Electronic Engineering

JURUTERA

Number 7, July 2013

IEM Registered on 1 May 1959

mA j lis b A g i s e si 2013/2014 (i em C O u N C i l s e ssi O N 2013/2014)

yAN g DipertuA / p resi D e N t:

Ir. Choo Kok Beng, FASC

t imb A l AN yAN g DipertuA / Deputy p resi D e N t: Y.Bhg. Dato’ Ir. Lim Chow Hock

N A ib yAN g DipertuA / Vi C e p resi D e N ts:

Ir. Prof. Dr Ruslan bin Hassan, Ir. P.E. Chong, Ir. Prof. Dr Wan Mahmood bin Wan Ab. Majid, Ir. Tan Yean Chin, Y.Bhg. Dato Ir. Dr Andy Seo Kian Haw, Ir., Prof. Dr. Lee Teang Shui, Ir. David Lai Kong Phooi

s eti Aus A h A Keh O rm At / hONO r A ry s eC retA ry: Ir. Prof. Dr Jeffrey Chiang Choong Luin

b e NDA h A ri Keh O rm At / hONO r A ry t re A surer: Ir. Hoo Choon Sean

b e KA s yAN g D ipertuA ter AK hir / imme D i Ate pA st p resi D e N t:

Ir. Vincent Chen Kim Kieong

be KA s yAN g D ipertuA / pA st p resi D e N ts: Y.Bhg. Dato’ Ir. Pang Leong Hoon, Y.Bhg. Academician Dato’ Ir. (Dr) Hj. Ahmad Zaidee bin Laidin, Ir. Dr Gue See Sew, Y.Bhg. Datuk Ir. Prof. Dr Ow Chee Sheng, Y.Bhg. Academician Dato’ Ir. Prof. Dr Chuah Hean Teik

WAK il Am / Ci V il r eprese N tAti V e: Ir. Gunasagaran a/l Kristnan

WAK il me KAN i KA l / m eC h AN i CA l r eprese N tAti V e:

Y.Bhg. Datuk Wira Lt. Gen. Ir. Ismail bin Samion (Rtd)

WAK il e le K ti K / e leC tri CA l r eprese N tAti V e:

Ir. Mohd. Aman bin Hj. Idris

WAK il s tru K tur / s tru C tur A l r eprese N tAti V e:

Ir. Yam Teong Sian

WAK il Kimi A / Chemi CA l r eprese N tAti V e:

Ir. Prof. Dr Abdul Aziz bin Abdul Raman

WAK il l A i N-l A i N D ispli N / r eprese N tAti V e tO Other Dis C ipli N es: Ir. S. Kumar a/l Subramaniam

WAK il multime D i A / m ultime D i A r eprese N tAti V e:

Ir. Noor Iziddin Abdullah bin Ghazali

A hli m A jlis / C O u NC il m embers:

Ir. Dr Tan Kuang Leong, Ir. June Lau Yuk Ma, Ir. Assoc. Prof. Dr Norlida bt Buniyamin, Ir. Ishak bin Abdul Rahman, Ir. Lee Cheng Pay, Y.Bhg. Dato. Ir. Samsuddin bin Ismail, Ir. Lee Boon Chong, Ir. Tu Yong Eng, Ir. Lai Sze Ching, Ir. Lee Weng Onn, Ir. Yap Soon Hoe, Ir. Li Thang Fai, Ir. Juares Rizal bin Abd. Hamid, Ir. Norazman bin Mohamad Nor, Ir. Ellias bin Saidin, Ir. Assoc. Prof. Dr Jimmy Mok Vee Hoong, Ir. Dr. Tan Chee Fai, Ir. Kok Hee Poh, Ir. Tiong Ngo Pu, Ir. Yau Chau Fong, Ir. Teh Piaw Ngi, Ir. Tay Yuh Her, Ir. Chong Chin Meow, Ir. Chin Kuan Hwa, Ir. Assoc Prof Dr. Vigna Kumaran Ramachandaramurthy

pe N gerusi CAWAN g AN / br ANC h C h A irm AN:

1. Pulau Pinang – Ir. Paul Phor Chi Wei

2. Selatan – Ir. David Lee Loke Hai

3. Perak – Ir. Dr Perumal Nallagownden

4. Kedah-Perlis – Ir. Hor Tek Lip

5. Negeri Sembilan – Ir. Hj. Baharuddin bin Ahmad Nasir

6. Kelantan – Ir. Hj. Syed Abdul Rahman bin Syed Abdullah

7. Terengganu – Ir. Mohd. Azmi bin Ali

8. Melaka – Ir. Vellan a/l Vengo @ Perumal

9. Sarawak – Ir. Kenny Thian Boon Khuin

10. Sabah – Ir. Lo Chong Chiun

11. Miri – Ir. Goh Soon Boon

12. Pahang – Ir. Tuan Haji Ahmad Kamal bin Kunji

A hli jAWAtANK uA s A i NFO rm A si DAN pe N erbitAN / s tAND i N g CO mmittee ON i NFO rm Ati ON AND publi CAti ON s 2013/2014:

Pengerusi/Chairman: Ir. David Lai Kong Phooi Naib Pengerusi/Vice Chairman: Ir. Yam Teong Sian Setiausaha/Secretary: Ir. Lau Tai Onn Ketua Pengarang/Chief Editor: Ir. Prof. Dr Lee Sze Wei Pengarang Buletin/Bulletin Editor: Ir. Yam Teong Sian Pengarang Prinsipal Jurnal/Principal Journal Editor: Ir. Prof. Dr Dominic Foo Chwan Yee Pengerusi Perpustakaan/Library Chairman: Ir. C.M.M. Aboobucker Ahli-Ahli/Committee Members: Ir. Yee Thien Seng, Ir. Tu Yong Eng, Ir. Chin Mee Poon, Y.Bhg. Dato’ Ir. Dr Andy Seo Kian Haw, Ir. Hj. Look Keman bin Sahari, Y.Bhg. Datuk Ir. Prof. Dr Ow Chee Sheng, Ir Dr Tan Chee Fai, Engr. Abul Aswad Abdul Latiff

IEM Secretariat: Pamela Jitab

the i N stituti ON OF e N gi N eers, m A l Ay si A Bangunan Ingenieur, Lots 60 & 62, Jalan 52/4, P.O. Box 223, (Jalan Sultan), 46720 Petaling Jaya, Selangor Darul Ehsan. Tel: 603-7968 4001/4002 Fax: 603-7957 7678

E-mail: sec@iem.org.my Homepage: http://www.myiem.org.my

dIMEnsIon publIshIng sdn. bhd. (449732-T)

level 18-01-03, PJX-hM Shah Tower, no. 16A, Persiaran Barat, 46050 Petaling Jaya, Selangor Darul Ehsan, Malaysia. Tel: +(603) 7493 1049 fax: +(603) 7493 1047 E-mail: info@dimensionpublishing.com Website: http://www.dimensionpublishing.com

Chairman R o BERT MEBRUER

CEO/Publisher PATRICK l EU ng patrick@dimensionpublishing.com

General Manager S h IR l E y T h AM shirley@dimensionpublishing.com

Business Development Manager J o SEP h ho W joseph@dimensionpublishing.com

Editor REIKA KUA KEE E ng & TA n BEE hong reika@dimensionpublishing.com & bee@dimensionpublishing.com

Creative Production Manager l EE SIEW l I siewli@dimensionpublishing.com

Graphic Designer n ABEE l A A h MAD beela@dimensionpublishing.com

Senior Advertising Executive MA SAKI yAP masaki@dimensionpublishing.com

Accounts cum Admin Executive yong y E n y I n yenyin@dimensionpublishing.com

for advertisement placements and subscriptions, please contact: di M ension publishing sdn. bhd. (449732-T) at +(603) 7493 1049, or E-mail: info@dimensionpublishing.com

Subscription Department E-mail: subscription@dimensionpublishing.com

Printed by

hoffset printing sdn. bhd. (667106-V) no. 1, Jalan TPK 1/6, Taman Perindustrian Kinrara, 47180 Puchong, Selangor Darul Ehsan, Malaysia. Tel: +(603) 8075 7222 fax: +(603) 8075 7333

Mailer

PERFECT MAIL SERVICES

14 Jalan TSB 2, Taman Perindustrian Sungai Buloh, Sungai Buloh, Selangor Darul Ehsan, Malaysia. Tel: +(603) 6156 5288

Jurutera Monthly Cir C ulation : 28,000 C opie s

Submission or placement of articles in JURUTERA could be made to the:Chief Editor

Th E In STITUTI on of Eng I n EERS, M A l Ay SIA , Bangunan Ingenieur, lots 60 & 62, Jalan 52/4, P.o. Box 223 (Jalan Sultan), 46720 Petaling Jaya, Selangor. Tel: +(603) 7968 4001/4002 fax: +(603) 7957 7678

E-mail: pub@iem.org.my or sec@iem.org.my IEM Website: http://www.myiem.org.my

© 2013, The Institution of Engineers, Malaysia (IEM) and Dimension Publishing Sdn. Bhd.

publi C ation dis C lai M er

The publication has been compiled by both IEM and Dimension with great care and they disclaim any duty to investigate any products, process, services, designs and the like which may be described in this publication. The appearance of any information in this publication does not necessarily constitute endorsement by IEM and Dimension. There is no guarantee that the information in this publication is free from errors. IEM and Dimension do not necessarily agree with the statement or the opinion expresssed in this publication.

C op yright

JURUTERA Bulletin of IEM is the official magazine of The Institution of Engineers, Malaysia (IEM) and is published by Dimension Publishing Sdn. Bhd. The Institution and the Publisher retain the copyright over all materials published in the magazine. no part of this magazine may be reproduced and transmitted in any form or stored in any retrieval system of any nature without the prior written permission of IEM and the Publisher.

Transformation of Malaysia’s Electronics Industry

by Ir. Dr Hor Poh Jin Chairman, Electronic Engineering Technical Division

since the inception of the Free Trade Zone concept introduced by the late Tun Dr Lim Chong Eu in the 1970s, the electrical and electronics (E&E) industry has taken root in Penang, and soon spread to many other regions of Malaysia. Back then, our low cost labour and political stability attracted foreign investments in the manufacturing sector – mainly in making simple electronic devices. Today, E&E is the leading component in Malaysia’s manufacturing sector, contributing significantly to the country’s manufacturing output (26.94 per cent), exports (48.7 per cent) and employment (32.5 per cent).

While the growth of the E&E industry has been spectacular, the rapid change of the industry, economy and technology landscapes has prompted the government to re-strategize and redouble its efforts in facing growing competition from newly emerging countries. The joint effort by the government and industry is well-reflected in the Entry Point Projects (EPPs) supporting the E&E sector as one of the 12 national key economic areas (NKEA). The focus now has shifted from repetitive mass production operation to high skill, low-volume and high-value manufacturing, and design and development activities.

Among some of the challenges that confront the E&E industry’s move to the next level are the parallel development of a local industrial ecosystem, the readiness of the available talent pool and a responsive government delivery system. To accelerate the transformation of the E&E sector, we must also have to put in place a well-connected network of supporting engineering services companies, especially SMEs.

Over the years, the Electronic Engineering Technical Division (eETD) of the IEM has been actively promoting networking among the stakeholders and professionals in the E&E sector in Malaysia. A joint organization of monthly technical talks by the eETD, universities and industry has brought together the companies, experts and government agencies to interact with each other. We are hopeful the interaction will positively affect the members and encourage them to drive forward their career development as electronic engineers. We would like to call upon all electronic engineers to come together and join the Division to help bring about the transformation that will contribute to the continued success of the country’s E&E sector.

The Malaysian Electrical & Electronics (E&E) Industry – At an Inflexion Point

Written

Ectrical & ElEctronics (E&E) is a major industry of Malaysia, which has grown by leaps and bounds since 1972. The total E&E export for 2012 was RM256.4 billion which represents 36.5% of Malaysia’s total exports and 59.3% of total manufacturing exports. The E&E industry employs about 700,000 people of whom 30 to 40 percent are engineers and managers. Meanwhile, foreign direct investments (FDIs) continue to grow while Design & Development (D&D) and business process operations/services have also grown significantly.

However, with over 40 years of experience, the E&E industry has come to a cross road, an inflexion point. How do we position the industry and move forward from here? We are neither cheap nor expensive. Talents are limited. We want to move to high paying jobs and high value added and high tech work. At the same time we must be competitive. Let’s take a closer look at these issues concerning the E&E industry since its beginning up to its current progress.

AN OVERVIEW OF THE E&E INDUSTRY

the Beginning of the E&E industry 1969 has marked a significant milestone in the history of E&E as it is the beginning of the Electrical & Electronics (E&E) Industry in Malaysia. As the Federal Government had revoked the Penang Free Port Status, the unemployment rate at that time was around 15% against the national average of 9%. The Chief Minister at that time, Dr Lim Cheong Eu was faced with this challenge and he needed to find a solution to create more job opportunities. Dr Lim had this vision of setting up some industrial parks, known as the Free Trade Zone (FTZ, now called Free Industrial Zone, FIZ) located in Bayan Lepas, Penang. Subsequently, Dr Lim established the Penang Development Corporation in November 1969 to promote the FTZ and to attract foreign direct investments (FDIs) with pioneer status given. The labour cost was low at that time and this idea of FTZ industrial parks was later extended to other states in Malaysia such as Selangor and Malacca.

Dr Lim and his team made numerous trips overseas especially to USA, Europe and Japan to promote the FTZ and many small medium enterprises (SMEs) came to visit the FTZ. One of the companies was Intel. Andy Grove, then CEO of Intel, visited the location. There was heavy rain the night before. The picture shows that his car was stuck in the mud as the road was not paved and he had to roll up his pants to walk as he visited the site, which basically was still a coconut plantation in the process of being cleared for the use of the industry.

There was a leap of faith when the companies decided to start up their factories in the Penang FTZ in 1972 although the site was not even readied to be used. This decision marked the start of the E&E industry in Penang and in Malaysia. The first eight companies

that came to Penang FTZ were Advanced Micro Devices Products Sdn. Bhd. (AMD), Hewlett Packard Sdn. Bhd. (now called Agilent Technologies), Clarion (M) Sdn. Bhd., National Semiconductor Sdn. Bhd. (now called Fairchild Semiconductor Sdn. Bhd.), Hitachi Semiconductor (M) Sdn. Bhd. (now called Renesas), Intel (M) Sdn. Bhd., Litronix Sdn. Bhd. (now called Osram Opto Semiconductors (M) Sdn. Bhd.) and Robert Bosch (M) Sdn. Bhd. The good news is all of the first eight companies are still around and growing although some were restructured or acquired with company names changed.

The Progress of e&e IndusTry

The following is an overview on the progress of the E&E industry for the past four decades, namely from the 1970s to 2010s.

in the 1970s

Due to a few key reasons such as low labour cost, availability of good engineers and technicians, competent architects and contractors, as well as a business-friendly government, FDIs were entering into Malaysia since early 1970s. Meanwhile, the support to the new factories from local SMEs (Small Medium Enterprises) had also started to grow.

Subsequently, as the companies gained experience, the local senior managers and engineers who were hungry to learn more and wanted more challenges had decided to convince their top management to transfer the testing responsibilities. The corporate leaders were hesitant to do this as they thought it would be too difficult for the Malaysian engineers. However, with their persistence, the corporate leaders decided to assess the situation and asked if the country had Masters and PhDs graduates in Science and Engineering. The company advertised and more than 100 resumes were received and they were passed on to the corporate leaders for review. The corporate leaders were impressed that Malaysia not only had MSc and PhD graduates from local universities but also from other parts of the world, namely, England, Australia, Japan, Taiwan and a few from the USA.

in the 1980s

Subsequently, since early 1980s, what had started as simple testing facilities had progressed into the state-of-the-art testing as Malaysians continued to demonstrate their capability and competence in handling sophisticated testers which cost more than US$1 million each. More local senior managers began to replace

by Y.Bhg. Dato’ Wong Siew Hai, Chair of Malaysian American Electronics Industry (MAEI), Honorary Governor, AMCHAM

the expatriates to head the companies and their operations. As the growth of the E&E industry was getting stronger, there was a need to drive productivity and this led to the start of mechanisation in the factory where local SMEs played an active role and assisted the Multi-National Corporations (MNCs) in improving their productivity through mechanisation such as auto unloaders and auto indexing, while precision tooling had kick-started in which the required tools can be made locally.

Eventually, shortage of manpower and insufficient time to train workers led to the need of outsourcing the manufacturing operations that started the setup of local contract manufacturing which supported the growth of the MNCs. Meanwhile, a wage spiral kicked in as companies headhunted for technicians and engineers. To arrest this problem, the industry, together with the government, proposed the establishment of a non-profit Penang Skill Development Centre (PSDC) to assist with the training of technicians, machinists for the local company and training the direct workers to perform some of the basic technician’s tasks, under “The Workforce Transformation” programme which aimed to enhance the knowledge and productivity of workers. The PSDC was set up in 1989, followed by SHRDC (Selangor Human Resource Development Centre) in 1992.

in the 1990s

As the MNCs gained experience, some companies began to set up design and development centres. Malaysian engineers were sent overseas, especially to the USA for training. Semiconductor packaging development, manufacturing process development and design activities kicked in, while the local SMEs were challenged to go for full automation, that is, to develop automated equipment for the MNCs. They took up the challenge and many were successful in developing automated handlers and also for other applications.

in the 2000s

MIDA and the State Governments continue to attract other industries beyond semiconductors. More investments were seen in optoelectronics, medical devices, and solar cells. Also, some existing MNCs started business process operations for Human Resources, Finance, Information Technology, etc. Some of these operations were supporting the region and some worldwide.

Limited profit and loss (P&L) responsibilities were also transferred during this time.

The local contract manufacturing continued to grow to support the MNCs. The SMEs supporting tooling and automation had also gone global to support MNC factories located in other parts of the world such as the Philippines, China and Central America. A few of them became public listed companies. Also, more engineers left the MNCs to become entrepreneurs to set up system design companies.

From 2010 onwards

Malaysia is no longer viewed as a low-cost country and it is caught in the middle-income trap. Labour-intensive operations are moved out of Malaysia into lower labour cost countries. The factories have moved from high-volume low-mix to high-mix low-volume operations to stay competitive. There is a big drive to go up the value chain into hi-tech, hi-value activities. The government is encouraging more companies to set up D&D (Design & Development) centres or expand the existing design centres, and to set up global procurement centres, regional logistics centres, operational headquarters and other high value operations such as companies with P&L responsibilities. As such, many companies are doing so.

the challenges in E&E industry

Referring to Diagram 2 on the evaluation of the E&E Industry relative to the value-added curve, manufacturing has the least value-added while research and market exploration are of the highest valueadded. The assessment is that solar cell production is basically at the bottom of the curve with mainly manufacturing, LED is slightly higher up the curve with some design activities, EMS (Electronics Manufacturing Services also known as contract manufacturing) is higher up with design capabilities, supply chain and service support, semiconductor with more design capabilities and product development, and automation with nearly full capabilities from market to design. As you can see, there is a lot more room to move up the value chain.

From the 2013 survey of the Malaysian American Electronics Industry members (MAEI), the growth of the D&D is in-line with the direction of the government to go up the value chain. From the graph below, the D&D expenditure has doubled from 2007 of RM1 billion to RM2 billion in 2012. The number of D&D engineers has also more than doubled from about 2,000 in 2007 to 5,500 in 2012.

The key challenge today is talent. We either do not have

(Continued on page 9)

Diagram 1: Evolution of Electronics Industry in Malaysia

Diagram 2: Evaluation of the E&E Industry in Malaysia

enough experienced engineers and/or the quality of engineers is not good enough. The companies have indicated that they could expand their D&D efforts faster if they could hire more quality and experienced engineers. The education standard needs improvement and English, both written and spoken, has to be improved, as it is an essential business language especially in the E&E industry as most manuals, specifications, meetings, equipment with interactive features are all in English.

The other challenge is to build the eco-system. With more D&D work being done, the companies are looking for capable local companies that can take on engineering challenges as they would like to outsource some of the D&D work. Such capability needs to be further developed.

Future Direction of the E&E industry

In terms of talent development, the government has taken the inputs of the industry into account. They are encouraging more scientists and engineers to study Masters and Doctorates through MyMSc and MyPhD programmes. The Northern Corridor Implementation Authority (NCIA) has set up the Centre of Excellence (CoE) for Microelectronics operated by USAINS Infotech Sdn. Bhd. At this E&E CoE, talents are being trained for microelectronic design. There is an MSc programme with the Universiti Sains Malaysia (USM) and the first batch of MSc in Electronics Engineering has graduated. It is also providing design engineering services to the MNCs. Furthermore, there is Talent Corp attracting talents back to Malaysia. As for expatriate talents, it is easier now to get

employment permits and many of them are given residential pass valid for 10 years.

strengthening the talent Pipeline through Education

However, the above will take time and it is still not sufficient to support the industry now and in the future. Diagram 4 shows more work need to be done in the area of education. We need to provide quality education from primary to secondary. The university standards need to be improved. The command of the English language is important and must be improved. Last but not least, we need to encourage more students to study science and engineering as the number of students studying these two subjects has decreased from more than 60% to currently at around 30%.

Establishing a strategic council for E&E industry

There is also a need to establish a strategic council that will consist of mainly experienced leaders from the E&E industry working with the government to develop strategies and directions for the industry. This will be a joint public-private driven effort focusing on strategic areas. The programmes will be supported for a longer-term implementation. It will set goals and it will also look at streamlining the government funding. One of the goals could be becoming a top 10 design centre in the world and the said council ought to think about what will it take to achieve such a goal.

Building the Eco-systems

Even though Malaysia has had more than 40 years of experience in the E&E industry, we have missed building the eco-system for the semiconductor sector. However, we have the opportunity now to build the eco-systems that are needed for green technology, LED, solar, embedded systems and bio-medical devices.

nurture More local sMEs to be Global companies with international Brands

There needs to be some strategic programmes to assist local SMEs to grow and compete globally. The assistance could be in areas of technology acquisition, product commercialisation, funding where necessary, branding and setting up global networks and business connections. On the other hand, we need SMEs that are hungry enough and have the passion to innovate and want to be recognised global players. Malaysia still has this dream that one day one of the local companies will establish a globally recognised brand such as Samsung, Apple or Nokia.

Diagram 3: D&D Workforce and Expenditure

Diagram 4: Strengthen Talent Pipeline through Education

Diagram 5: Set Up a Strategic Council for E&E Industry

e&e Industry from the Corporate’s Perspective

Interview Conducted by Reika Kua Kee Eng

in order to take a closer look at the issues highlighted by Y.Bhg. Dato’ Wong Siew Hai in the previous article, “The Malaysian Electrical & Electronics (E&E) Industry – At an Inflexion Point,” JURUTERA also conducted interview sessions with Mr. Chris Kelly, the General Manager of the Malaysia Design Center (MDC), Intel Malaysia; Dr. Hari Narayanan, the Director of Engineering, Head of Penang R&D Centre, Motorola Solutions Malaysia; Dr Kamarulzaman Mohamed Zin, Chief Executive Officer (CEO) of Silterra; and Mr. Dennis Au, Vice President of Sales, Marketing and Support for Asia, Agilent Technologies.

Electrical & Electronics (E&E) industry has experienced extremely high growth over the last two decades. Such progress has also led to various concerns in terms of sufficiency of workforce and talent, the contribution of MNCs to community and workforce, and the collaboration with institutions of higher learning for constant research and development of sustainable technology. Let’s take an in-depth look at these issues from the corporate’s perspective.

The ImPACT of globAl & regIonAl ComPeTITIons To e&e IndusTry

“Malaysia needs to continue to climb the value chain ladder and increase the capability of its workforce to support this task. Despite the growing cost of manufacturing in China and some manufacturing returning to our shores, we should not be distracted from the need to grow local R&D talents and to continue to innovate. Providing suitable incentives to cultivate and encourage MNCs, both foreign and local, as well as SMEs to develop world class technologies and products from Malaysia is vital,” suggested Mr. Dennis Au, Vice President of Sales, Marketing and Support for Asia, Agilent Technologies.

He added, “To achieve these objectives, we, as an MNC, need to continue building an ecosystem of supporting suppliers and SMEs in Malaysia. This deep-rooted eco-system will allow Malaysia to not only compete regionally and globally but will also encourage investments from overseas to take advantage of the country’s capability, infrastructure and incentives.”

According to Dr Hari Narayanan who is the Director of Engineering and Head of Penang R&D Centre, Motorola Solutions Malaysia, the electronic industry is rapidly changing and the ability to evolve and innovate to stay ahead of the curve is key for any technological company to become successful. It is imperative for Malaysia’s electronic industry players to have a robust set of strategies focusing on not just driving efficiency in its operations and cutting costs, but also the ability to be agile and nimble to move up the value chain (e.g. in areas of design and development) to complement its manufacturing base.

how well-reAdIed Are our TAlenTs?

As Malaysia is pushed to move up the technology value chain, how ready are our talents to weather such challenges? According to Dr Hari Narayanan, we have a capable workforce with potentials in Malaysia. However, there is a need to create the right environment and provide the right strategic leadership to enable these talents to meet the challenges.

Meanwhile, CEO of Silterra, Dr Kamarulzaman Mohamed Zin, also shared the same opinion with Dr Hari Narayanan that our talents should be readied to weather such challenges, “As shared earlier, most of our talents are locals trained in local and overseas institutions; and from that base of knowledge, our company builds its intellectual capital and assets through training, exposure and serving the customers. We constantly encourage our talents to further enhance their skills and competencies through formalised programmes as well as through unstructured self-driven programmes for our team to improve themselves. The role of management here is to give the resources for it to happen.

Our industry is like that – there is no sitting still”.

In addition, Dr Kamarulzaman also highlighted that integrated circuit (IC) design and fabrication actually sits at the top of the value-chain of the electronics industry. The advancements achieved in IC design and fabrication generally drive the innovations in nearly all of the activities of human endeavour.

Adding to the above, Mr. Chris Kelly, the General Manager of the Malaysia Design Center (MDC), Intel Malaysia commented, “To overcome the mismatch between industry needs and available talent, Intel has been working with education institutions to ensure that graduates are equipped with industry-relevant skills even before they enter the workforce. For example, Intel and MDeC signed a MoU in 2009 to provide industry-relevant training courses to faculty members of Malaysian universities to upgrade existing academic curriculum for graduates. Intel is also a key partner in the CREST research institution initiative”.

Intel works very closely with MoHE, Northern Corridor Implementation Authority (NCIA), various government agencies and the universities to develop curricula that will advance innovation in key areas of technology in an effort to increase the technical talent in the country. Intel Malaysia, MoHE and MDeC have collaborated to introduce its VSLI and TRIZ curricula to university professors to integrate into their lessons. The curriculum development offers training for faculty members to teach graduates and enhance their technical and systematic innovative problem solving skills which will be relevant to industry requirements. In addition, Intel has also worked with NCIA to develop a programme to train unemployed graduates on analog and digital design as part of the efforts to move up the value chain through human capital development, enabling the Design and Development growth for the nation.

“At Intel, we value our employees and are always looking for the right talent for the high-technology work we carry out. We hire on a needs basis and as high-volume manufacturing is automated, the priority for us is to move Intel Malaysia up the value chain to focus on high-value activity such as design and development and R&D. Our goal is for Intel Malaysia to be innovation-driven, in line with the government’s vision for the nation,” added Mr. Chris Kelly.

“Besides developing university programmes and opportunities for graduate trainees, we also provide in-house training and development programs for our employees. In our 41 years here in Penang, Intel has employed some tens of thousands of people! We also work very

(Continued on page 12)

closely with the government on its strategic initiatives like Talent Corp to attract creative and bright individuals back to the local scene,” said Mr. Chris Kelly.

CollAborATIon wITh InsTITuTIons of hIgher leArnIng

Both Mr. Dennis Au of Agilent Technologies and Dr Kamarulzaman of Silterra agree that universities do play a role in supporting technology innovation. However, they also pointed out that collaboration between major industrial players such the related MNCs would certainly make a difference and help bring more opportunities to existing and future talents in the E&E industry.

“The semiconductor industry has always been one of the most R&D-intensive industries today with strong traditional ties with the Universities. Our collaboration with the Universities, Polytechnics and Technical Training Institutes are very extensive indeed. We start with the academic personnel themselves – we open our doors to whoever who are interested to spend their sabbaticals with us, in the hope that by making our activities transparent to them we should be able to bridge the gaps between industry and academia,” said Dr Kamarulzaman.

He further elaborated that Silterra has internship programmes for graduates (locals and foreign) who want to embark on a career in the semiconductor industry, and such programmes are organised in collaboration with the different Government agencies (e.g. programmes with UNIMAP, USM, UNITEN, UTEM, UUM, NCIA and Talent Corp). Silterra has also invested and sponsored in various research projects with the academicians. Some of these projects lead to postgraduate qualification for our personnel. “We provide special and affordable services to the Universities and Academia to use our Multi Project Wafer Services (MPW) for them to convert their integrated circuit designs into actual silicon chips. Then, they would able to discover whether the designs actually work or work reliably according to specifications. A true moment of discovery indeed,” highlighted Dr Kamarulzaman.

Agilent is also actively partnering with the government and academia to cultivate and nurture academic excellence in science and engineering by supporting initiatives to set up effective laboratories with embedded educational kits that will enhance the learning experience of the students. In addition, Agilent works closely with universities to strengthen their curriculum at all levels, all the way to PhD level, including developing and delivering competency specific programmes that their engineers can leverage on to enhance their knowledge while they are working.

An example of a successful collaboration is the setting up of a Knowledge Worker’s Development Center to deliver specialised knowledge transfer and technology-sharing opportunities for postgraduate students. “To do this, we have set up comprehensive programmes to equip public labs to develop hands-on competencies in the fields of E&E, biotechnology and analytical chemistry,” said Mr. Dennis Au from Agilent Technologies. He continued, “Beyond education, we are also active partners in Malaysia’s newly established CREST initiative. Here, we will help to identify key market orientated research projects for local universities and research institutes. For some of these projects, Agilent will also be an active research collaborator”.

KeePIng uP wITh The exPeCTATIons of THE WORkFORcE AND cOMMUNITY

According to Mr. Chris Kelly, Intel Corporation has a very strong commitment to the communities where they work and live in. “We have strong interest in supporting education, environment and community programmes that deliver the kind of educational and technological advancement opportunities within our communities. This builds the framework for our community programmes, but each initiative is implemented and tailored to suit the needs of each unique Intel site”.

Such emphasis can be observed through its conducts which have earned Intel several recognitions. For instance, Intel has established a stellar track record of corporate citizenship in its efforts among the community. Intel Malaysia is recognized externally for its contribution in the CSR space, including winner of the inaugural Prime Minister’s CSR Award in 2007, Community and Social Development Category, and in 2009 for the Environment Category, with Honorable Mentions in Education and Workplace Practices.

“We have established several annual CSR programmes for the environment and the community, such as mangrove tree planting, Back-to-School programme, annual Hari Raya and Chinese New Year Festive Cheers. The impact of our CSR efforts in the community has been encouraging and we intend to step up. The spirit of volunteerism in Intel Malaysia runs deep in the veins of our corporate culture. Over 50% of our employees volunteer in communities where they work and live,” highlighted Mr. Chris Kelly.

“For Agilent, we see ourselves as one of the major players in proliferating interest in the Science, Technology, Engineering and Math (STEM) subjects in schools and universities. Interest in these fields will go a long way to encourage future generations to embrace science and engineering, and hence helping to ensure a continuous pipeline of science talents to power Malaysia today and beyond. Specifically, we actively engage the local community with a wide range of STEM-based outreach programmes that range from primary schools to universities,” emphasized Mr. Dennis Au from Agilent Technologies.

According to Mr. Dennis Au, “Agilent’s business model is based on global technology leadership in our areas of interest. Our continuing push to extend the technology boundaries in these fields will also be felt as we introduce these into the local community through our local workforce and technology outreach programmes”.

word of AdvICe for buddIng engIneers

According to Dato’ Wong Siew Hai, the E&E industry will continue to hire engineers for their growth and expansion in new projects and responsibilities. If a graduate’s plan is to be involved in D&D, then he or she needs to ensure that he or she gets a good foundation in engineering principles including software knowledge. “Although grades may not sound important, the new engineer will likely be called for an interview if he achieves a CGPA of 3 and above. If he has an MSc or PhD, he will have an edge over others. The company now also evaluates his soft skills, attitudes and areas of interests. One of the areas they will look into is his ability to communicate especially in English. If he cannot communicate his wonderful ideas, nobody will understand him and then nothing will happen. Also, it will be good if the engineer gets industrial experience through some form of internship before he graduates,” emphasized Dato’ Wong.

The Call to Refresh: IEM Must Remain Relevant

by Ir. Choo Kok Beng FASc

TIME waits for no one – we must keep up with the times in order to remain relevant. When even a second’s wait while surfing the Internet is frowned upon, it is unquestionably important for IEM to remain relevant in our fast-paced society.

Recognising this indispensable need to remain relevant, I believe that the call to refresh IEM should be taken seriously.

With IEM’s strong framework, I believe that my effort would be to refresh everything we have been doing in the past.

Don’t get me wrong – for a learned society like IEM to have lasted 53 years is quite an amazing feat. Many other bodies might have crumbled in the sands of time. During my presidential term I want to change the culture of IEM so that we are not as conservative as we were before. It is time to take risks. We need to innovate and change our approach in doing things so that we remain relevant to the industry as well as to our members.

I write as one who has seen IEM grow for over 34 years. My roots in IEM go a long way back to 1978 when I was still a drainage engineer in Johor. In a way, I had already set my foundation in IEM many years ago. I have also been able to encourage a lot of engineers who have the same mindset to be active in IEM. A ship cannot run with only the captain on board. If you are the captain and the sailors do not support you, the ship cannot sail.

EvERyonE wIll bE hEaRd

Sailing in the same ship that is IEM, part of my plans to refresh IEM is to ensure that everyone is heard. I believe that everyone deserves to be heard.

One of the things I promised when I took over the presidency is that I want to listen a lot before I can do anything more. I have a lot of ideas about what I can do. But before I go into the details of implementing these ‘refreshments’, I must learn to listen.

To execute my ‘listening plan’, I have set a target to visit all the IEM branches by the end of July 2013. So far, I have gone to Pahang, Malacca and Negeri Sembilan and will be covering Kedah, Perlis and Sarawak in the coming weeks.

In a turn of events, I found myself at the site in Penang where the freak storm in June caused horrific damage. There, I met Ir. Addnan Mohd Razali the Head of Engineering of Majlis Perbandaran Pulau Pinang and past Chairman of IEM branch and we discussed what could be done to solve the damage and to prevent further damages from occuring.

During my visits to the other branches, I will hold dialogues with the members to inform and educate them further about IEM.

Many members of IEM do not know what the institution is all about. Many do not know how strong the institution is nor do they know the opportunities they have within the institution. For example, we have created an ideal platform for them in the ASEAN Engineering Register (AER). They will be registered with the AER and recognised all over the ASEAN countries with a total population of 600 million people – so they do not have to restrict themselves to Malaysia’s population of 29 million people.

I founded the AER in 1998 under the ASEAN Federation of Engineering Organizations. The goal of AER is to have a database of all engineers in the ten ASEAN countries. From here, I hope IEM can facilitate the mobility of engineering within the country.

lookIng bEyond

Realising the brevity of my presidency term, I have set my mind to make as many positive changes as possible during my term.

As President of IEM, I only have a two-year term. That is all the time I have to play this role. So I have taken the opportunity to introduce a seven-year plan, rather than the usual five-year plan. The seven-year plan will bring IEM to the year 2020, coinciding very nicely with the country’s goals Vision for 2020.

The call to refresh goes beyond IEM and the present time. I believe that IEM’s role is paramount in national development. After being involved in the engineering fraternity for so many years, I find that the only way that a nation can be harmonious and peaceful is through the input of the engineering fraternity. That is what we hope to facilitate.

The IEM would like to congratulate Ir. Choo kok beng for being elected a Fellow of the Academy of Science Malaysia.

Ir. Choo Kok Beng FASc with Ir. Addnan Mohd Razali

Damage at the site

The FirsT AnnuAl GenerAl

MeeTinG oF

ieM

This is a compilation of articles under the Sub-committee on Documentation and Recording of IEM Historical Events.

At the Inaugural Meeting held on 1 August 1958, members of the IEM Council were elected to organise and carry out the functions and activities of the IEM. Before the end of Sessions 1958/1959 and 1959/1960, the Council arranged to hold the 1st Annual General Meeting (AGM) of the Institution on 23 April 1960. Accordingly, the election process to fill Council vacancies for Sessions 1960/1961 and 1961/1962 was carried out in accordance with the IEM Constitution and Bylaws before the end of the Session.

The 1st AGM was held on 23 April 1960 at 2pm at the Lecture Theatre, Faculty of Engineering, University of Malaya, Kuala Lumpur, attended by 22 members (see list attached). The meeting was called to order with En. Yusoff bin Hj. Ibrahim at the Chair.

Confirmation of the Minutes of the Inaugural Meeting

The minutes of the Inaugural Meeting was circulated among the members. Mr. Chin Fung Kee proposed that the minutes be adopted. His proposal was seconded by Mr. Tong Kay Chor. The minutes was unanimously adopted.

The Council’s Report

Honorary Secretary, Mr Lau Foo San, reported on the progress of the Institution since the Inaugural Meeting. The Institution was officially registered with the Registrar of Society, Malaya, on 1 May 1959 (Ref. PMM51/59). In the meantime, contacts were established with other international engineering institutions, for example ICE, IMechE, IEE etc. There were good responses from engineers to join the IEM and IEM already had members in every State. The Institution aimed to encourage engineers to come forward to serve the nation during its formative years.

There were 48 members for the years 1959-1960, comprising Members (2), Associate Members (24), Associates (2) and Graduates (20).

Among the activities organised were site visits to Klang Gate Dam and Bukit Nenas Purification Works. The following site visits had been planned for April – July 1960.

• 14 May 1960 - Microwave Station

• 4 June 1960 – University of Malaya

• 9 July 1960 – Malayan Film Unit

The Inaugural Dinner to celebrate the formation of IEM was initially planned for 23 April 1960 but was postponed to 16 July due to the demise of the second D.Y.M.M Yang diPertua Agong, Sultan Hisamuddin Alam Shah.

Mr. Lau reported that the Council had decided to publish a bi-annual Journal of The Institution of Engineers (Federation of Malaya) and that Mr. Chin Fung Kee had been appointed Honorary Editor.

Finally, questions were raised from the floor. Among others, Mr. J.G. Daniel sought clarification on the status of the Government’s recognition of IEM. The Chairman replied that the new Council would pursue the matter. With the above, the Report was unanimously accepted.

The Honorary Treasurer’s Report

Mr. Ow-Yong Hong Chiew, the Honorary Treasurer, presented the Balance Sheet for the period April 1959 to 31 March 1960, with a total balance of $1,737.80. Proposed by Mr. J.G. Daniel and seconded by Mr. Tong Kay Chor, the Statement of Accounts was accepted.

Office Bearers for Session 1960/1961

In December 1959, notice inviting nominations to fill Council vacancies was sent out, followed by the distribution of voting papers. When the ballot box was closed, the votes were counted. The list of successful candidates was presented at the 9th Council meeting (the last for the Session) on 12 February 1960. In accordance with the Bylaws, the results of the election were later presented and announced at the AGM. The successful candidates were:

President :En. Yusoff bin Hj Ibrahim

Vice President : Raja Zainal bin Raja Sulaiman

Hon. Secretary :Mr. Lau Foo San

Hon. Treasurer :Mr. Ow Yong Hong Chiew

Council Members :

Civil :Mr. Tong Kay Chor

Mechanical :Mr. Dalip Singh

Electrical : Mr. Chew Kam Pok

Other Branches 1 :Mr. Chin Fung Kee

Other Branches 2 :Mr. Chew Kit Lin

Appointment of Auditors

Two names were proposed, namely Mr. J.G. Daniel and Mr. Kow Tat Cheong. A vote was taken and Mr. J.G. Daniel was appointed Auditor for Session 1960/1961.

Other Matters

Mr. Joseph Liew suggested that greater publicity be given to the activities of the Institution. He was supported by Mr. Philip Chow who suggested that the Council appoint a Publicity Officer. On the question of recognition by the Government, the Chairman felt that members should take a more active part in making the Institution representative of all engineers in the country. He said it would be easier to obtain recognition when the Institution joins the Commonwealth Engineering Conference.

The meeting was adjourned at 4.05 p.m. Mr. Chin Fung Kee proposed a vote of thanks to the Chair and was seconded by Mr. Joseph Liew.

Since then, the IEM has gone through many AGMs and the 54th Annual General Meeting was held on 20 April 2013.

List of Attendees At The First Annual General Meeting

1. En. Yusoff bin Hj Ibrahim – Chairman / President 12. Mr. E. Sivapathsundram

2. Mr. Lau Foo San – Hon. Secretary 13.Mr. Kow Tat Cheong

3. Mr. Ow-Yong Hang Chiew – Hon. Treasurer 14. Mr. Philip Chow

4. Mr. Tong Kay Chor – Council (Civil) 15.Mr. Lim Eng Sun

5. Mr. Chew Kam Pok – Council (Electrical) 16. Mr. Khor Chin Poey

6. Mr. Chin Fung Kee – Council (Other Branches 1) 17. Mr. Michael Ting

7. Mr. Chew Kit Lin – Council (Other Branches 2)

8. En. Ibrahim bin Arshad

9. Mr. Joseph Liew

10. Mr. Thean Lip Thong

18.Mr. Chin Thean Huah

19.Mr. Charles Gabriel

20.Mr. Khoo Soo Hock

21.Mr. J.G. Daniel

11. En. Mohd. Azuddin G.H.Z Abidin 22.Mr. C.S. Maniam

Y.Bhg. Dato’ Ir. Pang Leong Hoon was formerly the Director-General of the Department of Irrigation and Drainage, Malaysia. He was also the Past President of IEM for Sessions 1984/1985 and 1985/1986.

by Dato’ Ir. Pang Leong Hoon

Wireless Handheld Meters for Increased Safety and Productivity in Installation and Maintenance

IntroductIon

The world economy has generally improved since 2009. However, most companies are constantly under pressure to lower operation costs and usually, this means employees have to do more for less.

This is especially so for installation and maintenance (I&M) workers in industrial plants and commercial facilities. The I&M engineers and technicians are required to improve their skill sets and to source for tools that can improve productivity and efficiency, including handheld digital multimeters (DMM) and clamp meters, two of the most used measurement tools for installation and maintenance.

Modern and versatile handheld meters equipped with wireless connectivity capability can greatly save time and resources while improving safety, especially in the challenging and hazardous industrial and commercial environment.

ProPrIetary WIreless connectIvIty for HandHeld Meters

Wireless engineering with the help of mobile phones in the 1990s, which evolved to 3G in 2000s, redefined portability in communication.

The world is now moving towards 4G (LTE) with higher connection speed but wireless connectivity in handheld meters was available only several years back.

In its simplest form, a wireless handheld meter is merely one with a detectable wireless display. When the display is detached, no measurement readings can be seen.

Another concept is a built-in proprietary wireless protocol to enable communication within the same series of single-function or limited-function meters or to a computer via a proprietary PC adapter. Wireless connection to offthe-shelf smart devices like Android (smartphone or tablet) or iOS (iPhone or iPad) is not always possible as most smart devices use open wireless connections like Bluetooth®, WiFi or GSM.

by

oPen WIreless reMote connectIvIty for HandHeld Meters

The smartphone is one of the greatest technological innovations in the history of electronic engineering. It has changed the way we work, learn and play. To enable wireless connectivity for handheld meters, technologies like Bluetooth or WiFi (which are commonly built into any modern computing or smart devices) can be added as builtin or plug in device. Considering factors such as ease of use and setup, power consumption and commonality, Bluetooth is a natural choice.

The other question is: “What is a better choice - a built-in or plug-in device?” Built-in is simpler but it limits the range of handheld meters to only those with built-in Bluetooth technology. On the other hand, a plug-in provides greater flexibility and leveragability.

One solution is the Agilent Wireless Remote Connectivity (WRC, Figure 1), which offers plug-in Bluetooth (U1177A IR-Bluetooth adapter) wireless connectivity for all the 15 models of U1200 series handheld meters (multimeters and clamp meters) with different performances and prices.

Chan See Yung Product Planner Agilent Technologies

Table 1: Comparison between proprietary and open wireless connectivity on handheld meters

Figure 1: Agilent Wireless Remote Connectivity (WRC) Solution, which enables plug in Bluetooth wireless to Android smart devices and PC through the U1177A IR-Bluetooth Adapter with broad range of compatible U1200 series handheld meters.

IMProvIng safety In a Hazardous envIronMent

When working in a hazardous environment, safety should always be the priority. Other than applying correct safety practices, tools (e.g. handheld meters must be within the right safety category, CAT IV 600V/CAT III 1000V as defined in IEC 61010 and certified by accredited labs like CSA or uL) also play a big role.

Measuring on live machinery or electrical system in industrial settings is both challenging and hazardous, but unavoidable. Often, maintenance engineers or technicians need to understand the loading conditions of the industrial system and this can only be done when the system is in operation. This is where wireless capability will be an added safety measure that allows engineers or technicians to view measurements at a safe distance.

When probing crowded electrical or industrial circuits, where connectors or test points are close to each other, audible output of meter’s readings will help bring safety to the next level (Figure 2). Engineers or technicians can now concentrate on probing without having to look out for short circuits.

do More WItH less In electrIcal systeM MaIntenance

In industrial and commercial settings, the measurement point is often a distance away from the control or switching point. To observe changes at a particular point affected by switch or control system, a technician would need to walk back and forth unless there are two persons doing the job. With wireless connectivity on handheld meters, only one technician is required to set up the measurement and observe the reading at control or switching point. Productivity is increased as there is no need to walk back and forth.

Certain wireless solutions (e.g. Agilent Wireless Remote Connectivity) allow wireless connection of up to 3 handheld meters (Figure 3). This means one technician in the control room can now observe 3 different measurements simultaneously. Again, productivity is increased without the need for added manpower.

IncreasIng ProductIvIty In IndustrIal troublesHootIng

Troubleshooting an intermittent or drift related problem can be very challenging and time consuming. On top of having the experience and skill, one may need a professional handheld meter with data logging capability to capture events when a problem occurs so that appropriate action can be taken. Typically, an engineer would save data in the handheld meter’s internal memory and then transfer the data to a computer for further analysis. Data can be transferred through USB connectivity.

The Bluetooth wireless connectivity implemented on the Agilent WRC solution has opened up a new level of portability on data logging application for handheld meters. At any one time, engineers can now log multiple measurements wirelessly and directly onto smart devices (e.g. smartphone or tablet). With intuitive touch screen controls on smart devices, analysis can be done on-site in real-time.

Smart devices are highly connected devices equipped with phone and network connectivity. With mobile apps (such as Agilent Mobile Logger, Figure 4), an engineer can configure to receive email or SMS alerts when anomalies are observed. These make multitasking possible as an engineer can attend to other problems until the anomalies do happen.

Figure 2: Android smartphone provides audible reading on multimeter’s measurement for greater safety

Figure 3: Wirelessly monitor 3 handheld meters’ measurements using free Agilent Mobile Meter apps

4: Data Logging using free Agilent Mobile Logger apps on Android tablet that is wirelessly connected to Agilent U1177A IR-Bluetooth adapter plugged into Agilent U1273A Industrial OLED digital multimeter

evolveMent of Portable MeasureMent systeM

Preventive and predictive maintenance (PM) strategies are increasingly being adopted in industrial I&M to prevent unplanned breakdowns which can be costly. Engineers and technicians perform periodic measurements on electrical and industrial control systems to gauge the condition of a system. Technicians will need to manually record the measurements, date, time, location, machine identity and other related information for PM. This can be tedious.

With smart devices, it is now possible for an innovative engineer to automate or semi-automate some of the tasks by developing mobile apps and this can be done in-house or externally. The apps can directly acquire readings from handheld meter and tag the reading to the machine ID (usually available on the machine) by scanning the barcode (there are many barcode scanning mobile apps available). The information can then be synchronised with corporate database on real-time basis to effectively create a portable measurement system that is able to significantly increase productivity and reduce human errors.

conclusIon

With Bluetooth connectivity on handheld meters, increased adoption of smart devices and its highly connected eco-system into workplaces, I&M engineers and technicians can now work smart and be more efficient.

See Yung chan is Product Planner for Industrial Handheld Instruments in the Basic Instruments Division, Agilent Technologies’ Electronic Measurement Group. He has been with Agilent since 2000. He holds a degree in telecommunication engineering from University of Malaya, Kuala Lumpur.

referenceS

[1] Datasheet and brochure of Agilent U1177A IR-Bluetooth Adapter.

[2] For more information about Agilent’s WRC solution, please refer www.agilent.com/ find/gowireless

[3] Contact Agilent at mobile-meter@agilent.com to get support for mobile apps creation.

IeM DIArY Of eVenTS

Kindly note that the scheduled events below are subject to change. Please visit the IEM website at www.myiem.org.my for more information on the upcoming events.

Engineering Education Technical Division

3rd August 2013 (Saturday) 17th Annual General Meeting

Building Services Technical Division

17th August 2013 (Saturday)

27th Annual General Meeting

Precast Concrete Products for Infrastructure

High precision engineering products such as segmental box girders, tunnel segments, railway sleepers, turnout bearers and others.

28, Jalan 7/108C,Taman Sg. Besi, 57100 Kuala Lumpur.

Tel: +603-7980 2728 Fax: +603-7980 5662 www.epmsb.com.my

Figure

LED Lighting: A Review of This Green Technology

In recent years, LED lighting has taken off at a quick pace as incandescent lamps fade out. This is due to the absence of dangerous chemicals like mercury, and minerals in LED lighting and, depending on the application, a significant reduction in energy consumption.

LED is a “green” lighting source. In the next 5-10 years, it is expected that the world, including Malaysia, will make the transition from incandescent and fluorescent lighting fixtures to LED technology which is definitely superior in terms of a long lifecycle, operating costs and energy consumption.

The introduction of LED luminaire technology to replace incandescent bulb is in line with Malaysia’s commitment to saving energy. This forward-looking initiative has opened up great opportunities for us to be a player in the global LED lighting industry which received a boost when a number of countries affirmed their commitment to ban the use of incandescent bulb (Figure 1).

• Europe banned the traditional 100 watt light bulbs from September 2008 and all incandescent bulbs from September 1, 2012.

• America started the incandescent light bulb phase-out on January 1, 2012.

• Japan called for the halt in production and sales of incandescent bulbs in 2012.

• The Chinese incandescent bulb phase-out policy started in October 1, 2012.

Malaysia, in line with its policy to upgrade itself to be an R&D based and high tech manufacturing country, has grasped the opportunity to ride this boom wave of the global LED luminaire business. The government has made great effort to support the local industry to be more competitive in the LED luminaire market here and on a global level.

An effective strategy to drive the development of the LED luminaire market is through enforcement of legislations that include:

• Restriction of Hazardous Substances (RoHS)

• Reducing waste from Electrical and Electronic Equipment (WEEE)

• Phasing out of incandescent lights by January 2014

• Energy Performance of Buildings Directive (EPBD) as a Green Technology initiative

• Enforcing the anti-dumping of light bulbs by manufacturers

• Energy Star certification for appliances.

But despite the advantages from supportive legislations and efforts by the government to boost the competitiveness of local LED luminaire manufacturers, the industry still faces great challenges such as:

1.0 ThE cosT of LED LuminAiRE mAnufAcTuRinG kEEps incREAsinG sTEEpLy:

At present, most of the raw and intermediate materials used in the assembly and packaging of LED luminaire are imported because of the following:

• The materials are not available locally, for example, epoxy, silicone and the wafer.

• Locally purchased materials can be more expensive because most of these are brought from outside the principal custom areas (PCAs) in which the local companies are located.

• Prices charged by local suppliers are not competitive, possibly due to the fact that raw materials are imported, with local value added processing accounting for only a minor part.

• Another explanation for the non-competitive pricing of materials from local suppliers is that local companies impose substantial profit margins.

• Most of the imported materials are subject to import duties. Local companies may apply for exemption but with the extensive and time-consuming documentation, there is added cost involved.

Figure 1: Timeline announced by countries to phase out the incandescent light bulb

by Goh Boon Chin Vice President of Operation QAV Technologies Group of Companies

• Materials supplied locally are often of poorer quality. Local technology is generally less advanced than the US, Japan or Taiwan. This has further prompted LED packaging companies to source from overseas.

Figure 2 shows the supply chain in typical LED luminare manufacturing.

2.0 LAck of cApAbiLiTiEs in LocAL mAchinERy AnD AuTomoTivE mAnufAcTuRinG:

Most of the machinery and equipment used by the local LED luminaire companies are imported. This has directly increased manufacturing costs.

• All the machines and equipment used in wafer fabrication and Front-ofLine process are imported. Examples of the latter are dicing machine, die attach and wire bonding machines.

• Locally-made machines and equipment are available for the End-ofLine process, especially those used for testing as well as tape and reel. Although locally-made machines and equipment are available, LED luminaire companies prefer to buy from abroad because:

• Prices of locally-made machines are not competitive.

• Locally-made machines are often of poorer quality. For example, ramping-up using imported machines and equipment is much faster than using locally-made ones.

• Figure 3 summarizes the LED luminare manufacturing equipment supply chain.

3.0 TEchnicAL chALLEnGE AnD REsouRcE chALLEnGE

• Local LED luminaire companies face difficulty in hiring technical people with the right skill sets and competency in LED and related technology. The shortage is especially acute in optic design engineering, thermal dynamic engineering, LED module design, luminaire system design and electrical designer for LED driver.

• The mismatch of technical competency between manpower supply and demand is a critical concern. This has become the “road stopper” to the local fast growing LED manufacturing and LED luminaire system integration and design industry.

• Companies require new employees to perform immediately. However, fresh graduates are not equipped with the know-how needed for their jobs. This situation must be addressed by local universities who need to design their curriculum to produce technically competent graduates who can meet the needs of the industry.

Local manufacturers face difficulty in finding trainers who can offer courses to upgrade their design and technical core staff. In the absence of

Precast Concrete Building Systems

Hollow core slabs, planks, precast columns & beams, precast walls, precast staircases, and other customized structural concrete products.

EASTERN PRETECH (MALAYSIA) SDN. BHD. 28, Jalan 7/108C,Taman Sg. Besi, 57100 Kuala Lumpur. Tel: +603-7980 2728 Fax: +603-7980 5662 www.epmsb.com.my

We

Figure 2: The LED material supply chain

structured training, technical and design knowledge has to be picked up on the job or through trial and error. This is a limiting factor for the local LED industry to move ahead and grow to compete with multinational companies which have the resources to provide comprehensive technical training, by drawing on technical expertise from their headquarters overseas.

4.0 sLow LocAL LED LuminAiRE pRoDucT ADopTion

• The adoption rate of LED products by local consumers is very slow Although the Malaysian government has announced the ban on the use of incandescent bulbs by 2014, there is no legislation yet (currently still in progress) and no organised campaigns to aggressively promote the advantages of LED luminaire products.

• Prices of LED lighting products are much higher than comparable compact fluorescent lamps (CFLs) which are already established in the market. This is due to several factors as discussed earlier.

• The ban on use of incandescent bulbs may well lead to an increase in the use of CFLs rather than LED lightings. This is due to a lack of information to educate the public on the advantages of LED luminaire products.

• Although the government has taken the first step to phase out incandescent lights, the market continues to favour traditional lighting which is well-established.

5.0 Low LEvEL of LocAL inDusTRiAL invoLvEm

LED LuminAiRE DEsiGn AnD sysTEm inTEGRATion

• In Malaysia the LED lighting industry is dominated by large foreign firms. Only a few local companies are involved and these have limited roles such as the low value added process of packaging. No local companies are involved in upstream activities like wafer fabrication.

• We also have very few local companies moving into LED luminaire driver, system design and application. What most of them do is to merely import luminaire products and market them locally. Limited to trading activities, these companies are not able to build up their competitiveness based on development of indigenous technology in LED. There are no unique features in the products to distinguish one company from another as their LED products are all purchased from overseas. Such unrestricted importing of LED luminaire products invariably leads to increased competition and price wars. The case for promoting LED luminaires as the advantageous alternative is lost in the fight over the price advantage.

• The lack of home-grown technology also means that local LED luminaire companies are unable to come up with product designs to compete with imported lighting or to make to the requirements of customers. Big overseas companies, however, are able to provide design services to meet specific needs or requests. This scenario has further slowed down

Figure 3: The LED luminaire equipment supply chain

the growth of the local LED industry and hindered the quick and widespread public acceptance of this green technology.

• There are some big foreign companies operating in Penang which are involved in LED luminaire system integration. However, almost all their products are sold in the US, Europe and elsewhere in Asia. Less than 1% of these is sold in the local market. Again, this has contributed to the slow pace of local use of LED products as what is available here is expensive, imported LED lighting.

REcommEnDATions

For local LED luminaire manufacturing to play a major role in getting Malaysia to adopt this green technology, it is important that this sector be sustained by government initiatives. These include doing more to educate the public and promote its use, spawning and developing SME into optoelectronics module and system integrators, and skill capacity building among lighting designers and architects in the application of lighting retrofit, lighting fixture, lighting module and lighting system using LED luminaire to replace conventional lighting.

Local companies must be given incentives to move into LED integration in particular in the application of LED lighting. This range of activities can generate better profit margins compared to LED packaging which is the focus of Malaysian companies in this industry. LED integration

companies have mushroomed in countries like Taiwan and China. Major companies that have positioned themselves in LED integration include giants like Foxconn, Delta Electronics, Chimei and AUO from Taiwan and Midea and TCL from China.

The government should capitalize on the availability of expertise in design at the system integration level to provide training for local technopreneurs in promoting and developing the LED integration industry. Local institutions and universities should include in their curriculum more courses that are in line with the country’s economic transformation plan that cater to high tech and green technology industries.

Incentives from the government should benefit local companies and encourage them to get involved in the LED industry, for example provide support on infrastructure, land and building, offer subsidy for high tech equipment for the manufacture of core LED components, abolish hiring restrictions on foreign knowledge workers and ease entry of expertise from overseas, exempt tax import duty for core raw materials and exempt on domestic sales of advanced LED products.

Goh boon chin is the current Vice President of Operation QAV Technologies Group of Companies. He built the test standard for LED and Luminaire testing for Malaysia and collaborated with Energy Commission, JKR, Sirim, GreenTech, to ensure all Luminaire entering Malaysia are of high standard. He obtained ANSI certification for luminaire and Led modules and qualified QAV into DOE/EPA to become 1st lab in South East Asia to have such accreditation. He has also worked with TUV Germany to get certification for automotive and medical products.

EVE n T outstanding young malaysian Award

Ir. Prof. Dr DomInIc foo chwan YEE has been awarded The Outstanding Young Malaysian Award 2012, for Scientific and Technological Development. The Professor of Process Design and Integration at the University of Nottingham Malaysia Campus (UNMC), is the Founding Director for its Centre of Excellence for Green Technologies.

He is a locally-trained expert on waste minimisation and resource conservation, with BEng, MEng and PhD degrees from Universiti Teknologi Malaysia (UTM). He obtained his full professorship at the age of 34, within five years of graduating from his PhD. He is a member of the International Scientific Committee at many important international conferences and often, he is one of the few representatives from Asia.

He is also on the editorial board of the journal, Transactions Of Institution Of Chemical Engineers (IChemE UK) as well as IEM Journal. Last year, he published two books, which are available in IEM library. Ir. Prof. Dr Dominic Foo is often invited to give talks and conduct workshops here and abroad, including talks and workshops for IEM. Prior to the Outstanding Young Malaysian Award, Ir. Prof. Dr Dominic Foo was also awarded the Innovator Of The Year Award 2009 by IchemE and Young Engineer Award 2010 by IEM.

book LAunchED

Ir. Prof. Dr Dominic Foo launched his book, Process Integration For Resource Conservation, on 2123 November, 2012, at the 26th Symposium of Malaysian Chemical Engineers held in conjunction with the 4th International Conference On Chemical And Bioprocess Engineering (SOMChEICCBPE-2012) at Kota Kinabalu, Sabah.

Ir. Prof. Dr Dominic Foo was the 2012/13 session chairman of the Chemical Engineering Technical Division of IEM.

A CETD committee member, Engr. Assoc. Prof. Dr Denny Ng Kok Sum receiving a copy of the book

The event started with an opening speech by Ir. Prof. Dr Abdul Wahab Mohammad, Chairman of IChemE Malaysia Board. Then Prof. Raymond Tan from De La Salle University, Manila, a long-term collaborator of Ir. Prof. Dr Foo, briefly explained the contents of the book and noted that the book came with Excel-based software and spreadsheet examples that allowed readers to do hands-on exercises. Ir. Prof. Dr Dominic Foo has donated a copy of the book to IEM library.

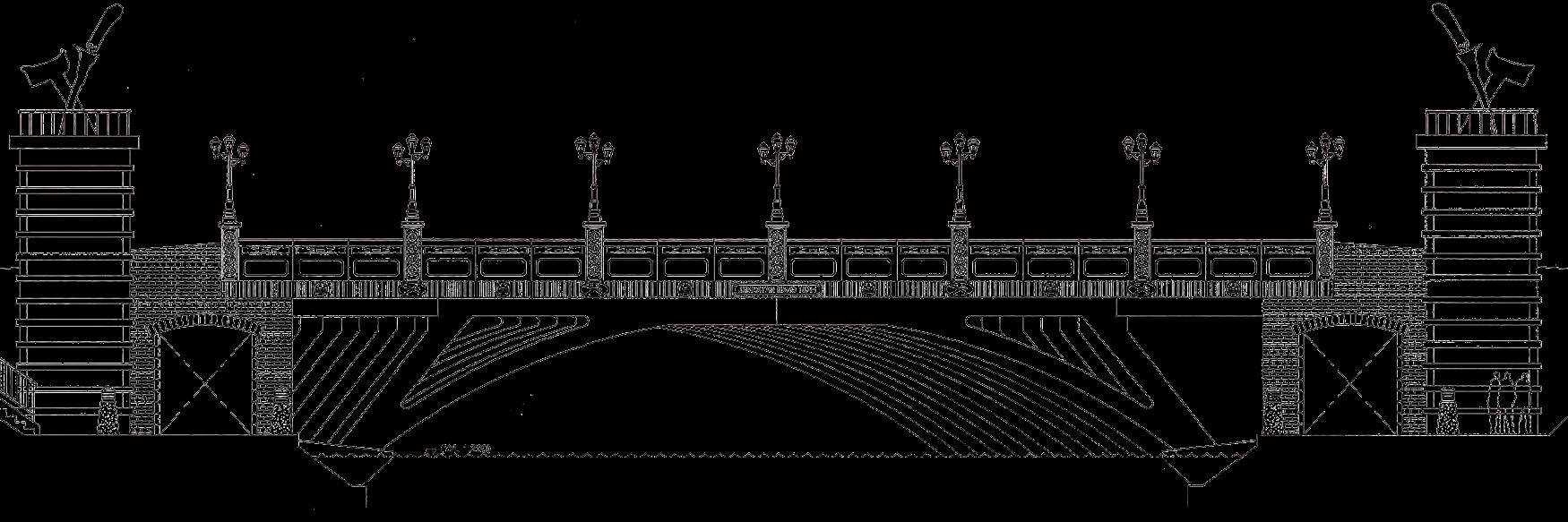

SECOND BRIDGE STILL AHEAD OF SCHEDULE

Despite the ramp collapse at the Batu Maung interchange on June 6, the Second Penang Bridge is expected to be completed ahead of time as the construction of the 24km bridge was two months ahead of schedule, said Azizi Azizan, public relations and communications department deputy manager, Concessionaire Jambatan Kedua Sdn Bhd (JKSB).

The bridge was originally slated for completion in November. However, JKSB had announced that it would instead be completed in September.

“Any delay now will depend on investigations carried out by the Department of Occupational Safety and Health (DOSH),” he said. DOSH had roped in a panel of experts to investigate the incident. State DOSH director Mohd Anuar Embi said a team of 13 men was investigating the cause.

Anuar added that the team’s initial investigation would focus on the failure of the support. “We will look at the design and installation of the support. Wrong design or installation and lack of maintenance would have caused the bridge to collapse,” he said.

(Sourced from NST, 10 June 2013)

VW, AUDI RECALL CARS IN AUSTRALIA

German car giant Volkswagen (VW) recalled nearly 26,000 vehicles in Australia and Audi followed suit with 6,000 cars due to a gearbox problem that could cause a loss of power while driving. This follow growing safety worries sparked by the death in Australia of a woman while in a 2008 Golf whose car slowed and was hit from behind by a truck on a Melbourne motorway in 2011.

The news sparked complaints from other VW owners whose cars had also cut out or stopped on busy roads. “In isolated cases, an electronic malfunction in the control unit inside the gearbox mechatronics may result in a power interruption,” VW’s Australian branch said. The models affected include Golf, Jetta, Polo, Passat and Caddy cars produced between June 2008 and September 2011.

Audi, whose parent company is VW, followed suit and recalled more than 6,000 hatchbacks in Australia due to the same gearbox concerns. AFP

(Sourced from NST, 13 June 2013)

LATEST TECHNOLOGY IMPORTANT FOR AIR FORCE

The Sultan of Pahang said mastering the latest in technology is important for the Royal Malaysian Air Force (RMAF) to be at its best. Speaking at the RMAF’s 55th anniversary parade here, Sultan Ahmad Shah said the ability to master the latest, sophisticated and precise technology would be a big advantage.

He said the deployment of EC-725 helicopters into its service in January has boosted RMAF’s battle-readiness, instantly enabling it to carry out missions in various weather conditions and tactical environments.

(Sourced from The Star, 8 June 2013)

BIGGER CASH PRIZES FOR PERODUA ECO-CHALLENGE 2013

The Perodua Eco-Challenge is back for the fifth year to test students on their knowledge and skills in the field of automotive engineering and marketing.

Perodua president and CEO Datuk Aminar Rashid Salleh said: “In conjunction with our 20th anniversary this year, we will be making the Eco-Challenge even more interesting with bigger prizes totalling RM127,000, an increase from last year’s RM103,000,”.

Ten institutions of higher learning have been selected to redesign the Perodua Myvi by December. This year, the institutions not only have to make the car more fuel efficient, but they also have to improve on its design to suit the needs and lifestyle of the public.

(Sourced from the NST, 4 June 2013)

MALAYSIANS HELP DESIGN INTEL’S 4TH GENERATION CORE PROCESSOR

Malaysian engineers are very much behind the success of Intel Corporation’s new fourth generation Intel Core processor, the first system-on-a-chip for personal computers.

Christopher Kelly, the General Manager of Intel Architecture Group (IAG), said 50 per cent of the 600-700 engineers worldwide who produced the core processor, are Malaysians.

“They were in charge of the physical design of the component and valuation testing,” he said at a media briefing on the Intel Core Processor.

(Sourced from the NST, 5 June 2013)

PROTASCO BAGS RM50M JOB

Protasco Bjd has received a letter of acceptance from Desaru Development Holdings One Sdn Bhd for the construction of a proposed infrastructure package, including road and drainage works to Desaru Coast Course in Johor, for RM50.4 million.

Christopher Kelly, the General Manager of Intel Architecture Group (IAG), said 50 per cent of the 600-700 engineers worldwide who produced the core processor, are Malaysians.

“They were in charge of the physical design of the component and valuation testing,” he said at a media briefing on the Intel Core Processor.

(Sourced from The Star, 11 June 2013)

Fruit for Thought

Scope

The first question that any Person-in-Charge should ask is the scope of what should be covered and the resources to make them work.

Let’s have a look at the scope. There has been a lot of literature on this subject and it is quite hard to remember the whole list. So let me give you a fruit for thought and we will keep the fruit in our mind for a while.

Think: PEAR

P – People (serious injuries, civil unrest, impact of natural disaster, etc.)

E – Environment (natural disaster, environmental spills and releases, etc.)

A – Assets (property damage, fire, etc.)

R – Reputation (integrity issues, accusations, bad Press, etc.)

I guess this is simple enough for you to start thinking about the events that should be covered. Sometimes one aspect can lead to another, for example, an environmental issue can become a community issue with Reputation risks (and “E” affecting a “P” and “R”).

BuSineSS impacT analySiS

The next step is to move into Business Impact Analysis. It is similar to your Risk Assessment (i.e. what is the highest threat to your business and your current level of preparedness). This exercise will help you prioritise your actions and resource allocation.

However to think through the PEAR and Business Impact Analysis, the Person-in-Charge cannot go it alone. He needs help.

Bccm Team

The next step is to set up the BCCM Team. Please do not confuse this team with your Emergency Response Team which is a tactical team to handle specific immediate incidents. Put simply, BCCM is actually the senior executive management team. Its roles are the same as its daily roles except there is more urgency and attention. It is important that each member has a secondary who is empowered to make decisions in his or her absence.

The team is usually supported by the BCCM Coordinator. This person actually supports the BCCM framework, from setting up training to updating contact lists and logging down incidents, etc. But the job is more than secretarial in nature as it does require a certain level of influence. Many companies appoint vice presidents or senior executives with influence to this position. During a crisis, the coordinator needs to cut across the whole organisation to help the Person-in-Charge get things done.