Tedds will automate your structural calculations and transform the way you work.

You can:

Use a broad library of calculations

Write your own calculations

Work within Microsoft Word

Produce transparent output

Archive documents electronically

Receive new calculations regularly

See Tedds online

You will:

Save time & increase pro t

Reduce calculation errors

Improve consistency

Reduce overheads

Enhance QA processes

SDN. BHD. (449732-T)

patrick@dimensionpublishing.com

shirley@dimensionpublishing.com

reika@dimensionpublishing.com

siewli@dimensionpublishing.com

beela@dimensionpublishing.com

alicia@dimensionpublishing.com

masaki@dimensionpublishing.com

sharon@dimensionpublishing.com

DIMENSION PUBLISHING SDN. BHD. (449732-T)

HOFFSET PRINTING SDN. BHD.

JURUTERA

YANG DIPERTUA / PRESIDENT:

TIMBALAN YANG DIPERTUA / DEPUTY PRESIDENT:

NAIB YANG DIPERTUA / VICE PRESIDENTS:

SETIAUSAHA KEHORMAT / HONORARY SECRETARY:

BENDAHARI KEHORMAT / HONORARY TREASURER:

WAKIL AWAM / CIVIL REPRESENTATIVE:

WAKIL MEKANIKAL / MECHANICAL REPRESENTATIVE:

WAKIL ELEKTRIK / ELECTRICAL REPRESENTATIVE:

WAKIL STRUKTUR / STRUCTURAL REPRESENTATIVE:

WAKIL KIMIA / CHEMICAL REPRESENTATIVE:

WAKIL MULTIMEDIA / MULTIMEDIA REPRESENTATIVE:

AHLI MAJLIS / COUNCIL MEMBERS:

BEKAS YANG DIPERTUA TERAKHIR / IMMEDIATE PAST PRESIDENT:

BEKAS YANG DIPERTUA / PAST PRESIDENTS:

PENGERUSI CAWANGAN / BRANCH CHAIRMAN:

AHLI JAWATANKUASA INFORMASI DAN PENERBITAN / STANDING COMMITTEE ON INFORMATION AND PUBLICATIONS 2012/2013:

Geotechnical Challenge: Geologists Act 2008 and the Development of Geotechnical Engineering

GEOLOGISTS by Ir. Liew Shaw Shong Chairman, Geotechnical Engineering Technical Division, IEM

THE INSTITUTION OF ENGINEERS, MALAYSIA

by Ir. Yee Thien Seng

Subsequent to the establishment of the Geologists Act 2008 (hereinafter referred to as “The Act”) on 27 August 2008, several issues of concern have emerged amongst practising engineers, especially in terms of professional responsibility and accountability. This is taken in view of the fact that the provisions of the Act seem to offer stout protection to the geological fraternity. To address these issues of concern, the Geotechnical Engineering Technical Division had recently organised a forum on the Act at the Tan Sri Professor Chin Fung Kee Auditorium, Wisma IEM.

TheforumwaschairedandmoderatedbyIr.DrChinYaw Ming, a former Committee Member of the IEM Geotechnical Engineering Technical Division. There were four (4) the panellists in this forum, namely Ir. Dr OoiTeikAun, Chairman of IEM Consulting Engineers Special Interest Group and Committee Member of IEM Geotechnical Engineering Technical Division and Consultant, Ir. Dr Mohd. Farid bin Hj. Ahmad, Chairman of IEM Tunneling and Underground Space Technical Division and Consultant, Ir. Dr Abdul Majid bin Dato’ Abu Kassim, Immediate Former President of the Association of Consulting Engineers Malaysia and Consultant, and Mr. Seet Chin Peng, Vice-President of the Institute of Geology Malaysia. They have brought forward several interesting opinions related to the grey area created by the provisions of the Act.

services’ as listed in the Act which would pose some

highlighted some of his personal experiences on them, which include the following:

i. Feasibility studies;

ii. Planning;

iii. Geological surveying;

iv. Implementing, commissioning, operation, maintenance and management of geological survey works or projects;

v. Any other services approved by the Board.

He cautioned that the provisions are very wide in coverage and, although the Act does declare that none of its provisions should be construed as permitting geologists to practise engineering under the Registration of Engineers Act 1967 (REA), they would inevitably have led to numerous instances of geologists encroaching into the engineer’s areas of work.

In planning, such practices are condoned by Local Authorities which require the inputs of geologists as a

for approval of development schemes in spite of Clause 27(6) in the Act which clearly stipulates that it is not mandatory to have geological services for the practice of

engineering unless so requested by a professional engineer. Thus, in the course of providing their inputs, it would be the engineering aspects of the work, and this could lead to an infringement of the REA.

process practised by some Local Authorities in receiving applications for Planning Approval for new hill slope developments, where the Jabatan Mineral dan Geosains Malaysia (JMG) approval of construction suitability on

prescribed policy guidelines prevails over all other technical departments’ or professionals’ opinions.

According to Ir. Dr Ooi, the Act as well as the constitution of the Board of Geologists do not have the necessary

safeguards to protect public interests, and appear to have been formulated to preserve the interests of geologists. Ir. Dr Ooi also highlighted that the Act empowers an inspector to apply for a magistrate’s warrant authorising him to enter and search the premises, as and when there is suspicion that an offence under theAct is being or has been committed, or in connection with any business carried on any premises. of up to one year, or both, may be imposed on any person who obstructs or impedes an inspector in the exercise of his duties. A similar penalty may also be imposed on any person found to have employed a person not registered under the Act to render any geological services. Further, any person found impersonating a registered geologist or RM20,000 or imprisoned for up to two years, or both. He cautioned that engineers working on dams, tunnels and

hillslope development projects can unwittingly commit and thereby fall foul of the Act.

Ir.DrOoithenpointedoutthatthegeologicfraternityenjoyed considerable media coverage following the occurrences of a number of highly dramatic landslides in recent times, starting with the Highland Towers collapse in 1993, which helped to trigger the creation of the Board of Geologists.

However, he also pointed out that all those landslides were simply the consequence of poor engineering and construction practices and had little connection whatsoever with geology. Instead, Ir. Dr Ooi revealed that in 2003 a large rock slope collapse within the reserve of the New Klang Valley tolled expressway actually had gone through an extensive geological study during its design; and yet it had failed to avert the collapse of the slope which resulted in the closure of the affected section of the expressway for several months.

Ir. Dr Ooi also provided towards the end of his presentation a short account of the one-day Seminar on Hill Site Development organised by the Board of Engineers Malaysia on 14 February 2009 along with the activities that followed. This included the updating of the IEM Position Paper on Hill Site Development in the same year.

in the Act presented earlier by Ir. Dr Ooi Teik Aun. He highlighted that the Act allows any person, irrespective of

date, to continue doing so provided he registers as a practitioner under the Act within twelve months from that date.

Ir. Dr Mohd. Farid noted that the Board of Geologists essentially could accept any individuals as registered practitioners of geology, whether or not they possess a university degree in geology, so long as these individuals

He also shared his experience in encountering cases whereby the geologists were required to prepare feasibility study reports for housing and condominium development projects. Ir. Dr Mohd. Farid remarked on the minor roles the geologists had, and yet their inputs were made to carry such great weight in the planning approval process by Local Councils. He also highlighted the limited nature of geological inputs in tunneling work and as a result the geologists employed in these project sites were trained to do geotechnical engineering work instead.

Ir. Dr Mohd. Farid then presented side-by-side comparisons of the university course contents for mining engineers and geologists. He commented that mining engineers work on processes culminating with the extraction of mineral resources from sources in the

geology listed in the Act cover many areas of their work. Whilst the geology course dealt with minerals in a clearly qualitative or descriptive manner, the mining engineers have to cover the same with very rigorous mathematics, reinforcing the treatment of the subject with engineering material science and engineering mechanics. It is such quantitative evaluations by mining engineers that make possible meaningful conclusions, and this holds true for all other disciplines of engineering.

Ir. Dr Mohd. Farid also warned fellow engineers that based on the manner in which the Act has been formulated, there lies the possibility that engineers may be charged with practising unlicensed geology in future given the rising trend in Malaysia towards a litigious society.

According to Mr. Seet, the work on the Act started in the 1980’s and has taken 28 years to accomplish; yet its main objective is to regulate the geological profession and its practice. The Highland Towers collapse was an initiating factor in its creation. He also emphasised that the Act was not intended to intrude into the engineers’ domain. Although

concerned with geological projects.

However, now that geologists have gotten involved in engineering projects, it could only mean that they have strayed from the Act’s intended objectives. Feasibility studies for housing development or construction projects do not constitute geological projects. Geological projects include feasibility studies for mineral exploration and for mine operations.

He explained that the Act recognises an individual who has been doing geological work before the Act was enforced, although he may not possess a university degree ingeology.ThroughregistrationasaRegisteredPractitioner, he is permitted by the Act to continue working as before. However, Mr. Seet said that a non-geologist foreigner who undertakes geological work in this country would not be permitted under the Act to practise once his term has expired. He explained that this was aimed at protecting the livelihood of local geologists and practitioners.

of the Act to require an engineer’s report to be signed by a registered geologist. However, it does require a contractors’ geological report submitted to the engineer to be signed by

a registered geologist. Mr. Seet added that theAct has been worded in very generic terms for ease of administration but its enforcement is intended to be made in conjunction with the accompanying Regulations to the Act. The Regulations however, have yet to be released.

Ir. Dr Abdul Majid observed that there are a number of similarities between theAct and the REA. He said that it was encouraging to learn from Mr. Seet that the vague wordings

consultations with the Board of Engineers.

He also pointed out the Act does not contain provisions that offer public representation on the Board of Geologists and there are no indications that the purpose of the Act is to protect and safeguard the public’s interests.

Ir. Dr Abdul Majid also highlighted that there is no professional liability attached to the geological profession, unlike in the case of engineers where the Uniform Building

be held responsible and liable for his work.

Ir.DrChinopenedthesessionbyaskingMr.Seetifengineers should register under the Act. Mr. Seet replied that only a person trained in geological sciences could do so. But their degrees would have to be recognised as admissible by the Board of Geologists before registration can be permitted. At the moment, as the Board of Geologists has yet to be established, registration is not possible.

In response to a question from Ir. Mohd. Jamil b. Ali on the availability of professional geological companies, Mr. Seet explained that the Act does not register companies. It will only register individuals who are practising geologists. Currently, there are no registered geologists in the country since the Board of Geologists has yet to be established.

Ir.DrMajidreiteratedthat,unlikeinthecaseofengineers,

working with geologists in the course of their work, and appealed to engineers and geologists to co-operate with each other.

Subsequently, Ir. DrAbdul Majid opined that an engineer has to recognise the limits of his own capability and not to practise beyond those limits, but to enlist the necessary assistance from individuals with the relevant expertise. This is in line with professional ethics. He suggested that there have been numerous instances of failures in constructed works resulting from incompetent and negligent acts by engineers and this situation has allowed others to claim the engineers.

Mr. Ng Chak Ngoon, a practising geologist, described an example of a geological report which mentioned the existence of non-existent minerals and made a mining company suffer business losses to justify the Act regulating against unauthorised practice. He then asked about the number of geotechnical engineers who have been charged in court for the many landslides that have been reported. Ir. Dr Ooi cited the case of the Highland Towers collapse where a structural engineer was made liable for certifying as-built drainage plans that he did not design nor supervise.

Ir. Yee Thien Seng added that no geotechnical engineer had been charged so far as none had been involved in

procure the services of registered geologists. Currently, the Local Authorities are imposing the requirement for geological services through their own procedures in addition to their respective local by-laws.

Ir. Look Keman Sahari commented from his personal experience that mining engineers received considerable education in geology to the point of making them more than

Person, although engineers have certainly been charged and found liable in other cases. Ir. DrAbdul Majid recounted a case where a consulting engineer was successfully sued for negligent conduct, though not under the REA.

Mr. Seet also explained that the Act would protect employees from being forced against their will by their employers to sign geological reports. Meanwhile, an engineer from Dewan Bandaraya Kuala Lumpur (DBKL) talked about the receipt of unreliable site investigation reports by her department and revealed DBKL’s practice of requiring geologists to review geotechnical engineering reports. She also considered this practice unusual, which was agreed by the panellists as well.

Mr. Ng Chak Ngoon likened the way the Act was being used by the Local Authorities (which require the services of geologists in applications for development approval) as a form of Development Tax since the services provide

another practising geologist, Mr. Tan Boon Kong, pointed out that the Local Authorities’ requirement for geological evaluations is a condition imposed by JMG and not a requirement of the Act.

IT was an honour for Geotechnical Engineering Technical Division (GETD) of the Institution of Engineers, Malaysia (IEM) to have Prof. Charles W. W. Ng from the Hong Kong University of Science & Technology (HKUST) deliver a technical talk at Tan Sri Prof. Chin Fung Kee Auditorium, Wisma IEM, recently in conjunction with the 23rd GETD Annual General Meeting. The talk was chaired by Ir. Liew Shaw Shong, the present technical division Chairman. The talk had received an overwhelming response with an audience of 115 participants.

The presentation started with a brief introduction of the geotechnical testing facilities in HKUST and was followed by a talk on the fundamental principles of geotechnical centrifuge modelling with schematic illustration on how rotating a test sample would generate a linearly increasing centrifuge stress within the test sample and enable the study of soil behaviours (dilative below critical state line and contractive above critical state line) as shown in Figure 1.

The following is a summary of the four principal applications of centrifuge technology:

a) Modelling of Prototypes such as slopes, piles, tunnels, excavations, geo-environmental and earthquakeinduced problems, and consolidation settlements;

b) Investigation of New Phenomena such as explosions, plate tectonics, liquefaction problems, and contaminant transports;

c) Parametric Studies such as bearing capacity of footings on slopes, and laterally loaded pile groups; and

d) Calibration of Numerical Models and Methods which shows the implication of a good match between the

by Ir. Liew Shaw Shong

that subsequently raises the following questions:

procedure or model parameters are being used?

and mechanism improved?

With the uncertainties in the ground conditions (such as non-homogeneity of the sub-soils, existence of cross-

lateral earth pressure at rest, zero displacement boundary, permeability and degree of saturation in sub-soils, etc.), which might not be fully captured in the numerical model, the good matching result would be highly possible due to mere coincidence bearing no true value to the problem. Hence, the direct calibration of numerical modelling to

However, physical model test using a 1g prototype model and centrifuge model test with known boundary conditions and ground conditions could be constructed to simulate the actual site conditions and verify both the numerical

In most piled foundation designs, it is very common to perform a static maintained load test at the ground level. If the project has a deep basement structure, a pile sleeve is usually provided along the pile shaft above the lowest basement level to prevent stress interaction from the embedded soils. However, the actual foundation piles with a deep basement often work underneath the basement structure to provide support to the columns. With the basement excavation, the actual stress in the subsoils embedding the piles below the basement would be reduced

as a result of stress relief. As such, the effect of stress relief on pile capacity and stiffness has seldom been examined when interpreting the static pile load test conducted at ground level well above the basement. Figure 2 illustrates the questionable representation of the conventional single test pile programme at ground level and at basement level to the actual pile working conditions.

Following are some of the relevant clauses extracted tests:

Clause 7.4.1 (1) – The design shall be based on one of the following approaches:

– the results of static load test;

– empirical,analytical calculation methods, dynamic load test whose validity has been demonstrated by static load tests;

– the observed performance of a comparable pile foundation.

Clause 7.5.1 (4) – If pile load test is to be carried out, it shall normally be located where the most adverse ground conditions are believed to occur.

This series of centrifuge model tests aim to:

a) Study the capacity of single piles with and without stress relief due to basement excavation;

b) Understand and quantify the governing mechanisms for shaft resistance of pile in both non-dilatant and dilatant soils; and

c) mechanism of 3x3 pile group with stress relief.

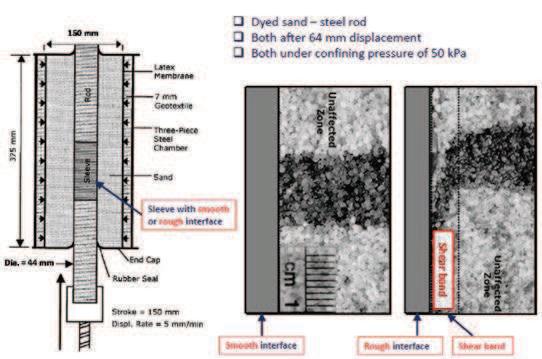

In order to characterise the soil-structure interface, normalised roughness (Rn = R max /D50) as shown in Figure 3 , it is used to determine the two possible failure mechanisms at the soil-structure interface (Fioravante, 2002) as stated below:

If R n < 0.02: non-dilatant interface – particle sliding along the interface;

If R n > 0.10: dilatants interface – failure happens within a shear band in the soil.

The photographic visualisation of two response types at soil-structure interface is illustrated in Figure 4.

To research the effect of the stress relief on pile capacity, four scenarios of the pile load testing condition as summarised below were explored in order to compare their performance:

a) Single pile tested at ground level prior to excavation resembling most of the conventional load tests, which are conveniently implemented at site before production

pile installation. Sometimes, a pile sleeve is introduced to eliminate interference of soil friction above the actual pile cut-off level.

b) Single pile subjected to stress relief due to excavation.

c) Elevated pile group (3x3) with stress relief and no contact between the pile cap and the soil platform for load transfer other than the piles.

d) Pile group (3x3) with stress relief, but the pile cap is in contact with soil platform enabling load transfer from pile cap to the soil platform.

Figure 5 visualises the above-mentioned testing programme with smooth pile shaft simulating low friction pile in nondilatant soils and rough pile shaft interface simulating high friction pile in dilatant soils. To increase the pile-soil interface roughness, the pile shaft surface was coated with epoxy and sand grains.

Roughness of pile-soil interface encourages rolling of soil particles over each other re-arranging themselves to a less compact state, hence, presenting a dilative behaviour of soil in shearing. The soil dilation within the shear band

(Continued on page 15)

will induce additional effective stress, which increases the frictional resistance when subject to shearing as presented in Figure 6.

To verify the soil dilatancy at the pile-soil interface,

plates with both smooth surface and epoxy coated with sand grains were carried out. Toyoura sand was compacted with relative density of 65% as the model soil. The shearing test results in Figure 7 show comparison of stress ratio and the dilative displacement in the high friction surface and the low friction surface.

In preparing the 3x3 pile group model, a 20mm thick aluminium plate adapted to nine aluminium model piles of 16mm diameter was used with pile centre-to-centre spacing krs, was larger than 25, the pile cap could be considered to be a rigid pile cap. The centre pile, corner pile and edge pile were equipped with instruments for load transfer measurement of pile axial load along the pile shaft with

contained in the space modelling the basement. The setting up and testing procedures of the centrifuge tests for both a single pile tested prior to excavation as in the conventional load test, and a single pile subjected to stress relief due to excavation are illustrated in Figure 9. The amount of stress relief to the soil platform beneath the basement will

out. Loading of 100N (10kN in prototype based on scaling laws for force) was applied incrementally to the model pile

Figure 10 shows the comparison of load-settlement curves for the single pile in a non-dilatant soil with pile sleeve (without stress relief) and with stress relief due to 20m deep excavation. Considering two failure criteria suggested by Ng et al. (pile load at settlement of 0.045D+0.5(PL)/(AE)) and Eurocode 7 (pile load at settlement of 10% of pile diameter), the measured pile capacity with stress relief was 20% and 16% lower than that without stress relief corresponding to the two failure criteria respectively.

In this series of centrifuge model testing, the effect of

with and without stress relief, it was observed that the pile with stress relief generally had lower overall pile capacity as shown in Figure 11. Similarly, the lower rate of reduction of axial load along the pile with stress relief was less than

the pile without stress relief, implying lower shaft resistance in the pile with stress relief, but more pile base resistance being mobilised in the pile with stress relief.

The excavation geometry (R/H) and ratio of excavation

capacity, the higher in either of the parameters implies more reduction in the pile capacity. For the tests conducted, the measured reduction in pile capacity was in good agreement with the FEM parametric study by Zheng, Diao and Ng (2011) as shown in Figure 12.

However, the performance of single pile in dilatant soils with stress relief in Figure 13 shows stiffer load-settlement curve leading to higher interpreted pile capacity based on

Figure 14, it is not surprising to observe the enhancing effect of pile shaft resistance in dilatant soils, even with the counteracting pile capacity reduction effect from the stress effect due to excavation. The increased effective normal stress around the pile shaft due to soil dilatancy during shearing has increased pile shaft resistance as evidenced

in Figure 14.

Figure 15 shows the interpreted unit shaft resistances mobilised at every instrumented segment of pile shaft with the two stress conditions (with and without stress relief). The soil dilatancy effect in the changes of effective normal stress appeared to be more dominant than the stress relief effect from excavation.

When the soil dilates during shearing, the normal stress on the pile-soil interface does not remain constant. Three boundary conditions for the pile-soil interface and the resulting shear resistances are shown in Figure 16. To study this dilative behaviour, Discrete Element Method (DEM) numerical model with constant normal stiffness

(Continued on page 18)

(CNS) boundary condition was used to simulate the cavity expansion behaviour relating to the outward displacement ( ) of the pile-soil interface and the increase of normal stress ( n ) in a parametric study.

The numerical results with CNS boundary condition in Figure 17 revealed that the mobilised stress ratio curve with stress relief (initial normal stress of 400kPa unloaded to 100kPa prior to shearing) has a peak value of about 1.0 (at 2% shear strain) before softening to a stress ratio of 0.72 (at about 10% shear strain) as compared to the result without unloading. It is evident that the soil dilatancy effect overwhelms the stress relief effect resulting in consistently higher normal stress increase during the entire shearing process.

Comparisons of the computed theoretical unit shaft changes in effective normal stress to the measurements in show reasonably good agreement.

conventional pile load test in non-dilatant material is not conservative. Hence, the most adverse condition for load test as required in Eurocode 7 (BS EN 1997-1:2004 Clause 7.5.1) will occur at the end of excavation. If such test is not possible, a reduction in pile shaft resistance proportional to stress relief should be considered in the calculation. However, for pile in a dilatant material, the most adverse condition might occur, either prior to excavation or after it, due to two counteracting effects on changes in normal effective stress. Though there is a reduction in effective normal stress due to stress relief, the effective normal

increase of pile capacity due to soil dilatancy in design.

Finally, the test results for pile capacity and observed failure mechanisms of elevated pile group subject to stress relief are presented in Figures 20, 21 and 22. Based on the failure criterion of pile settlement of 10% pile diameter as in Eurocode 7, Figure 20 shows the interpreted group pile capacity of 293MN, which is equivalent to 33MN per pile.

Comparing with single pile capacity of 45MN with stress

is approximately 0.7. From the load-settlement curves of single pile and group piles, the single pile appears to have stiffer load settlement performance.

When examining the unit shaft resistance of the single pile and group piles in the separating soil embedment zones, namely upper half and lower half as shown in Figure 21, the unit shaft resistances of both single pile and group piles are consistently higher in the lower half and that of the single pile is always higher than that of the group piles for the corresponding soil embedment zones. Mobilised unit shaft resistance along the upper half of each pile is only about 40% of the single pile at settlement up to 15% of pile diameter in this study. The normalised shaft resistance in upper half tends to be fairly constant (about 0.4) with increasing normalised pile settlement whereas, for the lower half, the normalised shaft resistance shows increasing trend with increasing normalised pile settlement.

of Eurocode 7 to the pile group centrifuge test simulating the pile group test (which is usually not performed in normal piling engineering practice), the interpreted pile group capacity of 293MN is presented in Figure 20.

In the normal pile group assessment from the result of single pile load test, there are two following practices suggested in Eurocode 7 (Clause 7.6.2.1(3)):

a) Failure of the pile individually

Assuming individual pile in the pile group has the same unit shaft and toe resistance as in the single pile, the computed pile group capacity would be 342MN (9 piles by 17%.

b) Failure of piles and the soil between them acting as a block

Assuming the pile group block has the same shaft and toe resistance as for a single pile, the computed pile group capacity would be 1497MN, which overestimates the pile group capacity by about 400%.As the test shows lower pile group capacity than the computed group capacity, there is likely to be other mechanisms other than the two aforementioned extreme cases. Thus, the computed pile group capacity is not conservative and has to be used with care.

a) Single pile in non-dilatant material: p n

stress relief of 20m deep excavation. Sometimes reduction in pile capacity may be up to 45%, depending on excavation geometry and pile length.

conservative (even with pile sleeve).

– The most adverse condition for a load test is to conduct the load test at the bottom of basement after the excavation.

single pile (without excavation) at the interpreted pile load with the failure criterion of Eurocode 7 corresponding to a conventional load test result. With the same failure criterion

– If this is not possible, reduction in shaft resistance proportional to stress relief should be considered for actual pile performance in service.

b) Single pile in dilatant materials: p n n

n is proportional to stress relief, but the magnitude of n increases by 30% when subjected to stress relief of 300 kPa for the piles

to excavation or after it, due to the two counteracting terms, namely the stress relief factor and the soil dilatancy during shearing:

– Reduction in n due to stress relief should be considered

– But also increase in n due to dilation and yields conservative result; may be ignored in design

c) 3x3 pile group capacity and failure mechanism:

7): Measured capacity of the pile group = 293 MN

each pile is only 40% of the single pile at settlement up to 15% of pile diameter in this study

– Assuming individual pile failure, overestimates capacity by 17%

– Assuming block failure, overestimates capacity by 400%

capacity may be lower than either case and is nonconservative.

byMr. Lim Teck Guan

Fill in the remaining 80 squares with single digits 1-9 such that there is no repeat of the digit in every Row, Column and Block of nine squares. The number at the top left hand corner of the dotted cage indicates the total for the digits that the cage encompasses.

For tips on solving, visit www.1sudoku.com.my © Twin Tree Publishing (Solution is on page 50 of this issue.)

During the Q&A session, there were active discussions of opinions. The technical talk ended with the presentation of a memento to Prof. Charles Ng by the former Chairman of GETD, Ir. Mun Kwai Peng

A Note of Appreciation: The author wishes to express his gratitude to Prof. Charles Ng for providing the presentation slides which have greatly helped in the preparation of this report, and also for the permission granted to upload the presentation slides onto the IEM website for the reference by our members.

1

(Sourced from The Star, 5 September 2012)

(Sourced from The Star, 5 September 2012)

(Sourced from New Straits Times, 23 August 2012)

(Sourced from The Star, 7 September 2012)

(Sourced from The Star, 4 August 2012)

RECENTLY, I met an acquaintance, who happens to be a regular follower of our Safe Tea Time column. This reader has given me a very good suggestion, which is to share the website links of the Environmental, Occupational Health and Safety (EHS) related agencies in Malaysia. Previously, Safe

Department of Occupational Safety and Health

National Institute of Occupational Safety and Health

Tea Time had shared with our readers the safety links of issue, entitled “Where do we stand?”).

Following are some of the recently collected web links of government (or government related) EHS-related sites:

- Main site for Occupational Safety & Health

- Legislation

- License and Approvals

- Competent Persons and Firms

- Approved Personal Protective Equipment

- Approved Training Centres

- Continuous Education Programme (CEP)

- Competency Training and Development

- Consultation

- R&D and Laboratory

Atomic Energy Licensing Board- Atomic Energy related

- Licensing

- Training

Fire and Rescue Department- Fire Safety

- Legislation

- Training

Civil Defence Department- Disaster Operation

- Emergency Response

- Training

Department of Environment- Main site for Environmental related information

- Legislation

- License and Approvals

- Contractors

Environment Institute of Malaysia

- Competency Training and Development

Social Security Organisation- Social Security

- Employee Injury Insurance

- Invalidity

- Return to Work

Ministry of Works- Public Works

Construction Industry Development Board

- Legislation

- Construction Industry

- Training and Development

- Green Card

- Site Safety Supervisor

- Contractor Continuous Development (CCD)

http://www.dosh.gov.my

http://www.niosh.com.my

http://www.aelb.gov.my

http://www.bomba.gov.my

http://www.civildefence.gov.my

http://www.doe.gov.my

http://www.doe.gov.my/eimas

http://www.perkeso.gov.my

http://www.kkr.gov.my

http://www.cidb.gov.my

Ministry of Housing and Local Government

Ministry of Energy, Green Technology and Water

- Building and related Housing Services

- Solid Waste Management Services

- Uniform Building By-Laws

- Other related legislation

- Main site for Energy, Green Technology and Water

- Legislation

Energy Commission- Energy (Electricity and Gas)

- Legislation

Sustainable Energy Development Authority

- Sustainable Energy

- Legislation

- Feed-in Tariff

Malaysia Green Technology- Green Technology

Pharmaceutical Services, Ministry of Health

Food Safety and Quality Division, Ministry of Health

- Green Directory

- Medicine

- Poisons

- Legislation

- Food Safety

- Legislation

Department of Agriculture- Pesticides

- Licensing

- Legislation

Marine Department- Marine related matters

- International Maritime Dangerous Goods

- Legislation

- Conventions

- Training

Department of Civil Aviation- Aviation related matters

- Dangerous Goods Regulations

- Legislation

- Training

- License

Road Safety Department- Road Safety

- Awareness and Promotion

sites than the main sites!

By the way, I intend to publish a follow-up article in the requirements.

http://www.kpkt.gov.my

http://www.kettha.gov.my

http://www.st.gov.my

http://www.seda.gov.my

http://www.greentechmalaysia.my

http://www.pharmacy.gov.my

http://fsq.moh.gov.my

http://www.doa.gov.my

http://www.marine.gov.my

http://www.dca.gov.my

http://www.panducermat.org.my

However, should there be any changes made to the links by the time this article is published, do drop me a note on the broken link. Besides, I could have missed some of the useful links.

If you are keen to share your additional links or would like to point out any changes to the above, just send an email to pub@iem.org.my and you will be linked in.

Tip: Did you know that the providers of global regulatory updates also source most of their information from the local government sites and industry groups? I suppose if you are running a region and your local country EHS heads are performing their job, you

GEOTECHNICAL

by Engr. Richard Ong Hwa Tiam

THE One-Day Workshop on Soil Parameters – Interpretation for Design was organised with the aim to provide engineers with practical knowledge to interpret geotechnical site investigation reports and make assessments on the data for the use in geotechnical engineering designs. The workshop was conducted at Tan Sri Prof. Chin Fung Kee Auditorium, Wisma IEM with an attendance of 66 participants.

The speaker, Mike Dobie, kick-started the workshop by illustrating soil behaviour using the phenomenon which can be observed as one steps on

respectively. He managed to get the participants’ attention, making the participants eager to know more about a number of important geotechnical concepts such as drained and undrained behaviour, soil shear strength and

This was followed by a discussion on soil index properties with the emphasis on meticulous review of the site investigation report data, in order to check on the consistency and reliability of the soils being tested. Dobie commented that index property values are generally plentiful in geotechnical site investigation reports, so they are vital as a means of checking both consistency of the data and the results of other tests, such as soil shear strength.

The second session of the workshop was on soil shear strength where Mike refreshed the participants’ knowledge on principle of effective stress and the appropriate shear strength to be used in design (i.e. drained or undrained shear strength). He also discussed about the procedure for measuring shear strength of soil using shear box test and triaxial test with highlights on the consequences from procedural error in testing.

In the third session on soil consolidation properties, Dobie discussed about the procedures of measuring soil compressibility using oedometer test while guiding the participant through practical examples on the determination

the application of some of the soil parameters and concepts discussed to and the arguments for drained versus undrained analysis.

Throughout the workshop, real examples of soil data and parameters were used to illustrate the various concepts and points made. In some cases, these examples had been arranged as workshop examples for the participants to review and comment on. In other cases, some simple calculations were required. These examples had served to encourage critical assessment of geotechnical data, before making a decision as to how the data may be used in a design.

Indeed, the workshop’s approach in dissecting the topic on interpretation of soil parameters for design had facilitated exchange of ideas during the question and answer session. All in all, the workshop had achieved its objective of imparting practical and useful information to the practising engineers.

by Ir. Lee Peir Tien

GEOTECHNICAL ENGINEERING TECHNICAL DIVISION

THE

Double Track Project from Alor Setar to Padang Besar was recently organised by the Geotechnical Engineering Technical Division (GETD) at the Tan Sri Prof. Chin Fung Kee Auditorium, Wisma IEM. The talk was delivered by Ir. EG Balakrishnan with an attendance of 65 participants. The speaker started his talk with an introduction to some Setar to Padang Besar. He then showed the participants ground from Alor Setar to Bukit Ketri, where soft ground is Bukit Ketri, the railway alignment traverses through rolling ground. Subsequently, the speaker demonstrated how topography and land use could be utilised as an indication of the ground condition, which is a very powerful tool for desk study, especially to demarcate the areas of concern.

Then, the speaker continued to explain to the audience the adopted design methodology for embankment over soft ground. He also presented the stringent settlement design criteria for the double track. He also highlighted the main considerations for selection of adopted ground treatment such as prefabricated vertical drains (PVD) with surcharge and other techniques.

Towards the end of the talk, the speaker presented some settlement monitoring results of a constructed embankment where the recorded settlement was generally in line with embankment with stone column as ground treatment. After an interactive Q&A session, a token of appreciation was presented to the speaker and the seminar ended with a big

AnoticeinvitingnominationsfortheElectionofCouncilMembers for Session 2013/2014 will be posted on the IEM Notice Board and IEM website by 7th December 2012. These nomination and after 7th December 2012.

Thank you.

Dato’ Ir. Pang Leong Hoon

GEOTECHNICAL ENGINEERING TECHNICAL DIVISION

THE Geotechnical Engineering Technical Division had recently organised an evening talk on “Consolidation Settlement” at the Tan Sri Prof. Chin Fung Kee Auditorium, Wisma IEM. The talk was delivered by Ir. Dr. Chan Swee Huat and a total of 51 participants had attended the talk.

The speaker started his talk with an introduction to the geographical areas in Peninsular Malaysia found with soft soils.Hethenexplainedthethreecomponentsofsettlement, namely the immediate settlement, consolidation settlement and secondary compression settlement. In particular, the consolidation process the dissipation of excess pore water pressure with time and accompanied by volume change, was illustrated using a piston and spring analogy.

The speaker then described and illustrated how the onedimensional consolidation test is performed to determine the compression parameters. It was highlighted that the parameters can be obtained.

The determination of pre-consolidation pressure using the Casagrande’s procedure and the determination of

of its simplicity and its lesser variation in determining the

requires a straight line to be drawn in the secondary compression region, which may require extended testing time for exhibition of clear secondary compression effect,

does not necessarily produce a straight line.

The speaker subsequently demonstrated how the consolidation settlement can be calculated in the case of normally consolidated soils and over-consolidated soils. After detailed outline of the basis behind the Terzaghi’s one-dimensional consolidation theory and solution, the speaker discussed and demonstrated how the time rate of consolidation settlement can be estimated. Throughout the talk, example problems were regularly used for the demonstration of various calculations.

appreciation was presented to the speaker. The seminar

Please be informed that the MS standards for cement would be mandatory upon the gazette of the amended CIDB Act. The Cement & Concrete Association of Malaysia (C&CA) as the appointed Standards Writing Organization (SWO) for cement standards in Malaysia, had reviewed and adopted the BS EN 413 as the new MS EN 413 for Masonry Cement. The old MS 794 for Masonry Cement will be superseded and replaced with the new MS EN 413 which is available for purchase at the SIRIM library.

For more information, please contact the C&CA Secretariat at 037492 1368 or cemca@tm.net.my

PROF. Kenichi Soga of Cambridge University, United Kingdom recently delivered a two-hour lecture to about 90 participants on “Landslides: Physical and Numerical Modelling of Large Ground Movements” at the Malakoff Auditorium, Wisma IEM in Petaling Jaya. The event was organised by CESIG, IEM and supported by UTM, GETD, TUSTD, ICE, SEAGS and AGSSEA

Prof. Soga began the lecture by showing the debris in Hawaii in 2003. He then proceeded to show how the

using centrifuge and numerical methods.

Landslides are known to cause loss of lives and property. It is also known that these landslides can move

The traditional way of evaluating the risk of landslide is by slope stability analysis and determining its Factor of Safety. However, this method does not assess the extent and speed of ground movements. Prof. Soga, using advanced computational and physical modelling, the movement of landslides.

Initially, Prof. Soga presented some animations of large-scale model tests on sand embankment that failed from seepage in two different manners. The sand levee that was initially wet or damp failed rather abruptly and more extensive as compared to the dry embankment where gradual failure occurred near its toe. Submarine landslide is known to move massive volumes and can travel at distances of up to 400km with a surface gradient

The key question in understanding submarine landslide impact is how to model the mass velocity and travelling distance correctly.

To further elaborate on this, Prof. Soga presented the latest research work at Cambridge, using a mini-drum centrifuge to model the submarine using suitable gravitational scaling laws. It should be noted that submarine affected by water entrainment, frontal shear and hydroplaning, basal shear,

Advances in numerical methods to solve continuum problems were introduced in the second half of the lecture. While many audiences may be accustomed to the commercially available programmes such as Finite all mesh-based techniques, conventional methods have limitations in simulating very large ground deformation. Particle or mesh-free methods,

consolidation formulation was developed to couple the effect of multi-phase soil and water movements. The model can also include partially saturated ground conditions.

An intriguing note was made concerning experiments on levee failure, properties of the soil, but is also sensitive to the angle of dilation. Remarkably, the MPM method is able to replicate various types of landslide movements, that is, from gradual retrogressive sliding to a more catastrophic failure

In the case of modelling submarine landslides, water entrainment that also highlighted some examples of new opportunities of slope monitoring Cambridge Geotechnical Research Group on slopes near a coastal area applications. For example, for slope monitoring purposes, it can be used to monitor lateral displacements similar to an inclinometer, measure axial strain in soil nails and detect subsurface shallow movement of an embankment. largest interest among the audience during the question and answer session.

We are ISO9001, ISO14001 and OHSAS18001 Certified

THE Highway and Transportation Engineering Technical Division of Institution of Engineers, Malaysia (IEM) recently organised a one-day international symposium on Intelligent Transport System (ITS) at the Armada Hotel in Petaling Jaya. The symposium was attended by 70 participants

The seminar was co-organised with ITS Centre, the University of Tokyo, Japan. It was supported by ITS Malaysia, ITS Japan, Transportation Science Society Malaysia (TSSM) and Universiti Tunku Abdul Rahman (UTAR). A total of 14 speakers from local universities and abroad presented papers on various research projects on ITS.

The symposium commenced with opening remarks from the President of the IEM, Ir. Vincent Chen Kim Kieong; the Director of ITS Centre, Institute of Industrial Science of the University of Tokyo, Japan, Professor Dr Yoshihiro Suda; the President of ITS Japan, Mr. Hajime Amano; and last but not least, the President of ITS Malaysia, Dato’ Ir. Hj. Mohamad bin Husin.

The seminar was divided into four sessions, delivering management, ITS in vehicle control as well as image processing and ITS sustainability.

In the ITS Innovation session, Prof. Mohamed Rehan bin Karim from University of Malaya presented his recent

include its simple installation feature, its ability to detect suitability for a wide range of road-related applications.

Meanwhile, Associate Professor Hiroshi Makino presented his research on infrastructure and vehicle cooperativesysteminJapan.Hestressedthatawell-integrated

from Taiwan highlighted his innovative research in web and cloud taxi services. He demonstrated to the participants that smart taxi services could be provided to users through proper utilisation of internet technology. The proposed system could enhance security in the taxi industry as well as reducing the empty rate of taxi services.

Farhan Mohd Sadullah from University Science Malaysia presented an overview of ITS development in Malaysia. He highlighted the practical issues and challenges in ITS implementation. He urged that there is an urgent need for the experts to learn from past lessons in determining the future strategies. Prof. Masao Kuwahara from Tohoku University presented the application of ITS sensing devices used for data collection. He showed that quality data is a

Prof. Toshio Yoshii from Ehime University presented a development of an area metering control method using the macroscopic fundamental diagram.

accurately. Prof. Edward Chung from Queensland University of Technology, Australia, demonstrated to the participants the utilisation of Bluetooth technology in a travel time study. The sensitivity analysis illustrated that the accuracy of the data collected is dependent on the relationship between travel time and duration (i.e. time for an active Bluetooth device to pass through the Bluetooth scanner detection zone ).

In the Vehicle Control and Image Processing session, Associate Professor Dr Yong Haur Tay from UTAR presented the potential applications of Android in ITS. He depicted that Android can be used as the information dissemination and data acquisition device. Besides, it is a low-cost solution for various high-end ITS applications.

Subsequently, Prof. Katsushi Ikeuchi from the University of Tokyo presented an idea of a four-dimensional virtual city. Based on current setting, the system would allow one to render the past and predict the future development in a city. Prof. Riza Atiq Rahmat from National University

management system. He showed the participants the development of a weigh-in-motion devices. He mentioned that street lighting posts can be

session continued with Prof. Yoshihiro Suda from the University of Tokyo, who presented a paper on sustainable transport. Prof. Yoshihiro Suda also shared with the participants the various ITS strategies that could reduce energy consumption.

In the last session, on Sustainability in ITS, Prof. Takashi Oguchi from University of Tokyo highlighted challenges that involve electric vehicles. The critical issue in promoting electric vehicles is to ensure that the battery power is long enough to support the users’ travel activities. As such, proper modeling of transport planning is needed to predict users’activities.Assistant Professor Dr Sungjoon Hong from University of Tokyo highlighted the framework developed to evaluate carbon dioxide reduction. The proposed framework consists of a micro-simulation model for carbon dioxide emission which has been calibrated and validated properly.

Finally, Prof. Sorawit Narupiti introduced the ITS research activities by Chulalongkorn University, Thailand. There are various on-going research initiatives in the university which involve multi-disciplinary experts.

The seminar had provided a platform for experts to discuss the emerging issues and challenges of ITS deployment. It is anticipated that further collaboration among local and international experts would be established. The seminar ended with the concluding remarks made by Engr. Assistant Professor Dr Hooi Ling Khoo (UTAR), who also took the opportunity to thank the secretariat, the co-organisers, and all the participants for their support.

CHEMICAL ENGINEERING TECHNICAL DIVISION

THE Chemical Engineering Technical Division (CETD) successfully organised the 7th Chem-e-Car Competition in collaboration with Universiti Malaysia Sabah (UMS) in Kota Kinabalu. The teams from Universiti Sains Malaysia (USM) managed to garner the two top spots. The car of Ziolite

line was a clear champion while the second team of USM, the Challengers, beat the team from Army Academy of the Republic of China (A.A. ROC) by a mere 1cm, securing the second placing in the competition

A.A. ROC took part in the Malaysian Chem-E-Car performance which was ahead of 30 teams (amongst 12 Malaysian universities and 3 foreign universities). A total of 33 teams participated in the competition setting another remarkable achievement despite the holding of team from USM and Brave team from Army Academy ROC

while t-Moment from UMS, the host university, won the third place.

Thisyear’scompetitionfurtherboostedtherecognitionof the competition as a stage for undergraduates to showcase their prowess in engineering design and innovation. The competition emphasized on the participants’ creativity in maximising performance of a model car powered by a self-built chemical or fuel cell as its propulsion system. The power required to drive the model car must be generated or converted from chemical energy.

Taking the cue from current worldwide educational trends which emphasize on outcome and continuous learning, the competition seeks to equip future engineers to play an essential role in the development and progress of their countries. Promoting teamwork as one of the major elements, the competition also attempts to promote cooperation between different disciplines by allowing undergraduates from other disciplines to join the team. Experience gained in the competition would be valuable in preparation for their professional careers.

The model car competition focuses on accuracy, testing water (100ml – 500ml). By revealing the load and distance

only about an hour prior to the start of the competition, and having different loads and distances for the two attempts for each model car, the competition further tested the participants’ ability to calibrate their model cars on the spot

model car that comes to a stop nearest to the designated line or distance would be declared the winner.

Out of the 33 teams in this year’s competition, there were two teams from Universiti Gajah Mada and one from Institut Teknologi Sepuluh Nopember of Indonesia. The National University of Singapore returned to the competition after a one year lapse with two teams, while the Army Academy team. The 7th competition was one of the most successfully organised competitions and the Chemical Engineering Technical Division owes this success to the contributions and support from lecturers and students of UMS as well as the IEM Organising Committee.

Theteams,despitetheintensecompetition,demonstrated superb sportsmanship by supporting each other. The winner of the car competition received a cash prize of RM3,000 while the second and third placed teams received cash prizes of RM2,000 and RM1,000 respectively. The results of the competition are presented in the table on page 35.

Table 1: Results of the competition

NoTeam NameBest of Two

1Ziolite (USM)0.02

2Challengers (USM)0.12

3A. A. ROC (Army Academy ROC)0.13

4ZEPHYR (UMS)0.19

5RED LEXUS (UKM)0.24

6t-moment (UMS)0.25

7Spe-k-tronics (IT SN)0.55

8Subali II (UGM)0.56

9Fast 4 (UTP)0.59

10UNSHAKEN (NUS)0.9

11Vector 2.0 (MICET)0.95

12Cross Team (UTAR)1.47

13Brave (Army Academy ROC)1.64

14Rogayah Yippie (MICET)1.79

15Sugriwa II (UGM)1.9

16DAS AUTO (UKM)1.95

17Vermi Energizer 2.0 (UTP)2.15

18BUMBLE BEE (UKM)2.57

19Elechem (USM)2.93

20Turbang (NUS)3.13

21InnoChem (UTAR)3.31

22KUDA BELANG (UiTM)4.66

23EXQUISITE (UNITEN)4.68

24MM’s Car (UMP)4.7

25ALPHA (UM)5.26

26Going Merry (TATiUC)5.54

27FURION (UMS)6.42

28Strikeforce (UMS)6.74

29Chem Troll-E-d (UTAR)8.78

30First Generation (UM)10.24

31The Chequered Flag (SEGi)11.01

32The Pro’s (Curtin Sarawak)11.33

33CHEMIST 221 (UiTM)13.42

The poster competition, held in the afternoon after the model car competition, was aimed at encouraging undergraduates to speak in public and to polish their presentation skills. Participants were given 10 minutes to present their model cars and to describe the propulsion system, as well as the innovative and creative ideas they have adopted in areas such as

performance. Assessment was made based on the following criteria:

a) Description of the chemical reaction/ power source/ stopping mechanism (20%)

b) Design creativity and unique features of the vehicle (20%)

c) Environmental and safety features (20%)

d) Economic aspects (20%)

e) Quality of the poster and team member presentations (20%).

Prefabricated Unit Bathrooms

are ISO9001, ISO14001 and OHSAS18001 Certified

UMS also hosted a pre-competition dinner, where engineeringstudentsfromUMSputupasuperbperformance of songs, dances and martial arts that awed the audience. The performance clearly put an end to the dull and boring “stereotyped” image of engineering students.

opening ceremony accompanied by the Vice-Chancellor of UMS, Y.Bhg. Brig. Jen. Prof. Datuk Seri Panglima Dr Kamaruzaman Hj. Ampon, and the Dean of UMS School of Engineering and Information Technology, Assoc. Prof. Dr

ceremony and presented the prizes to the winners of the competition.

The Organising Committee wishes to take this opportunity to thank and congratulate Universiti Malaysia Sabah for putting up a great show, its hospitality and its cooperative spirit by being a very good host. UMS had mobilised more than 60 students, 20 lecturers, and other support staff to organise the event from arrangement of food to accommodation and logistics.The Organising Committee also wishes to express its gratitude to the judges, the IEM Secretariat and others for making the event a success.

LAFARGE CONCRETE (MALAYSIA) SDN BHD (95483-H)

2, Jalan Kilang, 46050 Petaling Jaya, Selangor Darul Ehsan, Malaysia.

Tel : (603) 7787 2000

Fax : (603) 7781 7675 / 7787 2129 www.lafarge.com.my

The competition has indeed gained a lot of exposure as well as created tremendous interest in the institutions of higher learning, resulting in a number of them stepping forward to indicate their interest in hosting the next competition. After evaluating the proposals from various institutions, the CETD had selected Taylor’s University to be the host for the upcoming 8th Malaysian Chem-E-Car competition which is scheduled to be held in April 2013.

: http://www.llm.gov.my

YOUNG ENGINEERS SECTION, IEM

THE Young Engineers Section (YES) of The Institution of Engineers, Malaysia (IEM) recently organised a tree planting community project at Taman Botani Negara, Shah Alam. This project which is a continuation of various community projects had been organised by YES with the aim of “Giving Back to Society and Nature”. The project was jointly organised by Environmental Management & Research Association of Malaysia (ENSEARCH), which is also a non-governmental organisation (NGO) that serves as a platform to raise awareness about the environment and to strive in making environmental management as a way of life in Malaysia

The opening ceremony was performed by Ir. Choo Kok Beng, Deputy PresidentofIEMtogetherwithIr.ElliasSaidin,VicePresidentofENSEARCH,

favourable response with the participation of about 60 people, including Senior Members of IEM, Committee Members of YES, graduate engineers, lawyers from the KL bar and students of Universiti Tenaga Nasional and Universiti Teknologi Mara. A total of 190 trees were successfully planted along the hilly route at Taman Botani Negara, Shah Alam. The trees planted comprised various local fruit species native to our country.

Not only has this activity increased the number of trees in our country, but it has also increased the income of natives, since all seedlings were purchased from the indigenous community through ENSEARCH. Each of the seedlings was taken as “adopted seedlings” by various organisations and individuals. This project will increase awareness amongst young professionals in our country about the importance of an individual’s responsibility towards society and the environment.

MECHANICAL ENGINEERING TECHNICAL DIVISION

A total of 94 IEM members and guests took part in the IEM 2012 Annual Golf Tournament organised by the Mechanical Engineering Technical Division (METD). The event was recently held at the Bangi Golf Resort. The main objective in organising this annual golf tournament is for fellow engineers to socialise with each other as well as with corporate players within the engineering fraternity. This year, the organiser also took the opportunity to raise funds for Wisma IEM

The shotgun starting event teed off on time at 8.00 a.m. as planned despite a heavy downpour of rain from Petaling Jaya to Bangi at early dawn. However, surprisingly, the weather at the Bangi Golf Course was lovely with cloudy blue skies, without rain.

The mode of play for the tournament was Stableford System-36, which does not require players to declare their latest handicap based on handicap of the day. Each player

Replacing open pipe installations with Silvent compressed air nozzles normally means:

For more information, please contact:

Ck Wong 012-6695954

Gwen Lee 012-5758277

Kejuruteraan Semangat

Maju Sdn Bhd

9 Jalan USJ 10/1D, Taipan 47620

Subang Jaya, Selangor

plays on an individual basis and, to avoid slow play, the player is required to pick up the ball and proceed to the next hole if the Stableford points cannot be attained.

Ir. Mohd. Nor Alias emerged as the champion with a score of 38 net, out-driving the other golfers to win himself the Ir. Tan Sri Abu Zarim Challenge Trophy and a much

Baharin who won a 1-hp air-conditioner with his score of 37, followed by the second runner-up Ir. Loy TW who also scored 37 and received a digital camera.

For the non-members/sponsors category, the winner was Mr. Ho Kam Hoong who obtained a score of 39, and won a 1-hp air conditioner, while the second runner up, Mr. Lau Kok Yin, won a golf bag with his score of 38. The second runner up for this category, Mr. Lee Chok Kai, won a digital camera as well after scoring 38.

A lot of lovely prizes were given out to the winners from 4th to 10th placing. However, the best of them all was the “Hole-in-One” prize which was a 2-hp air conditioner, but none of the players managed to win it. There were also Novelty Prizes for the Longest Drive, Nearest to the Pin and Nearest to the Line as well as the Bull’s Eye category. No one managed to win the Bull’s Eye and the amount of RM1,260 collected was donated to the IEM Building Fund.

The prizes were given away by Y.B. Senator Dato’ Ir Donald Lim Siang Chai who was also the guest of honour at

the luncheon attended by the IEM President, Ir. Vincent Chen Kim Kieong, Ir. Noor Hisham bin Yahaya, the golf convener and the organiser of the event, and Ir. Gopal Narian Kutty who was the “emcee” for the prize presentation ceremony.

The prizes of the competition were electrical appliances combined with golf products which were different from the prizes offered in the previous years. The IEM and the organisers of the event would like to thank all the sponsors of the Golf Competition for their donations. The Organising Committee wishes to thank the following sponsors for their golf goodies and contributions:

1. ACSON Sdn. Bhd.

2. IMZ Sdn. Bhd. (Mitsubishi)

3. Dimension Publishing Sdn. Bhd.

4. Nehemiah Reinforced Soil Sdn. Bhd.

5. Boehringer Ingelheim (M) Sdn. Bhd.

6. Topaire Sales & Services Sdn. Bhd.

7. Tenaga Nasional Berhad.

At the end of the prize-giving ceremony, the organisers of the Golf Competition, Mechanical Engineering Technical Division (METD) presented a cheque of RM20,000 to the IEM President as the contribution from the proceeds of the golf tournament towards the IEM Building Fund for Wisma IEM. In his speech, the President thanked the Technical Division for their hard work. Subsequent to this, Y.B. Senator Dato’ Donald Lim pledged a donation of RM100,000 to the IEM Building Fund. Y.B. hoped that his gesture will entice more IEM members to come forward to generously donate to the IEM Building Fund. Y.B. felt that with the membership of over 25,000 members the remaining loan of RM6 million should be easily settled if each member could donate to the fund.

Results of the scores are as follows:

Ir. Mohd Nor Alias938

Ir. Hj Baharin1037

Ir. Loy TW1537

Ir. Nik Aries836

Ir. David Tan SK1536

Ir. Khalid Hassan1936

Ir. Khairul Anuar2336

Ir. Gopal Narian Kutty1835

Ir. Cha Hong Kam1935

Ir. Noor Hisham Yahaya2435

Mr. Ho Kam Hoong1439

Mr. Lau Kok Yin1238

Mr. Lee Chok Kai1338

Mr. Peter Tan1438

En. Mohd. Hanapi1438

Mr. Ong Kiat Lee1538

En. Mohd Noor837

En. Anuar Hamid1137

En. Wan Rasdi1437

En. S M Salim1437

The winners of the Novelties are as follows:

Hole 2Mr. Jeffrey Low14210

11En. Mohd Seehan1770

Hole 3Mr. Bernie Ooi24200

Hole 13Mr. Che Wei Li241

Hole 5Mr. David Chan16277 m

Hole 14En. Wan Shah18363 m

The Organising Committee wishes to express its sincere gratitude and thanks to all sponsors, participants and the secretariat staff who made this a successful event in the calendar of IEM.

EVER since the enforcement of Renewable Energy Act 2011, Feed-in Tariff has become a popular topic amongst the engineers and the public community. The Electrical Engineering Technical Division (EETD) of the Institution of Engineers, Malaysia (IEM) and Institution of Engineering and Technology (IET) Malaysia Network recently conducted a talk entitled, ‘The Malaysian Feed-In Tariff’ at the Tan Sri Prof. Chin Fung Kee Auditorium, Wisma IEM

This technical talk was presented by Ir. Ali Askar bin

(COO) of Sustainable Energy Development Authority Malaysia (SEDA) which is given the task to administer and manage the implementation of the feed-in tariff mechanism. The talk was attended by a total of 65 participants who come from various backgrounds.

Renewable Energy (RE) and introducing some of the RE available such as wind, ocean, solar, water, biomass, tidal and geothermal to the participants.

Ir. Ali Askar then provided the background of the RE development in Malaysia which started with the launching of the Small Renewable Energy Power Programme (SREP) on 11 May 2001. Under the SREP programme, the small RE power generation plants are allowed to sell the electricity to the Utility Company through the Distribution Grid System based on direct negotiated rate on a “willing seller, willing buyer” and “take and pay” basis. Under the SREP programme, the utilisation of all types of RE including biomass, municipal waste, solar, mini-hydro and wind are allowed.

Malaysian Building Integrated Photovoltaic (MBIPV) Project was introduced by Pusat Tenaga Malaysia (PTM) which is currently known as Malaysian Green Technology Corporation to focus on the market development for BIPV technology with the implementation of Suria 1000 project where a Government subsidy was provided for roof-top PV installation based on a bidding system until year 2010.

He explained that under the 8th Malaysian Plan, RE has 5% of the energy mix. Different RE capacity targets were included in the 9th and 10th Malaysian Plans. Ir. Ali Askar also described the development of the Government Policies on RE which started since the approval of the National Renewable Energy Policy & Action Plans by the Government of Malaysia on 2nd April 2010 until the RE Act was enforced in 1st Dec 2011.

He highlighted the three options which have been namely:

i. The subsidies through the previous Suria 1000 Project;

ii. The Renewable Portfolio Standards which is popular in the United States of America (USA) but was found to be less successful compare to Feed-in Tariff (FiT); and

iii. The Feed-in Tariff where small independent producers can sell their generated energy to the Utility at a Germany, China, Japan and Europe.

Ir. Ali Askar also highlighted the national RE targets which are as follows:

He explained that the tenth Entry Point Project (EPP) on Solar Power Capacity Initiative under the Oil, Gas and Energy National Key Economic Area (NKEA) provides the following target of solar power capacity:

He also highlighted that the Feed-in Tariff (FiT) has been introduced to achieve the numerous targets on RE. FiT that is produced from indigenous RE resources to be institutions.

Ir. Ali Askar also explained that Malaysia uses a legal instrument for FiT implementation via RE Act 2011, which includes the following:

i. Access to the Power Grid is guaranteed since the Utilities are legally obliged to accept all electricity generated by RE private producers;

ii. An FiT rate which is high enough to produce Return on

iii. The RE Fund which was established under the RE Act 2011 will be used to pay for the FiT rates and to guarantee payment over the contract period.The source of the RE Fund is 1% collection from the consumers’ electricity bills, as decided by Government of Malaysia in June 2011; and

iv. SEDA has been entrusted to implement the FiT.

clauses in the Renewable Energy Act 2011, namely the:

i. Section 4: Eligibility for participation in Feed-In-Tariff system – RE installation 30MW (or such higher installed capacity as may be approved by the Minister)

ii. Section 14: Priority of purchase and distribution

iii. Section 16: Payment of Feed-In Tariff

iv. Section 17: Degression of Feed-In Tariff

v. Section 23: Renewable Energy Fund.

Besides the RE Act 2011, Ir. Ali Askar also mentioned the relevant subsidiary legislations on RE to the participants.

Subsequently, he further elaborated on the FiT Schedules for various RE namely Biogas, Biomass, Small Hydropower

Web Portal. He also presented the planned annual RE Quota for 2012-2014 and the FiT quota as of 30th June 2012. The details are illustrated in Table 1 and 2.

the online application process of FiT using the SEDA Web Portal, beginning from the RE developer account creation up to the application of RE quota.

He also shared with the participants the problems faced by FiT, such as:

i. The non-user friendly issue of the e-FiT; ii. The excessive demand for solar PV quota; iii. The lack of interest in other technologies; and

iv. The slow action by Tenaga Nasional Berhad (TNB) in processing the interconnection facilities and signing of REPPAs.

He also pointed out that SEDA is encouraging the research and development (R&D) in all RE technologies associated with potential resources in Malaysia which is currently not included in the FiT. Those RE technologies include geothermal, wind, tidal, wave and ocean thermal.

during which he engaged with members of the audience at a personal level. Before he bode farewell, the speaker was presented with a memento by Ir. Chong Chew Fan on behalf of EETD and IET Malaysia Network, as a token of appreciation.

For three decades, engineering firms and transportation agencies have depended on InRoads for interchange, roundabout, and corridor design, survey data reduction, site development, bridge modeling, sanitary and storm water network design, and production of construction staking reports.

Now available as a standalone product, Power InRoads includes all the powerful capabilities of MicroStation®, along with dynamic 3D modeling functionality, complete mapping tools, and design automation to integrate all project phases, teams, and locations – ensuring your designs are ready for construction, operation, and rehabilitation.

The President of the Organising Committee of the Engineers Association of Timor Leste, Mr. Armando de Almeida and the President of the Accounting Association of Timor Leste, Mr. Apolinario Guterres paid a courtesy visit to IEM on 20th June 2012. The delegation sought assistance and guidance from IEM on formulating a work plan on the range of activities as an association, covering issues such as membership, internal organisational and professional development as well as assessment of the standard of existing tertiary educational programmes in Timor Leste.

Technological Associations in Malaysia (COSTAM) led by its President, Prof. Ir. Dr Ruslan Hassan (who is also an IEM Vice President) had a meeting with Y.B. Datuk Seri Panglima Dr Maximus Johnity Ongkili, Minister of Science, Technology and

to discuss on the issue of ‘Lack of Students Studying Science’ which is the current situation in the country.

The Annual Hari Raya Gathering Dinner was hosted by the Young Engineers Section (YES) of IEM on 5th September 2012. The guests included members of the IEM Council, Executive Committee, Standing Committees, Technical Divisions, YES volunteers and, last but not least, IEM Secretariat.

by Ir. Chin Mee Poon

IN August 2011, my wife and I spent 10 days trekking in the Swiss Alps. There were six other Malaysians in the group. We started from Chamonix, a famous French ski resort at the foot of Mont Blanc, the highest peak of the Alps. We would normally start our daily trek from a valley, where we would scale a mountain slope to reach a pass, and then descend into the next valley to put up for the night in a guest house located in a quaint little village, while enjoying the spectacular scenery on the way.

Trekking in the Alps was an exhilarating experience The villages nestling in the valleys that we were fortunate enough to visit are actually connected to one another by vehicular roads. Thus, one can quite easily visit all of them by car and still have a good time enjoying the mountain views from ground level. However, we had chosen to trek over the mountains to have a better appreciation of the beauty of the Swiss Alps from different angles.

On the ninth day of our trekking, we reached Zermatt around noon. Zermatt is a very charming town located at the foot of the Matterhorn and by far, it is the most famous one amongst the Alpine peaks. Its shape is easily recognisable as most people would have seen an image of it somewhere.

when I was still a young boy, but that cigarette brand was no longer in the market.

The common name of this 4,478m high peak actually comes from two German words, Matte, which means “meadow”,and Horn,whichimplies“peak”.TheMatterhorn’s Italian name is Monte Cervino and its French name, Mont Cervin. The Matterhorn was one of the last great Alpine end of the golden age of alpinism.

Some of us trekked in the shadow of the Matterhorn on the last day of our trek. We had a fantastic view of the Matterhorn as we moved along the mountainside separated from the peak by a river valley.

Zermatt is a famous resort town for mountaineering and be outnumbered several folds by tourists during the peak seasons. Nevertheless, the many beautifully-decorated buildings lining its main street make the place very pleasurable to stroll in. Zermatt is also the western terminus for the Glacier Express rail service connecting St. Moritz to the Matterhorn – Gotthard Bahn (MGB), one of the 8 scenic train routes in Switzerland.

Date: 10 September 2012

To All Members,

The following candidates have been approved to sit for the Professional Interview for 2012.

to passing the year 2012 Professional Interview.

Honorary Secretary,

Name

CHEMICAL ENGINEERING

EESAN MARKANDU A/L

KANAGASABAI BE HONS (BIRMINGHAM) (CHEMICAL, 2001)

CIVIL ENGINEERING

MOHD SHAHRIL BIN MOHDBE (HONS) (UPM) (CIVIL, 2002)

MOK YEW CHEONGBSc (ALABAMA) (CIVIL, 2001)

MONITHAA/P ANTHONISAMY BE HONS (USM) (CIVIL, 2004)

WONG SIONG ING, RITABE HONS (UTM) (CIVIL, 2005) MSc (NATIONAL UNIVERSITY OF SINGAPORE) (CIVIL, 2011)

ELECTRICAL ENGINEERING

MOHD GHAZALI BIN SHAARI BE HONS (UTM) (ELECTRICAL, 2001) MSc (UTM) (ELECTRICALPOWER, 2009)

MOHD HAFIDZ BIN JAMIL BE (HONS) (UM) (ELECTRICAL,2004)

SAFRI BIN IBRAHIM BE HONS (UiTM) (ELECTRICAL, 2004)

SANJAY KRISHNAA/L KRISHNAN BE HONS (UNITEN) (ELECTRICAL POWER, 2002)

ELECTRONIC ENGINEERING

IRYANI BINTI

MOHAMED RAWI BE HONS (UTM) (ELECTRICALTELECOMMUNICATION, 2002)

LAU KEAN HONG BE HONS (MONASH) (ELECTRICAL & COMPUTER SYSTEMS, 1996)

MATERIAL ENGINEERING

SALINA BINTI BUDINBE (HONS) (USM) (MATERIAL, 1993) MSc (USM) (MECHANICAL, 2003) PhD (USM) (2011)

MECHANICAL ENGINEERING

CHEW TZE SEANGBE HONS (UNITEN) (MECHANICAL , 2007)

MOHD SAFAR

BIN MAHFODZ BE HONS (UNITEN) (MECHANICAL , 2002)

MUHAMMAD SHAZWAN

BIN ZAKARYA BSc (CARNEGIE MELLON) (MECHANICAL, 2001)

NORZELAWATI

BINTI ASMUIN BE HONS (UKM) (MECHANICAL & MATERIALS, 1994) MSc (UPM) (AEROSPACE, 2000)

Solution for 1Sudoku published on page 20 of this issue.

TRANSFER APPLICANTS

Name

CHEMICAL ENGINEERING

45348CHO KAI SHINBE HONS (UMS) (CHEMICAL, 2004)

42438MOHD AZAHAR BIN MOHD ARIFF BSC (ARIZONA) (CHEMICAL, 1996)

CIVIL ENGINEERING

28044BEGUM IRDAWATI BINTI DOWLAD RAHUMAN

BSC HONS (UTM) (CIVIL, 2001) MSC (UPM) (HIGHWAY & TRANSPORT, 2006)

19953CHE BAKAR BIN CHE SOH BE (HONS) (UPM) (CIVIL,1999)

44132CHEW WAN CHIUBE HONS (ADELAIDE) (CIVIL & STRUCTURAL, 2006)

27103CHIN CHING WEIBE (HONS) (USM) (CIVIL, 2007)

41147KENNEDY @ MOHAMMAD ALFATIH BIN SARNANG BE HONS (UiTM) (CIVIL, 2009)

22258LEE WEI THIAMBE HONS (LEEDS) (CIVIL, 1999)

27563TING LEE YUNGBE HONS (UMS) (CIVIL, 2006)

19406WONG KIM CHEN @ DICKSON WONG BE HONS (NEWCASTLE) (CIVIL, 1998)

ELECTRICAL ENGINEERING

29041CHAN KAR MUNBE HONS (MALAYA) (ELECTRICAL, 2006)

24231FAIZAL BIN MOHD DOM BE HONS (UNITEN) (ELETRICAL & ELECTRONIC, 2001) MSC (UTM) (ELECTRICALPOWER, 2009)

43909JAFNI BIN ALIAS @ SULONG BE HONS (UTM) (ELECTRICAL, 2000)

29738LEE CHOO YONGPOSTGRAD DIP (EC) (2009) ME (UTM) (ELECTRICAL, 2008)

5 – 6 December 2013

Venue: Singapore

6287

3578 4 16 92

A MONTH from the date of

TRANSFER APPLICANTS Name

ELECTRONIC ENGINEERING

26766SAIFUL KADAR BIN SAIFUDDIN BE HONS (UTM) (ELECTRICAL, 2000)