MODULAR CONSTRUCTION CONSTRUCTION COMPONENTS

MODULAR CONSTRUCTION CONSTRUCTION COMPONENTS

BILDT was founded to answer the call of the industry – a fundamental need to deliver projects faster, safer and to a higher degree of quality than the industry standard. By moving construction out of the field and into the factory, we're reimagining how we plan, design and deliver buildings from the ground up.

This is where the future is built.

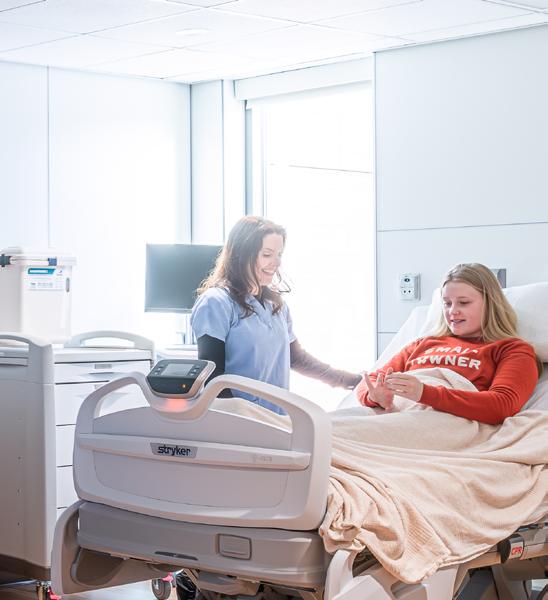

Imagine cutting construction times in half, starting to see patients and achieving revenue generation months sooner than you ever thought possible –without sacrificing quality or your system's design standards.

With our line of customizable permanent modular building offerings, available as additions to existing campuses, freestanding facilities, or slide-in rooms that fit into an existing core and shell, we have the perfect modular solution for your needs.

Meet your most urgent hospital demands with our flexible inpatient space. Optimized to provide critical elements for quality of care within a compact layout, the STAAT Mod Inpatient Unit is a fully volumetric, permanent modular addition capable of supporting clinical applications to supplement existing hospital operations or increase capacity.

Whether you start from the standard 16-bed configuration or scale to meet your hospitals needs, our design team will help configure spaces to your given site needs and intended use. Then select from a variety of exterior and finish options to better match your existing facility and design standards.

From low acuity to negative pressure airborne isolation, our fully volumetric modular inpatient additions are adaptable to meet your needs – fast.

FGI-compliant

Patient beds

Patient bathrooms

Staff bathroom

Soiled and clean

utility

Equipment storage

Medication room

Nourishment

alcove

Nursing / teamwork

AHU mechanical

Get critical healthcare where it's needed most, when it's needed – fast. Our modular dialysis clinic combines the speed of modular construction with the aesthetics and permanence of traditional construction within a highly optimized footprint.

Available as a freestanding outpatient clinic, the standard clinic design features a private consultation room, reception space, staff work space, and private and semi-private patient bays.

Available in a variety of exterior and finish options to better match your existing facility and design standards.

Meet your most urgent hospital demands with our flexible outpatient space. Optimized to provide critical elements for quality of care within a compact layout, the STAAT Mod Inpatient Unit is a fully volumetric, permanent modular addition capable of supporting clinical applications to supplement existing hospital operations or increase capacity.

Whether you start from the standard 16-bed configuration or scale to meet your hospitals needs, our design team will help configure spaces to your given site needs and intended use. Then select from a variety of exterior and finish options to better match your existing facility and design standards.

From low acuity to negative pressure airborne isolation, our fully volumetric modular inpatient additions are adaptable to meet your needs – fast.

Consultation rooms

Community meeting space

Staff work space

Class I medication storage vault

Observation Unit - STAAT Mod Features

Meet your most urgent hospital demands with our flexible outpatient space. Optimized to provide critical elements for quality of care within a compact layout, the STAAT Mod Inpatient Unit is a fully volumetric, permanent modular addition capable of supporting clinical applications to supplement existing hospital operations or increase capacity.

Whether you start from the standard 16-bed configuration or scale to meet your hospitals needs, our design team will help configure spaces to your given site needs and intended use. Then select from a variety of exterior and finish options to better match your existing facility and design standards.

From low acuity to negative pressure airborne isolation, our fully volumetric modular inpatient additions are adaptable to meet your needs – fast.

FGI-compliant Patient beds

Patient bathrooms Staff bathroom

Soiled and clean utility Equipment storage Medication room

Nourishment alcove Nursing / teamwork stations AHU mechanical yard

room / water / electrical room

The need for emergency services is more critical than ever; get critical healthcare where it's needed most, when it's needed – fast. Our fully volumetric modular freestanding emergency department (FSED) combines the speed of modular construction with the aesthetics and permanence of traditional construction.

Our modular FSED measures approximately 11,000 SF, comprising treatment rooms, resuscitation room, CT and X-ray, triage rooms, behavioral health room, EMS supply and lounge, utility and equipment spaces, nourishment room, and more.

Available in a variety of exterior and finish options to better match your design standards.

Treatment Rooms

Resuscitation Room

CT and X-Ray

Triage & Rapid

Assessment Rooms

Seclusion/

Behavioral Health Room

EMS Supply and Lounge

Soiled and clean

utility

Equipment storage

Medication Safety Zones

Nourishment room

Nursing Stations and Lounge

AHU mechanical/ electrical yard

Our modular medical office building gives you the flexibility to meet a diverse array of specialities and patient care needs, with the blistering fast speed to market only available through modular construction.

Designed to serve multiple providers with flexible waiting area solutions as well as a full suite of staff spaces. Choose from the standard 16-exam room configuration or scale to meet your needs, then customize finishes and exterior to match your design standards.

Fully customizable to the customer's program and requirements

Achieve speed-to-market efficiencies even in traditional construction with modular slide-in room pods. Ideal for integrating with existing structures or more dynamic facades, room pods include finished walls, ceilings, lights and finishes. Use with overhead racks and manufactured exterior wall systems for faster speed and lesser cost without sacrificing architectural aesthetics.

Fully customizable to the customer's program and requirements

Our volumetric modular bathrooms are ideal for large-scale projects or programs, helping accelerate your schedule cost-effectively. Pods arrive ready for installation, complete with fixtures and finishes. Our production process prioritizes your project workflow for just-in-time delivery, minimizing storage needs.

Fully customizable to the customer's program and requirements

Accelerate traditional construction schedules with our line of fully customizable clinical headwalls. Adaptable to a wide variety of acuity needs, our prefabricated headwalls are designed and constructed to enable efficient installation, making it the perfect complement to traditional construction methods.

Studs are rolled on-demand and in-house using our new, state-of-the-art Howick FRAMA 3200 series and FRAMA 5600 series machines. Custom crimping, dimpling and labeling of studs is available.

We offer a range of stud sizes and gauges, detailed, fabricated and kitted for delivery to your site.

Features

Features

Our exterior wall panels are the perfect product to accelerate traditional construction schedules, significantly reducing cladding time without sacrificing the look or quality of your building. Panels are high efficiency and available in a variety of designs.

Exterior wall panels can either be arranged for delivery to the site, or installed by our highly trained tradespeople*.

Features

Steel stud panels

Sheathing

Vapor barrier

Z-girts and rigid insulation

Hat channels

Siding

Boldt employs a pioneering approach to design for manufacturing and assembly (DFMA), integrating manufacturing and prefabrication techniques, fostering collaboration among teams, including trades modeling their work.

The result? Eliminating countless RFIs, change orders and painful value engineering exercises. Trades efficiently spool components direct from models virtually eliminating material waste.

The bottom line: far greater efficiency, precision, and cost-effectiveness for your project.

Manufactured construction means every activity is meticulously planned for efficiency, allowing us to go from raw chassis to ready-to-ship module in as few as 15 days.

While fabrication takes place in our off-site facility, the site team prepares the site and pours foundations. Executing on-site construction tasks concurrently to the module fabrication leads to significantly faster than projects using only traditional methods.

As one of the only modular manufacturers that also handles installation, our highly experienced teams complete the process by installing and stitching the modules on site, completing any final construction and MEP tie-ins and preparing the new facility for occupancy.

50%-60% REDUCED SCHEDULE, START GENERATING REVENUE MONTHS SOONER.