12DESIGNSFOR CIRCULARITY

Part1MeettheSuppliers

NEVERHEARDOFNEWWASTE?

THESUPPLIERS

PART1

MeettheSuppliers

In January 2024, THE UPCYCL launched the circular project "12 Designs for Circularity", featuring 24 of our amazing members. This project is a value chain initiative and part of Denmark’s largest circular economy program, “Closing Loops”. The focus is on how manufacturing companies' waste materials can become new products for other manufacturers.

Through the project, we are matching 12 suppliers of waste materials with 12 design companies that can integrate these materials into their production processes as alternatives to virgin resources.

In this first part of the publication, you will get an overview of the project’s progress this year, with a special focus on the suppliers of waste materials. Learn about the challenges they face in reducing waste and their motivations for joining THE UPCYCL, contributing to a more circular way of working.

At THE UPCYCL our goal is to work together to circulate materials between the production and development stages so that the supply chain will consist more of upcycled items. By sharing resources through THE UPCYCL, we free up time and generate revenue while reducing resource consumption and disposal impact.

THE UPCYCL is a tool and a catalyst for the utilization of materials - even those with skewed dimensions and unrefined edges. By setting requirements for the New Waste materials in the database on uniformity, continuity and volume, we ensure that it is possible to base entire collections and productionson a waste material. This replaces otherwise newly produced components with a upcycled alternative.

WHY?

Because the production or development stages cannot circulate materials with itself. We need each other and the supply or demand we each represent. This way, we can anticipate future carbon taxes and environmental regulations while meeting consumer demand for responsible solutions.

THE UPCYCL

NEVERHEARDOF NEWWASTE?

New Waste is, as the name suggests, entirely unused materials.

It comes from large-scale production, so it's always high quality, consistent and reliable. In other words, a largely untapped treasure trove for designers, producers and creators of all kinds.

THESUPPLIERS

Supply members of THE UPCYCL are manufacturing companies that contribute by sharing their surplus materials waste generated through industrialprocesses.

These companies join THE UPCYCL driven by a commitment to minimizingtheirindustrialwaste.Throughtheirmembership,thesematerials becomeavailableforothermembercompaniestorepurpose,turningwaste intoavaluableresource.

At THE UPCYCL, we refer to these materials as New Waste. For many manufacturers,optimizingproductiontocompletelyeliminatesuchwasteis challenging,asitoftenresultsfromprocessesthatarefundamentaltotheir operations. This type of waste is both consistent and predictable, a phenomenonthattheAAUDesignLabatAalborgUniversityidentifiesas “Statistically Predictable Waste”. By analyzing and quantifying these waste streams,companiesgaintheopportunitytodevelopsolutionstailoredtothe consistentflowofthesematerials,ensuringtheyareeffectivelyutilized.

Inthe12DesignsforCircularityproject,these“industrial-symbiosis”(Clean, 2024)arecreatedbetweencompaniesthatproducethesesteadywastestreams and those capable of repurposing them. The project shows how THE UPCYCL’s circular business model unfolds in practice among its member companies.

HEARDIRECTLYFROMTHESUPPLIERSINTHISPROJECTASTHEY SHARETHEIRPERSPECTIVESONREDUCINGWASTEVOLUMES, COLLABORATINGWITHTHEUPCYCL,ANDCREATINGINDUSTRIALSYMBIOSES.TOGETHER,WEARETRANSFORMINGWASTEINTOA VALUABLERESOURCE,EXTENDINGITSLIFECYCLE,AND COLLECTIVELYMOVINGHIGHERUPTHEWASTEHIERARCHY.

WHATDOTHE SUPPLIERSSAY?

JEVI-MANUFACTUREOFELECTRICALHEATING

SOLUTIONS

“Likealmostallotherindustrialcompanies,Jevihasexperiencedmassive priceincreasesinrawmaterials However,whatiscurrentlyanevengreater challengeisactuallyobtainingmaterials.This,inmyopinion,highlightsthe needforandthebenefitsofthinkinginacircularmanner.Throughour membershipwithTHEUPCYCL,wehavegainedinspirationtoformalize oursecondarysortingprocessandalsotoexploreotherpossibilitieswithin ourproduction”.

–TommyChristensen,CEO,Jevi

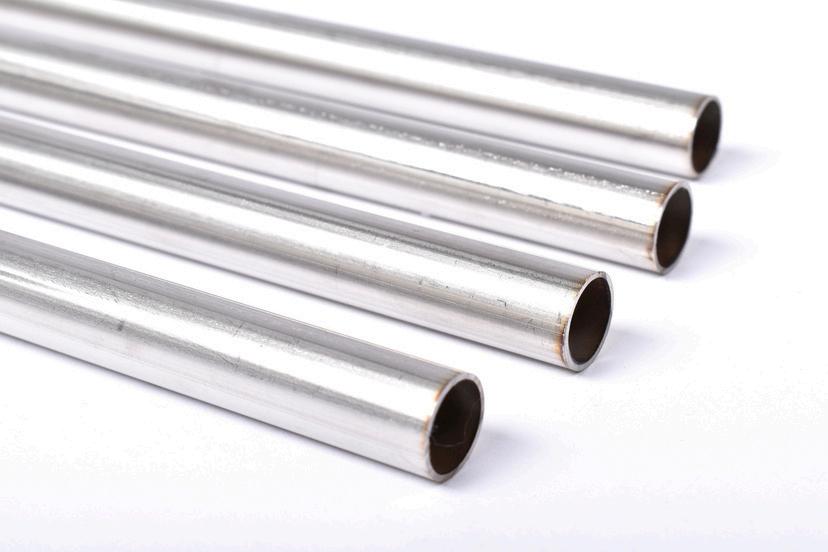

LINDAB-MANUFACTUREOFSOLUTIONSFOR VENTILATION

"AtLindab,weworkhardtofindnewwaystorecycleourmaterials That’s whyweparticipateinprojectslikethis,wherewegivenewlifetowhat otherswoulddiscard.”

–HenioJuhl,ManagingDirector,Lindab

PFP-MANUFACTUREOFCUSTOM-MADE COUNTERTOPS

“Formanyyears,wehavefocusedonreducingtheamountofwasteand leftovers.Wehaveachievedthisthroughprocessoptimizationusingthe machinerywehaveimplemented So,wehaveactuallyreachedarelatively lowlevel.However,therewillalwaysbesomeoffcutsandleftovermaterials, andthat'swhereTHEUPCYCLcanassistusindealingwiththeremaining wastematerialswehave.Theyhavehelpedusgettowherewewanttobe”.

–ClausChristiansen,FactoryManager,PFPA/S

THE UPCYCL

WHATDOTHE SUPPLIERSSAY?

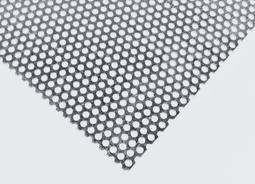

STOKOPLAST-MANUFACTUREOFPLASTIC COMPONENTS

“Wemayhavetorejectapanelduetoatinyimperfectionorsomeotherflaw inaninconvenientspot Asaresult,almostasquaremeterofthismaterial canbeusedelsewhere.WehavebeeninvolvedinTHEUPCYCLforquitea hilenow,andIfindittobeanexcitingjourney.Inournetwork,thegoalis findthesevaluablethingsthatdon'tneedtobediscardedorrecycled ecauseweskipmanystepsbyupcyclingtheproductinsteadofrecyclingit. ItmakesalotofsenseforyourCO2footprint”.

–SteffenClemmensen,CEO,StokoPlastA/S

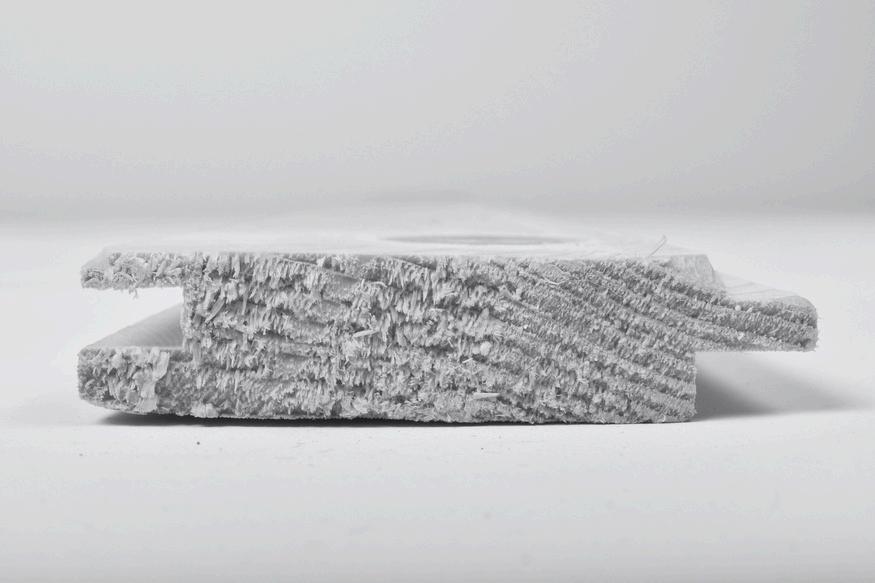

SUPERWOOD-MANUFACTUREOF SUPERWOOD™WOOD

“ThroughourmembershipwithTHEUPCYCL,wehavegainedinspiration toformalizeoursecondarysortingprocessandalsotoexploreother possibilitieswithinourproduction”

ofieMoraKristensen,GroupSustainabilityManager,Superwood

“Whenwesaythatwemaketheworld'sbestboard,westartbybuyingthe bestwoodwecanfind.However,whenitgoesthroughtheplaner,some flawstypicallyoccur,suchasfallenknots,resultinginasignificantnumber ofboardsbeingrejected,whichisfartoovaluabletosimplylabelas‘waste’ Welookforwaystoutilizethiswastesothatitcanbeusedsensibly.”

leDalsgårdNielsen,ManagingDirector,Superwood

THE UPCYCL

WHATDOTHE SUPPLIERSSAY?

KLINGER-GASKETINDUSTRY

“Wemayhavetorejectapanelduetoatinyimperfectionorsomeotherflaw inaninconvenientspot.Asaresult,almostasquaremeterofthismaterial canbeusedelsewhere WehavebeeninvolvedinTHEUPCYCLforquitea whilenow,andIfindittobeanexcitingjourney.Inournetwork,thegoalis tofindthesevaluablethingsthatdon'tneedtobediscardedorrecycled becauseweskipmanystepsbyupcyclingtheproductinsteadofrecyclingit ItmakesalotofsenseforyourCO2footprint”.

–NielsHøjensgaard,ProductionTeamManager,KlingerDenmark

"Wehaveamissiontoreducethewastepercentageincarscrapping.We achievethisbyextractingallresidualmaterialsbeforethecarisscrapped. However,forthistobeaprofitablebusinessforus,itisessentialthatthese idualmaterialscanbesoldtocustomersbeyondourown.Thatiswhy rcollaborationwithTHEUPCYCLisincrediblyimportant,astheir mmunityallowsustoreachcustomersoutsidetheautomotiveindustry"

LiseKorsgaard,SustainabilityManager,SallingAutogenbrug

THE UPCYCL

12DESIGNSFOR CIRCULARITY

In "12 Designs for Circularity", 12 innovative design companies will create designs using New Waste materials from 12 participating manufacturing companies. The result? A stunning collection set to launch in 2025.

"12 Designs for Circularity" is a value chain project and part of Denmark’s largest circular economy program, “Closing Loops”. "Closing Loops" receives co-financing from the EU and the Danish Board of Business and is spearheaded by leading clusters including Lifestyle & Design Cluster, Food & Bio Cluster Denmark, WE BUILD DENMARK, and Clean.

THE UPCYCL was at Loop Forum 2024, where we shared the “12 Designs for Circularity” project.

The development of 12 prototype designs is underway. Following the matches, a series of material-focused workshops were held, where participants experimented with New Waste materials. Based on this, each of the 12 designers has created a prototype.

NEXTSTEPS

Launch event in spring/early summer 2025: Designers will continue refining their prototypes, with the final designs ready by early summer 2025. At this point, we will launch 12 unique designs, all made from New Waste materials materials that would otherwise have ended up as waste but now have a new life.

Sharing the project’s results with the world: We will communicate the outcomes and insights from the project to inspire others to embrace circular solutions. s e ideas.