JURUTERA has an esteemed readership of 168,000 professionals, comprising ceriied engineers, decision makers, corporate leaders, CEOs, government oicials, project directors, entrepreneurs, project consultants, engineering consuling irms and companies involved with engineering products and services.

Our business partners can be assured that their products and services will receive the circulaion and exposure they deserve, thus maintaining a sustained adverising presence among our core readers of decision-making engineers and technical experts. Our website ofers an even wider market reach, with added internaional presence, aided by our internaional ailiaion with oicial engineering bodies all over the world. Our online and oline adverising features such as banner adverising, aricle sponsorship and direct e-mail announcements have proven to be successful markeing strategies that will set the businesses of our partners apart from the compeiion.

For adverising enquiries, please contact:

The new retail space at 550 West Broadway in Vancouver is an environmental LEED ® Silver ceriied building, which provides six stories of retail and oice space and four levels of underground parking.

To waterproof and protect the foundaion, Xypex Admix was added to the shotcrete walls and concrete slab on grade. The Xypex treated walls had drainage board maing placed between the wall and the soil nailed foundaion; alternaively against the single sided, backing form. Structural shotcrete was placed in 2.4 metre lits.

The structure was built into a hillside, with signiicant water low into the excavated foundaion hole from the surrounding soils. Minor repairs in the elevator shat were required. Leaking cracks in the exterior foundaion walls self-healed.

For more informaion on how our soluions can provide sustainable beneits for your concrete assets, please visit our website at www.xypex.com.au or LinkedIn Page.

Tel: +603-51928186 Fax: +603-51926826

Email: support@waterprooing.com.my www.waterprooing.com.my

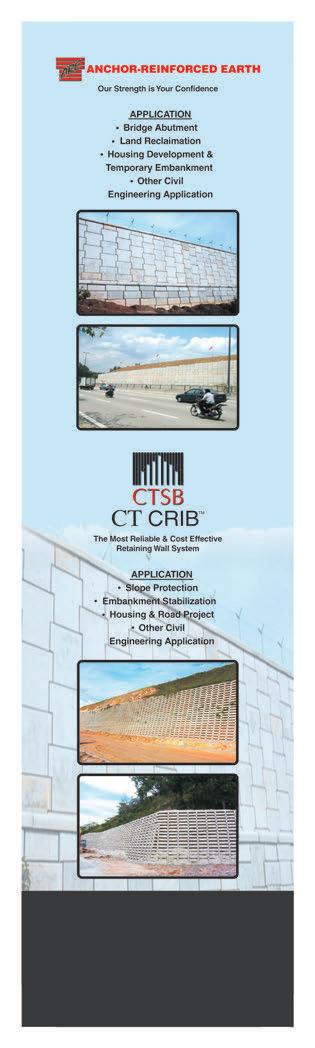

Sika® Carbodur® and SikaWrap® for:

• Increased loading requirements due to changes of policy or use of structures

• Exceptional or accidental loading

• Inadequate design or construction

• Durability problems due to poor or inappropriate construction materials

• Increased life-span of ageing infrastructure

• Change in structural system

Number 10, OCTOBER 2017 IEM Registered on 1 May 1959

MAJLIS BAGI SESI 2017/2018 (IEM COUNCIL SESSION 2017/2018)

YANG DIPERTUA / PRESIDENT

Ir. Dr Tan Yean Chin

TIMBALAN YANG DIPERTUA / DEPUTY PRESIDENT

Ir. David Lai Kong Phooi

NAIB YANG DIPERTUA / VICE PRESIDENTS

Ir. Prof. Dr Jefrey Chiang Choong Luin, Ir. Assoc. Prof. Dr Norlida bt Buniyamin, Ir. Ellias Bin Saidin, Ir. Prof. Dr Ruslan bin Hassan, Ir. Lai Sze Ching, Ir. Lee Boon Chong, Ir. Ong Ching Loon

SETIAUSAHA KEHORMAT / HONORARY SECRETARY

Ir. Yap Soon Hoe

BENDAHARI KEHORMAT / HONORARY TREASURER

Dr Wang Hong Kok

BEKAS YANG DIPERTUA TERAKHIR / IMMEDIATE PAST PRESIDENT

Y.Bhg. Dato’ Ir. Lim Chow Hock

BEKAS YANG DIPERTUA / PAST PRESIDENTS

Y.Bhg. Academician Tan Sri Dato’ Ir. (Dr) Hj. Ahmad Zaidee bin Laidin, Y.Bhg. Dato’ Ir. Dr Gue See Sew, Y.Bhg. Dato’ Paduka Ir. Keizrul bin Abdullah, Y.Bhg. Academician Dato’ Ir. Prof. Dr Chuah Hean Teik, Mr. Choo Kok Beng

WAKIL AWAM / CIVIL REPRESENTATIVE

Ir. Dr Lee Yun Fook

WAKIL MEKANIKAL / MECHANICAL REPRESENTATIVE

Ir. Fam Yew Hin

WAKIL ELEKTRIK / ELECTRICAL REPRESENTATIVE

Ir. Lim Kim Ten

WAKIL STRUKTUR / STRUCTURAL REPRESENTATIVE

Ir. Dr Ng Soon Ching

WAKIL KIMIA / CHEMICAL REPRESENTATIVE

Ir. Prof. Dr Thomas Choong Shean Yaw

WAKIL LAIN-LAIN DISPLIN / REPRESENTATIVE TO OTHER DISCIPLINES

Ir. Roznan bin Abdul Rashid

WAKIL MULTIMEDIA DAN ICT / ICT AND MULTIMEDIA REPRESENTATIVE

Ir. Dr Chuah Joon Huang

AHLI MAJLIS / COUNCIL MEMBERS

Ir. Mohd Khir bin Muhammad, Y.Bhg. Dato’ Ir. Hj. Hanapi Bin Mohammad Noor, Ir. Dr Ahmad Anuar bin Othman, Ir. Ishak bin Abdul Rahman, Ir. Chong Pick Eng (PE Chong), Ir. Ng Yong Kong, Ir. Tejinder Singh, Ir. Sreedaran a/l Raman, Ir. Roger Wong Chin Weng, Ir. Assoc. Prof. Dr Ahmad Kamil bin Arshad, Ir. Dr Tan Kuang Leong, Ir. Hoo Choon Sean, Y.Bhg. Lt. Jen. Dato’ Wira Ir. Ismail bin Samion (Ret. RMAF), Y.Bhg. Dato’ Ir. Hj. Anuar bin Yahya, Ir. Mah Way Sheng, Ir. Gunasagaran a/l Kristnan, Ir. Chen Harn Shean, Ir. Mohd Aman bin Hj. Idris, Ir. Gopal Narian Ku�y, Ir. Dr Jimmy Mok Vee Hoong, Ir. Dr Leong Wai Yie, Ir. Razmahwata Mohamad Razalli, Ir. Abdul Razak Yakob, Ir. Yau Chau Fong, Y.Bhg. Dato’ Ir. Foong Choy Chye, Y.Bhg. Dato’ Ir. Kisai bin Rahmat, Ir. Yam Teong Sian, Y. Bhg. Dato’ Ir. Low Keng Kok, Y. Bhg. Dato’ Ir. Hj. Abdul Rashid bin Maidin

PENGERUSI CAWANGAN / BRANCH CHAIRMAN

1. Pulau Pinang: Ir. Ting Chek Choon

2. Selatan: Ir. Mohd Khir Muhammad

3. Perak: Ir. Abdul Razak bin Ali

4. Kedah-Perlis: Ir. Prof. Dr Rezuwan bin Kamaruddin

5. Negeri Sembilan: Y. Bhg. Dato’ Ir. Zainurin bin Karman

6. Kelantan: Ir. Hj. Mohd Zaim bin Abd. Hamid

7. Terengganu: Ir. Atemin bin Sulong

8. Melaka: Ir. Dr Tan Chee Fai

9. Sarawak: Ir. Vincent Tang Chok Khing

10. Sabah: Ir. Hj. Yahiya bin Awang Kahar

11. Miri: Ir. Paul Chiew Lik Ing

12. Pahang: Y. Bhg. Dato’ Ir. Sharuddin bin Mohd Simin

AHLI JAWATANKUASA INFORMASI DAN PENERBITAN / STANDING COMMITTEE ON INFORMATION AND PUBLICATIONS 2017/2018

Pengerusi/Chairman: Ir. Prof. Dr Ruslan Hassan Naib Pengerusi/Vice Chairman: Ir. Mohd. Khir Muhammad Seiausaha/Secretary: Ir. Lau Tai Onn

Ketua Pengarang/Chief Editor: Ir. Prof. Dr Ruslan Hassan Pengarang Bulein/Bullein Editor: Ir. Mohd. Khir Muhammad Pengarang Prinsipal Jurnal/Principal Journal Editor: Ir. Prof. Dr Ruslan Hassan Pengerusi Perpustakaan/Library Chairman: Ir. C.M.M. Aboobucker Ahli-Ahli/Commi�ee Members: Ir. Lee Boon Chong, Ir. Ong Guan Hock, Ir. Yee Thien Seng, Ir. CMM Aboobucker, Ir. Chin Mee Poon, Ir. Dr Oh Seong Por, Ir. Tejinder Singh, Ms. Michelle Lau Chui Chui, Ir. Abdul Razak bin Yakob

LEMBAGA PENGARANG/EDITORIAL BOARD 2017/2018

Ketua Pengarang/Chief Editor: Ir. Prof. Dr Ruslan Hassan Pengarang Bulein/Bullein Editor: Ir. Mohd. Khir Muhammad Pengarang Jurnal/Journal Editor: Ir. Prof. Dr Ruslan Hassan Ahli-ahli/Commi�ee Members: Ir. Lau Tai Onn, Ir. Ong Guan Hock, Ir. Yee Thien Seng, Ms. Michelle Lau Chui Chui, Ir. Dr Oh Seong Por Secretariats: Janet Lim, May Lee

THE INSTITUTION OF ENGINEERS, MALAYSIA

Bangunan Ingenieur, Lots 60 & 62, Jalan 52/4, P.O. Box 223, (Jalan Sultan), 46720 Petaling Jaya, Selangor Darul Ehsan. Tel: 603-7968 4001/4002 Fax: 603-7957 7678 E-mail: sec@iem.org.my Homepage: h�p://www.myiem.org.my

5

COVER NOTE Innovations in Palm Oil Industry

COVER STORY Innovations in Palm Oil Industry 6 - 11

FEATURE ARTICLES

Harnessing Innovation in the Palm Oil Mills ..........12 From Waste to Wealth ............................................16

Use of Unmanned Aerial Vehicles (UAVs) in Oil Palm Plantations .............................................24 12 - 28

FORUMS

Visit to Essential Oil Processing Plant and Stingless Bee Honey Production Site .................29 Introduction to Basement Design .......................30 Sustainable Palm Oil: Challenges to the Industry & Engineers ...........................................32

CEO Series of Talk 2

Re-engineer Global Monetary Policy ..................35

Technical Visit to Malaysian Global Innovation & Creativity Centre (MaGIC) .............38

One-Day Seminar on Pile Foundation ................40

GLOBE TREKKING Pyrmont Bridge in Darling Harbour Sydney

DIMENSION PUBLISHING SDN. BHD. (449732-T)

Level 18-01-03, PJX-HM Shah Tower, No. 16A, Persiaran Barat, 46050 Petaling Jaya, Selangor Darul Ehsan, Malaysia.

Tel: +(603) 7493 1049 Fax: +(603) 7493 1047

E-mail: info@dimensionpublishing.com

Website: www.dimensionpublishing.com

Chairman

ROBERT MEBRUER

CEO/Publisher

PATRICK LEUNG

General Manager

SHIRLEY THAM shirley@dimensionpublishing.com

Head of Markeing & Business Development

JOSEPH HOW joseph@dimensionpublishing.com

Editor

TAN BEE HONG bee@dimensionpublishing.com

Contribuing Writers

PUTRI ZANINA & ZOE PHOON putri@dimensionpublishing.com zoe@dimensionpublishing.com

Senior Graphic Designer

SUMATHI MANOKARAN sumathi@dimensionpublishing.com

Graphic Designer

NABEELA AHMAD beela@dimensionpublishing.com

Adverising Consultants

THAM CHOON KIT ckit@dimensionpublishing.com

Accounts cum Admin Execuive

YEN YIN yenyin@dimensionpublishing.com

For adverisement placements and subscripions, please contact:

DIMENSION PUBLISHING SDN. BHD. (449732-T)

Level 18-01-03, PJX-HM Shah Tower, No.16A, Persiaran Barat, 46050 Petaling Jaya, Selangor Darul Ehsan, Malaysia.

Tel: +(603) 7493 1049 Fax: +(603) 7493 1047

E-mail: info@dimensionpublishing.com

Subscripion Department

E-mail: info@dimensionpublishing.com

Printed by

HOFFSET PRINTING SDN. BHD. (667106-V)

No. 1, Jalan TPK 1/6, Taman Perindustrian Kinrara, 47180 Puchong, Selangor Darul Ehsan, Malaysia.

Mailer

PERFECT MAIL SERVICES (648839-P)

14 Jalan TSB 2, Taman Perindustrian Sungai Buloh, Sungai Buloh, Selangor Darul Ehsan, Malaysia.

Tel: +(603) 6156 5288

JURUTERA MONTHLY CIRCULATION: 22,500 COPIES

Submission or placement of aricles in JURUTERA could be made to the:Chief Editor

THE INSTITUTION OF ENGINEERS, MALAYSIA (IEM) Bangunan Ingenieur, Lots 60 & 62, Jalan 52/4, P.O. Box 223 (Jalan Sultan), 46720 Petaling Jaya, Selangor. Tel: +(603) 7968 4001/4002 Fax: +(603) 7957 7678 E-mail: pub@iem.org.my or sec@iem.org.my IEM Website: h�p://www.myiem.org.my

© 2017, The Insituion of Engineers, Malaysia (IEM) and Dimension Publishing Sdn. Bhd.

PUBLICATION DISCLAIMER

The publicaion has been compiled by both IEM and Dimension with great care and they disclaim any duty to invesigate any products, process, services, designs and the like which may be described in this publicaion. The appearance of any informaion in this publicaion does not necessarily consitute endorsement by IEM and Dimension. There is no guarantee that the informaion in this publicaion is free from errors. IEM and Dimension do not necessarily agree with the statement or the opinion expresssed in this publicaion.

COPYRIGHT

JURUTERA Bullein of IEM is the oicial magazine of The Insituion of Engineers, Malaysia (IEM) and is published by Dimension Publishing Sdn. Bhd. The Insituion and the Publisher retain the copyright over all materials published in the magazine. No part of this magazine may be reproduced and transmi�ed in any form or stored in any retrieval system of any nature without the prior wri�en permission of IEM and the Publisher.

by Ir. Yong Hong Liang Chairman, Agricultural & Food Engineering Technical Division

alaysia accounts for about 40% of global palm oil production. With over 100 years in the industry, it is not surprising that we have a wealth of knowledge in palm oil operations.

But innovation is important to ensure the industry is sustainable, efficient and productive. Many experts today offer the latest innovations in palm breeding, agronomy, pest and disease management, mechanisation, palm oil milling and downstream activities.

These include remote sensing, unmanned aerial monitoring, tissue culture, farm operation software, flood mitigation, palm oil mill waste treatment, etc.

Innovation needs strong engineering support, from conception and development to application. Huge capital investments and expertise are required to ensure these are well received by the industry but, without such innovations, we will need to open up more land for cultivation to meet the growing demands for palm oil and more manpower to run the plantations.

The large quantity of palm oil waste produced by the mills can also be harmful to the environment and cause anxiety among local communities. But with new technology, yield will be improved and the production process made easier.

In the past few decades, modern innovations have revolutionised the palm oil industry. Increasing oil recovery in the mill, especially from palm oil wastes, has always been an important goal for industry players.

According to Mr. Wong Wee Voo, executive director of Renergy Industries, any innovation should always result in better performance, be more cost-effective, more userfriendlyandrequirelessmaintenance as well as be more durable.

Mr. Wong, who has more than three decades' experience in boiler manufacturing and marketing, said: "Innovations must aim to address business challenges, environmental sustainability and consumer demands."

To this end, Dato' Yeong King Hui and IHI Centrifuge Japan have jointly developed a very efficient palm oil recovery decanter. The centrifuge decanter is said to be the best palm oil recovery system for the industry since 1994.

A good centrifuge decanter can save hundreds of millions of ringgit for the industry and raise its efficiency level so that it is able to face continuous challenges from neighbouring countries.

Dato' Yeong is technical director for both CustomCraft (M) Sdn. Bhd. and Renergy Industries Sdn. Bhd. He said that revolutionary changes made on the effluent side have contributed to positive environmental impact. He added thatthesewerelargelytheresultofeffortsoflocalengineers.

"The set up for biogas digestion to trap the biogas and then put it to good use, such as for power generation or as boiler fuel, is a good example" he said.

"The result is less pollution which means the industry is more environmentally-friendly."

Palmoilmillcompoundsandspacearealsobeingbetter utilized. For example, making the digestors vertical instead of horizontal, has helped to increase plant capacity.

In the 1950s and 1960s, boilers were small and used fire tubes, which meant limitations in pressure and capacity.

Over the years, local engineers have acquired the expertise towards greater automation as well as reduction in air and noise pollution.

Turbines that are lower in pressure and with higher steam consumption can take more rough water. In the past, spent fuel was considered garbage and proved costly to dispose of.

Many companies have since improved their boiler efficiency in the mills with reduced remaining fibre, shell and burning off empty fruit bunches for converting to fertiliser ash which is then used for mulching in the field and as an inorganic fertiliser substitute.

Fuel is an essential resource for downstream activities, which have more by-products and processing requirements that need more power.

There are still palm oil millers who continue to use the conventional systems but they can also utilise those with a higher-efficiency design; this way, they get an additional 10-30% power even without having to replace their boilers and turbines or changing any other equipment.

Seven years ago, when engineers conducted research and development, they started to modify and improve turbine shortfalls and managed to achieve 10-30%.

Dato' Yeong said the biggest challenge the industry faced was the price factor and this often led to constraints, especially if the cost of a project was under-quoted.

"Customers should understand that if the quotation for a project is too low, they may end up with equipment installed that does not have the proper compliance," he said.

"Besides the obvious delays, there will also be requirements not met and which the customer will have to resolve later."

Mr. Wong said that in engineering, specifications must always be followed closely; there should never be any cutting of corners.

He said that undersized or poorly set-up installations will display operational side effects which then result in breakdowns.

"You need a professional who will be responsible for the turbine generator set in biomass operation," he said.

"Just knowing how it works is not enough to set up the project operation. For precision parts, tolerance is very important and the engineer must be in a position to cater to the client’s needs."

For technology catering to the front end of the mill, it is more a question of how the fresh fruit bunch can be better handled or manoeuvred rather than innovation.

When the sterilisation is done in vertical containers (for space-saving purposes), the crop at the bottom will be crushed and, if the stacking is too high, oil will be trapped in the centre.

Air removal and condensate drainage from the fruit bunch stack will also become restricted and this impedes heat penetration.

In such cases, to increase the oil yield, the empty fruit bunches will have to be shredded and pressed to recover the oil trapped in the stalks and fibres.

The process of continuous sterilising was introduced as an alternative to pressure vessels and batch process of sterilisation; this offers an advantage in terms of the use of unpressurised heating cabin and steady steam demand for the sterilisation process.

While avoiding fluctuations in the steam flow to the sterilisation process provides a considerable advantage in maintaining overall process steam pressure and temperature in the mill, the high energy consumption would be a significant disadvantage.

The extracted oil may also contain harmful substances such as potassium, chlorine and phosphatides from the empty fruit bunch contamination and this is detrimental to the oil production if not removed fully.

According to Dato' Yeong, one of the best new technologies introduced into the mill oil room is the threephase decanter.

"Three-phase decanters separate the palm oil sludge into oil, water and solids during the de-watering process," he explained.

"The compact and modular design is space-saving. It is especially designed for the highly-efficient, simultaneous sedimentation of solids and separation of two liquid phases. This is vital because what happens at the front end can and will affect the downstream."

The highly-polluting waste water, combined with waste from the steriliser condensate and cooling water from palm oil processing, is known as Palm Oil Mill Effluent (POME). This is often discharged into disposal ponds, resulting in the leaching of contaminants which will pollute groundwater andsoilaswellasreleasemethanegasintotheatmosphere.

For every ton of fresh fruit bunches processed, a standard palm oil mill generates, on average, about one tonne of liquid waste which will pose environmental issues.

However, since no chemicals are added during the oil extraction process, POME is non-toxic and is a good source of nutrients for microorganisms.

Biogas is also produced during the treatment process for POME, although this gas is flared off.

Dato' Yeong said that effluents from palm oil mills can be anaerobically converted into biogas which, in turn, can be used to generate power through gas turbines or gasfired engines.

"When effluent water is evaporated, the two elements left are oil loss plus solids. This makes the biogas system redundant," he said.

"However, most palm oil mills have no time to clear effluent ponds because of the need to concentrate on production."

Mr. Wong said the evaporation system is clearly revolutionary for the next generation.

"If we can produce an oil-recovery machine that can reduce wastage to 0.5% or even 0.2%, then the evaporation process may not even be required. At the end of the day, the business focus and direction for millers is to convert waste into revenue."

The palm oil industry generates the biggest amount of biomass in the country but the biomass generated is renewable organic matter.

The industry has been looking at producing sustainable biomass in order to minimise the risks of being charged with greenwash. This means that it has to ensure implementation of more environmentally-sound practices.

Besides being used as compost, the burning of empty fruit bunches in fuel boilers has long been a practice in local palm oil mills and the residue is converted into energy for optimum efficiency.

Success has also been achieved in using waste byproducts to power steam turbines, such as the processing of FFB to palm oil that includes the capture of methane.

However, there is much feedstock that is still underutilised. There is also the question of pollution to the

environment and the food miles generated in reaching consumers which involve the burning of fossil fuels.

Locating refineries closer to the mills will contribute towards reducing energy usage.

Dato' Yeong said designers of boilers and furnaces had produced models that enabled complete combustion with no pollution.

This involved changing the configuration in order to use biomass efficiently, producing steam from burning and converting the biomass into power and energy.

Said Dato' Yeong: "Many big plantations have adopted plans for biomass power plants. Besides biofuels, biomass can also be turned into furniture, plywood, pulp and paper."

New demands for electrical power in the mills have come especially from downstream activities. There is a higher demand for operational needs such as heating as well as solvent oil extraction recovery, empty fruit bunches press, long fibre drying, kernel crushing and composting into fertiliser base.

Therefore, mills should select power-generation equipment that is efficient.

Mr. Wong pointed out that in the 1980s, 800kW of power was required to process 60 tonnes of fresh fruit bunches per hour for an 80% output. By the 2010s, up to 2,500kW of power was required to process a similar amount of FFB for 90-95% output.

"Turbines should be customised and tailored to activate the best efficiency," said Dato' Yeong.

"This will be translated into savings on investment, savings on space as no additional equipment is needed within a tight space environment, savings on fuel for a similar power output which also means additional revenue.

"The majority of the market is currently using the singlestage steam turbine which is more affordable."

Through constant research and development, Malaysia has maintained its leading position in the palm oil industry.

Recently, a genome initiative to develop oil palm trees with higher yields will reduce the need for more land.

R&D activities are also being focused on downstream businesses, including specialty products and nutritional palm oil-based food items.

Another innovative breakthrough is the use of palm kernel expeller for chicken feed instead of using imported maize or corn.

In the palm oil factories, an oil recovery enhancer is being incorporated into conventional mills to overcome the mechanical limitations in oil recovery as treated oil will be more easily recovered at lower operating costs.

There is interest centred on reducing Greenhouse Gas (GHG) emissions which requires inventories associated with

the carbon footprint of the products, services and events in the industry to be examined.

More R&D activity is needed to focus on new practices aimed at reducing GHG emissions while keeping yields and nutritional quality high.

Meanwhile, by combining the emissions over the supply chain (which include the various production, processes, refinery, manufacturing and transport processes), new research areas can be identified where carbon footprint of GHG emissions is ready for quantification.

The palm oil industry will continue to be scrutinised for its contribution to carbon footprint, based on standards established by ISO.

Sustainability can be further improved if the planting andreplantinginvolvelesslogged-overandsecondary forest, and peat and fields are replanted from oil palm areas in terms of the land-use change.

As for palm oil mills, Dato' Yeong said those in Malaysia still have some way to go when compared to others in the region.

"Improvements are still needed, especially as factories are continuing to discharge waste into the environment around the refineries," he said.

"We also lag behind our Thai counterparts in the cleanliness factor."

He said mills should be at least 75 per cent automated to allow the system to be more efficiently monitored.

Mr. Wong added that biomass boiler systems with proper filter systems will reduce the ash in the air with better emissions standards.

The Malaysian palm oil industry needs to innovate to remain competitive in the global market. The outlook for engineering innovation in Malaysia is rather bleak but the government and stakeholders have implemented various initiatives to stimulate creativity and innovation in the palm oil industry.

Financial incentives and technical support from related agencies are also provided to encourage capital investment in innovation in mills. Most new technologies introduced in palm oil mills are imported to solve local mill problems. Some entrepreneurs are merely marketing people who are unable to provide in-depth technical guidance and engineering support services to the millers for operating and maintaining the machinery system eficiently.

Without adequate technical support services, the technology cannot develop roots and become a permanent feature in the palm oil mills and any potential innovation would be pre-maturely dismissed as technology not suitable for use in palm oil mills.

A concerted effort is needed by all those involved in the palm oil industry, namely the entrepreneurs (who import and supply the new technologies), the millers and the relevant implementation and regulatory agencies, to work towards creating conditions that are conducive for new innovations in the palm mills.

Thelocalpalmoilindustrymustinnovatetoremaincompetitive in the global market. Innovation is the driver of sustained growth in any industry (OECD, 2010). The new technologies, products and services adopted will create new jobs, foster start-ups and rejuvenate the industry. Innovation involves the whole process, from opportunity identiication and ideation or invention to development, prototyping and production as well asmarketing,salesandusage.

The 3 essential ingredients of innovation are:

1. Skilled people.

2. Creative ideas.

3. Hardware and software to sell/use the technology eficiently.

Innovation is the creative exploitation of what has worked by creating a higher value for existing products, doing things differently, uncovering new opportunities and developing more options. Harnessing innovation in the palm oil mill will require the right people to be involved at every stage of the process.

The Malaysian government and stakeholders have implemented various initiatives to facilitate the innovation process in the palm oil industry (Ooi and Kumar,

2017), including the setting up of Agensi Inovasi Malaysia (AIM, 2016), Sustainable Energy Development Authority (SEDA) and the Malaysian Biotechnology Corporation.

The technology and innovation introduced into the palm oil industry were mostly developed by the industry and, in some cases, were jointly developed by the industry and Malaysian Palm Oil Board (MPOB).

New milling technology and new waste treatment technology developed by MPOB (2014) included the use of the decanter-drier system to reduce the volume of clariication sludge by up to 75%. The solids from Palm Oil Mill Efluent (POME) were harnessed using a rotary drier which obtained its heat from boiler exhaust gas. The new milling technologies were expected to increase the oil extraction rates to 23-25% compared to 19-20% in conventional mills. However, the commercialisation and transfer of technology from MPOB to the mills is very slow.

“Innovation is created only when the entrepreneur succeeds in the commercialisation of the new technology or invention.” (McGraw, 2007).

Innovation is successful if it provides value and beneit to both the entrepreneur and the users of the technology. With innovation in the palm oil mill, there is change and sustained growth in the industry.

Technologies that have made inroads into the industry include machinery systems involved in palm oil recovery from the steriliser condensate, from POME in Sludge Pit, from pressed mesocarp ibres (using hexane extraction) and from pressed Empty Fruit Bunch (EFB) liquor. Project proposals involving oil recovery systems have short payback periods of less than 2 years and so, are more readily accepted by millers.

Many of the oil recovery technologies were originally developed for use in other industries. They were brought in by entrepreneurs and transplanted in palm oil mills. According to Hargadon (2003), the three prerequisite conditions for successfully transplanting an imported technology are:

• Practical ideas about how the imported technology can be used eficiently in the new industry.

• Skilled workers who know how to use the technology competently (technology supplier to train the user).

• Knowledge about the physical hardware and software of the technology.

Discover the MGE Galaxy 300 10-80kVA

• Secure: Maximum protecion and availability with double-conversion online topology

• Compact: Wide or narrow tower in space-saving footprint

• Simple: Easy to install and operate

• Eicient: up to 93.5%, reduces cost of ownership

• Flexible: 1+1 parallel capability meets redundancy needs

• Serviceable: Push-open, front access to maintenance bypass and slide-out boards make servicing easy

• Fast-charging: Shorter ba�ery recharge ime prevents deep discharge damage

• Compaible with Schneider Electric's lithium ion ba�ery soluion

Lithium Ion Ba�ery features

Reduces footprint

Improved ba�ery lifeime / reduced maintenance

Improved backup storage predictability and manageability

Reduce cooling constraints

Reduce weight

Reduce total cost of ownership

Call us now. We can help you to optimize energy and sustain performance.

Northern

Mr. Paul Phuah

Central

Mr. Steven Ong

Mr. Louis Loke

Southern

+6012-477 1671 Bioenergy Projects Sdn. Bhd.

+6012-690 6920 KVC Industrial Supplies Sdn. Bhd.

+6016-330 1366 MCL Berhad

Mr. Chee +6016-723 4723 MCL Berhad

Mr. Steven Ong

East Malaysia

+6012-690 6920 KVC Industrial Supplies Sdn. Bhd.

Mr. Neo +6016-710 0013 MCL Berhad

Schuchardt et al., (2007) reported that the amount of POME and sludge produced by palm oil mills can be reduced from 65% Fresh Fruit Bunch (FFB) to 25% FFB by incorporating the new technologies such as in the sterilisation and oil recovery system (Table 1).

facilities to lock and unlock the steriliser door, to lift and lower the cantilever drawbridge and to operate the Indexer System.

After sterilisation, the FFB cages are moved to the automated Cage Tipper Station where the Sterilised Fruit Bunches (SFB) are unloaded onto the SFB conveyor. The cage tipper is operated on a preset tipping sequence and is linked with the SFB conveyor to control the feed rate of SFB to the conveyor. The conventional horizontal steriliser with Indexer System, as described above, was developed further into steriliser systems which offered savings in space and labour requirements (CMC system and II system).

The other two categories of new steriliser systems are equipped with conveyor systems which transfer the FFBs from the loading Ramp all the way to the inlet of the Sterilisation Vessels without the use of cages. After sterilisation, the SFBs are discharged onto the SFB conveyor and transferred to the thresher (Eaton, 2012).

Proper sequencing of the opening and closing of the steriliser doors with the running of the conveyor systems, is provided by the automated system control panel. Steam is supplied to cook the fruit in the steriliser vessels and proper sequencing of valve movements for de-aeration, steam inputs, steam blow-offs and condensate removal in the sterilisation process in more than one steriliser vessel, are provided for using automation technology.

Sterilisation of oil palm FFBs is the irst step in the sequence of processes to extract the oil (Kandah et al., 2002). Many mills use the conventional sterilisation system, which consists of two or more horizontal steriliser vessels.

At the Loading Ramp, FFBs delivered to the mill are transferred into cages which are moved along rails to the sterilisation vessels using steel cables, winch and bollard. Steam is introduced into the horizontal pressure vessels to cook the FFBs in the cages.

The new sterilisation technologies being introduced into new mills can be classiied into 3 categories:

1. Horizontal Steriliser with Indexer system (including Compact Modular Continuous or CMC system and Integrated Indexer or II system).

2. Vertical Sterilisers (including the Tilting, Oblique and Spherical variations).

3. Continuous Steriliser.

Many mills have upgraded the conventional horizontal steriliser system to the Indexer System to replace the winch and bollard system in handling the FFB cages. With the Indexer System, the conveyor system is used to transfer the FFBs from the Loading Ramp to the Cage Filling Station.

The Indexer System moves the cages from the Cage Filling Station into the Steriliser Vessel. The Cage Transfer Carriage is used to move the FFB cages to the next rail. With the Indexer System, the number of workers in the marshaling yard is now reduced from 12 male workers to 4 (including female workers).

In some mills, CCTV (close circuit television) and solenoids are installed to enable the loading ramp sliding door system to be operated remotely from the mill control room. The Automated Steriliser Door, Drawbridge and Indexer System use dual hydraulic cylinder actuation

Automation can be used throughout the palm oil mill to monitor and regulate the operations of the processing machinery. The sensors are installed in the systems to check, measure and regulate the processing operations continuously to maintain the required processing conditions and product quality. The Supervisor Control & Data Acquisition (SCADA) system provides the operation graphical interface, informatics reporting system, realtime process monitoring and alarm monitoring. SCADA is equipped with an interlocking system to detect and prevent unsafe operation (Ooi, 2015).

Technologies being forced upon palm oil millers by DOE (Department of Environment) include the tertiary treatment (or polishing) of POME and the air pollution reduction systems.

The Clean Air Regulation 2014 requires all mills to install the boiler emission monitoring and control system by 2019. All mills are expected to install a biogas capture or reduction facility by 2020.

The DOE regulatory requirements have pushed mill owners and technology suppliers to experiment with new technologies. They include the generation of renewable energy and the use of environmental sciences to create new innovations in the mills and trigger growth in the industry.

Malaysia needs about 500,000 scientists, engineers and technologists (3% of a total 15 million workforce) to achieve a developed nation status by 2020. Another 500,000 skilled workers are needed in support services (ASM, 2015). However, it was reported that, in 2014, only 21% of Malaysian students in upper secondary schools chose to study science subjects. The Research and Development (R&D) expenditure

per Gross Domestic Product (GDP) by the Malaysian business sector in 2012 was very low at 0.7%, compared to that of South Korea at 3.1%.

The outlook for engineering innovation in Malaysia is rather bleak. Most palm oil millers are not interested in new technology unless it can bring in more proits without disrupting the existing mill processes and their steady source of income. Machinery systems and technologies which are readily accepted by millers, include oil recovery from steriliser condensate, oil recovery from EFB, oil recovery from pressed mesocarp ibre, oil recovery from efluent in sludge pit and oil recovery from efluent cooling pond.

The adoption rate of automated machinery system is slow because millers fear equipment breakdowns and poor after-sales service from technology suppliers. The millers are still hesitant to switch from manual systems to automated systems. They usually insist on having manual override control incorporated into the automated machinery systems.

Technology suppliers must make it their responsibility to supply the appropriate technicians on contract basis and to train mill workers so that they will be competent enough to take over. Without such elaborate technical support services, technology cannot develop roots in the industry and the potential innovation in the palm oil industry is pre-maturely dismissed as unsuitable for use by the palm oil mills (Ooi and Kumar, 2017).

The government can play a key role in creating conditions that are conducive for innovations to take place in the palm oil mills by coordinating the policies and strategies on innovation, education and entrepreneurship for the betterment of the industry (OECD, 2010). More technicians will be needed to operate and maintain the new innovations eficiently.

We need the concerted efforts of those in the palm oil industry, namely the entrepreneurs who import and supply the new technologies, the millers and the relevant implementation and regulatory agencies, to work together to create conditions which are conducive for harnessing new innovations in the mills.

[1] AIM (2016) Agensi Inovasi Malaysia. http://innovation.my/

[2] ASM (2015) Science Outlook 2015. Academy of Science Malaysia. http://www. akademisains.gov.my/index.php/publication

[3] Eaton (2012) Eaton Automation Control in Steam Utilisation http://www.novaflow.com. my/wp-content/themes/webtemp/pdf/ICE-PO%202012%20Part3.pdf

[4] Hargadon, A (2003) The Surprising Truth About How Companies Innovate.http://credu. bookzip.co.kr/Resource/Englishbook/PDF/AE30162.pdf

[5] Kandiah, S ; Hasan, M ; Yaacob, M (2002). Overview of automation in a palm oil millthe sterilisation process. Computing & Control Engineering Journal Volume: 3, Issue: 1, Jan. 1992. pp 45 - 52 http://ieeexplore.ieee.org/document/124645/

[6] MPOB (2014) Biogas Capture and CDM Project Implementation For Palm Oil Mills. National Biogas Implementation (EPP5). National Key Economic Areas (NKEA)

[7] OECD (2010) Harnessing innovation for sustainable growth. Organisation for Economic Co-operation and Development (OECD) .https://www.oecd.org/sti/41965313.pdf

[8] Ooi, H.S. (2012) Applying Green Technology in the Palm Oil Industry. Jurutera IEM Bulletin, January 2012 pp18-24 http://dspace.unimap.edu.my/dspace/ bitstream/123456789/23062/1/pg%2018.pdf

[9] Ooi, H.S. (2015) Automation in the Palm Oil Industry. Technical Talk at Wisma IEM on 17August 2015. Organised byAgricultural & Food Engineering Technical Division, IEM

[10] Ooi, H.S. and Kumar, S. (2017) Managing Engineering Innovations in the Palm Oil Industry. The Planter, Kuala Lumpur, 93 (1091): 85-98 (2017). Incorporated Society of Planters (ISP), Malaysia

Author's Biodata

Ir. Ooi Ho Seng, is a director of SGT Konsult Sdn. Bhd. (an engineering consultancy irm) and of O3 Solutions Sdn. Bhd. (a Bio-Nexus waste management company). He was Deputy Chairman, Chairman, Advisor of AFETD from 2000 to 2009). He has been a Committee member of AFETD since 2010.

Malaysia has abundant waste and biomass resources generated from agriculture-based industries, particularly Crude Palm Oil (CPO). The decomposition of agro-industry waste releases biogas via microbiology processes through the methanogensis stage after the hydrolysis and acidification stage. The biogas, mainly methane, is considered Green House Gas (GHG).

Due to environmental concerns over the GHG emission effect, the proactive action, besides the compliances concerned from the industry players, is to treasure biogas as an abundant source of renewable energy that is untapped but commercially valuable as it’s easily available.

This proactive move is supported by nations as a way to minimise our dependence on the use of fossil fuel. We still depend largely on conventional energy sources (fossil fuels such as oil, natural gas and coal) but in the next few decades, it is hoped that we will gradually become less dependent on them.

The technology for harnessing green energy is not new. It has been continuously developed over the last few decades and has grown in intensity in Malaysia and all over the world.

To enhance the tapping of green energy from biomass and biogas in industries, team work and collaboration between the various parties concerned – governing bodies, industry players and technology providers – are crucial.

What are the matured engineering approaches that can be adopted in this context? What would be the expected challenges, technically and commercially?

BIOGAS GENERATION

Any industry that produces large amounts of organic waste, is a candidate for biogas production. A standard biogas production system begins with large anaerobic digesting tanks/ponds where the organic waste is converted into biogas.

There is the presence of naturally occurring bacteria, mainly Thermophylic and Mesophyllic types. Given the right temperature and feeding environments, the bacteria will thrive and propagate.

The palm oil based liquid waste, mainly organic loading containing oil and shredded waste, will increase the surface area available to microbes in the digesters and so increase the speed of digestion.

The anaerobic digestion process takes place in an airtight containment (O2 depleted) which will be the digester. The irst stage of chemical reaction Anaerobic Digester (AD) is hydrolysis, where complex organic molecules are broken down into simple sugars, amino acids and fatty acids with the addition of hydroxyl groups.

There are many conigurations of Anaerobic Digesters and these can run at different target temperatures; the most common are Mesophillic (35°C) or Thermophilic (50°C). There are different populations of anaerobic microbes that thrive in these temperature zones. Digesters can combine all the main process chemistry steps (hydrolysis, acidification, acetogenisis, methanogenis) either in a single process reactor tank or in two separate reactor tanks. The separation of digestion phases allows for additional process control but it does incur additional capital costs.

This is followed by three biological processes:

1. Acidogenesis – further breaking down by acidogenic bacteria by into simpler molecules, volatile fatty acids (VFAs) occurs, producing ammonia, CO2 and hydrogen sulide as byproducts.

2. Acetogenesis – the simple molecules from acidogenesis are further digested by bacteria called acetogens to produce CO2, hydrogen and mainly acetic acid.

3. Methanogenesis – methane, CO2 and water are produced by bacteria called methanogens. The pH levels are kept between 5.5 and 8.0 and the temperature between 30°C and 60°C, in order to maximise digestion process.

A large amount of the climate impact of the emission of methane can be mitigated by capturing the gas and using it to fuel the power plant; biogas technology has been used successfully for decades and can produce renewable electricity at a cost that’s competitive with traditional fuels.

Under anaerobic conditions, organic material is decomposed by microorganisms in a number of steps to get the inal products, methane and carbon dioxide.

Your equalizer to handle simple to complex jobs at an affordableprice

MULTI PUROSE LICENSE KEY THAT PROVIDES A SINGLE USER ACCESS TO THE STAAD & RAM PRODUCT LINES.

VR-CAM Technologies SdnBhd

No 79, OG Business Park, Tmn Tan Yew Lai, 58200 Kuala Lumpur

Tel: (03) 7782 8898, 7785 8898 Fax: (03) 7782 6898

Web: http://www.vrctech.com

Contact :-

S.Naren: 013-3477317 :Email: naren@vrctech.com

Ruben : 017-8818893 : Email: rubenp@vrctech.com

Automate wind notional & seismic loads with ease.

BS 8110,BS 5950 2000, BS 5950 part 5, BS 5400 part 2 & part 3, BS 8007

EC-2,EC-3,EC-5,EC-8 – Includes various country annexes

Malaysia Annex for EC-2 & EC-3 included, UBC, IBC & etc

acids, alcohols, etc.)

The enforcement of the Renewable Energy Act 2011 (Act 725) on 1 December, 2011, enabled the implementation of Feed-in-Tariff (FIT), paving the way for a sustainable Renewable Energy (RE) growth trajectory in Malaysia. Renewable Energy includes solar photovoltaic, small hydro, biomass and biogas.

All RE resources show promising development as can be seen from the number of projects which have beneited from FIT.

As the agency responsible for the facilitation of RE growth, SEDA Malaysia is playing its role to ensure that installations, especially those under the FIT mechanism, meet and comply with international standards in terms of quality, reliability and safety as this will indirectly impact the performance of the biogas power plants.

At 1 m3 biogas of CH4 at 60% concentration……..

Low heating value (LHV) = 21474 KJ/NM3

Replace biomass (PKS and Fibre) with biogas

• 1 m3 of biogas can replace 1.4 kg of palm kernel shell (PKS).

Replace diesel usage with biogas

• 1 m3 of biogas can replace 0.60 litres of diesel.

Generate electricity with biogas

• 1 m3 of biogas can generate 1.5-2.0 KWH of electricity.

Replace gasoline usage with biogas

• 1 m3 of biogas can replace 0.67 litres of gasoline.

Replace wood usage with biogas

• 1 m3 of biogas can replace 1.5kg of wood.

Replace LPG gas usage with biogas

• 1 m3 of biogas can replace 0.46kg of LPG (Liquid Petroleum Gas). Complex organic material (proteins, carbohydrates, fats etc.) Soluble organic compounds (amino acids, sugars, etc.)

Biomethane is produced from biogas through an Upgrading Process with water wash technology involving apuriicationprocessthatessentiallyremoves all Hydrogen Sulphides (H2S), Carbon Dioxide (CO2) and Siloxanes. Biogas has actually gained increasing positive response and popularity in developed countries as the leading green fuel alternative. Being renewable based and without conventional fossil fuel pollutants, biomethane is being utilised increasingly by international institutions of alternative fuel, now and in the future. Malaysia is in the correct time zone currently to develop and enlarge the utilisation rate nationwide and so acquire a greener image in the global market.

Biogas (Typically)

CH4: ~60%

CO2: ~39%

N2+O2: <1%

H2S: 50-5000ppm

H20: Saturated

Biogas (Achievable)

CH4: >96%

CO2: ~1%

O2: <0.4%

H2S: <1ppm

H20: <1ppm

Siloxanes: TraceSiloxanes: <1ppm

Chemically, biomethane is no different from natural gas, thus making it the ideal replacement for use in Natural Gas Vehicles (NGV). Obviously its commercial value is remarkable besides it being environment-friendly.

There are generally 2 types of Anaeroboic Digesters (AD): Tank System and Lagoon System.

1. Tank System (Tank Farm)

a) Concrete is commonly used to make the digester tanks as it can store and retain heat uniformly. The tanks can be cylindrical or oblong in shape. It can be constructed on an in-situ basis or prefabricated in a workshop, shipped to the project site and assembled there. Sometimes, a coating is applied to the inner wall of the tank, especially in the corrosive gas/water interface zone, to ensure long-term durability.

b) Steel is another material that’s also commonly used to make digester tanks. Steel tanks can be erected in bolted basis together with panels or as welded steel panels. The steel can be either stainless steel or steel coated with epoxy paint, a common industrial practice. The material selection is the key part to ensure durability and resistance to corrosion.

2. Lagoon System (Soil Lagoon or Engineered Lagoon)

This anaerobic system is built in a rectangular shape and covered with High Density Polyethylene (HDPE) plastic sheet or PVC and used as a container for the biogas generated. The sheets may cover the whole lagoon or only the parts generating methane. The system also increases contact area of bacteria sludge with waste water and develops a system to pull sludge with pipes. In other words, the lagoon houses the methanogenesis process and the lagoon top section is the gas storage buffer zone.

Raw Biogas Composition

Methane50-60%60-72% Co2 25-40%25-35%

H2S 3000ppm8000ppm

FACTORS AND PARAMETERS AFFECTING BIOGAS GENERATION

√ The amount of waste efluent (m3/day)

√ The amount of Chemical Oxygen Demand (COD).

√ The COD removal rate of the design system.

√ Methane-COD equivalent (kg-CH4/kg-COD).

√ Methane gas density (kg/Nm3).

√ Methane gas concentration.

√ Ambient Biogas temperature.

OPTIMISATION OF BIOGAS SYSTEM

It is crucial to have the process low running in optimum condition as optimisation will eventually lead to sustainability. Most importantly, all operating factors highlighted in this paper must be in optimal mode, regardless of time, day or place. By having zero/minimum luctuations on the key operating factors and parameters as highlighted above, the quality and quantity of the biogas generated can be secured and sustained.

TECHNICAL & COMMERCIAL CHALLENGES

The expected challenges in biogas projects can be basically summarised, but not limited to, as below:

Commercial Challenge No. 1

High capital investment, especially the luctuation of global market currency

√ Overall trading currency is in USD.

√ Capital investment in millions of ringgit.

√ Duration of completion at least 12-18 calendar months.

Commercial Challenge No. 2

Strategic location of the plant: Ensure FIT is available

√ Strategic location, meaning FIT is necessary.

√ Authorities involved: Energy Commission (ST), SEDA, Tenaga National Berhad (TNB) and others.

√ Need to carry out Power System Study (PSS) before a project can be claimed to be overall feasible.

√ Need to purchase quota earlier from the authority (SEDA, in this context).

√ Ensure to purchase quota with the best rate (basic rate + others bonus rates).

√ Bonus rates offered by SEDA are inclusive but not limited to G1 (Agricultural Waste), G2 (Electrical Eficiency) and G3 (Local Assembly Status).

Commercial Challenge No. 3

Practical business strategy: Ensure that power generated can be utilised internally, besides the FIT purpose.

√ Ensure the company is able to consume the power generated (Palm Oil Mill, downstream plants and staff quarters).

√ The power generated can be used for the entire factory and complex.

√ No wastage concerns.

√ Overall, the key consideration is on the demand and supply of electrical power.

Commercial Challenge No. 4

To get the support and approval of Malaysia Industrial Development Authority (MIDA) on tax deduction/ exemption on green energy development

√ Biogas energy is classiied as Green and Renewable Energy.

√ MIDA giving tax incentives to green technology providers and end users.

√ Need for comprehensive documentation before submitting to apply.

Technical Challenge No. 1

Good feed stocks on the raw materials: Consistency & Regularity

√ Raw materials, in this context, is Fresh Fruit Bunch (FFB) and Palm Oil Mill Efluent (POME).

√ Supply must be consistent and suficient (daily, monthly and annually).

√ Able to purchase FFB and produce POME consistently.

√ Have a buffer zone on POME storage.

√ Good milling and processing eficiency.

√ Good marketing strategy to obtain raw materials.

Technical Challenge No. 2

Management of bio-solids formed during the biogas capturing process

√ Solid handling (do not underestimate).

√ Solid generated should be handled and well managed. Prevent the occurence of any potential environmental issue.

√ Good practice = disposal (manageable). Poor practice = dumping (uncontrollable).

√ Accumulation of solids can affect biogas plant performance by reducing the hydraulic retention time.

√ Convert to value added products (N,P,K).

Technical Challenge No. 3

Footprint and location for the biogas project

√ Space and land area concern.

√ Control the footprint.

√ Inthevicinityofpalmoilmill=minimumcostonhandlingandtransportation.

√ Power supply and water supply.

√ Road and transport = accessibility.

Technical Challenge No. 4

Technically competent personnel must be in the operating team

√ Well-trained personnel.

√ Competency in POME treatment handling.

√ Mentally, technically and physically prepared.

√ Not only can generate but also able to manage (control).

√ Safety concern.

√ Power management.

Technical Challenge No. 5

There are numerous tests and inspections (initial and regular) involved

√ SEDA ATPA test.

√ TNB safety test-Islanded Test and loss of main.

√ TNB PQ Test.

√ TNB availability test.

√ In-house test-all aspects.

√ Instrument calibration and testing.

√ JKKP plant annual inspection.

CONCLUSION

If we want to make the world a greener place and to enhance the degree of tapping on green energy (biogas in this context) from agro-industry waste, it is crucial to have team work and collaborative efforts of the various parties (governing bodies, industry players and technology providers) involved.

To be able to transform and diversify to reach sustainability stage, industry players must realign their direction, both technically and commercially, and move forward. The initiatives and proactive behaviours of industry players are crucial to turn positive transformation into reality. Remember, the planet is owned by all living beings.

Author's Biodata

EV Connection is a prominent expert in Electric Vehicle (EV) and Plug-in Hybrid Electric Vehicle (PHEV) charging. We are one of the pioneers in providing electric vehicle charging services in Malaysia.

Our Products & Services include:

Supply & Install EV charging stations for residential homes, condominium, o ces, hotels, shopping malls and etc.

Supply EV charging cables and accessories for Electric Vehicle & Plug-in Hybrid Electric Vehicle.

In conformity with the requirements of standard MS IEC 61851-1:2013 and MS IEC 61851-22:2013.

*Applicable for GBI Certification under Innovation Category

Type 1Type 2Type 3

EV Connection Sdn Bhd B716, Block B, 7th Floor, Kelana Square, No. 17, Jalan SS7/26, Kelana Jaya, 47301, Petaling Jaya, Selangor. Tel: 03-7887 2912 Fax: 03-7806 2677

Website: www.evconnection.com.my

E-mail: support@evconnection.com.my

Salesperson: Kevin Lim (017-453 7750) Mr. Lee (017-255 9777)

We are the second largest producer of palm oil in the world after Indonesia. There are 4.49 million hectares of land in Malaysia under oil palm cultivation. Malaysia produces 17.73 million tonnes of palm oil and 2.13 tonnes of palm kernel oil. The palm oil industry also provides employment for over half a million people.

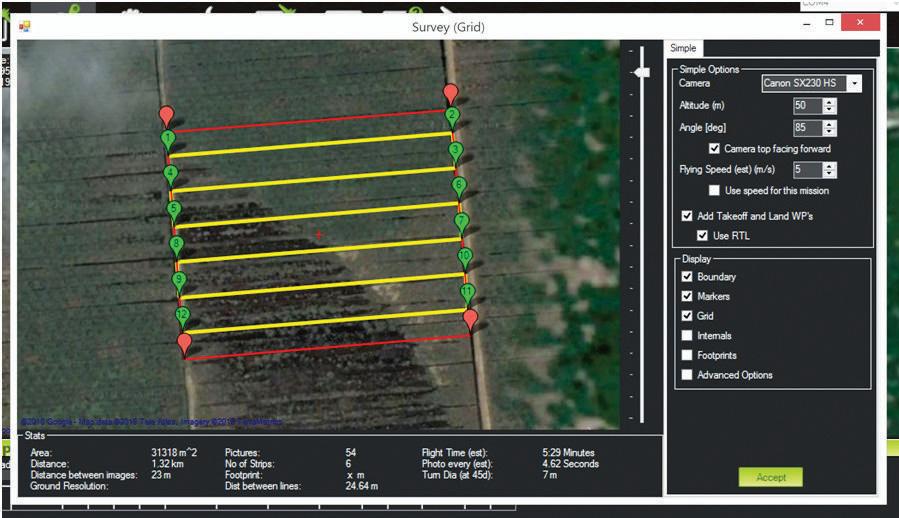

Precision Farming (PF) is about managing variations in the ield accurately to produce an optimum yield. It involves data collection, data processing, and data analysis to produce ield variability maps, a support system for decisions and proper management practice. Short revisit times are also necessary to allow a prompt response to ield conditions. But it is time consuming to acquire larger datasets to assess ield variability, especially in larger farms such as in an oil palm estate.

Satellite images and aerial photos are widely used for crop monitoring and yield prediction. However, the use of satellite images is limited as images are not always available when needed and sometimes, the resolution of available images is too low to be of use. In addition, a manned airborne platform has disadvantages on operational complexity, high costs and lengthy product delivery.

Recently, Unmanned Aerial Vehicles (UAVs) are being used as an alternative platform for this purpose. UAVs carry many types of sensors, such as multispectral, hyperspectral, Near Infrared (NIR), thermal, microwave and laser scanners. It is an ideal platform for PF operation since it can provide high spatial resolution for up to centimetres, as well as having low operational costs and real-time data acquisition.

There are two broad platforms for UAVs, namely rotary wing and ixed wing. Rotary wing UAVs have the advantage of being able to take off and land vertically. However, they have a short light range due to mechanical complexity and shortened battery power. Fixed wing UAVs have the advantage of being able to ly at high speeds for long durations with simpler aerodynamic features. Some do not require a runway or launcher for take-off and landing; they have a light duration of 1-2 hours, which allows an area of 50-300 hectares to be photographed per light.

Currently, besides the availability of sensors for data acquisition, data analysis methods and algorithm development are improving rapidly. The most common indices used are the Green - Red Ratio Vegetation Index (GRVI), Normalised Green - Red Difference Index (NGRDI), Leaf Area Index (LAI), Normalised Difference Vegetation Index (NDVI), and Visible Vegetation Index (VVI). However,

the capability of these indices, which are developed using multispectral images, is limited when compared to hyperspectral images since, normally, it only has ive bands.

Hyperspectral images contain many continuous spectral bands to record spectral responses of materials

and so allow more information to be extracted, which provide for various applications, such as vegetation cover condition, plant cell structure condition and plant structural water content as well as some other valuable information. Generally, healthy vegetation covers signify high reflectance in near infrared and low reflectance in the visible region of the electromagnetic spectrum.

The most common applications of UAV in oil palm plantation can be categorised into four major activities: Surveillance, mapping, monitoring and spraying.

Before the opening of new areas for oil palm plantations, operators can irst make a survey and map ields from the air, showing terrain and drainage. This is to facilitate decisions on the provision and inancing of projects to be implemented. The same process is also applied during replanting programmes. Furthermore, monitoring land work progress during planting is more practical using UAVs instead of conventional methods which are more laborious.

Digital maps derived from UAV images can be used to create an inventory of assets in a plantation, such as roads, number of trees, culvert, ramp, ofice, etc. They are useful tools for planning, as well as for cost projections such as for fertiliser and pesticide budgeting, proits projection, road maintenance, plantation management, environmental management and many other applications.

Furthermore, variable rate application maps can be generated using spectral data to understand the nutrient uptake in a ield. Therefore, by applying the appropriate amount of fertiliser, it reduces costs and increases yields.

UAVs can also be used to monitor the health status of oil palms and keep tabs on disease, water stress and

nutrient deiciency. This inspection work can be done by utilising various sensors and vegetative indices. Recently, many investigations were carried out to demonstrate the hyperspectral capability in early detection of plant diseases as well as ganoderma disease detection in oil palm plantation. This approach makes crop inspection much easier and saves time. In the areas of labour shortages and improper infrastructure systems, especially steep slopes, UAVs can be employed to spray fertiliser and pesticide. Urea foliar spraying can raise the percentage of nitrogen in leaves and even the quantity used is smaller than that used by sows. The spraying of pesticides can overcome the problem of insects, especially if the spread of insects cannot be controlled manually.

While the ability of data analysis methods and algorithm development keep growing, the use of UAV in oil palm plantations is still not without challenges. Most UAVs face restrictions in terms of weather vagaries, such as wind and rain. Furthermore, the capability of the UAV sensors is limited in that it cannot ly into canopies, so information below canopies, such as soil properties cannot be retrieved directly.

The application of UAVs should be expanded to many other activities in the future, for example, replacing the normal pollination process when there is a reduction in number of insects (due to disease outbreaks) which help to pollinate oil palms.

Hopefully, UAVs can also help overcome labour shortage by being used for major daily tasks done by plantation workers, such as front pruning, counting the number of Fresh Fruit Bunches (FFBs), identifying mature

We are a supplier of high quality geosynthetic products used for soft soil stabilization, slope reinforcement, coastal erosion protection, river bank protection, landfills, drainage, road and railway construction.

Our Products:

NEXTILE NON-WOVENS

NEXFORCE HIGH-STRENGTH WOVENS

NEXGRID GEOGRIDS

We also provide design, specification, bill of quantities, cost estimate and drawings free-of-charge.

FFBs, harvesting and collecting the FFBs. Despite current limitations and challenges, technology UAVs offer a brighter future for the oil palm industry and help increase yield production as well as provide better plantation management.

Author's Biodata

Assoc. Prof. Dr Siti Khairunniza Bejo, is Head of Department at the Department of Biological and Agricultural Engineering, Faculty of Engineering, UPM. She is also a Key Researcher at Smart Farming Research Centre, UPM and Research Associates at Institute of Plantation Studies, UPM.

Title: 2nd Mentors Workshop 2017: “Log Book Training Scheme –Guidelines for Mentors” - POSTPONED FROM 9 SEPTEMBER 2017

21 October 2017

Organised by: Standing Committee on Admission and Practical Training Time : 8.30 a.m. - 12.30 p.m.

CPD/PDP : 3.5

Title: 32nd Annual General Meeting of the Mechanical Engineering Technical Division, IEM 21 October 2017

Organised by: Mechanical Engineering Technical Division Time : 11.00 a.m. - 1.00 p.m.

CPD/PDP : 2

Get in touch with us: Tel: 03-6142 6638 Fax: 03-6142 6693 sales@neusynthetics.com

Sales Team: Gordon (012-355 0872)

www neusynthetics com N E H E M IA H G E O S Y N T H E T IC S S D N B H D No 45-3, Jalan PJU 5/20, The Strand, Kota Damansara, 47810 Petaling Jaya, Selangor Darul Ehsan Malaysia

Title: Technical Visit to MMU Cyberjaya 24 October 2017

Organised by: Electrical Engineering Technical Division Time : 8.00 a.m. - 12.30 p.m.

CPD/PDP : 3.5

Title: Technical Visit to SKF Bearing Industries (M) Sdn. Bhd. 24 October 2017

Organised by: Mechanical Engineering Technical Division Time : 2.00 p.m. - 4.30 p.m.

CPD/PDP : 3

Kindly note that the scheduled events below are subject to change. Please visit the IEM website at www.myiem.org.my for more information on the upcoming events.

(The Geotechnical Specialist Since 1986) Solutions to Your Geotechnical Needs / Problems Using

JACKED ANCHORS RETAINING WALL (Patented System)

by Ir. Shum Keng Yan

Let us look at the ABC again through a scenario:

It was almost the end of the shift but there was an urgent job that needed to be carried out. A group of technicians was called in to do the repairs. As you walked past, you observed that some of the technicians were not wearing the proper Personal Protective Equipment (PPE) and were not using the right tools. They also seemed to be in a hurry.

Why do you think?

A: Let us look at the immediate environment “before” the behaviour or Activators. Here are some possibilities:

1. It was time to go home.

2. The PPE and tools had been locked up and it would slow down the job to get them out.

3. Wearing PPE was uncomfortable.

4. Wearing PPE would slow down the job.

5. “My colleagues are doing the same”.

B: This leads to the observed Behaviours of:

1. Not wearing PPE.

2. Using the wrong tools.

3. Rushing.

C: What were the possible Consequences (the immediate environment “after” the behaviour)?

1. No one got hurt.

2. The production team was pleased with the repair work.

3. The repair job was done in a more comfortable environment.

4. It was done much faster.

5. The technician team was happy.

So, will they repeat the behaviours again?

Highly likely. Here is how it looks like in the ABC model:

1. Time to go home.

2. Slow to take out PPE and tools.

3. PPE is uncomfortable.

4. PPE slows the job.

5. Colleagues do the same.

1. Not wearing PPE.

2. Using the wrong tools.

3. Rushing.

Our Services Include: Problem Appraisal, Proposal, Construction, Monitoring

Please Contact: 019 382 4875 (Aw), 019 310 1760 (Yu), 019 382 2688 (Su), 03 7729 9826 (Office)

1. No one got hurt.

2. Production team is happy.

3. It was more comfortable.

4. It was much faster.

5. Technician team is happy.

Try and run through the above scenario with your team. What do they think?

Share the other possible ABCs with me at: pub@iem.org.my

Working safely may get old, but so do those who practise it.

reported by AGRICULTURAL

On 5 April, 2017, the Agricultural & Food Engineering Technical Division (AFETD) organised a technical visit to the Malaysian Agricultural Research and Development Institute (MARDI) in Serdang, Selangor, for 21 IEM members and non-members.

The participants were welcomed by Ir. Mohd. Fazly Mail, a senior scientist from MARDI who was also an AFETD committee member. First, the participants attended a briefing on the programme which included technical talks and visits to the essential oil processing plant and the stingless bee honey production site.

There was also a briefing on an incubator programme. The first speaker was Encik Zulkifli Abdul Rahman from MARDI Kuala Linggi, Melaka, who talked about the production of essential oil.

Two distillation methods are adopted: Steam and hydro. Essential oils are extracted from various plants such as tea tree (Melaleuca alternifolia), kesum (Polygonum minus), patchouli (Pogostemon cablin), citronella (Cymbopogon nardus L), lemongrass (Cymbopogon citratus), sweet cinnamon (Cinnamomon zeylanicum), kaffir lime (Citrus hystrix) and lime (Citrus microcarpa).

In the second session, Encik Mohd. Fahimee Jaapar spoke on the production of stingless bee honey, focusing on farming and beekeeping. Stingless bee honey is said to have therapeutic properties and there is an increasing demand for this type of honey. The local name for stingless bee is kelulut and the common type found in Malaysia is Trigona itama. The participants were given an introduction to the stingless bee as understanding the behaviour of the bee would help increase the quality of honey production.

A colony of stingless bee can produce up to 500g honey each month and the bees will search for flowers within a 300m radius. The physiology of the flowers too will influence the quality, aroma and taste of the honey.

The last session of the technical talk, given by Cik Siti Shurazizah Sukhur, was on Inkubator, an incubation programme by MARDI Kuala Linggi. The programme is also to help new entrepreneurs in the production of their products, particularly essential oil. The incubator centre

for the essential oil processing plant is certified by Australian Certified Organic (ACO) and acts as a technology transfer medium for those interested to start their own businesses. Some oftheprogrammesofferedincludetechnicalservices,facilities/ infrastructure services and business/marketing services.

After the briefing sessions, the participants boarded a tram to go to the essential oil pilot plant and the stingless bee farm. At the essential oil pilot plant, they learnt that the pilot plant was used for showcasing MARDI products during Malaysian Agriculture,Horticulture&Agrotourism(MAHA)andforproduct testing.

A larger-scale pilot plant was located at MARDI Kuala Linggi, Melaka and the participants were told that the pilot plant operated and manufactured essential oil on a daily basis.

After this, the participants visited the bee farm and had a taste of the stingless bee honey directly from the hives box.

At the end of the technical visit, AFETD chairman Ir. Yong Hong Liang, on behalf of IEM, presented Encik Zulkifli with a token of appreciation.

CIVIL & STRUCTURAL ENGINEERING TECHNICAL DIVISION

reported by

The Civil & Structural Engineering Technical Division (CSETD) organised an evening talk on Basement Design, on 20 April, 2017, at Auditorium Tan Sri Prof. Chin Fung Kee in Wisma IEM.

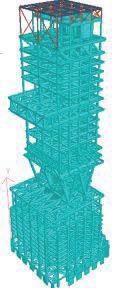

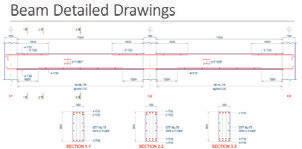

The speaker was Mr. Tony Chin, a chartered professional engineer in Australia with 15 years’ experience in the building structures industry. Mr. Chin spoke on a few topics, including Project Requirement, Client Expectations, Geotechnical Aspects & Constraints, Structural Design Basis and Examples of Projects completed in the Middle East, Singapore & Australia. The talk, attended by 77 participants, was chaired by Ir. Siow Yun Tong of CSETD.

Mr. Chin listed some Codes which an engineer should use when communicating with the client as well as showed a few examples and images on basement standard. Gravity wall and embedded wall are two common basement walls. These are designed to resist earth and water pressure. He said surcharge loads of between 5 and 10 kN/m2 must be considered in the design. Examples of surcharge load are vehicles, road inishes and construction plant.

There are three types of construction sequences for basements. The irst is Open-Cut where construction is done in open excavation. The basement is excavated to formation level, leaving battered slopes to support the surrounding ground.

The second method is Top-Down, where perimeter secant wall piles are installed, followed by bearing piles with the plunge columns. Then the ground loor slab, irst

loor slab, second loor slab and middle basement slab will be cast accordingly.

The third type of basement construction sequence is Bottom-Up, which has a few advantages as it is move safe, faster and requires minimum propping.

Mr. Chin also shared his experiences in the design of the retaining wall. He had adopted two types of wall systems: Gravity wall and embedded wall. He showed participants images of both systems and explained their advantages and disadvantages. He emphasised the importance of structural design considerations and advised engineers to consider future rises in ground water, unplanned excavations and surcharge loading. He ended his presentation with a few case studies of his completed projects.

Title: 2-Day Course on “Integrating Operational Perspective for Cohesive Design of Plant and Building Facilities”

25-26 October 2017

Organised by: Oil, Gas and Mining Engineering Technical Division

Time : 9.00 a.m. - 5.00 p.m.

CPD/PDP :12

Kindly note that the scheduled events below are subject to change. Please visit the IEM website at www.myiem.org. my for more information on the upcoming events.

reported by

The Agricultural & Food Engineering Technical Division (AFETD) of IEM organised a technical talk titled Roundtable on Sustainable Palm Oil: Challenges to the Industry & Engineers, on 8 May, 2017, at Wisma IEM.

The talk, attended by 27 participants, was delivered by Mr. Jan Van Driel, Head of Certification at Roundtable on Sustainable Palm Oil (RSPO).

The worldwide demand for vegetable oil is growing fast over the years. In 2016, global oil production was 65 million tons (MT) of palm oil, 50 MT of soya oil, 28 MT of rapeseed oil and 15 MT of sunflower oil.

Palm oil is popular because it is relatively cheap, versatile, gives a high yield per unit area of plantation and is the most widely produced. It is stable for cooking at high temperatures and is a healthy oil.

But despite the increasing demand, supply is limited as the oil palm can only be grown in countries near the Equator. Some concerns have also been raised over the sustainability of oil palm plantations; the clearing of forests to grown oil palm also means a decrease in environment for the orang utan, an endangered species.

RSPO was established in 2004 to promote the growth and use of sustainable oil palm products through credible global standards and engagement of stakeholders. The seat of the association is in Zurich, Switzerland, while the secretariatiscurrentlybasedinKualaLumpur,withasatellite office in Jakarta.

RSPO is an association under Swiss Law composed of various organisations from different sectors of the palm oil industry (producers, processors, traders, consumer goods manufacturers, retailers, banks & investors, environmental or nature conservation NGOs and social or developmental NGOs) for the purpose of developing and implementing global standards for sustainable palm oil.

RSPO has developed a set of environmental and social criteria which companies must comply with in order to produce Certified Sustainable Palm Oil (CSPO). When properly applied, these criteria can help to minimise the negative impact of oil palm cultivation on the environment and communities in palm oil-producing regions. The RSPO has more than 3,000 members worldwide who represent all the links along the palm oil supply chain. They are

committed to produce, source and/or use sustainable palm oil certified by the RSPO. In return, the CSPO carries a premium price in the global commodity trade, especially the European market.

So far, 11.77 MT of palm oil are certified sustainable; this is about 20% of global palm oil production. Of these, 51% of RSPO Certified oil comes from Indonesia, 42% from Malaysia and the rest from Papua New Guinea (5%), Brazil (1%) and Colombia (1%).

The RSPO Certification Scheme covers a large sector of the palm oil industry, i.e. oil palm growers, palm oil processors and traders as well as consumer products manufacturers.

The Principles & Criteria, which forms the basis of the RSPO certification scheme, comprise eight basic principles: Commitment to Transparency, Compliance with Applicable Laws and Regulations, Commitment to Longterm Economic & Financial Viability, Use of Appropriate Best Practices by Growers and Millers, Environmental Responsibility & Conservation of Natural Resources and Biodiversity, Responsible Consideration of Employees and of Individuals & Communities Affected by Growers & Millers; Responsible Development of New Plantings and Commitment to Continuous Improvement in Key Areas of Activity.

In order to claim compliance with the P&C and to achieve RSPO certification, growers must be assessed by a third-party RSPO-accredited certification body every five years, with an annual audit for continued compliance. Members of the RSPO must submit Annual Communications of Progress(ACOP)reportsinordertoassesstheirprogresstowardsproducingand procuring RSPO-certified sustainable palm oil, to any of the four supply chain models for RSPO Certified Sustainable Palm Oil (CSPO): Identity preserved, segregated, mass balance and book and claim. A crucial component of the ACOPs is Timebound Plans (TBPs), in which members must state clear timelines for producing or sourcing 100% RSPO CSPO.

RSPO Next, launched in 2015, is a voluntary commitment in addition to the existing P&Cs and incorporates more stringent assessment standards, with guidelines regarding deforestation, fire, peat, human rights and landscape approaches, among other issues.

One of the important criteria highlighted here is the RSPO New Plantings Procedure (NPP). Key steps for NPP include conducting impact assessment (through licenced assessors), preparing implementation plan, verification by certification body and public notification on the RSPO website for at least 30 days.

RSPO has biodiversity protection measures that depend heavily on a High Conservation Value (HCV) approach and requires implementation of Best Management Practices (BMPs) for peatland management.

It has a cut-off date of November, 2007, after which new plantings should not replace primary forest or areas required to maintain HCV areas. Areas cleared after this date will not be certified unless an RSPO-approved compensation plan is developed (in line with its newly released guidance for compensation).

On social themes, RSPO has comprehensive requirements for Social Impact Assessment (SIA), detailed standards for “free, prior and informed consent” (FPIC) and guidance on workers’ rights and health and safety. It prohibits the use of forced labour and has a policy aimed at protecting women in the workplace.

A third party accredited auditor is required to carry out the certification process. In order to be certified, full compliance with all criteria is required, or an approved timebound plan for addressing minor non-compliances. RSPO provides on-line status updates and a relatively high level of transparency throughout the complaint resolution process.

As time was limited, the presentation only covered the tip of the iceberg. Engineers interested in this field may refer to RSPO website for further details and the IEM website for courses organised by AFETD, particularly on RSPO. The talk ended with AFETD chairman Ir. Yong Hong Liang presenting a memento to Mr. Jan Van Driel.

Title: 2-Day Course on “STRATEGIES in sustaining BOILER RELIABILITY –design, erection & maintenance” 26 - 27 October 2017

Organisedby :MechanicalEngineeringTechnicalDivision

Kindly note that the scheduled events below are subject to change. Please visit the IEM website at www.myiem.org.my for more information on the upcoming events.

http://www.ctsbare.com

IEM BUSINESS CLUB

reported by

Ir. Mah Siew KienIr. Yam Teong Sian