APRIL 2024 globalindustryfocus.com ISSUE-09 FOR EVERYTHING ELECTRONICS & OFF-BOARD IN THIS ISSUE: Bimos Scienscope Data IO Aegis Apollo Seiko IPC Apex Expo 2024 WNIE Radio

There are always two sides to every story!

There are always two sides to every story!

New AOI inspection system for top and bottom inspection NEW 3DAOI

www.viscom.com

NEW 3DAOI www.viscom.com

New AOI inspection system for top and bottom inspection

Find out more at: Booth A2.177

Find out more at: Booth A2.177

CONNECTING WITH INDUSTRY 04 INTRODUCTION Welcome to the ninth issue of Global Industry Focus 06 BIMOS Workplace Seating Solutions for Industry and Laboratories 10 SCIENSCOPE Celebrating 30 Years of Innovation and Excellence 12 DATA IO Impact of Automotive Megatrends on Electronics Manufacturing and Flash Memory 16 AEGIS Closing the Manufacturing Skills Gap 20 APOLLO SEIKO Pioneering Excellence in Automated Soldering Solutions 24 IPC APEX EXPO 2024 CONNECT WITH THE GLOBAL ELECTRONICS COMMUNITY 25 WNIE RADIO Interviews with ASTUTE 26 AEGIS Technology’s Role in Shaping the Next Generation of Manufacturing 27 ABOUT US Meet the Global Industry Focus team CONTENTS 3 hello @ globalindustryfocus.com APRIL/MAY 2024 GLOBAL INDUSTRY FOCUS

Welcome to Issue 9 of Global Industry Focus!

IPC Apex Expo moves back to Anaheim this year, Global Industry Focus and What’s New in Electronics will be there interviewing some of the key players exhibiting and attending the Expo. This issue of GIF celebrates the breadth of innovation and knowledge that drives this industry forward.

Something that effects every business is the ongoing skills gap Aegis offer some solutions, observing that “As of June 2023, there’s a shortage of almost 600,000 US-based stable manufacturing jobs. If left unaddressed, the manufacturing skills gap could result in 2.1 million unfilled jobs by 2030,”

Data IO offers an incisive overview of the affect that the revolution in automotive electrification is having on the electronics manufacturing industry,

This issue, please enjoy articles from Aegis, Bimos, Scienscope, Apollo Seiko and Data IO, as well as interviews with Astute Electronics and a preview of IPC Apex Expo 2024

Enjoy the read!

Kirsty Hazlewood Editor

INTRODUCTION

APRIL/MAY 2024 GLOBAL INDUSTRY FOCUS Tel: + 44 1428 746 378 4

GLOBAL INDUSTRY FOCUS www.globalindustryfocus.com SCAN FOR YOUR FREE NEWSLETTER YOUR ONLINE CONNECTION TO THE WORLD OF ELECTRONICS FIND US AT IPC APEX EXPO STAND 430

Revolutionizing Workplace Seating Solutions for Industry and Laboratories

In the dynamic realm of industrial and laboratory environments, the significance of ergonomic seating cannot be overstated. Bimos, a leading innovator in this field, has been at the forefront of providing cutting-edge seating solutions tailored to the unique demands of these workspaces. As a brand under the umbrella of Interstuhl Büromöbel GmbH & Co. KG, Bimos exemplifies a commitment to excellence, combining more than five decades of expertise with a dedication to enhancing productivity, health, and motivation for individuals in these specialized settings.

Bimos operates under the ethos of delivering not just products but comprehensive solutions. The company’s close collaboration with users in the field and experts in occupational science positions it uniquely to swiftly develop innovations that precisely address the specific needs of industrial and laboratory environments. This commitment to understanding the intricacies of diverse workplaces has made Bimos a frontrunner in the industry.

Operating as a brand of Interstuhl Büromöbel GmbH & Co. KG, Bimos is part of a family-run company firmly rooted in its responsibility to people, the environment, and the region. With a workforce of over 650 employees, all Bimos products are crafted exclusively in Germany, adhering to the principles of “German Engineering.” This commitment to quality and sustainability extends to the United States, where Bimos has a division based in Chicago, IL, led by Mark Scelfo, the US Managing Director.

“We are the leading manufacturer of the best chairs for industry and the laboratory,” said Scelfo. “Our expert knowledge, technical skills, and passion have ensured that for more than 50 years we have been providing the seating that enables people to enjoy working productively and healthily in every possible workplace.” He added that everything the company does it does with passion, and that Bimos doesn’t think in terms of product, but in terms of solutions. As a result, it achieves maximum benefits for each of its customers with its high-performing chairs.

This ties into the company’s mission, which is to make life in the workplace better every day. Thanks to task-specific ergonomics in industry and the laboratory, outstanding design that motivates staff and provides them with feelings of value, and active assumption of social and ecological responsibility in the development of its chairs, Bimos is able to exceed its goal of providing chairs that truly help customers.

Bimos prides itself on possessing unparalleled knowledge about seating and the practical requirements of diverse workplaces. This knowledge, combined with expert advice and unwavering commitment, allows the company to create optimal solutions for customers. Bimos’s reliability is evident in its uncompromising approach to rapid reaction times, ensuring that customers receive top-notch support in advice, training, sampling, delivery, and after-sales assistance.

BIMOS

APRIL/MAY 2024 GLOBAL INDUSTRY FOCUS Tel: + 44 1428 746 378 6

Diverse Product Portfolio

Behind the robust design of a Bimos work chair is the full innovative strength of the leading manufacturer of seating solutions for professional use. Together with occupational physicians and researchers, the company develops top products for every field of application that are fully adapted to the requirements of the respective workstation – whether it is a lab chair or an ergonomic seat for production.

The company’s most popular line is its laboratory chairs. Laboratories demand a level of precision and cleanliness that surpasses many other work environments. Bimos’s laboratory chairs are designed to meet these stringent requirements while providing the hygienic, flexible and compact comfort most needed. Laboratory chairs from Bimos not only adapt to the postures typically found in this area, i.e. the forward-leaning position at the microscope, but they also are functional and contribute to the overall aesthetics of the laboratory environment. Additionally, they can be easily adjusted, taking into account different protection levels and the comfort preferences of employees. These are seating solutions that ideally adapt to the special challenges faced by laboratory workers.

“Science + Technology Seating is a smart investment from a workplace and employee performance standpoint,” Scelfo said. “When you consider scientists and engineers have been provided secondclass seating solutions for decades, there is a huge opportunity and need for companies to spend dollars wisely in product that directly impacts the workers’ daily experience, which translates into really favorable contributions to recruiting, retaining, reward, recognition, and support health and safety. The workplace reflects the culture more than ever and every tool a company can use to make the work experience more positive for their employees is of high value.”

The lab chairs also offer important benefits:

Hygienic Design and Laboratory Ergonomics: Cleanliness is the basic requirement for safe, high-quality work carried out in the laboratory. Whether from dust, dirt, or invisible pollutants – contamination can influence, falsify, and destroy investigative results. Because of this, the company’s laboratory chairs have their own hygienic design. Not only can they be washed, disinfected and withstand all commonly used cleaning agents,

7 hello @ globalindustryfocus.com APRIL/MAY 2024 GLOBAL INDUSTRY FOCUS

but they also have a seamless design. There are no cracks or gaps in which residue can gather. And when it comes to ergonomic quality and user comfort, its laboratory chairs have set the bar high.

Simple, Compact and Design-Oriented:

Adjusting the laboratory chairs from Bimos to suit personal requirements and working situation is selfexplanatory. After all, maximum flexibility only makes sense when it is actually put into use. The compact and sturdy design of the laboratory chairs saves on valuable space in the laboratory, while also reducing the risk of damage caused by heavy use and a regular change of users.

BIMOS offers a comprehensive range of laboratory chairs for many different requirements. Depending on which protection level the laboratory belongs to, there are different characteristics that are crucial for laboratory chairs. Scelfo said that it is important that employees regard the laboratory chairs as comfortable and perceive them as an enhancement. At some workplaces, stools without backrests are more helpful to be as agile as possible, while at other places, employees appreciate laboratory chairs with rests that gently support the back. Regardless of the place of use and the comfort of the laboratory chair, employee health should be considered.

In addition to laboratory chairs, the company provides chairs for other environments:

Work Chairs in Production: Maximum Freedom, Optimum Ergonomics

Production environments pose unique challenges, and Bimos’s work chairs for production workstations are crafted to address these challenges. These chairs combine maximum freedom of movement with optimum ergonomics, flexibility, and resilience. The anatomic shape of the seat and backrest, easily replaceable upholstery, and materials resistant to grease, sparks, and splinters make Bimos’s work chairs the ideal seating solution for production settings.

ESD Chairs: Comprehensive Protection for Electronic Workstations

In electronic workstations, electrostatic discharge (ESD) can cause substantial damage to microelectronic components. The company’s ESDcompliant work chairs provide comprehensive protection by preventing the charging of objects and people. These chairs incorporate conductive comfort upholstery, conductively coated steel parts, volume conductive plastic, and more, ensuring a reliable overall system. Meeting both industry standards and practical everyday demands, these chairs are a testament to Bimos’s commitment to excellence.

Cleanroom Chairs: Premium Seating Solutions for Sterile Environments

Industries such as microelectronics, pharmaceuticals, optics, and medical technology require contamination-free environments. The company’s cleanroom chairs are developed in collaboration with industry and research representatives to meet the highest standards of sterility. With sealed upholstery, back-foaming technology, enclosed mechanisms, and electrostatically conductive materials, these chairs offer premium properties tailored to the demands of everyday use in cleanrooms.

BIMOS

APRIL/MAY 2024 GLOBAL INDUSTRY FOCUS Tel: + 44 1428 746 378 8

For more information

Contact Mark Scelfo, US Managing Director

1235 N. Clybourn #349, Chicago, IL 60610; 630-725-8284

Standing Work and Standing Aids: Supporting Health and Productivity

Recognizing that nearly half of employees need to stand for extended periods, Bimos extends its product range to include high-performance standing aids. These aids provide physical relief without imposing a specific position or hindering work. From simple support for a brief rest to more flexible solutions for prolonged standing, the company’s standing aids are compact, portable, and designed to enhance the well-being of individuals in various work environments.

Bimos stands as a beacon of innovation and excellence in the realm of seating solutions for industrial and laboratory environments. With a rich history, a commitment to customer satisfaction, and a diverse product portfolio tailored to specific workplace needs, Bimos continues to redefine the standards of ergonomic seating. Scelfo concluded, “As industries evolve and workplaces become more specialized, we remain at the forefront, ensuring that individuals across various sectors can enjoy working productively, healthily, and comfortably every day.”

E-mail: m.scelfo@interstuhl.com;

Web site: www.bimos.com, www.interstuhl.com

9 hello @ globalindustryfocus.com APRIL/MAY 2024 GLOBAL INDUSTRY FOCUS

Celebrating 30 Years of Innovation and Excellence: SCIENSCOPE International Marks a Milestone

SCIENSCOPE International, a pioneering force in Electronic Industry, is elated to announce its 30th anniversary. Since its founding three decades ago, SCIENSCOPE International has been at the forefront of innovation, shaping the landscape of electronics with dedication to quality, and firm passion for advancement.

Throughout its history, SCIENSCOPE International has embraced change and an evolving market dynamics to stay ahead of the curve. Its commitment to innovation has resulted in groundbreaking solutions that have transformed industries and empowered businesses worldwide.

SCIENSCOPE

APRIL/MAY 2024 GLOBAL INDUSTRY FOCUS Tel: + 44 1428 746 378 10

Founder and CEO Eddy Lin

Here are some key moments from the company’s timeline over the years:

1994 - The Optical Microscopes:

The company specializes in optical inspection, utilizing cutting-edge technology to provide comprehensive solutions for a wide range of industries.

2000 - X-ray Inspection System:

Scienscope’ s X-ray system revolutionizes the way products are inspected, enabling unprecedented levels of accuracy and efficiency.

2015 - X-ray Component Counter:

Having achieved a significant milestone with the development of the first X-ray component counter, this accomplishment marks a transformative shift in the domain of component counting and inventory management.

2020 – Incoming Material System:

Setting a new standard for efficiency and reliability in material management process.

2022 – Smart Storage Rack:

Marking a new era of intelligent and automated storage solutions and providing a complete Material Management solution.

Reflecting on this significant milestone, Founder and CEO Eddy Lin remarked, “With immense pride, let’s raise a glass to 30 years of excellence and to many more years of groundbreaking innovation!”

The 30th anniversary of SCIENSCOPE International is not just a celebration of the past, it’s about adapting to the present and creating the future that lies ahead. As it embarks on the next chapter of its journey, the company reaffirms its commitment to excellence, innovation, and making a positive impact on the world.

Here’s to 30 years of innovation and endless possibilities!

11 hello @ globalindustryfocus.com APRIL/MAY 2024 GLOBAL INDUSTRY FOCUS

The Impact of Automotive Megatrends on Electronics Manufacturing and Flash Memory

By Jennifer Higgins, Marketing & Communications Manager, Data I/O Corporation

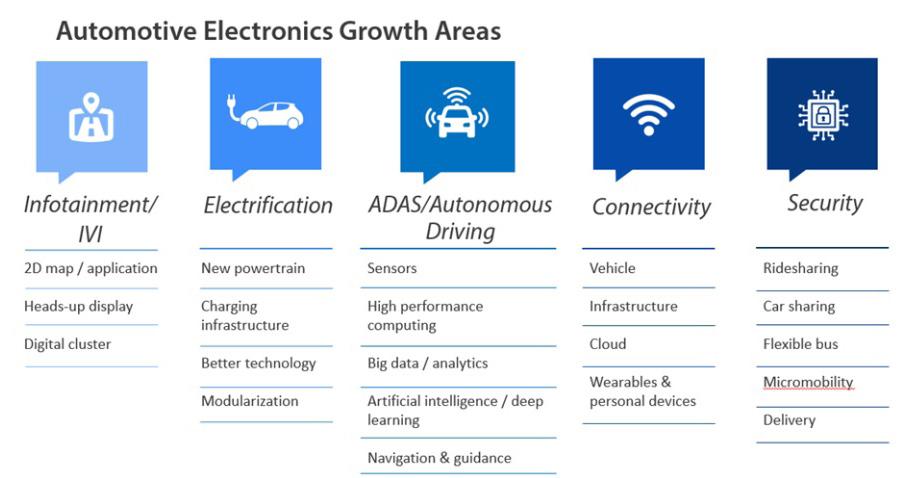

Automotive megatrends, particularly those for connected and autonomous vehicles, are shaping the evolution of Flash Memory technologies and defining new programming requirements for automotive electronics manufacturing.

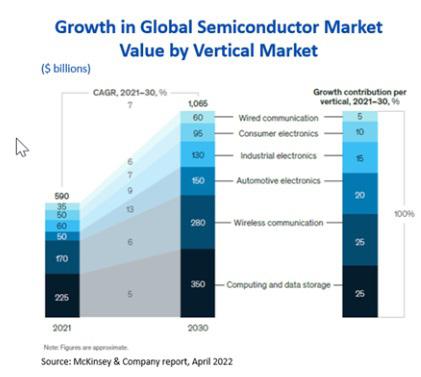

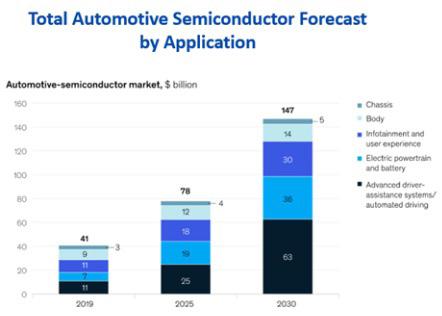

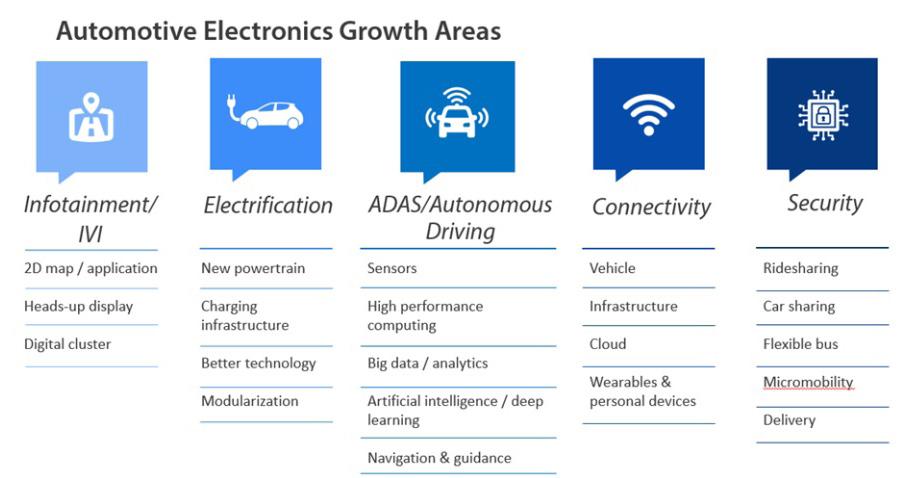

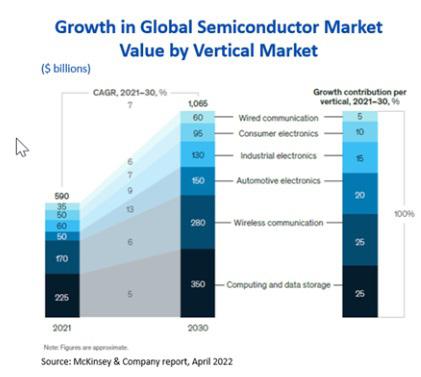

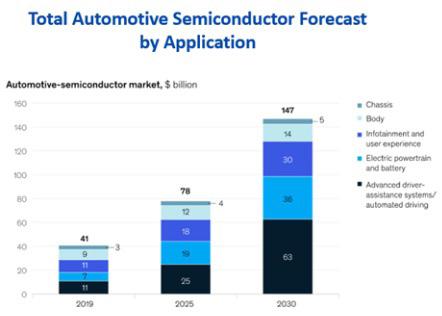

The automotive electronics market is rapidly expanding, driven by five key megatrends: autonomous driving, infotainment, electrification, connectivity, and security. Industry analysts predict a threefold rise in demand for automotive

DATA IO

APRIL/MAY 2024 GLOBAL INDUSTRY FOCUS Tel: + 44 1428 746 378 12

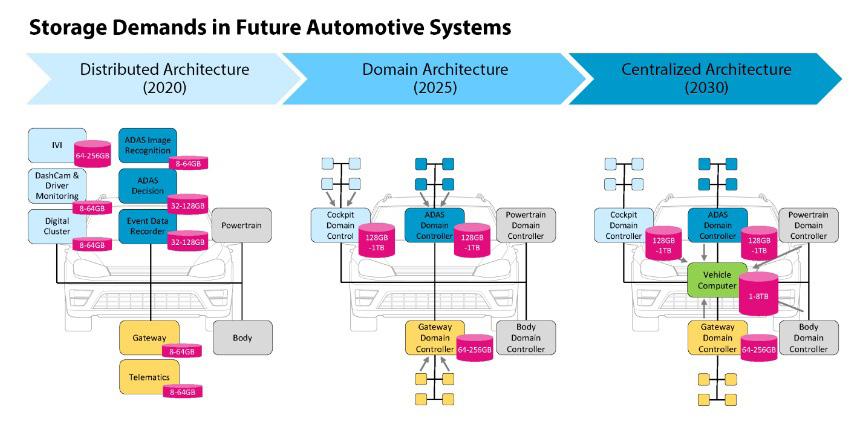

semiconductors within the next eight years. These next-generation automotive applications require more storage for advanced features and event recording. UFS (Universal Flash Storage) has emerged

as the preferred memory solution for IVI (In-Vehicle Infotainment) and ADAS (Advanced Driver Assistance Systems) applications. By 2025, over half of these automotive applications will utilize UFS devices, with the majority transitioning from eMMC to UFS by 2030. This shift is driven by a notable increase in programmable content with faster processing speeds for read/write operations, that cater to new requirements for advanced Flash Memory capabilities.

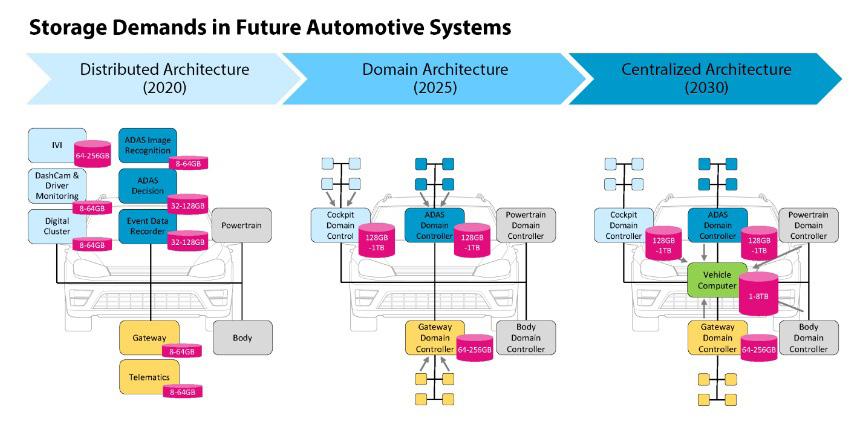

Impact of Automotive Trends on System Architecture and Manufacturing Processes

Connected and autonomous cars are evolving from a hardware-centric to a software-centric design to support new complex features, communication protocols, and security requirements. This is driving changes to the automotive electronics architecture and new flash memory demands. Within the automotive electronics architecture, the shift from a traditional distributed architecture consolidates a multitude of distinct ECUs (Engine Control Units) into a domain-controlled architecture with fewer, more powerful ECUs to support enhanced performance, efficiency, safety, security, and connectivity. The domain architecture consolidates functions like ADAS and infotainment into distinct domains, streamlining resource usage. As vehicles progress towards a more integrated autonomous design, automotive electronics designs will continue transitioning to a centralized or zone-focused approach. This change necessitates advancements in semiconductor technology with higher performance and processing power, increased programmable content, additional storage, and bolstered security.

13 hello @ globalindustryfocus.com APRIL/MAY 2024 GLOBAL INDUSTRY FOCUS

To meet these demands, automotive electronics are transitioning from eMMC to UFS, which offers faster data access and superior memory capacity. This shift poses challenges for manufacturing, including:

• Maintaining throughput as file sizes grow.

• Ensuring data retention for high-density Flash memory durin g x-ray and reflow processes.

• Achieving a cost-effective transition from eMMC to UFS.

• Strategic planning is essential for manufacturers to smoothly transition their programming process to support UFS and prepare for new requirements that optimize the manufacturing process and address evolving automotive industry needs.

To prepare for the impact of the automotive megatrends and the transition to UFS on your manufacturing and programming process consider these six key questions:

1. Can Your Programming System Support UFS and Large Files? Ensure your programming technology can be easily upgraded to accommodate future production demands.

2. What is Your Programming System’s Capacity and Can You Scale it? To combat declining production throughput due to growing file sizes, a programming system with high socket capacity enables manufacturers to expand production throughput without investing in a new programming system.

3. Is your Supplier Innovative and Financially Stable?

A financially stable supplier with a strong history of innovation is essential to reduce the risk of disruption to your manufacturing process when new semiconductor technology is introduced.

4. Can Your Supplier Support New Automotive Security Requirements? New automotive architectures will drive new security provisioning requirements that will impact manufacturing. A programming system that can be upgraded to support security provisioning for hardwarebased security by injecting security credentials into ECUs, DCUs, ZCUs, and CCUs into | secure microcontrollers that support automotive cybersecurity standards and models like e-HSM (embedded Hardware Security Modules), SHE (Secure Hardware Extensions) and EVITA (E-safety vehicle intrusion protected applications) during manufacturing is critical.

5. Does Your Supplier Collaborate on Technical Challenges? Your programming system supplier should have strong industry partnerships and provide co-developed best practices to maximize your quality and throughput.

6. Is Support Easily Accessible? Manufacturers can’t afford delays in production due to equipment issues. Global service that is available 24/7 and remote support tools are vital to keep production running.

DATA IO

APRIL/MAY 2024 GLOBAL INDUSTRY FOCUS Tel: + 44 1428 746 378 14

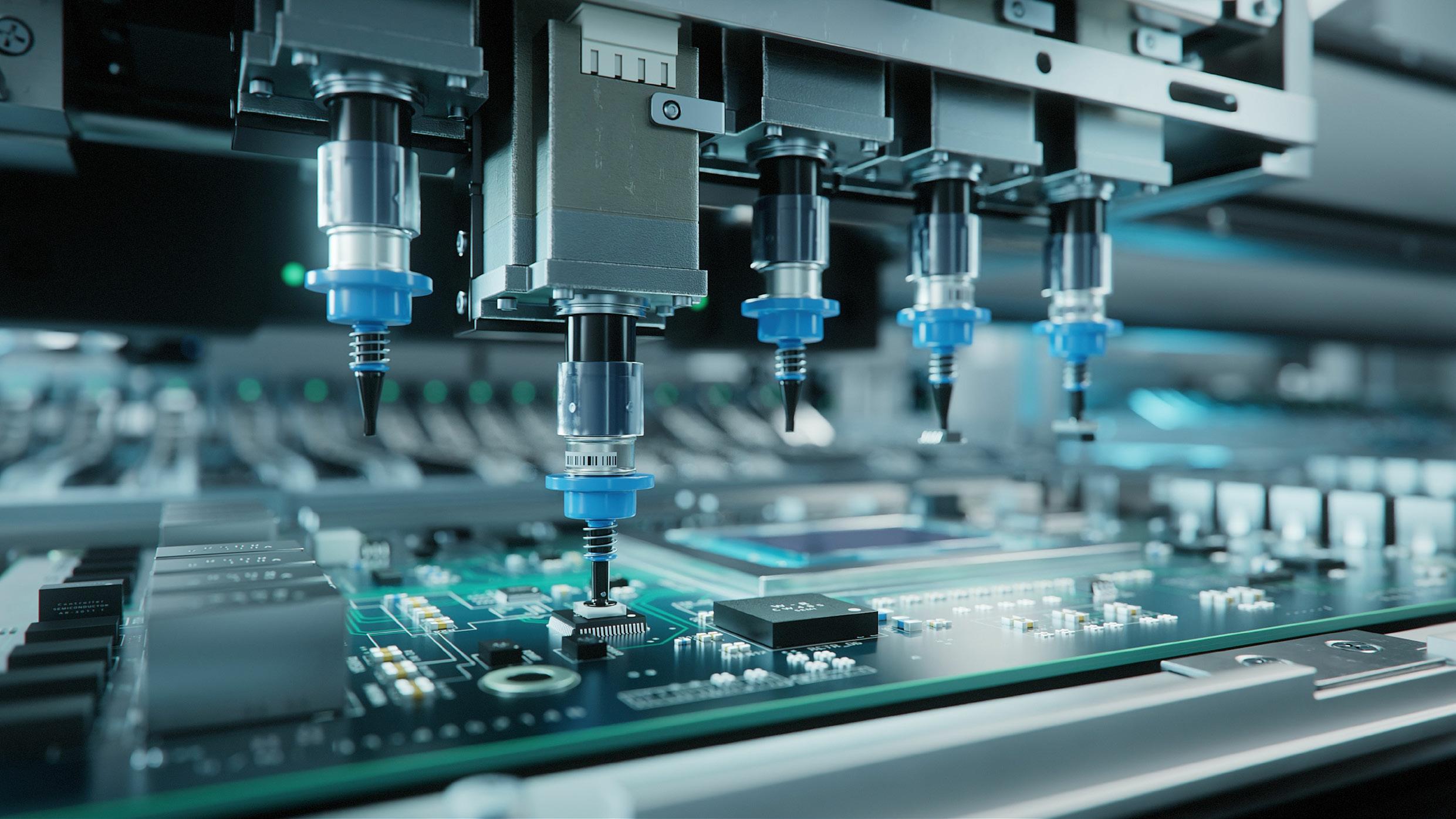

The Global Standard for Automotive Programming

Data I/O, a trusted supplier and partner to automotive electronics manufacturers, supports the latest automotive programming requirements with the PSV systems and LumenX programming technology. By doubling the programming performance for UFS devices and quadrupling the verification performance with VerifyBoost™, Data I/O streamlines the programming process and offers unmatched efficiency, quality, and cost benefits. In addition, Data I/O’s PSV systems can be upgraded to support security provisioning during the preplacement programming process with SentriX, simplifying security provisioning at scale for the lowest total cost of ownership.

With the PSV systems, Data I/O provides industryleading automated programming solutions, combining state-of-the-art robotic handling with LumenX Programming technology for unmatched throughput, programming performance, and socket density for the lowest total cost of ownership. With over 500 installations worldwide and a trusted supplier to 18 out of the top 20 automotive electronics suppliers, customers can upgrade their PSV system to support UFS seamlessly, ensuring flexibility and throughput at a great value. Are you ready to program UFS?

Data I/O’s Automotive Highlights:

• UFS Programming Expertise: 18 of the top 20 automotive electronics manufacturers use Data

I/O systems with over 50 automotive customers programming UFS.

• Strategic Collaborations: Strong partnerships with leading Flash Memory & UFS suppliers.

• Performance Excellence: Remarkable results including 10x UFS programming performance improvement.

• Ongoing Innovation: A 30x performance improvement on LumenX in 8 years.

• Lowest Total Cost of Programming: VerifyBoost™ for LumenX lowers the total cost of programming for UFS applications by up to 70%.

• Committed R&D: 25% of sales are dedicated to research and development.

• Expertise in Security Provisioning: Upgrade a PSV programming system to support hardware-based security during pre-placement programming.

• Global Support: Over 60 engineers worldwide for consistent production support.

• Future-Proof Solutions: Ensuring readiness for current and future demands.

Data I/O is dedicated to providing customers with advanced solutions for automotive electronics programming challenges. To learn more about Data I/O and how it can help program UFS in manufacturing and support new programming requirements for the automotive industry, contact the company at 6645 185th Ave. NE, Suite 100, Redmond, WA 98052; 425-881-6444;

Website: www.dataio.com

15 hello @ globalindustryfocus.com APRIL/MAY 2024 GLOBAL INDUSTRY FOCUS

Closing the Manufacturing Skills Gap: How Manufacturers Can Leverage Technology to Mitigate Workforce Challenges

Deb Geiger, Aegis Software

As a driving force for economic development, the manufacturing industry catalyzes efficiency, optimization, and productivity. But despite manufacturing’s pivotal role, the industry is grappling with a critical challenge that threatens its growth and stability: the widening skills gap.

According to this Deloitte and The Manufacturing Institute report, a staggering 94% of executives acknowledge a noticeable skills gap in the US workforce. As of June 2023, there’s a shortage of almost 600,000 US-based stable manufacturing jobs. If left unaddressed, the manufacturing skills gap could result in 2.1 million unfilled jobs by 2030, with the potential to cost the nation $1 trillion in 2030 alone. These challenges persist worldwide as well—the global manufacturing labor shortage could exceed 8 million people by 2030. In the recent World Economic Forum Future of Jobs Report 2023, almost three in 10 manufacturing and service firms reported production constraints in the second quarter of 2022 due to a lack of workers.

This skills deficit has far-reaching implications, impacting customer demand, technological advancement, productivity and output, product quality, customer service, innovation, and international expansion. So, what exactly can be done to close this widening gap in the industry?

This article explores the progression of technology in manufacturing, the effect of poor knowledge transfer on the skills gap, and how the right systems and technology can enable the connected worker—

driving tangible progress in narrowing the gap for the entire industry.

The Tech Evolution and Growing Skill Requirements

The skills gap doesn’t just affect individual workers; it has a ripple effect on manufacturing operations as a whole. Delays, disruptions, and increased production costs are only a few of the direct consequences of insufficiently skilled or trained workers. A study by Accenture reveals that 64% of manufacturers believe the skills shortage has negatively impacted their ability to meet customer demand.

As manufacturing continues to make technological strides, the skill requirements for the workforce have similarly risen in technical complexity. Industry 4.0, characterized by integrating smart technologies, automation, data exchange, robots, and smart machines working alongside people, demands a workforce equipped with digital literacy, data analysis skills, and a proactive mindset. Preparing the workforce for this evolution is crucial to bridging the skills gap.

These digital shortcomings are substantiated by a Deloitte and The Manufacturing Institute report, which specifies several functional areas that are most impacted by the skills gap. These include:

• Digital skills: Digital skills encompass a range of

AEGIS

APRIL/MAY 2024 GLOBAL INDUSTRY FOCUS Tel: + 44 1428 746 378 16

competencies related to using digital tools, software, and technologies. In manufacturing, this skill set most often pertains to data analysis, process automation, and the operation of digital systems.

• Technology use: Technological proficiency is a driving force in modern manufacturing. Using advanced machinery and other cuttingedge technologies is essential to enhancing efficiency, precision, and overall productivity.

• Supply chain management:

In the manufacturing industry, supply chain management involves coordinating raw materials, production processes, and distribution networks. Effectively managing these processes ensures timely production, cost reductions, and operational efficiency.

• Problem-solving capabilities: In manufacturing, the day-to-day often involves overcoming complex challenges or unexpected setbacks. Because of this, problem-solving skills are essential for identifying and addressing issues in production, quality control, and process improvement.

Compounding this skills shortage is an aging workforce that will soon result in an institutional

knowledge gap, which poses significant challenges in onboarding and retaining talent. According to Deloitte, 2.7 million baby boomers are expected to retire by 2025, creating a vacuum of experience and skills in manufacturing that needs to be filled. So not only does the industry need to attract new talent who can efficiently fill the skills gap, but it also needs to ensure that knowledge is adequately transferred from retiring workers simultaneously.

The Struggle for Information: Transferring Knowledge Between Workers

As the manufacturing industry witnesses the retirement of a substantial portion of its workforce, a pressing challenge emerges in the form of knowledge capture. The accumulated expertise and tacit knowledge held by veteran employees become vulnerable to loss, posing a threat to the continuity of efficient operations. The retiring workforce often possesses a wealth of experience and insights gained over years of service, yet the means to effectively capture and transfer this knowledge to the incoming generation of workers becomes a complex task. The lack of comprehensive knowledge retention strategies can lead to a significant skills gap, hindering the seamless transition of critical insights and best practices.

AEGIS

Simultaneously, younger workers entering the manufacturing sector encounter their own set of challenges. The conventional perception of manufacturing as a labor-intensive sector might discourage certain individuals from considering opportunities within the industry. Moreover, the perception of manufacturing jobs as being disconnected from modern technology and innovation can deter younger individuals who are more accustomed to digital environments. In addition, the fast-paced evolution of technology within the manufacturing landscape may overwhelm new entrants, making it essential for organizations to provide comprehensive training programs to bridge the gap between the skills these workers possess and those needed for modern manufacturing processes. Overall, the industry faces the dual challenge of preserving valuable institutional knowledge from retiring workers while actively engaging and preparing the younger generation for the evolving demands of contemporary manufacturing.

To mitigate these issues in information sharing, the efficient management of systems, training, and tools is truly vital for maintaining a well-informed and agile workforce. This allows knowledge to be seamlessly transferred as the makeup of the workforce changes. Striking the right balance between centralized (within the organization) and decentralized (individual) knowledge-sharing efforts is key, as this ensures information is up-to-date, accessible, and relevant while preventing it from being lost in personnel changes.

Collaborative platforms, learning initiatives, and more digital-focused teams are powerful tools for managing and transferring knowledge and can help manufacturers achieve this balance. However, their efforts are often hindered by outdated systems and a lack of integration in the manufacturing environments they work in. Investing in better processes and systems that facilitate collaboration, version control, and real-time updates can empower digital workers to contribute more effectively to knowledge management.

Technology’s Impact on the Connected Worker of Tomorrow

The right technology solutions can bridge the skills gap by enabling efficient work processes and facilitating skill development in a scalable way. Leveraging a composability approach in manufacturing solutions enables the creation of personalized and real-time, context-aware work instructions that can dynamically adapt to changing production variables, reducing downtime, and preventing costly mistakes. Composability, as a system design principle, revolves around the inter-relationships of components, allowing for their selection and assembly into diverse combinations that meet specific user requirements. Embracing composability can empower the connected worker and transform their interactions with manufacturing execution systems (MES), real-time work instructions, IoT integrations, and personalized user interfaces. Because of this, the connected worker can now operate in an environment where instructions align seamlessly with the evolving context, enhancing overall operational efficiency. This vast access to contextualized data gives operators actionable insights to facilitate informed decision-making. It allows connected workers to respond proactively to emerging trends, identify areas for improvement, and drive continuous innovation.

In addition, harnessing the true potential of automation and other advancements plays a pivotal role in managing knowledge and improving efficiency within the manufacturing sector. Implementing smart knowledge management systems that leverage artificial intelligence (AI) can streamline information retrieval, reduce errors, and enhance overall productivity. For example, AI-driven systems can analyze historical data to predict future challenges, enabling proactive decision-making. Manufacturers at the forefront of the industry already know this. According to a study by McKinsey, leading manufacturers are 25% more likely to leverage advanced analytics and artificial intelligence in their operations.

APRIL/MAY 2024 GLOBAL INDUSTRY FOCUS Tel: + 44 1428 746 378 18

But staying ahead in an evolving industry requires more than technology—it demands a strategic solution that puts people first. Navigating the transition to Industry 4.0 involves adopting new technologies and defining a human-centric approach to connected frameworks.

According to a report by PwC, successful manufacturers are 50% more likely to prioritize human experience in their digital transformation initiatives. Creating frameworks that enhance the worker experience is critical for attracting and retaining top talent. These frameworks should prioritize continuous learning, collaboration, and a supportive work environment, combining the best technology and the human workers who power it. The merging of human and machine collaboration creates an exciting environment that can even be leveraged during the recruiting process, providing multiple career paths that may not have been possible before. This path empowers workers and positions them for success from day one.

Leveraging an MES that Drives Efficiency to Shrink the Skills Gap

Tackling the manufacturing skills gap requires a multifaceted approach that combines strategic workforce planning, technological innovation, knowledge sharing, human-centricity, and a commitment to a collaborative work environment. Addressing these requirements starts with ensuring the right system is in place to enable more efficient and connected operations. Modern Manufacturing Execution Systems (MES) provide real-time insights, intelligent analytics, and a composable approach to designing personalized user experiences to bolster efficient workflows, streamline knowledge management, and enhance worker capabilities. It should give the teams tailored information and real-time feedback that

19 hello @ globalindustryfocus.com APRIL/MAY 2024 GLOBAL INDUSTRY FOCUS

Apollo Seiko: Pioneering Excellence in Automated Soldering Solutions

Established in 1969, Apollo Seiko is a worldwide leader in the selective soldering industry. For the past 55 years, Apollo Seiko has been committed to the research and development of advanced soldering solutions and building strong customer partnerships. Apollo Seiko has dedicated the past five+ decades to the design and development of automated soldering systems. Founded by the visionary George Kawaguchi, the company has played a pivotal role in revolutionizing the soldering industry through the development of advanced automated soldering systems.

Apollo Seiko’s journey began with Kawaguchi’s recognition of the need to automate the laborintensive process of hand soldering. In response to this challenge, the company dedicated the past five+ decades to designing and developing cutting-edge automated soldering systems. These systems have not only increased output but also enhanced the quality of soldering through precise, repeatable robotic processes.

Since then, Apollo Seiko has consistently led the way in selective soldering technology, securing numerous patents for innovations such as versatile iron tip design, innovative solder feeding techniques, and nitrogen integration. These advancements have resulted in cost-effective, lead-free soldering solutions suitable for both robotic and hand soldering applications. “From automotive to biotechnology, we believe all electronics industries can benefit from automated soldering,” added Rick Schiffer, Director. The company’s commitment to pushing the boundaries of technology is evident in its diverse portfolio of advanced systems, accessories, and consumables.

North American Operations

The North American operations of Apollo Seiko, based in Bridgman, MI, are spearheaded by the experienced and visionary leader, Rick Schiffer. With decades of expertise in manufacturing automation, Rick brings unparalleled dedication to providing quality soldering solutions that cater to a diverse and growing need for mechanization. The centrally located facility in Bridgman features a state-of-the-art demo room, fostering a collaborative environment that aligns with the company’s high expectations. Schiffer added, “In this facility, we build things we are proud of. Our growing interdisciplinary team consists of knowledgeable engineers and technical staff ready to build strong partnerships with our customers.”

The company has a global reputation for quality, innovation, and service. As a leader in selective soldering, Apollo Seiko has developed a portfolio of advanced technology systems, accessories, and consumables.

Product Offerings

Apollo Seiko offers two tiers of products to meet the varied needs of its customers:

Automated Soldering: Known as the most advanced range of automated soldering options, systems include iron tip soldering, sleeve soldering, laser soldering, and selective flow soldering, as well as alternative methods such as a line of high-powered manual soldering stations and heat units capable of providing a solution for a variety of applications across multiple industries.

Apollo Seiko’s iron-tip machines are unique and superior because they use advanced iron cartridge

APOLLO SEIKO

APRIL/MAY 2024 GLOBAL INDUSTRY FOCUS Tel: + 44 1428 746 378 20

technology that provides numerous benefits, including 8-second iron cartridge exchange without tools. The iron tip always returns to the exact same position after replacement, and the direct heating system conducts the heat quickly to the iron tip. Additionally, users can select the most suitable tip profile from a wide variety of iron cartridges, including custom-shaped, and built-in nitrogen nozzle iron cartridges are available.

Sleeve soldering provides a constant, consistent amount of solder without spattering because the high-conductivity sleeve encapsulates the complete melting process. Solder wire is cut to a programmed length before being melted in the ceramic sleeve. It then flows out, leaving nothing behind. This means precise control over solder used without the risk of solder clogs. It also uses fewer consumable parts, offers less repairs, and provides easy maintenance. Using a ceramic sleeve eliminates worries around iron-tip plating oxidizing or eroding. Additionally, wetting the solder in the sleeve does not affect the ceramic. This results in virtually no consumable costs due to the long life of the ceramic sleeve. The simply designed head allows for quick and easy maintenance. Maintenance is as effortless as wiping the sleeve because flux fumes do not come in contact with the mechanical feeding components.

Laser soldering is a non-contact process that eliminates the risk of marring or damaging sensitive components. Robots are capable of producing microsized laser beams for otherwise difficult applications too small for iron tip soldering. The company’s advanced optical technology provides a reliable solution for micro and narrow pitched parts used in high-density electronic equipment. The laser soldering process depends on the type of solder to be used (wire, pre-form or paste). In the case of solder wire, laser irradiation is performed in advance to the joint area (pre-heating). This is the most important process to wet and allow the solder to flow easily when supplying the solder wire to the joint area.

21 hello @ globalindustryfocus.com APRIL/MAY 2024 GLOBAL INDUSTRY FOCUS

As part of its automated soldering line, the company offers its selective flow line of selective soldering systems capable of both inline and all-in-one manufacturing.

Peripheral Equipment: Apollo Seiko’s second tier includes robotic equipment for dispensing, screw tightening, and board cutting, providing a comprehensive solution for full assembly needs.

Accessories & Supplies

The company offers a comprehensive range of accessories and supplies to enhance the performance and flexibility of its machines. These include fume extractors, solder feeders, camera systems, nitrogen generators, measuring units, iron tip cleaners, temperature control, and position control.

In addition to accessories, Apollo Seiko offers a vast selection of soldering supplies and consumables, such as in-house solder, wire feeder tubes, iron tips and cartridges (including custom-made).

Wire Feeding Tubes: The flexible double layer solder feed tubes are designed for the company’s various automated and manual soldering solutions and feeders, ensuring smooth and precise feeding of solder wire.

Iron Tips and Cartridges: With more than 100 types of iron cartridges of varying heater types and length for robotic applications, and over 20 varieties for manual soldering, Apollo Seiko offers both lead and lead-free tips, along with custom-made cartridges on request

Lead-Free Solder: The company’s comprehensive portfolio of lead-free solder, including cored-wire, bar,

and paste for robotics, ensures high-quality soldering with good wettability and minimal spattering.

Additional Benefits and Services

Apollo Seiko goes beyond product offerings, providing additional benefits and services to its customers:

Application Evaluation Program: Customers can take advantage of Apollo Seiko’s application evaluation program by sending a sample board with production details and limitations. The company’s experts determine the most suitable machines for the project.

Technical Information: Recognizing the importance of technical information, Apollo Seiko offers product manuals and specifications on its website, ensuring customers have access to valuable resources.

Videos and Demos Library: The company maintains a comprehensive library of videos and demos on its website, showcasing its robots in action and providing insights into their capabilities.

Apollo Seiko stands at the forefront of the soldering industry, driven by a rich history of innovation and a commitment to customer satisfaction. With a diverse range of automated soldering solutions, accessories, and consumables, the company continues to shape the future of soldering technology. Schiffer concluded, “As we look towards the future, Apollo Seiko remains dedicated to providing cutting-edge solutions that meet the evolving needs of our customers as well as the electronics industry.”

For more information about Apollo Seiko, contact the Rick Schiffer, Director, at 3969 Lemon Creek Rd., Bridgman, MI 49106; 269-465-3400; E-mail: info@ apolloseiko.com; Web site: www.apolloseiko.com.

APOLLO SEIKO

APRIL/MAY 2024 GLOBAL INDUSTRY FOCUS Tel: + 44 1428 746 378 22

Connect with the Global Electronics Community at IPC APEX EXPO 2024

By John W. Mitchell, IPC president and CEO

The show floor. Keynote speakers. Receptions. Awards ceremonies. The best and brightest minds in electronics manufacturing. It’s one of my favorite events of the year – IPC APEX EXPO. I enjoy attending the many receptions, meeting young and upcoming engineers at the Newcomers reception, visiting with our many global colleagues at the international reception, and stopping by the Women in Electronics reception to see many industry leaders, not to mention the exhibitors who showcase the newest equipment available to us.

IPC APEX EXPO offers many opportunities to learn from experts in the field, and to discuss the subjects that are uppermost on our minds: sustainability, factory of the future, workforce, PCB fabrication and materials, advanced packaging and design to name just a few. IPC APEX EXPO 2024 will be held in Anaheim for the first time in 17 years, and we are proud to host the 16th Electronic Circuits World Convention (ECWC16), the international PCB symposium, with an expanded, global technical symposium featuring more than 70 presentations over nine technical tracks.

The diversity of the industry is one of the things that makes us strong, and we see that in committee meetings that provide insight into how our important standards are being revised and developed to include the rapid changes occurring in electronics manufacturing and design. Talking to our cohort of Emerging Engineers and their mentors allows us to see in real-time the passing of the torch from one

generation to the next. The awards ceremonies celebrate those committee members and emerging engineers, as we acknowledge the valuable work they do to build electronics better.

Keynote addresses are an important part of IPC APEX EXPO, and an opening keynote from Paul Bailey, former Principal Concept Technical Director, Walt Disney Imagineering, will be fascinating. Paul developed the projection system used in Millennium Falcon: Smuggler’s Run and directed the delivery of the attraction: Star Wars: Rise of the Resistance. He was also responsible for bringing the Astromech droids to life, earning him the illustrious distinction of “R2D2 expert.”

I will present the luncheon keynote on Wednesday, discussing the future of the human workforce and the role people will play in an increasingly AI driven world. Shawn DuBravac, IPC chief economist, will present the closing keynote on Thursday, providing insight into the next wave in electronics, and what trends are reshaping the industry.

IPC APEX EXPO provides the opportunity to see the community we’ve built up close, to see it grow, expand, and become more tightly knit as the years go by. It’s an exciting time to be in electronics, a wonderful time to be in sunny California, and a valuable opportunity to connect with the larger global electronics community. I hope to see you there, and I hope you’ll seek me out and say hello.

IPC APEX EXPO 2024

APRIL/MAY 2024 GLOBAL INDUSTRY FOCUS Tel: + 44 1428 746 378 24

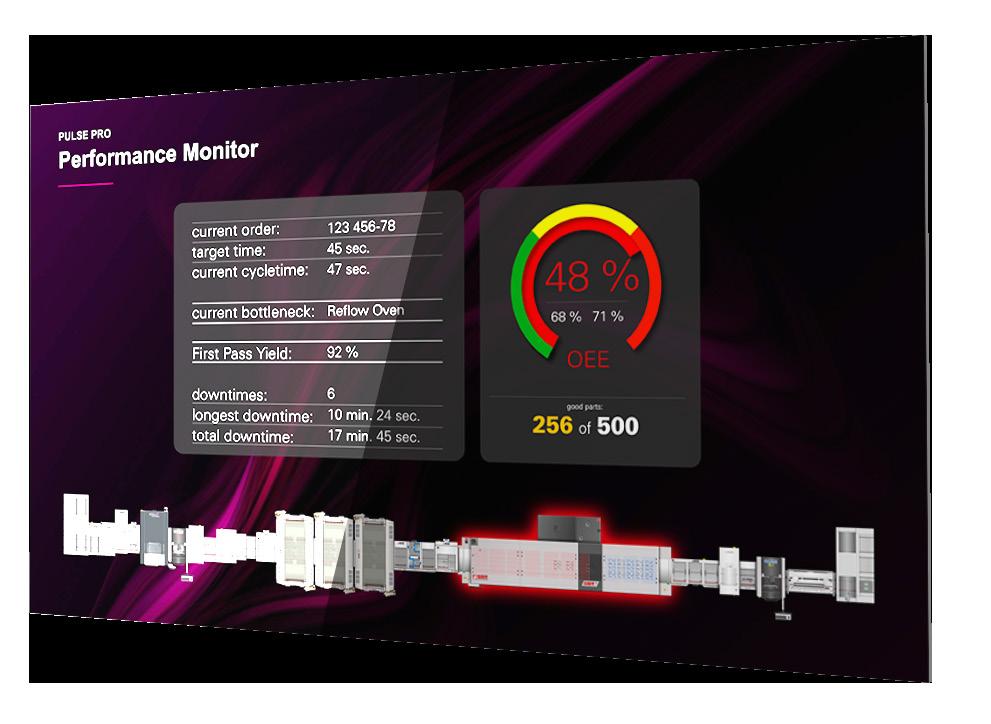

WNIE Radio: Astute Group

Astute is one of the world’s most knowledgeable experts in international electronic component procurement, distribution, and supply chain management

25 hello globalindustryfocus.com APRIL/MAY 2024 GLOBAL INDUSTRY FOCUS RADIO At the heart of the electronics industry Scan to find out more!

Breaking the Mold

Technology’s Role in Shaping the Next Generation of Manufacturing

The evolving landscape of manufacturing is ushering in a new era. Are your operations poised for the advancements ahead?

Manufacturers looking to break away from the pack must ensure their teams are fully equipped with the right tools to elevate productivity and agility and meet the demands of a new generation of manufacturing.

Leveraging a “power applet” approach to composability is the key to transforming laggard organizations into leaders through its ability to simplify complex manufacturing processes and ensure streamlined, error-free operations. It not only empowers teams who are suffering the effects of the pervasive skills gap, but it enables personnel to work to their fullest potential.

This whitepaper covers today’s manufacturing complexities, the effect of the skills shortage, the “power applet” impact on manufacturing and the connected worker, and what it really looks like in action.

Download this whitepaper to learn: Today’s global disruptions and their impact on the supply chain.

How to scale the pervasive skills gap.

How the connected worker of tomorrow can leverage composability.

What the “power-applet” approach to composability looks like.

And more.

AEGIS

DOWNLOAD NOW APRIL/MAY 2024 GLOBAL INDUSTRY FOCUS Tel: + 44 1428 746 378 26

Who We Are:

This digital industry publication offers a global perspective for the whole of the electronics and off board sectors. Complimenting our existing industry hub and weekly WNIE (What’s New in Electronics) platforms, we are confident that in this ever changing world these titles will offer companies a complete marketing solution.

ADVERTISE IN GLOBAL INDUSTRY FOCUS

Offering a magazine that’s targeted at the entire industry will add huge benefits for advertisers too. To maximise budgets, companies need to appeal to both designers and purchasers, inclusion in Global Industry Focus allows enhanced visibility and access to the whole electronics industry, including multiple sectors and multiple job functions, all in one magazine at one cost.

Advertising Packages

We have packages to suit your requirements, either bespoke or ready-made and with an opportunity to advertise across both the Global Industry Focus (GIF) and the What’s New In Electronics (WNIE) industry hub and newsletter.

A Digital Magazine

Global Industry Focus (GIF) is 100% digital, why did we choose a digital publication instead of print?

Digital issues offer:

• Larger circulations

• Reduced advertising costs over printed issues

• Direct delivery to readers in-boxes

• Traceability offering peace of mind to advertisers

• Digital offers more innovative ways for companies to market themselves such as embedded videos.

• Digital delivery of information is now the preferred choice for reading the industries latest news.

CLAIRE SAUNDERS Publisher ROB SAUNDERS Features Editor KIRSTY HAZLEWOOD Editor in Chief TOM SAUNDERS Account Manager IAIN HAZLEWOOD Designer SHELLEY SMART Account Manager

27 hello @ globalindustryfocus.com APRIL/MAY 2024 GLOBAL INDUSTRY FOCUS