Motivated by a growing awareness of the important role nutrition plays in health and quality of life, consumers are increasingly turning to Nutraceuticals – nutritional supplements, functional foods, vitamin and mineral supplements, herbs and phytonutrients – to foster good health and prevent and treat disease.

Recent explosive growth in the Nutraceuticals market is driven by consumers’ willingness to assume responsibility for their own health and the general aging of the population. The market for Nutraceuticals is expected to continue to grow rapidly as nutrition research reveals new links between nutrients and promotion of health.

To meet the demands of this dynamic and increasingly complex market for nutritionally enhanced products, sophisticated facilities for product development, testing, manufacturing and distribution facilities are required.

Due Diligence

Incentive Negotiation

Location Strategy

Site Selection

The Austin Company helps nutraceutical companies apply operational improvements that improve their bottom lines. From planning and site location to construction and start-up, Austin ensures your next facility project’s complete success.

Our team has gained experience over hundreds of projects and possesses the knowledge and understanding to implement FSMA, FDA, USDA, cGMP and HACCP requirements.

DESIGN

Architectural Design

Conceptual Design

Master Planning & Layout

Production Line Layouts

Refrigeration System Design

Austin’s team specializes in production process planning, providing an innovative, broad spectrum of technical capabilities — from systems design, engineering, integration and installation, to technical assistance and plant start-up. In addition, Austin has extensive experience providing services around existing operations, so clients face little to no down time or lost production during facility expansion, construction or relocation.

ENGINEERING

Electrical

Fire

HVAC Plumbing

Process

Structural

CONSTRUCTION

Preconstruction

Complete Design-Build Services

Construction Management

Operations & Maintenance

Project Management

Start-Up & Commissioning

Integrate sanitation into the facility design and equipment

Design site with pest defense in mind

Design proper environmental building finishes

Design sanitation access around equipment

Design sanitary utility runs throughout production and packaging areas

Control building hygienic zones

Control personnel, product and material flow

Control water accumulation in facility design

Control room temperature and humidity

Control room airflow and pressures

Design wastewater treatment systems

Address varying levels of personnel hygiene

Flow equalization to minimize the overall treatment footprint

Segregation of streams to treat specific wastes in smaller, more concentrated solutions prior to dilution

Segregation of storm systems from the process wastewater systems

pH adjustment of CIP system discharges and production wastes

Oil/grease removal from wastes, utilizing conventional interceptors, along with rope/belt skimmers

Solids removal, screens, clarifiers, thickeners, filtration and multiple types of dewatering systems

Precipitation for conversion of dissolved solids

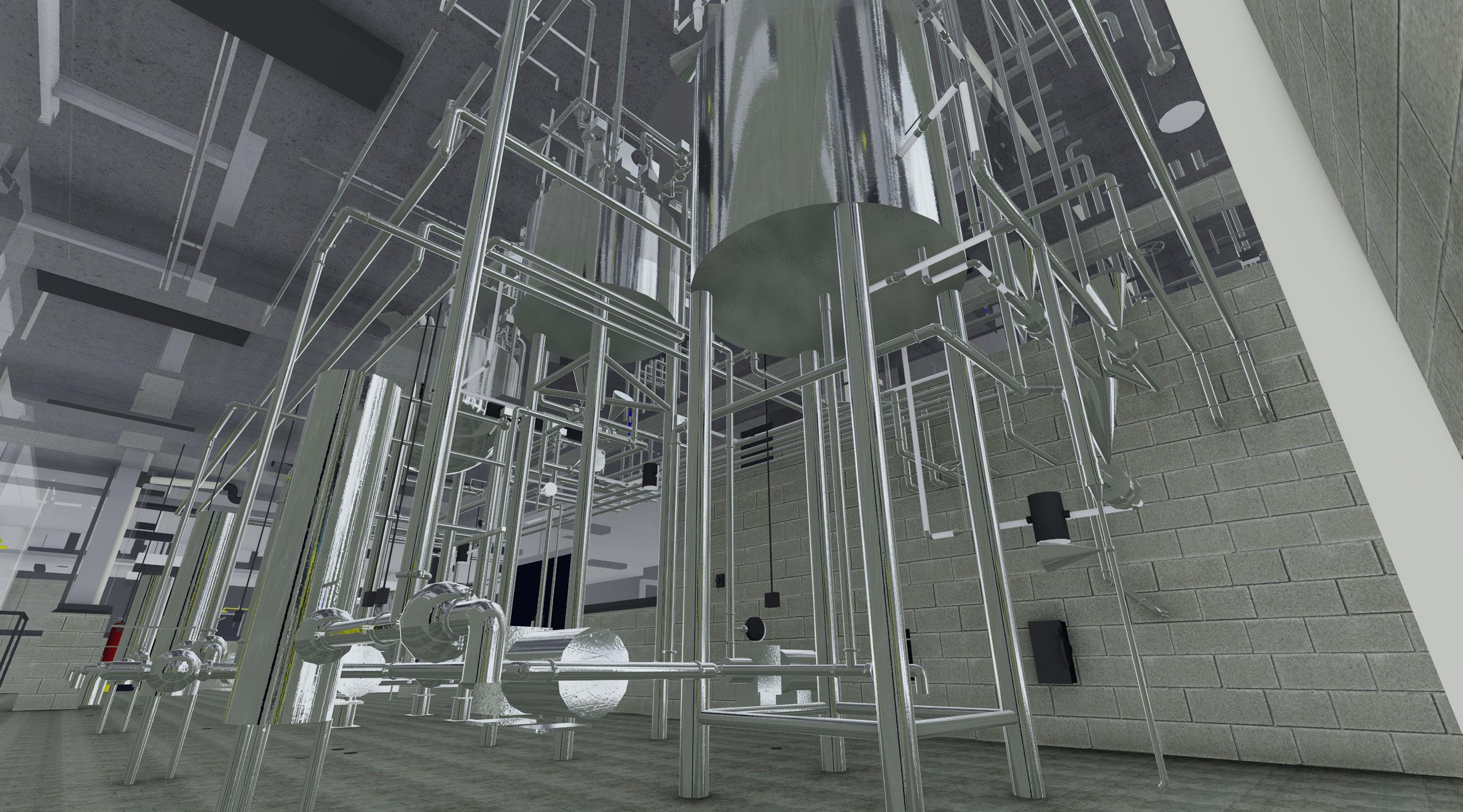

High pressure and high temperature piping systems

Modularization of major piping systems

Ammonia refrigeration systems and related equipment

CO2 refrigeration systems and related equipment

Refrigeration system and refrigerant conversions

Cascade CO2 and ammonia systems

3D system design platforms

PSM to satisfy OSHA 1910 for large NH3 piping systems, including pipe stress analysis

Design of freezer walls, racking, floors, under floor freeze protection system, and vapor barrier

Concept definition and feasibility

Scope and functional requirements documentation

Detail design

Equipment selection assistance and procurement

Construction, installation, commissioning and start-up

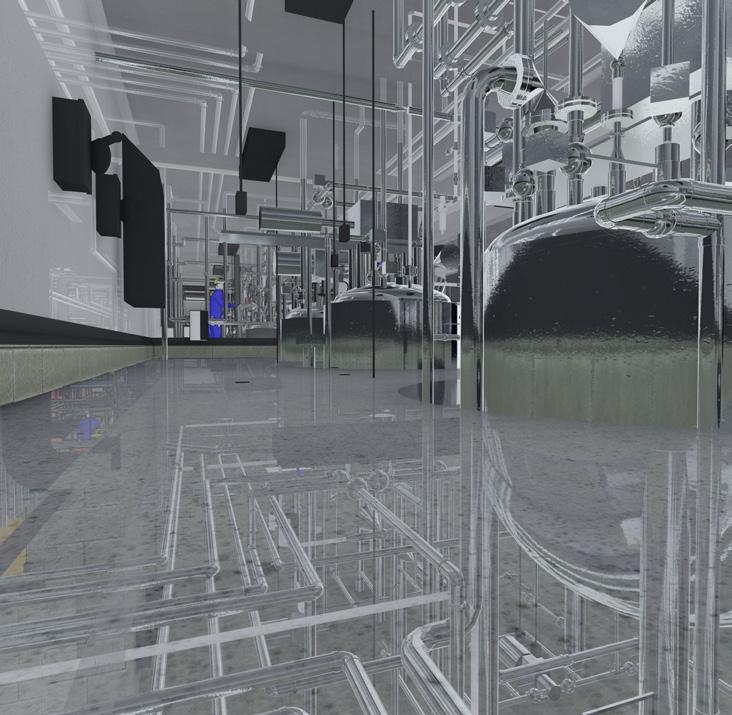

In the design and construction industry, adopting and utilizing virtual design and construction (VDC) technology provides layers of data not previously available. Autodesk tools such as Revit, AutoCAD, Plan 3D, Navisworks and BIM 360 Glue improve the efficiency and accuracy of projects through the entire project life cycle.

With VDC, clients can see virtual 3D views of their designs long before construction, providing a deeper understanding of the design and revealing what can’t be seen in standard 2D views. This results in fewer changes after the design is complete, lowering project costs and allowing for better control of the project schedule.

• Reduced risk

• Clash detection

• Leveraging of model information

• Increased efficiency

• Increased collaboration and coordination

• Improved decision-making

Lean design and construction maximizes value and project efficiency. Austin applies Lean methods to our design, engineering and construction services to continuously improve our approach to developing and managing projects through relationships, shared knowledge and common goals.

Potential for earlier project completion due to minimized inefficiencies