetmechanismofpush-outmechanismmustbeset

10.Formoldswithsidecore-pullingmechanism,pushingpositionofpushrodshouldtrytoavoid movementinterferencewithresetactionofsidecore

11.Endofpushrodatthepositionofdiverterconeshouldbedesignedintheshapeofdiverter cone,soastoplaytheroleofdiverteratthesametimeasdivertercone

12Whensettingpushrodoninclinedsurfaceofdiecasting,inordertopreventrelativesliding duringpushingoutprocess,multipleparalleltransversegroovesshouldbesetonpushingend slopeofpushrod.

13Whendie-castingpartsarenotallowedtohavethimblemarksandtightnessisnotlarge,push rodscanbeinstalledatrunnersandoverflowgrooves

14Positionofpushrodshouldavoidwaterway

Typeofputter:

Endfaceshowninaisplanar,whichisthemostcommonlyusedform

Whendiameterofpush-outsectionislessthan8mm,tailcanbethickened,asshowninb

Endfacesshownincanddareconical,andatthesametimeofejection,itprovidesapositioning conepitfordrillingandalsoactsasadivertercone

Whateshowsispushrodsetononesideofreinforcingrib,onesideofwhichconstitutesapart offormingsideofreinforcingrib,andatthesametimeplaystheroleofpushingout.

fshowshookpushrodOnhorizontalcoldchamberdie-castingmachine,whenthereisno overhangingactiontopushoutremainingmaterialofrunner,usehookpushrodtorelease remainingmaterialofrunnerfromspruesleeve,thenpushoutremainingmaterial,runnerand diecastingtogetherwithpushrod4ondiecasting,asshowninfigurebelow.

5Corepullingsystem

Core-pullingsystem:Whenthereareundercutsontheoutsideorinsideofdie-castingandcannot bedemoldeddirectly,itisnecessarytodesignpartsatcorrespondingcharacteristicpositionsas movableparts.Mechanismthatresetsextractedmovablepartsandcompletesaboveactionsis core-pullingmechanism

Corepullingsystemgenerallyconsistsofformingelements(sidecores,inserts,etc.),moving elements(sidesliders,inclinedsliders,etc),transmissionelements(obliquepins,racks,hydraulic corepullers,etc.),lockingelements(Lockingblock,wedgeblock,etc.),limitingcomponents (limitingblock,limitingnail,etc)

Compositionofcorepullingmechanism

1-limitblock;2,8-clampingblock;3-obliquepin;4-rectangularslider;5,6-core;7-circularslider; 9-joint;10-stopblock

Core-pullingsystemdesignprinciples:

1.Coreshouldbesetinmovable(fixed)moldperpendiculartopartingsurfaceasfaraspossible, andcoreshouldbepulledoutbyopeningmoldorpushingout,avoidinguseofahuge core-pullingmechanismasmuchaspossible,andusingfixedmoldcore-pullingaslittleas possible

2.Atthepositionofslendermovablecore,trytoavoiddirectimpactofalloyliquid.

3Whencoreispulledouttofinalposition,lengthofsliderleftinguidechuteisgenerallynotless than2/3oflengthofslider,soastoavoidaccidentscausedbytiltofsliderwhencoreisclamped.

4Whenusingmoldopeningandclosingmovementastransmissionofcore-pullingmechanism, attentionshouldbepaidtoresetofmovablecoreandinterferenceofpush-outcomponents whenmoldisclosedGenerally,itisrequiredthatnopush-outcomponentsshouldbeinstalled withinprojectedareaofmovablecore,andhydrauliccorepullingshouldbestrictlyoperatedor safetydevicesshouldbeinstalled.

5Ontheplaneofslider,itisgenerallynotsuitabletoinstallagatingsystemIfagatingsystem mustbeinstalledonit,areasonablelayoutshouldbecarriedout,andplaneofslidershouldbe increasedtopreventgatingsystemfrombeingplacedonguide-slidingmatchingpartofsliderand moldbody,whichwillaffectnormaloperationofsidesliderontheonehand,andmakematching parthaveenoughthermalexpansiongap

6.Die-castingmoldsseldomuseinnerslidersorlifterblocks,becauseproductiontemperatureof die-castingmoldsishigh,moldexpansionislargeandthereisalotofdross,gapbetweenlifter andguideblockisverysmall,problemofstickingisveryeasytooccurduringproductionprocess, resultingincontinuousproductionofmold

Structuraldiagramofobliquepincore-pullingmechanism:

Compositionofsidecorepullingmechanism

1-movablemoldcoverplate;2-movablemoldinsert;3-sidecore;4-punch;5-fixedmoldinsert; 6-fixedmoldcoverplate;7-obliquepin;8-cylindricalpin;9-Sideslideblock;10-clampingblock; 11-tierod;12-stopblock;13-spring;14-washer;15-nut

Actionprocessofobliquepincore-pullingmechanism:

Structuraldiagramofbentpincore-pullingmechanism:

Structuraldiagramofbentpincore-pullingmechanism:

Bendingpincorepullingmechanism

1-spring;2-limitingblock;3-columnscrew;4-clampingblock;5-bentpin;6-slidingblock;7-core Actionprocessofbentpincore-pullingmechanism:

Structureandactionprocessofinclinedslidercore-pullingmechanism:

Inclinedslidersidecorepullingmechanism

1-fixedmoldinsert;2-fixedmoldcoverplate;3-core;4-inclinedslider;5-pushrod;6-corefixed plate;7-limitscrewpin;8-movablemoldcoverplate;9-gatesleeve

Structuraldiagramofrackandpinioncorepullingmechanism:

6.Heating/coolingsystem

Heatingsystem:

Mainlyusedforpreheatingmold,orlocallyheatingmoldtemperaturearea

Whenpouringtemperatureishigh,fluidityofmoltenalloyisgood,andsurfacequalityofcasting isgood,butgassolubilityandoxidationinmoltenalloyareintensified,lifeofdie-castingmoldis short,anditiseasytocausestickingphenomenonforaluminumalloy

Whenpouringtemperatureislow,fluidityofmoltenalloyispoor,andsurfacequalityofcastingis poor,butitprovidesconditionsforuseofadeepexhaustchannel,therebyimprovingexhaust condition,andshrinkageisalsosmall,reducingpossibilityofshrinkageandporesinthickpart duetounevenwallthickness,alsoreducingerosionandstickingofmold,therebyprolonginglife ofmold.

Recommendedpouringtemperaturesforvariousalloysaregivenbelow:

Zincalloy

Aluminumalloy620-710

Thereareseveralheatingmethods:

Magnesiumalloy640-730

Copperalloy 910-960

1Flameheating,suchasblowtorchesandsprayguns,hassimplemethodsandlowcost,but flameheatingwilloverheatsurfaceofmoldbodyorraisedlocalarea,andinsufficientheatingof insideorconcavelocalareaofmoldbody,overheatingwillcausecavityofdie-castingmoldto softenandreducelifeofmold;

2Circulatingheatingwithheatmedium,usingcoolingwaterchanneltofeedhotoil,hotsteam andotherheatingmediumtoheatmoldincirculation,whichissimpletomanufactureandlowin cost;

3.Heatingwithmoldtemperaturecontroldevices,suchasresistanceheaters,electricinduction heaters,andinfraredheatersUsingmoldtemperaturecontroldevicescannotonlyeffectively controlmoldtemperature,butalsoprolongmoldlife;

4Heatingmethodoftubularelectricheatingelementsisgenerallyplacedonmovableandfixed moldsetsorsupportplates,andinstallationholesofelectricheatingelementsaresetaccording toactualneeds

Coolingsystem:

Duringdie-castingprocess,alloyliquidissolidifiedandcooledtopush-outtemperature,and releasedheatisabsorbedbymoldInordertomaintainbalancebetweenheattransferredinto moldandheattransferredfrommold,coolingsystemisoftenrequiredforforcedcooling Reasonabledesignofcoolingsystemcanincreaseproductivityofdiecasting,improvequalityof castingsandprolongservicelifeofmold.

Therearetwomainmethodsofmoldcooling:

1.Watercooling

Coolingwaterchannelissetinmold,andheatistakenawaybypassingwaterintomoldWater coolingefficiencyishighandeasytocontrol.

2Aircooling

Forparticularlyslenderandsmallcoreindie-castingmoldorpartsthataredifficulttousewater cooling,aircoolingmethodofcompressedaircanbeused

Coolingchanneldesignpoints:

1Coolingwaterchannelisrequiredtobearrangedintheareawiththehighesttemperatureand relativelyconcentratedheatincavity,runnermustbesmoothandfreeofblockage

2Distancefromcoolingwaterchanneltocavitysurfaceshouldbeasequalaspossible,distance betweenwaterchannelwallandcavitysurfaceisgenerally12-15mm

3Diameterofcoolingchannelholeisgenerally8-16mm,dependingonsizeandwallthicknessof diecasting

4Temperaturedifferencebetweenentranceandexitofwaterwayshouldbeconsideredassmall aspossibleduringdesign

5.Whencoolingwaterchannelpassesthroughtwoormoretemplatesorparts,sealingmeasures arerequiredtopreventleakage,andrubbersealingringsorsealingsheetsareoftenusedfor sealing.

6Waterpipejointshouldbesetasfaraspossiblebelowmoldoronsideoppositetooperator, anditsouterdiametershouldbeuniform

5.Diecastingprocessandprocessparameters

Diecastingisdividedintofollowingfourprocesses: a.Moldclosingb.Injectionc.Moldopeningd.Pushoutandreset

Themostcriticaloftheseisinjectionprocess:fromtimeinjectionpunchstartstomoveuntil cavityisfilledwithpressure(hotchamberdie-castingmachine),oruntilpressurizationends(cold chamberdie-castingmachine)

PressureandspeedaretwoimportantprocessparametersininjectionprocessDynamic characteristiccurvethatrecordspressureandspeedduringinjectionprocessiscalledinjection processcurve

Duringinjectionprocess,withdisplacementofinjectionpunch,speedandpressurechange accordingtosetpattern

Movementofliquidmetalinpressurechamberandcavitycanbedecomposedintofourstages.

Largeandmedium-sizeddie-castingmachinescurrentlyusedarefour-stageinjection,smalland medium-sizeddie-castingmachinesaremostlythree-stageinjection(secondandthirdstagesare combinedintoonestage),whilehotchamberdiecastingismainlybasedontwostagesof injection(first-speedliquidliftingandsecond-speedfilling)

Thefirststage:Fromstartingpositionofinjectionpunchtopositionbeyondgatingopening Features:Lowpressure,lowspeed,smoothmovement,preventsmoltenmetalfromoverflowing fromthepouringport,andfacilitatesgasdischarge

Thesecondstage:Frompositionbeyondgatetopointwheremoltenmetalfillsuptoinnergate Features:Aspressureincreases,speedofinjectionpunchincreases.Aftercrossingpouring opening,injectionpressureincreases,speedofinjectionpunchspeedsup,andmoltenmetalfills pressurechambertopouringsystem.Atthisstage,airentrainmentshouldbepreventedand moltenmetalshouldnotentermoldcavityinadvance

Thethirdphase:Frompointwheremoltenmetalfillsinnergatetothetimewhencavityis completelyfilled

Features:Injectionpressureincreasesagain,injectionspeeddecreasesslightly,andmoldfilling speedisthefastestSincecross-sectionalareaatinnergateisgreatlyreduced,flowresistance increasessharply,injectionspeeddecreasesslightly,butmoldfillingspeedisthefastestatthis time

Stage4:Chargingends

Features:Injectionpunchstopsmoving,andpressureincreasessharply,reachingthehighest

valueintheentireprocess.Aftercavityisfilled,boosterpressurepressessolidifyingmoltenmetal intochamberInjectionpunchmaymoveforwardslightlyAftermoltenmetalsolidifies,boost pressureisremovedandinjectionprocessends.

Duringdiecasting,therearemanyfactorsthataffectfillingandmoldingofmoltenmetal, includingpressure,speed,temperature,timeandotherparameters

1Pressure

Injectionforce:Workingfluidininjectioncylinderofdie-castingmachineactsoninjectionpunch, causingittopushmoltenmetaltofillmoldcavityThisiscalledinjectionforce Injectionforce

Pg-workingpressureininjectioncylinder,PaD-diameterofinjectioncylinder,m

Specificpressure:forceonunitareaofdie-castingalloyliquidinpressurechamber,thatis,ratio ofinjectionforceofdie-castingmachinetocross-sectionalareaofinjectionpunchSpecific pressureduringfillingiscalledinjectionspecificpressure.Whenthereisaboostermechanism, specificpressureaftersuperchargingiscalledsuperchargingspecificpressure,whichdetermines finalpressureondiecastingandsizeofexpansionforceformedatthistime.

Injectionspecificpressure

Expansionforce:Duringdie-castingprocess,whenmoltenmetalfillscavity,pressureexertedon cavitywallandpartingsurfaceiscalledexpansionforceDuringdie-castingprocess,finalstageof boostingspecificpressureistransmittedtodie-castingmoldthroughmoltenmetal.Expansion forceatthistimeisthelargestInordertopreventdie-castingmoldfrombeingexpanded, clampingforcemustbegreaterthanresultantforceofexpansionforceinmoldclosingdirection Expansionforce

A-Sumofprojectedareasofdiecastings,gates,andoverflowsystemsonpartingsurface

Choosingappropriatespecificpressurecanimprovemechanicalpropertiesofdiecastings

Whencastingsolidifiesunderahighspecificpressure,tinyporesorbubblesinsideitare compressed,densityandstrengthofinternalstructurearehigh.However,asspecificpressureis toohigh,plasticityindexofcastingdecreases,strengthalsodecreases,andmechanicalproperties decline.

Ahigherinjectionspecificpressurecanimprovemoldfillingabilityofmoltenmetal,prevent castingfromcoldshutorinsufficientfillingdefects,andmakeoutlineclearer.However,ifspecific pressureistoohigh,itwillintensifyimpactofmoltenmetalonmoldcavityandacceleratewear ofmold.Generally,alowerspecificpressureisselectedonthepremiseofensuringformingand userequirementsofdiecasting

2.Speed

Therearetwotypesofspeed:injectionspeedandgatespeed

Injectionspeed(punchspeed):speedatwhichinjectionpunchpushesmoltenmetal,whichis speedofinjectionpunch

Innergatespeed(fillingspeed):Linearspeedofmoltenmetalpassingthroughinnergateiscalled ingatespeed

Gatespeed

-Innergatespeed(m/s)

-Injectionspeed(m/s)

d-Injectionpunch(orpressurechamber)diameter(m)

-Innergatecross-sectionalarea

eta-resistancecoefficient,generally03-06

-Liquiddensityofalloy(kg/m3)

Injectionforceislarge,gatespeedishigh;alloyliquiddensityishigh,gatecross-sectionalareais large,andgatespeedislowDuringdie-castingprocess,innergatespeedcanbeadjusteddirectly orindirectlybyadjustinginjectionspeed,changinginjectionpunchdiameter,specificpressure andinnergatecross-sectionalarea

3.Temperature

Temperatureofdie-castingmainlyreferstoalloypouringtemperatureandtemperatureof die-castingmold.

Alloypouringtemperaturereferstoaveragetemperatureofdie-castalloyliquidwhenitenters moldcavityfrompressurechamber.Experiencehasproventhatwhenpressureishigh,pouring temperatureshouldbereducedasmuchaspossibleItisbesttodie-castwhendie-castingalloy liquidisviscousand"porridge-like",whichcanreducefluctuationofsurfacetemperatureof cavityanderosionofcavitybydie-castingalloyliquidHowever,foraluminumalloyswithhigh siliconcontent,itisnotadvisabletodie-castwhendie-castingalloyliquidis"porridge-like", otherwisealargeamountofsiliconwillprecipitateandexistinafreestateinsidecasting, worseningprocessingperformance.

Pouringtemperaturesofvariousdie-castingalloysvarydependingontheirwallthicknessand structuralcomplexity.Pleaserefertotablebelowfortheirvalues.

Pouringtemperatureofvariousdie-castingalloys(unit:℃)

Die-castingmoldmustbepreheatedtoacertaintemperaturebeforeuseFunctionofpreheating istoavoidthermalimpactofhigh-temperaturedie-castingalloyliquidoncold-pressurecasting moldandextendservicelifeofdie-castingmoldThesecondistopreventdie-castingalloyliquid fromquicklylosingfluidityduetoquenchinginmold,sothatcastingcannotbefilledsmoothly.

Forworkingtemperatureofdie-castingmold,pleaserefertotablebelow

4Time

Diecastingparametertime:1.Fillingtime2.Pressurizationtime(pressurebuildingtime)3. Pressureholdingtime(pressureholdingtime)4Moldretentiontime

Fillingtime:Timeittakesformoltenmetaltoentermoldcavityuntilitfillscavityiscalledfilling timeItslengthdependsonsizeandcomplexityofdiecasting,cross-sectionalareaofinnergate, speedofinnergate,etc

Boostingtime:Timerequiredfrommomentmoltenmetalfillsmoldcavitytoreaching predeterminedboostingpressure,thatis,timerequiredforspecificpressureinboostingstageto risefrominjectionspecificpressuretoboostingspecificpressure.Fromperspectiveofdie-casting process,theshorterthistimeis,thebetter,butminimumboostingtimeofamachinewithbetter performanceisnotlessthan0.01s.

Holdingtime:Timefromwhenmoltenmetalfillsmoldcavitytowheninnergateiscompletely solidifiedandpunchpressureactsonmoltenmetal.Ifholdingtimeisinsufficient,thickwallof castingthatisfinallysolidifiedwillnotbecompressed,resultinginshrinkageporositydefectsIf holdingtimeistoolong,castinghassolidifiedandpunchisstillapplyingpressure.Pressureatthis timenolongeraffectsqualityofcastingCommonlyusedholdingtimeinproductionisasfollows:

Moldretentiontime:periodfromendofpressureholdingtomoldopening.Ifmoldretention timeistooshort,castingwillbeeasilydeformedorcrackedduringdemouldingduetohigh temperatureandlowstrength.Ifmoldretentiontimeistoolong,productivitywillbeaffected,

andcastingtemperaturewillbetoolow,resultinginlargeshrinkage,increasedresistancetocore pullingandejectionofcastingHotbrittlealloyswillalsocausecrackingofcastingCommonmold retentiontimeforeachalloyisasfollows:

Commonlyusedmoldretentiontime/s

Selectionofprocessparametersindie-castingproductioncanbecarriedoutaccordingto followingprinciples:

1Ifproductionconditionsareconducivetofillingofalloyinmoldcavityandshrinkageor shrinkageholesofdiecasting,asmallerspecificpressurecanbeselected.Otherwise,alarger specificpressureshouldbeselected

2.Thethickerwallofcastingandthemorecomplexstructure,thegreaterinjectionforceshould be

3.Thethinnerwallofcastingandthemorecomplexstructure,thefasterinjectionspeedshould be

4.Thethickerwallofcasting,thelongerpressureandmoldretentiontimeshouldbe.

5Thethinnercastingwallandthemorecomplexstructure,thehighermoldpouring temperatureshouldbe.

6Analysisofdie-castingdefects

Therearemanydefectsindie-castingparts,andtheirformationiscausedbymanyfactors.Their classificationcanbemainlydividedintofollowingthreecategories:

1.Surfacedefects,poorappearanceofdiecastings,suchasstrains,flowmarks,coldinsulation, undercasting,burrs,etc

2Geometricdefects,shapeandsizeofdie-castingpartsdeviatefromtechnicalrequirements, suchasdeformation,dimensionaldeviation,deflection,etc

3Internaldefects,suchaspores,shrinkageporosity,shrinkagecavities,cracks,etc

Influencingfactorsgenerallyincludefollowingpoints:

1Causedbyalloymaterials,composition,cleanliness,ratio,smeltingprocess,etcofraw materialsandrecycledmaterials

2Causedbydie-castingmachine,whetherinjectionforce,injectionspeed,clampingforceare sufficient,whetherdie-castingprocessparametersareappropriatelyselected,etc.

3Causedbydie-castingoperations,alloypouringtemperature,meltingtemperature,paint sprayingamountandoperation,productioncycle,etc.

4Causedbydie-castingmold,moldstructure,pouringsystemsizeandposition,ejectorpinand layout,coolingsystem,etc.

5Causedbydie-castingdesign,die-castingwallthickness,roundedcorners,draftangle,hotspot location,deeprecess,etc.

Commondefects,characteristics,causesandimprovementplansofdiecastingcanbeseeninthe

followingtable:

Defect name CharacteristicsCause Improvementplan

StrainPartrubsmold during demoulding process, leavingtraces along demoulding direction

1Molddemouldingangleis small

2Cavitysurfaceisrough

3.Releaseagentisnotsprayed inplace/evenly

4.Partejectiondeflection.

5Alloybondingmold(iron contentinaluminumalloyisless than06%)

6Alloypouringtemperatureis highormoldtemperatureistoo high

1Increasedemouldingangle

2.Trimming,grindingand polishingmolds

3.Replacereleaseagent

4Adjustposition,specification andquantityofpushrodtomake ejectionbalanced

5.Appropriatelyincreaseiron contentto06%-08%

6Reducealloyliquid temperatureandcontrolmold temperaturewithinprocessrange

Flow marks Alloyliquid that first enteredmold cavityformed anextremely thin and incomplete metallayer, whichwas later compensated bytracesleft byalloyliquid

Cold insulati on

Surfaceof castinghas obvious, irregular sunkenlinear lines

1.Tracesleftbytwostreamsof moltenmetalfillingmoldcavity outofsynchronization.

2Moldtemperatureislow

3.Fillingspeedistoohigh.

4Excessivedosageofrelease agent.

1.Adjustcross-sectionalareaor positionofinnergate

2.Adjustmoldtemperatureand increaseoverflowtank

3.Appropriatelyadjustfilling speedtochangeflowpatternof alloyliquidfillingcavity.

4Usereleaseagentsrationally

CrackSurfaceofdie castinghas linearorwavy lines,which arenarrow

1Alloyliquidpouring temperatureislowormold temperatureislow

2.Poorfluidityofalloyliquid.

3Alloyliquidisfilledinparts andfusionispoor.

4Excessivedosageofrelease agent.

5Lowfillingspeed(longfilling time)

6Poorexhaust

1Appropriatelyincreasepouring temperatureandmold temperature

2.Selectalloycorrectlyto improvealloyfluidity

3.Increaseinjectionspeedand increasecross-sectionalareaof innergate.

4Usereleaseagentsrationally

5.Increaseinjectionpressureand shortenfillingtime

6.Addoverflowgrooveand exhaustgroove

1.Structureofpartis unreasonable,shrinkageis hindered,androundedcorners ofpartaretoosmall

2.Core-pullingandejection

1.Improvepartstructure,reduce wallthicknessdifference,and increaseroundedcorners.

2Trimmold

3.Increasemoldtemperature.

andlong,and tend to developunder action of external forces.

devicesaredeflectedduring operationandreceiveuneven stress

3.Moldtemperatureistoolow andstressislarge

4.Excessivedosageofrelease agent

5.Moldopeningandcorepulling timearetoolate

6Moldtemperatureistoohigh andcastingcycleisshort

4Usereleaseagentsrationally

5.Shortenmoldopeningandcore pullingtime

6.Lowermoldtemperature appropriatelyandadjustcasting cycle

Not cast Alloyliquid doesnotfill moldcavity, and incomplete fillingappears onpart.

1.Alloyliquidtemperatureis low

2.Lowmoldtemperature

3Poormoldexhaust

4.Excessivedosageofrelease agent

5.Alloyliquidcontainshighgas contentandisseverelyoxidized, resultinginreducedfluidity.

6Wallofworkpieceistoothin orthicknessisverydifferent

7Insufficientpouringamountof alloyliquid

8Lowpouringpressure/short injectiontime

1.Providealloyliquid temperature

2.Providemoldtemperature

3Addoverflowgrooveand exhaustgroove

4Usereleaseagentsrationally

5.Usecorrectsmeltingprocessto eliminategasesandnon-metallic inclusions.

6Improvestructureofpartsand adjust wall thickness appropriately

7Increasepouringvolume

8Adjustpouringparameters

Bubble s Thereare bumpssizeof ricegrainson thesurfaceof die-casting partsand cavitiesare formedunder skin

1Moldtemperatureishighand alargeamountofwatervaporis generatedwhenspraying releaseagent.

2Fillingspeedisfast,andtoo muchgasisinvolvedinmetal flow

3.Improperselectionofrelease agent(containstoomany volatiles)

4Poormoldexhaust

5.Alloymeltingtemperatureis toohigh,resultingintoomuch airinit

1Reducemoldtemperature

2.Adjustinjectionparameters

3Reasonableselectionofrelease agents

4Addoverflowgrooveand exhaustgroove

5Adjustsmeltingprocessand lowertemperature

2.Addoverflowgrooveand exhaustgroove

3.Reasonablycontroldosageof

Shrinka ge cavity

cavityisrolled intobodyto formholes withregular shapesand smooth surfaces

During condensation processof product,holes withirregular shapesand roughsurfaces areformed due to insufficient internal compensation

4Releaseagentcontainstoo manyvolatiles

5Highmoldtemperature

6.Pouringspeedisthroughhole andproducesturbulence

releaseagent

4.Reasonableselectionofrelease agents

5.Reasonablycontrolmold temperature

6.Reducepouringspeed

1Pouringtemperatureofalloy liquidistoohigh

2Structuralwallthicknessis uneven,resultinginthermal junctions

3Overflowtankcapacityisnot enoughandoverflowopeningis toothin

4.Excessivedosageofrelease agent

5.Localtemperatureofmoldis toohigh

6.Innergateissmall

7Pouringpressureissmalland speedisslow.

1Reducepouringtemperature

2Improvepartstructure, uniformwallthickness,andslow transition

3.Increasecapacityofoverflow tankandthickenoverflow opening.

4Usereleaseagentsrationally

5.Reasonablycontrolmold temperature

6.Increasecross-sectionalareaof innergatetofacilitatepressure transmission.

7Increasepouringpressureand speed

Defor mation

Overallorlocal changesin geometric shapeofpart thatdonot conformto design requirements

1Poorstructuraldesignof parts,causingunevenshrinkage

2Insufficientcoolingtime/high moldtemperatureand insufficientrigidityofpart

3.Moldejectionsettingposition isunreasonableandejectionis deflected.

1Improvepartstructuretomake wallthicknessuniform

2Increasecoolingtime/reduce moldtemperature

3Adjustpositionofejection mechanismtoensurebalanced ejection

4.Eliminatestickymold

Stepmarks appearonthe surfaceofdie casting

4Partssticktomoldandcause deformation.

5Thereisalargetemperature differenceindifferentpartsof moldcavityandunevencooling

1Misalignmentofmovingand fixedmolds

2Sliderismisaligned,looseand retreats

3.Causedbythickcape

1Adjustmatingsurfaceof movingandfixedmolds

5Reasonablycontrolmold temperaturetoensurethatthe overalltemperatureofmold cavitytendstobebalanced. Level (step differe

2Fastensliderandothermoving parts

3.Re-process,grindorincrease clampingforce

Sticky mold During die-casting process,alloy

1Moldorcoreheattreatment problem,nonitridingor oxidation

1Surfacenitridingoroxidation treatmentofthemold

2Reasonableselectionofrelease

adheresto moldcavity partiallyor evenentirely.

BurrsMetalflakes appearingon edgesofparts oratjointsof moldcavities

2Releaseagenthaspooreffect

3.Releaseagentisnotsprayed inplace/evenly

4.Designproblemsorstructural problemsofcastingitself

1Insufficientclampingforce

2Partingsurfaceisnottightly sealed,andtherearegapsor debris

3Thereisovercutin close-fittingpartofmold

4.Moldsliderorinsertisworn. 5Moldstrengthorrigidityis poor,resultinginelastic deformation

6.Highinjectionpressure/fast injectionspeed

7.Gapbetweenslidingpartsin cavityandcoreistoolarge

8.Moldisnotpressedtightly duringinstallation

9.Moldlockingelementfails, sliderretreatsandgap

agents

3.Usereleaseagentsrationally

4Adjustproductstructure

1Increaseclampingforce

2Adjustmoldandre-fitloose fittingparts/removedebris

3Weldover-cutpartsand re-processandgrindthem

4Checkwearandtearandrepair orreplace

5Increasethicknessof formwork/increaseformworkor addsupportcolumns

6.Adjustinjectionprocess parameters

7.Adjustmoldtoreducegap betweenslidingpartsofcavity andcoreparts.

8Reinstallcompressionmold

9.Repair/replacelocking components(cylinders,wedge plates,etc)