The Original Built To Last spacemaker.ae byrnetechnical.com COMPANY OVERVIEW Manufactured in UAE & KSA

INTRODUCTION

Since its inception in 1990, Spacemaker has grown to become one of the highest quality modular building construction suppliers in the Middle East. A turnkey solution provider at the fore-front of modular construction, setting manufacturing benchmarks in the region with our engineering excellence. We are able to deliver off-site prefabricated modular building solutions, straight from our state of the art manufacturing facilities in KSA and UAE, spanning over 80,000m2. We have the capability to build 240,000m2 of modular units in our space alone.

All the engineering necessary is provided by our in-house team of various disciplines which include structure, MEP, HVAC, architecture and more. Their combined experience of more than 30 years in the field has enabled us to complete over 3,000 projects within the MENA region to date, across a multitude of industries including energy and oil & gas.

Whatever the project and however remote or complex, we can provide design, manufacturing, logistics, installation and commissioning. Our innovation strategy ensures creative solutions and the most up to date technology is considered for every project.

Spacemaker is supported by our sister company Byrne Equipment Rental, one of the largest plant and equipment rental companies in the Middle East with 19 operational bases, covering the UAE, KSA, Kuwait, Oman and Bahrain, a fleet of over 15,000 items of plant and a team of over 1,500 people.

2 The Original Built To Last

3 The Original Built To Last

Our Certifications

ISO 9001:2015 (Quality)

ISO 14001:2015 (Environment)

ISO 45001:2018 (Health & Safety)

ISO 17065 (Product Certificationfire rated wall panels)

4 The Original Built To Last

QUALITY

It is Spacemaker’s policy to identify the requirements of our customers and provide a service that meets or exceeds these requirements by the use of processes, materials or products that avoid, reduce or control pollution and comply with relevant laws, standards and regulations applicable to our business.

Our internal quality procedures adhere to the highest standard in the industry - from detailed documentation of material procurement to thorough certified inspections. This internal process ensures the highest quality of workmanship is met at all times.

ISO Certification

Recognising the hazards present in our industry, we take every practical step to provide and maintain a safe and healthy work environment for all employees, subcontractors and visitors who may be affected by or come into contact with a Spacemaker project.

At Spacemaker, our structured process for managing quality, health, safety and environmental activities in compliance with ISO certification is consistent with QHSEMS standards. Our QHSE management system procedures are documented to ensure our activity, conditions and tasks affecting quality, health, safety and environmental protection are planned, organised, executed, reviewed and improved.

5 The Original Built To Last

PRODUCT RANGE

Robust skid mounted units, suitable for use in the O&G industry. These units are durable and able to withstand extreme weather conditions and are an ideal solution for relocatable camps.

Ready for immediate deployment, BlastSpace are fitted to the highest specification and are certified to withstand almost any blast of duration up to 200ms.

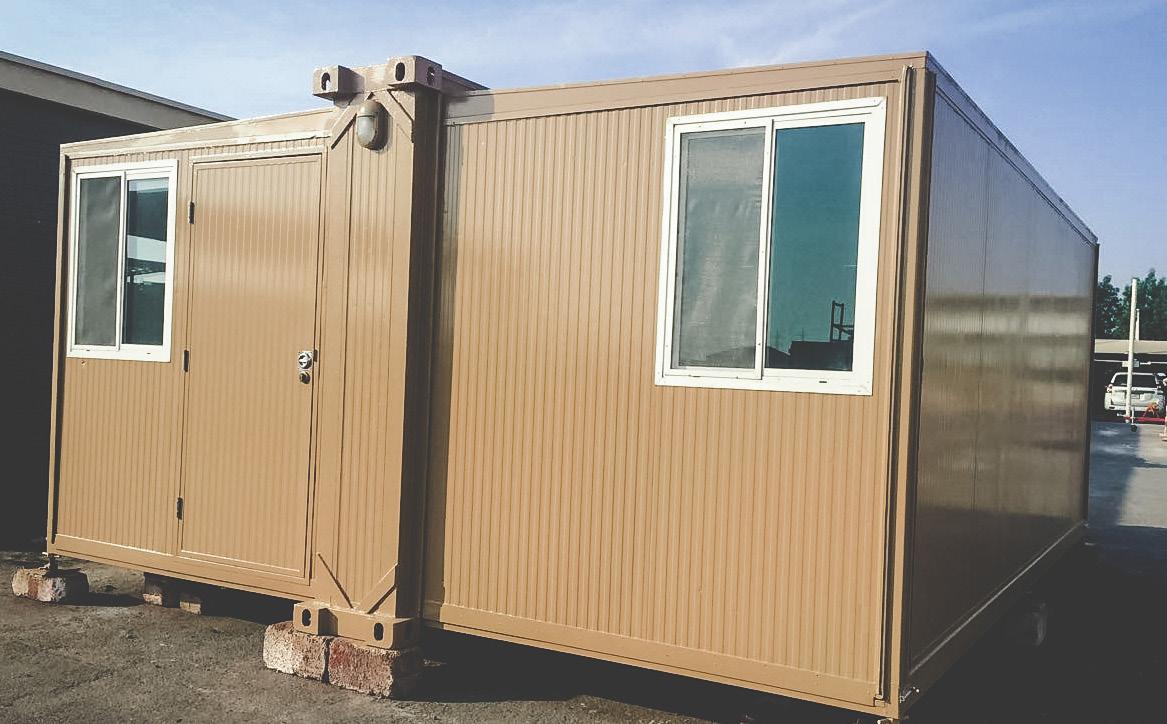

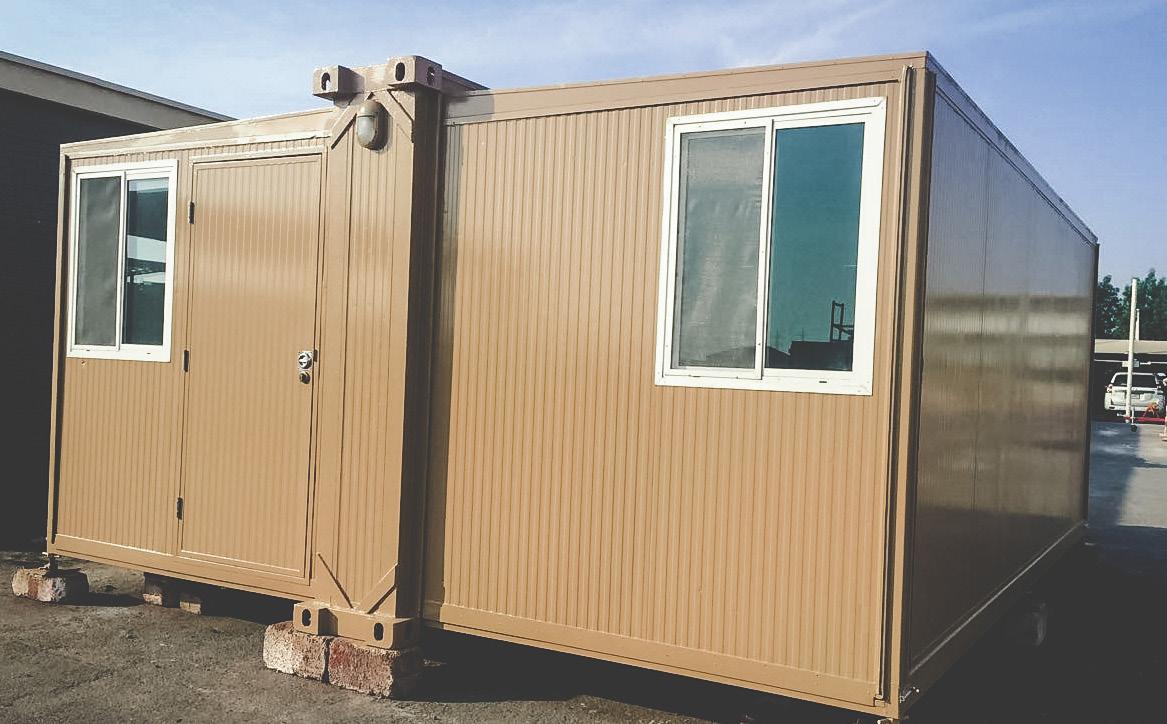

Modified ISO containers that are easily transportable, versatile and can be used in a variety of ways from accommodation to showers and sanitation facilities.

Long lasting, cost effective buildings ranging from single level to three floor accommodation. Suitable for large scale worker welfare villages that support large projects.

Transportable flat-pack warehouse, ideal for setup in remote locations to provide secure storage. Able to install and complete a footprint of 500m2 in just one day.

Long lasting, cost effective buildings ranging from single level to three floor accommodation. Suitable for large scale worker welfare villages that support large projects.

6 The Original Built To Last

This unique building system is mass produced so it is a cost-effective option. Lightweight and long lasting, it is engineered to international standards.

Able to deployed in just 20 minutes, this non-mechanical shelter is suitable for immediate response to any disaster or crisis, from healthcare clinics to full military camps.

Quick and cost-effective solution, with minimal deployment time required for each module, making it an ideal choice for immediate response as well as export projects.

High grade steel-based structure able to withstand a variety of penetration levels. Suitable for military camps in remote locations, an economical and quick solution.

Trailer mounted units which can be transported with ease. These units are most suitable for and frequently utilised as portable offices and accommodation.

Highly technical enclosures built to house and protect electrical systems, switch gears and plant control systems in a secure transportable unit.

7 The Original Built To Last

LuxSpace is a specialised product line of state of the art buildings made solely from modular sections - SmartSpace, PodSpace, LivingSpace and RetailSpace.

These bespoke luxury semi-permanent buildings can be used for offices, hospitality facilities, embassies, airport terminals, hospitals, residential units and more.

An efficient alternative to traditional builds, LuxSpace structures can be constructed in half of the time, utilising less materials resulting in less manpower required.

They are more beneficial than the traditional, precast construction methods due to their sustainable design, demonstrating the potential to create buildings that not only improve living conditions but also respect the natural environment.

The holistic approach of developing and successfully implementing a sustainable design is to avoid or reduce the depletion of critical resources such as energy, water and raw materials. Furthermore, this approach aims to prevent environmental degradation caused by facilities and or infrastructure throughout the cycle of the project.

8

OFF-SITE STEEL MANUFACTURERS SUSTAINABLE LIVING LUXURY CONCEPT MADE LOCALLY MODULAR SOLUTIONS MODERN DESIGN SMART CONSTRUCTION 9 The Original Built To Last

These self-contained luxury units have no limits and can be utilised as a self-contained living space, hotel room, office space and more. Versatile and robust, SmartSpace units come fully furnished and interior designed to a high standard with ambient, refreshing colour tones.

Self-contained prefabricated plug and play pods with diverse capabilities from luxury sanitation facilities to complete kitchen spaces.

Flexible, without compromising on design, our PodSpace units are custom-designed to your specifications, offering a wide selection of quality finishes and fittings, making them ideal for spaces of all styles and budgets.

10 The Original Built To Last

LIVING

LivingSpace is designed for long term, high end accommodation. Available in G+1 designs from 2 to 5 bedrooms, these luxury prefabricated villas are durable, with strong walls designed for acoustic benefits and stunning concrete flooring.

Each unit is unique with interchangeable designs. They are built with sustainability in mind, designed to have fresh air systems inside to create a carbon free living space.

RETAIL

RetailSpace caters primarily to large Food and Beverage brands that want to establish in remote locations within a short period of time, accommodating all heating and preparation facilities to suit the exact requirements.

The units come pre-fitted with HVAC and personnel areas for resting and can be custom designed to exact specifications ensuring the units align with company branding or fit in with

11 The Original Built to Last

To Last

BENEFITS

Reduced Materials Waste - Pre-fabricated construction methodology makes it possible to optimise construction materials, minimising on-site waste while offering a higher quality product to the buyer. Bulk materials are delivered directly to the manufacturing facility where they are stored in a protected environment safe from potential theft and exposure to the environmental conditions of a job site.

Reduced Material Exposure to Inclement Weather – The majority of indoor air quality issues identified in new construction results from high moisture levels in the framing materials. As the modular structure is substantially completed in a factory-controlled environment using dry materials, the potential for high levels of moisture being trapped in the new construction is eliminated.

Reduced Site Disturbance – The modular structure is constructed off-site simultaneously with foundation and other site work, thereby reducing the time and impact on the surrounding site environment. As well as reducing the number of vehicles and equipment needed on site, this increases the higher level of sustainability on site and across the overall project.

Flexibility – When requirements change, modular buildings can be disassembled and the modules relocated or refurbished for their next use, reducing the demand for raw materials and minimising the amount of energy expended to create a new building. In essence, the entire building can be recycled dependent on the materials utilised on the project.

Adaptability – Modular buildings are adaptable, modules can be added or removed in a short space of time with ease, minimising disruptions to adjacent buildings and surroundings.

12 The Original Built To Last

Safer Construction – Modular construction is a safer alternative compared to conventional construction. With conventional construction, conditions can be challenging with various temperatures or any combination of natural conditions. Furthermore, the potential for injury including falls, the most common work site risk, is much higher in conventional construction.

In a factory controlled setting, each worker is assigned to a work station supplied with all the appropriate equipment needed to create the safest work environment possible. At Spacemaker, we follow the highest level of HSE at both the factory and on site which is closely managed by dedicated teams, headed by very experienced personnel and overseen by Senior Management.

Built to Code with Shorter Build Times – The bottom line is that with modular construction you will have a facility built to the same local codes with construction quality as good or better than a comparable site built structure in much less time. Additionally, the abbreviated construction schedule allows you to have a quicker return on your investment while minimising the exposure to the risks commonly associated with protracted construction schedules.

Architectural Flexibilities – The optional hybrid concrete floor systems and integrated light weight concrete wall systems we utilize allows our buildings to have the conventional characteristics whilst also complying to building codes in the region. Our offsite building systems have test certification for both structural integrity and fire tests by reputable third parties. Other features include the use of a light weight façade which is easy to install and maintain, is architecturally pleasing and customisable with design and colour schemes to suit the perfect visitor/ exployee experience.

13 The Original Built To Last

PROJECT PROFILE

PROJECT - EXPO 2020 HEADQUARTERS

Spacemaker was contracted to deliver a hybrid mixed-use building to meet the energy efficient criteria and sustainability requirements of EXPO 2020 in Dubai. Forward thinking engineers were able to provide a cost effective, tailor made modular design in accordance with the stringent requirements of EXPO whilst reducing build time compared to a traditional build.

The innovative design was made up of 106 prefabricated modular sections, pre-plumbed, pre-powered and pre-commissioned, ready for installation on site within fifteen days of contract award. Interior works included the installation of elevators, majalis, VRF AC system, glazing, marble works, external terrace areas, IT and fire alarm connectivity and final commissioning.

In order to meet the client’s schedule, Spacemaker operated 24/7 both in the factory and on-site. The building plot was cut and ready for foundations within seven days of mobilisation; seven days later the precast foundations were complete and installed on-site and on the fifteenth day the first module was in place. After a total of six weeks the building structure and first fix service connections were completed and tested. On the eighty-ninth day the building was occupied in record time.

14 The Original Built To Last

PROJECT PROFILE

PROJECT- AIRPORT CREW TERMINAL, UAE

Spacemaker was awarded the build of a new airport crew terminal and briefing center consisting of a 3,600sqm two story building.

An ambitious timeline combined with a desire to minimise cost meant that Spacemaker’s modular buildings were an ideal solution.

Spacemaker designed and built a state of the art briefing center, made solely from modular sections.

Working closely with the client to finalise design, engineering and approve materials, the first module was on-site within two months and the handover of the centre was completed a month later.

The build was managed by an onsite team who project managed the installation while liasing closely with security staff due to working on an operational airport site.

Our flexibility in design enabled us to meet the architectural requirements and was one of the greatest advantages to our client who had never used modular sections to build a semi-permanent structure. The flexibility allowed the airline to add, remove or modify architectural design with no impact on the structure.

15 The Original Built To Last Bui

RigSpace series is a specialised product line solely focused on driller / rig and military camps that need to be both highly durable and mobile. The product can be delivered as a turnkey camp solution anywhere in the world and is inclusive of power generation, water and sewage management, STP, RO and installation facilities. With the advantage of a plug and play system, the installation period is highly controlled to suit the toughest of schedules.

The combination of good quality, globally sourced materials and innovative architectural design results in visually appealing and comfortable accommodation despite the modular layout of the build.

Technical sizes range from 7m (23 ft), 9.6m (31 ft), 1m (22 ft) and 12m (40 ft) with widths ranging from 2.4m (8 ft), 3m (10 ft) and 3.6m (12 ft) respectfully.

The product also has fire rating conformance to the ASTM E119 standard for a one hour fire rating, certified with a well-established globally accredited certifying body.

16 The Original Built To Last

PROJECT PROFILE

Project – KOC Drill Rigs

We were honored to be awarded the build of two rig camps consisting of two sets of main and rig camps. This required a total of 156 RigSpace units and utility buildings. To ensure longevity of the camps, we used premium highly insulted and durable products within the make-up of the product. This included the furniture, white goods, kitchen equipment, internal wall finish and more.

Spacemaker ensured that the structural integrity of these builds was up to par and also met the necessary wind loads which is important in such remote locations. Safety was also an integral factor of this build - the installation included a fire alarm system (portable addressable system) and specialized H2S systems.

The Rig camps were completed successfully with Spacemaker even monitoring the initial rig moves with the major highlight of the project being the need for 40ft long accommodation units which were to move on master skids.

17 The Original Built To Last

EcoSpace is a rapidly developing product suitable for an array of industries. Utilising the highest quality materials, EcoSpace and the cost effective EcoSpace+ can be utilised to service short term projects between 1-5 years and long term between 5-25 years.

- Temporary Construction Facilities (TCFs)

- Satellite offices

- Construction and labour villages

- Senior management accommodation

- Construction site offices

- Headquarter offices

- Recreation rooms

- Kitchen and dining facilities

EcoSpace is frequently utilised by EPC contractors, main contractors, sub-contractors and international oil companies. With a large variety of designs and material options, EcoSpace is Spacemaker’s most customisable product due to the vast options available including:

- Large open spaces without columns

- Increased ceiling heights up to 4.2m

- Building module lengths ranging between 6m-15m and widths from 2.4m- 4.5m

- Fire ratings between 30 mins to 2 hours (test certificates available)

- Variety of material and finishing options

- Quick deployment of manufactured units

18 The Original Built To Last

PROJECT PROFILE

Project – Yas Island 10,000 Man Camp

Spacemaker was awarded a very prestigious project to accommodate at peak over 10,000 men. This village had to support senior, junior and labor categories and meet the industry standards enforced by the regulatory authorities.

The village was also powered by our sister company Byrne Equipment Rental and subsequently managed by Byrne to allow for uninterrupted services. The customer was then able to directly focus on the primary project.

The village consisted of kitchens and mess halls, large laundry facilities, both indoor and outdoor recreational facilities, sewage and water integrated networks, addressable and integrated fire alarm and suppression system, PA systems and much more.

The design and engineering was completed in-house which allowed Spacemaker’s flexibilities in making the village a lot more efficient and cost effective.

19 The Original Built To Last

Overview

Our blast resistant modules (BRMs) are built to protect people and equipment, and are available in single or multi-unit modules. Ready for immediate deployment and fitted out to the highest standard, they are certified to withstand almost any blast of duration up to 200ms.

With two medium response specifications (5psi and 8psi) and a high response (10psi) available, BRMs can be used in the most hazardous areas of the upstream, midstream and downstream sections of the Oil & Gas industry, or by the military.

20 The Original Built To Last

Overview

We manufacture fully welded, all steel modular buildings and complexes. We specialise in high grade purpose designed ballistic frontline security modules. Due to high integrity of steel used by Spacemaker, we ensure and guarantee a high quality product.

Features:

- Reliable

- Heavy duty steel external walls

- Fire proof internal walls

- Ballistics resistant

21 The Original Built To Last

The FlatSpace product line supports a series of independent requirements and is the perfect solution for remote, logistically challenged project sites. The ease of assembly, embellished by a highly durable and sustainable product assures engineering ingenuity to our customers. The product allows customers to benefit from transportation efficiencies allowed by a ‘knock-down’ component.

The applications include satellite offices, accommodation (labor, junior, senior), kiosks, mess halls and more.

- 20’ x 8’ units and stackable up to G+2

- Pre-conduited and pre-plumbed allow for easier assembly on site

- Highly durable even for sea transportation

- Ability to place eight 20ft x 8ft open plan units within one 40ft trailer

- Fire rated options include 30 mins and 2 hours (ASTM E119)

- Colour options available

- Flat and low rib internal finishes available for aesthetic appeal

- Ease to expand or reduce in overall size of the building

- Easy to demobilise and remobilise to locations across the country

- Addressed to meet UFC standards

22 The Original Built To Last

PROJECT PROFILE

Project – Kyrgyzstan Military Project

Spacemaker supported a large multinational defense contractor who required a project in a military zone with intense weather conditions where the temperature often drops to below minus 20°C. This customer required accommodation and large dining facilities to house and cater for 150 key personnel.

Flatspace was a perfect product range for this area as the building could be flat packed and transported easily, even after completion. Due to the remote location of the military zone, this was a great advantage for the customer. The project was successfully engineered and completed in three months.

23 The Original Built To Last

Purpose-designed containerised housing solutions suitable for accommodation, kitchen and dining facilities, workshops, recreation areas, satellite offices, ablution and latrines, command centres, laundries and security checkpoints.

We can also build units to support offshore requirements.

Features

- Highly durability and re-usability

- Fire rated options between 30 mins to 2 hours

- Several options available for different end use

- Utilising sustainable materials

- Logistically efficient

- 10ft, 20ft and 40ft available options

24 The Original Built To Last

PROJECT PROFILE

Project – Hail Island 600 Man Camp

During an island expansion project at Hail Island in Abu Dhabi, we provided a complete turnkey solution including not only EcoSpace accommodation but also oilfield standard buildings, facilities management, power generation and water treatment facilities which allowed our customer to focus on their main EPC contract.

Through an alliance with a reputable life support services company, we ensured a smooth changeover from the village’s earlier occupants to the new residents without any disruptions.

Some of our other services provided included catering, housekeeping, laundry, on-call building and operational maintenance 24/7 STP, RO and building maintenance.

25 The Original Built To Last

Overview

Our modular warehouse is a unique product developed for situations where an immediate space solution is required.

Transportable in a flat-pack arrangement, even a warehousing requirement in the most remote location can be facilitated in a short space of time.

Each cell has an erection time of two hours, meaning a warehouse of 500m2 can be erected in just one day.

- Quick deployment

- Module ranges between 9.6m and 12m modules

- Re-deployable storage solutions

- Expandable options with customisations available

- Perfect solution for small aircraft hangers, dry storage, covered car parking

- Simple requirement for foundations which can be engineered in-house

26 The Original Built To Last

Overview

With the ability to be deployed in just 20 minutes, the non-mechanical RapidSpace shelter system is suitable for implementation in the immediate aftermath of a disaster or crisis, for example as a hospital or as an initial military camp set up.

Our traditional base camps/disaster shelters can be quickly supplied anywhere in the world, either as flat packs or as fully assembled modules.

- Hinged floor, roof and wall panels make for quick and easy installation ( 20 mins per unit )

- Packed size in meters range from 6.058(L) x 0.61 (W) to 6.058(L) x 2.41 (W)

- Deployed size in meters range from 6.058(L) x 4.81 (W) to 6.058(L) x 6.61(W)

- Area size ranges from 27 sqm to 37 sqm

- Designed occupancy ranges from 1 – 6 persons

- Height of support frame is 2.591m for all units

- Built in fixtures like kitchen cabinets, WC, basins and showers are accommodated inside the unit in the packed condition

27 The Original Built To Last

The unique TrailerSpace product line fulfils the requirements of the geo-technical and exploration sectors allowing customers to focus on their primary activities using a purpose-designed mobile unit.

With re-location being a regular occurrence, it is critical to have a robust, heavy duty and well-engineered product that provides a variety of accommodation such as workshops, temperature-controlled areas (e.g. freezer/chiller), water tanks, ice makers, fuel storage, utility trailers, toilets, showers and sleeper trailers.

- Highly durable with options for off-road trailers

- Sizes range from standard 12m to customised 14m and 17m trailers

- Built to withstand harsh terrain and weather

- Specialist paint systems for longevity and aesthetically pleasing

- Limited maintenance required, spare parts easily available

- Self-sustainable to include power with fuel system, HVAC, water storage and sewage management

- Steel external and sandwich panel options available

- Towable options available / goose neck trailers

- 60hz and 50hz options available to comply with British and American standards

- Built to meet ADNOC, PDO, Aramco and KOC standards

28 The Original Built To Last

PROJECT PROFILE

Project – Seismic Study Algeria / Nigeria

Spacemaker was awarded a flagship project to support seismic study activities in several areas of KSA.

The project entailed building approximately 300 self - sustained rugged TrailerSpace units with maximum durability to withstand harsh climate conditions.

The units were purpose manufactured from our KSA manufacturing facility and included accommodation (senior and junior types), kitchen and diners, freezers, ice makers and mud labs.

29 The Original Built To Last

Our fleet of DNV certified (DNV 2.7-1, DNV 2.7-2, SOLAS) products are used mainly offshore and include certified A-60 units designed to accommodate two, four or eight people. The units include offices and accommodation.

Overview 30 The Original Built To Last

Overview

Our eSpace units are highly technical enclosures built to house and protect client’s electrical systems, switch gears and plant control systems. Fully equipped and self-contained, these units are high specialised HVAC and fire detection supression systems that can be built to spec in as little as 6-8 weeks.

We can supply both containerised and customer built option.

31 The Original Built To Last

The Original Built To Last spacemaker.ae byrnetechnical.com Manufactured in UAE & KSA