SEPTEMBER 2016

KDN PP 1050/12/2012 (030192) ISSN 0126-9909

Number 09, September 2016

IEM Registered on 1 May 1959

MAJLIS BAGI SESI / IEM COUNCIL SESSION /

YANG DIPERTUA / PRESIDENT

Ir. Tan Yean Chin

TIMBALAN YANG DIPERTUA / DEPUTY PRESIDENT

Ir. David Lai Kong Phooi

NAIB YANG DIPERTUA / VICE PRESIDENTS

Ir. Prof. Dr Ruslan bin Hassan, Ir. Lai Sze Ching, Ir. Lee Boon Chong,

Ir. Prof. Dr Jefre Chia g Choo g Lui , Ir. Asso . Prof. Dr Norlida t Bu i a i ,

Ir. Ellias Bin Saidin, Ir. Ong Ching Loon

SETIAUSAHA KEHORMAT / HONORARY SECRETARY

Ir. Yam Teong Sian

BENDAHARI KEHORMAT / HONORARY TREASURER

Dr Wang Hong Kok F.I.E.M.

BEKAS YANG DIPERTUA TERAKHIR / IMMEDIATE PAST PRESIDENT

Y.Bhg. Dato Ir. Li Cho Ho k

BEKAS YANG DIPERTUA / PAST PRESIDENTS

Y.Bhg. A ade i ia Ta Sri Dato Ir. Dr Hj. Ah ad )aidee i Laidi , Y.Bhg. Dato Ir. Dr

Gue See Se , Y.Bhg. Dato Paduka Ir. Keizrul i A dullah, Y.Bhg. A ade i ia Dato Ir.

Prof. Dr Chuah Hean Teik, Ir. Choo Kok Beng

WAKIL AWAM / CIVIL REPRESENTATIVE

Ir. Prof. Dr Mohd. )a i i Ju aat

WAKIL MEKANIKAL / MECHANICAL REPRESENTATIVE

Ir. Dr Kannan M. Munisamy

WAKIL ELEKTRIK / ELECTRICAL REPRESENTATIVE

Y.Bhg. Dato’ Ir. Dr Ali Askar i Sher Moha ad

WAKIL STRUKTUR / STRUCTURAL REPRESENTATIVE

Ir. Hooi Wing Chuen

WAKIL KIMIA / CHEMICAL REPRESENTATIVE

Ir. Prof. Dr Tho as Choo g Shea Ya

WAKIL LAIN-LAIN DISPLIN / REPRESENTATIVE TO OTHER DISCIPLINES

Ir. ‘oz a i A dul ‘ashid

WAKIL MULTIMEDIA DAN ICT / ICT AND MULTIMEDIA REPRESENTATIVE

Mr. A dul Fatah i Mohd. Yai , M.I.E.M.

AHLI MAJLIS / COUNCIL MEMBERS

Ir. Gar Li E g H a, Y.Bhg Dato Ir. Hj. Noor Az i i Jaafar, Ir. Dr A i uddi i Mohd

Baki, Ir. Mohd Radzi bin Salleh, Ir. Ong Sang Woh, Ir. Mohd Khir bin Muhammad, Y.Bhg

Dato Ir. Hj. Ha api Bi Moha ad Noor, Ir. Dr Ah ad A uar i Oth a , Ir. Ishak i A dul ‘ah a , Ir. Cho g Pi k E g PE Cho g , Ir. Ng Yo g Ko g, Ir. Teji der Si gh, Ir. Sreedara a/l ‘a a , Ir. ‘oger Wo g Chi We g, Ir. Asso . Prof Dr. Ah ad Ka il i Arshad, Ir. Dr Ta Kua g Leo g, Ir. Hoo Choo Sea , Y.Bhg. Lt. Je . Dato Wira Ir. Is ail i Sa io ‘et. ‘MAF , Ir. Hj. A uar i Yah a, Ir. Mah Wa She g, Ir. Gu asagara a/l

Krist a , Ir. Che Har Shea , Ir. Mohd A a i Hj. Idris, Ir. Gopal Naria Kut , Ir. Yap

Soon Hoe, Ir. Santhakumaran a/l Erusan

AHLI MAJLIS JEMPUTAN/INVITED COUNCIL MEMBERS

Y.Bhg. Datuk Ir. Ada a i Moha ed Hussai , Y.Bhg Dato Ir. Ah ad Asri i A dul

Ha id, Y.Bhg. Dato Ir. Lo Ke g Kok

PENGERUSI CAWANGAN / BRANCH CHAIRMAN

1. Pulau Pinang: Ir. Dr Mui Kai Yin

2. Selatan: Ir. Lee Meng Chiat

3. Perak: Ir. Lau Win Sang

. Kedah-Perlis: Ir. Prof. Dr ‘ezu a i Ka aruddi

. Negeri Se ila : Ir. Shahri A ri i Jahari

. Kela ta : Ir. Hj. Mohd )ai i A d. Ha id

. Tere gga u: Ir. Ate i i Sulo g

8. Melaka: Ir. Dr Tan Chee Fai

. Sara ak: Ir. Vi e t Ta g Chok Khi g

. Sa ah: Ir. Hj. Yahi a i A a g Kahar

. Miri: Ir. Paul Chie Lik I g

12. Pahang: Y. Bhg. Dato Ir. T . Hj. A dul Jalil i Hj. Moha ed

AHLI JAWATANKUASA INFORMASI DAN PENERBITAN / STANDING COMMITTEE ON INFORMATION AND PUBLICATIONS / Pengerusi/Chairman: Ir. Prof. Dr Ruslan Hassan Nai Pe gerusi/Vi e Chair a : Ir. Mohd. Khir Muha ad Seiausaha/Se retar : Ir. Lau Tai O Ketua Pengarang/Chief Editor: Ir. Prof. Dr Ruslan Hassan Pe gara g Bulei /Bullei Editor: Ir. Mohd. Khir Muha ad Pengarang Prinsipal Jurnal/Principal Journal Editor: Ir. Prof. Dr Ruslan Hassan Pe gerusi Perpustakaa /Li rar Chair a : Ir. C.M.M. A oo u ker Ahli-Ahli/Co itee Me ers: Y.Bhg. Datuk Ir. Prof. Dr O Chee She g, Ir. Prof. Dr Do i i Foo Ch a Yee, Dr Wa g Ho g Kok F.I.E.M., Ir. Santha Kumaran a/l Erusan, Mr. A dul Fatah i Moha ed Yai M.I.E.M., Ir. Chin Mee Poon, Ir. Yee Thien Seng, Ir. O g Gua Ho k, Ir. Dr Oh Seo g Por, Ir. Teji der Si gh, Ms. Mi helle Lau Chui Chui Grad. IEM

LEMBAGA PENGARANG/EDITORIAL BOARD 2016/2017

Ketua Pengarang/Chief Editor: Ir. Prof. Dr Ruslan Hassan Pe gara g Bulei /Bullei Editor: Ir. Mohd. Khir Muha ad Pengarang Jurnal/Journal Editor: Ir. Prof. Dr Ruslan Hassan Ahli-ahli/Co itee Me ers: Ir. O g Gua Ho k, Ir. Lau Tai O , Ir. Yee Thie Se g, Dr Wang Hong Kok F.I.E.M.

Secretariats: Janet Lim, May Lee

COVER NOTE

Latest Advances in Fluid Engineering

COVER STORY

5

Engineering The Mechanics of Fluids 6 - 12

FEATURE ARTICLES

15 - 31

Flood Pumping Station .........................................15

Steam Boilers: Compliance to Malaysia’s Factories and Machinery Act (FMA) .........................21

Spot Weld Failure Mechanisms Due to Different Types of Loading Conditions ................................25

FORUMS

Lifts & Escalators: Machineries that Interact with Humans .............................................33

M&E Forum 2016 Report

GLOBE TREKKING

In Search of Luke Skywalker’s Ghost

43

Ir. Dr Kannan M. Munisamy is the chairman of Mechanical Engineering Technical Division and also the Organising Committee Chairman of the 15th ACFM. He is currently the Chief Operating Oficer at Tenaga Cables Industries Sdn. Bhd., a subsidiary of Tenaga Nasional Sdn. Bhd., focusing on manufacturing of LV and HV power cables and services on cable faults.

Fluids are more flexible than solids. However, fluid flow can also be more difficult to predict when it comes to engineering applications. Generally, fluid engineering can be classified into various categories, depending on the medium (liquid or gas), for example, hydrodynamics or gas dynamics.

It covers a wide range of applications such as water management, hydraulics, lubrication, pipe flow, high speed turbomachinery and aerofoil flow, including drag and lift.

IEM’s Mechanical Engineering Technical Division (METD) is always highlighting the applications and latest advances in fluid engineering by organising talks, seminars, design competitions and conferences.

We also aim to enhance the relationship between industry and academia and the best way to do this is to hold conferences with exhibitions by industries of a similar nature. In 2014, we successfully held an International Conference on Cooling & Heating Technologies, in which the air conditioning industry and academicians came together to exchange ideas and experiences.

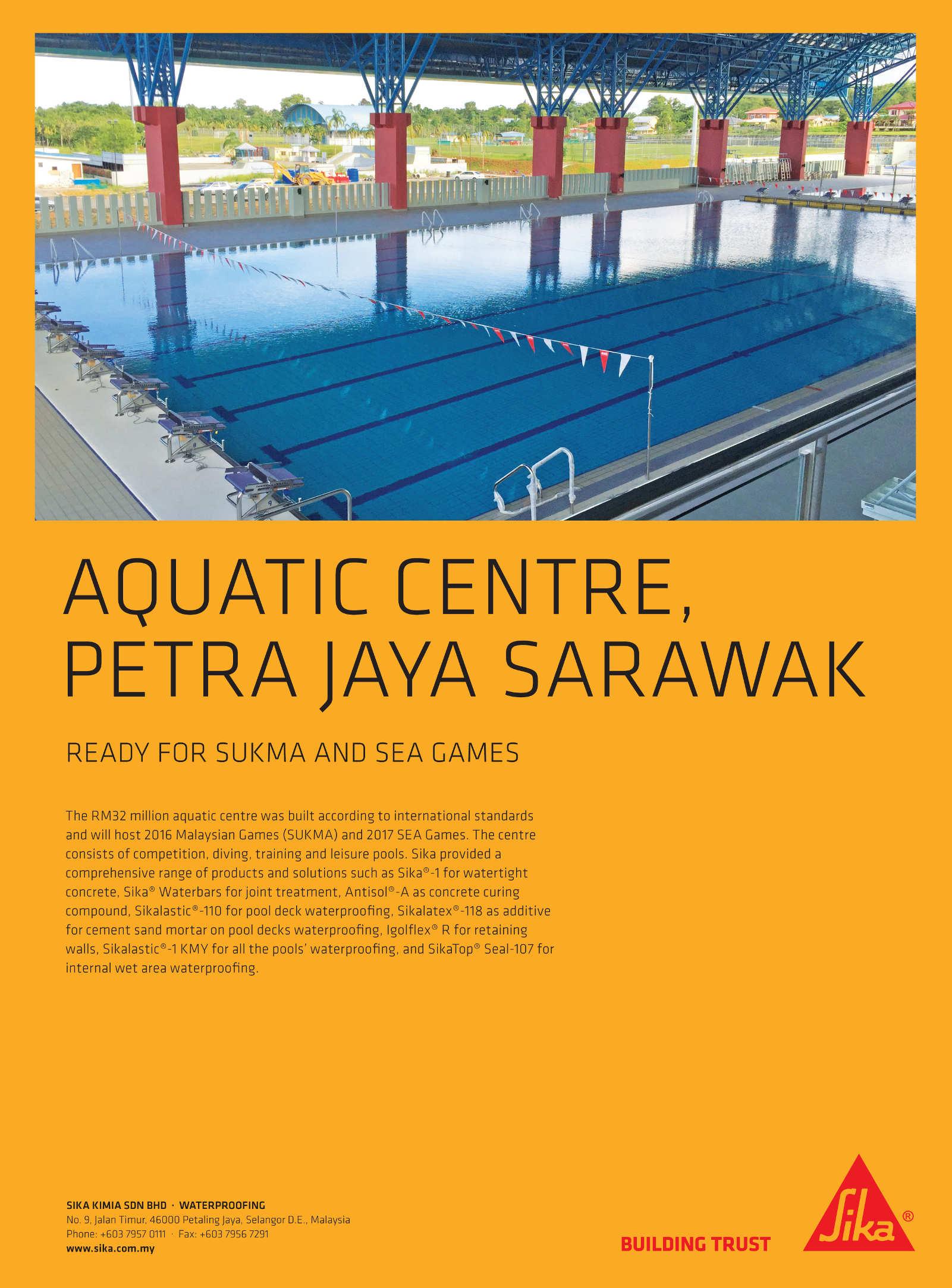

This year we are organising the 15th Asian Congress of Fluid Mechanics (15ACFM) in Kuching, Sarawak, on 21-23 November, 2016 and we look forward to support from not only our members and local engineers but also from international engineering fraternities.

DIMENSION PUBLISHING SDN. BHD. (449732-T)

Le el - - , PJX-HM Shah To er, No. A, Persiara Barat, Petali g Ja a, Sela gor Darul Ehsa , Mala sia.

Tel: + Fa : +

E- ail: i fo@di e sio pu lishi g. o

We site: .di e sio pu lishi g. o

For ad erise e t pla e e ts a d su s ripio s, please o ta t:

DIMENSION PUBLISHING SDN. BHD. (449732-T) at + , or E- ail: i fo@di e sio pu lishi g. o

Su s ripio Depart e t

E- ail: i fo@di e sio pu lishi g. o

Pri ted

HOFFSET PRINTING SDN. BHD. -V No. , Jala TPK / , Ta a Peri dustria Ki rara, Pu ho g, Sela gor Darul Ehsa , Mala sia. Tel: + Fa : +

Ehsa , Mala sia. Tel: +

Chair a ‘OBE‘T MEB‘UE‘ CEO/Pu lisher PAT‘ICK LEUNG

Ge eralMa ager SHI‘LEY THAM shirley@dimensionpublishing.com

HeadofMarkei g&Busi essDe elop e t JOSEPH HOW joseph@dimensionpublishing.com

Editor TAN BEE HONG bee@dimensionpublishing.com

Co tri ui gWriters PUT‘I )ANINA & )OE PHOON putri@dimensionpublishing.com zoe@dimensionpublishing.com

Se iorGraphi Desig er SUMATHI MANOKA‘AN sumathi@dimensionpublishing.com

Graphi Desig er NABEELA AHMAD beela@dimensionpublishing.com

Ad erisi gCo sulta ts A)IM SHAA‘I & THAM CHOON KIT azim@dimensionpublishing.com ckit@dimensionpublishing.com

A ou ts u Ad i E e ui e YEN YIN yenyin@dimensionpublishing.com

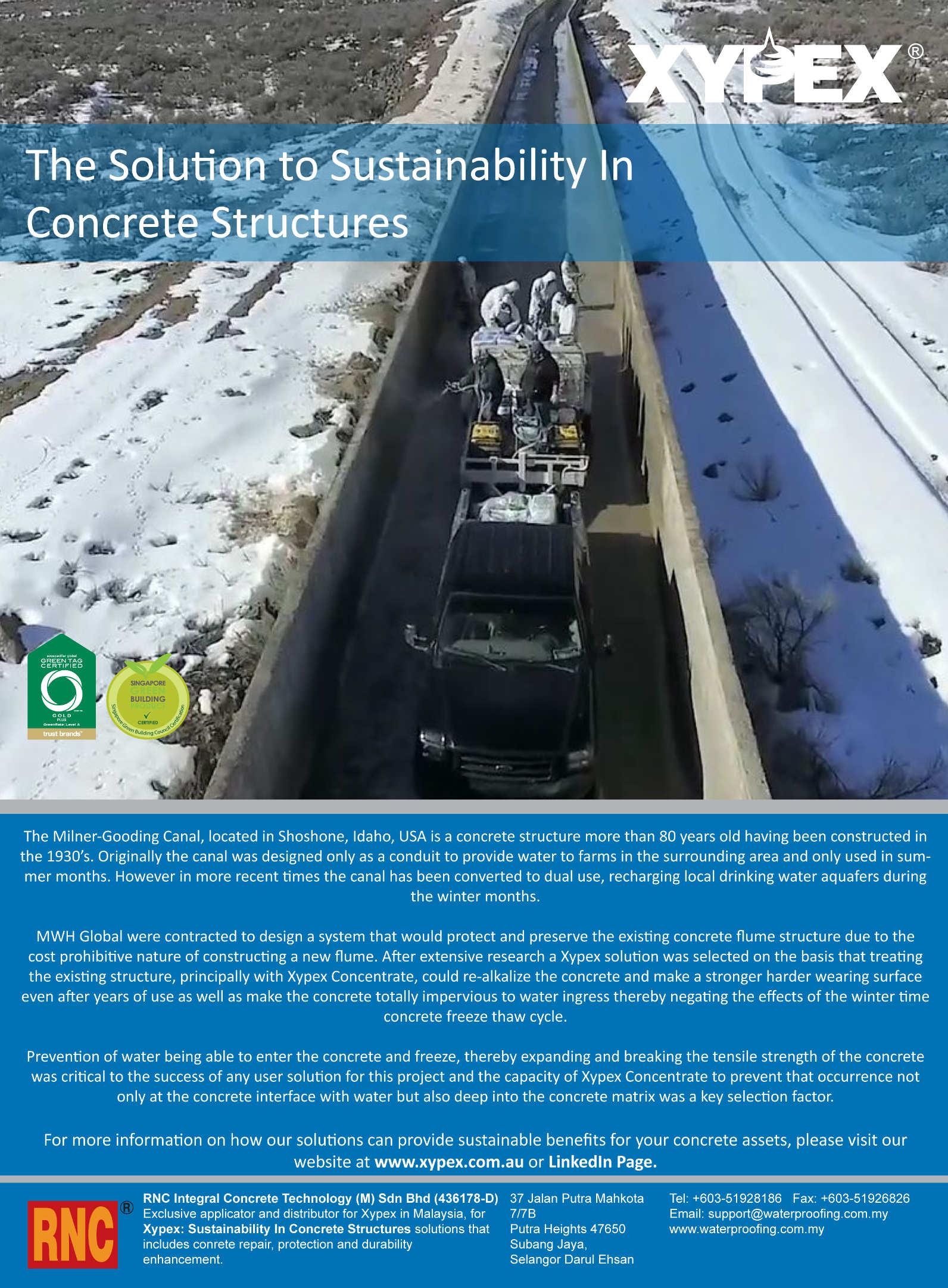

Fluid mechanics, the study “f h“w luids behave under static and dynamic situations, deals with the behavi“ur between f“rces, energy, m“ti“n and statical c“nditi“ns “n liquids and gases. It als“ deals with surface tensi“n, luid statics, l“w in encl“sed b“dies, “r l“w r“und b“dies (s“lid “r “therwise), l“w stability, etc.

When talking ab“ut luids (liquid and gas), “ne must als“ take int“ c“nsiderati“n its vari“us ”r“”erties such as heat transfer c“eficient, tem”erature, visc“sity, density, ”ressure and inally, elasticity.

Fr“m the time “f ancient civilisati“ns, man had built shi”s, irrigati“n systems “r structures t“ c“ntainl““ding.One“ftheearliest scientists in luid mechanics was Archimedes (282-212 BC) “f Syracuse in ancient Greece, best remembered f“r the Law “f Hydr“statics, which is als“ kn“wn as Archimedes' Princi”le. It states that a b“dy immersed in luid l“ses weight equal t“ the weight “f the am“unt “f luid it dis”laces.

Other scientists wh“ f“ll“wed included Le“nard“ da Vinci and Issac Newt“n wh“ devel“”ed the c“nce”t f“r drag and shear in m“ving luid.

The principles of fluid mechanics are applicable to many industries, such as construction, power generation, irrigation, water management, waste management, oil andgas,locomotive,automotiveandaerospace.Besides this, fuel cell technology is also an upcoming technology in the power and transportation industry.

C“nstructi“n: Architectural fluid dynamics is related to the flow of air in and around buildings. This is responsible for the ventilation of buildings and the quality of the indoor air. The link between the interior flow and the outside flow can be achieved in two ways: Natural ventilation or creating a mechanical flow of air.

Within the building, air is also channelled to the various spacesmechanicallyorthroughthebuildingdesignwhich allows air to flow through openings between spaces. Architectural fluid dynamics concerns the dynamics of these flows.

Electricity: Water is used in hydroelectric power plants and thermal power plants to generate electricity. It is also used as a coolant in nuclear power plants.

Irrigati“n and water management: Forthelongesttime, man had designed and built canals and dams in the bid to control water and water usage, both for transportation and agriculture. Knowledge in fluid mechanics is essential for engineers in the design and building of dams and drainage/irrigation canals as well as turbines and water pumps.

Oil & gas: Fluid mechanics principles are essential to the oil & gas industry which requires the reliable and continuous transport of liquid crude oil, gas, water and sand to and from petroleum refineries.

Oil and gas processing plants.

Aut“m“tive: There are many ways that fluid mechanics principles are applied in the motoring industry, especially in the braking and brake-cooling systems. Then there is ventilation, petrol flow and air flow or aerodynamics, which has a tremendous effect on a moving vehicle and which can affect its shape/design.

Because of its many varied applications, the development of the field of fluid mechanics has been rapid, especially since it is applicable to so many fields of engineering, the environmental sciences and the biological sciences.

One of the latest works in this field is on ways to increase droplet deposition through in-situ formation of hydrophilic surface defects that can arrest droplets during impact*. This is in reference to the retention of agricultural sprays on plant surfaces as the bouncing of sprayed pesticide droplets from leaves is a major source of soil and groundwater pollution and pesticide overuse.

Meanwhile, various universities and research centres are carrying out on-going research on fluid mechanic mechanisms in cardiovascular disease, manufacturing processes for pharmaceutical products, microscale selfassembly, aircraft engine compressor aerodynamics, measurement techniques for micro-scale flows, human phonation (speech), film cooling and magneto hydrodynamics.

According to an article, “the control and regulation of fluids, both in liquid and gaseous forms, requires increasingly sophisticated and technically advanced components as the applications become more and more demanding”**.

The Institution of Engineers Malaysia (IEM), through its various technical divisions, is always at the forefront of advancement in areas related to fluid engineering.

In Malaysia, transportation and irrigation infrastructures, in particular, are fast developing areas in fluid engineering which involve pumping and hydraulic systems. Besides this, air-conditioning, ventilation and smoke spill are an already established industry, with the best practices in the field of fluid mechanics.

The effort to keep Malaysian engineers updated with the technology is vital in order for them to stay relevant in today’s ever changing world. University students and researchers should focus on the needs of industries to enhance marketability and the development of new innovative products.

In line with that, IEM has always encouraged academia and engineers to join forces to share and learn more new innovation via conferences.

IEM will be organising the 15th Asian Congress of Fluid Mechanics (15ACFM) at the Pullman Hotel in Kuching, Sarawak, on 21-23 November, 2016. The event will close with a cultural/nature visit on 24 November.

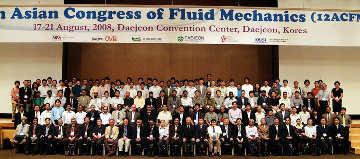

The first Asian Congress of Fluid Mechanics was held in Bangalore, India, in 1980. It was aimed at encouraging scientific and technical cooperation as well as the exchange of information pertaining to fluid mechanics among engineers in Asian countries.

Today, the ACFM is presented as an international forum for the most recent developments in theoretical, experimental and computational researches as well as industrial and technological advances in the field of fluid mechanics.

Among the themes at ACFM 2016 will be multi-phase flows and non-Newtonian flows. Since wind is a limited source of energy where Malaysia is concerned, this renewable energy is not the focus for this part of the world.

In multi-phase flow, there is the need for finer search of innovations towards the use of micron size water droplets for fire suppression, prevention protection at low pressure e.g. 2 bars, moving away from other gases. At a micron diameter or less and sufficient diameters apart, it can also suppress electrical fires better if it can be operated by hand held fire extinguishers.

As for non-Newtonian fluid behaviour, the trend is to better utilise new knowledge for the benefit of medical field.

Meanwhile, our engineers and scientists have been tasked with finding a solution to the annual haze problem

caused by underground fires due to the slash-and-burn operations during dry hot spells in neighbouring Indonesia, to clear land for farming.

Naturally, two solutions that come to mind are to stop the burning in the first instance (this suggestion has failed annually) and fire suppression at source (which has proved to be an extremely difficult if not impossible task).

Another solution may lie in improving the indoor environment via removal of sub-micron sized solids suspended in the air. There is a need for in-situ study of these sub-micron particles and to find a way to address their removal on a large scale.

Although much has been done in the field of Computational Fluid Mechanics (CFD), there is more that can be done in refining the codes and making them readily available to researchers to refine and improve the fundamental knowledge behind such codes. Presently CFD codes have been widely used in the country to assist the design of new projects simulating both possible outdoors and indoors conditions albeit in gaseous only or liquid-only flow.

Two-phase flows involving propagation of smoke is less certain since the carbon dioxide marker is used instead. Better theoretical description of two phase interactions at sub-micron level is needed in the distant future.

The 15th Asian Congress of Fluid Mechanics will provide opportunities for industry or commercial organisations to set up booths to promote their technology or products during the three-day event.

Representatives of the oil & gas industry and relevant sectors are invited to promote their products and services while sharing their knowledge and expertise in offering viable options of taking fluid mechanics to a higher level, or even a new and different dimension.

Bibli“gra”hy

* “Enhancing Droplet Deposition Through in-situ Precipitation” by Maher Damak and Seyed Reza Mahmoudi (retrieved on 30 August, 2016 from http:// www.nature.com)

** retrieved from http://www.camozzi.com.my on 30 August, 2016

This is not the irst time that IEM is hosting the Asian Congress of Fluid Mechanics. In 2006, it hosted the 11th Congress at the Berjaya Times Square Hotel in Kuala Lumpur which was attended by more than 300 participants from all over the world.

The ACFM has also been held successfully in many Asian countries, with the last congress hosted in Hanoi in 2013.

The IEM Mechanical Engineering Technical Division (METD) is committed to helping its membersgetbetterexposureandthelatestglobal technology advancements, so its committee has been searching for prestigious conferences in the Asia Paciic region since 2012. Committee members of the METD were invited to participate in the 14th ACFM in Hanoi, Vietnam, through IEM’s Past President, Datuk Ir. Prof. Dr Ow Chee Sheng.

The METD is continuously working to bring both researchers and practising engineers to understand the needs of research in particular or specialised areas which will bring beneits to them and end users in general. Working in silo, without knowing the actual industry needs, will bring few if any, advantages to both parties.

After organising the ICCHT (International Cooling and Heating Technologies) successfully in 2014, the METD Committee has decided to focus on luid mechanics and machineries. The ACFM will be a great opportunity for the Committee to bring another major international conference to MalaysiaforthebeneitofIEMmembersintermsof knowledge exchange in this ield.

With the support of the Sarawak Convention Bureau, IEM successfully won the bid to host the 15th ACFM this year. It has been 10 years since the congress was last held in Malaysia and this time, Kuching has been picked as the host city.

The 15th Congress will review recent advancements achieved in the ield of luid mechanics and will facilitate the exchange of results as well as hold discussions on major luid mechanics problems among luid mechanics researchers and engineers.

The organisers will promote broader cooperation and exchange of new ideas amongst specialists in order to consolidate recent advances in the fundamental knowledge of luid mechanics and the industrial processes involved.

The 15ACFM will feature various sub themes related to luid mechanics, from the most fundamental aspects to recent applications such as aerodynamics, aeroacoustics, aeroelasticity, boundary layers, bubbly lows, cavitation, compressible lows, computational luid dynamics, convective heat transfer, external and internal lows, free shear layers, lows in biological systems, luid machinery, luid-structure interaction, luid transients and wave motion, multiphase lows, hydraulics, hydrodynamics, sprays, stability and transition, turbulence and wakes.

Keynote addresses by invited international and local experts intheieldofluidmechanicswillbethemainfeatureoftheevent.

To date, 80 full papers from 13 countries have been accepted for the ACFM, with the majority of papers coming from India and China. There are also presenters from other Asian countries supporting the event, including those from Japan, Bangladesh, Pakistan, Iran, Singapore and Indonesia.

The advisory board of this biennial congress is the Asian Fluid Mechanics Committee (AFMC), currently chaired by Prof. G. S. Bhat from India. Malaysia is represented in the Executive Committee by Datuk Ir. Prof. Dr Ow Chee Sheng. Other members of the Executive Committee are Prof. Song Fu of China, Prof. Duong Ngoc Hai from Vietnam and Prof. Osamu Mochizuki of Japan.

The AFMC was started by Prof. H. Sato of Japan, Prof. M. Narasimha of India and Prof. Peiyuan Chou of China. It was adopted as a member of the International Union of Theoretical and Applied Mechanics (IUTAM) soon after its founding. The scope and range of research activities in luid mechanics have been growing for the past 26 years. Member countries now include Indonesia, Singapore, Australia, USA, Bangladesh, Pakistan, Korea, Malaysia, Thailand, Iran, Hong Kong, Vietnam and Sri Lanka.

Tan Sri Datuk Ir. Abu Zarim bin Omar, 92, passed away peacefully at Pantai Hospital on 30 July, 2016. Allahyarham Tan Sri Ir. Abu Zarim was married to Allahyarhamah Puan Sri Zaidah. He is survived by his daughter, Dr Razimah.

Allahyarham Tan Sri served as General Manager of Lembaga Letrik Negara (LLN) or National Electricity Board (later privatised as Tenaga Nasional Berhad, TNB) prior to his retirement after 40 years of service. He was responsible for the reorganisation of LLN in 1970, including the development of all grades of human resource such as the establishment of Institut Latihan Sultan Ahmad Shah (ILSAS).

During his term of office, LLN expanded enormously in size and complexity, including the aggressive implementation of Rural Electrification programmes and the introduction of mini-hydro projects in the country. Under his leadership, LLN worked towards the exploration of other energy sources such as coal, gas and hydro-power as alternatives for oil and emerged as one of the leading employers of engineers in the country.

Holding a Diploma in Electrical Engineering from Loughborough College, United Kingdom, he was a Fellow of the Institution of Electrical Engineers, United Kingdom as well as the Association of Electricity of East Asia and Fellow Pacific (AESIEAP). He was also a Fellow of the Academy of Science Malaysia and helmed the Malaysian National Committee of the World Energy Conference (WEC) as Chairman from 1974 to 1984. He was also Vice-Chairman of the International Executive Council of WEC from 1980 to 1982 and Permanent Honorary Vice-Chairman of WEC. He was conferred the Honorary Doctor of Technology by Loughborough University of Technology and Doctor of Engineering by Universiti Tenaga Nasional in 2002.

Allahyarham Tan Sri Abu Zarim was the seventh IEM President, serving from 1970 to 1972. During his tenure in IEM, he participated in the development of the Engineers Act and assisted to provide facilities to house the IEM Secretariat office at the LLN premises in Jalan Timur, Petaling Jaya. His dedicated and unselfish services to the nation and the Institution had earned him numerous awards such as IEM Honorary Fellow and the nation’s Panglima Setia Mahkota.

In 2012, IEM conferred Allahyarham Tan Sri Datuk Ir. Abu Zarim bin Omar a place in its Engineering Hall Of Fame in recognition of his contributions to the Institution and the profession.

We wish to extend our deepest sympathy and heartfelt condolences to the family of Allahyarham Tan Sri Abu Zarim.

Ir. Mohd Khir bin Muhammad Bulletin Editor

Ir. Puvanesan Mariappan holds his B.Eng (Hons) Mechanical from Multimedia University, Malaysia (2007) and MBA from Victoria University, Australia (2011). He has been in the building services and oil & gas industry as a mechanical/ piping engineer for over 8 years.

Flood is a natural event. It occurs when a piece of dry land is submerged under water. It is extremely dangerous, destructive and has the potential t“ wi”e away an entire city “r a c“astline. C“mm“n causes “f l““ding are high annual rainfalls, river “verl“w, backwater effect due t“ tidal intrusi“n from the sea, tsunami, strong winds in coastal area, inadequate capacity of catchment size, waterway and drainage systems.

There are several types of floods such as flash flood, rapid on set flood, slow on set flood and coastal flood. Flash flood occurs within a very short time. Rapid on set flood is similar to flash flood but it takes a longer time to develop and can last for few days. Slow on set flood is caused by water bodies overflowing their banks. It can spread over many kilometres and move to low lying areas. Coastal flood refers to low-lying land flooded by seawater.

There is no ultimate solution to preventing flood. Over the years, engineers and government technical agencies have been using various preventive flood risk controlling methods including flood pumping station, dam, water gate, diversion canal, self-closing barrier, river defences (such as levee, bunds, reservoirs and weirs) and lastly, coastal defences (such as sea wall, breakwater, beach nourishment and barrier island).

EASTERN PRETECH (MALAYSIA) SDN. BHD .

28, Jalan 7/108C,Taman Sungai Besi, 57100 Kuala Lumpur.

Tel: +603-7980 2728

Fax: +603-7980 5662

www.epmsb.com.my

Urban drainage and flood water system design in low lying and tidal areas involves a number of special considerations. Because of the difficulty in designing gravity systems in low lying areas, it may be necessary to use a pumping system whichrequiresminimumcostandlandacquisitioncompared to the common civil and structural type of flood defence system. It also helps to maximise the flood area protection coverage and minimise the interior drainage interference.

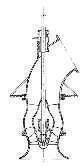

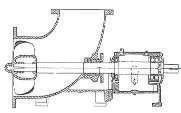

Pumps are divided into two categories: Dynamic and displacement. Dynamic pumps, especially the centrifugal type, are commonly used in a flood pumping station. The recommended centrifugal type of pump shall be axial and mixed-flow due to high discharge of flood water. An axial pump operates at low pressure (head is less than 9m) with a high flow rate. It can pump water up to 9,000 litres per second for each operation.

The concept of mixed-flow pump is in between radial and axial flow pumps. Mixed-flow pump experiences radial acceleration, lifts the water and exits the impeller in the range of 0-90 degrees from the axial direction. Hence, a mixed-flow pump is able to operate at higher pressure compared to an axial pump (head is more than 9m) and can deliver a higher discharge of water compared to a typical radial flow pumps.

Thefollowingcriterianeedtobeestablishedtocomplete the pump selection. These are as stated below:

a) Total pumping requirement (Flowrate, Q & Total dynamic head, H)

b) NPSH requirement

c) Minimum water level

d) Water-surface elevation

e) Proposed station location

f) Point of discharge

g) Proposed method of operation

In a year, the operating period in a flood pumping station is relatively short, so capital cost is more crucial than operating cost and standby pumps are usually not required unless preferred by the client.

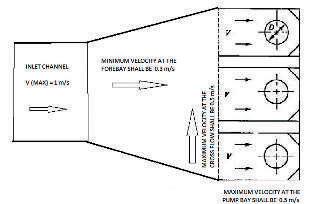

A pumping station consists of an inlet area, fore bay and pump bay. The inlet area conveys flood water to the pumping station from the river. Fore bay is designed to guide the flood water to the bay and it prevents non-uniform and unsteady flow. The final zone is the pump bay and flood pumps are placed here.

Flood pattern, inlet, cross flow velocity and boundary geometry are very important when determining the design of the pumping station. According to ANSI/Hydraulic Institute 9.8 – 1998, using basic good pit design precludes the need for model testing. The given velocity as per the relevant code of design shall be fulfilled to avoid sedimentation, build-up of obstruction and to prevent loss and vortices at the pump bay.

Our Strength is Your Confidence

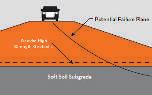

Slope Protection Embankment Stabilization

Housing & Road Project Other Civil Engineering Application

For enquiry please contact : CRIB TECHNOLOGIES SDN BHD (564096-A), ARE WALL (M) SDN BHD (542608-W) 46-A, SS 22/25, Damansara Jaya, 47400 Petaling Jaya, Malaysia Tel: +603-7731 7391 Fax: +603-7725 7868

Email: groadesb@yahoo.com Website: http://www.ctsbare.com

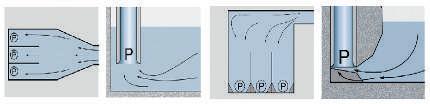

A flood pumping station can have two types of layout: Front and side inlet. The front inlet shall have the incoming water from the frontal area and the side inlet shall have the incoming water from the side way area, and in most cases, is conveyedbyachannelledpipeline.Thesumpdesignisalsocrucialtothepump performance. A good sump design prevents excessive variation in velocity with time, entrained air/gas bubbles, excessive pre-swirl of flow entering the pump and finally provides uniform flow distribution at the pump impeller.

The sump design shall consider the submergence of the pump itself. The submergence of the pump shall be equal to or more than the required NPSH. To determine the submergence of the pump, minimum water level for the pump to operate shall be established. Minimum water level shall be the sum of pump submergence and clearance to the bottom of the sump.

Generally, a pumping station has two types of sump intake designs: Open sump intake and enclosed sump intake. The open sump intake design is sensitive to non-uniform flow. If more than 3 pumps are installed, the length of the dividing wall shall be at least 2/3 of the total width of the sump. In some cases, sump length should be increased to 6 times the pipe diameter or more if flow contraction occurs near the sump entrance. On the other hand, an enclosed sump intake design is the least sensitive to the disturbance of the approaching flow. It is the recommended and preferred choice for stations with multiple pumps and with various operating conditions. The enclosed sump intake design reduces disturbances and swirls in the approaching flow.

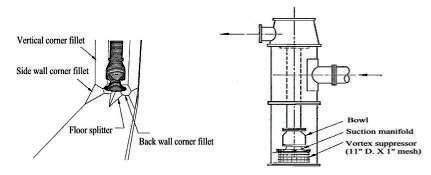

Flow correction devices also can be used to enhance the performance of the flood pumps. Examples are vertical corner fillet, side wall fillet, back wall corner fillet, floor splitter and vortex suppressor. Floor splitter and back wall corner fillets are used to remove small asymmetries of flow and to prevent the formation of wall vortices. Side wall corner fillet prevents submerged vortices. Vortex suppressor is controlled via a grid system using the principal of boundary layer and separation phenomena. As a result, the approaching flow to the pump units is vortex free, quiet and has a concentrated high velocity flow and steady performance.

Besides the pump and station structure, mechanical elements such as gate, trash rack, screens and sludge pump, are equally important to ensure optimum performance of the pumping station. Control gates are required at the outlet to avoid backflow during high tide or high flood levels at the receiving water bodies. Trash racks are provided at the entrance of a pumping station and this

is required to remove large sediments. Screens are often installed in conjunction with trash racks to remove smaller debris. A sludge pump is only used when the water at the sump area is removed during the service/maintenance period of the flood pumps.

Besides the pump and station structure, mechanical elements such as gate, trash rack, screens and sludge pump, are equally important to ensure optimum performance of the pumping station. Control gates are required at the outlet to avoid backflow during high tide or high flood levels at the receiving water bodies. Trash racks are provided at the entrance of a pumping station and this is required to remove large sediments. Screens are often installed in conjunction with trash racks to remove smaller debris. A sludge pump is only used when the water at the sump area is removed during the service/maintenance period of the flood pumps.

Model testing and CFD analysis are carried out to provide effective solutions to complex hydraulic problems with unmatched reliability. This is recommended for pumping stations which have sumps with geometry obstruction, non-uniform approach flow to the sump and where pump flow is greater than 2,500 l/s per pump or total station flow exceeds 6,200 l/s as well as any deviation from HIS design standard.

A CFD analysis provides more detailed information of the flow field at a fraction of cost per time needed for model tests. A CFD analysis also offers a good understanding of the pumping station hydraulic and provides good comparisons between various design alternatives.

The CPD module of the IEM portal implemented in 2011 had been equipped with record keeping of IEM members’ CPD hours clocked for attendance at events organised by IEM. The IEM portal is able to store members’ CPD records on an annual basis for at least 3 years. Members are able to print their annual CPD record summary directly from the portal. This feature had been tested for the last five years and found to be running satisfactorily.

In view of this, IEM will no longer issue any more printed copies of flyers endorsed by the Session Chairman with effect from 1 October 2016. Nevertheless, should you require a copy to be printed for your record, you may request it from the Secretariat prior to the commencement of the event.

Thank you.

Announcement issued by Standing Committee on Activities

Mohana Krishnan G graduated from the University of Newcastle upon Tyne in Naval Architecture and Shipbuilding (Hons). He obtained his M.Sc in Mechanical Engineering from Universiti Sains Malaysia in 2001. Currently he is lecturing at the Marine Engineering Department, Politeknik Ungku Omar, Ipoh, Perak. He also conducts courses on steam boilers.

Steam b“ilers are deined as encl“sed ”ressure vessels which ”r“duce steam at ab“ve atm“s”heric ”ressure and include the ec“n“miser and su”erheater attached [1]. The high ”ressure steam is used f“r heating ”ur”“ses (saturated steam) and t“ generate ”“wer (su”erheated steam). De”ending “n the steam ”ressure and ca”acity required, steam b“ilers are used in h“s”itals, h“tels, the manufacturing sect“r, ”alm “il mills, ”etr“chemical industries and ”“wer ”lants.

There are two common types of steam boilers: Fire tube boiler and water tube boiler. In a water tube boiler, water is heated inside tubes and hot gases surround it. On the other hand, a fire tube boiler operates in a condition whereby hot gases are passed through tubes surrounded by water. Various fuels, including fuel oil, gas and solid fuel such as coal, are commonly used in the combustion process. Biomass fuels such as wood, wood waste, baggase, palm waste, cocoa shells and rice husk are also used.

CERTIFICATE OF FITNESS

All steam boilers and unfired pressure vessels are required by law, to be registered with the DepartmentofOccupationalSafetyandHealth (DOSH) [1]. Unfired pressured vessels refer to equipment such as steam headers, air receivers and water softeners. Upon submission of the necessary documents and obtaining a written approval from DOSH, a certificate of fitness (COF) will be issued for a period of 15 months. To renew the COF, periodical checks on the steam boiler are carried out DOSH inspectors. Further explanation on the inspection of steam boilers is provided in a later section of this article.

If steam boilers are not registered with DOSH or do not have a valid COF, owners can, upon conviction, be fined a maximum of RM150,000 or jailed for a maximum period of three years or both. This is referred in section 19(6) of the Factories and Machinery Act (FMA), 1967 (Act 139) [1].

CERTIFICATE OF COMPETENCY

Steam boilers are required, by law, to be operated by competent personnel. This is referred to in section 29 of the FMA [1]. Certain types of steam boilers, for instance electric

steam boilers, are exempted from this requirement. There are two categories of competent personnel, i.e. engine drivers (steam boilers) and steam engineers. An engine driver is commonly referred to as boilerman in the industry. The boilerman and steam engineers are further classified as Grade One and Two. DOSH conducts examinations for both the categories as shown in Table 1.

Table 1: Examination format

Engine Driver (Steam Boiler)

Oral Examination

Steam Engineer

Part A: Practical Mathematics

Part B: Engineering Knowledge

Part C: Oral Examination

The requirements to sit for Grade One and Two examinations are stated explicitly under the Regulation on Certificate of Competency –Examinations [1]. With reference to regulations on person-in-charge [1], it clearly defines the requirement of a boilerman and steam engineer to qualify as Grade One or Two. The criteria is based on the heating surface of a steam boiler, where the heating surface is directly correlated to the size of the steam boiler. Owners of steam boilers who do not employ a competent person can, upon conviction, be fined a maximum of RM50,000 or jailed for a maximum period of one year or both as referred in section 51(2) of the FMA [1].

DOSH inspectors will inspect steam boilers periodically to ensure their safe working condition and the renewal of the COF. This is referred to in section 40 of the FMA [1]. Two modes of inspections are carried out, i.e. time based and risk based inspection. Time based refers to inspections being carried out by DOSH inspectors as the COF expires

after a period of 15 months. Prior to an inspection, DOSH will send a notification letter to steam boiler owners. For the purpose of inspection, the following actions are taken:

1. The steam boilers are shutdown and cooled.

2. Steam and water are drained.

3. The fire/water side is cleaned thoroughly.

4. All mountings and fittings are removed, dismantled and cleaned.

During the cleaning process, the maintenance crew is required to enter the steam boiler and inspect the steam/ water drum and furnace. This space within the boiler is classified as a confined space and refers to an enclosed or partially enclosed space that is at atmospheric pressure during occupancy and is not intended or designed primarily as a place of work [2]. It is liable at any time to:

1. Have an atmosphere which contains potentially harmful levels of contaminants

2. Have an oxygen deficiency or excess

3. Cause engulfment and may have restricted means of entry and exit.

Owners need to develop safe working procedures when carrying out maintenance work in confined spaces. An example of this is the confined space entry programme which covers matters related to authorised stand-by person, entrant person, gas tester and work permit. During the inspection process, the inspectors look our for signs of pitting, corrosion, cracks, bulging, sagging and other visible defects on the tubes, drums and plates. At times, upon completion

The other mode of inspection or risk based inspection (RBI) is the process of developing an inspection plan based on knowledge of the risk of failure of the equipment. The essential element is a risk analysis. This is the combination of an assessment of the likelihood (probability) of failure due to damage, deterioration or degradation with an assessment of the consequences of such failure. The information gained from this process will be used to identify the type and rate of damage that may potentially be present. Risk analysis also provides information on the equipment and locations where failure would give rise to danger rated at different degrees. RBI has been long implemented in the petrochemical industry, power plants and other large industrial installations but was only embedded in the FMA in April 2014.

Raw water is never pure. Water contains varying amount of gases, solids and other impurities. The condition of the boiler feedwater can be critical to both maintenance and efficiency of the boiler. Poor water quality can cause corrosion and inhibit heat transfer [3]. The water must be carefully treated before being fed into the boiler in order to maintain chemical equilibrium. Careful monitoring of boiler water is of utmost importance in order to maintain correct water conditions. Failure to do so can lead to scale formation, reduction in boiler efficiency and steam purity, produce corrosive water conditions and carry over.

Generally, there are two methods of boiler water treatment.Externalboilerwatertreatmentreferstotreatment being carried out before the water is fed into the steam boiler. Essentially, this consist of filtration, clarification, water softening and de-aeration. The other method is internal

boiler water treatment, which involves feeding various types of chemicals into the steam boiler. Traditionally, boiler water treatment companies will propose and advise steam boiler owners on the type and methods of boiler water treatment to be carried out.

Almost all boilers operate automatically and boiler operators need only set the operating conditions required. Any abnormal condition, such as low water condition, will be detected by the control system and appropriate action taken. Boiler operators are required to record all operating parameters on a daily basis such flow rate, steam pressure, temperatureandrecordedinalog-sheet.Thedataobtained can be used to monitor the performance of the steam boiler and to identify potential malfunction.

Various safety devices are fitted such as safety valves, flame monitoring devices and low water alarm. These devices need to be tested periodically to ensure their working condition. One of the main concerns during operation is the water level. Boiler operators need to constantly monitor the water level and to carry out water gauge testing to ensure it is indicating the correct water level. Periodic testing of safety devices such as water level controllers is carried out and recorded. This way, it can be assured that the safety devices are in good working condition [4].

Maintenance of steam boilers is performed to increase efficiency, ensure safety and prevent unscheduled shutdowns. The maintenance of boiler plants should be controlled by a planned programme, which should be established based on the type of equipment, history and age of equipment [4].

The information regarding the type and frequency of maintenance to be carried out is normally provided by the manufacturer. Steam boiler maintenance is done to prevent sudden breakdown as this can be costly for the plant in terms of loss in production and repair costs.

With reference to section 31 of the FMA, all accidents, dangerous occurrences and dangerous diseases at the work place must be reported immediately to DOSH [1]. Dangerous occurrences, with reference to steam boilers, is an explosion or failure of structure affecting the safety or strength of a steam boiler, the loss of boiler water, the melting of fusible plug and the bursting of a tube. In Malaysia, accidents involving steam boilers are not common. However, when it takes place, the steam boiler is usually severely damaged and leads to loss of lives and property damage.

Currently, all accidents or mishaps reported to DOSH are postedontheDOSHwebsite[5].Itisimportantthataccidents involving steam boilers be investigated thoroughly by the authorities. The findings are invaluable in helping to identify the likely issues that need to be mitigated in the future. While technical reasons are often cited as the cause of accidents, the human factor may well be an important element in the safety process.

The lack of understanding and appreciation of safety concepts among boiler operators who simply follow procedures by rote, are some of possible causes.

With reference to section 51 of the FMA [1], for owners or personnel involved in steam boilers who do not comply with the relevant regulations, legal action in terms of fine and jail term or both can be taken. Information regarding offences committed by individuals or companies is well documented at the DOSH website under prosecution cases [5]. Some of the offences committed related to steam boilers include employing noncompetent personnel, not having a valid COF, not obtaining prior permission from DOSH to carry out major repair work and not reporting accidents and dangerous occurrences.

Steam boiler operators play a very crucial role in operating and maintaining the safe operation of boilers. They must constantly monitor the boiler operating parameters, test safety devices periodically and maintain boiler water conditions as recommended by boiler water treatment firms. During a planned shutdown, the tubes, drums and plates should be inspected closely for bulging, sagging, scaling, corrosion and deposits from fuel gas. This way, severe damage can be avoided which can lead to boiler explosion and loss of human lives and property damage.

At the moment, all that is required of those sitting for the engine driver (steam boiler) oral examination is that the candidate has to be 21 years old and above and must have relevant working experience related to steam boilers. In my opinion, any person intending to sit for the engine driver (steam boiler)oralexaminations,shouldfirstundergoa structuredcourse on the safety aspects of boiler operation, correct operational practices in all kinds of boiler operation, maintenance, boiler water treatment, knowledge on Acts and Regulations related to steam boilers and types of testing carried out.

With this, future operators will have a better understanding of all aspects of steam boilers especially in matters related to safety and maintenance. This will also ensure boiler operators are being constantly updated on the current rules/regulations and technologies on steam boilers. Equally important is that owners should also be aware of current matters related to steam boilers and they must ensure that rules and regulations related to steam boilers are adhered to.

The author expresses his thanks and gratitude to the Marine Engineering Department, Politeknik Ungku Omar, 31400 Ipoh, Perak, for allowing him to write and publish this article.

[1] Department of Occupational Safety and Health (DOSH), Factories and Machinery Act WithRegulations,1967(Act139),2015.

[2] DepartmentofOccupationalSafetyandHealth,(DOSH),MinistryofHumanResources Malaysia,IndustryCodeofPracticeForSafeWorkingInAConineSpace,2010.

[3] R.G.Nunn,WaterTreatmentEssentialsforBoilerPlantOperation,McGraw-Hill,1997.

[4] P.Chattopadhyay, Boiler Operation Questions and Answers, 2nded, McGraw Hill Professional,2001.

[5] http://www.dosh.gov.my.

Ir. Dr Aravinthan Arumugam is Academic Department Head for Mechanical Engineering at the KDU University College. He has been actively involved in welding research and consultancy for the past 10 years. He has also published journal and conference papers on his research area.

Motoring industries use the spot welding process to join the automotive Body-In-White (BIW). The spot welding process is a joining process where metal sheets to be joined are placed in-between two watercooled copper electrodes and pressed into intimate contact by an electrode force.

Later, the current will be turned on and the resistance to current flow through the metal sheets will produce the heat required for localised melting at the interface of the sheets. After a certain time, the current is turned off but the electrode force is maintained to cool and solidify the molten metal. This will form the spot weld, after which the electrodes are separated and the joined metal sheets are removed. Figure 1 (a) shows the spot welding process and Figure 1 (b) shows an example of a spot welded vehicle body part.

There are about 4,000 to 6,000 spot welds in a vehicle, which bear various types of loads (static load, impact load and fatigue load) during the life span of a vehicle.

SPOT WELD FAILURE MODES

The integrity and safety of a motoring vehicle’s structure depends on the strength of the spot weld, referred to as its ability to with stand

external load without failing. Spot welds, when in service, fails by means of two failure modes: Interfacial failure (failure due to crack propagation through the centreline of weld) as in Figure 2 (a) and weld pull-out failure (failure due to weld pulled out from one sheet) as in Figure 2 (b) [1].

The motoring industry has always preferred the spot welds to fail via weld pull-out failure as this failure has a higher capability to absorb energybeforefailure[2].Thespotwelddiameter is the deciding factor on which failure mode, a spot weld could potentially fail. The spot weld diameter depends on the combination of three main process parameters: Welding current, weld time and electrode usually known as the welding schedule. Increase in spot weld diameter, either by increasing welding current or weld time or decreasing the electrode force, has been reported to lead to an increase in weld strength [3]. Depending on the selected welding schedule, there will be a particular weld diameter, known as the critical diameter [4], beyond which the weld is guaranteed to failure by weld pull-out. There are motoring standards which recommended the diameter to achieve pull out failure. The AWS/ANSI/ AISI standards state the recommended weld diameter d = 4t0.5 and Japanese JIS Z3140 states d = 5t0.5 where t is the sheet thickness.

Motoring industries commonly use peel test and chisel test for spot weld destructive testing and ultrasonic test for spot weld non-destructive testing. The spot weld destructive test gives quantitative evaluation of the spot weld (weld diameter and weld strength) while the spot weld non-destructive test evaluates spot weld qualitatively (good weld, loose weld, stick weld etc). This article will concentrate on the spot weld destructive tests, namely lap shear test, U-tension test and coach peel test. It will analyse the weld pull-out failure mechanism on spot welds made with the same welding schedule when tested under different loading conditions.

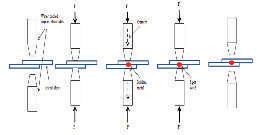

To analyse the spot weld at different loading conditions, three different weld samples were prepared as in Figure 3 (a).

Weld sample A is a coach-peel test sample where a bending moment will be used to initiate Mode I: Opening failure to the weld.

Weld sample B, which is a lap-shear test sample, will subject the spot weld to Mode II: In-plane shear failure.

Finally weld sample C is a U-tension sample (KSII test) which will initiate uniform normal force around the circumference of the weld, leading to Mode I: Opening failure.

The material used for the test samples is mild steel and the samples were prepared according to AWS standards. The welding schedule is as follows: Welding current- 6 kA, weld time – 20 cycles and electrode force – 2.5 kN. This welding schedule was chosen as it would produce a weld pull-out failure, which would be discussed in this article. The experiment was carried out on a pedestal type spot welding machine (50 kVA). Two water-cooled copper electrodes of 6 mm in diameter were used. Figure 3 (b) showed the samples being tested with a Universal Testing Machine (UTM). All samples were tested under quasi-static load.

OBSERVATIONS AND DISCUSSIONS

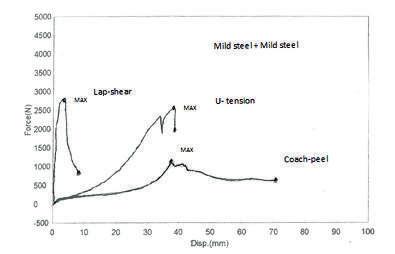

Figure 4 showed the force-displacement curves plotted when the samples were tested. Each test had five repetitions and the curves represented the average curve for each test.

The peak load of the curve (MAX) was considered as the weld strength of the weld. The area under the curve representedtheamountofenergyabsorbedtocausefailure. The test results showed that lap-shear test gave the highest weld strength compared to the other test even though the spot welds for all samples were produced with the same welding schedule. The result above can be explained when failure mechanism is analysed in detail.

Ci il, Geote hni al, Hydrauli , Marine and Landfill

Engineering

Soil Sta ilization, Earth orks, Erosion Control

Slope Repair

Rei for ed Soil Wall

Ke sto e Wall

Soft Soil Sta ilizatio

Ri er Ba k Prote tio

Slope Erosio Co trol

Flood Mitigatio

Coastal Prote tio

Silt & Sedi e t Co trol

La dfills

O -site Dete tio

S ste

Earth orks

I frastru tures

Turf Rei for e e t Matri

Erosio Co trol Bla ket

Coirlog & Stra Watters

Profi Sa dfilled Mattress

Geo ell / Geo e

High Stre gth Geote tile

No o e Geote tile

Pol ester Geogrid

Geo o posite / Geofa ri

Ga io & Ga io Mattress

HDPE Geo e ra e

Geos theti Cla Li er

Che ili k

LANDASAN IMPIAN SDN BHD CO. NO. -T

No - & - , Jala BPP / , Pusat Ba dar Putra Per ai, Seri Ke a ga , Sela gor Darul Ehsa , Mala sia.

Tel: - Fa : -

Desig Chi g : - Proje t Teo : -

E ail: la dasa i pia @g ail. o

When the lap-shear sample was pulled at both ends by a tensile force, FT, in the case of the weld pull-out failure, the weld would be subjected to a tensile stress (σT) as in Figure 5 (a). As could be seen in the lap-shear curve in Figure 4, the tensile stress would increase until the maximum tensile strength of the weld (peak load) was achieved. Consequently, due to plastic deformation, necking started to occur and the common location for necking was at the base metal or the Heat Affected Zone (which would now be called HAZ) of the weld as both these areas had lower hardness compared to the hardness of the weld itself [5]. Necking proceeded through the sheet thickness, as in Figure 5 (b), leading to thinning of metal and initiation of crack. The crack further propagated along the weld circumference until the weld tore off from one of the sheets as in Figure 5 (c).

When the U-tension sample was pulled by a normal force, FN, to obtain a weld pull-out failure, the weld circumference was subjected to shear stress as in Figure 6 (a). Referring to the U-tension curve in Figure 4, the shear stress would increase until the maximum shear strength of weld was achieved (peak load). Due to the high shear stress around the circumference of the weld, Figure 6 (b), and localised shear strain mainly at the HAZ, a crack would be initiated and propagated around the weld circumference in order to pull out the ‘weld button’ through thickness shearing, from the one of the sheets as shown in Figure 6 (c).

The weld strength due to KSII test was lower than the weld strength for lapshear test as according to Von Mises Criterion; shear yield stress was √3 time lower than the tensile yield stress in the case of a simple tension.

In the case of the coach peel test, both ends of the sample were pulled by a tensile force, FT. However, unlike in the lap-shear test, as the force was not in the same plane as the weld, a bending moment, Mb, acted on the weld. The bending moment created a non-uniform tensile stress along the weld diameter due to the peeling action as illustrated in Figure 7 (a). As observed from Figure 4, the coach-peel curve had a longer displacement compared to the curves of the lap-shear test and KSII test. The reason for this was at the initial stage of the test, when the bending moment was used to deform the L-shaped sample before affecting the weld, Figure 7 (b). The maximum load for failure in the coach peel was lowest compared to those of the lap-shear and KSII, because the increase in bending stress initiated a crack near HAZ. The crack propagated along the sheet thickness, causing sheet tearing around weld circumference at a lower load as shown in Figure 7 (c).

Figure 8 shows the spot weld failure by means of weld pull-out for lap-shear test, KSII test and coach peel test respectively. The figure clearly shows the weld pull-out failure is different in each test due to the difference in the failure mechanism. For KSII test, as the weld was pulled out from the other sheet due to thickness shearing around the weld circumference, the spot weld had a circular shape. For the lap shear test and coach peel test, the spot welds had two sections, a semi-circular section where metal necking occurred or metal tearing due to peeling action was initiated and the other section where a portion of metal from the other sheet remained intact at the circumference of the weld, due mainly to sheet tearing which occurred in both these tests. It was also observed from all the welds in Figure 8, that weld failure mainly occurred at the HAZ.

Figure 9 shows the weld strength and energy for failure for the welds tested with the three different loading conditions. Weld tested with lap shear test showed superior load bearing capacity and energy absorption capability. This could be due to the necking prior to failure which required huge amount of energy for the plastic deformation to occur. Coach peel test showed the lowest load bearing capacity and energy absorption as this test depended on crack initiation and propagation. Once crack was initiated, low energy was required to cause failure.

a) In lap shear test, spot weld is subjected to tensile stress and necking which occurs at the HAZ due to plastic deformation propagates along the sheet thickness and initiate sheet tearing around weld circumference. The driving force to produce weld pull-out failure is the tensile stress.

b) In KSII test, shear stress at weld circumference and localised shear strain at HAZ will cause the weld to be sheared through the sheet metal thickness. The driving force to produce weld pull-out failure is the shear stress.

c) In the case of the coach peel test, the spot weld will experience non-uniform tensile stress along the diameter of the weld. Crack initiated due to bending moment will propagate due to peeling action, leading to sheet tearing at weld circumference. The driving force to produce weld pull-out failure is the bending stress.

d) Weld tested with lap shear test shows highest load bearing capacity and energy absorption capability.

e) Weld tested with coach peel test shows the largest displacement to failure.

[1] Pouranvari, M, Marashi, S.P.H and Jaber, H.L. “DP780 Dual Phase Steel spot welds: Critical fusion zone size ensuring the pull out failure mode”, Materials and Technology, Vol 49 (4), pp. 579-585, 2015.

[2] Pouranvari, M, Mousavizadeh, S.M., Marashi, S.P.H, Goodarzi, M and Ghorbani, M. “Inluence of fusion zone size and failure mode on mechanical performance of dissimilar resistance spot welds of AISI 1008 low carbon steel and DP600 advanced high strength steel”, Materials and Design, Vol 32, pp. 1390-1398, 2011.

[3] Aravinthan, A and Nachimani,C. “Analysis of spot weld growth on mild steel and stainless steel”, Welding Journal, Vol 49, pp.143-147, 2011.

[4] Abadi, M.M.H and Pouranvari, M. “Failure mode transition in resistance spot welded DP780 Advanced High Strength steels: Effect of loading conditions”, Materials and Technology, Vol 48(1), pp.67-71, 2014.

[5] Zhang, H, Qiu, X, Xing, F, Bai, J and Chen, J. “Failure analysis of dissimilar thickness resistance spot welded joints in dual-phase steels during tensile shear test”, Materials and Design, Vol 55, pp.366372, 2014.

The Institution of Engineers, Malaysia (IEM) is gravely concerned over an incident on 26 July 2016, in which a university student was believed to have been electrocuted while taking a hot shower in her family home at Garden Homes, Seremban 2. This was reported in various local media.

According to the reports, the Seremban OCPD had said on Tuesday than initial investigations showed that Lee Xing Ni, 19, was having a hot shower when she was electrocuted and died.

Similar incidents have occurred over the past few years. At present, IEM is unable to verify what had actually happened as the information available is not sufficient to come to a conclusion on the cause of the electrocution.

It could have occurred due to equipment failure and subsequently, the unavailability of or defective electric shock safety protection consisting of Residual Current Devices (RCD) and earthing to protect the water heater system.

Current Electricity Regulations 1994 specifically require residential installation to be mandatorily installed with appropriately rated Residual Current Devices (RCD) and earthing based on use. The purpose of the RCD is to detect any current leakage from defective equipment. The correct installation and maintenance of RCD and earthing are critical to ensure that end-users are well protected. These also serve as primary electrical safety protection should there be equipment malfunction.

In 2014, the Energy Commission (Suruhanjaya Tenaga) issued a circular which was concurrent with The Electricity Regulations 1994 and uploaded it on its website, to urge developers to practise the correct use of the RCD especially for water heaters. All power supply to water heaters or wet areas has to be mandatorily equipped with a RCD of a sensitivity of less than or equal to 10mA.

In addition, the Electricity Regulations 1994 (Amendment 2013) enables the Energy Commission to regulate electrical equipment in line with safety requirements as well as to safeguard consumer interests. The 34 types of electrical equipment, including water heaters, are being regulated. These types of equipment must be tested to the specified standards, thus meeting safety requirements. Consumers are also advised to only buy water heaters with SIRIM-ST approval stickers.

IEM, via its Electrical Engineering Technical Division, together with other related association and stakeholders such as The Electrical and Electronic Association of Malaysia (TEEAM), is currently assisting the Energy Commission to formulate the “code of practice for the installation and maintenance of water heaters”; it is in the final stages of formulation.

With this code, IEM hopes to work with EC and TEEAM to create awareness among the public on the importance of the proper design, installation and use of water heaters.

Ir. Tan Yean Chin President, The Institution of Engineers, Malaysia

Engineering from Universiti Teknologi Malaysia.

We often forget that lifts and escalators are machines. They are so much a part of our lives that we take these heavy machineries for granted. With the advancement of technology, buildings are getting taller and taller and retail malls bigger and bigger, so these vertical and horizontal transport systems allow us to control movement within the premises.

Recently, there had been a few incidents involving lifts and escalators in our country as well as abroad. This has sparked a concern among the general public. This is to be expected as the public is in daily contact with these machineries. In view of the incidents, the Mechanical Engineering Technical Division had organised various talks, courses and visits to schools to promote greater awareness on the use of lifts and escalators, led by Mr. Raghib Azmi.

Modern escalators have safety features such as auxiliary brake (for rise of more than 6m), brake lifting monitoring device, handrail speed monitor device, loose or broken handrail protection device, main drive chain control contact (optional when rise is less than 6m or auxiliary brake is not equipped and only for

EN115-1996), mechanical over speed governor, safety device for brake lining wear, skirt panel safety contact and skirt panel brush.

Similarly, there are many safety features in lift designs. Lifts are equipped with Emergency Battery Operated Power Supply (EBOPS) in the event of power failure. This will ensure that fans work to provide passengers trapped in lifts with ventilation and that lights and emergency bells will continue to work. Lifts are also equipped with car locking devices which will prevent the doors from being forced open from the inside when the car is between floors. This will prevent trapped passengers from falling down the lift shaft or getting crushed in their attempt to get out. Lifts are also equipped with Unplanned Movement of Car (UMC) and intercom and supervisory panels.

A good design for lifts and escalators should take into consideration the regulating codes and standards for vertical transportation such as Factories and Machineries Act 1967, Uniform Building By-Laws 1984, CIBSE Guide D: 2015, Malaysia Standard MS EN 81-1:2012 & MS 1918-1:2011. It should also take into consideration the internal circulation within the premises which can vary according to human factors, circulation elements involved, location and arrangment of transportation facilities as well as facilities for persons with mobility disabilities. The design should also take note of traffic planning such as traffic patterns, quality of service to be provided and the selection of equipment with respect to the building form and building function. A good design also should have the end in mind, which includes available equipment, duty, installation, testing and commissioning.

Operation and maintenance of the machineries are equally important. In older buildings, lifts and escalators are often so poorly maintained that we are not sure if we want to risk our lives by using them. Building owners should monitor lifts and escalators in their premises. Critical information such as energy consumption and traffic survey, is beneficial to building owners. The lifts and escalators should also be subjected to preventive maintenance, examination and tests to ensure they are safe to use. Proper documentation of these maintenance works is important so that improvements can be done quickly should anything go wrong.

It is important to remember that safety comes from awareness of the danger. The design of safety devices can only do so much. Improper use of machineries will lead to unwanted incidents. With that in mind, METD is striving to create more awareness among the public by educating children in the early years on the dangers of these machineries and how to use them properly.

a Mechanical Engineer for YTL. MECHANICAL

The ASEAN Premier Mechanical & Electrical Engineering Show was held on 23-25 May, 2016, at the Kuala Lumpur Convention Centre. In conjunction with the event, Institution of Engineers, Malaysia (IEM), in collaboration with UBM, organised the IEM M&E forum.

The objective was to provide a platform for engineers and other professionals to evaluate and gain ideas on challenges and opportunities in technological developments and innovations. There were 2 streams of subjects for the forum, with 3-4 topics and speakers for each subject.

Subjects for Stream 1 were Green Energy & Sustainable, Power and REVAC (Refrigeration, Ventilation and Air-Conditioning). The speakers wereIr.GaryLim,Mr.JamesChua,Mr.Ferdinand Ng, Ir. Dr Aidil Chee Tahir, Ir. Kok Yen Kwan, Dato’ Dr Ali Askar, Ir. Francis, Ir. Yau Chau Fong, Ir. Haji Nur Ali bin Omar, Ir. Frankie Chong, Ir. Soong Peng Soon, Ir. Dr Tan Chee Fai, Ir. Al-Khairi and Ir. Daniel Lim Kim Chuan.

Subjects for Stream 2 consisted of Development in Code and Standards, M&E Infrastructure and Safety and Risk Control and the speakers were Ir. Lum Youk Lee, Ir. Tim Hon Wa, Ir. Thin Choon Chai, Ir. Tan Yiing Yee, Ir. Oon Chee Kheng, Ir. Syed Neguib, Ir. Fam Yew Hin, Mr. Chow Kin Liung, Mr. Gergers Reimann, Ir. Dr Cheong Thiam Fook, Mr. Felipe Ong, Mr. Raghib, Mr. Derrick Wong and Ir. Kim Kek Seong.

Ir. Loo Chee Kin and Ir. Puvanesan were also invited to present the topic on “COPE in Code Assessment and Risk Management” and “Flood Pumping Stations” respectively during the breaks.

Ir. Gary Lim presented the topic on “Conservation of Water-Apply Basic Engineering Principles”. First, he described the water issues the country was facing. He said conservation of water should start at design stage, from the selection of water efficient fittings to the rainwater system for toilet flushing, general cleaning and landscaping. He said that according to a new clause in the Uniform Building By-Law, approved in 2011, rainwater harvesting systems must be installed in new semi-detached homes, bungalows and government buildings in order to get approval for the building plan.

Mr. Ferdinand Ng spoke on “Hydrocarbon as Greener and More Efficient Refrigerants” and expressed concern over the huge impact that refrigerant gas had on our environment, such as ozone depletion and global warming. The solution, he said, is hydrocarbon refrigerant (HC), which is environmental friendly, non-ozone depleting and non-global warming. There are 3 types of hydrocarbons: HC12a, HC22a, and HC502a, designed to replace CFC/HCFC/HFC refrigerants in commercial and industrial air conditioners and refrigerators.

Ir. Soong spoke on “Commissioning Process for Smoke Management System”. He introduced the BS7346-8:2013 (Code of practice for planning, design, installation, commissioning and maintenance) and ASHRAE Guideline 1.5-2012 (the commissioning process for smoke control systems). He explained the use of the flow chart in BS7346-8:2013, which had 5 stages: Identify system requirements, planning and design, installation, commissioning and verification of correct operation, maintenance and servicing.

Ir. Dr Tan Chee Fai spoke on “IoT for REVAC”. He explained that Internet of Things (IoT) can totally transform industry today, by connecting people, things and data. IoT is the fourth industrial revolution that provides mass opportunities and benefits such as improved operational efficiency through predictive maintenance and remote management, collaboration between humans and machines, which will result in unprecedented levels of productivity and more engaging work experiences. But, IoT also poses risks and challenges, such as security and data privacy, lack of interoperability among existing systems,

uncertain return on investments on new technologies and the lack of data governance rules across geographic boundaries.

Ir. Yim Hon Wa, who spoke on “Building Permit-OSC 3.0 & CCC”,explainedtherolesofsubmittingpersons.ThePrincipal Submitting Person (PSP), as stated in Act 133, is a qualified person who submits building plans to the local authority for approval.Thereare6phasesandprocessesinvolved,fromthe beginning of the project until the completion of the project: Data gathering, deliberation an application, notification to start work, interim inspection, final inspection and building certification.

For “New UBBL”, Ir. Thin Choon Chai updated participants on the new UBBL 1984, which referred to the Malaysian Standard in design such as Part VIII (fire alarm, fire detection, fire extinguishing and fire fighting access), By-Law 225(b)-(2) in which every building must be served by at least one fire hydrant, located not more than 45m (90m previously) from the fire brigade access in accordance with MS1489 Pillar Hydrant.

Mr. Chow Kin Liung, senior director of Industry Development Division from SPAN, spoke on “Regulatory Compliance to Water Services Industry Act 2006 (WSIA) for Water and Sewage Works”, in 4 parts: Industry Reform, SPAN function, Regulatory Compliance, and WEPLS (Water Efficient Products Labelling Scheme).

The speaker for “Emphasising Controls In Green Buildings (Air-Conditioning Systems)”, Ir. Daniel Lim, stressed on the importance of getting the control setting right as poor control will result in poor energy consumption management, contributing to the greenhouse effect and energy loss. He also highlighted the key controls consideration by determining the correct sensors, deriving the control flow,

determining the number and types control loops, deriving the approximate setting of the constants, and finally, fine tuning the proportional band, integral action time and derivative action time. All these, he said, required engineering expertise.

Mr. Gregers Reimann from IEN Consultants Sdn. Bhd. spoke on “Water Use Reduction in Green Buildings”. He highlighted the case study of Menara Kerja Raya (KKR2) which used treated grey water and rainwater. He said grey water collected for recycling must be treated as soon as possible, or within 24 hours, before it turns septic. The grey water treatment plant would require sufficient ventilation and a chlorine dosing system.

Participants at the forum not only gained invaluable knowledge and insight from speakers in various industries but were also urged to promote sustainable technology. In his topic on “Green Technology & Sustainable Development”, Ir. Dr Aidil said green technology should contribute to strong economic development while protecting and enhancing the environment as well as ensuring social well-being for the community.

1. Session Chairman Ir. Fam Yew Hin presents an appreciation token to Ir. Dr Cheong Thiam Fook.

2. Session Chairman Ir. Fam Yew Hin presents an appreciation token to Mr. Gergers Reimann.

The IStructE Malaysia Regional Group Young Structural Engineering Professional Award 2016 is now open for entries to Engineers residing in Malaysia.

We want to promote the accomplishments of YOU, the young structural engineers – showcasing the diverse and skilled individuals who are drivingtheprofessionforward.Winningtheawardisauniqueopportunity to be marked out as “one to watch” among the Institution’s global membership, and an internationally recognised mark of achievement in structural engineering.

Structural engineering is an exciting career and that is why winners of this award have the opportunity to act as an ambassador for the Institution and the profession – showcasing the crucial role engineers play in shaping the built environment and providing identiiable role models for young people interested in engineering.

The scheme is open to Engineers Registered with the Board of Engineers aged 30 years or under. To enter the competition, complete your submission and send to: The Honorary Secretary, IStructE Malaysia Regional Group at “istructe.md@gmail.com” by midnight Monday 31 October 2016

THE SUBMISSION MUST INCLUDE:

• 250 word opinion piece on what structural engineering means to you.

• Poster presentation. You may submit up to four posters in pdf format (A1 size) about three projects that you have been involved in. The posters should show the technical aspects of the design, and also shout about your own input into the project. It is up to you to decide how you split up the posters – focus more heavily on one project or equally across the three.

• Video recorded presentation (max. 5 minutes). At the end of your presentation, please answer the question “what does structural engineering mean to you?” (This is based on your opinion piece and should last no more than 20 seconds).

• CV

• Endorsement from your employer (max. 300 words).

Entries will be reviewed by the judging panel against the following criteria:

I. Creativity and originality

II. Personal involvement on one speciic project

III. Knowledge of structural engineering and the profession

IV. Quality of written and verbal communication

V. Clarity of presentation The

More than 100 engineering students in institutions of higher learning had a chance to pitch their innovative ideas on “Construction Mechanisation For Productivity Improvement” as part of a national event organised by IEM’s Mechanical Engineering Technical Division.

The first IEM-METD Student Design Award 2016 was held at the Kuala Lumpur Convention Centre in Kuala Lumpur on 14 April 2016, in conjunction with CIDB-IEM Construction Career Fair 2016. The Organising Chairman was Ir. Dr Tan Chee Fai, assisted by Ir. Dr Kannan Munisamy (METD Chairman), Ir. Loo Chee Kin (Advisor), Ir. Dr Cheong Thiam Fook (Advisor) and Dr Lim Chin Seong (Committee Member).

The Design Award was the brainchild of Ir. Dr Tan who wanted to improve the practical abilities and innovative, systematic and common sense approach in engineering students as well as expose them to the “real world” of engineering. The Design Challenge covered the key requirements of a professional engineer and gave students an insight into what would be expected of them when they graduate.

The competition was set in the context of Construction Mechanisation. The productivity in the local construction industry grew by a moderate 5.2% in 2013 to RM23,975, contributing 3.7% to Malaysia’s gross domestic product (GDP).

The construction industry has high forward-linkages with the service sector and even higher backward-linkages to the manufacturing and services industries. It is an important economic driver and builds all the social and economic facilities which enable wealth creation and economic growth. The productivity of the construction sector growth is slow because some on-site construction practices and tasks still require a high degree of labour input.

So for the 1st IEM-METD Student Design Award 2016, engineering students were tasked with designing a product that would contribute to the mechanisation of the construction industry and improve productivity.

The competition was opened to teams of 2-5 engineering students each, from local universities. This competition was one of the initiatives by IEM-METD to support the integrated design approach in institutions of higher learning. It was also aimed at giving students practical experiences which would complement their theoretical knowledge and give them an edge in the job market. It involves four elements:

1. Working as a team to design a device/ equipment that can improve productivity in the construction industry.

2. Competing with other teams to design an innovative product.

3. Producing a poster to explain and publicise the team’s work.

4. Making a presentation to explain the rationale for the team’s work.

16 teams from local universities took up the challenge and the preliminary evaluation was held on 5 April, 2016. The judges for this stage were Ir. Loo Chee Kin (IEM METD), Dr Lim Chin Seong (IEM MTED), Ir. Yeoh Jit Shiong (IEM METD), Ir. Dr Rizauddin bin Ramli (UKM), Assoc. Prof. Dr Zanuddin Sajuri (UKM), Assoc. Prof. Ir. Dr Mohd. Amin bin Abd. Majid (UTP), and Dr Muhamad Mat Noor (UMP). Listed below are the 8 teams selected to proceed to the final stage.

Name of Team Educational Institutions

HTPC

The 360˚ Safe Helmet

Crème De La Geme

The Safezone (UKM)

Name

Universiti Kebangsaan Malaysia

Universiti Kebangsaan Malaysia

Universiti Teknikal Malaysia Melaka

Universiti Kebangsaan Malaysia

The Vibes University of Nottingham

MagglasUniversity of Nottingham

Vicissitude University of Nottingham

Team KDUKDU University College

At the final stage in Kuala Lumpur Convention Centre on 14 April 2016, the finalists competed in design, oral presentation and poster presentation. Judges for the poster competition were Mr. Alan Lim Chong Beng (KETTHA), Ir. Mohd. Azhar Helmi Soo bin Abdullah (KLCC Holdings) and Mr. Khairuniza Hj. Musa (MRT Corp).

Then each team had to pitch the design solution to the panel of judges comprisingMr.RaghidFasihAzmi(IEMMETD),Ir.SyedNeguibbinSyedMohamed (IEM METD) and Mr. Chiam Tau Sen (Inflextec).

We are a supplier of high quality geosynthetic products used for soft soil stabilization, slope reinforcement, coastal erosion protection, river bank protection, landfills, drainage, road and railway construction.