7-8 August 2024

Crown Promenade Melbourne

7-8 August 2024

Crown Promenade Melbourne

From Decarbonisation to Digital Twin; and Mental

Wellbeing to Misunderstanding the Reliability Engineer –MAINSTREAM is not your average conference.

Join the MAINSTREAM community in Melbourne for two amazing days of content, networking, knowledge-sharing and fun as we celebrate the people, technology and ideas transforming asset management.

MAINSTREAMacknowledges theWurundjeri Woi Wurrung and Bunurong Boon Wurrung peoplesof the Eastern Kulin as the traditional owners of the greater Melbourne area We pay our respect to the ancient and continuing cultures and connections to land and to Elders past, present, and emerging.

Misalignment Between Asset Strategy and Company Strategy

Poor Asset Data that Compromises Decision-Making

Significant Loss of Institutional Knowledge as the Workforce Ages

Decreasing Quality and Integrity in Work Management Fundamentals

Uncertainty About the Impact of Decarbonisation on the Asset Manager

Declining Mental Health and Well-being of the Maintenance Workforce

Inadequate Alignment of Safety, Risk Management, and Asset Maintenance Plans

Concerning

“MAINSTREAM is the best Asset Management and Reliability Conference in the world.”

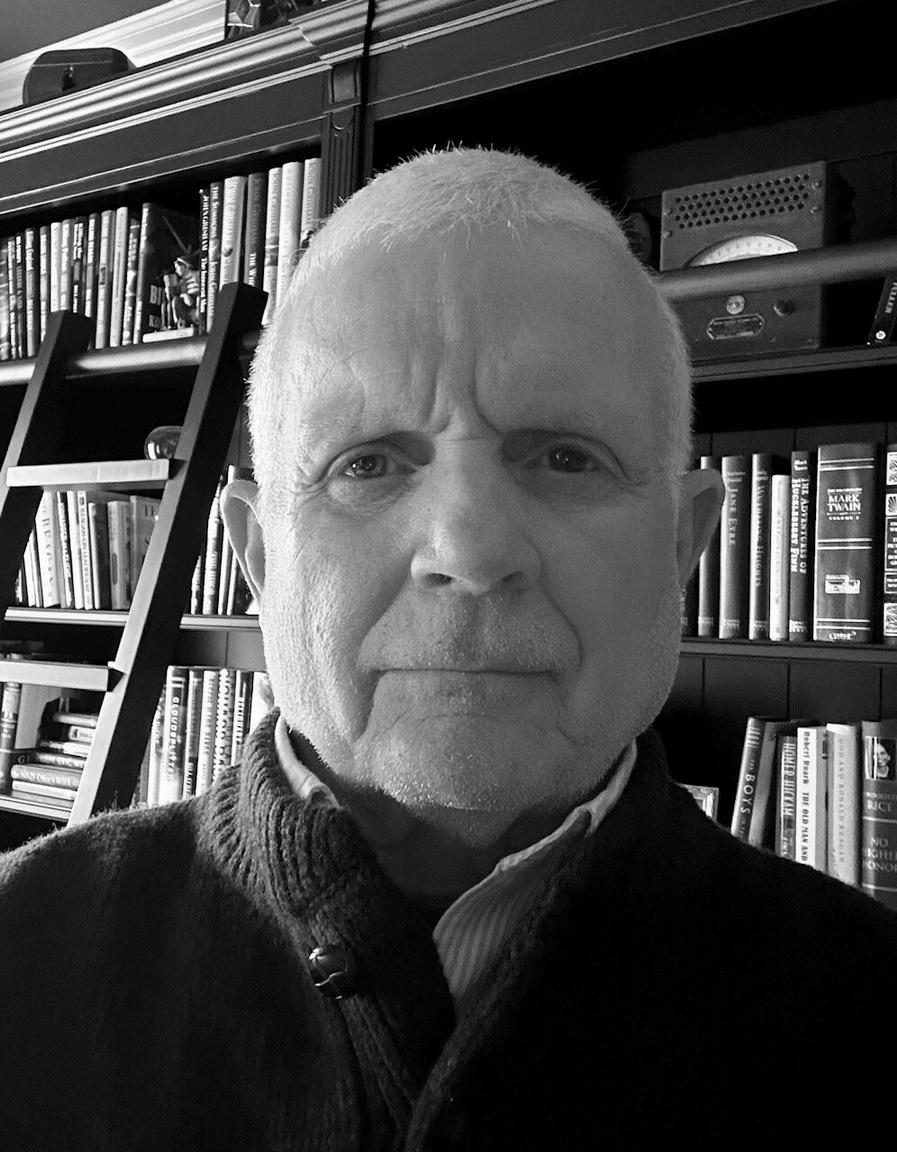

Drew Troyer

“Just when I think it can’t be better… MAINSTREAM goes to the next level”

David Kramer

Curated Content Across Nine Tracks

Access to all Keynotes, Tracks and Demos

Choice of ten 90-minute Masterclasses

Lunch, Morning & Afternoon Teas

MAINSTREAM Networking Function

Mobile App & Meeting Planner

Searchable Attendee List

Access to all Content After the Event

Year-Long Membership to the MAINSTREAM Online Network Platform

Earn CPD points

19.00 - 21.00

JumpStart & Pre-registration at The Boatbuilders Yard

07:15 - 08:15

Registration, Tea & Coffee & Expo

08:20 - 17.15

Keynotes

Vision Stage

Asset Stage

Maintenance Stage

Reliability Stage

Data Stage

Root Cause Stage

Uptime Stage

Education Pavilion

Innovation Theatres

17:15 - 18.45

Networking & expo

19:15 - 23:00

MAINSTREAM After Dark

08/08 Thursday

07:15 - 08:15

Arrival Tea & Coffee & Expo

08.20 - 11.35

Keynotes

Exchange Sessions

Innovation Theatres 11.35 - 16.00

Masterclasses Panel Discussions Closing Keynote 16.05

MAINSTREAM Close

Admired by industrial companies and business schools the world over, the Toyota Production System (TPS) is revered as an organisational culture as much as it is a plant operating system It’s core philosophy to motivate and develop people so that they can surface and solve problems quickly and build a culture of continuous improvement extends beyond the company’s own walls to include its suppliers.

When Toyota’s North American Manufacturing centres were not achieving equipment reliability goals consistently, Ed Welch was appointed to lead the NA Engineering and Maintenance organisation.

A five-year maintenance ‘Hoshin’ (what, why, how) was established, and activities were aligned with specific targets for improvement around Safety, Quality, Productivity, Human Morale, and Cost

Relationship between Toyota Production System and Total Productive Maintenance

Respect for People.

Getting back to basics.

12 principal attributes of Total Productive Maintenance.

TPM implementation methods.

Using the knowledge base of all the employees to improve equipment reliability

Open communication between operators and engineering.

Training production personnel to perform routine maintenance

Assuring a culture of sustained Continuous Improvement (PDCA).

Decarbonization is a once-in-a-lifetime challenge for all our companies, requiring a complete overhaul of production processes, investment in new technologies, and a shift in equipment maintenance and reliability strategies and tactics.

In this keynote panel discussion, we look at decarbonisation through the lens of different stakeholders –senior asset management leaders, regulators and technology providers, discussing the importance of collaboration to drive meaningful emission reductions.

In a MAINSTREAM first, the Clean Energy Regulator (CER) will outline their role and explain the impact of the Safeguard Mechanism and the Australian Carbon Exchange. Thereafter we tackle key principles like risk, skills, and communication The session encourages interaction and is designed for you to discover how you and your team can support and positively influence these initiatives in your company.

Leveraging site strengths on the decarbonisation journey

Balancing operations, performance, maintenance costs, risk, and emissions

Educating and empowering teams to make an impact

Real-world examples of achieving reduction targets and future improvements

Communicating the decarbonisation transition to the frontline workforce

Working with regulators and proactively adapting to stay compliant

Addressing the risks associated with stranded assets

Managing capacity and resources as we all decarbonise together

Strategic Accounts and Enterprise Growth Market Director, Baker Hughes

Anglo American

General Manager

Clean Air Regulator

When you look around your plant, site, or facility, why is it that are some people are more innovative, influential, and inspirational than others? And critically, how are they able to repeat their success over and over

In this thought-provoking keynote, Angus will provide you with valuable insights to unlock potential and deepen meaning - for yourself, your teams, and your organisation

For greater impact and thinking time, this session is split into two parts

Part 1: "Discovering Your Purpose", kicks off day 2 and focuses on the experiences leaders could choose to identify their purpose, core values and strengths Through reflective exercises and interactive discussions, you will learn how to articulate your own purpose and understand its significance in the broader organisational context

Part 2: "Leading with Purpose", closes out MAINSTREAM at the end of day 2 by building on the insights gained in the morning, with opportunities to test throughout the day, and practical ways for embedding purpose into leadership practices and organisational culture.

·Exploring what it takes to discover personal purpose

·Understanding why purpose-led teams and organisations are successful

·Embedding purpose into leadership and translating into action

Unlocking some secrets to collective performance, with purpose at its heart

·Learning from case studies of thriving purpose-led leaders and organisations

Angus is the former GM of Leadership and Capability at NZ’s largest company, Fonterra, where he led the development of leadership, management and functional capability and deployment through the learning ecosystem across the global Co-operative of 22,000 employees He has extraordinary energy with an insatiable motivation to be of service, create meaning and leave a lasting impact. He commits to those who step into discomfort, act vulnerably and authentically, and go wherever it takes to notice, learn and be their change.

In this inspirational keynote session, Dan Allen and Ed Ross, Co-founders of TradeMutt and TIACS, will tell their story on why they hung up the nail bag and went about shaking up the workwear industry

You’ll hear how a very personal event inspired this duo to change the culture when it comes to the issue of mental health conversations within a community traditionally adverse to such discussions. Learn how Australia's biggest Social Impact workwear company has reframed the conversation around mental health to a more accessible, fun, and optimistic one.

You’ll hear about their amazing journey as they took necessary traditional safety garments and redesigned them to provoke discussions on mental health.

They’ll discuss how this formed the creation of a free and ongoing counselling service aimed at guiding those struggling with mental health via text and call Their journey has enabled TIACS to successfully help thousands of tradies, truckies, rural and blue-collar workers.

Data-driven, automated asset management processes are now in full flight across businesses. The challenge that it has created is turning the huge amounts of information into actionable metrics that drive organisational change and create more mature asset management conversations and decision making

Spending time thinking about how customers and other business stakeholders perceive and look at assets, what the asset’s function is from someone else’s perspective and linking asset management back to tangible real-world examples allows powerful, informed decisions to be made.

Improved communication is the key to obtaining stakeholder buy in and seeing asset management as an opportunity

Communication and listening to others is the key to success

Data quality isn’t a problem, finding ways to clearly communicate the data is the real challenge. Breaking up the problems and solving them is key to making organisational change

David Mate

The meat industry is traditionally reactive. In most cases we’ve given up on proper reliability strategy because of the assumption it’s not sustainable due to nightly tear downs followed by high pressure and temperature washdowns with chemicals.

But this is simply not true, and the Smithfield Foods Maintenance and Reliability team made it their mission to change this mindset. It all came to LANGUAGE.

Why we don't get our reliability initiatives funded.

Why we don't get access to the equipment we need to work on

Aligning the asset strategy with the company strategy.

A satisfied maintenance workforce, with work clarity and accountability

Processes that were easy to understand and train on.

Building a culture that brought operations and maintenance together

Ability to choose the right strategy [predictive or preventive or RTF, etc.].

Simple ways to get back-to-work management fundamentals

A tangible 7% gain in operations capacity throughout the company.

Steve is the Director of the Asset Reliability across 42 manufacturing plants for Smithfield Foods, the largest pork producer in the world, employing more than 50 000 people. Together, Steve and his plant teams jointly created the Smithfield Standard Reliability Process which became a gamechanger in the companies’ respect and understanding of Reliability.

Diversity within the workforce is important as it drives higher performing teams and greater team culture In this session we will examine how Amy recently led a program to increase diversity within a major mining organisation.

We’ll look at how you can attract and retain a diverse workforce in a sustainable way. Focusing on how Amy designed and set up a program to train and embed these individuals within the workforce, rotate through different teams and ultimately find the right place in the organisation for them.

Learn how having a person-centred approach was important to match the talent within the right teams and ensure they felt supported and empowered while coaching and mentoring them on their journey This ultimately saw diversity within the workforce increase, across gender, LGBTQ+ and Indigenous employees with low attrition and higher employee satisfaction.

People focused diversity hiring is important but ensuring the right supports and mechanisms are in place is key to success

Don't forget about the rest of your workforce, bring them on the journey.

Promote internally to create space for the new talent.

Inclusion is everyone’s business

Building internal pipeline of talent is hugely important for the future of maintenance. With the ageing maintenance workforce population in Australia, and slimming talent pool to recruit from, building the capability of maintenance professionals requires development within the organisation.

Traditionally, Reliability and Continuous Improvement positions are leveraged via entrance into the maintenance world through the mining industry. Most of the learning and development left solely to the time spent in the role, with new employees finding their own way to develop core skills needed to be successful in maintenance roles.

Over time, these reliability positions saw a huge churn, varying from 6 months to 18 months. Job dissatisfaction and role clarity were the key drivers behind this turnover

Boral designed a 6-month Reliability Capability program, incorporating education, exposure, and experiential learning elements to elevate capability of 200+ reliability engineers and specialists.

Examining the Reliability Capability program to enhance role clarity and deepen technical, leadership and professional skills of reliability professionals from diverse backgrounds. Why and how we developed internal and external contributors, presenters, facilitators, content developers, and engaged with key internal stakeholders to ensure buy-in from leadership, and reward for participants

The importance of delivering virtual programs through support of external vendors, internal support teams

In this session, we’ll explore how Woodside successfully reduced thousands of maintenance hours and banked over 7 figures in savings by optimising maintenance strategies

We’ll dive into the innovative maintenance strategy review tool that was developed in-house, utilising diverse data sources and applying fundamental reliability techniques. This approach quickly pinpointed over, under and incorrectly maintained equipment, facilitating targeted reviews for datadriven decision making

Uniting reliability fundamentals and data science

The effectiveness of a minimum viable product (MVP) for quick wins.

Deep dive into the strategy review tool & how we achieved rapid business integration and sustained value delivery.

Future plans and application advancements

7 figures in annualized savings by optimising maintenance using operational data and reliability principles.

Saving thousands of maintenance hours.

The direct benefits of a data-driven approach.

Slowly changing culture around data collection and the benefits of good data collection

As Defence launches into its SAP implementation journey, we’ve had to transform how we think about, and manage data The legacy data landscape has grown organically, resulting in a complicated ecosystem where the source of truth hard is to determine, and data sharing is difficult.

Realising the full potential of this mammoth transformation required an uplift in processes, technology, and most importantly – people. Cultivating a data mindset has been a challenge. Adam will share lessons learnt and challenges faced in understanding how to apply a consistent model that also provides enough flexibility to meet user's specific needs, and gains business buy-in.

A framework that empowers and support data custodians.

Fom legacy ways of working to leveraging data insights

Engaging and listening to the business.

People need ownership

Training (what) versus education (why).

Building trust over time to enable successful transformation

Data is not always meaningful to stakeholders.

Pitching the message at the right level to resonate with different areas of the business.

COL Adam J. Dobney

Janvi will zero in on practical lessons from leading and supporting in large, cross-organisational transformational asset management programs based on her experience in working in both private and public sector organisations. Janvi will describe the common challenges and successes faced by organisations when driving such change programmes as well as what affects its successful embedment in the organisations. Janvi brings to life some of her recent experience of working with both regulated and non-regulated sector which have one thing in common that is Asset Management is at the heart of everything they do

Setting out the why: what is the case for change when starting long term asset management transformation programmes.

Setting out the what: What are the vital components that drive successful implementation of asset management programmes.

Personal touch: What in Janvi's experience was the magic ingredient that is necessary when the going gets tough in long change programs.

Building the asset management workforce for the future.

Dr Janvi Shah, is a Chartered Engineer and an Experienced Asset Management Professional working in both public and private sector Formerly held the roles of an Assistant Director for Strategy and Performance at the Birmingham City Council (Europe's largest Council) and Head of Asset Management Strategy at National Highways responsible to lead the multi-year Asset Management Transformation Programme.

Too often in our industry, organisations focus on the latest technology, and the basics of Maintenance and Reliability take a back seat That is a major reason why Reliability often suffers We end up being controlled by our machines and operate in “Reactive Mode,” rushing around putting out fires. Profits suffer and so do our teams

Nancy reveals how to achieve your Reliability goals using Reliability Centered Maintenance (RCM). You will leave empowered to bring five basic skills to the forefront of your own organisation and learn how to have long term success with RCM.

Starting her RCM journey at the Naval Air Warfare Center in 1997, Nancy embraced RCM for Aircraft Launch and Recovery Equipment (ALRE) Progressing to RCM Team Leader, Nancy and her team achieved remarkable results, reducing maintenance, enhancing availability, and cutting costs.

Transitioning to private practice in 2001 with The Force,Inc , Nancy has applied RCM across diverse equipment, notably benefiting projects like the CH-47 Chinook, the US Army’s heavy-lift helicopter, and the National Security Complex. Nancy was personally mentored by John Moubray.

How do we explain the enormous volume of asset and equipment data we collect in a way that tells a story? For people working daily in the data, it makes complete sense, and we understand what it means. For the management staff that we require approval and funding from, it does not make sense

– and they don't have the time to sit and figure it out

After watching the CEO of global sport analytics company, Catapult, at last year’s MAINSTREAM, I started telling stories based on the data, using a narrative that is a priority for our business. This significantly decreased the time spent explaining data so that we could get decisions made.

Paint the story of what you see in the data.

Make sure to align your desired outcome with the larger business strategy in the narrative

Be able to speak to the raw data, when questioned.

Capex business case

Resourcing for contracts.

Piloting new technology

Ruan Welman

Melbourne Airport actively seeks and values diversity in its workforce, including targets within its corporate score card To improve diversity numbers and encourage retention of staff, we established support groups and initiatives including APAC Pride, Women at APAC, celebration of culturally significant days, vignettes showcasing women at Melbourne Airport, pay parity and flexible working

Active recruitment of women into the Asset Management Team.

Identification and celebration of female apprentices and staff within the facilities management contractor workforce.

Initiatives to retain the women in our workforce

The importance of story gathering and sharing.

The energy grid is experiencing a monumental shift, marked by a departure from traditional passive, onedirectional energy assets to the emergence of active assets capable of multi-directional operation. This transformative landscape is driven by the integration of solar and battery technologies, fundamentally altering the operational paradigm for businesses. Beyond merely reducing carbon footprints, these technologies offer businesses the potential to cultivate new revenue streams.

However, this evolution presents both opportunities and pitfalls for asset managers seeking to deliver enhanced value to businesses Ty will delve into the intricacies of this dynamic energy transformation, exploring how asset managers can navigate the challenges to unlock superior value for businesses while avoiding potential pitfalls

A baseline of energy systems and the transformation already happening.

Energy assets as a new, active asset class to be managed and leveraged.

What are the potential pitfalls, and who can you trust?

Why energy literacy is the new competency for asset management success

Ty is a former General Manager, Asset Management with Endeavour Energy with 40 years experience in the energy industry. He led the introduction of new technology into the electricity supply industry; such as large scale battery storage, embedded generation, and digital asset management techniques

At the heart of the Primary Crusher Maintenance Optimization project are the people who maintain our assets and their safety. What started as a maintenance frames project, naturally became a holistic approach to safe performance of crusher maintenance in shutdowns.

Delivering a suite of maintenance aids, innovative solutions, and structured rebuild methodologies, this Asset Management Operational Readiness project at Rio Tinto’s Guidai-Darri Iron Ore Mine embodies Rio Tinto’s core values of Care, Courage, and Curiosity. Driving innovation and continuous improvement in frontline shutdown management resonates with our company's purpose: Finding better ways to provide the materials the world needs.

Aids to reduce safety risks and improve work efficiency.

Dedicated maintenance area and maintenance strategy using SPMT's to deliver ratable components.

Detailed contingency plans that were utilized when the dedicated fixed tower crane failed.

Involvement of frontline management of all work to enable continuity between engineering, operations, and maintenance teams

Replicating learnings from across industry during operational readiness is critical for setting teams up for success

Embracing asset ownership and assigning dedicated resources to critical shutdown tasks reduces overall asset risk and increases frontline safety

Auditing is a great way to establish a baseline understanding of maturity for your asset management functions. It involves ranking yourself against best practices, identifying what you are good at, and where you need to improve It is an integral part of developing the action plan that will allow you to continue to mature and add value in the future.

Organisations who regularly audit their asset management functions tend to be well disciplined and operate with a steady cadence that drives value for their shareholders or owners. The results from their audits trend positively and reflect on the maturity within the organisation This furthermore reflects in the culture within the teams, their engagement with everyday business, and the retainment of the workforce

There are those organisations that while they regularly audit themselves and identify the gaps, the process ends there. They fail to construct an action plan that would address the gaps to create further value, or they fail to deploy and implement their action plan. There is no surprise then that their regular auditing results show no improvement, or worse a decline in maturity After all, value is created from the improvement process by implementing the actions from the audits, not by simply completing the audit

You don't have to gold plate everything

You need to implement the actions.

If you do what you say you will do and demonstrate an improvement, then you can shift the culture dial in the right direction.

Developing and executing the roadmap for improvement.

Continually re-auditing to show the maturity improvement and to realign the roadmap.

Tim Rice

Maintenance and operations working together to drive outstanding results in manufacturing is a challenge. By focusing on the fundamentals of manufacturing and listening to your frontline workers, reliability can be increased dramatically while lowering your costs at same time. We are surrounded by many technology advancements, but having a strong foundation is a must to enable the new technology solutions of the future.

Focus on the 5 foundations of manufacturing: Centerlines, CILs, PMs, Master Cleaning Schedule, & 5S.

Operations and Maintenance Working Together

Listening to your associates (frontline workers) - they will tell you the answers.

Continuously improve the fundamentals

Ron has worked for Mars Inc for over 34 years in engineering, operations, R&D, and maintenance He has a passion for connecting associates globally to drive collaborative solutions across the 130+factories within Mars. Ron is a big supporter of technology, but always balances this with the fundamental tools and the value of human relationships

One of the most impacted industries during Covid, was the Airline industry.

Bringing multiple data sources into one single view and pane of glass to make informed and smarter decisions, was vital to change the maintenance program – and bring aircraft back online after long term groundings and storage Airlines needed to look at over a year's worth of data to ensure that the aircraft were safe while minimising any potential surprises.

The was also a need to improve work scope to maximize capability, helping to cope with losing skills and an aging workforce, post-COVID, that is almost impossible to replace at the same rate. New skillsets were created in the team to extract value from this data, combining data analytics and practical knowledge of the systems. Bringing this all together brought success to predictive maintenance and defect management teams

Combining data sources of sensors, maintenance information data, in-flight alerting, spare parts type provisioning, and other general IP into an accumulated data centralised capability speeds up the research activity This effectively aggregates the data, bringing it into a common format or common location Hear how these systems (often SAAS) result in much more varied data sources, reducing the specialist capabilities and coding capabilities required They also don’t need to be implemented across all the infrastructure across the business.

Benefits are being better at maintenance activity, continually improving our maintenance program to lower the cost of maintaining the asset, maximizing yield, improving safety and minimizing disruption.

There is no perfect tool – just start the journey and your use of the tools will evolve. extracting the data away from the original source allows great manipulation

Understand that technology is accelerating at a rate faster than most of our assets.

You have to develop the skills within your team to make smarter decisions

EDL Energy owns and operates power generation and renewable gas generation assets across 83 sites in Australia, North America, and Europe The complexity of the assets, as well as the difference in how we build or acquire our assets meant that while most of our sites utilise a CMMS to manage maintenance activities, there are some sites that still managing maintenance activities manually. Furthermore, not all sites have comprehensive asset hierarchies and maintenance strategies included in the CMMS.

Recently, EDL Energy embarked on a journey in implementing an integrated ERP across all operations. This also included working on developing a comprehensive and consistent asset hierarchies, as well as developing and optimising maintenance strategies for our assets using an asset performance management application

Due to resource constraints, we could not complete this journey ourselves within the required time frame. This led to EDL partnering with multiple specialist consultancies to deliver the scope of work to enable EDL Energy to manage our assets more consistently, effectively, and efficiently.

The retirement of experienced maintenance professionals is becoming the "new normal". These people have been working in the same roles for years, with so much knowledge that isn't captured or well documented.

Hear how we handled the pending retirement of a key resource that managed the maintenance plans in our asset management system for the entire utility

We used a configuration management approach to record the complex details of how the maintenance plans were put together and maintained, and improved the visibility of the "maintenance plan black box" to key stakeholders.

developed a system to record configuration that was in people's heads. improved procedures and asset register to include missing information

automated our compliance auditing (i.e. does every asset have the correct maintenance plans assigned?)

It's never too soon to identify your key resources and what to do if they leave Companies must accept that you won't be able to replace roles with people with the same amount of experience. But it can be a great opportunity to improve your processes.

Knowing where you want to go means that you need to know where you are starting from! This is easier said than done, so this session will help you define your starting point! Once this is established, we can begin building your roadmap to where you want to be on how to get there on your MRO journey.

I often use the following quote, "what we do not measure, we cannot understand What we do not understand, we cannot improve". Truer words have not been spoken, so I will help you put on X on the map once we've defined where you first step will be taken

A set of metrics that can be implemented quickly to define your MRO position

Initial steps to consider to begin improving your MRO performance

Opportunities available in the short term and long term

To effectively transfer the knowledge and skills necessary for organisations to build profitable and sustainable maintenance and reliability programs, we need to understand 'what needs to be done' and 'why it needs to be done.'

If it's best practice, then why isn't it our standard practice?

How to make good work management happen.

Creating a maintenance philosophy.

The 10 major work management processes.

Getting away from buy-in and getting to work

Measuring for success.

John is a best-selling author and the creator of the Certified Professional Reliability Engineer certification program He has more than three decades of Maintenance and Reliability experience He is a former Captain in the United States Air Force, a commander of the F-111F Field Training Detachment, and a Gulf War veteran He is also a college professor at North Carolina State University’s Maintenance and Reliability Management (MRM). CEO,

After 12 years of bouncing around the corporate side of council I noticed the massive gap in understanding between field and the corporate staff. I developed good working relationships with the field staff and knew their frustrations. Everyone wants the same outcome, but the method of communication wasn’t landing. I went into business improvement to try and bridge the gap, but still couldn’t make the required impact.

My only remaining option was to attempt to make change on the inside. So, I jumped in the deep end and became a team leader

From beauty therapist to leading sewer infrastructure maintenance teams

Understanding the communication rift between corporate and field.

Infiltrating a new team and gaining their trust – how I did it.

Healing the consequences of broken communication.

Learn about your people and use them for their strengths.

Celebrate diversity, encourage inclusivity

Doing things differently.

Leading is about being vulnerable, consistent, and fair

Having all the technical knowledge is not a necessity.

The work continues, but I now have a growing team of fitters and electricians who are happy to come to work, tackle more complex jobs, have less unplanned sickies, who reach out for help with mental health, and apologise to each other when frustrations have been high.

Emma Jefferis

Each year we run our Aurizon People Insights Survey. Last year’s showed that our people were feeling less energised, lacked clarity as to how they linked to the business strategy, and that they felt they were not able to share opinions without fear of retaliation. As a leadership team, we created annual people plans to address the poor morale, low accountability, lack of clarity, and diminishing relationships

Results are in for the initial stages. Last year we had 66% participation. This year was over 90%! This is already a great demonstration of improved psychological safety and people feeling their voice is valued and that it's safe to speak up.

It was also identified that our leaders needed support and development. Aurizon mandated 2-day workshops, followed by coaching pods over 8-12 weeks, for all frontline leaders The workshops focus on building trust, enabling courageous conversations, adapting to different situations and personalities, and what not to say The coaching pods require leaders to take those skills and apply them in real life environments. These have been pivotal in many of the challenging and uncomfortable conversations I have had during my time in leadership

Setting team rituals.

1:1 wellbeing framework to address team and personal growth

Reset BU expectations across teams to improve clarity and purpose.

The importance of language

How to build healthy foundations in the team.

Safe environments so that people can speak up, learn, and share

Framing conversations to enable curiosity, not finger pointing.

Tools to identify how people are feeling

Collaborating with your team to address challenges and support them.

How, why, and when to provide feedback.

Marissa Cowcher

Although we have policies, procedures, work instructions and contracts they may not necessarily provide a practical easy to follow work management flow The relationship between different processes in some cases were not readily identifiable. To overcome these problems, we have been developing Process Maps to help all stakeholders engaged in Work and Service Delivery management. Our guiding principle has been to develop common maintenance delivery objectives and connecting processes and procedures.

Along the way we discovered gaps in our current documents. We also realised we had been placing unreasonable expectations on people in the absence of a defined process

Identify the problems (Gap analysis)

Create a framework between procedures and process maps.

Stakeholder engagement and workshops

Build mutual understanding and consistency.

Design your process maps to support end users

Strike the right balance between requirements and simplicity.

Protect your organisation from knowledge loss.

Anthony Cook

When systems break (and they regularly do) we often turn to root cause analysis to understand what went wrong. While this approach will hopefully prevent that individual failure from reoccurring, other, perhaps closely related parts of the system are still prone to cause the same outcome. Different cause, similar effect.

From a decade of intentionally breaking systems, Shaanan presents new ways to find the systemic causes of faults: whether these be in organizations, digital systems, or physical systems.

How to build better models to find failures in large-scale operations.

Ways that the adversarial mindset can identify weaknesses before they become a crisis

Plus, a good few cyber war-stories!

During this session Steve will explain the journey he undertook when taking on the role of Director of Asset Reliability for Smithfield Foods, the world’s largest pork producer with over 40,000 employees in the United States. In short the situation he inherited was chaotic. What he found were many IOCs that were coming together, with a lack of clear processes and workflows that made maintenance work haphazard at best, and chaotic at worst. In this practical session Steve will explain how the team built a strategic plan, built and implemented clear processes to align leadership, plant teams with external resources and created work aids, documents, and metrics to ensure they achieved successful outcomes.

In this session learn how Steve:

• Created and aligned on a clear mission

• Built out a future world better than the previous

• Introduced gamification into the execution

Whether its relentless organisational change, lack of empathy from leadership, FIFO rosters, or the stress of working in high pressure, dangerous work environments – mental health challenges and their associated ripple effect is a rising problem for most industrial companies.

As the CMHO for Australia Post, and previously working across a range of public and private sector organisations, Simon was struck by the need for some practical and scalable strategies to cut through the complexity of the mental health landscape. Key principles around risk assessment, job design and workload management are critical success factors in any Mental Health strategy.

Importance of a simple and lean approach to mental health; and the avoidance of "fads" and unsupported techniques

Focus on the basics of good supervision and leader clarity to build a culture that enables team members to thrive

Building the capability of front-line supervisors to ensure confidence in managing Mental Health risk

Designing effective risk assessment and analysis processes to enable a lean and effective mitigation approach for critical MH risks.

Helping to prioritise those risks that the workplace should rightly be held accountable for Reducing unnecessary focus on those risks that were more relevant to individual employees.

Most organisations have developed impressive and clear asset management policy and strategy. However, on occasions, we face challenges when implementing these strategies, resulting from realisation of planned or unplanned risks. These risks could be a result of combination of things including but not limited to historic funding challenges, ageing asset, deteriorating asset performance or external factors such as detrimental impacts of climate change

A strategy that enables an outcome driven approach focussing on service to customers whilst effectively managing asset risks is paramount. In addition, having a clearly defined risk-based approach to asset management supports organisations to prioritise the limited funding where there is greatest need.

Creating customer-focussed Asset Management strategy and delivery plans.

Developing a risk-based approach to prioritisation of asset maintenance.

Creating a holistic end to end approach for effective management of asset risk

Reviewing technical standards, policies, processes, and training people.

Having reliable and suitable asset performance data

A journey from the harsh underground mining environment to the busy streets of India An ex-soldier and underground miner has augmented his hi-vis and hard hat with a yoga mat and ancient wisdom. Join Shane as he shares his mission to add this ancient tool to the way we approach men’s mental health, specifically in the blue-collar industries.

In this session you will learn about how he drew inspiration for his own struggles to tackle the taboo topic of men’s mental health in the mining and construction industry, by offering a safe place and familiar face for men to practice yoga for the first time.

Suicide rates are at an all-time high in mining

Addressing the root cause and hitting the topic head.

Breaking down the stigma of working-class men doing yoga

Developing a safe place for men.

Yoga as a preventative, maintenance & complementary therapeutic tool

Alignment between asset and engineering management is crucial for successfully developing, operating, and maintaining infrastructure assets These two areas have different but complementary roles in ensuring that assets are designed, constructed, and operated effectively and efficiently.

PTA identified significant process gaps due to completing project priorities vs maintenance, which leads to a high level of network disruption and risk to asset operation. These issues can lead to entry into service delays, operational challenges, increased costs, and potential risks Other common problems include incomplete asset information, poor integration between project and asset teams, inadequate documentation and handover, poor system assurance, budget constraints, insufficient training, and project delays.

To protect the above challenges, a proactive, standardised, and integrated engineering management plan with clear safety-critical milestones includes all deliverables of asset readiness as per the best practices of asset management and the obligation of the Railway National Safety Law

PTA has an engineering management strategy (EMS) defining the PTA asset life cycle model, including EM4P – Engineering Management for Projects and EM4M – Engineering Management for Maintenance as an engineering governance & assurance process for PTA for delivering safe, reliable, predicted assets life cycle. EM4P is driving the Metronet project engineering assurance activities and provides authorities with enough confidence to make informed decisions for asset readiness and start revenue services.

Engineering and Asset Management Manager

When I started as an apprentice I could not have imagined where my career path would take me

Progressing through the trade ranks I made the move into the world of Work Planning. What a different world that was starting as the sole Planner then building a team all against the backdrop of utilities privatisation. However, during this time I branched out into work management systems implementations, contracting bids and developing maintenance plans and standards These extracurricular activities created a natural progression for me into Asset Management. As for the future, it’s looking bright on the road to renewable energy.

Key takeaways:

Why you need Mentors and Coaches in your career

Successes & Fails (Learning lessons the really hard way)

The impacts of stress and the importance of wellbeing

In this session we’ll showcase a company that acquired another company ending up with two disparate, different ERP systems. Each had years of free-form text descriptions for MRO items, duplicate records, dirty data, inability to visualise inventory levels, stock-outs of critical parts, and lack of spend aggregation and purchasing power.

One of main objectives was to avoid a catastrophic equipment failure which could lead to toxic gases escaping a plant, causing environmental, community and human harm Key processes and strategies were:

Define company-wide data standards to know what good, clean MRO master data needs to look like to support the various business processes that consume that data, so each can run better, faster, cheaper, and more sustainably

Get your data clean, using a proper MRO technical dictionary, monitor data cleanliness over time and keep the existing data clean while creating new data as per data standards using approved workflows and rules that are enforced in an MDM platform

Assure adoption, training, sustainment, and support of the overall end-to-end process, technology and trust in the data by employing policies and procedures that are organisationally operationalised and adapted.

It is all too common that companies fortunate enough to have Reliability Engineers haven’t engaged them properly It has become acceptable practice to misuse skills and talent and even labels Instead, we create high priced part-finders, over-qualified maintenance supervisors, and number crunchers churning out metrics no one really cares about It is time we start putting reliability back into Reliability Engineer. A Certified Professional Reliability Engineer understands the math involved and can compel organizations to follow a path forward.

In this masterclass, you’ll gain ammunition needed to make a compelling case to finally let Reliability Engineers do some reliability engineering

The science of failures

The appreciation for inherent reliability.

The mathematical relationship between Reliability, Availability, & Maintainability

A reliability culture that is hell-bent on making data driven decisions.

Constructing an effect Asset Reference Plan

Compel others to see the vision.

The confidence to make a fiscal argument for greater reliability efforts.

Creating value in the mining industry comes down to three factors –market conditions, geological quality, and the performance of physical assets. As is the case with most commodities, management has little control over the market We trust that the geology is good, otherwise, we wouldn’t be mining the area

The performance of the physical assets is the one dimension over which management wields a great deal of control

Asset management is often viewed as synonymous with maintenance – generally considered a cost centre In this Masterclass, we intend to change your perspective Managing the performance of the assets must be viewed through a different lens – as a value centre.

We begin with an overview of the four primary value and loss/risk drivers:

How upper quartile asset management practices drive EBIT/EBITDA

The potentially disastrous effects of asset management gone awry.

How asset management increases safety performance

Asset management and your energy and carbon footprint.

We’ll conduct an interactive workshop to address how asset management drives EBIT/EBITDA, a lean balance sheet, and ultimately, RONA/ROCE – the true value of a company. Then we’ll set our sights more strategically and discuss how asset management can differentiate you in the market and create a competitive advantage.

Still experiencing more unplanned failure than you would like, along with high maintenance costs and a short, busy, and reactive planning horizon?

Why does having APM and Reliability Engineers not deliver on the promise of balancing risk cost and performance, transitioning the business out of a reactive cycle into a more planned and predictable operation?

Asset management has changed significantly with the advent of RCM, APM, Industry 4.0, IIoT, the acceleration of sensor capabilities and applications, ERP evolutions, mobility, and cloud deployments.

However, it seems we have yet to make the transition from reactive to proactive, from disorder to order, and from uncertainty to predictability

With all the technological advancements, the evolution of the asset management discipline, the expanded focus on reliability, and the use of APM solutions, why have we not made the advancements we would expect?

This Masterclass will explore this question and present some surprisingly simple concepts that can unlock progression and support the success of the large programs and initiatives underway in your organization.

Safety policies, rules, systems, procedures, and training are developed with the best intentions: to enhance overall safety performance and ensure everyone returns home safely each day.

Even well-intended leaders can inadvertently communicate or act in ways that conflict with the intended culture Leaders' behaviour strongly influences the safety culture, determining the daily reality employees experience.

As an executive leader overseeing multiple major hazard facilities in both New Zealand and Canada, Brian has learned from personal experience how challenging it can be to ensure that my own behaviours align with and enhance the intended safety culture.

Even the best written rules, policies and procedures are not enough to prevent mistakes

Your response could enhance or limit the ability to learn when mistakes occur.

Other, unnoticed, environmental, and cultural aspects in the workplace that shape behaviours (often after an incident these become known).

A high level of trust and genuine care in the workplace is critical for genuine progress

High-trust workplaces underpin the desired safety culture.

Developing behaviours that align with the intended safety culture

Avoiding behaviours that undermine the desired safety culture.

Strategies to address behaviours that could derail the desired safety culture.

Every single business in the world has some degree of indirect materials (MRO) that it consumes and therefore spends money on How much it spends and consumes determines the level of effort that is applied to ensure the spend is optimised or not. This deep dive will take you through five key areas of MRO materials management to help you gauge how well you are balancing a core piece of your cost base.

We will discuss the following:

Demand Signal (the trigger that set EVERYTHING into motion)

Material Master Data

This discussion will help you better understand were you may have gaps in process, people, or tools and where you need to focus to get results as quickly as possible that stick

In this deep dive session, we’ll demystify the common misconceptions about Reliability Centered Maintenance (RCM) These misunderstandings stem from seven key misconceptions of the RCM process:

RCM seeks to analyze every Failure Mode 1.

RCM is too time and resource intensive 2.

RCM only produces a maintenance plan 3

Failure Modes and Effects Analysis (FMEA) is not included in RCM 4.

The consideration of Condition Based Maintenance (CBM) is a separate process 5

RCM should be applied to all assets 6.

RCM has serious weaknesses in an industrial environment 7

This presentation not only debunks each of the seven misconceptions surrounding RCM It offers an overview of the RCM process while delving into key principles including the importance of writing Functions correctly, proper techniques for writing Failure Modes, and clarifying a vital yet commonly misunderstood Condition Based Maintenance (CBM) concept. It is enriched with practical insights from real-world examples. Nancy Regan guides attendees as they discover just how robust, powerful, and uncomplicated the RCM process really is

Many leaders fall into the trap of thinking they need to know all the answers and tell their teams what to do However, I have seen the opposite Leaders are more successful when they ask great questions and then LISTEN instead of trying to tell them exactly what to do. In this interactive session, we will explore how to do this and change your culture in a positive/sustainable way Attend this session if you want to have fun while learning a powerful way to impact your teams and business from Front Line Workers to Sr Leaders

In this session participants will take away how to

o Lead and Manage your teams to change the culture

o Create Ownership with your teams

o Influence others in a positive way

o Change from a Reactive to Proactive

Ron has worked for Mars Inc for over 34 years in engineering, operations, R&D, and maintenance. He has a passion for connecting associates globally to drive collaborative solutions across the 130+factories within Mars. Ron is a big supporter of technology, but always balances this with the fundamental tools and the value of human relationships

Understanding why your assets exist is a simple yet important question for leaders to ask. Once we understand this, we then need to ensure our strategic asset management approaches, maintenance plans and renewal triggers are supporting the reason for existing. Asset Management is about balancing risk, cost, availability, and safety within the constraints of your business environment

These Asset Management leaders will discuss how they have tuned their asset management approaches to align to organisational goals and are managing their assets for the full asset life cycle.

Understanding why your assets exist

Balancing ideal asset management with operational imperatives.

Keeping an eye to the future to ensure your decisions today are helping not hindering your assets future effectiveness.

Defined Asset Standards, Policies and Strategic Asset Management Plans

Aligning your approach to climate adaptation requirements.

TOTEX and options for the Capital and Maintenance mix assessment

Drew Hellyer

High Trust leads to:

Higher levels of productivity – extending high trust to employees typically leads them to feel empowered make decisions and allowing them to work more effectively. Decisions can be made quicker

Enhanced Safety Culture – in a high trust environment employees feel safe raising concerns, admitting mistakes, providing full disclosure and transparency when things go wrong leading to better learning outcomes

Higher employee engagement and retention – people in high trust environments tend to feel valued and respected for their contribution, regardless of their level/role within the organisation, leading to increased loyalty and commitment to company success.

Innovation and collaboration – in high trust environments people are not inclined to want to protect their patch or withhold ideas/information, ideas flow freely because it is not a competition within the organisation. There are no hidden agendas.

What does a high trust working environment look like?

What are the benefits of high trust to an organisation?

What erodes trust in an organisation?

Even though generally well-intended how do leaders influence levels of trust within an organisation?

What is critical for high trust?

In today's globalised world, workplace diversity is essential for organisations to remain competitive and thrive. A diverse workforce can bring fresh perspectives, innovative ideas, and a range of skills and experiences that can help organisations stay agile and adaptable in the face of change. However, simply having a diverse workforce is not enough To fully leverage the benefits of diversity, organisations must also foster a culture of inclusion, where every employee feels valued, respected, and supported. In this panel, we will explore the challenges and opportunities people leaders are facing when building a culture of belonging in the workplace, with a focus on diversity, equity, and inclusion.

Our panellists will share their experiences and insights on:

Best practices for creating an inclusive workplace.

Strategies for recruiting, hiring, and retaining a diverse workforce.

Promoting equity and fairness in the workplace

Creating an inclusive culture where everyone feels empowered to contribute their best.

Our panellists will also discuss how organisations must can DEI initiatives, and the importance of engaging employees at all levels in creating a more inclusive workplace We will explore how organisations can measure the impact of their DEI efforts, and the benefits of creating a more diverse, equitable, and inclusive workplace for employees, customers, and the broader community

Maintenance and reliability professionals are increasingly turning to data-driven approaches to enhance operational efficiency and asset longevity. This panel discussion delves into the two paramount challenges we're facing as we navigate the complexities of data utilization: data quality and integration, and the skill gap in data analytics.

Ensuring data quality and seamless integration still poses a significant hurdle Maintenance and reliability operations generate vast amounts of data from diverse sources, including sensors, equipment logs, and maintenance records However, inconsistencies, inaccuracies, and fragmentation in data can undermine decision-making processes. The panel will explore strategies for improving data quality, standardizing data formats, and integrating disparate data sources to create a cohesive and reliable data ecosystem.

The skills gap in data analytics also remains a critical issue. While advanced data analytics tools and techniques offer tremendous potential, the lack of personnel with the requisite expertise to leverage these tools effectively hinders progress This discussion will address the need for upskilling existing staff, attracting new talent with data science proficiency, and fostering a culture of continuous learning within maintenance and reliability teams

Join us as industry leaders share insights, experiences, and practical solutions to these pressing challenges, paving the way for a more data-savvy and resilient future in maintenance and reliability.

David Kelly

Health and Wellbeing is very much front and centre for maintenance and reliability leaders. Creating mentally healthy workplaces is a necessity for employee productivity, satisfaction, and organisational success.

This engaging conversation will explore the strategies and practices that leaders are using to build workplaces that support and empower employee well-being, engagement, and productivity How do we manage the growing concerns regarding the mental health and well-being of our workforce and teams. During this session we will focus on the projects bringing results

In this session we will:

- Learn how organisations can use technology effectively

- Hear about the key tactics we can employ to communicate with traditionally hard to engage workers

- Examine the key support services in a hybrid/online environment to bring about benefits

- Look at the changing psychosocial risk landscape – regulation and compliance “ fit for purpose solutions”

Ed Ross

Thrilled to announce that Andrew returns to host MAINSTREAM And by POPULAR DEMAND!

Energetic, enigmatic, and witty, Andrew's managed to have a crack at just about every aspect of the entertainment industry, probably more out of necessity than by design. He's appeared on TV – some good, some great and some entirely forgettable, presented radio programs, podcasts, appeared on stage and a long, long time ago, even made a few movies. But much closer to home, Andrew's an accomplished engineering and maintenance hack but more about this at MAINSTREAM!

Designed and curated for deeper discussion around crowd-sourced topics, these 60-minute Xchange sessions on day 2 are interactive and moderated by a facilitator. All are limited in numbers to ensure maximum engagement, learning and exchange.

There is a need to modernise our IT and data systems to better align and integrate safety, risk, and Asset Maintenance plans. Without tight integration, different departments and teams operate in silos, leading to fragmented decision-making

Good operational readiness models are often an afterthought. Most people, including leadership, are focused on business as usual. As a result, operational readiness budgets do not get enough attention and are often inaccurate This makes selling the value of operational readiness difficult For operational readiness projects to succeed this is not a good outcome. It is vital that there is strong link between business as usual and operational readiness. The change management required is also often overlooked. When change is taken seriously, the entire team can be aligned. This means scoping together, planning together, and executing together This process is invaluable in instilling a culture that continues to take operational readiness seriously

If it’s agreed that assets are important for the business and that data is important for the business to optimise these assets, then it follows that capturing, storing, and making data-led decisions should be of equal importance. However, organisations are now generating enormous amounts of data from their plants and assets, and we are drowning.

A working group for Maintenance and Reliability professionals looking after rail and bus networks Discussion will focus on areas unique to this sector including configuration planning, capacity analysis, resource planning, operations and maintenance cost estimating and optimization, budget planning, cost control, regulatory issues, and labour/management relations consulting.

While the benefits of implementing innovative Predictive Analytics Tools and Software are incredibly attractive on the eye in the short and long term, organisations are struggling with actualising these potential benefits The community talked of their challenges managing data quality and integration issues, scoping budget correctly and piloting projects to demonstrate value Organisations are grappling to create a clear business case, hire or train the teams with the correct skillsets, and have the basic foundations in place to enable the digitised future.

When it comes environmental management, Asset Managers naturally drift to compliance and administrative headaches. However, if you peel away the compliance layers, there is a tremendous profit opportunity by reducing parasitic friction and fugitive emissions This is where the physical asset manager can shine In round figures, the industrial sector is responsible for 25% of all GHG emissions These improvements also translate into improved bottom line, reduced asset wear and tear, extending asset life and reducing cost of ownership.

There is often a disconnect between decisions made at senior levels of the organisation and ongoing performance expectations We have all seen decisions to defer capital and major maintenance spend during times of austerity, yet management expect the same level of asset performance. It all leads to huge disappointment when the asset fails. How can we work with management to ensure we can effectively play the long game, and good initiatives are not abandoned before full implementation because of the time taken to see results?

The early adopters of Predictive Analytics Tools and Software might be burning their fingers, but they are setting themselves up for long term success and competitiveness for the long haul. Can your organisation overcome the fear factor of a digital future by scoping correctly and piloting projects to demonstrate value? Does your organisation have a clear business case to invest? Do you understand the impact that Predictive Analytics Tools and Software can have?

Over the next decade, the community will be confronted with one of the most significant workforce challenges ever faced. Automation and AI and decarbonization are poised to reshape the landscape of future job roles and required skill sets It is essential for us to have open discussions about upskilling and reskilling our Maintenance and Reliability Teams. We can start by acknowledging the impact of automation and the need for acquiring new skills. By fostering a culture of continuous learning and providing resources for upskilling, we can empower our teams to adapt to new technologies and thrive in the changing landscape of maintenance and reliability

There is no doubt that the future is here with us and applications like ChatGPT are just a tip of the iceberg. Will we still need Maintenance SMEs or Advisors to tell us how to troubleshoot or direct us on possible causes and resolution? Or will the machines take over and do it better than us?

What are the reasons companies have not realised the promises of an asset performance management implementation, and positioned Integrated APM as an evolution of traditional approaches which drives the connection between current disparate data sets and supports asset performance improvement at scale?

With the benefits of data analysis, inventory management improvements go hand in hand with maintenance efficiencies. The ease with which we can track things such as MRO part needs and availability, means that more manufacturers will be aware of the inefficiency of their current inventory practices They will also be mindful of the benefits that they can gain from implementing a technology- and data-driven inventory plan. Benefits include accurate ordering and forecasting, easier location of spares, more control over storeroom management & faster, efficient maintenance.

Many of our companies have institutional maintenance and reliability knowledge residing with an ageing workforce of engineers and trades. Without appropriate information-sharing strategies there is significant business risk that the knowledge leaves with them. How are we managing knowledge retention, documentation, and transfer?

The Work Management process can often be confusing and inefficient Many organisations have adopted systems to digitally capture the information required whereas people, effectively manage the process with the aid of systems that are correctly aligned All that is really required to go about your work is to ensure that the right work is done the right way at the right time.

The need for Reliability Engineering in High Reliability Organisations (HRO's) is clear: to avoid catastrophes in an environment where normal accidents can be expected due to risk factors and complexity. In other industries this need is less obvious, so business leaders are challenged with finding the correct level of investment in reliability and reliability engineers. How do we get the best out of our reliability engineers?

Large digitisation projects are all the rage How do we prioritize these projects and investments in Asset Management? Is it digital twin, mobility, augmented reality, or predictive analytics? Where is the low hanging fruit? Which digital platforms are best?

Arrive armed with specific work experience in line with your Reliability and Maintenance functions. Exchange knowledge, experiences and programs of work while sharing the good, bad and the ugly parts of the work that we perform.

More than 75% of our community reported experiencing major supply chain disruption over the past 12 months. How is our community coping with a perfect storm right now. We are still feeling the impact of COVID. But add in the complexity of wars, climate change and cyber security threats are forcing us to implement creative solutions.

Companies reported that the issue is greater than it’s ever been and getting worse Relentless organisational change, high job demand, pressure to perform, lack of empathy and understanding from leadership, and the imbalance between effort and reward. Poor mental health has a significant impact on an individual’s health, attendance, performance, engagement, and safety.

There is an acceptance that DEI is a crucial issue for the future success of their organisation But many significant questions remain in how to practically make this a reality How can we attract and retain a diverse workforce in maintenance and reliability? What role can maintenance and reliability teams play in promoting DEI throughout the organisation? How can we create a culture of inclusion where all employees feel valued and respected?

MAINSTREAM Conference in 2 minutes

Transforming the way asset intensive organizations manage asset reliability, through innovative technology , advisory services and decades of reliability engineering experience.

ARMS Reliability is now a part of Baker Hughes within the Bently Nevada portfolio Combining our broad range of asset management and reliability solutions, software and expertise, with Bently Nevada's asset condition monitoring and protection, we deliver full asset lifecycle solutions to market and provide unparalleled access to a depth of capabilities.

The Super Saver rate of $2895 is for Industry Practitioners. This rate does not apply to Consulting, Technology, Advisory, Service and Solution Providers - please see Vendor tickets below.

AndrewCompson AssetManagementLead, EngineeringFunction BAESystems

PaulO'Brien GroupReliabilityManager SaputoInc.

EmmaSmith Connection&Development Manager PowerlinkQueensland

RebeccaYianakis ProductionManager SydneyWater

COLAdamJ.Dobney Director–ERPData GovernanceandLifecycle DepartmentofDefence

AndyBarrow GroupManager-Asset Management WhitehavenCoal

JeffBuckett Principal-Work Management AGLEnergy

DrewHellyer ManagerAssetData& Assurance Aurizon

DavidMate AssetPerformance Manager EndeavourEnergy

AnthonyMurphy IronmakingMaintenance Superintendent NewZealandSteel

KarlaHalliday BusinessLead,Work Management Unitywater

LeanneCorner

AssetStrategy&Reliability Manager,WAIOFixedPlant BHP

MartinSassenberg Manager,Asset Management&Assurance QueenslandSugarLimited RussellNoon GroupReliabilityEngineer Glencore-CoalAssets Australia

BrettJurd ExecManagerAssetMgt DalrympleBayCoal Terminal

MattCarter HeadofAssets TransdevAustralasia

NadineMore ProcurementOperations Manager OjiFibreSolutions

MelissaAspinall AssetPerformance RegionalManager WaterCorporationofWA

JodieJinnette HeadofAssetManagement MelbourneAirport

MitchellBluett Engineering&Reliability Superintendent Fortescue

MalcolmHurley Manager-Treatment Performance TasWater

ScottMilliner HeadofMaintenance& Outages AGL

MichaelJohnstone HeadofRenewablesand FirmingOperations CSEnergy

Download your report to understand best practices, compare your companies’ performance and working environment to those inside and outside your industry, and make informed and effective decisions around your assets and your people.

ty.com/conference/topics