Soaring 190 metres above the mighty Mississippi River and its St Louis, Missouri, home, the gleaming stainless steel Gateway Arch is the centrepiece of the Gateway Arch National Park and a popular attraction that draws more than three million visitors each year. In 2009, a plan was developed to dramatically expand and redesign the landscaping and facilities around the base of the Gateway Arch to integrate it more fully with downtown St. Louis and provide the visitor experience befitting one of the world’s greatest monuments. The complete renovation of the pre-existing 32,000 square metre Museum of Westward Expansion, the construction of a 90 metre wide park extension over an adjacent highway, flood abatement measures, revised landscaping for the 91-acre park, and the renovation of two major plazas that lead west from the park into downtown St. Louis.

The $380 million Gateway Arch renovation and expansion took four years to complete. McCarthy Building Companies, Inc., the country’s oldest privately held national construction company, was the primary general contractor for the Gateway Arch Park redevelopment. Built below the publicly accessible level of the new visitor centre is a network of mechanical tunnels, measuring 3 metres high, 4 metres wide, and running a total of 165 metres. The tunnels carry various utilities, including steam and electrical lines, and provide pathways for employees to traverse the facility without entering public spaces. These tunnels required Xypex Concentrate and Xypex Modified to ensure a watertight and durable concrete solution. For more information on how our solutions can provide sustainable benefits for your concrete assets, please visit our website at www.xypex.com.au or LinkedIn Page.

Tel: +603-51928186 Fax: +603-51926826

Number 11, NOVEMBER 2018IEM Registered on 1 May 1959

Majlis Bagi s es i 2018/2019 (ie M Coun C il s es sion 2018/2019)

ya N g D I p ER tua / pRE s IDEN t

Ir. David Lai Kong Phooi

tIMB ala N ya N g D I p ER tua / D E puty pRE s IDEN t

Ir. Ong Ching Loon

n ai B Yang Dipertua / Vi C e p re si D ent s

Ir. Prof. Dr Ruslan bin Hassan, Ir. Lai Sze Ching, Ir. Lee Boon Chong,

Ir. Prof. Dr Norlida bt Buniyamin, Ir. Prof. Dr Jeffrey Chiang Choong Luin, Ir. Ellias Saidin, Ir. Gopal Narian Kutty

s etiausaha Kehor M at / h onorarY s eC retarY

Ir. Mohd Khir bin Muhammad

B ENDaha RI K E h ORM at / hONOR a Ry tRE asu RER

Ir. Dr Tan Chee Fai

B EK as ya N g DI p ER tua t ER a K h IR / IMMEDI at E past pRE s IDEN t

Ir. Dr Tan Yean Chin

BEK as ya N g DI p ER tua / past pRE s IDEN t s Y.Bhg. Academician Tan Sri Dato’ Ir. (Dr) Hj. Ahmad Zaidee bin Laidin, Y.Bhg Dato’ Ir. Dr Gue See Sew, Y.Bhg. Dato’ Paduka Ir. Prof. (Dr) Haji Keizrul bin Abdullah, Y.Bhg. Academician Dato’ Ir. Prof. Dr Chuah Hean Teik, Ir. Choo Kok Beng

Wa K il aWa M / Ci V il r epre sentati V e

Ir. Dr Lee Yun Fook

Wa K il M e K ani K al / MeC hani C al r epre sentati V e

Ir. Fam Yew Hin

Wa K il e le K t r i K / e leC tri C al r epre sentati V e

Ir. Lim Kim Ten

Wa K il s tru K tur / s tru C tural r epre sentati V e Ir. Dr Ng Soon Ching

Wa K il Ki M ia / Che M i C al r epre sentati V e Ir. Prof. Dr Lee Tin Sin

Wa K il lain-lain D isplin / r epre sentati V e to other Dis C ipline s Ir. Roznan bin Abdul Rashid

Wa K il M ulti M e D ia Dan i C t / i C t an D Multi M e D ia r epre sentati V e Ir. Dr David Chuah Joon Huang

Wa KI l Ju R ut ER a Wa NI ta / W OM a N EN g INEER s R E p RE s EN tat IVE

Ir. Mah Siew Kien

ahli M a jlis / Coun C il Me MB er s

Ir. Assoc. Prof. Dr Ahmad Kamil bin Arshad, Ir. Dr Tan Kuang Leong, Ir. Hoo Choon Sean, Y.Bhg. Lt. Jen. Dato’ Wira Ir. Ismail bin Samion (Ret. RMAF), Y. Bhg. Dato’ Ir. Hj. Anuar bin Yahya, Ir. Mah Way Sheng, Ir. Gunasagaran a/l Kristnan, Ir. Chen Harn Shean, Ir. Mohd Aman bin Hj. Idris, Ir. Wong Chee Fui, Ir. Prof. Dr Leong Wai Yie, Ir. Razmahwata Mohd Razalli, Ir. Abdul Razak Yakob, Ir. Yau Chau Fong, Y. Bhg. Dato’ Ir. Foong Choy Chye, Y. Bhg. Dato’ Ir. Kisai bin Rahmat, Y. Bhg. Dato’ Ir. Nor Hisham bin Mohd. Ghazali, Ir. Vincent Wong Khien Ngie, Ir. Dr Jeyanthi Ramasamy, Ir. Dr Wang Hong Kok, Ir. Yam Teong Sian, Y. Bhg. Dato’ Ir. Hj. Fakharazi bin Hj. Wahijan, Ir. Yasotha Ramachandran Chetty, Ir. Mohmad Asari bin Daud, Ir. Salimi bin Md Saleh, Ir. Dr Lai Khin Wee

Wa K il B ahagian jurutera sis Wa Z ah / Young engineers seC tion

RE p RE s EN tat IVE s

Yew Weng Kean, Addison Koh, Tony Ong, Kuugan Thangarajoo, Cheah Khai Chun pengerusi C aWangan / B ran C h C hair M an

1. Pulau Pinang: Ir. Ting Chek Choon

2. Selatan: Ir. Teo Ki Yuee

3. Perak: Ir. Abdul Razak bin Ali

4. Kedah-Perlis: Ir. Haji Abdullah bin Othman

5. Negeri Sembilan: Ir. Dr Oh Seong Por

6. Kelantan: Ir. Abrizan bin Abdul Kadir

7. Terengganu: Ir. Atemin bin Sulong

8. Melaka: Ir. Sreedaran a/l Raman

9. Sarawak: Ir. Haidel Heli

10. Sabah: Ir. James Yong Hon Min

11. Miri: Ir. Prof. Dr Lau Hieng Ho

12. Pahang: Y. Bhg. Dato’ Ir. Sharuddin bin Mohd Simin ahl I JaWata NK uas a IN f ORM as I Da N p ENERBI ta N / stan D ing C o MM it tee on in F or M ation an D pu B li C ations 2018/2019

Pengerusi/Chairman: Ir. Prof. Dr Ruslan Hassan Naib Pengerusi/Vice Chairman: Ir. Dr Lee Yun Fook Setiausaha/Secretary: Ir. Lau Tai Onn Ketua Pengarang/Chief Editor: Ir. Prof. Dr Ruslan Hassan Pengarang Buletin/Bulletin Editor: Ir. Abdul Razak Yakob Pengarang Prinsipal Jurnal/Principal Journal Editor: Ir. Dr David Chuah Joon Huang Pengerusi Perpustakaan/Library Chairman: Ir. C.M.M. Aboobucker

Ahli-Ahli/Committee Members: Ir. Ong Guan Hock, Ir. Yee Thien Seng, Ir. Chin Mee Poon, Ir. Dr Oh Seong Por, Ms. Michelle Lau Chui Chui, Ir. Prof. Dr Abdul Aziz bin Abdul Samad, Ir. Dr Wang Hong Kok, Ir. Razmahwata bin Mohd Razalli, Dato’ Ir. Nor Hisham Mohd Ghazali, Ir. Yasotha Ramachandran Chetty, Dr Sudharshan N. Raman

l EMB aga p EN ga R a Ng/EDI tORI al BO a RD 2018/2019 Ketua Pengarang/Chief Editor: Ir. Prof. Dr Ruslan Hassan Pengarang Buletin/Bulletin Editor: Ir. Abdul Razak Yakob Pengarang Jurnal/Journal Editor: Ir. Dr David Chuah Joon Huang

Ahli-ahli/Committee Members: Ir. Lau Tai Onn, Ir. Ong Guan Hock, Ir. Yee Thien Seng, Ms. Michelle Lau Chui Chui, Ir. Dr Oh Seong Por, Ir. Dr Wang Hong Kok, Ir. Dr Lee Yun Fook, Ir. Yasotha Ramachandran Chetty, Dr Sudharshan N. Raman

Secretariat: Janet Lim, May Lee

th E IN s t I tut ION O f EN g INEER s, M alays I a Bangunan Ingenieur, Lots 60 & 62, Jalan 52/4, P.O. Box 223, (Jalan Sultan), 46720 Petaling Jaya, Selangor Darul Ehsan. Tel: 603-7968 4001/4002 Fax: 603-7957 7678 E-mail: sec@iem.org.my Homepage: http://www.myiem.org.my

5

COVER NOTE & EdiTOR’s NOTE

6 - 13

COVER sTORy

Malaysia’s Upstream Oil & Gas Asset Decommissioning - on the verge of growth and expansion

15 - 21

fEaTuRE aRTiClEs

Well Plugging & Abandonment Oil & Gas Asset Decommissioning ......................15

Readiness of Hook-Up and Commissioning Works .................................................................19

22

New Penang Hill Railway 24 safE TEa TiME Safety in Food Preparation

ENGiNEER’s lENs

fORuMs

PETRONAS

Drilling Engineering: The Art of Making a Hole.....25

Pipeline Integrity Challenges and Technological Advancement ................................29

Technical Visit to Melaka Gateway .....................32

37

43

NEWs fROM BRaNCH

Technical Visit to Kibing Group (M) Sdn. Bhd., Negeri Sembilan

ENGiNEER’s adVENTuREs

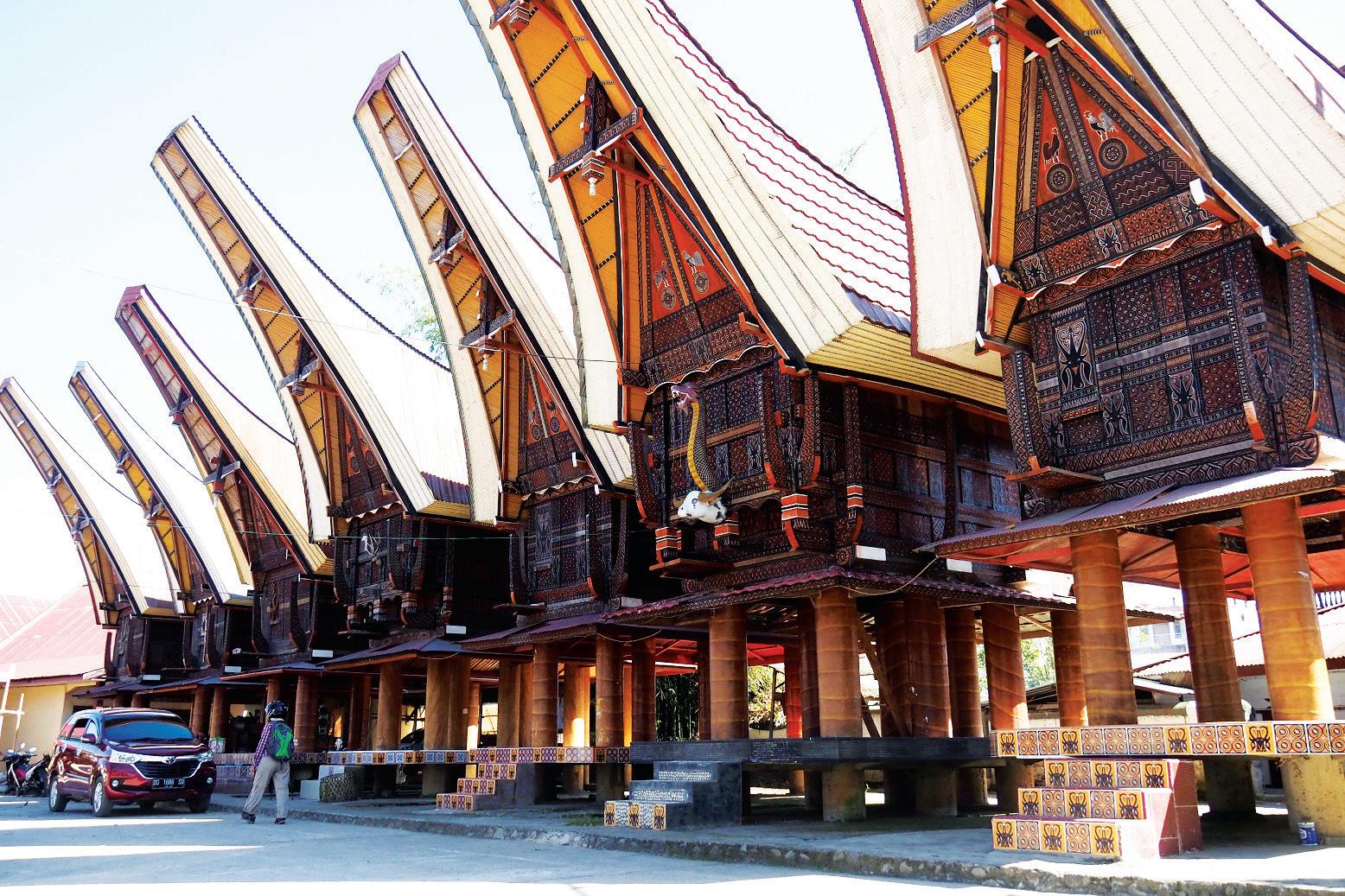

Hassles to Get a Glimpse of Torajan Culture

piNk paGE Professional Interview

45

25- 33 BluE paGE Membership List

DIMENSION PUBLISHING SDN. BHD. (449732-T)

Level 18-01-03, PJX-HM Shah Tower, No. 16A, Persiaran Barat, 46050 Petaling Jaya, Selangor Darul Ehsan, Malaysia. Tel: +(603) 7493 1049 Fax: +(603) 7493 1047

E-mail: info@dimensionpublishing.com Website: www.dimensionpublishing.com

ROBERT MEBRUER

PATRICK LEUNG

SHIRLEY THAM shirley@dimensionpublishing.com

JOSEPH HOW joseph@dimensionpublishing.com

TAN BEE HONG bee@dimensionpublishing.com

PUTRI ZANINA & ZOE PHOON putri@dimensionpublishing.com zoe@dimensionpublishing.com

SUMATHI MANOKARAN sumathi@dimensionpublishing.com

NABEELA AHMAD beela@dimensionpublishing.com

THAM CHOON KIT ckit@dimensionpublishing.com YEN YIN yenyin@dimensionpublishing.com

For advertisement placements and subscriptions, please contact: DIMENSION PUBLISHING SDN. BHD. (449732-T)

Level 18-01-03, PJX-HM Shah Tower, No.16A, Persiaran Barat, 46050 Petaling Jaya, Selangor Darul Ehsan, Malaysia. Tel: +(603) 7493 1049 Fax: +(603) 7493 1047

E-mail: info@dimensionpublishing.com

Subscription Department E-mail: info@dimensionpublishing.com

Printed by

PERCETAKAN SKYLINE SDN. BHD. (135134-V) No 35 - 37 Jalan 12/32B, TSI Business Industrial Park, Off Jalan Kepong, 52100 Kuala Lumpur. Mailer

SM UNIQUE MAILING SERVICES SDN. BHD. (44277-W) 80, Jalan Nadchatiram Satu, Taman Taynton View, Cheras, 56000 Kuala Lumpur, Malaysia. Tel: +(603) 9132 9192

JURUTERA MONTHLY CIRCULATION : 22,500 COPIES

Submission or placement of articles in JURUTERA could be made to the:Chief Editor

THE INSTITUTION OF ENGINEERS , MALAYSIA (IEM) Bangunan Ingenieur, Lots 60 & 62, Jalan 52/4, P.O. Box 223 (Jalan Sultan), 46720 Petaling Jaya, Selangor. Tel: +(603) 7968 4001/4002 Fax: +(603) 7957 7678 E-mail: pub@iem.org.my or sec@iem.org.my IEM Website: http://www.myiem.org.my

© 2018, The Institution of Engineers, Malaysia (IEM) and Dimension Publishing Sdn. Bhd.

PUBLICATION DISCLAIMER

The publication has been compiled by both IEM and Dimension with great care and they disclaim any duty to investigate any products, process, services, designs and the like which may be described in this publication. The appearance of any information in this publication does not necessarily constitute endorsement by IEM and Dimension. There is no guarantee that the information in this publication is free from errors. IEM and Dimension do not necessarily agree with the statement or the opinion expresssed in this publication.

COPYRIGHT

JURUTERA Bulletin of IEM is the official magazine of The Institution of Engineers, Malaysia (IEM) and is published by Dimension Publishing Sdn. Bhd. The Institution and the Publisher retain the copyright over all materials published in the magazine.

No part of this magazine may be reproduced and transmitted in any form or stored in any retrieval system of any nature without the prior written permission of IEM and the Publisher.

by Ir. Mohd Azwira bin Mohd Azmi Chairman, Oil, Gas and Mining Technical Division (OGMTD)

ngineers are usually very excited when a new project starts as this is where they will see their vision and hard work turn into a money making tool and prove their worth. A new project can be the discovery of a new oil well, project development and construction of new facilities or even the start of operations.

But when a project reaches its economic limit and is no longer profitable, operations must cease and the facilities decommissioned. Many forget about this part as it will happen only 30-50 years later. Decommissioning is a crucial part of the project, with its own planning and execution, to ensure public safety and minimal impact on the environment.

This month, the focus is on Oil and Gas Asset Decommissioning and Encik Muhammad Zamri Jusoh, Vice President of Malaysia Petroleum Management, PETRONAS, shares with us his thoughts on and knowledge of decommissioning activities.

There is a huge opportunity for engineers to develop this specific experience and skill, knowledge and capability and to provide services in O&G Asset Decommissioning outside of Malaysia.

Iam excited about this month’s issue because OGMTD is focusing on the theme, Oil & Gas Asset Decommissioning. Yes, it plainly means curtains down. What do we do when it all ends? No tears, no standing ovation but just hard work to ensure the environment is restored to its natural state, as much as is practically possible.

There’s a vast opportunity in this business because it’s not just Malaysia but the rest of the world is also heading in the same direction. So get yourselves prepared. Read JURUTERA!

Pssst..... do you know that IEM will be celebrating its 60th Anniversary in 2019? Yes, we are! For the April 2019 issue, the Editorial Board is planning for a special bumper issue to commemorate the event. If you want to be part of this historical event, submit your articles about IEM. If you have old photographs of IEM or IEM events that you’d like to share, this is the opportunity.

In seeking to ensure everyone benefits more as a member, IEM has launched a “What Do You Want” survey. You will be receiving details in your email soon. We welcome feedback to find out what else we can do for members. The JURUTERA Readership Survey is also incorporated in the email. So exercise your rights and tell us what you want!

The Editorial Board would also like to wish “Happy Deepavali” to all Malaysians who are celebrating the Festival of Lights.

Let’s continue to engineer our country to greater heights!

Decommissioning of oil and gas (O&G) assets is the dismantling, removal and safe disposal of installed structures and associated infrastructures of O&G assets at the end of their operational life. It is also called abandonment.

Decommissioning has gained a lot of attention in recent years. It is the duty of each and every one in the petroleum industry to develop awareness on good decommissioning practices to ensure sustainable petroleum exploitation practices, and at the same time pay due care towards the preservation of our natural environment.

PETRONAS is a state-owned, multinational Oil & Gas corporation with proven value driven success across a fully integrated O&G value chain. MPM is the regulatory unit under PETRONAS accorded with the authority to regulate the upstream oil & gas industry in Malaysia. The Vice President of Malaysia Petroleum Management (MPM), Encik Muhammad Zamri Jusoh, tells JURUTERA how this is done. Encik Zamri begins with defining “decommissioning” in the context of the industry and explaining the role played by PETRONAS.

Decommissioning, or Abandonment of oil and gas assets can be simply described as the dismantling, removal and safe disposal of the installed structures and associated infrastructures of oil and gas assets at the end of their operational life. PETRONAS, being the custodian to manage the sustainable exploitation of Malaysia’s petroleum resources, has as one of its duties the authority to regulate the Upstream decommissioning activities in the country, in accordance with the applicable statutory and contractual obligations.

When asked about the quantum of abandonment in Malaysia, Encik Zamri says that, from a timeline perspective, abandonment activities are now on the verge of growth and expansion, with some very large projects either underway or in the planning stages.

While more matured O&G regions have undertaken waves of abandonment activities in the past decade, it is only recently that South East Asia is facing the emerging reality of abandonment. Just like all the challenges that the industry has faced in the past, tackling abandonment will require collaboration between PETRONAS (as Host Authority) and Production Sharing Contractors (PSC), Service Providers and other relevant stakeholders.

Looking at the country’s abandonment landscape, Encik Zamri says the challenges the industry is facing are significant. Abandonment activities require huge capital and their execution is likely to span several decades. As such, activities should be carried out safely and with due care to protect the environment.

It has been over a century since the Malaysian petroleum industry was first established in 1910 in Sarawak. In 1974, the Petroleum Development Act (PDA) was enacted by the Malaysian Parliament and on 17 August that same year, PETRONAS was incorporated.

Today, estimates show that 40% of PETRONAS’ structures and 37% of its pipelines have been in operation for more than 30 years. The number of depleted well strings now stands at 11% as compared to active strings and continues to grow.

From these statistics, it’s obvious that abandonment activities will increase. As such, Encik Zamri says, it is a must to maintain the highest standards of safety and asset integrity, regardless of whether the oil price is high or low and to be prepared to carry out abandonment activities with minimal environmental impact. Safety is something that PETRONAS will never compromise on, he adds.

Abandonment is a relatively new industry here. In the past 15

Zamri Jusoh, Vice President of Malaysia Petroleum Management, joined PETRONAS in 1991. He also sits on the board of various PETRONAS subsidiaries as well as Malaysia-Thailand Joint Authority (MTJA) and Malaysia Petroleum Resources Corporation (MPRC). He holds a BSc in Mechanical Engineering from Polytechnic School of Engineering, New York University.

years, PETRONAS has executed only a limited number of abandonment projects for its petroleum facilities, with modes ranging from total onshore removal to rig-to-reef removal of leased floaters and well P&A (plug and abandonment).

Moving forward, the growth in the market for abandonment activities in Malaysia is imminent amidst its portfolio of maturing assets where increasing numbers of fields have reached the end of their economic life. When a field reaches its economic life, the revenue generated from production is enough to cover operating costs. Based on an external forecast conducted in 2017 (Wood MacKenzie Study: “380 fields on the front line” as per presented during SPE Workshop in October, 2017, in Kuala Lumpur), the local abandonment market is valued at approximately US$2-3 billion for the next 10 years.

Encik Zamri feels that the industry must look at undertaking

abandonment activities collectively. There is a need to significantly reduce abandonment costs through an increased efficiency and, more importantly, industry transformation. The O&G industry in Malaysia needs to be prepped to equip itself for this emerging reality.

It is important to note that abandonment presents substantial opportunities for value creation through innovation, industry collaboration and development of regional skills and capability. Ultimately, the potential for the industry to grow in this area is almost guaranteed, as more assets degrade and reach their economic limit.

Since the incorporation of PETRONAS in 1974, the O&G industry in Malaysia has been primarily managed through PSCs issued to Petroleum Arrangement Contractors (PACs). Therefore, for the duration of the PSC, the decommissioning obligation lies with the PACs. Most PSCs contain a standard duty for PACs to perform and fund abandonment activities. When asked about abandonment requirements in the country and if there’s any law associated with this, Encik Zamri says Malaysia is legally bound to undertake abandonment activities. As in the case of any activity throughout the Exploration & Production (E&P) life-cycle, abandonment activities shall adhere to the established framework and applicable statutory and contractual provisions. As party to the United Nations Convention on the Law of the Sea (UNCLOS), Malaysia is duty bound to undertake abandonment activities in accordance to the provisions included in the convention. Currently, there is no specific Malaysian abandonment law and so, control on associated liabilities is exerted only through relevant existing laws and commercial contracts. The existing laws relevant to abandonment activities are also fragmented. In this regard, there are fragments of provisions in the PDA 1974, the Exclusive Economic Zone Act 1984 and the Continental

Sika offers a diverse range of services and state-of-the-art technological solutions to leading companies operating in the Oil & Gas Industry. Our focus remains on technological advancements in the fields of roofing, flooring, tank lining, sealing & bonding, machinery grouting, concrete repair, pipes protection with strengthening and marine repair and protection.

Shelf Act 1966, which contain the duty to perform abandonment in general. There is also the Petroleum (Safety Measures) (Transportation of Petroleum by Pipelines) Regulation 1985, which is essentially a written procedure for abandoning pipelines.

For application purposes, PETRONAS uses, as its reference due to its practicality, the Guidelines & Standards for the Removal of Offshore Installations and Structures on the Continental Shelf and in the Exclusive Economic Zone issued by the International Maritime Organisation (IMO) as the recognized competent organisation by UNCLOS.

Essentially there are 4 possible options for abandonment listed under the IMO Guidelines, such as total removal, partial removal, other use and leave in-situ. PETRONAS has adopted the options in the IMO Guidelines and encourages operators and service providers to explore innovative ways within these options to optimise abandonment cost while adhering to all applicable statutory and regulatory requirements on the environment and reducing potential liabilities.

Encik Zamri says that PETRONAS plays an active role in promulgating the formulation of a pragmatic national abandonment law aimed at establishing a clear duty and liability assignment, as well as the timely abandonment of assets.

In the current context, all abandonment activities shall adhere to the established framework and applicable statutory and contractual provisions. The committee which regulates offshore activities, including abandonment, is the Jawatankuasa Zon Ekonomi Eksklusif (JKZEE). All abandonment projects require JKZEE’s approval before any offshore work can be executed, in a fashion similar to development projects. Through the Asset Decommissioning team under the Malaysia Petroleum Management (MPM) division, PETRONAS is continuously working on the arrangement with JKZEE. All submissions to JKZEE go through the Asset Decommissioning team for review and technical approvals. MPM

also conducts regular stakeholder engagement programmes with the regulators to ensure all works are executed in line with the regulatory requirements.

Encik Zamri explains that in the context of the industry in general, both the Government and PETRONAS have crucial roles to play in developing a supportive statutory and regulatory environment as well as encouraging collaboration between industry players.

As the custodian managing the sustainable exploitation of local petroleum resources, PETRONAS has the authority to regulate the upstream abandonment activities. In line with this duty, it spearheads the industry in shaping the landscape of abandonment activities here.

In addition, PETRONAS has an excellent synergy with the Government. For example, PETRONAS and the Department of Fisheries are exploring rig-to-reef (R2R) opportunities as part of efforts in sustainability development. When assets are no longer in use for O&G operations, using the decommissioned structures as reefs will benefit the marine habitat and the local community as a whole.

In driving the growth and building capabilities in the local abandonment sector, PETRONAS is looking at clustering activities associated with abandonment, with the main objective to strive for economies of scale by driving efficiencies and enabling synergies.

“Our goal is to achieve abandonment costs of RM10k/MT for structure abandonment, and RM10Mil/well for medium complexity wells,” says Encik Zamri.

On a regional level, PETRONAS collaborates with energy and petroleum ministries of other ASEAN countries as well as regulators and national oil companies (NOCs) through the ASEAN Council of Petroleum (ASCOPE) platform.

Abandonment is a key strategic topic taken for collaboration discussed within this platform. At this level, collaboration is focused

on several value-driven areas such as joint sharing of resources for decommissioning, standardisation of guidelines and utilisation of disposal yards between countries.

Encik Zamri says that as the owner of petroleum assets, it is vital for PETRONAS to be precisely sure that an asset has in fact reached the end of its life before any decision is taken to abandon it.

It is crucial to ensure that the whole process, from late-life management to final abandonment, is as effective as possible in order to maximise returns from the asset. “This is what we called sweating the assets,” says Encik Zamri.

To do this, PETRONAS addresses abandonment through portfolio management throughout the life of each field. Prior to the decision to abandon or Cease of Production (COP), an asset will be subjected to a periodic technical and commercial review. This thorough review process will ultimately propose the way forward for a late-life asset – whether it should be extended, preserved, divested or decommissioned. The decision to abandon will only be taken after all options have been explored exhaustively.

Once a decision to abandon an asset is made, it will be managed through an integrated execution plan via gated reviews in order to drive cost efficiency and meet set objectives, with an emphasis on collaboration among PACs.

Abandonment Works is not without challenges and uncertainties but Encik Zamri says it is important to note that abandonment in Malaysia has a low barrier entry for PACs and service providers. Most installed platforms are of the fixed jacket/substructure type and a large number are located in shallow waters.

He adds that local players have capabilities on par with global players. Existing well intervention companies and installation contractors are capable of performing abandonment activities which are, essentially, not too

disparate from their current expertise, as these do not require complex engineering.

Pioneers in abandonment activities will definitely have an advantage in the regional playing field as similar demands are expected to grow in South East Asia, in particular Thailand and Indonesia.

Having said that, the cost and pace for abandonment activities are not without challenges such as: Technical & Commercial

1. Oil price dynamics impact technocommercial cut-offs of fields and timing for abandonment.

2. Uncertainty of market timing will impact the service sector’s readiness.

1. Immaturity of the regional market to support abandonment.

2. Lack of direct experience by PACs and service companies.

3. Lack of availability of a complete network for disposal of structures including the handling of schedule waste such as mercury.

1. Cash flow management: The oil price crash in 2014-2016 forced companies to reduce expenditure to boost cash flow.

2. Price dynamics will impact the rate of resources and abandonment cost.

3. High cost of well abandonment: For well P&A, the associated cost normally falls within 40-50% of the total cost.

Meanwhile, PETRONAS is actively addressing the challenges and uncertainties by looking into liability management and cost compression for abandonment activities.

From a broader angle, stakeholders need to look into the requirements pertaining to abandonment processes and to provide a natural incentive to encourage a broad and healthy service industry. This is to ensure a robust and functioning abandonment sector that will be able to support maximising value extraction from O&G fields in Malaysia.

In a nutshell, all parties involved in abandonment will need to play their part to ensure the O&G industry is

Removed platform structures placed on a barge for subsequent abandonment activity

ready to deliver proper abandonment works in the country.

In driving cost efficiency, PETRONAS is always open to creative and innovative approaches.

Together with the relevant parties, PETRONAS is currently pursuing several focused approaches aimed at reducing abandonment unit costs in Malaysia. These include:

1. Design for decommissioning through value engineering during the development stage.

2. Innovative cutting and removal methods instead of conventional cutting which was applied in the Gulf of Mexico.

3. Synergy with the Government to explore rig-to-reef (R2R) opportunities to maximise the value of decommissioned structures.

4. Collaboration and synergy across operators and PACs to achieve economies of scale.

5. Abandonment in a clustering model as the basis of abandonment activities.

There are plenty of opportunities for local petroleum service providers in abandonment works. The opportunity to generate value in the near future is imminent and service providers should position and prepare themselves

to tap value from this. The ones that pioneer effective approaches will stand to gain and, in turn, will be able to market their technical expertise regionally and globally. Furthermore, PACs which run efficient late-life assets and minimise abandonment costs, will find that there are many opportunities to create value.

As far as numbers are concerned, Encik Zamri recalls that, in a keynote address at an event organised by the Malaysian O&G Services Council (MOGSC) late last year, he had mentioned that more than 20 platforms and 200 wells would be decommissioned in the next 5 years.

As for market readiness, Petronas is confident that it is feasible to nurture and develop local capabilities to meet the abandonment demand because:

1. Abandonment in Malaysia has a low barrier entry for PACs as almost all platforms are of a fixed jacket type and are mainly located in shallow waters.

2. Local players have a capability on par with global players. Existing well intervention companies, installation contractors and existing fabrication yards are capable of performing abandonment demand, which

JURUTERA has an estimated readership of 168,000 professionals. Our esteemed readership consists of certified engineers, decision making corporate leaders, CEOs, government officials, project directors, entrepreneurs, project consultants, engineering consulting firms and companies involved with engineering products and services.

Our business partners can be assured that their products and services will be given the circulation and exposure they deserve, thus maintaining a sustained advertising presence to our core readers of decision-making engineers and technical experts. Our website offers an even wider market reach, with added international presence, aided by our international affiliation with official engineering bodies all over the world. Our online and offline advertising features such as banner advertising, article sponsorship and direct e-mail announcements have proven to be successful marketing strategies that will set the businesses of our partners apart from their competition.

For advertising enquiries, please contact:

is not much different from their current expertise.

3. In Malaysia, technology is yet to be a key differentiator as most of the current demand does not require complex engineering. Pioneers will gain an advantage as similar demands are expected to grow within the South East Asian region, in particular Thailand and Indonesia.

While Malaysia has PETRONAS Procedure & Guidelines for Upstream Activities (PPGUA), there are no exclusive guidelines and regulations for Decommissioning work.

However, Encik Zamri says that in the latest PPGUA, version 4.0, launched in October, 2017, abandonment was accorded its own section under Volume 9.0.

On top of PPGUA, PETRONAS is fully aware of the need to minimise

the costs for abandonment. Thus, under the Upstream Initiative, the development of the PETRONAS Basic Technical Requirements for Abandonment is on-going. These will be the minimum acceptable requirements for abandonment activities developed around the existing technical, safety and current regulatory requirements.

Referring to Downstream assets, the abandonment of downstream assets is performed on a case-bycase basis and is not covered under the PPGUA.

In closing, Encik Zamri says there will be increased scrutiny in managing asset integrity and decommissioning of facilities in the near future. Therefore, building capabilities in this area will be crucial in balancing cost competitiveness and prioritizing safety, as well as minimizing impact to the environment.

He says PETRONAS hopes to achieve many more successful and smooth abandonments of its petroleum facilities through collaboration with the PACs, the Government of Malaysia and other relevant regulatory bodies.

Explore our full set of Professional and Integrated PUBLISHING MANAGEMENT SERVICES:

» Project Management

» Crea�ve Management

» Ad Space Management

» Mailing Management

» Print Management

• Annual Reports

• Booklets • Brochures

• Bun�ngs • Business Cards

• CD / DVD Replica�ons

• Calendars • Cards & Invita�ons

• Cer�ficates • Custom Prin�ngs

• Envelopes • Folders

• NCR Bill Books • Notepads

• Leaflets • Le�erheads

• Paper Bags • Posters

• S�ckers • Others

Well Plugging & Abandonment (P&A) is the process of removing tubing, completion equipment and casing that has been used as a conduit to bring hydrocarbon from downhole to the surface. It is one aspect of Oil & Gas (O&G) asset decommissioning.

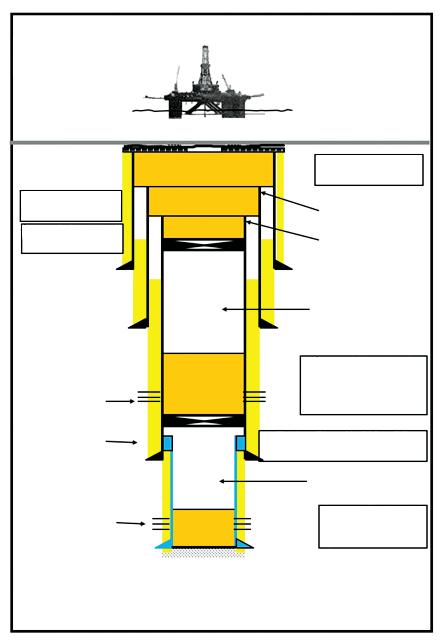

When talking about offshore O&G asset decommissioning, most people will immediately think of the removal of the offshore platform and pipelines but few will be able to tell if well P&A has been completed because this is something that happens below the surface of the sea and below the sea floor. Before surface structures can be removed, downhole structures decommissioning need to be completed first and more importantly, to restore the environment to its natural state as much as practically possible.

The environment refers to not only land or sea areas but also to that below the sea floor. It is the responsibility of each O&G operator to ensure the environment is left with as little disturbance or changes as practically possible. Prior to any development, as part of the field development plan, environmental impact assessment (EIA) is conducted on the area to analyse the impact of drilling and producing of hydrocarbon operations on the environment and socioeconomy of the people living in the area.

In Malaysia, the central reference for all upstream oil and gas operations is the PPGUA (PETRONAS Procedure and Guidelines for Upstream Activities). This is the ultimate reference for all O&G operators here and all requirements, which are based on international standard adapted for Malaysia’s operations, must be met; for any exception, a waiver’s approval from PETRONAS is required.

While this is the minimum requirement, many operators perform above and beyond these requirements, based on their company policies as

Note : Depth Measurement is in mDF (Drill Floor).

seabed @ 88 mDF

Cut Cond Csg @ 91 mDF

Cement Plug No 4

Cement Plug No 3

Conductor Casing @ 600 mDF

Sur face Casing @ 1600 mDF

Perforation Zone Group 1 sand

Top of Liner @ 1800 mDF Production Casing @ 1850 mDF

Perforation Zone Group 2 sand

Production

Liner @ 2200 mDF

Floor to Sea level @ 27m Cement Plug No. 2 30m above perforation zone Cut Prod Csg @ 170 mDF Cut Sur f Csg @ 140 mDF

Plug @ 1700 mDF

9.6ppg Brine

Cement Plug No. 1 30m above perforation zone Cement Plug No 5

1: Sample of Proposed Plug and Abandonment Diagram

well as needs for an individual well. Every well is unique, so it will require individual design as assessment. Volume 8 of the PPGUA is dedicated to “Drilling and Well Operations”. Section 9 of Volume 8 laid out the “Plug and Abandonment of Well” requirements. If a P&A is found to be not properly executed within these requirements, PETRONAS reserves the right to ensure that the operator re-abandons the well again.

Well P&A is not only conducted during decommissioning but also during

exploration and development stages. During exploration, when the well has been tested and all information required have been gathered, P&A of the well is conducted before the area is left. During development, if somehow the well is found to be “dry”, and unusable for any development functions (such as producing, testing or sidetracking) in the near future, then the well shall be P&A. Another instance for P&A requirement is when a well is no longer producing economically. There are many other instances where P&A may be required; the idea is to ensure the hole is

sealed completely according to the provisions before the well can be abandoned. Other instances which may lead to P&A of a well or a portion of the hole, are accidental sidetrack, drilling into a wrong location and a stuck pipe. Before any well or part of the hole is P&A, detailed reasons and P&A design with justification are required for submission to PETRONAS for approval. Upon completion of P&A work, another complete report is required to be submitted to PETRONAS. This is to ensure that every hole made for the purpose of hydrocarbon exploration and development is accounted for and referenced for future records and studies.

The request for approval submission has to at least include the proposed P&A programme and diagram. The information required include well depth, all perforated intervals including those that have been plugged, casing and tubing depths and description, estimated tops of cement in each casing annulus, subsurface equipment and depths, plug types, locations and lengths, types and density of fluids left in hole, perforating and casing cutting plans, casing removal depths and reservoir strata as well as subsurface pressures of all known potential. The list may seem extensive but the information is crucial for future reference.

It is important that we restore the environment to its natural state as much as possible. Although we know that this will never be entirely possible, professionally we must ensure there is minimum impact on the environment. This is a question of how much can be done and at what cost. A good balance between what is possible and what is feasible, from the environmental and financial perspectives, must be considered.

Engineering work can determine and recommend this balance and PPGUA ensures that this balance is practiced by all operators tapping into our natural resources. PPGUA has gone through a few revision cycles to meet international environmental protection requirements and be in-

line with the guidelines with major multi-national O&G operators.

We must abide by 3 principles when permanent abandonment is conducted on a well or a portion of the open hole. The first is to provide downhole isolation between hydrocarbon zones. The second is to protect freshwater aquifers and the third is to prevent migration of formation fluids through the wellbore. Downhole isolation between hydrocarbon zones is important because each formation layer can actually be differently pressured due to the naturally formed formation movement. Leaving the different layers to communicate with each other will impact the pressure maintenance of the area. Freshwater aquifers need to be protected to ensure there is no contamination. Migration of formation fluids through the wellbore must not be allowed, because this will allow mixing of formation fluids from the different formations. In practice, for permanent abandonment of a well or portion of the hole, we must ensure the following: Isolation of zones in open hole, isolation of open hole, plugging of perforated zone and plugging casing stub. Isolation of zones in open hole, regardless of whether it is hydrocarbon bearing or not, is to ensure there is no communication between zones when the well is abandoned.

For offshore operations, decommissioning operations include clearing the area of any structure above the sea surface, above the sea floor and below the sea floor. P&A operations involve removing as much material as we can from the downhole.

Figure 1 shows a sample of a proposed P&A diagram for an exploration well. Upon obtaining all the information from the process of coring, logging and production testing, the well is evaluated for P&A.

Once this is decided, a programme is prepared and approval to P&A is obtained. After the hole is cleaned, cement plug # 1 is placed at the bottom of the well to seal off the

perforation zone for Group 2 sand. The cement plug is extended up to 30m above the perforation zone to ensure the zone is ultimately sealed off. Then a bridge plug or a mechanical seal is placed below the Group 1 sand perforation zone. This bridge plug acts as a barrier to leakage from Group 2 sand and as a holder to the cement plug # 2 which also extends 30m above the perforation zone. On top of these sealing elements, the hole is also protected with liner (casing which does not go up to the surface) and casing.

In the O&G industry, two or more barriers are usually required to ensure safety of the operations. The hole is never left empty but instead, is filled with fluids which weigh more than the formation pressure. In this case, brine is used.

The process is repeated for the rest of other cement plugs.

Whenever possible, the casing is cut and retrieved from the hole to ensure that minimum materials are left in the hole. It is not possible to retrieve most parts of the casing because this is cemented on the outside to provide support during drilling operations to ensure that the inadequately supported formation does not cave in.

Well P&A has many other complexities such as additional procedure/approval if radioactive source is accidentally left in hole, temporary abandonment or well suspension, unplanned sidetracking requirement etc. However, the principle of P&A is the always the same, that the environment be restored to its natural state as much as practically possible. Once all the wells from a platform have been P&A and completely secured, surface equipment decommissioning can proceed.

Engineering is not just about making money; it is also about recommending the most optimised solution to a problem while ensuring safety, sustainability and operational excellence in the most professional way governed by engineering ethics.

Hook-up and Commissioning (HuC) is a major business in the Oil & Gas industry. HuC works range from minor fabrication and installation to modification, tie-in and commissioning (startup for equipment or system).

HuC is applied to both green field (new field) and brown field (field that has been producing for some time) projects. Several aspects need to be checked, monitored and planned early to ensure smooth HuC execution at the site.

Many operators issue minor fabrication, modification work, improvement plan and commissioning work under HuC tender for a small-scale budget and team size.

Several aspects and area of concern need to be checked prior to execution.

i. Constructability review.

ii. Construction HAZID (Hazard Identification).

iii. Work-pack review & challenge.

iv. Material readiness.

v. Manpower loading and schedule.

vi. Equipment.

vii. Cost.

viii. Marine spread.

ix. SISO (Specific Instruction for

Simultaneous Operations) and offshore execution monitoring.

The work-pack is the most critical element in HuC execution. This is because the contractor needs to develop the job card, job card summary, job hazard analysis, estimate manhours and job card acceptance sheet. From the workpack, the contractor can also further extend/develop the constructability document and HAZID. The level of information in the work-pack must be comprehensive and adequate so that the Client/Operator can check off contractor readiness for the incoming work to be carried out. In addition, the contractor also needs to estimate the manhours for each job card in the work-pack. This information can be used for costing purposes.

Another factor that needs to be considered prior to mobilising personnel to offshore, is material

readiness. A contractor must develop a series of checklists from the purchase order for equipment readiness at the warehouse. This monitoring process needs to be parallel with progress of the fabrication team as the team cannot execute/start work without materials in place.

Marine spread is the most expensive part in a HuC contract. During the proposal, a contractor needs to ensure that the vessel to be used is not to “overpromise” or “overspec”. For instance, in Malaysia, the workboat average rate for 2018 is about RM45,000/day, a workbarge is about RM75,000/day and SV (Supply Vessel) DP2 (Dynamic Positioning Level 2) is RM135,000. The rates does not include fuel consumption, so the total cost can be dramatically high. The vessel to be used should be fit-forpurpose and suitable for the offshore execution team mobilisation.

On the other hand, the SISO document is one of the key elements in ensuring a successful offshore execution. This document will include pertinent documents detailing all the operations involved during that time. If this document is not prepared in time for approval by the client, the commissioning of work can be denied.

HuC work is usually slotted within a very small window of time and is carried out at the same time as many other operations. If this time slot is missed, then the next slot will be considered but this may jeopardise operations significantly.

HuC scaffolding work on topside facilities

Source: http://www.globalconstructionreview.com/news/ scaffolders-earn-more-architects-uk-body-says/

With proper monitoring and planning tools, the HuC business promises very good returns on investment. Project Management Team (PMT) and service contractors need to be proactive and should work together to keep up with the high pace

operations. The estimation of cost needs to be relevant and accurate in order to secure profit. The cost estimate should consider a margin of errors from schedule or change of decision, must have a strong basis and, at the same time, flexibility for last minute changes.

Ir. Izwan Noor, a committee member of OGMTD, has over 14 years’ experience in marine and offshore structural engineering design, appraisal and verification in the South East Asia region.

IEM

NOTICE ON NOMINATION PAPERS FOR COUNCIL ELECTION SESSION 2019/2020

A notice inviting nominations for the Election of Council Members for Session 2019/2020will be posted on the IEM Notice Board and IEM website from 16 November 2018 for the information of all Corporate Members of IEM. Thereafter,following the close of nominations on 20 December 2018, the election exercise will proceed. All Corporate Members residing overseas are requested to take note of the requirements of the Bylaw, Section 5.12, as shown below.

The voting paper shall, not less than twenty eight (28) clear days before the date of the Annual General Meeting, be sent by post to all Corporate Members residing in Malaysia and to any other Corporate Members who may, in writing, request to have the paper forwarded to him. The voting paper shall be returned to the Honorary Secretary in a sealed envelope so as to reach him by a specified date not less than seven (7) days before the Annual General Meeting.

Voting papers will be posted out by 25 February 2019

Corporate Members residing outside Malaysia, who wish to receive voting papers, are advised to write to the Honorary Secretary on or before 10January 2019.

Thank you.

Election Officer, IEM

Nehemiah-OVM provides the following products and services:

- Post-tensioning solution provider

- Carpark Flat Slab

- Transfer Plate

- Beams, Box Girders

- Alternative design solutions

- Cable systems (stay cable, main cable, hanger)

- Bridge bearing and expansion joint

- Construction solutions (heavy lifting ILM etc)

- Monitoring, repairing and strengthening for structures

Head Office

Nehemiah Prestress Sdn Bhd 1140945-A No. 45-3, Jalan PJU 5/20

The Strand, Kota Damansara 47810 Petaling Jaya

Selangor Darul Ehsan

Malaysia

Tel: (603) 6142 6638

Fax: (603) 6142 6693

Email: enquiry@nehemiahpt.com

Certified by the European Organization for Technical Approval

Oby Ir. Razmahwata

ne may not think that food safety is integral to running expensive industrial complexes. However, if one considers the number of remote locations that have been engineered, one may want to think again. There are many civil, marine, oil, gas and mining activities in remote locations with limited exit strategies. Sharing a confined space also becomes more stressful if sanitation facilities are always fully occupied or there is insufficient manpower to run the project or facility at full speed, impacting safety, schedules and shareholders.

Statistics show that 1/3 of food-borne diseases in the home is caused by cross contamination (e.g. using a cutting board to dress uncooked meat and then using the same cutting board to prepare a raw salad without proper cleaning in between).

Therefore, in addition to double checking your figures, keeping a tidy working environment and maintaining your tools, do the following:

• Thaw food in a microwave or refrigerator, not on the kitchen counter.

• Wood cutting boards are hard to clean, so use plastic, glass or marble instead.

• Make sure meat is well cooked instead of leaving the centre pink.

• When removing meat from the grill, do not use the same dish that had held the raw meat.

Your tummy, the porcelain bowl and your investors will thank you.

Do you know that as long as your membership is still active (Oops, don’t forget to pay your membership fees), you are entitled to enjoy benefits from a range of merchant partnerships that are exclusively provided to IEM members. For members seeking comfortable rest overnight during business trips, there are hotels listed with discounted rate offered. For an upgrade of your vehicle for a safer, reliable and faster travelling, just look at the listed merchants for a discount!

What if you don’t need a hotel stay or car? You still can get discounts from Focus Points, World of Sports, Red Wing Shoes, or even medical health checkup from BP, IJN or equip your knowledge through UTAR partnership.

This list is not the end. We are stepping up efforts to add more partnerships from a wider range of dealers/merchants to bring you more member benefits. For more information on Membership Benefits, please log on to IEM Website below: http://www.myiem.org.my/content/corporate_rates-656.aspx

Contributed by Ir. Dr Oh Seong Por

The funicular Penang Hill Railway, designed by Arnold R. Johnson, an engineer with the Federated Malay States, started operations on 1 January, 1924, with 4 wooden carriages. In 1977, these were upgraded to 2 red coaches equipped with fans and automatic sliding doors.

After a series of breakdowns, the railway was closed on 22 February, 2010, for a complete overhaul. New tracks were laid and 2 Swiss-made coaches weighing 14,500kg with a payload of 7,500kg each, were

introduced. The coaches, equipped with modern airconditioned system, can carry 100 passengers each and are powered by a 710kW electric motor. They are connected to a haul rope with a diameter of 38 mm which provides maximum traction speed of 10 m/s.

The railway service resumed full operations on 25 April, 2011. The railway line cuts through a steep tunnel and lush green vegetation, allowing passengers to enjoy the clean environment of Mother Nature.

reported by OIL, GAS AND MINING TECHNICAL DIVISION

Ir. Thamim Anser bin

IHabibullah Khan Ir. Razak Yakob

n Armageddon (1998), we saw Bruce Willis saving the world.

In Deepwater Horizon (2016), the hero was Mark Wahlberg. But these two major box office films about drilling operations don’t really showcase drilling engineers in the best light. Please be assured that drilling engineers are just like you and me, engineers. You’ve had glimpses of drilling operations in the films mentioned but have you ever wondered how wells are drilled and what kind of tools are used?

With this in mind, the Oil, Gas & Mining Technical Division (OGMTD) arranged for IEM members to visit a drilling tools manufacturing plant in Nilai. It was not as glamorous as in the films, but it was fun and beneficial for the participants who broadened their horizons.

The main objectives of the visit were to learn the mechanics of tools used to drill wells and to understand what how Omni Oil Technologies is able to manufacture tools of international standards which are made in Malaysia, by Malaysians. For some of the tools, its research team has even produced new designs that have proven effectiveness in adding significant values to the efficiency of well drilling operations and reducing operational risk. These tools will ensure success during drilling operations.

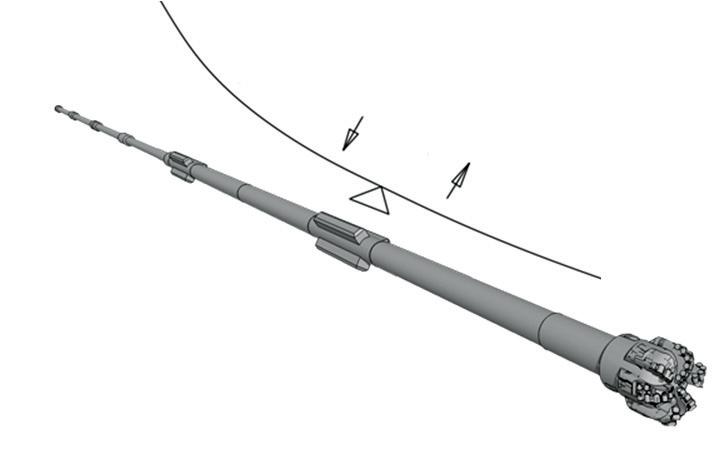

Figure 1 shows a piece of drilling equipment known as drill string. It comprises a set of components with specific functions and it needs to work alongside other equipment. A drill

Figure 1: Example of a drill string

Source: https://encrypted-tbn0.gstatic.com/images?q=tbn:ANd9GcTnXkG73T1do0SuLdRM60 KnnjEFbaxHJ8me7sx4z8eToiGFaNPE

string can be very simple for simple wells or can be very complex for complex wells and wells that require it to have additional functions such as the ability to monitor location, collect formation information, regulate pressure or be used as a directional tool.

Some of the major components are drill bit, stabiliser, drill collar and heavy weight drill pipe. These components make up for the Bottom Hole Assembly (BHA) of a drill string. Drill bits are used to make holes. The centraliser mechanically stabilises the BHA in the borehole in order to avoid unintentional sidetracking, vibrations and to ensure the quality of the hole being drilled. Drill collars are used to provide drill string with weight to ensure the string is always in tension to prevent buckling. Heavy weight

drill pipe is a thicker drill pipe which is stronger with high tensile strength to provide a flexible transition between drill collar and drill pipe. Lastly, it is the drill pipe all the way to the surface. However, as and when required, the drill string can include tools such as mud motor, measurement while drilling, logging while drilling, pressure while drilling etc. Sometimes, an underreamer is included to enlarge the hole.

We saw some of these equipment at the manufacturing area.

Apart from drilling tools, Omni Oil Technologies also produces completion equipment such as dual packers, landing nipple, sliding sleeve, flow coupling and blast joint. It also produces cementing accessories and equipment used during cementing operations of the

equipment, skilled technicians, testing facilities and quality control laboratory. Some upcoming studies and ventures that Omni Oil Technologies is embarking on are new thermal plastic centralisers, new PDC hole opener design, casing scraper insert design and manufacturing steel body bit for a European drill bits company. We thank Omni Oil Technologies for its hospitality and knowledge sharing with IEM.

If, after reading this article, you still don’t understand much of the jargon and some of the interesting things about drilling engineering or you are still wondering how wells are drilled, please sign up for a 2-day course that OGMTD is planning in early 2019!

• Mechanical Engineering

KPT/JPS (N/521/6/0065)(FA4095) 12/18

• Petroleum Engineering

KPT/JPS (N/524/6/0027)(FA4141) 12/18

• Chemical Engineering

KPT/JPS (N/524/6/0029)(FA4097) 01/19

• Construction Project Management

KPT/JPS (N/526/6/0057)(FA4168) 12/18

• Quantity Surveying

KPT/JPS (N/581/6/0050)(FA4369) 06/19

reported by OIL, GAS AND MINING TECHNICAL DIVISION

Ir. Dr Jeyanthi Ramasamy

After 5 months of planning, the Oil, Gas & Mining Technical Division (OGMTD) held the Pipeline Technical Day on 20 September, 2018, at Armada Hotel in Petaling Jaya, Selangor. There were six speakers who were experts in various areas of pipeline and 43 participants.

For the Oil & Gas (O&G) industry, pipelines are the cheapest and safest way to transport hydrocarbons. Low oil and gas prices have forced the industry to rethink the way it typically carries out engineering and operational activities in both brown and green field developments. On new field developments, a lower cost is critical to ensure project financing. New concepts and innovative solutions are required to reduce costs while maintaining the same operational and safety requirements.

For existing pipeline infrastructures, operators need to take a hard look

Speakers and Participant of the event

at managing their operations so as to reduce costs and drive sustained profitability. While pipeline asset integrity management is crucial to ensure safe operation throughout the design life, regular inspections and maintenance may be postponed or even neglected due to the pressure to cut costs. The Pipeline Technical Day symposium focused on technology advancement and current practices that provided cost-effective ways to manage pipeline integrity.

The first speaker was Encik Mohd Suhaimi Mohd Yusoh, a Pipeline Engineer at Murphy Oil Corporation with over 15 years’ experience in O&G, particularly the pipeline segment. He highlighted the company’s operations in Malaysia and explained the challenges of pipeline operation and maintenance. He shared his experiences in commissioning a water injection pipeline and presented a

case study on managing the integrity of a deep water gas pipeline by applying direct assessment concept for both internal and external corrosion. He emphasised the importance of pre-assessment study – which included flow assurance and corrosion modelling, qualifications of proprietary technology, execution and statistical analysis – to ensure a successful direct assessment programme. Currently, Encik Suhaimi is working on developing integrity management for Fluid Transfer Line –Gravity Actuated Pipeline (FTL GAP), the world’s first floating pipeline system.

The second speaker was Encik Adeeb Aisamuddin, Technical Manager for Specialist Inspection Services at Oceaneering Services Malaysia. He covered Inspection and Non-Destructive Testing techniques to ensure pipeline integrity during

manufacturing, construction and inservice. He spoke on the basics of the various NDT tools and techniques used as well as current advancement in the technology which can help meet the challenges of the pipeline industry such as making inspection faster, safer and more accurate. Technologies covered included Phased Array Ultrasonic, Guided Wave testing, Pulsed Eddy Current as well as Condition Monitoring tools such as wireless Ultrasonic Testing.

Ms. Michelle Lau is a certified Cathodic Protection Specialist and General Manager at Mach3 Engineering Sdn. Bhd. She has been an active member of NACE International for over 17 years and served as its Director for East Asia & Pacific area for 20142017. She emphasised the need to take corrosion aspects into consideration during the initial design stage and shared the latest global report on the cost impact of corrosion. Following this was a presentation for a crosscountry pipeline as an example of cost optimisation analysis with the use of today’s technology and connectivity.

With over 20 years in offshore O&G industry, Mr. Soren Hauch is an experienced pipeline engineering professional with R&D, service provider and operator backgrounds. He spoke on the use of inline pipeline inspections over the last few decades to help operators manage the integrity of their pipeline infrastructure and to significantly reduce the number of pipeline containment failures. But, in terms of what can be achieved when combining the latest inline inspection technology, integrity assessments methods and integrity management software, the journey has just started. Today, we are better

able than ever to detect and assess material properties, geometric anomalies, metal loss, cracks, old repairs and coating damage, allowing for early detection of integrity threats and to accurately measure the efficiency of preventive actions. The result is increased longterm profitability and opportunities for life extensions of assets which will otherwise be condemned for decommissioning. These requirements need to be complied with, with increasingly stringent regulatory and, at the same time, address public concerns relating to the safety of the environment and neighbouring communities.

Mr. Sha Yong, Lead Engineer at 2H Offshore Engineering Sdn. Bhd., has 11 years of experience in offshore O&G industry, including concept studies, design and integrity management of pipeline, top tension riser, steel catenary riser, free-standing hybrid riser and lazy wave flexible riser. Flexible pipes have been used for over 30 years in both riser and pipeline applications. Mr. Yong spoke on flexible pipe failure or damage modes. A riskbased assessment strategy of the flexible pipeline was discussed to qualify flexible pipeline risk level efficiently. Besides this, inspection and monitoring interval calculation were incorporated for integrity management.

With over 13 years’ experience in deepwater and subsea engineering, Ir. Dr Jeyanthi Ramasamy is Technical Solutions Manager at Oceaneering International. Her presentation covered major and minor pipeline repairs in shallow and deepwater operations. For a minor repair, a split-sleeve clamp with sealing and mechanical grips capability may be installed on the pipeline to provide structural integrity. In shallow waters, divers need to tighten a number of bolts in a specified sequence to ensure the compression of elastomeric seals and actuation of the mechanical grips. However, repair work which cannot be achieved using the split-sleeve repair clamp, is classified as major pipeline repair. The connection between the old pipeline and new repair spool can now be achieved using subsea pipeline connectors. For depths beyond that for divers, the connectors will have additional features for remote operated vehicle (ROV) intervention for installation purpose. A subsea pipeline repair is a complex operation which requires an experienced team, meticulous planning and execution. Participants benefitted from the symposium and came away better informed about new technology in the pipeline business, networked with other players and learnt from the experiences of O&G operators as well as contractors/consultants. The event ended with closing remarks from the OGMTD Vice Chairman and the presentation of tokens and certificates to the speakers.

Error on Feature entitled “Signalling System in Railway Transportation“ published in JURUTERA October 2018 issue – in Page 25.

Author’s surname: Mok Zhen Yick. The error is much regretted.

Urban EnginEEring DEvElopmEnt SpEcial intErESt groUp

reported by

Ir. Jagjeet S. Sidhu

The Urban Engineering Development Special Interest Group (UEDSIG), IEM, organised a technical visit to Melaka Gateway on 30 June, 2018, in cooperation with master developer KAJ Development Sdn. Bhd. (KAJD). It was attended by 25 participants.

The Melaka Gateway Development Project was first initiated in 2013 as a mixed development project by KAJD to establish connectivity and trade opportunities along the Straits of Malacca route which is also the world’s busiest trading route.

The project, started in 2015, is targeted for completion in 2025, with an estimated gross development value of RM42 billion and will add 2.5 million tourists and 45,000 jobs.

Totalling 1,366 acres, it comprises 3 reclaimed islands and 1 natural island (Pulau Panjang), located between Kuala Lumpur and Singapore, as well as within Melaka City’s commercial centre.

Upon arrival at KAJD offices, located on Pulau Melaka, adjacent to the site, we were welcomed by En. Izahar Hamidon (Head of Strategic Investment), Ir. Stanley Kow (General Manager Project Management) and Mr. Yong Kiang Keen (Chief Operating Officer). Our hosts led us to a large model display located at the main entrance lobby. Mr. Yong then briefly described the Melaka Gateway project by highlighting the 4 islands (Table 1) involved.

He and his team then engaged in a Question & Answer session with the participants. We briefly discussed the mandatory requirements for a Detailed Environmental Impact

International

and Ferry

Private Gateway

Ferris Wheel, Shopping Mall, Entertainment Precincts and a world class Theme Park, Cultural Heritage Village, Walkaway Boulevard, fashion and retail brands, Health and Wellness lifestyle, Education Centre, Gateway Beacon 288m Tower.

Banks, Financial Institutions, trading, Offshore Financial Hub, International Integrated Logistics services provider, Specialised business services, support and shared services, High-Technology Park, Halal Park, International zone for foreign nationals/ entities.

With Storage facilities and Liquid Cargo Terminal, benefiting oil trading in Southeast Asia, Asian countries, Europe and the Middle East, Capable of receiving the largest of deep-sea going vessels.

Marine Engineering & Manufacturing, Container Terminal and Port Logistics, Bulk and Break Bulk Terminal, Ship Building and Repair & Docks.

1: Ground Improvement

Assessment (DEIA) for coastal reclamation works of 50 hectares or more as required by the Department of Environment (DOE).

Typically, tidal data is required to predict the safe finished construction levels of various facilities in order to prevent flooding during storm surges.

Following the discussions, the hosts gave a video “fly-thru simulation” presentation of the project showing future planned

development of the project as per the 4 islands.

After the presentation, we boarded a coach for the Gateway site where a KAJD safety officer greeted us and ensured that we had put on personal protection equipment (safety shoes, hard hat and vest) before allowing us into the site area. We then surveyed the site on foot, with our hosts explaining the work progress along the way.

Title: Technical visit to Halal product Research institute, Universiti putra malaysia

15 november 2018

Organised by : Agricultural and Food Engineering Technical Division

Time : 9.00 a.m. - 1.00 p.m.

CPD/PDP : 3

We noted that construction was still at an early stage, with reclamation works, geotechnical ground improvement works and stockpiling of revetment rocks still in progress. We also observed heavy machinery in operation within the site areas.

During the walk-about, our hosts (KAJD) and the participants were fully engaged in a question-and-answer session. It was a successful and beneficial visit for the participants.

Title: Technical visit to agensi angkasa negara (national space agency (anGKasa), malaysia space Centre, 42700 Banting, selangor)

15 november 2018

Organised by : Public Sector Engineers Special Interest Group

Time : 9.00 a.m. - 1.00 p.m.

CPD/PDP : 0

Kindly note that the scheduled events are subject to change. Please visit the IEM website at www.myiem.org.my for more information on the upcoming events.

Global Product Certifications

LV, MV, & HV Motor

Safe and Hazardous Area

IEC and Nema designs

Voltage up to 13,800V

Power rating up to 110,000 kW

VFD Drive Technologies

Variable Speed Drives

Soft Starter

Voltage up to 6,900V

Modular Geared Motor

Multi voltage up to 90 kW up to 20,000 Nm up to 8,600 ratio

! !"#"$%$&'%()*%+',%-./$01%0$ !""#$%%&&&'()*+(',-.'() 023%1.4%"2%0#%5'5,'/%67.8% +"11%#''%$&'%9*'5,'/%:.4;"2<%"2%/'3%0$%$&'%$.-%/"4&$%&023%=./2'/%.>%$&'%-04'?

• Visit the IEM web portal at h �p://www.myiem.org.my and log in as member (you will see the “Member Log-in” in red at the top right hand corner of the page)

• Login with your username and password (if you don’t have one, please register.

! :.4"2%+"$&%7.8/%8#'/205'%023%-0##+./3%6">%7.8%3.2@$%&0A'%.2'B%-1'0#'%/'4"#$'/C% ($% "#%>0#$%023%>/''?

• It is fast and free)

! D=/.11%3.+2%$.%$&'%/0+(1+-23+4"*,562023%=1"=E%.2%/7*-"89:2;*1-9-)6

• Scroll down to the “Member Sec�on” and click on “Virtual Library”

! F&0$@#%"$C%G"23%011%$&'%,..E#%7.8%+02$C% ($%"#%011%>/''%,'=08#'%7.8%0/'%02%()*% *'5,'/H

• That’s it. Find all the books you want. It is all free because you are an IEM M ember!

17th November 2018

15th December 2018

19th January 2019

23rd February 2019

Wisma IEM 9am – 1pm at

The Negeri Sembilan Branch (IEMNS) of The Institution of Engineers, Malaysia, organised a technical visit to Kibing Group (M) Sdn. Bhd., at the Tuanku Jaafar Industrial Zone, Sg. Gadut, Negeri Sembilan, on 4 August, 2018. The group of 26 participants from engineering consultant firms, industry sectors, universities and the IEMNS office spent half a day at the plant which is a subsidiary of China Kibing Glass Company.

The company occupies a land area of 130 acres but only 68 acres are used for the glass plant which still makes it the biggest industrial glass maker in Negeri Sembilan. Kibing Glass Company bought the plant which was previously operated by Samsung Corning Malaysia. Reconstruction began in 2016 and mass production started on 20 April, 2017. It has two production lines with a combined capacity of 1,400 tons per day. One line is dedicated to low-energy coated glass production and the other

is for high-end multi-colour glass production.

The delegates, led by Ir. Dr Oh Seong Por, Branch Chairman of IEMNS, arrived at the plant at 9.30 a.m. where they were welcomed by Kibing Managing Director Mr. Lim Swee Ee. They were briefed on the company profile, product portfolio, production capacity and waste heat recovery system.

At about 10.30 a.m., the delegates toured the production lines to see in detail the float glass manufacturing technique which comprises the following:

1. Metering and charging of raw material (fine sand rich in silica and other chemical compounds).

2. Melting process using a furnace burner to raise the temperature to 1,500 o Celsius to transform the raw materials to molten glass.

3. Forming , in which glass is floated on melted tin to evenly spread width and thickness.

4. Annealing which is gradually cooling down glass sheet to prevent distortion.

5. Cutting the cooled and solidified glass sheet to the desired dimensions.

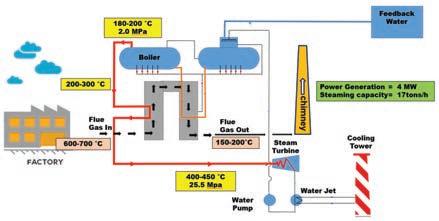

Figure 1 illustrates the process flow of float glass. The process layout is an in-line design which enables float glass to flow in a straight line. Along the process, the glass temperature profile is well regulated to sustain thickness, width, strength and to prevent distortion. These conditions set the production line at about 1 km long, from raw material charging to the stacking of glass sheet. A high level of automation is applied throughout the entire process flow, including automatic mixer, robot to transport work piece, continuous visual inspection system and automatic cutting mechanism.

The participants enjoyed the 2km walking tour of the entire production line. They also observed the multi-million-ringgit waste heat recovery system (see

schematic diagram in Figure 2).

The flue gas (residual gas) from the melting furnace remains at a high temperature of 600˚- 700˚ Celsius. The waste heat recovery system recycles this flue gas to reheat the

steam to superheat temperature levels of 400˚- 450˚ Celsius and raise its pressure to 25.4MPa.

These conditions enable the steam working fluid to propel the steam turbine and generate

electric power up to 4MW which, according to Mr. Lim, is enough to meet 90% of the electric energy consumption of the entire plant. It also helps reduce the flue gas temperature to 150˚-200˚ Celsius before it is released into the environment via a 125m-tall chimney.

Indeed, because of this green technology which conserves energy and protects the environment, Suruhanjaya Tenaga Malaysia has recommended a green tag certification for the Kibing Glass Group.

After the tour, the delegates went to the Visitor’s Lobby where Mr. Lim and Ir. Dr Oh conducted a wrap-up session that ended with the exchange of souvenirs and taking a group photograph. n

Awareness Talk & PI Workshop on Enhanced Process

Date : 17 November 2018 (Saturday)

Time : 9.00 a.m. to 1.00 p.m.

Venue : Wisma IEM

Approved CPD : 3

Speaker : Ir. Chen Harn Shean

Date : 3-4 December 2018 (Monday - Tuesday)

Time : 9.00 a.m. to 5.00 p.m.

Venue : Wisma IEM

Approved

CPD : 14

2 - Day Course on “Good Project Management Practices for Successful Project Delivery”

Speaker : Ir. Dr Ahmad Anuar Othman

2 - Day Course on Cost Management

Date : 12 - 13 December 2018 (Wednesday - Thursday)

Time : 9.00 a.m. to 5.00 p.m.

Venue : Wisma IEM

Approved

CPD : 15

Speaker : Ir. Faizal Abdullah Sanusi

Renewable Energy Forum

Date : 22 November 2018 (Thursday)

Time : 9.00 a.m. to 5.00 p.m.

Venue : Wisma IEM

Approved CPD : 7.5 (CCD hours – 10)

Speakers : Ir. Loo Chee Kin

Ir. Fam Yew Hin

Ir. Luk Chau Beng

Ir. Dr Aidil Chee Tahir

Ir. Dr Alvin Yap Chee Wei

Ir. Derick Chia Chee Weng

Mr. Raghib Fasih Azmi

IEM-Standards Malaysia-Suruhanjaya Tenaga ASEAN Electrotechnical Symposium & Exhibition 2018

Date : 4-5 December 2018 (Tuesday - Wednesday)

Time : 9.00 a.m. to 5.00 p.m.

Venue : Connexion, Bangsar

Approved CPD : Applying

Speaker : Various Presenters

1 - Day Course on “Adapting the Challenges and go for Sustainability on Optimum Process Control”

Date : 15 December 2018 (Saturday)

Time : 9.00 a.m. to 5.30 p.m.

Venue : Wisma IEM

Approved CPD : 7

Speakers : Ir. Hor Kok Luen

Ir. Wendy Ooi Mong Lee

2 - Day Course on “Basic Welding Knowledge in Engineering and Construction”

Date : 26-27 November 2018 (Monday-Tuesday)

Time : 9.00 a.m. to 5.00 p.m.

Venue : Wisma IEM

Approved CPD : 14

Speakers : Ir. Nik Mohd Hasmizie

1 - Day Course on “Empower Your Brand for Success”

Date : 5 December 2018 (Wednesday)

Time : 9.00 a.m. to 5.00 p.m.

Venue : Wisma IEM

Approved CPD : N/A

Speaker : Ms. Evelyn Ch’ng

2 - Day Course on Malaysian Civil Engineering Standard Method of Measurement (MyCESMM2)

Date : 17 - 18 December 2018 (Monday-Tuesday)

Time : 9.00 a.m. to 5.00 p.m.

Venue : Wisma IEM

Approved CPD : 13.5

Speakers : Ir. Hj. Shahul Ikram bin Adnan Ir. Ho Kin Wing Ir. Gunasagaran Kristnan

For further details on the various events, please

Explore our full set of Professional and Integrated PUBLISHING MANAGEMENT SERVICES:

» Project Management

» Crea�ve Management

» Ad Space Management

» Mailing Management

» Print Management

• Annual Reports

• Booklets • Brochures

• Bun�ngs • Business Cards

• CD / DVD Replica�ons

• Calendars • Cards & Invita�ons

• Cer�ficates • Custom Prin�ngs

• Envelopes • Folders

• NCR Bill Books • Notepads

• Leaflets • Le�erheads

• Paper Bags • Posters

• S�ckers • Others

Yes! I would like to be a subscriber of The Institution of Engineers, Malaysia’s publications

Name: _________________________________________________________________________________________________________

Mailing Address: _________________________________________________________________________________________________

Country: ________________________

Company/Institution: ______________________________________________________________________________________________

Title: ____________________________________________________________________________________________________

Telephone No: _________________________ Fax: _________________________ Email: _________________________________

New Subscriber Renewal

Please commence my subscription from: _________________________(month/year) Signature: _______________________________

To start your subscription of IEM’s publications, complete this form and mail it back to the address below. For faster processing, fax it to: +603 7493 1047. Thank you.

What is your primary job title?

Corporate Management (including chairman, president, proprietor, partner, director, vice president, general manager, division manager, import/export manager, other corporate title)

Management (including project/contract/equipment/service/transport district manager, clerk of works, other technical or operating manager)

Engineering/Design (including chief engineer, chief designer, civil/ highway/mechanical/planning engineer, other engineering/design title)

Buying/Purchasing (including chief buyer, buyer, purchasing officer, other buying/purchasing title)

Titles allied to the field (architect, consultant, surveyor, research and development professor, lecturer, supervisor, superintendent, inspector or other allied title)

Others (please specify) ____________________________

What type of organisation do you work in? (Tick one box only)

Contractor

Sub-contractor specialist

Design and build contractor

Consulting engineering/architectural/quantity surveying practice

Mining/quarrying/aggregate production company

Petroleum producer

International/national authorities

National/regional/local government

Public utilities (electricity, gas, water, deck and harbour, other)

Manufacturer

Distributor/importer/agent

Construction department of large industrial/Commercial concern

Association/education establishment/research

Construction equipment hire/rental company

Project/construction management consultancy

Others (please specify) _______________________________

What are the main activities of your organisation? (Tick all that apply)

Constructions of:

Roads/bridges

Manufacturer of:

Construction equipment

Dams/reservoirs/irrigation Cement