Agilia ™ is a new horizon for self-compacting and self-leveling concrete that spreads e ortlessly. The new concrete technology used in Agilia ™ allows for placing without difficulty , providing excellent quality concretes with superior surface finishes. Requiring no vibration , Agilia ™ moves easily through highly congested reinforced areas , with no bleeding and segregation. It is robust and esthetically pleasing. Agilia ™ gives flexibility on worksites at all levels, for all types of applications including foundations, architectural, horizontal and vertical structures.

LAFARGE CONCRETE (MALAYSIA) SDN BHD (95483-H)

LAFARGE CONCRETE (MALAYSIA) SDN BHD (95483-H)

2, Jalan Kilang, 46050 Petaling Jaya, Selangor Darul Ehsan, Malaysia.

2, Jalan Kilang, 46050 Petaling Jaya, Selangor Darul Ehsan, Malaysia.

Tel : (603) 7787 2000 Fax : (603) 7781 7675 / 7787 2129 www.lafarge.com.my

Tel : (603) 7787 2000

Fax : (603) 7781 7675 / 7787 2129 www.lafarge.com.my

YANG DIPERTUA / PRESIDENT: Ir. Choo Kok Beng, FASc

TIMBALAN YANG DIPERTUA / DEPUTY PRESIDENT:

NAIB YANG DIPERTUA / VICE PRESIDENTS:

Ir. Prof. Dr Ruslan bin Hassan, Ir. P.E. Chong, Ir. Prof. Dr Wan Mahmood bin Wan

Teang Shui, Ir. David Lai Kong Phooi

SETIAUSAHA KEHORMAT / HONORARY SECRETARY:

BENDAHARI KEHORMAT / HONORARY TREASURER: Ir. Hoo Choon Sean

BEKAS YANG DIPERTUA TERAKHIR / IMMEDIATE PAST PRESIDENT: Ir. Vincent Chen Kim Kieong

BEKAS YANG DIPERTUA / PAST PRESIDENTS:

Y.Bhg. Dato’ Ir. Pang Leong Hoon, Y.Bhg. Academician Dato’ Ir. (Dr) Hj. Ahmad

Chee Sheng, Y.Bhg. Academician Dato’ Ir. Prof. Dr Chuah Hean Teik

WAKIL AM / CIVIL REPRESENTATIVE:

Ir. Gunasagaran a/l Kristnan

WAKIL MEKANIKAL / MECHANICAL REPRESENTATIVE:

Y.Bhg. Datuk Wira Lt. Gen. Ir. Ismail bin Samion (Rtd)

WAKIL ELEKTIK / ELECTRICAL REPRESENTATIVE:

Ir. Mohd. Aman bin Hj. Idris

WAKIL STRUKTUR / STRUCTURAL REPRESENTATIVE:

Ir. Yam Teong Sian

WAKIL KIMIA / CHEMICAL REPRESENTATIVE:

Ir. Prof. Dr Abdul Aziz bin Abdul Raman

Ir. S. Kumar a/l Subramaniam

WAKIL MULTIMEDIA / MULTIMEDIA REPRESENTATIVE:

Ir. Noor Iziddin Abdullah bin Ghazali

AHLI MAJLIS / COUNCIL MEMBERS:

Ir. Dr Tan Kuang Leong, Ir. June Lau Yuk Ma, Ir. Assoc. Prof. Dr Norlida bt. Buniyamin, Ir. Ishak bin Abdul Rahman, Y.Bhg. Dato’ Ir. Abdul Rashid bin Maidin, Ir. Lee Cheng

Pay, Y.Bhg. Dato. Ir. Samsuddin bin Ismail, Ir. Lee Boon Chong, Ir. Tu Yong Eng, Ir. Lai Sze Ching, Ir. Lee Weng Onn, Ir. Yap Soon Hoe, Ir. Li Thang Fai, Ir. Juares Rizal bin Abd. Hamid, Ir. Norazman bin Mohamad Nor, Ir. Ellias bin Saidin, Ir. Assoc. Prof. Dr Jimmy Mok Vee Hoong, Ir. Dr. Tan Chee Fai, Ir. Kok Hee Poh, Ir. Tiong Ngo Pu, Ir. Yau

Ir. Assoc Prof Dr. Vigna Kumaran Ramachandaramurthy PENGERUSI CAWANGAN / BRANCH CHAIRMAN:

1. Pulau Pinang – Ir. Paul Phor Chi Wei

2. Selatan – Ir. David Lee Loke Hai

4. Kedah-Perlis – Ir. Chua Teik Seng

5. Negeri Sembilan – Ir. Hj. Baharuddin bin Ahmad Nasir

6. Kelantan – Ir. Hj. Syed Abdul Rahman bin Syed Abdullah

7. Terengganu – Ir. Mohd. Azmi bin Ali

8. Melaka – Ir. Vellan a/l Vengo @ Perumal

10. Sabah – Ir. Tan Koh Yon

11. Miri – Ir. Goh Soon Boon

12. Pahang – Ir. Tuan Haji Ahmad Kamal bin Kunji

AHLI JAWATANKUASA INFORMASI DAN PENERBITAN / STANDING COMMITTEE ON INFORMATION AND PUBLICATIONS

2013/2014:

Pengerusi/Chairman: Ir. David Lai Kong Phooi

Naib Pengerusi/Vice Chairman: Ir. Yam Teong Sian

Ketua Pengarang/Chief Editor: Ir. Prof. Dr Lee Sze Wei

Pengarang Prinsipal Jurnal/Principal Journal Editor: Pengerusi Perpustakaan/Library Chairman: Ir. C.M.M. Aboobucker

Yazrin Mohd. Khairi

LEMBAGA PENGARANG/EDITORIAL BOARD 2013/2014: Ketua Pengarang/Chief Editor: Ir. Prof. Dr Lee Sze Wei

Fai, Ir. Hj. Look Keman Sahari, Ir. Yee Thien Seng, Ir. David Lai Kong Phooi, Y.Bhg.

(IEM Secretariat: Pamela Jitab)

P.O. Box 223, (Jalan Sultan), 46720 Petaling Jaya, Selangor Darul Ehsan. Tel: 603-7968 4001/4002 Fax: 603-7957 7678

DIMENSION PUBLISHING SDN. BHD. (449732-T)

by Ir. Wong Chu Loong Chairman, Building Services Technical Division, IEM

shirley@dimensionpublishing.com

joseph@dimensionpublishing.com

bee@dimensionpublishing.com

siewli@dimensionpublishing.com

beela@dimensionpublishing.com

masaki@dimensionpublishing.com

yenyin@dimensionpublishing.com

DIMENSION PUBLISHING SDN. BHD. (449732-T)

HOFFSET PRINTING SDN. BHD.

JURUTERA MONTHLY CIRCULATION: 28,000 COPIES

PUBLICATION DISCLAIMER

COPYRIGHT

by Ms. CC Tan

RICHARD Chan of RCMC Sdn Bhd is one of the leading pioneers in Malaysia’s shopping centre and high-rise retail complex management industry. With over 33 years of in 1980, taking over the management responsibility for Ampang Park Shopping Centre at a time when the industry

He has since become the founder member and is one of the past presidents (1987-2006) of Malaysia Shopping Malls Association, which is also known as PPK Malaysia. He is also a member of FIABCI Malaysia (International Member) – he was its vice-president in 2005 – as well as a National Committee Member. In 2004, he became one of the founding members of the Council of Asian Shopping Centres. Presently, he is one of the committee members of the Building Management Association Malaysia).

Q: In Malaysia, we are often criticised for having a

Chan:

aren’t really there yet, especially if you look at the number of buildings collapsing all around the country. There are quite a few factors at work here. I always believe in going back to the basics, i.e. the planning. From the planning stage itself, all consultants involved should plan and design correctly, which means they should be sure to design and build it for the purpose it was meant for. For e.g., we shouldn’t see instances such as a carpark in Penang where not even a Kancil could be parked. Was this the architect’s fault? Yes it was, as he was the one tasked with designing the plans so he should know the correct measurements needed. Was it the structural consultant’s fault, as he was

If the parking bay couldn’t take the load of a Kancil, then he

Basically, we need to have the consultants involved look also plays a role because to a lot of developers, especially private developers, cost is always an issue. They would

ed in se

M develop

Currently involved in several (Alor Setar, Kedah), Selayang Star City (Selangor), M3 (Taman Melati, Selangor) and two retail development

s Bandar P Ch rom his bu ment in rticularly ve of a gement several g Melati, opment

Selangor), as well as Bandar Puteri Jaya (Sg. Petani, Kedah), Chan took some time off from his busy schedule to sit down with JURUTERA to share his views on building management in Malaysia today, particularly from the perspective of a retail facility management expert.

Puteri Chan h

prefer to cut cost, to incur the lowest material cost, as much as possible. Having said that, it’s up to these consultants and professionals to tell the developers that they cannot cut cost blindly because the consequences can be disastrous.

and built it correctly, then it must be maintained properly –

their cars. Firstly, the owners must ask themselves, have they budgeted for it?

a building is opened for use, that they need to do a budget (for the building’s management), with maintenance factored

issue we face now: A critical lack of skilled workers.

Chan: the power needs of a building. There are chargemen but not the authorities. I would say these people are a dying breed. Most are trained by Tenaga Nasional Berhad and they work

for years with the company. The experience and training they have gained would qualify them as chargemen but the

until they are near retirement age. This is because the they will walk out to a higher-paying position elsewhere.

But the law states that we need a chargeman for every building. Yes, we have MARA, which is the only one training

When the problem was pointed out to the designer, he suggested building catwalks for me. But how were my

solution ourselves: We took a lift to the highest point and we went into the motor room of the lift. From there, we had to open up a hole to climb into the ceiling to access the catwalk and change the bulbs.

So you can see here that the design of a building can present huge problems to the end user if the purpose of use is not taken into consideration.

Chan: Well, it’s usually because of extreme cost-cutting measures. For example, recently we have many cineplexes coming up. A lot of the walls between the cinemas are supposed to be soundproofed. But most of the brickwalls do not pass the sound-test. Why? That is a construction problem. Most of our workers now are foreign workers. In the older days, we have our local bricklayers. Their skilllevel was like that of bricklayers in Australia today, where is laid properly, with the mortar evenly spread out. Here, the work is done shoddily, resulting in gaps between the bricks. These are the gaps where sound passes through. So this is about quality workmanship.

Then, there are the mechanical and electrical systems.

constitutes about 30% of the capex (capital expenditure).

That’s a lot of money, so many developers try to cut costs

or system. For example they might get the right chiller, but then they might settle for undersized pumps.

“ If it is a mechanical or electrical error and we need to put in mitigation measures, it might just affect a portion of the building. But if it’s a structural error, you might have to tear the whole building down.”

Chan: Structure is usually the most critical part and this is where the mistakes usually start. To be fair, our architects and engineers are not specialised enough, so most of them

have to go for CPD (Continuous Professional Development) courses to have their licences renewed. Further, building managers, the end-users, should provide feedback to these engineers to help them learn and understand why shopping complexes are designed differently to accommodate different types of businesses.

Here’s another example: In Penang, we had a case ceiling). So it was more than 60 feet high. The designers put downlights in the ceiling. It looked good but overlooked a maintenance issue. How would we change the lightbulbs?

Chan: I think it would have to be structural mistakes. If it is a mechanical or electrical error and we need to put in building. But if it’s a structural error, you might have to tear the whole building down, as any mitigation measures

forward-thinking as well as be more frank and honest with wants, but you should also tell them the consequences of changing certain specs or of not doing something.

Chan: Yes, budget is still a very critical thing, not only in Malaysia,butworldwide.However,Ithinkitismoreprevalent in Asian countries – not because they think short-term, but passes inspection.

(Continued

„This is just perfect for my needs: in any variant for any application purpose.“

Example of an architectural design issue: After six months

Chan:

way, a question will be asked: Have you value-engineered evaluated whether the building designs or plans were of goods or products and services by using an examination of their functions.

“ Engineers have to be a bit more forward-thinking as well as be more frank and honest with their clients. Yes, it is not wrong to just do what the client wants, but you should also tell them the consequences of changing certain specs or of not doing something.”

It is, in a way, to cut cost and that’s not necessarily a consultant proposed installing 500 security cameras. There and a lift. After re-assessing, we found that it could be cut

So, in this instance, when we value-engineered, it improved a situation by providing the same measure of as an excuse to cut cost. For example, I would go with a two-tonne lift for a shopping centre, but to cut cost, others lifts, like a 12-passenger lift. It’s cheaper for the client up front but in the long run, it may not be good for the business,

check out a cinema. If you’ve never designed a hypermarket

And do talk to us, the facility and building managers. For instance, my company does market studies to assess the needs of a place, whether they need a mall and if so, what kind of size can the market sustain. A simple development can easily take two to three years to complete, if you’re lucky. So if you build a mall that opens shop in 2015 or 2016, you may later realise that a lot of things have changed. Technology would have changed, people would have changed as well as their needs and wants.

Just look at Sungei Wang Plaza. Look at the people who frequented it and the kinds of shops it had then and now. So we have a role to play to tell designers what to design for, by looking forward to as far as 20-30 years into the future. The only constant in retail is change.

Chan: You should think of yourself as an end user. If you have never designed a cineplex before, go buy a ticket and

Chan: We’re sorely lacking in skilled people in this sector.

but also the mechanical workers. What we have done in the last two years through BMAM (Building Management Association of Malaysia), is to push for more skilled workers.

Malaysia – we provided the necessary syllabi for them –and they’re now conducting a diploma and degree course

a degree and a Master’s in building management. There’s great demand now for such trained, skilled people, so people in our line are quite highly paid.

Facility management today is no longer what it used to

a business. For example, if you’re managing a shopping complex like Pavilion or the Mid Valley Mega Mall, you are, essentially, looking after a business with possibly hundreds of millions of ringgit in turnover. So the facility or building manager has to be a business-minded person, with sharp business acumen and a spirit of entrepreneurship. He or she must manage the building in a way that he or she can enhance its value. The building is an asset. Whether the price appreciates or depreciates depends on management and maintenance.

Chan: Basic education is one thing, but it doesn’t stop there. There must be continuous professional development and training. Just like how engineers have their Continuous Professional Development courses, so too should facility managers

by Ir. Choo Kok Beng, FASc

“We pray for the big things and forget to give thanks for the ordinary, small (and yet really not small) gifts.”

– Dietrich Bonhoeffer

MORE than just giving, Christmas is an excellent time to pause and give thanks for what we have.

Many IEM members and employees have been such strong yet silent pillars to IEM’s success. I’d like to highlight these forgotten, unsung heroes during this season of giving. Everyone has a different character but under IEM’s banner, all our talents are enhanced beautifully.

I do not mean to demean those who are direct or known contributors. I trust everyone will understand my point. This month’s President’s Corner is dedicated to celebrating your efforts.

Ir. Ellias is extremely active in IEM, but not many people are aware of his contributions.

association that promotes effective ways to manage the impact of human activities on the environment. That alone demonstrates what a big heart this man has, and IEM is grateful for the contributions of this quiet and peaceable man.

I always admire Ir. Gurmit’s no-nonsense personality and I salute him for his passion and determination in all that he sets out to do. A passionate activist, Gurmit enjoys provoking others to greater thoughtfulness and responsibility. Gurmit is an environmentalist and IEM is proud of his leadership and unrelenting efforts to champion ecosystem preservation so passionately for the future generation.

Clearlyinaclassofhisown,Dato’Ir.LeeYeeCheonghas far surpassed IEM’s expectations of a member. He rose from IEM and, today, he is well known in the international arena. He was President of the World Federation Of Engineering Organizations (WFEO) from 2003-2005. He is also the Honorary President of Commonwealth Engineers Council (CEC), to name a few. Yet Dato’ Ir. Lee remains a humble member and a very good friend. He has contributed much to IEM and remains an active member.

Miss Ooi has been with IEM for more than 40 years,

worked her way up to the post of Chief Administration

She is widely known as the walking encyclopedia of IEM. All the leaders of the 9 countries in the ASEAN Federation of Engineering Organisations (AFEO) know her personally.

In fact, after her retirement, IEM created a special post for her to remain in IEM. She is now the General Manager of Special Projects, focusing mainly on internationalising IEM’s image.

In case some of you might feel left out, we would like to say we do recognise faithful members who are active in other State branches. The limelight is always on the headquarters but you are always in our thoughts and never forgotten. We areawarethatthereisatremendousamountofvolunteerism in each branch and knowing there is so much love for the Institution brings tears to our eyes.

Lastly, we would like to thank the silent contributors to the Wisma IEM Building Fund. We are still receiving regular contributions from many of you even though the

This is invaluable to us and we appreciate every donation whether it is big amount or small. Likewise, to donors of the education and benevolent funds who have responded to our annual appeal, I say “Thank you!”

Have a Merry Christmas, from IEM.

Haw, Ir. David Lai Kong Phooi, Ir. Prof. Dr Lee Sze Wei and Ir. C.M.M. Aboobucker

by

AT its 19th meeting on 13 January 1961, the IEM Council considered the need to start a building fund with the view to have its own building one day. Towards the end of 1970, the IEM Secretariat shifted from the Station Hotel (Railway

Jalan Timur, Petaling Jaya. Squatting there since 1970, IEM was mindful then that it could not occupy temporary facilities forever

Sub-Committee was chaired by Y.M. Raja Zainal bin Raja

appointed with the following Council Members as Chairman:

Mr. Thean Lip Thong (Oct 1966 to June 1968)

Mr. Chester Ho Hong (July 1968 to Dec 1970)

The Committee considered various ways and means to raise funds including the sale of car badges, organising

Council Member contributed a minimum of $100 to the fund. Appeals for contributions were also made in the IEM

Initially, the efforts were not very fruitful or effective because there was not much information available on the site and on the design of the proposed building. However, after the site was decided on in 1966 (i.e. QT(R) 5514 Lot 60-62 Jalan 52/4, Town of Petaling Jaya, Selangor) and the preliminary design of the proposed IEM building was made

it was $127,020.31 (Ref: IEM Bulletin No. 5, No. 6 and No. 10). This amount was made up of: $19,089.00 contributed by 217 members; others.

The total sum was $127,030.31

decided to organise fund raising dinners. Two functions

1975 (under the Organising Chairman En. Mohd. Razali bin Bidin) and $58,000 on 6 November 1976 at Hotel Merlin, Kuala Lumpur (under the chairmanship of Mr. Cheah Kok Cheang). The total sum raised was $191,275 (Ref: IEM Annual Report Session 1978/79).

of Main Contributors and Amounts

Sir William Halcrow & Partners (£2,500)

Preece, Cardew & Rider$10,000

Steen Sehested & Partners$6,000

Association of Consulting Engineers$5,000

The Singapore/Borneo Joint Group$2,899.08

Lim Kah Ngam Ltd.$2,000

With the contributions received and the available resources of the IEM, BANGUNAN INGENIEUR was completed in May 1976 and opened by the then Deputy Prime Minister, Y.A.B. Dato’ Seri Dr Mahathir Mohamad on 22 April 1977.

Committee under the chairmanship of both Datuk Wira Ir. Md Sidek binAhmad and Dato’Ir. Dr Gue See Sew entrusted with the task to raise funds for WISMA IEM. Members are

the bank loan.

Y.Bhg. Dato’ Ir. Pang Leong Hoon was formerly the Director-General, Department of Irrigation and Drainage, Malaysia. He was also the Past President of IEM for Sessions 1984/1985 and 1985/1986.

by Ir. Gary Lim

INTRODUCTION

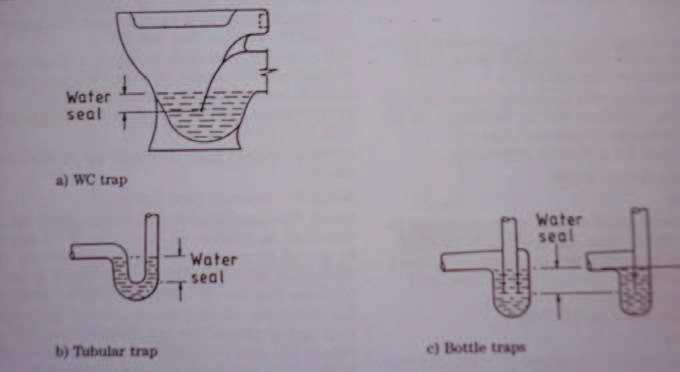

When entering a toilet, all users would prefer a non-smelly for soil, waste and vent (SWV) systems.

Why then is the air inside toilets still foul? The reasons are Integrity of the water seal trap.

INTEGRITY OF THE WATER SEAL

STANDARDS AND CODE OF PRACTICES

Building Part1 – Design, where emphasis is on the

is to use any trap where the water seal is maintained most of the time.

COLLECTED DEBRIS ROTTING

foul air emitted will enter the premises. The solution is to

DISTANCE BETWEEN THE WATER SEAL AND THE INLET PIPE TO THE WATER SEAL

on the walls of the pipe will emit foul air into the toilet. The

MYTHS OF FOUL AIR REMOVAL FROM THE TOILETS and fall. tiles

wasteful use of water

Ventilation fans are a standard design to maintain programmes

URINAL DISCHARGE TO THE TOP OF THE WATER SEAL OF A FLOOR TRAP

CONCLUSION

to prevent siphoning and loss of the water seal. offers temporary relief. water seal to ensure its integrity.

Ir. Gary Lim Eng Hwa is a Co-Opted Member of Building Services Technical Division and current term Council member. Since his retirement, Gary conducts courses regularly on Fire Engineering and Plumbing Engineering courses at IEM.

Develop both sides of the brain with 1Sudoku by Mr. Lim Teck Guan

Fill in the remaining 80 squares with single digits 1-9 such that there is no repeat of the digit in every Row, Column and Block of nine squares. The number at the top left hand corner of the dotted cage indicates the total for the digits that the cage encompasses. For tips on solving, visit www.1sudoku.com.my © Twin Tree Publishing (Solution is on page 43 of this issue.)

Withahistorydatingbackto1821,wehaveestablished a reputation for world-class teaching and practical, leading-edge research, which has made us one of the top UK universities for business and industry.

Heriot-Watt University Malaysia offers you the opportunity to study programmes that help you establish a successful career in areas such as Engineering, Actuarial Science, the Built Environment, Oil and Gas and Business and Management.

Schools and Institutes:

Contact Us:

HWUM@hw.ac.uk +603 - 8881 0918 +603 - 8810 0194 www.hw.ac.uk/malaysia

Over 94% of Heriot-Watt graduates are in employment or further study within 6 months of graduation.

(Continued on page 22)

Safety and Quality Improvement Activities

Organisation and Management

Special Requirement

Human Resource and Development

Policies and Procedures

Safety and Security Management

Hazardous Materials Management

Emergency Management

Fire Safety

Biomedical Management

Utility Systems

Facilities and Equipment

CONCLUSION

[1] MSQH Standards 4th Edition January 2013.

[2] Joint Commission International Standards for Hospitals, 4th Edition.

Ir. Al-Khairi Mohd. Daud is a Committee member of Building Services Technical Division with 20 years’ experience in research, as well as in the cement, oil and gas, petrochemical, oleo-chemical industries and in Health Care. He has gained wide experience in design, construction, testing and commissioning, operation and maintenance of facilities and plants, abroad and locally. He also served in various roles as the engineer and manager of the plant and facilities.

High precision engineering products such as segmental box girders, tunnel segments, railway sleepers, turnout bearers and others.

28, Jalan 7/108C,Taman Sg. Besi, 57100 Kuala Lumpur.

Tel: +603-7980 2728 Fax: +603-7980 5662 www.epmsb.com.my

We are ISO9001, ISO14001 and OHSAS18001 Certi ed

Maintenance Procedure:

Method of Maintenance:

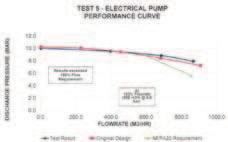

On-site Fire Water Pump Performance Test

Procedure:

Method of testing:

Analysis of test result:

Hollow core slabs, planks, precast columns & beams, precast walls, precast staircases, and other customized structural concrete products.

CONCLUSION

EASTERN PRETECH (MALAYSIA) SDN. BHD. 28, Jalan 7/108C,Taman Sg. Besi, 57100 Kuala Lumpur. Tel: +603-7980 2728 Fax: +603-7980 5662 www.epmsb.com.my

We are ISO9001, ISO14001 and OHSAS18001 Certi ed (184774-P)

2014 c om i n g s o on APRIL

GROUP OF COMPANIES

ALPINE PIPE OCTG Casing & Tubing

ALPINE PIPE Welded Steel Pipes

ALPINE PIPE API 5L Linepipe Formwork System

HIAP TECK Mild Steel Plates

Screen System

Tubes & Fittings

Scaffolding

ALPINE PIPE Square & Rectangular Hollow Sections

HIAP TECK Mild Steel Channels

HIAP TECK Universal Beams Shoring System

HUATRACO SCAFFOLD SDN BHD (240510-T)

Lot 6088, Jalan Haji Abdul Manan, Batu 5½, Jalan Meru, 41050 Klang, Selangor Darul Ehsan, Malaysia. Tel: +603-3377 8999 Fax: +603-3377 8988

HIAP TECK HARDWARE SDN BHD (276336-A)

HIAP TECK Steel Sheet Piles

Wisma Hiap Teck, Lot 6096, Jalan Haji Abdul Manan, Batu 5½, Off Jalan Meru, 41050 Klang, Selangor Darul Ehsan, Malaysia. Tel: +603-3377 8888 Fax: +603-3377 8898

HIAP TECK Mild Steel Angels

ALPINE PIPE MANUFACTURING SDN BHD (267844-V)

Lot 6085, Jalan Haji Abdul Manan, Batu 5½, Jalan Meru, 41050 Klang, Selangor Darul Ehsan, Malaysia. Tel: +603-3377 8688 Fax: +603-3377 8788

by Ir. Gary Lim Eng Hwa

THE Oil & Gas (O&G) industry in Malaysia is governed by the Petroleum (Safety Measures) Act 1984. Under the Act, “petroleum” means any mineral oil or relative hydrocarbon and natural gas existing in its natural condition and casing head petroleum spirit, including bituminous shales and other products

THE BIGGEST LV COMPONENTS MANUFACTURER IN CHINA AND REGISTERED UNDER SHANGHAI STOCK EXCHANGE (REG: 601877)

spill in the Gulf of Mexico in April 2010. Then to a lesser extent, the release of toxic chemicals from on-shore operating plants (these are used in the

1.

2. Gasoline

3. Naptha

4. Reformate

5. Kerosene

6. Diesel

7. Fuel Oil

8. Base Oil

9. Lubricating Oil

10.Asphalt/Bitumen

11. Grease and Wax

For liquid products:

Heat of combustion (HOC) (KJ/kg): The amount of heat produced by burning a given amount of material.

Burning rate (BR) (kg/min): The amount of material burnt per minute.

Rate of Heat Release (RHR) (KJ/min):

For products in the gas phase: If it exists in the surroundings and a heat source could trigger an explosion. This may trigger a series of

ALPHA AUTOMATION (SEL) SDN BHD (Reg. : 372711-D )

ALPHA CHINT SWITCHES SDN BHD (Reg. : 952175-T ) 5, Jalan Pemberita U1/49, Temasya Industrial Park, Glenmarie, 40150 Shah Alam, Selangor, Malaysia. Tel: +603-5569 3698 Fax: +603-5569 4099 Email: alphamail@alphasel.com Website: www.alphasel.com

The Fire Triangle consists of fuel, oxygen and heat source. accelerate the building up of the concentration. Vapourcloudexplosionsorgasexplosionshavethemost areas because these are spontaneous and sudden. In this respect, a detection system to detect explosive vapour clouds and gas is most critical as it may then trigger an processes.

severe as it is foreseeable and mitigation measures can

protection system should be designed based on the

100o surrounding air, thus reducing the level of oxygen in the air.

are available to complement the centralised pumping located on the coast.

The design philosophy of assuming that no outside Rescue Department Malaysia may increase the duration as necessary.

in the number of incidents in the past. Water and foam protection systems are control elements to mitigate the

large droplets to overcome the buoyancy force of hot protected area.

The National Fire Protection Association (NFPA) provides a comprehensive list of standards for engineers to design the

NFPA has available a comprehensive list of standards to guide engineers in the design of such protection systems

Ir. Gary Lim Eng Hwa is a Co-Opted Member of Building Services Technical Division and current term Council member. Since his retirement, Gary conducts courses regularly on Fire Engineering and Plumbing Engineering courses at IEM.

(Sourced from The Star, 20 November 2013)

JAKS Unit Wins RM237mil Contract

(Sourced from BERNAMA, 19 November 2013)

Northport Awards RM260 Million Contract For Tugboats

(Sourced from The Star, 19 November 2013)

(Sourced from BERNAMA, 21 November 2013)

(Sourced from The Star, 19 November 2013)

(Sourced from NST, 20 November 2013)

(Sourced from NST, 20 November 2013)

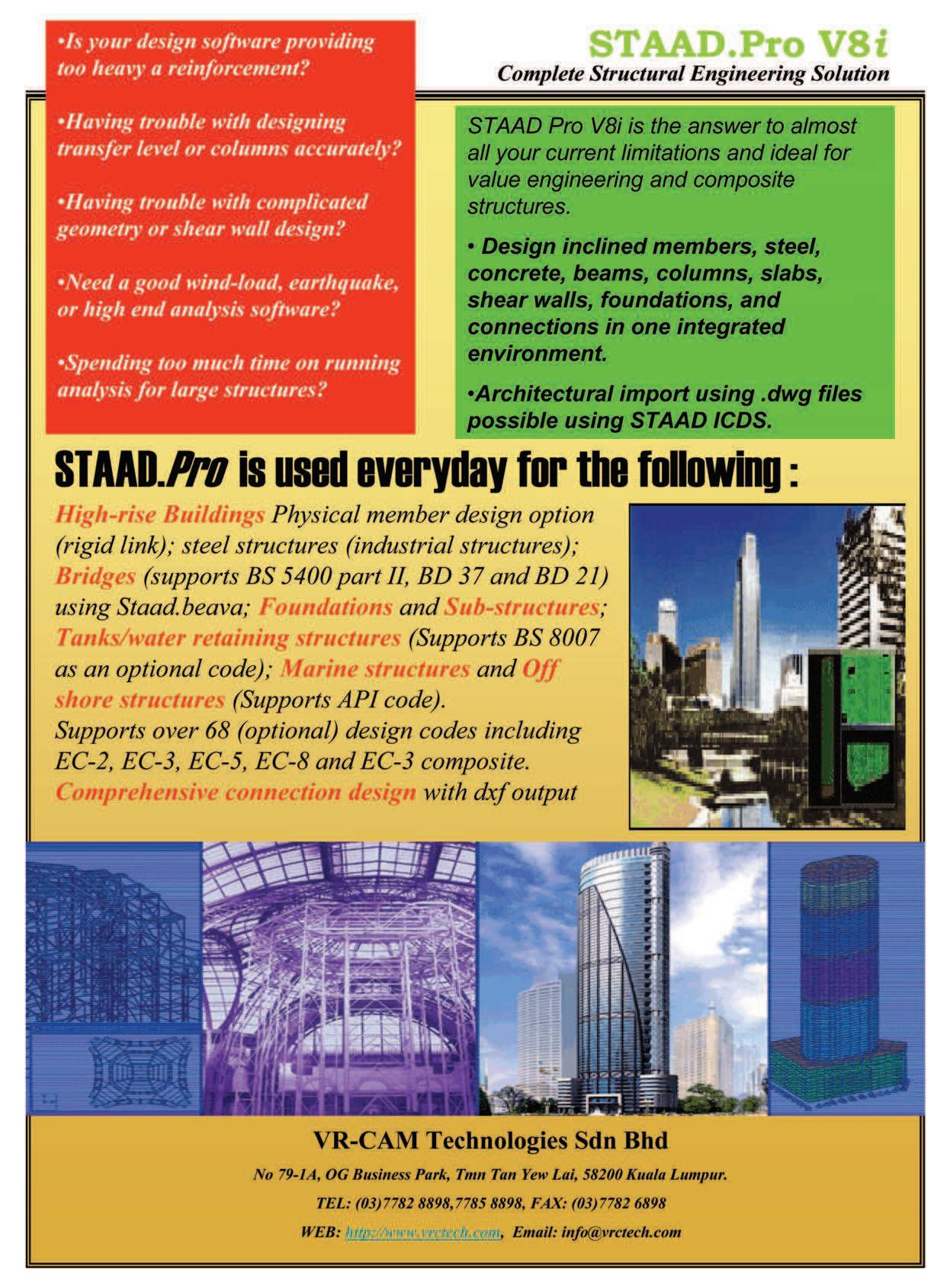

IEM President Ir. Choo Kok Beng visited the IEM Sarawak Branch on 4th and 5th of September 2013, to further discuss plans for the development of the proposed IEM Training Centre to be constructed on a six-acre piece of land in Kota Samarahan, Kuching. He was accompanied by members of the sub-committee comprising Ir. David Lai Kong Phooi, Advisor Dato’ Ir. Hong Lee Pee and myself

On arrival in Kuching, we were received by Ir. Kenny Thien, the Chairman of IEM Sarawak Branch 2013, who brought us to the site of the proposed land allocation. We were informed that, under the overall aspirations of the Sarawak State Government, the area had been earmarked for institutional buildings. As such, the planning of the IEM Training Centre would be in line with the State development policies. Ir. Kenny also pointed out that the area was served by a shopping mall and was in the vicinity of Universiti Malaysia Sarawak (UNIMAS).

In the evening, a dinner meeting was held with past and present members of the IEM Sarawak Branch who were involved with this project several years ago. These included Ir. Albert Ting, Ir. Haji Zawawi Hj. Embong and Ir. Dr John Panil, who is also the General Manager of the Borneo Development Corporation. The proposal to develop a portion of the land for a commercial project by the BDC was discussed and after some deliberation, it was agreed that IEM Sarawak Branch would approach ICAT Sarawak about a joint collaboration to develop a skills training centre there. The committee was told that in view of SCORE taking off, skills training ranks highly with the State government.

a collaboration of this nature would serve the needs of the Institution at the present moment. Ir. Albert Ting would proceed to approach ICAT and report back on the progress in a few weeks.

The next day, Ir. Kenny invited Ir. Choo to visit the hinterland near the Sarawak-Indonesia border where the infamous town of Bau was located, about 30km south-west of Kuching. This quaint town used to be a hub of activity for gold mining. In 1857, during the Gold Miners Rebellion, the miners fought with the White Rajah’s army. The miners were killed and their dead bodies scattered all over the town, resulting in it being named Bau (Bahasa Melayu for smell). The name remains till this day.

Near Bau, a lake called Tasik Biru is evidence of the gold mining activities which had resulted in the lake being

poisoned with arsenic. The local people are not allowed to engage in any activity in the lake or to use the water for drinking. Perhaps engineers can come up with a solution to detoxify the lake.

On the way to the airport, Ir. Kenny hosted us to lunch. We were treated to a sumptuous and exotic meal of turtle soup, local game, free range chicken and authentic Sarawakian Foo Chow noodles. It was an excellent way to conclude a fruitful visit to the branch.

The group will meet again in a few weeks to review the proposals by the branch for further deliberation. A vote of thanks to IEM Sarawak Branch.

Yam Teong Sian is currently the Vice Chairman of the Standing Committee on Information and Publications and Bulletin Editor. He has served as Council Member of the Institution since 2000 and is currently the Executive Committee member for 2013.

Email: concet2014@iem.org.my

Email: choy.iemtc@gmail.com

For more details, please refer to www.myiem.org.my

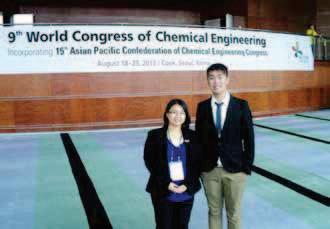

CHEMICAL ENGINEERING TECHNICAL DIVISION

GENERAL INFO ABOUT APCChE CONGRESS 2013

REPORT BY MISS LEE HUA CHYN

Engr. Rex T.L. Ng obtained his B.Eng (Hons) in Chemical Engineering in 2011withFirstClassHonoursfromUniversitiTunkuAbdulRahman,Malaysia. He is currently a PhD candidate in The University of Nottingham, Malaysia Campus. He works closely with his industrial sponsor, Global Green Synergy Sdn. Bhd. on optimisation of palm-based biomass utilisation. To date, he has published eight papers in various international refereed journals.

Miss Lee Hua Chyn is a MEng student under the supervisions of Dr Cheng Chin Kui and Dr Jolius Gimbun, members of the Centre of Excellence for Advanced Research in Fluid Flow (CARIFF) in Universiti Malaysia Pahang (UMP). Her research interests are in catalysis and reaction engineering. Her project was awarded a grand prize in Shell Inter-Varsity Student Paper Presentation Contest (S-SPEC) 2013 held at UTM.

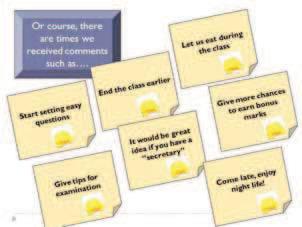

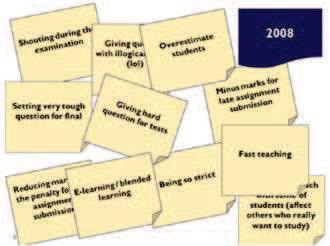

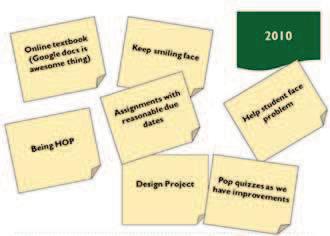

THE Engineering Education Technical Division organised a talk entitled “Start-Stop-Continue – What Does It Take To Change?” on 22 July 2013, at the Auditorium Tan Sri Prof. Chin Fung Kee, 3rd Floor, Wisma IEM, Petaling Jaya. The talk was delivered by Dr Koh Yit Yan. A total of 34 participants attended the talk

Dr Koh, a senior lecturer from the Mechanical Engineering Department of INTI International University, Nilai campus, began with a summary of the topic. He then explained the meaning of teaching and learning, followed by the need for feedback. All these are part of a process called Continuous Quality Improvement that involves the

Dr Koh said it is necessary to get feedback from students even as the teaching and learning process is on-going. Apart from promoting the process of teaching and learning,

path towards enhancing their performance. Furthermore, this feedback mechanism enables the lecturer to quickly make changes for improvement.

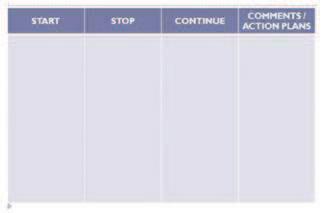

According to Dr Koh, the feedback system consists of 4 important parts. They are:

a) Start: Anything that you feel the lecturer has not done in this course, but should START doing to improve the learning.

b) Stop: Anything that you feel that the lecturer is doing in this course, but should STOP doing to improve the learning.

by Engr. Chua Yaw Long

c) Continue: Anything that you feel that the lecturer is doing in this course and should CONTINUE doing to improve the learning.

d) Comments: Any comment students may have on the lecturer’s way of teaching. What is the student’s action plan to improve himself or herself on the subject?

Dr Koh went on to share some of the feedbacks he had received from students over the years. Dr Koh also highlighted some new initiatives taken that were based on feedback received to make the teaching and learning process more interesting to students.

the presentation of a memento to Dr Koh and a round of applause from the participants

Engr. Chua Yaw Long is currently a committee member of IEM Engineering Education Technical Division (E2TD). He is also a lecturer in the Mechanical Engineering Division of Universiti Tenaga Malaysia.

SUB-COMMITTEE ON MEMBERSHIP DRIVE AND PROMOTION

THE Sub-Committee on Membership Drive and Promotion (MDP) under the Standing Committee on Admission and Practical Training (APT) successfully organised a half-day forum on Membership Drive and Promotion on 6 July 2013. The forum was facilitated by Ir. Noor Hisham Yahaya. Panel members comprised Ir. Choo Kok Beng (IEM President), Ir. Gunasagaran Kristnan (APT Vice Chairman) and Ir. Dr Cheong Thiam Fook (Chairman of the Sub-Committee on MDP).Also present were more than 22 representatives from the various Technical Divisions and its branches (Penang and Sarawak)

The main objective of the forum was to review the effectivenessofthecurrentmembershipdriveandpromotion programmes and to ensure that these were aligned with

IEM’s Vision of achieving 100,000 members by 2017.

presented statistics on the membership drive’s success in the past 5 years, as well as the failure to retain members. It was encouraging to note that IEM recorded the highest ever number of members in May 2013, with a total of 30,000 members registered. The Sub-Committee on MDP requested all members to work together to recruit and retain members, as it was our collective responsibility to achieve the target membership by 2017.

In his address, President Ir. Choo gave some valuable points for the further enhancement of the membership drive, as follows:

Ir. Choo urged members to play a more effective role and to organise activities that are relevant to the members. He stressed that re-branding of IEM should start with a proper business card. Noting that IEM business cards carried the ISO900 logo, he said the association with renowned international engineering organisations was a powerful advertising tool that would help members in their business transactions.

had been shortened to mere hours for Graduate Members and a few days for Non-Corporate Members and Corporate Members. In addition, the Professional Interview process is also being reviewed for a smoother process.

The IEM President announced that the Fully Paid Life Membership scheme would be implemented soon to address and resolve the issue of membership drop-out. The payment procedure for such a scheme would be published in the near future.

Ir. Choo said many other suggestions were being considered and reviewed for the betterment of the engineers in Malaysia and to enhance greater public recognition of the profession.

Next on the agenda were the following:

1. How to increase IEM membership

2. How to resolve membership retention issue

3. Branding of IEM.

Questions and answers as well as a fruitful exchange were observed during the entire forum. Some of the notable topics were:

1. Student membership will be registered in bulk. IEM is currently working with universities for the bulk registration of students during the enrolment period (via MoA between universities and IEM). This initiative will resolve all existing administrative problems. Leading the way is UTHM and three other universities are expected to enter into a similar arrangement by the end of the year. This programme is expected to be extended to include all local universities.

2. The shortening of on-line registration time was discussed and it was proposed that IEM should emulate IET which only took 10 minutes to complete its on-line membership registration.

members, such as e-library and motorcycle group insurance for students in universities.

4. For graduate members, IEM will conduct more technical talks and site visits to assist them in their professional career development.

5. IEM or the Training Centre will conduct more talks on the subject of PI Workshops and Route to MIEM/PE for young members.

6. In order to attract blue ocean engineers, the Mentor Log Book system shouldbemorewidelypublicisedandmadeaccessibletotheengineering industry so that more engineers working in the organisations without MIEM/PE would have another option to seek professional development.

7. The MILO theory, currently being promoted, should be extended to schools and colleges (diploma holders) so that engineering studies are widely introduced in the early stages of education.

8. In order to give recognition to engineers in the society, IEM is considering awarding Honorary Memberships to industry players who have

such as for Safety Engineers and Quality Engineers, as the industry is currently facing an acute shortage of such personnel.

10.To set up an IEM Scholarship Fund to assist needy students who wish to pursue degree courses in engineering.

There were many other suggestions and proposals which would be reviewed by the Sub-Committee on MDP and action would be taken accordingly. The Session Chairman, Ir. Dr Cheong, concluded that the forum was a success with everyone contributing ideas and suggestions and he urged theTechnical Divisions and all branches to join hands with MDP.

Lastly, Ir. Dr Cheong extended his thanks to the President, all participants and the secretariat staff.

Ir. Dr Cheong Thiam Fook is the Executive Director-Operations of George Kent (Malaysia) Berhad. He is also a Co-opt Member of Mechanical Engineering Technical Division.

The portal aims to provide enhanced interaction between IEM and members with new features like online membership application, online registration for events, online CPD, online booking of Library books etc. www.myiem.org.my

FIRST TIME LOGIN ACTIVATION

TUTORIAL VIDEO

URL address bit.ly/VGL3zw (case sensitive)

FIRST TIME LOGIN ACTIVATION AND ONLINE PAYMENT TUTORIAL VIDEO

URL address bit.ly/Ugb5Gs (case sensitive)

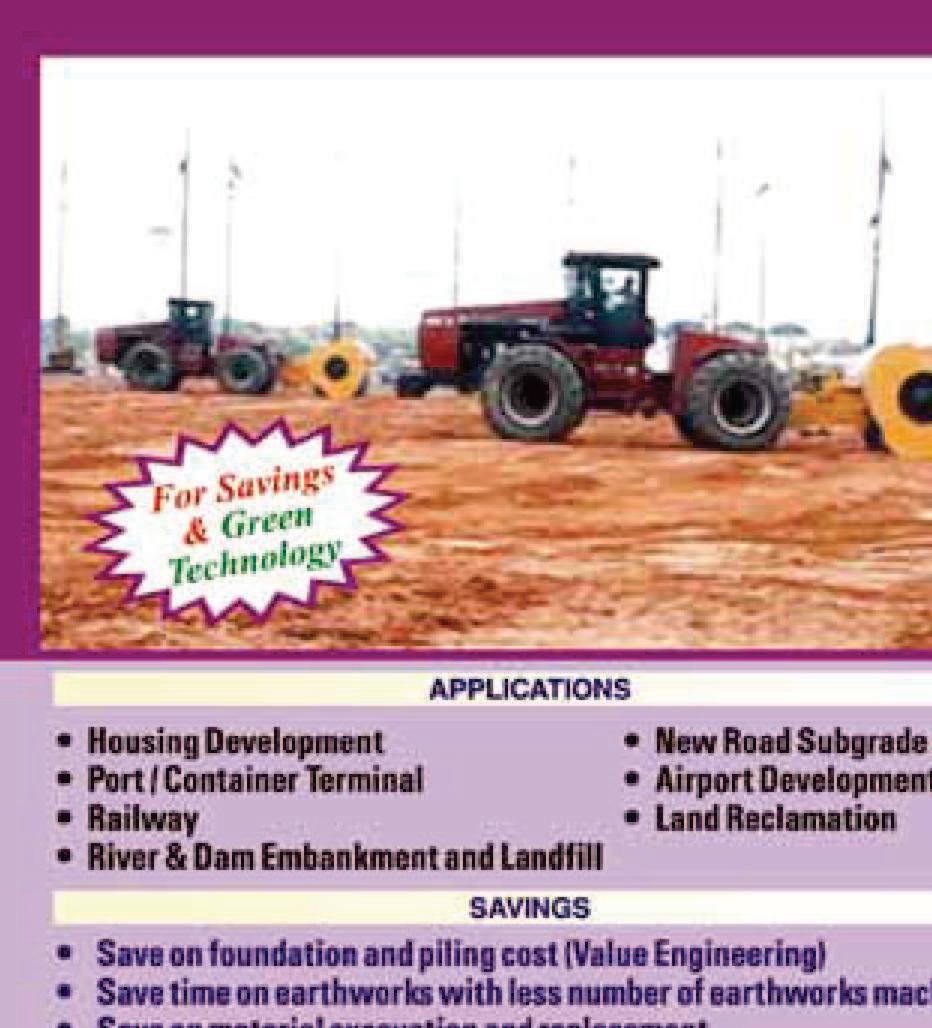

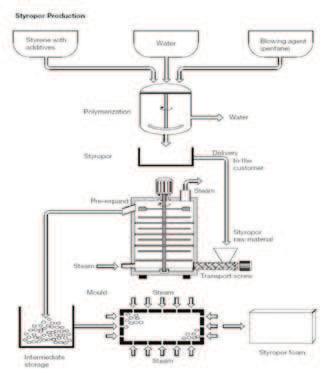

THE evening talk onApplication of EPS in Civil Engineering was organised by the Geotechnical Engineering Technical Division 28th August 2013 at the Tan Sri Prof. Chin Fung

Kee Auditorium of Bangunan IEM. The talk was delivered by Ir. Dr Hj. Affendi Abdullah and was attended by 68 participants

Ir. Dr Hj. Affendi began by outlining his presentation as follows:

a) What is EPS (Expanded Polystyrene)

b) Manufacturing Process of EPS

c) Features of EPS

d) Mechanical and Physical Properties

e) Chemical Resistance

f) Why Use EPS?

ttmizi2000@yahoo.co.uk

g) Quality Assurance for EPS

h) Some Construction Aspects

i) Considerations in EPS Design

j) Some EPS Applications in Malaysia

k) Some Application Using EPS

l) Some Application Using EPS in Road Construction

m) Most Recent Case Study Using EPS in Road Construction

n) Monitoring Data

o) Use of EPS other than in Road Project

Ir. Dr Hj. Affendi told the audience that EPS is a thermal plastic material, free of CFC, HCFC and formaldehyde. The

and Malaysian Plastic Standard of SIRIM. The material retains its physical properties. He went on to explain the manufacturing process as shown in Figure 1.

The salient feature of the ultra-lightweight EPS is that it

Expanded Polystyrene (EPS): 20 kg/m³

Wood Chip: 850 kg/m³

Leca: 1500 kg/m³

Clay: 2000 kg/m³

Ir. Dr Hj. Affendi then talked about the mechanical, physical and chemical properties of EPS as well as the different grades of EPS available.

portrayed in the following table:

Ir. Dr Hj. Affendi then touched on Quality Assurance by relating the frequency for testing material strength to density, as shown below:

Vibratory compaction plant should not be used to laterally from the polystyrene and should be limited to a maximum weight of 600kg/m width until the capping layer

levels. A minimum 150mm thick reinforced concrete slab should be cast directly on the Expanded Polystyrene (EPS) blocks. The concrete mix should be designed for strength of fabric to BS 4483. The blocks should be laid such that the difference in level between adjacent blocks, measured at the joint, does not exceed 3mm.

Ir.DrHj.Affenditalkedaboutthestressconditionsrelated to the design of EPS in Civil Engineering works. He showed examples of EPS usage in road construction in Malaysia and said the most recent application where the sub-soil beneath the RE wall was still undergoing consolidation and

The consolidation time would extend beyond the allowable construction programme. Other solutions were examined but the EPS solution could match the required construction

and C respectively. The requirement was a need to control settlement to an acceptable level.

The light weight solution provided reduced stresses at foundation level and managed to control settlement to an acceptable level.

Ir. Dr Hj. Affendi presented the settlement monitoring data for the project which showed acceptable settlement levels. The predicted settlements were larger than the actual measured settlement.

Finally he gave a short presentation on the use of EPS in projects other than roads, and then answered a number

of applause from the audience and the presentation of a token of appreciation to Ir. Dr Hj. Affendi.

Block dimensions and evenness should be one out of every 25 blocks. Evenness and subsoil surface below EPS should be checked in cross-sections every 10 metres.

Ir. Dr Hj. Affendi also highlighted the construction issues relatedtoEPS.Noconstructionplant,otherthancompaction plant, shall be driven or placed on the polystyrene until a layer has been placed over the polystyrene.

Reconstructing a major intersection to decrease traffic congestion, improve access, and enhance safety takes more than a civil engineering design package. Just ask Creighton Manning Engineering, LLP. This 2012 Be Inspired Award-winning firm selected Bentley’s innovative information modeling software to design this entire project in 3D. It created information models for intelligent, better-performing transportation infrastructure that reduced production time and lowered project costs by providing accurate data for automated grading during construction.

There are some places ONLY Bentley can take you! For more than 25 years, transportation professionals have depended on Bentley to design and build the world’s most innovative projects. You can too.

THE Engineering Education Technical Division coorganised a talk on Commissioning Strategy of a Large Control System Project with the Engineers Australia Malaysia Chapter, on 19th July 2013, at Auditorium Tan Sri Prof. Chin Fung Kee, Wisma IEM, Selangor. The talk is delivered by Ir. Dr Kevin Lam. A total of 40 participants attended the talk

Ir. Dr Lam said that today, equipment operations are increasingly becoming automated and business operations are becoming more dependent on control systems. He said huge control systems are seldom fully tested off-site because of the prohibitive cost and time involved in carrying out a full-scale simulation. So testing and commissioning are considered the last though most important work processes in the implementation of a control system to ensure that the delivered system will perform according to

more important in an upgrading project where the safety and functionality of the existing system must be maintained as an error might lead to a disruption of operations. In such an event, successful commissioning of the system can be achieved by adopting vigorous preparation and planning, mitigating risks and ensuring that contingency measures are established to support the system transition, based on deploying an organisation that is accountable and an informed reporting structure.

For a mega project with multiple local sites controlled by a control center, Ir. Dr Lam said that the testing and commissioning processes would involve a large number of operations and maintenance employees. He reiterated that careful planning and effective communications were essential factors that would contribute to the success of the project implementation.

Ir. Dr Lam then proceeded to name those directly involved in the commissioning of a large control system:

1. The Central Control Operator (CCO) who monitors and controls the whole system at the Central Control Room.

2. The Local Control Operators (LCO) who operate the system through a local backup panel if required.

3. The local maintenance teams who report to the maintenance organisation.

4. The project management team.

by

5. The project design team.

6. The project implementation team.

7. Turnkey contractors employed to design and install the system.

8. The supervisors and managers of the above groups of people.

Ir. Dr Lam said that as the number of people involved was large, there were a lot of existing practices, differences in understanding of the commissioning practice and different expectations of the system. Furthermore, during each stage of the commissioning process, the involvement and expected response of each party might not be clear and, while training was important so that all those involved would fully understand the new system after it was installed, there would still be a gap during the commissioning of the system. Therefore, effective communication was one of the essential factors that would contribute to a successful commissioning of the system.

He then elaborated on the importance of information dissimulation during the commissioning of the control system. He pointed out that there was a lot of information that would need to be communicated to the project team and to those indirectly involved in the project. To this end, preparing a Commissioning Strategy Document would be essential to dissimulate information pertaining to the commissioning process.

methodology and procedures that would be adopted for precommissioning, commissioning and post-commissioning of the new system, and would be produced in association with the Contractor’s Installation Plan, Commissioning Plan

chapters that describe:

1. Project information

2. Overall management processes

3. Pre-commissioning phase activities

4. Hand-over phase arrangement

5. Post commissioning phase arrangement.

Ir. Dr Lam then went on to discuss the above in detail.

a) The objective of the commissioning process should be clearly stated so as to enable team members to understand the underlining principle and direction of activities.

b) The scope of work should be described in detail. This include the actual work and the process that would commissioning works not included with the projects should also be clearly listed.

c) A list of contacts on the Employer’s and Contractor’s staffs involved in the commissioning process should be prepared. This would facilitate direct communication between team members during commissioning.

d) Systems Assurance activities such as Design Hazard Analysis, Installation Hazard Analysis, and Operational Hazard Analysis should be clearly described to ensure that the introduction of the new system would not adversely affect normal operations.

e) The commissioning program based on the relationships of each activity, resources, timing, etc. should be drawn up in Gantt Chart format.

f) Any known operating constraints should be listed out with appropriate supporting procedures.

g) The Contractor document that would be referred to and included in the Appendix.

The processes involved would comprise:

a) Fault Reporting & Corrective Action System (FRACAS) whereby all faults or perceived malfunctions or irregular operations appertaining to the new system are registered in the Commissioning Logbook at a

b) wherebyaCommissioning Change Control Board which consists of the project manager, implementation manager and the contractor project manager, is established to manage and coordinate any changes from the commencement of the Pre-commissioning Phase through to completion of the Works.

c) whereby any new work or enhancements to the original scope of work are managed and tracked so that each request is recorded, evaluated, and impact analyzed and target date set to complete them immediately or in the future.

d) Acceptance Review whereby the works associated with a particular commissioning phase is assessed for completeness before the commencement of the next phase of the commissioning process.

The Pre-Commissioning Phase would include all the activities required that would lead to the readiness of the new system and should be completed prior to proceeding to the Hand-over Phase. It would consist of the following:

a) Site preparation Stage

This is when site surveys are conducted to ascertain the condition of the existing system and to mitigate any adverse impact to the existing operational equipment.

b) Installation Stage

This is when the new system is installed into an existing operational environment and will subsequently co-exist with the existing system for a period of time.

c) Point-to-Point Tests Stage

This is when Point-to-Point tests are conducted to validate the installation and prove the correct entry of

d) End-to-End Tests Stage

the control system as the End-to-End tests are designed to validate the correct alignment of the HMI displays (at the Central Control Room, Local Control Panel and processor equipment.

e) Site Integration Tests Stage

Site Integration tests are conducted to demonstrate that the new system is functioning after it has been installed on site.

f) Stability Run Stage

The new system is required to run for a prescribed period of continuous operation to ensure that no adverse failures are detected or reported.

Plan, which is a designed mechanism that transfers the monitoring and control back to the existing system should there be any major incident or undesired event during the Stability Run Stage. He also talked about the various operation support activities conducted to ensure that the new system would be prepared for its introduction into an operational environment, and the Acceptance Review upon the satisfactory completion of the Stability Run Stage.

The Hand-over Phase would include all the activities required to ensure that the new system has been successfully introduced into the operational environment. These would include:

a) Enable Local Control

This is when the local maintenance engineer transfers the local control functions to the new system.

b) Enable Central Operation

Upon completion of the enabling of the local processor

c)

controls, the operation of the new system is transferred to the Central Control Operators who then conducts their operational duties for the pre-commissioned location from the new system.

Upon the successful completion of the Enable Central issued by the representatives of the Operations and Maintenance groups.

d) Parallel Running Stage

This is when the new system is monitored to ensure a period of continuous operation has been achieved without any adverse failure.

As for a Fallback Plan, Ir. Dr Lam explained that the existing system would serve as a backup system that might be redeployed if requested by the commissioning engineer or the that, the Contractor should also provide operation and technical support such as Operator Assistance, On-call support, and First Line Maintenance during the hand-over phase.

UponthesatisfactorycompletionoftheParallelRunning, an Acceptance Review meeting would be conducted to ascertain as to whether the new system could be accepted

The Post Commissioning Phase would include:

a) new system from the commissioning engineer to the customer.

b) Decommission Existing System Stage

The existing equipment is decommissioned at this stage.

c) Site Acceptance Tests Stage

This is to ensure that the decommissioning and removal of the existing system do not impair the functioning of the new system.

d) Remedial Work

The Contractor is required to undertake the remedial work within the dates as stated in the Handing-Over

e) Acceptance Review-Post Commissioning

The Acceptance Review meeting is to monitor and completed.

f)

Upon the satisfactory outcome of the Acceptance Review, the project manager then recommends the

g) Warranty Period commencement of the Warranty Period.

Upon the completion of the commissioning process, said Ir. Dr Lam, the System Acceptance Tests would then be

maintainability demonstrations, reliability and availability demonstrations, in accordance to the System Acceptance

system of a railway project before he concluded the talk by stating that the commissioning plan and the commissioning strategy document provided a systematic and effective tool in the commissioning of a large control system project. He then answered some questions raised by the participants before the talk ended with the presentation of a memento to Dr Lam, followed by a round of applause from the participants

Note: The above report was prepared with the help of presentation slides and the paper of the same title, courtesy of Ir. Dr Kevin K.C. Lam.

Ir. Chew Weng Yuen is currently a committee member of IEM Engineering Education Technical Division (E2TD). He is the Deputy General Manager of Forefront Tiara Sdn. Bhd., a property development company.

For more information, please contactthe IEMSecretariat (Membership Department) at 03-7968 4007 or email to sec@iem.org.my

GEOTECHNICAL ENGINEERING TECHNICAL DIVISION

IT was a great honour for the Geotechnical Engineering Technical Division (GETD) of IEM to have Dr Bengt H. Fellenius conduct a whole day short course at Hotel Singgahsana, Petaling Jaya, on 14 June 2013. The former Professor of Civil Engineering at the University of Ottawa is an internationally recognised foundation engineering consultant and the author of more than 300 technical papers

Organised by GETD and attended by 144 participants, advertisements as well as strong support from the public sector, government-linked companies, and the oil and gas industry.

Dr Bengt H. Fellenius demonstrated that deep value of capacity. He outlined the essential data one must pull together for the necessary analyses and calculations friction and the associated drag load and down drag were emphasised. The presentation included broad generalities and in-depth details as well as addressed aspects such as where to install instrumentation, perform a test and analyse the test data. Settlement analysis was of vital importance to the design of piled foundations and the course addressed principles of settlement analysis and provided some of the mechanics in calculating settlement.

One of the main focal points of the course was that one should design for settlement rather than for capacity. Other aspects such as Limit States Design (LSD), Ultimate Limit States (ULS), Serviceability Limit States (SLS) by Canadian terminology, Load and Resistance Factor Design (LRFD) by US terminology, and construction case histories were also covered.

course ended at 6.00 p.m. with the organising committee posing for pictures with Dr Bengt H. Fellenius.

Acknowledgment: The organising committee wishes to express thanks to Dr Bengt H. Fellenius who has agreed to allow members who had registered for the course to download the presentation slides from his website (http://www.fellenius. net/Course).

CALL FOR PAPERS

SUBMISSION OF ABSTRACTS: 31 JANUARY 2014

ACCEPTANCE OF ABSTRACTS: 31 MARCH 2014

SUBMISSION OF MANUSCRIPT: 30 JUNE 2014

ACCEPTANCE OF MANUSCRIPT: 30 SEPTEMBER 2014

SUBMISSION OF FINAL PHOTO READY PAPER: 31 OCTOBER 2014

For more details, please contact: Secretariat

International Conference on Tunnelling & Underground Space 2015 (ICTUS 2015) c/o IEM Training Centre Sdn. Bhd.

Email: choy.iemtc@gmail.com

by Anti-Corruption NKRA, PEMANDU and Mechanical Engineering Technical Division

IN this last article of the Corporate Integrity Column, we would like to share with our fellow members the potential business as well as highlight the potential disadvantages of not having such a programme. It is hoped that this information will encourage business owners to put in place the necessary measures to curb potential irregularities.

business and your associates will be better protected against legal penalties, loss of licences and blacklisting.

A reputation as a business with ethics increases your chances of being selected as a supplier to large multinationals in their supply chain, and better access to international markets.

A business with ethical standards is a good place to work in and will encourage good working relationships and morale. organisations.

If you are considering selling your business, a good reputation will be more attractive for acquisition.

You, and not some bribe payer or bribe receiver, will be in control of your business decisions. Your organisation will save money which might otherwise be squandered on bribes, gifts and inducements.

the upcoming events.

9 January 2014

Time : 1.30 p.m. – 5.30 p.m. (CPD/PDP: 3)

Venue : Wisma IEM

21 January 2014

Time : 9.00 a.m. – 1.00 p.m. (CPD/PDP: 3.5)

Venue : Wisma IEM

Bribery is illegal, and therefore a criminal offence which imprisonment for directors and managers responsible. Even if the country in which you operate in or to which selling to other countries which can enforce penalties for corruption.

If you are hoping to do business with the supply chains of large companies, they will want to know because multinationals are subject to particular laws and disclosure requirements which also extend to their suppliers. Many large companies now have due diligence review processes and, if you do not have an be selected or you may have to sign up for the clients’ programmes.

A bribery conviction may mean loss of export licences,

A bribery conviction will taint a business and bring about inevitable loss of reputation and even blacklisting by particular organisations. Banks, auditors and lawyers will have to report any unexplained or irregular accounting under laws passed to counter money laundering and terrorism

Note: We would like to thank Transparency International Malaysia for sharing the above summary.

by Ms. CC Tan

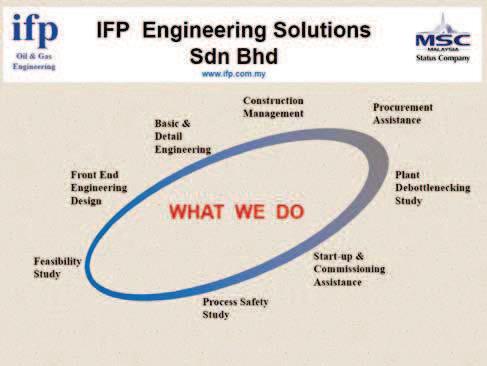

According to a recent survey by Ernst & Young Global Ltd, 22% of oil and gas respondents it polled indicated that Bhd, one of the biggest challenges the in oil and gas design engineering”, said its managing director, Dr Ragunath Bharath.

for the procurement and development of “historic lack of investment in skills” as some experts have put it, have pushed the human point in some countries. out in handling gas, liquid and chemical

processing before moving up the value-chain engineering procurement company, today a range of detail engineering services.

training,” Dr Ragunath said on his recipe to that the industry, among many others in the country, faces today.

Being an MSC-status company has helped term contracts.

IFP, but also other similar companies in the same predicament; the entrance of expats

as the presence of foreign talents has made locals, possible.

to ensure our people are given more said Dr Ragunath.

In this, it is not hard to imagine that IFP it has also been accorded a Pioneer Status service-oriented.

Forging ahead: A relative newcomer to the O&G sector, IFP has been chalking up a record of sterling performances in the provision of engineering services in the revamping and modifying of onshore processing

the Malaysia External Trade Development measures, contributed to the development that Dr Ragunath believes has enabled IFP to needs, locally and abroad.

progress IFP has made in the industry in the

Equally notable is being put in charge from engineering to mechanical, is understandable that Dr Ragunath Energy Company Private Ltd in Houston transfers,” said Dr Ragunath.

a PhD in chemical engineering and has CBM and shale gas have, in recent decades, countries like the United States and Canada.

Disclaimer: IEM and Dimension do not give any warranty as to the completeness or accuracy of any information, instruction, advice and /or opinion stated in this Publication and IEM and/ herein shall be deemed to be an endorsement of any product or opinion by IEM or Dimension.

by Ir. Chin Mee Poon www.facebook.com/chinmeepoon

I love Mother Nature. Some of my happiest hours are spent in forests, up on mountains or among coral reefs. When I visit Singapore, I usually make it a point to visit the Botanic Gardens. In Singapore, the tropical rainforests are decimated and small, so the Botanic Gardens, though manmade, is the closest thing to nature where one can spend a whole day in.

occupied 32 hectares of land in Tanglin and was managed by theAgri-Horticultural Society. The government took over

based on an early design by Laurence Niven.

But before the Botanic Gardens, there was the years later.

Singapore is very fortunate that the Botanic Gardens had been overseen by a succession of eminent botanists during its formative years. These botanists not only contributed to shaping the gardens into what it is today but they also left of South-East Asian nations.

and

(Haveabrasiliensis) were transferred to the Botanic Gardens of Singapore from London’s Kew Gardens. The plant was a

for latex without seriously damaging the tree and he spent many years promoting rubber as a commercial product. He was largely responsible for establishing the rubber industry in Malaya.

Professor Eric Holttom, director of the Gardens from

works and techniques resulted in Singapore becoming one of the top centres for commercial orchid growing in the world. The three-hectare National Orchid Garden within the

an application to the UNESCO World Heritage Committee to consider the Botanic Gardens of Singapore for listing as a World Heritage Site.

from travelling to different parts of the globe, capturing fascinating

sharing his experiences with others through his photographs and writing.

Mudajaya Group Berhad is a leading company in the Construction, Energy and Property Sector and has received reputable external recognition. Our core businesses include construction, property development, independent power production, project management services, manufacturing and trading of building materials. We are committed to bring out the best in our people to advance the future together. Due to our rapid expansion, we invite like-minded and high caliber professionals to be part of our dynamic and winning team.

Our recent projects:

• Degree in Civil / Mechanical/ Electrical Engineering or equivalent.

• At least 12 years contractor experience in delivering large civil/ power/ structural projects, out of which at least 5 years as leading the team.

• Good knowledge of Construction management, High End Concrete Technology, Estimate techniques, Project Planning and Cost Control systems.

• Sufficient knowledge on contract administration and be familiar with standard forms of conditions of contract.

• Possess vibrant personality with strong leadership, team management and interpersonal skills.

• Degree in Civil/ Mechanical/ Electrical Engineering or equivalent.

• At least 8 years’ experience in large civil/ power/ structural projects.

• Able to lead & coordinate work amongst the project team, sub-contractor & client

• Good working attitude, ability to organise, plan, meet deadlines and work well under pressure.

• Degree in Civil/ Mechanical/ Electrical Engineering or equivalent.

• At least 3 years’ design experience for design engineers and 3 years’ site experience for project engineers.

• Good working attitude and work well under pressure.

• Degree in Civil Engineering or equivalent.

• At least 3 years’ relevant planning experience and good knowledge in Primavera Project Management software.

• Good working attitude and work well under pressure.

∗ WINNER OF THE EDGE BILLION RINGGIT CLUB CORPORATE AWARDS 2010, 2011, 2012 & 2013, Construction Sector

∗ ASIA ‘ 200 BEST COMPANIES UNDER A BILLION DOLLAR AWARD FOR YEARS 2010, 2011, 2012 & 2013 –FORBES ASIA

∗ WINNER OF THE KPMG SHAREHOLDERS VALUE AWARD 2007, SECTORAL WINNER FOR 2008, 2010 & 2011, Construction and Property Sector

Interested candidates please submit a detailed resume stating current and expected salary, a passport-sized photograph and contact number to:

MUDAJAYA GROUP BERHAD (605539-H)

Level 11, Menara Mudajaya, No. 12A, Jalan PJU 7/3, Mutiara Damansara, 47810 Petaling Jaya, Selangor Darul Ehsan. Tel: +603-7806 7899 Fax. No.: +603 - 7806 7900

E-mail: hr@mudajaya.com Website: www.mudajaya.com

Tarikh: 14 November 2013

Kepada Semua Ahli,

Berikut adalah senarai calon yang layak untuk menduduki Temuduga Profesional bagi tahun 2013.

sebulan dari tarikh penerbitan dikeluarkan.

PERMOHONAN BARU NamaKelayakan

KEJURUTERAAN AUTOMOTIF

AZMIR BIN MOHD ISABSc (COLUMBIA) (MECHANICAL, 1997) MSc (UiTM) (MECHANICAL, 2005)

KEJURUTERAAN AWAM

BAHRIN BIN MOHD ZAINBE HONS (UTM) (CIVIL, 2000)

MAZLAN BIN MUHAMMADBE HONS (HATFIELD POLYTECHNIC) (CIVIL, 1988)

MOHD NOORHATTA

BIN MOHAMAD BE (HONS) (CIVIL, 1998)

MUHAMAD RADZIF

BIN MAT HASAN BE (HONS) (UTM) (CIVIL, 2002)

SHAHRIZAL BIN

SHAHAROM BE HONS (UNISEL) (CIVIL, 2007)

SITI NORBAITI

BINTI MOHD YUSUF BE HONS (UTM) (CIVIL, 2005) MSc (UiTM) (CIVIL STRUCTURAL, 2011)

KEJURUTERAAN ELEKTRIKAL

EDWINAANAK MANDAKBE HONS (UM) (ELECTRICAL, 2003)

MOHD HAKIMI

BIN UDAAHMAD BE HONS (UM) (ELECTRICAL, 2000) MSc (UKM) (ENERGY TECHNOLOGY, 2008)

SALMIZAN BIN MUHAMMAD SALLEH BE HONS (UNITEN) (ELECTRICAL POWER, 2007)

KEJURUTERAAN KIMIA

BEE SOO TUEENBE HONS (UTM) (CHEMICALPOLYMER, 2006) ME (UTM) (POLYMER, 2009)

KEJURUTERAAN MEKANIKAL

KOO MENG CHIUBE HONS (MONTANA STATE) (MECHANICAL, 2000)

LING HUNG PANGBE HONS (BRADFORD) (MECHANICAL, 2002)

MOHD IKHWAN

BIN AHMAD NAWAWI BSc (PURDUE) (MECHANICAL, 2003)

WONG CHEOK GIDBE (NEWCASTLE) (MECHANICAL, 1992)

PERPINDAHAN AHLI

No. Ahli NamaKelayakan

KEJURUTERAAN AWAM

27954AU YONG BOONBE HONS (UTM) (CIVIL, 2002)

30783AU YONG THEAN SENG BE HONS (UKM) (CIVIL & STRUCTURAL, 2007)

44534AWANG ZAKRI BIN AWANG ADENI BE HONS (UKM) (CIVIL & STRUCTURAL, 2006)

24299CHAN SIEW WENBE HONS (UKM) (CIVIL & STRUCTURAL, 2005)

39209MAH SZE CHINBE HONS (UM) (CIVIL, 2004)

60649MELVIN @ FRANCIS HUMOC BE HONS (UMS) (CIVIL, 2001)

33122MOHD BUKHARI BIN MOHD KASIM BE HONS (UiTM) (CIVIL, 2008)

60625MOK KEN LOONGBE HONS (UKM) (CIVIL & STRUCTURAL, 2004) MSC (YONSEI, KOREA) (CIVIL & ENVIRONMENTAL, 2011)

18641MUHAMAD ZAINI BIN HASNAN BE HONS (UiTM) (CIVIL, 2000) ME (UKM) (CIVIL, 2007)

25563ONG TAI BOONBE HONS (USM) (CIVIL, 2004)

47590QUAH BOON JINBE HONS (NEW SOUTH WALES) (CIVIL, 2008) MSC (NEW SOUTH WALES) (TRANSPORT, 2008)

29221SUKHVINDER SINGH HARBANS SINGH ME (PORTSMOUTH) (CIVIL, 2003)

28967YONG FEI THIMBE HONS (UTM) (CIVIL, 2000)

KEJURUTERAAN ELEKTRIKAL

61147CHENG WENG SIONG BE HONS (MONASH) (ELECTRICAL & COMPUTER SYSTEMS, 2008)

64807GOH KUANG SEONGBE HONS (UNITEN) (ELECTRICAL POWER, 2007)

52323SHARILAZRI BIN MUKHTAR BE HONS (UNITEN) (ELECTRICAL & ELECTRONIC, 2002)

61907SRI DARAN A/L RAMAKRISHNAN BE HONS (UNITEN) (ELECTRICAL, 2007)

20220TAN KHENG BOONBE HONS (UTM) (ELECTRICAL, 2001)

KEJURUTERAAN ELEKTRONIK

51243BABUL SALAM BIN KSM KADER IBRAHIM BE HONS (KUiTTHO) (ELECTRICAL, 2002) ME (UTM) (ELECTRICAL, 2005) PHD (SHEFFIELD) (2011)

37922TEOW YOK WOOI, MATTHEW BSC (ROBERT GORDON) (ELECTRONIC & ELECTRICAL, 1994) ME (UTM) (ELECTRICAL, 1999)

62027YAP KOK YOONGBE HONS (KUiTTHO) (ELECTRICAL, 2003)

KEJURUTERAAN LEBUHRAYA

50749ABD WAHID BIN DAUD BE HONS (UTM) (CIVIL, 2008) ME (UPM) (HIGHWAY & TRASPORTATION, 2011)

KEJURUTERAAN PEMBUATAN

25820LIM YING PIOBE HONS (UTM) (AERONAUTICS, 1993) MSC (WARWICK) (MANUFACTURING, 1996) PHD (UPM) (MANUFACTURING SYSTEMS, 2006)

Persidangan Majlis IEM yang ke-389 pada 21 Oktober 2013 telah meluluskan sebanyak 4,323 ahli untuk permohonan baru dan permindahan ahli. Berikut adalah senarai ahli mengikut disiplin kejuruteraan:

PERMINDAHAN AHLI

KEPADA AHLI FELLOW No. AhliNamaKelayakan

KEJURUTERAAN AWAM

7980ANNIES BIN MD. ARIFF BSC HONS (WALES) (CIVIL, 1978)

PEMINDAHAN MENJADI AHLI ‘SENIOR’ No. AhliNamaKelayakan

KEJURUTERAAN AWAM

19154GAN CHOON HOCKBSC (NATIONAL CHENG KUNG UNI.) (CIVIL, 1990) ME (ASIAN INST. OF TECH.) (CIVIL, 1997)

KEJURUTERAAN ELEKTRIKAL

15667MANOHARAN PREM KUMAR A/L ARUNASALAM BE HONS (NOTTINGHAM TRENT) (ELECTRICAL & ELECTRONIC, 1995)

PEMINDAHAN AHLI

KEPADA AHLI KORPORAT No. AhliNamaKelayakan

KEJURUTERAAN AWAM

38054CHEONG WING GOHBE HONS (LEEDS) (CIVIL, 1998) MSC (SHEFFIELD) (CIVIL & STRUCTURE, 2000)

41109DEZALFHIE BIN ALIMBE HONS (UiTM) (CIVIL, 2005)

27867FOONG CHOON WOH BE HONS (USM) (CIVIL, 2007)

21542HAMIZAN BIN HAMZAH BE HONS (UTM) (CIVIL, 2000)

27994HANIF BIN MAT SALIM BE HONS (UTM) (CIVIL, 2000)

28611JOHNNY CHU KAM VAI BE HONS (CURTIN) (CIVIL & CONSTRUCTION, 2009)

33831KAMARUDDIN BIN HASSAN BE HONS (UTM) (CIVIL, 2001) MSC (USM) (PROJECT MANAGEMENT, 2003)

09988KOSHY NAINAN A/L T.K. NAINAN BE HONS (UM) (CIVIL, 1985)

21338KUEH MENG YAWBSC (MISSOURI) (CIVIL, 1999)

41388KWONG KOK ZEEBE HONS (CURTIN) (CIVIL & CONSTRUCTION, 2009)

53702LEE CHOON HONGBE HONS (UM) (CIVIL, 2005)

10969MOHAMAD BIN IBRAHIM BSC (PURDUE) (CIVIL, 1984)

49220MOHD IZWAN BIN MOHD NOOR BE HONS (UM) (CIVIL, 2004)

38902MOHD KHIZAM BIN MD ALI BE HONS (UTM) (CIVIL - CONSTRUCTION MANAGEMENT, 2007)

16030MOHD ZAMRI BIN ALIAS BSC (COLORADO) (CIVIL, 1989)

29198ROHANI BINTI HAROON BE HONS (EAST LONDON) (CIVIL, 1997)

48517TAN KHAI YIHBE HONS (UTM) (CIVIL, 2001)

42548TANG KUAN PUIBE HONS (USM) (CIVIL, 2006)

28925WAN MOHD FIRDAUS BIN WAN OMAR BE HONS (UNISEL) (CIVIL, 2008)

29653YEE HOOI MINBE HONS (USM) (CIVIL, 2006) MSC (USM) STRUCTURAL ENGINEERING, 2007) PHD (USM) (2011)

29252YONG HONG LEEBE HONS (UTM)(CIVIL, 2004) MSC (UTM) (CONSTRUCTION MANAGEMENT, 2006)

KEJURUTERAAN ELEKTRIKAL

26460CHRISTINA CHIN KIM OI BE HONS (UNITEN) (ELECTRICAL, 2004)

43909JAFNI BIN ALIAS @SULONG BE HONS (UTM) (ELECTRICAL, 2000)

28067KHAIRULANWAR BIN A. RAZAK BE HONS (UITM) (ELECTRICAL, 2006)

32605LOGESWARAN A/L SELVARATNAM BE HONS (UNITEN) (ELECTRICAL POWER, 2006)

39960LOO WAI CHIANBE HONS (USM) (ELECTRICAL, 208)

49886MOHAMMAD FAUZI BIN AWANG BE HONS (UTEM) (ELECTRICAL - CONTROL, INSTRUMENTATION & AUTOMATION, 2007)

27188MOHAMMAD HAZMIN BIN NOOR MAHADI BE HONS (UTM) (ELECTRICAL, 2009)

54288TAY WEI LIBE HONS (UM) (ELECTRICAL, 2005)

29744WONG CHOON CHEEN BE HONS (UTM) (ELECTRICAL, 2001)

KEJURUTERAAN ELEKTRONIK

24838GOBI A/L VETHARATNAM BE HONS (UM) (ELECTRICAL, 1998) MESC (MULTIMEDIA) (2003) PHD (MULTIMEDIA) (2011)

24528HONG KUN YEEBSC (PURDUE) (ELECTRICAL, 2002)

31731MOHD SYUHAIMI BIN AB. RAHMAN BE HONS (UKM) (ELECTRICAL, ELECTRONIC & SYSTEMS, 2000) ME (UKM) (ELECTRICAL, ELECTRONIC & SYSTEMS, 2003) PHD (UKM) (ELECTRICAL, ELECTRONIC & SYSTEMS, 2007)

21959MURALINDRAN MARIAPPAN BE HONS (USM) (ELECTRICAL & ELECTRONIC, 1998)MSC (UMS) (ELECTRICS & ELECTRONICS, 2004) PHD (UMS) (ROBOTICS, 2008)

19782PANG WAI LEONGBE HONS (UPM) (ELECTRICAL & ELECTRONICS, 2002)

48499ZAMANI BIN MD SANIBE HONS (USM) (ELECTRICAL & ELECTRONIC, 2000) ME (USM) (ELECTRICAL & ELECTRONIC, 2009)

KEJURUTERAAN KAWALAN & INSTRUMENTASI

21231TAN SHIEW SUNIEM/BEM PART II (ELECTRONIC, 2000) BE HONS (LINCOLN) (ELECTRONICS & CONTROL, 2001)

KEJURUTERAAN KIMIA

49890CHAI SIEW WUNBE HONS (USM) (CHEMICAL, 2004)

36914CHAN OI YEEBE HONS (UTM) (CHEMICAL-BIOPROCESS, 2002) MSC (LONDON) (ADV. CHEMICAL, 2004)

24979CHANG LAI CHENBE HONS (UM) (CHEMICAL, 2005)

33757LOW YAM KIMBE HONS (UM) (CHEMICAL, 2006)

KEJURUTERAAN MEKANIKAL

29757ABDUL MUNIR BIN ABDUL KARIM ME HONS (IMPERIAL COLLEGE LONDON) (MECHANICAL, 2005)

29607KHAIRUL FADZLI BIN AHMAD FAUDZI BSC (RENSSELAER POLYTECHNIC) (MECHANICAL, 2002)

48066MOHD ADZRIE BIN HJ. RADZALI BE HONS (MULTIMEDIA) (MECHANICAL, 2005)

20778MOHD FAIRUZ BIN HARON BE HONS (UiTM) (MECHANICAL, 2006)

49982MOKHTAR AWANGBE (DETROIT MERCY) (MECHANICAL, 1994)

51306NG WEI KITBE HONS (UM) (MECHANICAL, 2008)

48486ROSMAHADI BIN ALIBSC (THE GEORGE WASHINGTON) (MECHANICAL, 1992)

03963SHAHROM BIN SHAARI BE HONS (UTM) (MECHANICAL, 1981)

31754SHAMSUL IRWAN BIN ISMAIL BE HONS (UiTM) (MECHANICAL, 2002)

51698TAN BOON TIONGBE HONS (UM) (MECHANICAL, 2009)

38335WONG YIINGBE HONS (UTM) (MECHANICAL, 2005)

KEJURUTERAAN LEBUHRAYA & PENGANGKUTAN

21054KHOO HOOI LING@ LAI HOOI LING BE HONS (UM) (CIVIL, 2002) MESC (UM) (2005) PHD (SINGAPORE) (2009)

23936LEONG LEE VIENBE HONS (USM) (CIVIL, 1999) MSC (USM) (HIGHWAY & TRAFFIC, 2000) PHD (USM) (2004)

19404RAGURAMAN RAMASAMY BE HONS (UPM) (CIVIL, 1997)

KEJURUTERAAN TELEKOMUNIKASI

23649FOO DING KHENBE HONS (UTM) (ELECTRICALTELECOMMUNICATIONS, 2002)

LULUS PPP (BEM) No. AhliNamaKelayakan

KEJURUTERAAN AWAM

12320LAW PAK CHONGBE HONS (UTM) (CIVIL, 1993)

16686MOHAMAD ZAIDI BIN IBRAHIM BE HONS (UiTM) (CIVIL, 1997)

27139QUEK SWEE JINBSC (MICHIGAN TECHNOLOGICAL) (CIVIL, 1999)

KEJURUTERAAN ELEKTRIKAL

21572CHONG CHOON CHIN BE HONS (UTM) (ELECTRICAL, 1995)

44615MOHD KAFRI BIN ZAKARIA BE HONS (UM) (ELECTRICAL, 2005)

KEJURUTERAAN MEKANIKAL

23761WONG KHEE VEAIBE HONS (UM) (MECHANICAL, 2006)

PERMOHONAN MENJADI AHLI KORPORAT NamaKelayakan

KEJURUTERAAN AWAM

AHMAD ALLNADHOR BIN HAMIM BE HONS (UTM) (CIVIL, 2000)

ASMANINI BINTI ISMAILBE HONS (UTM) (CIVIL, 2002)

AZIZAH BINTI MOHAMED BE HONS (CNAA-MIDDLESEX POLYTECHNIC, 1987)

CHEONG WOON KOONBE HONS (BIRMINGHAM) (CIVIL, 1998)

DZULKIFLE BIN SULONG BSC (MARQUETTE) (CIVIL, 1988)

HOW YOKE TENGBE HONS (UTM) (CIVIL, 2002)

JAFFRE BIN CHE LAH @WAHAB BE HONS (UTM) (CIVIL, 2002)

MOHD ARAFAT BIN

MUHAMAD ARIFIN BE HONS (UiTM) (CIVIL, 2003) MSC (UITM) (CIVIL-STRUCTURES, 2011)

TEOH PEI LIMBE HONS (UM) (CIVIL, 2005)

UNG NENG HUI, STEPHEN BE HONS (LIVERPOOL) (CIVIL, 1998)

WAN HASITINAZIAH BINTI MOHD HASSAN BE HONS (UTM) (CIVILCONSTRUCTION MANAGEMENT, 2002)

KEJURUTERAAN BAHAN

STANLEY BALANG ANAK PETER JANG BE HONS (UM) (MATERIALS, 2002)

KEJURUTERAAN ELEKTRIKAL

ASMIZAN BIN IBRAHIMBE HONS(UiTM) (ELECTRICAL, 2003)

EDWINA BINTI HAMZAHBE HONS (UNITEN) (ELECTRICAL & ELECTRONICS, 2001)

MICHELLE LUBE HONS (CURTIN) (ELECTRICAL, 2006)

MOHD AZANI BIN

ABDULAZIZ BE HONS (UTM) (ELECTRICAL, 2004)

MOHD SUHAIDI BIN AWANG BE HONS (UiTM) (ELECTRICAL, 2006)

SHAHRUL HISHAM BIN SAMSUDIN BE HONS (UiTM) (ELECTRICAL, 2006)

ZAINAL BIN SHAMSUDDIN BSC (WIDENER) (ELECTRICAL, 1990)