THE MONTHLY BULLETIN OF THE INSTITUTION OF ENGINEERS, MALAYSIA

2015

KDN PP 1050/12/2012 (030192) ISSN 0126-9909

Compliance to International Standards and Regulations on Vehicle Safety

Sustainability In Concrete Structures

2015

KDN PP 1050/12/2012 (030192) ISSN 0126-9909

Sustainability In Concrete Structures

The Spice is a mix development project located in Penang, a state north of Kuala Lumpur. It includes a Sales Gallery Of昀椀ce, Convention Centre and Aquatic Centre.

XYPEX Admix C-1000NF, XYPEX Concentrate and XYPEX Modi昀椀ed have been used in various areas such as Basement Slab, Floor Slabs, Skin Walls, Retaining Walls, Lift Pit, Water Features and Internal Floor Finishes.

Xypex solutions were chosen for its ability to selfheal static hairline cracks up to 0.4mm wide, resist extreme hydrostatic pressure, and chemical protection, will contribute to enhance the durability, increase service life and reduce future maintenace costs of these structures very long into the future.

For more information on how our solutions can provide sustainable bene昀椀ts for your concrete assets, please visit our website at www.xypex.com.au or LinkedIn Page.

Number 04, April 2015

IEM Registered on 1 May 1959

MAJLIS BAGI SESI 2014/2015 (IEM COUNCIL SESSION 2014/2015)

YANG DIPERTUA / PRESIDENT

y.Bhg. Dato’ Ir. Lim Chow Hock

TIMBALAN YANG DIPERTUA / DEPUTY PRESIDENT

Ir. Tan Yean Chin

NAIB YANG DIPERTUA / VICE PRESIDENTS

Ir. P.E. Chong, Ir. Prof. Dr Wan Mahmood bin Wan Ab. Majid, Ir. Prof. Dr Lee Teang Shui, Ir. David Lai Kong Phooi, y.Bhg. Dato Ir. Dr Andy Seo Kian Haw, Ir. Lee Weng Onn,

Ir. gopal Narian Ku琀琀y

SETIAUSAHA KEHORMAT / HONORARY SECRETARY

Ir. Gunasagaran a/l Kristnan

BENDAHARI KEHORMAT / HONORARY TREASURER

Ir. Prof. Dr Je昀昀rey Chiang Choong Luin

BEKAS YANG DIPERTUA TERAKHIR / IMMEDIATE PAST PRESIDENT

Ir. Choo Kok Beng

BEKAS YANG DIPERTUA / PAST PRESIDENTS

Y.Bhg. Dato’ Ir. Pang Leong Hoon, Y.Bhg. Academician Tan Sri Dato’ Ir. (Dr) Hj. Ahmad

Zaidee bin Laidin, y.Bhg. Dato’ Ir. Dr gue See Sew, y.Bhg. Datuk Ir. Prof. Dr Ow Chee Sheng, y.Bhg. Academician Dato’ Ir. Prof. Dr Chuah Hean Teik

WAKIL AWAM / CIVIL REPRESENTATIVE

Ir. Prof. Dr Mohd. Zamin bin Jumaat

WAKIL MEKANIKAL / MECHANICAL REPRESENTATIVE

Ir. Dr Kannan M. Munisamy

WAKIL ELEKTRIK / ELECTRICAL REPRESENTATIVE

Ir. Ali Askar bin Sher Mohamad

WAKIL STRUKTUR / STRUCTURAL REPRESENTATIVE

Ir. Hooi Wing Chuen

WAKIL KIMIA / CHEMICAL REPRESENTATIVE

Ir. Prof. Dr Abdul Aziz bin Abdul Raman

WAKIL LAIN-LAIN DISPLIN / REPRESENTATIVE TO OTHER DISCIPLINES

Ir. S. Kumar a/l Subramaniam

WAKIL MULTIMEDIA DAN ICT / ICT AND MULTIMEDIA REPRESENTATIVE

Engr. Abdul Fa琀琀ah bin Mohd. ya琀椀m, M.I.E.M.

AHLI MAJLIS / COUNCIL MEMBERS

Ir. Lee Boon Chong, Ir. Tu Yong Eng, Ir. Lai Sze Ching, Ir. Yap Soon Hoe, Ir. Li Thang Fai, Ir. Juares Rizal bin Abd. Hamid, Ir. Norazman bin Mohamad Nor, Ir. Ellias bin Saidin, Ir. Assoc. Prof. Dr Jimmy Mok Vee Hoong, Ir. Dr Tan Chee Fai, Ir. Kok Hee Poh, Ir. Tiong Ngo Pu, Ir. yau Chau Fong, Ir. Teh Piaw Ngi, Ir. Assoc. Prof. Ahmad Kamil bin Arshad, Ir. Kim Kek Seong, Ir. Chong Chin Meow, Ir. Chin Kuan Hwa, Ir. Assoc. Prof. Dr Vigna Kumaran Ramachandaramurthy, Ir. Lee Cheng Pay, Ir. Ong Ching Loon, Ir. Gary Lim Eng Hwa, y.Bhg. Dato’ Ir. Noor Azmi bin Jaafar, Ir. Aminuddin bin Mohd. Baki, Ir. Mohd. Radzi bin Salleh, Ir. Ong Sang Woh

AHLI MAJLIS JEMPUTAN / INVITED COUNCIL MEMBERS

Dato’ Ir. Hj Hanapi bin Mohamad Noor, Datuk Ir. Rosaline ganendra, Dato’ Ir. Abdul Rashid bin Maidin

PENGERUSI CAWANGAN / BRANCH CHAIRMAN

1. Pulau Pinang: Ir. Dr Mui Kai Yin

2. Selatan: Ir. Assoc. Prof. Haya琀椀 bin琀椀 Abdullah

3. Perak: Ir. Dr Perumal Nallagownden

4. Kedah-Perlis: Ir. Chua Teik Seng

5. Negeri Sembilan: Ir. Shahrin Amri bin Jahari

6. Kelantan: Ir. Hj. Syed Abdul Rahman bin Syed Abdullah

7. Terengganu: Ir. Hj. Abdullah Zawawi bin Mohd. Nor

8. Melaka: Ir. Nur Fazil Noor Mohamed

9. Sarawak: Ir. Haidel Heli

10. Sabah: Ir. Tan Koh Yon

11. Miri: Ir. Steven Chin Hui Seng

12. Pahang: Ir. Tuan Haji Ahmad Kamal bin Kunji

AHLI JAWATANKUASA INFORMASI DAN PENERBITAN / STANDING COMMITTEE ON INFORMATION AND PUBLICATIONS 2014/2015

Pengerusi/Chairman: Ir. Prof. Dr Lee Teang Shui

Naib Pengerusi/Vice Chairman: Ir. Dr Tan Chee Fai Se琀椀ausaha/Secretary: Ir. Lau Tai Onn

Ketua Pengarang/Chief Editor: Ir. Prof. Dr Lee Teang Shui

Pengarang Bule琀椀n/Bulle琀椀n Editor: Ir. Mohd. Khir Muhammad Pengarang Prinsipal Jurnal/Principal Journal Editor: Ir. Prof. Dr Dominic Foo Chwan yee

Pengerusi Perpustakaan/Library Chairman: Ir. C.M.M. Aboobucker Ahli-Ahli/Commi琀琀ee Members: y.Bhg. Datuk Ir. Prof. Dr Ow Chee Sheng, Engr. Abdul Fa琀琀ah bin Mohamed ya琀椀m, M.I.E.M., Ir. Dr Kannan a/l M. Munisamy, Ir. Siow yun Tong, Ir. Chin Mee Poon, Ir. yee Thien Seng, Ir. Tu yong Eng, Ir. Ong guan Hock, Engr. Aida yazrin Mohd. Khairi, Engr. Kok Jing Shun

LEMBAGA PENGARANG/EDITORIAL BOARD 2014/2015

Ketua Pengarang/Chief Editor: Ir. Prof. Dr Lee Teang Shui

Pengarang Bule琀椀n/Bulle琀椀n Editor: Ir. Mohd. Khir Muhammad

Pengarang Jurnal/Journal Editor: Ir. Prof. Dr Dominic Foo Chwan yee Ahli-ahli/Commi琀琀ee Members: Ir. Dr Tan Chee Fai, Ir. Ong guan Hock, Ir. Lau Tai Onn, Ir. Yee Thien Seng

IEM Secretariat: May Lee

Front Cover: Photo is courtesy of PROTON Holdings Berhad

COVER NOTE

Automotive Engineering: Vehicle Safety 5

COVER STORY

Reaching New Levels of Safety... How Adoption of New Standards & Regulations Are Ensuring Cars Are Safer Than Ever 6-11

HISTORY OF IEM Wisma IEM Part 3 - Final 12 - 13

FEATURE ARTICLES

Evaluation of Hot Press Forming Parts for Euro NCAP5 in P3-21A..............................................14

Professional Competency Exam......................23

Implementation of the UNECE R66 Regulation for Safer Bus Body Structure in Malaysia...........................................................24 14 - 27

FORUMS

CSETD AGM Talk: Fundamentals on Blast and Impact Loading on Structures..........................28

Talk on Introduction to Tunelling by Drilling and Blasting............................................................31

Understanding Ground Movements Around Excavations in Cities – Talk by Prof. Guy Houlsby............................................................34

IEM POSITION PAPER

Benchmarking The Quality of Engineers 42 PRESS STATEMENT 43

DIMENSION PUBLISHING SDN. BHD.

The o昀케cial publisher of THE INSTITUTION OF ENGINEERS, MALAYSIA (IEM) – is proud to present the IEM DIRECTORY, which compiles cri琀椀cal businessdatafrombusinesspartners,andprovidesna琀椀onwideexposure to key professionals in the engineering industry.

Our esteemed readership consists of cer琀椀昀椀ed engineers, decision making corporate leaders, CEOs, government o昀케cials, project directors, entrepreneurs, project consultants, engineering consul琀椀ng 昀椀rms and companies involved with engineering products and services.

IEM DIRECTORY is circulated to more than 30,000 registered members of The Ins琀椀tu琀椀on of Engineers, Malaysia (IEM), with an es琀椀mated readership of 120,000 professionals.

ADVERTISING BENEFITS

Our business partners can be assured that their products and services will be given the circula琀椀on and exposure it deserves, thus maintaining a sustained adver琀椀sing presence to our core readers of decisionmaking engineers and technical experts. Our website o昀昀ers an even wider market reach, with added interna琀椀onal presence, aided by our interna琀椀onal a昀케lia琀椀on with o昀케cial engineering bodies all over the world. Our online and o昀툀ine adver琀椀sing features such as banner adver琀椀sing, ar琀椀cle sponsorship and direct e-mail announcements have proven to be successful marke琀椀ng strategies that will set the businesses of our partners apart from their compe琀椀琀椀on.

The IEM DIRECTORY is an excellent resource for businesses looking for engineering related products and services, business opportuni琀椀es and coopera琀椀on with engineering 昀椀rms, suppliers, distributors, consultants and quali昀椀ed professional engineers for major projects and business interests. Our content includes:

• Malaysia’s most comprehensive directory of engineering companies and consulting firms.

• Detailed descriptions of major and on-going projects.

• A decisive listing of companies providing goods and services to engineers and engineering businesses in a concise format, as well as an easily searchable index of companies sorted by engineering disciplines.

• A complete list of all current IEM Honorary Fellows, Fellows, Members, graduate and Student Members.

• List of major Engineering related events, seminars and exhibitions in Malaysia.

by Ir. Mohd. Khir Muhammad Bulletin Editor

He is currently a

engineering and project management company in aerospace, automotive and offshore engineering. He was the Head of Aero Lab, Universiti Teknologi Malaysia from 1994 to 2013 where he was involved in the setting up of as well as operations of the 昀椀rst wind tunnel facility in Malaysia for the aerodynamics testing of automotive models.

How safe are our cars? Safety features and star ratings have become more and more important to consumers and are unique selling points for car manufacturers.

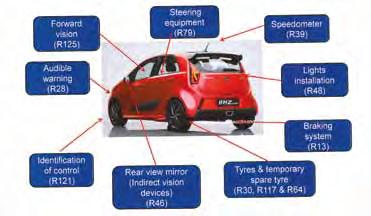

The UNECE WP.29 is a legal framework for various countries including Malaysia, to establish regulatory instruments related to motor vehicle safety. Malaysia is a signatory to UNECE and has implemented the international WP.29 regulations through the Vehicle Type Approval (VTA) process.

This is in-line with our National Automotive Policy (NAP) to transform the domestic car industry and to integrate it into the increasingly competitive regional and global industry network. One of the aims is to safeguard consumer interests by offering safer and better quality products at competitive prices.

In the cover story, we have highlighted the efforts made by our national car manufacturer, PROTON Holdings Berhad, to comply with regulation UNECE WP.29 and to meet new standards such as NCAP (New Car Assessment Programme) so as to improve vehicle safety and to venture into newer markets. Proton’s chief technical of昀椀cer speaks passionately about the safety features of Proton cars and how Proton plans to achieve UNECE WP.29 regulations by year 2020.

The use of HPF (Hot Press Forming) technology in Proton cars has also proven to improve body structure stiffness. A feature on the process of HPF and how it meets Euro NCAP 5 stars requirements is presented.

In recent years, the number of fatal accidents involving buses is increasing at an alarming rate. The implementation of UNECE regulations for a safer bus body structure is also highlighted.

A car with the right safety features can be made stylish and affordable; it doesn’t have to be a high-end model. Active Safety features can help prevent accidents while passive safety features protect the occupants of the car in the event of an accident. No car is entirely safe without Active Safety features and it is these active safety features that qualify a car to be elevated to a 5-Star NCAP status.

As the saying goes, Safe Cars Save Lives!

DIMENSION PUBLISHING SDN. BHD. (449732-T)

Level 18-01-03, PJX-HM Shah Tower, No. 16A, Persiaran Barat, 46050 Petaling Jaya, Selangor Darul Ehsan, Malaysia. Tel: +(603) 7493 1049 Fax: +(603) 7493 1047 E-mail: info@dimensionpublishing.com Website: www.dimensionpublishing.com

For adver琀椀sement placements and subscrip琀椀ons, please contact: diMension publishing sdn. bhd. (449732-T) at +(603) 7493 1049, or E-mail: info@dimensionpublishing.com

Subscrip琀椀on Department E-mail: subscrip琀椀on@dimensionpublishing.com

Printed by

hoffset printing sdn. bhd. (667106-V) No. 1, Jalan TPK 1/6, Taman Perindustrian Kinrara, 47180 Puchong, Selangor Darul Ehsan, Malaysia. Tel: +(603) 8075 7222 Fax: +(603) 8075 7333

Mailer

PERFECT MAIL SERVICES (648839-P)

14 Jalan TSB 2, Taman Perindustrian Sungai Buloh, Sungai Buloh, Selangor Darul Ehsan, Malaysia. Tel: +(603) 6156 5288

Jurutera Monthly CirCulation: 30,000 Copies

Submission or placement of ar琀椀cles in JURUTERA could be made to the:Chief Editor

THE INSTITUTION OF ENgINEERS, MALAySIA (IEM) Bangunan Ingenieur, Lots 60 & 62, Jalan 52/4, P.O. Box 223 (Jalan Sultan), 46720 Petaling Jaya, Selangor. Tel: +(603) 7968 4001/4002 Fax: +(603) 7957 7678

E-mail: pub@iem.org.my or sec@iem.org.my IEM Website: h琀琀p://www.myiem.org.my © 2015, The Ins琀椀tu琀椀on of Engineers, Malaysia (IEM) and Dimension Publishing Sdn. Bhd.

Chairman ROBERT MEBRUER CEO/Publisher PATRICK LEUNg

General Manager SHIRLEy THAM shirley@dimensionpublishing.com

Head of Marke琀椀ng & Business Development JOSEPH HOW joseph@dimensionpublishing.com

Editor TAN BEE HONg bee@dimensionpublishing.com

Contribu琀椀ng Writers ARMAN PFORDTEN & PUTRI ZANINA pfordten@dimensionpublishing.com putri@dimensionpublishing.com

Senior Graphic Designer SUMATHI MANOKARAN sumathi@dimensionpublishing.com

Graphic Designer NABEELA AHMAD beela@dimensionpublishing.com

Adver琀椀singConsultants ABDUL AZIM BIN SHAARI&THAM CHOON KIT azim@dimensionpublishing.com ckit@dimensionpublishing.com

Accounts cum Admin Execu琀椀ve yONg yEN yIN yenyin@dimensionpublishing.com

publiCation disClaiMer

The publica琀椀on has been compiled by both IEM and Dimension with great care and they disclaimanydutytoinves琀椀gateanyproducts,process,services,designsandthelikewhichmay be described in this publica琀椀on. The appearance of any informa琀椀on in this publica琀椀on does notnecessarilycons琀椀tuteendorsement by IEMand Dimension. Thereisnoguaranteethat the informa琀椀oninthis publica琀椀onisfreefromerrors.IEMandDimensiondonotnecessarilyagree with the statement or the opinion expresssed in this publica琀椀on.

Copyright JURUTERA Bulle琀椀n of IEM is the o昀케cial

by Aman Pfordten

Mr. Abdul Rashid Musa Chief Technical Of昀椀cer PROTON Holdings Berhad

WMr. Abdul Rashid Musa, graduated with a Bachelor Degree of Engineering (Mechanical) with honours from the University of Malaya in 1989. With a career spanning over 25 years in various automotive projects and organisations tied to the automotive industry which are not only limited to local industries but also at an international level when he was posted to Group LOTUS (England) and Mitsubishi Motors (Japan). His involvement in the automotive 昀椀eld started in 1990 when he joined Automotive Industries Sdn. Bhd. (a subsidiary of UMW Toyota) followed by Mitsubishi Japan in 1993, HICOM Engineering Sdn. Bhd. in 1995 and Lotus UK in 1997. In 2008 and 2012, he was entrusted to lead HICOM Automotive Manufacturers (Malaysia) Sdn. Bhd. (formerly known as AMM) at DRB-HICOM, Pekan Complex, Pahang. He was given the challenge to turn around the company's image and performance with a vision to be the preferred Automotive Assembler. There, he was able to hone his skills and knowledge further when he worked with global renowned partners like Volkswagen, Mercedes Benz and Suzuki.

Rashid holds several portfolios here in PROTON Holdings Berhad, where he oversees project collaboration as Chief Technical Of昀椀cer mainly on the New Perdana introduction and several new developments that include PROTON’s new and technologically advanced hatchback, the Iriz. Apart from that, Rashid also holds several Board of Director positions of several PROTON af昀椀liated companies. He has diligently contributed indirectly and directly to uphold the corporate governance, integrity of decisions and policies in PROTON. With his passion to elevate the quality standards of our locally produced cars, Rashid is also involved with several nonpro昀椀t governmental bodies & relevant authorities on policies and regulations. Rashid has been very vocal on advocating passenger safety regulations to be at par with international standards. He has led a strong team to ensure PROTON's latest models namely the Suprima S, Prevé and Iriz achieve the highest rating (5 stars) in terms of safety from ASEAN ANCAP and Australian NCAP respectively. In the education arena, Rashid was involved in the early stage of the setting up of ICAM (International College of Automotive) in Pekan, Pahang. He was appointed as an ICAM Academic Advisory Panel and has participated in project collaboration with Warwick University, England.

P.29 was established in 1952 as the Working Party on the Construction of Vehicles, a subsidiary body of the Inland Transport Committee (ITC) of the United Nations Economic Commission for Europe (UNECE). In March 2000, WP.29 became the "World Forum for Harmonisation of Vehicle Regulations (WP.29)" with the objective to initiate and pursue actions aimed at the worldwide harmonisation or development of technical regulations for vehicles. Providing uniform conditions for periodical technical inspections and strengthening economic relations worldwide, these regulations are aimed at improving vehicle safety, protecting the environment, promoting energy ef昀椀ciency and increasing antitheft performance (Source: UNECE website).

JURUTERA interviews Proton Chief Technical Of昀椀cer and an IEM member Mr. Abdul Rashid Musa on how Proton is complying with international regulations like UNECE WP.29 and meeting new standards such as New Car Assessment Programme (NCAP) to improve safety for its customers and venture into newer markets.

What are the various aspects of safety when it comes to ensuring overall safety of a passenger in a vehicle? There are basically three areas when it comes to the safety of vehicles and transportation.

Firstly, there is the safety of the road itself. This is an aspect that concerns civil engineers. They try to make the road safer in terms of turning radii, gradients and so on.

Secondly, there is user behaviour. This is an important aspect, because it is the trigger for the other two. We can create a safer car, but if the consumer doesn't wear his seat belt, then the outcome is still the same.

In Malaysia, we need to improve more on this. Thirdly, it is the safety of the vehicle itself. This is an area where our community is increasingly gaining awareness for.

The Malaysian government has signed up with World Vehicle Type Approval (WVTA). It was gazetted in 2010, and commenced enforcement in 2012. We are approaching it via

the process of gradual enforcement. Malaysia will be in full compliance of WVTA by the year 2020.

The need for world certi昀椀cation only came about because PROTON is a manufacturer that designs, tests and builds its cars entirely, for sale worldwide. As a long time employee who has been with the company since it built its 昀椀rst in-house designed car, what are the challenges faced in making a product that is sold on the world stage?

Our former prime minister Tun Dr Mahathir Mohamad had this aspiration of having a national car back in 1979. I joined the company in 1990. Back in 1979, Malaysia only had plantation as the main thrust of our economy. It was mostly agriculture – with oil palms and rubber plantations mostly.

In those days people used to say that Malaysia doesn't even have the skill to produce a needle. As engineers, we took this as a challenge. In 1982, Tun Dr Mahathir found a partner, Mitsubishi, to create a national car. In 1983, PROTON was set up and the 昀椀rst rollout of its car was in 1985.

How PROTON works is actually beyond business. It's not just talking about buying and selling or trading, but more about the national interest of developing a national industry. Why? Because it can spin off a lot of other industries.

Then we come to the aspect of world standards. Being in this business, PROTON must be a global company. We have to comply with international requirements. This is what the WVTA is all about.

There are 232 countries in the world. Out of this, only 14 countries cars and have the capability and capacity to build their own car. Out of the 14, only one is from a developing country. The car itself is very international in nature.

Can you brie昀氀y describe the UNECE regulations which PROTON now needs to comply to?

There are 134 regulations in total under this regulation. It goes back to the safety aspect, which is paramount to any design.

In the Asean region, we are the only OEM that comply to this regulation. We started in 2012, and will achieve full compliance by the year 2020.

In the world, there are many other similar regulations as well. For example, there is the Japanese International Standards (JIS) in Japan and The Federal Motor Vehicle Safety Standards for the US.

Many countries in the world are changing to ECE based European Economic Commission regulations. Even Russia is changing to the European-based regulation.

Is this regulation an important step for the motoring industry in the country as well?

Malaysia has a high proportion of cars to people. At 1 car per 2.5 persons, it is quite high, compared to Indonesia and Thailand.

We have more than 10 million cars on the road currently. Of this, 3.7 million are Proton cars. This means that out of 10 cars, 3 or 4 of them will be Proton cars. Unfortunately, we have many older generation cars on the road right now. In my opinion, the government should have "end of life" policy on this matter.

Circula琀椀on and Readership Pro昀椀le Ouresteemedreadershipconsistsofcer琀椀昀椀edengineers,decision makingcorporateleaders,CEOs,governmento昀케cials,project directors,entrepreneurs,projectconsultants,engineeringconsul琀椀ng 昀椀rmsandcompaniesinvolvedwithengineeringproductsandservices.

JURUTERA iscirculatedtomorethan 30,000 registered members ofTheIns琀椀tu琀椀onofEngineers,Malaysia(IEM),withan es琀椀mated readership of 120,000 professionals.

Adver琀椀sing

Our business partners can be assured that their products and serviceswillbegiventhecircula琀椀onandexposureitdeserves,thus maintainingasustainedadver琀椀singpresencetoourcorereadersof decision-makingengineersandtechnicalexperts.Ourwebsiteo昀昀ers anevenwidermarketreach,withaddedinterna琀椀onalpresence,aided byourinterna琀椀onala昀케lia琀椀onwitho昀케cialengineeringbodiesallover theworld.Ouronlineando昀툀ineadver琀椀singfeaturessuchasbanner adver琀椀sing,ar琀椀clesponsorshipanddirecte-mailannouncements haveproventobesuccessfulmarke琀椀ngstrategiesthatwillsetthe businessesofourpartnersapartfromtheircompe琀椀琀椀on.

Roadworthiness is very important. Many regulations have been introduced, and the old vehicles have become obsolete. They are no longer safe. The seat belts are not safe. Other things like emission levels are also not up to par.

What are the basic principles used in UNECE regulation testing?

The testing of components is done on three levels.

Firstly, they are done on the component level, consequently at system level and 昀椀nally, vehicle level. In order for a vehicle to comply, it must have all three test reports.

All 134 items have to be done on three levels. When the vehicle is fully built up – a crash test is done.

Who are the custodians of the standard in Malaysia, and why is it important now to regulate car makers?

The authority who oversees the implementation in Malaysia is the Road Transport Department (RTD). In order for approval to be obtained, it must 昀椀rst be approved by a committee. The committee consists of representatives from the Ministry of Transport, Ministry of International Trade and Industry or MITI, PUSPAKOM, SIRIM and so on. I'm also recommending that the Fire and Rescue Department (Bomba) be on the committee. This is because when a car is involved in an accident, they

are the ones who have to handle the situation 昀椀rst hand. Our cars today are made with Hot Press Forming (HPF) parts. Their steel structure strength is at 1500 MPa, or 昀椀ve times stronger than normal steel. Therefore, the rescuers can't simply cut the roof. In most cases, they would just need to open the door.

Today's cars are designed so that the passenger cage does not collapse. It is very strong. If they try to cut through it, it will take a very long time and is almost an impossible feat.

If we export cars to certain countries which have adopted the UNECE, then we have to comply. This is regulation. When they do type approvals for certain things, we can carry over the results.

We try to harmonise the enforcement. In Malaysia, we are the only ones in the region who are so far advanced. Even our northern neighbouring country, despite having signed the WVTA, has yet to enforce it. That's why there are new cars there without airbags. Meanwhile, our closest neighbour, Indonesia has yet to sign the WVTA. This is probably why some car makers are taking advantage of low regulatory practices in these countries. In Malaysia, we have one of the highest regulations in ASEAN countries.

In terms of safety, we are ahead of the others in the ASEAN region in two aspects. Our Total Industry Volume (TIV) is relatively small at 700,000 as opposed to Thailand at 1.2 million and Indonesia, 1.4 million but in terms of regulatory safety requirements and education, we are way ahead.

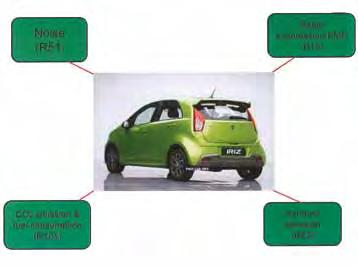

What are some of the new regulations introduced recently under UNECE?

Safety is not the only aspect regulated under UNECE. It also regulates such diverse aspects such as tyre rolling sound - which is also a detailed part in this regulation. It takes into consideration of the level of decibels (dB) allowed on each type of tyre. It details how to conduct proper tests by the authorities. In 2015, there will be 19 new more regulations.

In 2017, there will be mandatory UNECE R101 regulations for fuel consumption and emissions.

How do the changes in regulations affect PROTON? Is it challenging to comply with the regulations compared to other car companies operating here?

This makes it very dynamic for us. It takes a minimum of two years to design a car. PROTON builds complete vehicles with its own platform, powertrains and top hats. It has registered 2,865 intellectual property rights over the years.

We make our own engine, and we have a casting plant. Because the supporting industries in the country are relatively weak, we have to play a bigger role.

We are not just assemblers. Even for our tooling, we have a companythatsuppliestooling.Sinceweknowthatinvestorsdon't have the money to invest in say, a casting plant, we invested in casting plants that make cylinder blocks. As I've mentioned, PROTON is beyond business. We are more responsible than that. We develop the vendors, industry and capabilities. We can make our own engines, platforms and cars of our own.

I'm very proud that even though we have less than 1,000 engineers working with us – they nevertheless have been

producing world class cars. At the end of the day, to get your car sold in UK, you must meet all the requirements.

The Road Transport Department (RTD) is the authority in Malaysia. There is a committee led by RTD. That is their role. For example, during the submission of our Iriz car, the RTD has to send a witness or receive documentation every step of the way. They even have to audit the vendor supplying our parts, as every element must be submitted and accounted for.

Even the glass is tested and submitted. Often people ask why it costs so much to build a car. Sometimes it is unfair, because we are a true OEM, and as an OEM we must have this capability. For crash testing alone, we spend roughly RM7 million.

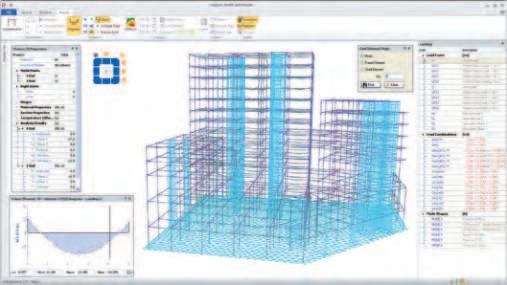

We are now employing a lot of CAD and CAE as well as virtual testing so that we can reduce the number of tests done but it is still challenging. The safety requirements are not segmented, and stand on their own.

If a car has 10 airbags but the body structure is not strong, it will collapse, so we must consider safety from the design stage itself.

Before UNECE, there were no standards here. Suf昀椀ce to say, before this, there were many abuses to the system. That's why a car that looks the same elsewhere in the world, may not have the same speci昀椀cation when it is sold in Malaysia.

Some cars may look the same, but they have different speci昀椀cations when sold in this country. The European cars however, often only have one set of speci昀椀cations.

You can clearly see this when some models are not even sold in other parts of the world. They tailor-make these vehicles to comply with affordability issues and so on. I'll be frank and say that I'm quite upset that the authorities sometimes give exemptions. This is something that we protest. There is a recently launched car from a China car maker. Third seat belt is now mandatory for new models. Cars have to have a center seat belt. It has to be a three point seat belt. I had a look and there were only two seat belts. This does not follow regulations. Apparently, they asked for an exemption. If we (PROTON) go to Australia, will we be given exemptions? Why do the authorities give exemptions here?

In 2012, I made a report on this - stating that 70 car makers had been given exemptions.

Besides regulations under UNECE, what other standards does PROTON aspire to achieve?

Market expectations are very different now. Many consumers are aware of the New Car Assessment Programme (NCAP). This is a voluntary test for cars. In Malaysia, we have the Malaysian NCAP. This is handled by Malaysian Institute of Road Safety Research (MIROS).

On the international level, there is World NCAP, so that consumers know a car's safety rating before they buy it. It's sort of like reading the ingredients and safety label at the grocer. When we buy food, we can 昀椀nd out how many calories from the packaging.

SAVED!!! The driver standing by the roadside, after the accident.

Similarly for cars, this is the rating standard to measure safety. The ASEAN NCAP has just been formed. It's a process of gradual implementation as well.

How does NCAP ratings ensure passengers buy safer cars?

When we talk about the safety aspect of passenger cars, we are talking about safety on three levels. Firstly, there is passive safety. This relates to the safety provided by the passenger cage, airbags, and other design features during the accident.

The second level is active safety. These are features that help prevent an accident, such as Anti-Lock Braking Systems (ABS), Electronic Stability Control (ESC), Brake Assist (BA) as well as Traction Control (TC). A manufacturer needs to have good active safety set of system to get a very good rating.

If a car only has good passive safety features, you will not score a 昀椀ve-star rating.

If you have a strong body structure and you score very highly on passive safety with more than 14 points but you don't have active safety, you will not get 昀椀ve-star NCAP.

For example, without ESC and seat belt reminder, you can get a maximum 4-star even though you score highly. This is because it is important to prevent an accident from occurring. As they say, prevention is better than cure.

By 2017, there will be more stringent requirements. In NCAP, points are calculated based on the level of injury as measured by the crash test dummies.

Cars hit an offset deformable barrier at 64 kmh. Side impacts are tested at 50 kmh. From points obtained, they calculate the car safety level.

The next level is cognitive safety. PROTON is now developing it but it's not in the market yet. This includes items such as autonomous braking system. Our Iriz demonstration vehicle has an autonomous braking system. If there is an obstruction ahead, it will brake by itself. It works by using radar with the doppler effect and a 3D camera. You don't have to press the brake, it will stop by itself.

Thentherearethingssuchaslanedeparturewarning indicators and signage recognition.

For example, if you are in a 90km/h area, and you drive at 100 km/h it will trigger off an alarm. There is also the collision avoidance system. If a motorcycle comes from the rear, it will trigger an alarm.

In the Iriz, when you come to a slope, you don't have to worry while you press the brakes. The car will automatically lock the hydraulics so it doesn't roll back.

The Iriz has Electronic Brake Distribution (EBD), which means that if passengers are in the rear, the car will electronically distribute more forces to the rear.

Although it is a 2-wheel drive car, it behaves almost like a 4-wheel drive. We can manipulate the brake power to the rear, by controlling the rotation of the rear brake. It also has keyless entry. The doors can be programmed, not only for safety, but also for security.

You can program it to open only one door. Therefore, if you are alone, it is safer.

Many of these features we have developed for the Iriz. Iriz is our new technology car. It has a platform that can be powered by a traditional internal combustion engine, a hybrid or even fully electric.

Well, the Iriz is a RM40,000 car with a 5-star ASEAN NCAP. Some features, like the ESC can only be found on RM100,000 cars.

This is the best ever Proton car. We have evolved in technology. All the best knowledge and features are in the Iriz.

Under the Australasian NCAP, Proton cars are performing better. We are better than many other foreign cars that come into our market. For our Prevé, we scored just 0.25 points behind Audi A4 under Australasian NCAP. This is a great achievement for us. But it's still hard to convince the public. Our Prevé has won an award on safety. Now safety has become our Unique Selling Point (USP).

The behaviour and attitude of the occupants is the most important. For intance, Proton cars have seat belt warnings. I know many users connect the seat belt and sit on it. At an accessories shop, they sell seat belt buckles to be inserted into the belt holder so that the alarm doesn't go off. They don't want to wear seat belts.

by Dato’ Ir. Pang Leong Hoon

Dato’ Ir. Pang Leong Hoon was formerly the Director-General, Department of Irrigation and Drainage, Malaysia. He was also the Past President of IEM for Sessions 1984/1985 and 1985/1986.

This is a compilation of articles under the Sub-Committee on Documentation and Recording of IEM Historical Events under the chairmanship of Datuk Ir. Prof. Dr Ow Chee Sheng. Committee members comprise Ir. Chiam Teong Tee, Dato’ Ir. Pang Leong Hoon, Ir. Gunasagaran Kristnan and Ir.

C.M.M.Aboobucker

The Fund Raising Committee, set up at the request of the Excomm, prepared an action plan to raise funds for “the purchase of a 4½-storey building at 21 Jalan Selangor, 46000 Petaling Jaya, Selangor”.

This paper was presented to the Council at its Extraordinary Council Meeting held on 20 June 2007. It was later revised and re昀椀ned for presentation to the Council at its 358th Meeting held 16 July. It gave an overview of the 昀椀nancial status of the IEM and a 昀椀nancial plan for the purchase. The Council considered the paper and gave its approval.

The Fund Raising Committee comprised:

• Dato’ Ir. Abu Hashim Abdul Ghani (Chairman)

• Datuk Paduka Ir. Hj. Keizrul bin Abdullah

• Dato’ Ir. Prof. Chuah Hean Teik

• Ir. Choo Kok Beng

• Dato’ Ir. Ahmad Zaidee bin Laidin

• Dato’ Ir. Prof. Dr Ow Chee Sheng

• Dato’ Ir. Hj. Abdul Rashid Maidin

• Dato’ Dr Ir. Judin Abdul bin Karim

• Ir. Rocky H.T. Wong

• Ir. Ng Yong Kong

The paper presented the fund raising strategy:

a) Internal – from members

b) External – from Private Organizations

Internal: Sources of revenue for 昀椀ve years from members through cess, 昀椀xed donations, members’repayableloan,rentalsandactivities – estimated to be total RM10.79 million.

External: Donations from private organisations targeted at RM3.0 million. The Excomm had approached a couple of banks for favourable bank loans of RM12.15 million.

Appeal letters were sent to IEM members and well-wishers through the IEM Bulletin and circular letters in July.

The Fund Raising Committee was able to raise RM140,000.00 by the end of 2007. By the end of 2014, this 昀椀gure had reached RM3,256,516.20. Details of major donations and the list of donors are displayed at the entrance to Wisma IEM.

It is important to note that a sum of RM77,000 for the lawyer’s fee (Messrs Chye, Chow Chung & Co. Advocates & Solicitors) was donated by Madam Low Bin Hwa (wife of Ir. Oon Chee Kheng). The IEM only paid “out of pocket” expenses. A special “thank you” goes to Madam Low and Ir. Oon.

The Building Fund is still open. Members are encouraged to come forward and contribute to help reduce the bank loan for Wisma IEM.

A few commercial banks were approached for the bank loan and, after considering the various offers, the Council decided to get the loan from Alliance Bank Berhad, 53 & 55 Jalan SS2/55, 47300 Petaling Jaya, Selangor.

The main details of the bank loan, amounting to RM12.15 million, were made known to members in the Annual Report of the Institutionpresentedatthe49thAnnualGeneral Meeting held on 19 April 2008. Here is an extract from the Annual Report: “IEM Council decided to acquire the building across the road from the current Bangunan Ingenieur in April 2007 at a price of RM13.5 million. From its reserves, IEM was able to put up the 昀椀rst 10% of the purchase price. The balance was settled via a loan from Alliance Bank (M) Berhad. The term loan was obtained for a 15-year period with a monthly repayment sum of RM91,402.00 for the 昀椀rst year, RM103,399.00 for the second year and thereafter, RM107,826.00 until the 15th year”. (For more details please refer to the minutes of the 359th Council Meeting held on 22 October 2007).

To secure the loan, IEM had to mortgage Wisma IEM to the bank. Under our Constitution (Ref: Article 603 and Article 9.4), the consent of members was required, so an exercise was carried out to this effect.

Notices of the proposed mortgage and voting papers were sent out to members on 27 August 2007, with the closing date set for 14 September 2007. The result of the voting was 1,236 votes in favour (91.3%). With this approval from the members, the loan agreement with the Alliance Bank Berhad was concluded and

signed on 13 November 2007. The signatories on behalf of IEM were:

• Datuk Paduka Ir. Prof. (Dr) Hj. Keizrul bin Abdullah, President IEM

• Dato’ Ir. Prof. Dr Chuah Hean Teik, Deputy President, IEM

• Ir. Oon Chee Kheng, Hon. Secretary, IEM

The outstanding bank loan at the end of 2014 stands at RM4,316,997.60.

Once IEM took possession of the building in November 2007, a general check was made to identify what had to be done to spruce up the building and to make necessary improvements.

The works were carried from February to August 2009 at a total cost of RM235,618.00, mainly for labour and installations. Some well-wishers donated the following items:

a) Materials for reroo昀椀ng

- Bluescope Lysaght Sdn. Bhd.

b) Light Fitting for Lecture Rooms

- Acumen Marketing Sdn. Bhd.

- Chan Peng Light Fittings Sdn. Bhd.

- Media Network Lighting Service Sdn. Bhd.

c) P.A. System, Auditorium

- Digistar Holdings Sdn. Bhd.

d) Air Conditioners

– Technitus Engineering Sdn. Bhd.

– Enhance System Engineering Sdn. Bhd.

– Smartech Sales & Services Sdn. Bhd.

– UAT Aircondition Sdn. Bhd.

In June 2009, the Excomm decided to install a lift to provide easier access to the upper 昀氀oors, a feature most welcomed by the senior members. After two tender exercises, the contract was awarded to Messrs. Ryoden (M) Sdn. Bhd.

The lift, costing RM138,000.00 for design and installation, was supervised gratis by Ir. Teh Piaw Ngi of Messrs Jurutera Perunding PN Teh. Our special thanks to Ir. Teh.

The name for the building was considered at the 419th Excomm Meeting held on 8 September 2008 and the 364th Council Meeting held on 20 October 2008. A few names were proposed including Istana IEM, Wisma IEM, Menara IEM, Engineers Square and Bangunan IEM. After some discussions, the Council decided on Wisma IEM. (See item 4.6 of IEM Annual Report to the 50th AGM held on 18 April 2009).

The50thAnnualGeneralMeetingoftheInstitutionwasheldatWismaIEMfor the 昀椀rst time on 18 April 2009, attended by 361 members.

TThe auditorium was donated by the Geotechnical Engineering Division with a generous contribution of RM200,000.00 towards the Building Fund. It was of昀椀cially declared open on 7 November 2009 and named Tan Sri Prof. Chin Fung Kee Auditorium, in honour of our illustrious member and a founding member of IEM.

by Hisham Razuli bin Halim

Hisham Razuli bin Halim is currently working as a Staff Engineer in the Vehicle Development & Engineering Division with PROTON Holdings Berhad. He graduated with Bachelor of Engineering Mechanical (System) from Universiti Putra Malaysia (UPM).

by

Nurul Hazirah binti Abdul Aziz is graduated with Bachelor’s Degree (Hons) in Mechanical Engineering from Universiti Teknologi PETRONAS. Formerly she was an engineer in Body and Engineering Design, Vehicle Development and Engineering Section at PROTON Holdings Berhad.

PROTON's 昀椀rst global car project, the P3-21A is required to meet the Euro NCAP 5 stars requirements and maintain the Body In White (BIW) light weight target of under 300kg. Current models use the Ultra High Strength Steel (UHSS) to meet the targeted safety requirements. However there are limitations of stamping UHSS which involves part accuracy problems.

Alternatively, the thickness of High Strength Steel (HSS) can be increased, but it would also add unnecessary BIW weight. Our objective here is to discuss the process of Hot Press Forming (HPF) and its impact on meeting the Euro NCAP 5 stars requirements in terms of weldability and crash worthiness as well as maintaining BIW weight target of individual parts. The implementation of HPF is based on the study of the HPF process and lab tests such as weldability and crash tests. The results of these tests prove that the P3-21A model can meet the Euro NCAP 5 stars requirements and the BIW weighs less than the target (298.8kg) with the adoption of HPF process. Further study should be conducted on the full utilisation of HPF process for all BIW parts without jeopardising the Built of Material (BOM) cost.

Key words: Euro NCAP, Body in White, Hot Press Forming, light weight.

The P3-21A model is Proton's 昀椀rst global car project which aims to be marketable in Europe, Middle East & Australia. In order to do so, the P3-21A model must meet the regulations of these regions, including ful昀椀lling the Euro NCAP 5 stars requirements. As an additional challenge, the model should also maintain its BIW light weight target of < 300kg. The light weight target is mainly to check off high fuel consumption of the car caused by excessive body weight.

The conventional stamping process uses the HSS or UHSS sheet metal and produces parts which may meet the required Tensile Strength but does not guarantee > 90% part accuracy. The main problem often encountered in stamping is spring back, caused mainly by high thickness or high Tensile Strength of the produced part.

Thus, HPF process is introduced to P3-21A project to increase the Tensile Strength of Manganese-Boron steelmaterial(e.g.Usibor1500P)upto1500MPaandstill meet the required part accuracy percentage as well as maintain the light weight target. The HPF process is done by heating the sheet metal in the furnace, performing the part drawing and quenching it at the same time by using a hydraulic press machine.[1] The advantages of adopting the HPF process in BIW parts are as follows:

1. Very high formability with very low built-in strain, good energy absorption qualities and low tooling force required (4001200MPa)

2. Increase opportunities of complex designs

3. High Tensile Strength (up to 1500MPa)

4. Good repeatability without spring back

5. Good weldability - mild steel with low carbon

6. Well suited with crash requirements – good energy absorption with Ultra High Strength (UHS) mechanical properties

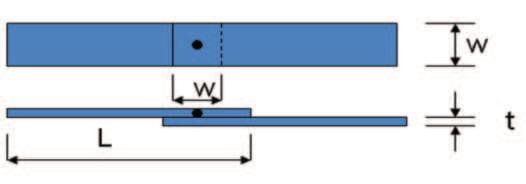

Figure 1 shows 12 BIW parts of P3-21A which adopts HPF process.

6

7Front

8

a.

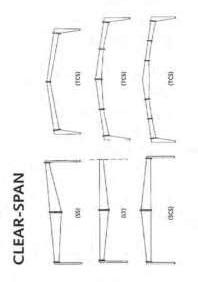

The process of HPF begins with heating the sheet metal (i.e. Usibor1500P; Tensile Strength 600 MPa) in the furnace at a temperature range of 9000C to 950 0C for 5 minutes. The heated sheet metal (Tensile Strength ≤100 MPa) is pressed (single stage) and quenched at the same time for at least 30 0C/s. Descaling is only needed for non-coated steel sheet, which is done right after the pressing and quenching process. There are two types of HPF process, which is the direct process and indirect process. The indirect process adds a pressing die before the heating process to form the complex pro昀椀le of the part. The part is pressed again after the heating process to produce a perfect pro昀椀le part. Figure 2(a) and 2(b) shows the direct and indirect HPF process layout.

The cold press forming produces large strain and rough shape to the part, whereas the hot press forming in the later stage of the process produces small strain part with accurate shape. The HPF product cools down quickly thus retain the shape accuracy of the part.

The formed product has an increased Tensile Strength of ±1500 MPa with Martensite structure. Figure 3 and Figure 4 shows the before and after quenching microstructure of the metal. Al-Si coated product can also be used as corrosion resistance to the sheet metal.[2]

A sample data was taken from Nippon Steel Corporation (NSC) showing the Tensile Strength of the sample material (NHPB-1500) after quenching. Two sample pieces were tested and the results are shown in Figure 5(a) and Figure 5(b).

Sample 1 gives a maximum Tensile Strength of 1590 MPa and Sample 2 gives a maximum Tensile Strength of 1651 MPa. The Chemical Composition and Mechanical Properties of the sample material (NHPB-1500) can be seen in Table 1 and Table 2. Legend:

There are three main factors taken into account and study before the HPF process is implemented and utilised in the P3-21A project. The HPF steel must meet the production workability (i.e. steel weldability), meet the crash effectiveness (in requirement of EuroNCAP 5 stars) and, most importantly, maintain the BIW light weight target of < 300 kg.

Weldibility is de昀椀ned by the American Welding Society as “the capacity of a metal to be welded under the fabrication conditions imposed into a speci昀椀c suitability designed structure and to perform satisfactorily in service”. One of the factors affecting the quality of steel welding is the carbon content. Carbon is a strengthening element in iron, which increases the metal Tensile Strength but reduces the ductility. High carbon content promotes the formation of hard, brittle microstructures upon cooling. For HPF process, high carbon content is not necessary since the process itself is suf昀椀cient to increase the Tensile Strength of the steel. The chemical composition of the boron alloy steel used for HPF (refer Figure 6) shows low carbon content makes it favourable for welding.

Crashworthiness is de昀椀ned as the ability of a structure to protect its occupants during an impact and this is rated through various vehicle assessments such as the Euro-NCAP. As the P3-21A project aims to achieve the Euro-NCAP 5 stars rating in terms of safety, vehicle crashworthiness status is a high priority. The implementation of HPF process is believed to be the ultimate option to pass the EuroNCAP 5 stars rating requirement, considering the guarantee of high Tensile Strength of the product material. With the implementation of HPF process to the selected parts (refer Figure 1), the P3-21A model is believed to sustain high impact crash.

The change in the metal microstructure of the HPF steel (i.e. boron alloyed steel) is affected by the heat transformation throughout the HPF process. Refer to Figure 6 for the heat transformation chart. The initial material structure of the HPF steel is Ferrite + Pearlite. The heating effect of the steel changes the material structure into Austenite which makes it easy to form in the pressing die. Then the quenching process cools the steel and hardens it. The hardening process changes the material structure to Martensite with maximum Tensile Strength of ≥1500 MPa

ThemotoringindustryhasadoptedGreenTechnologyandismoving towards the mass reduction of CO2 gas emission. Therefore, the fuel consumption of a unit vehicle should be minimised by 昀椀rst eliminating unnecessary weight on the car body at the development stage. In previous projects, the stiffness of the frontal and side impact areas is increased by adding patches of steel metal or by increasing the thickness of the steel metal.

However such conventional methods add unnecessary weight to the car body. The metal patches and extra thickness are now

replaced by adopting the HPF process, where similar stiffness of the frontal and side impact areas is achievable with a single piece metal.

ThemainevaluationsofHPFpartsforP3-21Aprojectareimplemented through several in-house and outsourced testings as the following:

a) Weldability Test

The weldability test was conducted by the Proton Homologation and Testing Department to analyse spot welding condition of HPF parts combination. The facilities used for this activity are the Medium Frequency Direct Current (MFDC) with adaptive control welding gun and the Universal Instron Tensile Strength machine. Figure 7 shows the layout of the test specimen[4]

The width and length of the test pieces vary with thickness. Table 3 shows the width and length of the test pieces according to the speci昀椀ed metal thickness to be tested.

The load application direction is indicated in Figure 8.

Test speed: 200 mm/min.

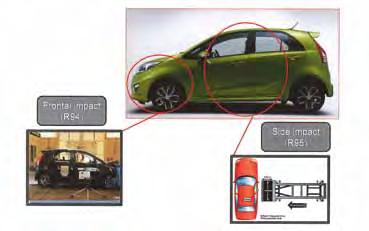

b) Frontal crash & side impact test

The F-Proto Crash Program was conducted in Idiada, Spain on the 21 February to 9 March 2011. The main objective was to assess whether the body structure of P3-21A met the Euro-NCAP 5 stars requirements. The test set-ups are shown in Table 5.

Table 5: Frontal crash & side impact test set-ups

Frontal Crash (64 kph)

Side Impact

Mobile Deformable Barrier , MDB (50 kph)

There were 6 samples tested for weldability using the Tensile Strength Machine, with speci昀椀ed welding pressure variables (320 kgf, 400 kgf, 450 kgf, 500 kgf). The test was basically done for 2 and 3 metal pieces with different thicknesses. Refer Table 4 for the sample pieces combinations.

Side Impact Pole (29 kph)

The main parts measure for the Frontal Crash offset is shown in Figure 9.

A study was conducted in the early stage where 4 types of materials were benchmarked for use to meet the requirements of EuroNCAP 5 stars. The BIW weight and kerb weight were measured by conceptually designing the BIW with the selection of materials in requirements of the Euro-NCAP 5 stars requirement. The 昀椀xed BIW weight target for P3-21A is under 300 kg.

a) Weldability

The minimum target Tensile Shear Strength is 23 kN and the minimum target for the welding nugget diameter is 6.3 mm. Table 6 shows the test results based on the minimum targets of the TSS and Nugget Diameter respectively.

From the frontal impact test, the passenger cabin structure shows good integrity. The dummy injuries status is 11.5 (severity rating scale), less than the targeted value (13). The displacement in the crossmember (HPF part) is caused mainly by the assembly connection. The results of the side impact tests (MDB and Pole) are shown in Table 8(a) and Table 8(a) respectively.

b)

The intrusion results of the Frontal Crash Test is shown in Table 7.

The results of the side impact tests show that the passenger cabin structureisinverygoodcondition.TheB-pillar(HPFpart)showsminimal displacement during the crash test, compared to previous model test. Figure 10 shows the difference of side impact results between P3-21A (HPF B-pillar) and Exora (without HPF B-pillar).

The result of the BIW weight assessment based on selected materials is shown in Table 9.

[6]

The results clearly show the HPF is the best process to be implemented in the P3-21A project to meet the Euro-NCAP 5 stars requirements. This is because the HPF material gives the highest possible Tensile Strength, with maximum of 10kg additional weight (for optimum BIW stiffness case) and the minimum kerb weight of 1326kg.

The implementation of HPF technology in P3-21A model has been proven to improve the body structure stiffness towards meeting the requirements of Euro-NCAP 5 stars. This is shown by various test results conducted on the P3-21A CBU throughout the project development phase. The BIW weight target is also met with the actual 昀椀gure of 298.8kg (BIW & sealant) for P0-1 phase.

a) Weldability

The weldability test results show that it is possible to weld HPF parts in the normal production conditions, with up to 3 layers of welding. Table 10 shows the recommended welding pressure for the HPF parts at the assembly line.

A1.5 x 1.75320, 400

B1.75 x 1.75320, 400

C1.5 x 2.0320, 400

D1.6 x 2.0 x 1.5320, 400

E0.7 x 1.75 x 1.75500

F1.6 x 1.6320, 400

b) Crashworthiness

The stiffness of the HPF part is proven by the retained shape of the cross-member after the crash. This is clearly shown in Figure 11.

The results of the side impact tests highly recommend the optimisation of the B-pillar as a major part of the restrain system. Hence, the adoption of high-end restrain system such as side air-bag can be minimised.

c) BIW Light Weight Target

During the P0-1 phase, the BIW weight is measured in different 昀椀nish conditions(additionalweightvariables)andtheresults(referTable11) prove that the light weight target is achievable.

ACKNOWLEDGEMENTS

The authors wish to acknowledge the contribution and assistance from the following persons:

1. QETS Coordinator – En. Meor Mohd. Rizal bin Ismail

2. Internal Panels – Dr Mohd. Azman bin Zainal Abidin, En. Fauzy bin Ahmad and En. Fuad bin Alias

3. External Panels – Dr Hairi (UTM), Dr Mohd. Fadlee (NEST), Dr Rahizar (UM), Dr Shuhaimi (UTM), and Dr Salmiah (UTM)

4. Head of Dept, Body Design - En. Azri昀椀n Bin Amin, Head of Dept, Body Design.

[1] Kamarul Effendy B. Khalid, “Feasibility Study of Hot Press Forming Hot Press Forming (HPF) line,” Perusahaan Otomobil Nasional Sdn. Bhd., 2011.

[2] Thomas Vietoris, “Hot stamping with USIBOR1500P®,” ArcelorMittar, 2011.

[3] Nippon Steel Corporation, “Hot Stamping Material,” Japan, 2009.

[4] Homologation & Testing Dept, “P321A HPF Round 3 TSS & Macro Analysis,” Perusahaan Otomobil Nasional Sdn. Bhd, 2011.

[5] Ekman Zashua Zahari, “P3-21A F-Proto Crash Program,”. Perusahaan Otomobil Nasional Sdn. Bhd, 2011.

[6] Hisham Razuli & Ahmad Faridz, “Decision Matrix for Structural Direction for P321A Towards NCAP,” Perusahaan Otomobil Nasional Sdn. Bhd, 2010.

[7] Fan Dongwei, “Literature Review of Hot Press Forming,” Pohang University of Science and Technology (POSTECH), Korea, 2008.

Stresscon piles are high strength prestressed concrete square section piles specially designed for low to medium rise buildings and light civil engineering structures namely factories, low-rise apartments, terrace houses and shop houses.

Plenty of Stocks

High production rate

Experienced with more than 1000 projects in all kinds of soil conditions

Technical transfer from renowned prestressed concrete pile manufacturer – Hi-Stress Concrete Ltd.,New Zealand.

STRESSCON PILING (M) SDN BHD (114405-H) 25-2, Block C, Jalan 2/109F, Taman Danau Desa, 58100 Kuala Lumpur,Malaysia. Tel: 603-7981 0061 Fax: 603-7981 8433

Contact: stresscongroup@yahoo.com www.stresscon.com.my

by Ir. Lai Sze Ching

Ir. Lai Sze Ching is currently a Council member and an EXCOMM member in IEM.

He is the Vice-Chairman of Standing Committee of Examination and Quali昀椀cation, Secretary of the Standing Committee of Professional Practice, Chairman of the subcommittee on Amendment of IEM Constitution and the Chairman for the subcommittee of Legislations Affecting Engineering Profession. Ir Lai is also a committee member of the Amendment of Registration of Engineers Act under the Board of Engineers Malaysia.

Many engineers have been informed of the amendment to the Registration of Engineers Act 1967 and that a new examination known as Professional CompetencyExamwillbeintroduced.

So what is the Professional Competency Exam and how will it affect engineers?

Under The Street, Drainage and Building Act 1974, only Professional Architects or Professional Engineersarequali昀椀edtobea“submittingperson”, i.e. the person with the authority to submit plans other than building plans, to the local authority or other relevant statutory authority in accordance with the Act or any by-laws made thereunder.

Between 2009 and 2011, over 200 complaints were made to the Board of Engineers Malaysia (BEM) by members of the public, government bodies, house buyers and even engineers. Among the main complaints were the failure of engineering works in Bukit Antarabangsa (KL) Hill Slope collapse, Jaya supermarket (Petaling Jaya) structure collapse, Gong Badak (Kuala Terengganu) Stadium roof collapse etc. All these prompted the public to voice their grave concerns over the competency of the engineers who had carried out the design and construction of the said structures.

In view of the many engineering failures and the liberalisation of engineering services, the RegistrationofEngineersAct(The“Act”)underwent major amendments and the Amendment Bill was 昀椀nally passed by Parliament in December 2014 and gazetted on 24 February 2015.

One of the proposed amendments is the introduction of Professional Competency Examination (PCE), aimed at complementing the current Professional Assessment Examination (PAE). This is vital for the following purposes:

• Upholding the standard of engineering professionalism

• Maintaining a minimum standard of pro昀椀ciency and competency in the building industry

• Safeguarding measures to protect public’s interest against sub-standard engineering services provided by local engineers and/ or foreign engineers (whose registration has been made possible under the liberalisation of engineering services).

This is why one of the major amendments under The Act is to introduce a two-tier system for the registration of Professional Engineers. Under this system, one class of Professional Engineers will comprise those who have passed the existing PAE or who are Corporate Members of the Institution of Engineers Malaysia (IEM). The other class will be professional engineers who possess valid Practicing Certi昀椀cates.

Pursuant to the amendment, it is incumbent for a Professional Engineer who wishes to be a submitting person to obtain a valid Practicing Certi昀椀cate by passing the PCE. Accordingly, the submitting person has to be a Professional Engineer with a valid Practicing Certi昀椀cate.

The main aim of the Professional Competency Examination is to test the competency of candidates within the limits of “professional engineering services” as de昀椀ned by the Registration of Engineers Act 1967, in the engineering disciplines of civil & structural, mechanical and electrical engineering.

The PCE will be structured to test the candidate’s knowledge, experience and application of:

• Regulations and rules of engineering practice by BEM

• Statutory laws, design codes, regulations and

• Standards of professionalism and ethical behaviour imposed by BEM With the introduction of this two-tier system, it is hoped that the quality of engineering services will show marked improvement in view of better knowledge and higher quality to be expected from an engineer.

As for current Professional Engineers registered with BEM, the amending Act stipulates that they may apply to BEM for the Practicing Certi昀椀cate within one year from the date of The Act coming into force. If they do not do so within the stipulated period, they will be required to sit for the PCE and pass in order to obtain the Practicing Certi昀椀cate.

is a consulting engineer with Automotive Department, Road Transport Department Malaysia. He possesses a PhD from Eindhoven University of Technology, the Netherlands. His 昀椀elds of expertise include commercial vehicle technical design, UNECE Regulations, vehicle type approval and industrial design engineering. Currently, he is Hon. Secretary of Mechanical Engineering Technical Division as well as Council Member and Executive Committee Member of IEM.

bin

is mechanical engineer with the Automotive Department, RTD Malaysia. He has a Bachelor's in Mechanical Engineering from Universiti Teknikal Malaysia Melaka (UTeM). His 昀椀elds of expertise are vehicle technical design, including commercial vehicle and public service vehicle, UNECE Regulations and vehicle design engineering.

lecturer at the Department of Languages, Centre for Languages and Human Development, Universiti Teknikal Malaysia Melaka.

Buses are a very important mode of transportation. They can be used for short and long distance ground travel. They are very competitive price-wise when compared with air travel and trains. Air travel may offer greater comfort and a shorter travel time but passengers are required to spend time at the airport for checking in, luggage check-in, security check, Immigration check and Customs inspection etc. For long distances, travel by train may take a longer time than air travel but trains are less noisy than planes and buses.

In Malaysia, buses are important for economic reasons because they are affordable and can go to places which may not be serviced by other modes of transport. There are different types of buses as de昀椀ned by Ministry of Transport (MOT) Malaysia:Stagebus,expressbus,minibus,industrial workers bus, feeder bus, chartered bus and school bus (Table 1). About 500 buses are registered with MOT every three months. As at 31 December 2013, there were 62,672 buses on the road (MOT, 2014).

In the recent years, the number of accidents involving buses is increasing at an alarming rate. Table 2 shows bus accidents that involve fatalities. On 13 August 2007, 22 people died in a bus accident at Bukit Gantang, Perak.

One factor that contributed to the deaths was that the roof of the bus did not comply with the United Nations Economic Commission for Europe (UNECE) Regulation No. 66. In the accident, the entire roof was separated from the body of the bus, and the pillars were fractured (MIROS, 2009). The rollover was one of the worst bus accidents in the country and it claimed many lives (Lin & Nian, 2006).

After the Bukit Gantang accident (Photo 1), the bus construction law based on UNECE R66, was adopted into the Malaysia Road Transport Rule and now, every bus or coach builder has to abide by the UNECE R66 requirements. The Road Transport Department is the agency that enforces the new regulations.

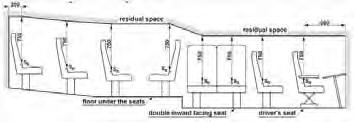

The UNECE R66 applies to single-deck rigid or articulated vehicles designed and constructed to carry more than 22 passengers, whether seated or standing, in addition to the driver and crew.

Theregulationsensurethatthesuperstructureof the vehicle is strong enough to protect the residual space during and after the rollover of the vehicle.

The superstructure of the bus contributes to its strength. The residual space is where passengers, driver and crews are located. Parts such as pillars, safety rings and luggage racks should not intrude into the residual space during a rollover. In addition, no parts from the residual space should

1.

KM 229.1 PLUS Expressway Bukit Gantang 13 August 2007 22

2. Jelapang North South Expressway Toll Plaza 11 December 2007 8

3. KM 146.5 PLUS Expressway - Tangkak 7 December 2008 10

4.

5.

KM 272.8 PLUS Expressway 26 December 2009 10

KM 223 PLUS Expressway - Simpang Ampat 10 October 2010 15

6. KM 15 Jalan Cameron Highlands –Simpang Pulai 20 December 2010 27

7.

8.

KM 3.5 Jalan Genting Highlands 21 August 2013 37

KM 11 Jalan KuantanKuala Lumpur 12 April 2014 3

project outside during rollover. The speci昀椀ed residual space as per UNECE R66 (UNECE, 2006) is shown in Photo 2.

The four types of tests as de昀椀ned by UNECE R66 (UNECE, 2006) are:

1. Rollover test on a complete vehicle as the basic approval method

2. Rollover test on body sections which are representative of the complete vehicle

3. Quasi-static loading tests of body sections

4. Computer simulation with dynamic calculations of the basic rollover test on a complete vehicle

a) Lateral arrangement

b) Longitudinal arrangement

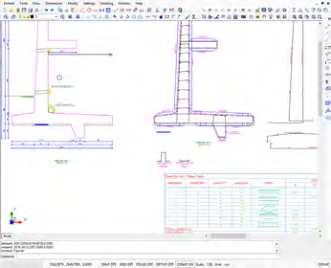

Malaysia coach builders are not in favour of items 1 to 3 because these are expensive and time consuming. They prefer computer simulation instead.

Based on UNECE R66, the rollover test on a complete vehicle is a lateral tilting test. As shown in Photo 3, the bus is put on the tilting platform with blocked suspension. During the test, the platform will be tilted at a constant speed until the bus is in an unstable equilibrium position. The rollover test starts here with zero angular velocity and the axis of rotation runs through the wheel-ground contact points. The bus falls to the ground from an 800mm high platform.

A bus rollover is a serious matter. There have been many deaths caused by rollovers. Becauseofthis,theMalaysiangovernment,throughtheRoadTransportDepartment, has enforced the UNECE R66 regulation to protect bus passengers or reduce the number of casualties from accidents caused by rollovers. Different parties such as government agencies, coach builders and consultants need to work together to ensure the implementation of UNECE R66.

[1] A.H. Arif昀椀n, M.K. Rahman, M.S. Solah, K.A.A. Kassim and S.V. Wong, 2012, Stability of highdeck buses in a rollover and contact-impact with traf昀椀c barriers, MRR 01/2012, Kuala Lumpur, Malaysia Institute of Road Safety Research.

[2] Guler, M.A., Atahan, A.O. and Bayram, B., 2009, Effectiveness of seat belt usage on the rollover crashworthiness of an intercity coach, In Proceedings of the International Technical Conference on the Enhanced Safety of Vehicles (ESV), paper no. 09-0205.

[3] Lin, Y. And Nian, H., 2006, Structural design optimisation of the body section using the 昀椀nite element method, SAE 2006 World Congress & Exhibition, Paper no. 2006-01-0954.

[4] Ministry of Transport Malaysia (MOT), 2014, http://www.mot.gov.my/.

[5] United Nations, 2006, Regulation No. 66: Uniform Technical Prescriptions Concerning The Approval of Large Passenger Vehicles with Regard to the Strength of Their Superstructure.

Title: Talk on Turbo Machinery Remote Monitoring and Diagnostic –Oil and Gas Application

11 Apr 2015

Organised by : Oil, Gas and Mining Engineering Technical Division

Time : 9.00 a.m. – 11.00 a.m.

CPD/PDP : 2

Title: 100 Common Problems of Construction Contracts

13 – 14 April 2015

Organised by : Project Management Technical Division

Time : 9.00 a.m. – 5.00 p.m.

CPD/PDP : 14

Title: Talk on “TV White Space for Rural Wireless Broadband in Malaysia”

16 April 2015

Organised by : Engineering Education Technical Division

Time : 5.30 p.m. – 7.30 p.m.

CPD/PDP : 2

Title: Recognized Good Practices of Project Management

21 – 22 April 2015

Organised by : Project Management Technical Division

Time : 9.00 a.m. – 1.30 p.m.

CPD/PDP : 14.5

Title: Talk on “Finite Element (FE) Modelling of Offshore Structures

25 April 2015

Organised by : Oil, Gas and Mining Engineering Technical Division

Time : 9.00 a.m. – 11.00 p.m.

CPD/PDP : 2

Kindly note that the scheduled events below are subject to change. Please visit the IEM website at www.myiem.org.my for more information on the upcoming events.

We are a professional supplier of geosynthetic products used for separation, reinforcement of ground soil, and for retaining ground stabilization in civil engineering projects on soft ground; such as coastal areas, rivers and wetlands. Our Products: NEXTILE NON-WOVENS

NEXFORCE HIGH-STRENGTH WOVENS

NEXGRID GEOGRIDS

We also provide design, specification, bill of quantities, cost estimte and drawings free-of-charge.

reported by Ir. Hooi Wing Chuen

Ir. Hooi Wing Chuen obtained his Bachelors Degree in Civil Engineering from the University of Canterbury, Christchurch, New Zealand. He has over 25 years of experience in the Cement, Concrete and Construction industries in New Zealand, Hong Kong, Macau, Zhuhai (PRC) and Malaysia. His expertise includes design, engineering, manufacture & construction of precast concrete structures and pavements.

Technical Division (CSETD) organised a technical talk on “Fundamentals of Blast and Impact Loading of Structures” on 19 July 2014. The talk which was organised as a precursor to the 28th AGM of the CSETD, was held at the Tan Sri Prof. Chin Fung Kee Auditorium at Wisma IEM, Petaling Jaya.

We are a civil structural engineering consultant with a vacancy for a civil engineer in Seremban

The 136 participants included engineers from engineering consultants, contracting 昀椀rms, government agencies and local authorities, as well as faculty members from local institutions of higher learning. The speaker, Engr. Dr Sudharshan N. Raman, is a senior lecturer at the Faculty of Engineering and Built Environment, Universiti Kebangsaan Malaysia (UKM) and a Committee Member of the CSETD. He is also a Committee Member of the American Concrete Institute Kuala Lumpur Chapter (ACI-KL).

Minimum Requirements:-

- A civil engineering degree - With minimum 5 yearsworking experience

Interested applicant please call Ms. Cindy at 06-763 8042 or send/fax/email application and resume to:

The Advertiser

153-1 Jalan Toman 7, Kemayan Square, 70200 Seremban, N.S.D.K.

Email: ktpjjp@yahoo.com Fax: 06-763 7655

Dr Raman commenced his talk by discussing the need to include protective design and features in the construction of critical infrastructure and shared several examples of explosions that occurred around the globe in the past two decades.

He then described what is de昀椀ned as blast load and explained the main distinctions of blast load in comparison to other common types of quasi-static and dynamic loadings that structures are subjected to. Dr Raman also explained the fundamentals of protective design and presented some examples of technical

manuals or “codes” available for the analysis and design of protective structures.

The subsequent part of the talk covered categorising of explosions as being physical, nuclear or chemical explosions and the classi昀椀cation of explosivematerialsbasedontheirphysicalstateorontheirsensitivitytoignition. He then went on to the detailed examination of the parameters governing the characteristics of an explosion such as TNT equivalence ratio, blast wave scaling laws and the characteristics of blast pressure-time history pro昀椀les. In addition to these, he discussed examples of how blast parameters can be quanti昀椀ed for selected blast scenarios using the charts provided in UFC-3-34002 (2008) code.

He also talked about the fundamentals of impact loadings by referring to their classi昀椀cation, causes, impact velocity, the resulting stresses, response mechanism and damage modes. The available techniques to evaluate and analyse impact mechanism in a laboratory environment were also shared, with references made to several case examples that he had worked on.

Then Dr Raman talked about the various computational codes and programmes available to model and simulate blasts and impact events. In principle, he said, the available computer codes can be utilised for two main functions of analysis, i.e. for predicting the effects of the impulsive loads on structures and to analyse structural response due to the applied loads. He demonstrated how these computer codes can be applied in the analysis of structures being subjected to impulsive loadings by using real case studies that he had worked on. Some of these examples demonstrated how the analysis 昀椀ndings were incorporated into the design to improve the protective features of structures.

Dr Raman drew the participants’ attention to several books and literature available for enhancing their knowledge and understanding in the 昀椀eld of protective analysis and design. A question and answer session followed, during which many participants raised queries in a lively discussion with the speaker.

At the end of the event, the Session Chair, Ir. W.C. Hooi thanked the speaker and invited the incumbent Chairman of the CSETD, Ir. S.W. Ong to present a token of appreciation to Engr. Dr Sudharshan N. Raman.

Title: Day Course on “Finite Element Analysis For Engineers”

25 April 2015

Organised by : Mechanical Engineering Technical Division

Time : 9.00 a.m. – 5.00 p.m.

CPD/PDP : 6.5

Title: ENETD : Talk on Conversion of Organic Wastes and Unused Biomass to Valuable Materials and Energy Using Sub-Critical Water

25 April 2015

Organised by : Oil, Gas and Mining Engineering Technical Division

Time : 5.30 a.m. – 7.30 p.m.

CPD/PDP : 2

Kindly note that the scheduled events below are subject to change. Please visit the IEM website at www.myiem.org.my for more information on the upcoming events.

reported by Ir. Hj. Look Keman bin Sahari

Ir. Hj. Look Keman bin Sahari is a mining engineer with M.Sc in Explosives Ordnance Engineering from Royal Military College of Science, Cran昀椀eld University. He retired from the Mines Department in 1996 and had been working as Consultant/Blasting Engineer specialising in Explosives, Mining and Quarrying ever since. He is a committee member of TUSTD. He had given lectures at IEM on construction blasting and Drill & Blast for tunnelling work.

The talk was conducted on 6 December 2014 by Ir. Hj. Look Keman a committee member of IEM TUSD and Engr. Mohammad Razif bin Kemat from Tenaga Kimia Bhd, the largest supplier of explosives and accessories and the sole manufacturer of emulsion explosives in the country.

Ir. Hj. Look Keman said tunnelling work dated back to the time of the Roman Empire. The Romans dug tunnels to transport water to Romeand sewage out of the city.

When gun powder was discovered more than 200 years ago, it was used in the drilling and blasting of tunnels in mines. This was a common method for obtaining minerals underground. The deepest mine in the world is about 4,000 metres underground and powerful explosives are needed to break up the ore in the extremely hard rock. The techniques used to break rock in mine tunnels are different from that used in civil engineering work. Mine tunnels are not designed to be permanent and do not need

a comprehensive support system. Generally, tunnels in mines are abandoned once the ores are obtained. In civil engineering work though, it is quite common to design tunnels that can last for 100 years.

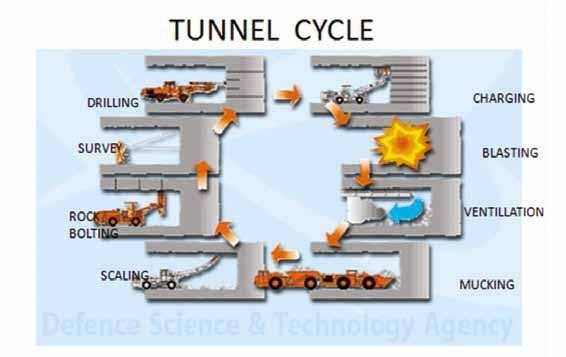

Ir. Hj. Look Keman said the sequence in tunnelling by drill and blast begins with a survey to ensure the tunnel is proceeding in the right direction and that the holes are drilled at the right location, followed by the charging process. The explosives and the accessories are then inserted in the boreholes with a correct pattern and delay system to ensure safety and ef昀椀ciency. The boreholes in the centre are charged by using bulk explosives while at the perimeter, small cartridge explosives are used to minimise overbreak. The explosive charges are then detonated or blasted according to the correct sequence. After blasting, dust from fragmented rock and fumes from explosives are removed through the ventilation system. When this is done, broken rocks are then removed using

excavators and dump trucks. The loose rocks from the tunnel are then scaled out to prevent rock falls which may endanger workers and machineries.

The roof support system, such as rock bolt, is then installed where required, followed 昀椀nally by shotcreeting. The process is repeated in the same cycle.

Next, he talked about the training of shot昀椀rers and blasting engineers.

Currently in Malaysia, there is no speci昀椀c training for those working in drilling and blasting tunnels. All shot昀椀rers actually learn their trade from the quarrying industry and proceed to learn tunnel blasting on the job. There is no speci昀椀c course available on drilling and blasting for tunnelling, even though arrangements can be made to conduct such courses with the local explosives manufacturer and local institution of higher learning.

The next speaker, Engr. Mohammad Razif, talked about explosives and accessories available from his company and currently available for the quarrying, mining and construction industry. Emulsion explosives used in tunnelling are available in various formulations to suit different applications.

When additional energy is needed in tunnelling to overcome heavy con昀椀nement, aluminium powder is added. In tunnelling application, about 8% aluminium is added. Shock tube initiation system is normally used to provide in-hole delays and the surface delays while the detonating cord and the electric detonator will initiate the whole system. The shot昀椀rer will 昀椀re the charges from the safe distance. The tunnel perimeter holes are charged with small cartridge emulsion explosive while remainder with exception with a few uncharged boreholes at the centre were charged with bulk explosives.

Short videos on charging and blasting were shown to illustrate blasting work. The participants were then shown samples of explosives dummies and accessories used in tunnelling, mining and construction work. The talk ended with a lively question and answer session. The speakers were asked about the availability of blasting engineers who are needed to supervise blasting work, particularly in highly

sensitive residential and commercial areas as tunnelling below such areas may cause damage to the existing structures. Some participants were interested in the blast design and other advanced subjects related to blasting work in tunnelling.

The speakers will look into conducting more speci昀椀c courses on drilling and blasting for tunnelling in the future with the aim to produce more professional shot昀椀rers and blasting engineers.

The talk ended at 11.00 a.m.

Note: This is continuation of the list of building fund donation list which was 昀椀rst published on page 36 in March Issue 2015.