3,200/page

3,200/page

The publisher reserves the right to edit, revise or reject any advertisement deemed unsuitable or inappropriate. •

This one-time-only special rate o er is for new advertisers.

Space availability is subject to booking on a first-come-first-served basis.

Clients will provide ready-to-print artwork in PDF format with 300dpi.

Full page: 210mm x 297mm, 3mm extra bleed sizes for 4-sided.

Advertising space must be utilised before 31 December 2024.

*Please note that the above rate will be subjected to 8% SST. For overseas advertisers, an additional 25% will be charged.

Rate shown above excludes 15% advertising agency commission.

Payment term: Full advance payment.

Artwork submission deadline is on (or before) the 1st week of the prior month of publication.

After the material deadline, no cancellation or alteration to the advertisement will be entertained.

Any cancellation after signing the advertising order will result in a 50% penalty charge.

Name of Company: Address: Tel:

Publica�on month/s:

Company’s Stamp & Authorised Signature

JURUTERA has an estimated readership of 200,000 professionals. Our esteemed readership consists of certified engineers, decision making corporate leaders, CEOs, government officials, project directors, entrepreneurs, project consultants, engineering consulting firms and companies involved with engineering products and services. Circulation & Readership Profile

(s):

Date

MAJLIS BAGI SESI 2024/2025

(IEM COUNCIL SESSION 2024/2025)

Yang Dipertua / President

Ir. Prof. Dr Jeffrey Chiang Choong Luin

Timbalan Yang Dipertua / Deputy President

Ir. Yau Chau Fong

Naib Yang Dipertua / Vice Presidents

Ir. Dr Siti Hawa binti Hamzah, Ir. Fam Yew Hin, Ir. Chen Harn Shean, Ir. Ts. Prof. Dr David Chuah Joon Huang, Y.Bhg. Dato’ Ir. Wan Nazari bin Wan Jusoh, Ir. Dr Bernard Lim Kee Weng, YBhg. Dato’ Ir. Nor Hisham bin Mohd Ghazalli

Setiausaha Kehormat / Honorary Secretary

Ir. Ts. Prof. Dr Tan Chee Fai

Bendahari Kehormat / Honorary Treasurer

Ir. Dr Siow Chun Lim

Bekas Yang Dipertua Terakhir / Immediate Past President Dato’ Ir. Prof. Dr Norlida binti Buniyamin

Bekas Yang Dipertua / Past Presidents

Y.Bhg. Academician Tan Sri Dato’ Ir. Prof. Dr Chuah Hean Teik, Y.Bhg. Dato’ Paduka Ir. (Dr) Hj. Keizrul bin Abdullah, Y.Bhg. Dato’ Ir. Lim Chow Hock, Ir. Dr Tan Yean Chin, Ir. Ong Ching Loon

Wakil Awam / Civil Representative

Ir. Tu Yong Eng

Wakil Mekanikal / Mechanical Representative Ir. Ng Yong Kong

Wakil Elektrik / Electrical Representative

Ir. Mohd. Aman bin Hj. Idris

Wakil Struktur / Structural Representative

Ir. Dr Tan Kuang Leong

Wakil Kimia / Chemical Representative

Ir. Kim Kek Seong

Wakil Lain-Lain Displin / Representative to Other Disciplines

Ir. Assoc. Prof. Dr Wong Yew Hoong

Wakil Multimedia dan ICT / ICT and Multimedia Representative Ir. Assoc. Prof. Dr Lai Khin Wee

Wakil Jurutera Wanita / Women Engineers Representative Ir. Ts. Assoc. Prof. Dr Syuhaida binti Ismail

Wakil Bahagian Jurutera Siswazah / Young Engineers Section Representatives

Mr. Muhammad Ashiq Marecan bin Hamid Marecan, Grad. IEM, Mr. Lim Yiren, Grad. IEM, Mr. Darshan a/l Balasubramaniam, Grad. IEM, Mr. Chuah Pei Lim, Grad. IEM, Ms. Ong Ye Shian, Grad. IEM Ahli - Ahli Majlis / Council Members Ir. Rusnida binti Talib, Ir. Prof. Dr Lau Hieng Ho, Ir. Muhammad Azmi bin Ayub, Ir. Arul Hisham bin Abdul Rahim, Ir. Razmahwata bin Mohd Razalli, Ir. Simon Yeong Chin Chow, Ir. Dr Chan Seong Phun, Ir. Yam Teong Sian, Ir. Kwok Yew Hoe, Ir. Dr Lee Choo Yong, Ir. Sharifah Azlina binti Raja Kamal Pasmah, Ir. Ts. Dr Wan Syakirah binti Wan Abdullah, Ir. Dr Mui Kai Yin, Ir. Shamil bin Abu Hassan, Ir. Ts. Wan Rizaluddin Abdullah bin Wan Ali, Ir. Dr Lam Wei Haur, Ir. Dr Angelia Liew San Chuin, Ir. Prof. Dr Zuhaina binti Zakaria, Ir. Begum Irdawati binti Dowlad Rahuman, Ir. Chong Chee Yen, Ir. Khoo Chee Min, Ir. Abdul Razak bin Yakob, Ir. Dr Chan Swee Huat, Ir. Alex Looi Tink Huey, Ir. Sukhairul Nizam bin Abdul Razak, Y.Bhg. Dato’ Ir. Ting Chek Choon (casual vacancy for YBhg. Dato’ Ir. Nor Hisham bin Mohd Ghazalli) Ahli - Ahli Majlis Jemputan / Council Members by Invitation

YBhg. Dato’ Ir. Ts. Abdul Razib bin Dawood, Ir. Gopal Narian Kutty, Ir. Oon Chee Kheng

Pengerusi Cawangan / Branch Chairman

1. Pulau Pinang: Ir. Chan Wah Cheong

2. Selatan: Ir. David Puen Ming Shen

3. Perak: Ir. Assoc. Prof. Dr Nursyarizal bin Mohd Nor

4. Pahang: Ir. Ab Rahman bin Hashim

5. Kedah-Perlis: Ir. Roshasmawi bin Abdul Wahab

6. Negeri Sembilan: Ir. Shahrin Amri bin Jahari

7. Kelantan: Ir. Abrizan bin Abdul Kadir

8. Terengganu: Ir. Mazlan bin Che Ku Ahmad

9. Melaka: Ir. Lim Su Hian

10. Sarawak: Ir. Sim Hui Kheng, Stephanie

11. Sabah: Ir. Mohd Yaakob bin Jaafar

12. Miri: Ir. Meheron Selowara Joo

AHLI JAWATANKUASA INFORMASI DAN PENERBITAN / STANDING COMMITTEE ON INFORMATION AND PUBLICATIONS 2024/2025

Pengerusi / Chairman: Ir. Fam Yew Hin

Naib Pengerusi / Vice Chairman: Ir. Alex Looi Tink Huey

Setiausaha / Secretary: Ir. Ts. Assoc. Prof. Dr Hum Yan Chai Ketua Pengarang / Chief Editor: Ir. Fam Yew Hin Pengarang Prinsipal Buletin / Principal Bulletin Editor: Ir. Alex Looi Tink Huey Pengarang Prinsipal Jurnal / Principal Journal Editor: Ir. Ts. Prof. Dr Teo Fang Yenn Pengerusi Laman Web / Chairman Webportal: Ir. Dr Hasril bin Hasini Pengerusi Pusat Sumber / Resource Centre Chairman: Ir. Razmahwata bin Mohd Razalli Ahli-Ahli / Committee Members: Ir. Ong Guan Hock, Ir. Lee Chang Quan, Ir. Lau Tai Onn, Ir. Dr Oh Seong Por, Ir. Yee Thien Seng, Ir. Dr Lee Choo Yong, Ir. Ts. Dr Tan Kim Seah, Ir. Assoc. Prof. Dr Lee Tin Sin, Ir. Tu Yong Eng, Ir. Dr Bhuvendhraa Rudrusamy, Ir. Rusnida binti Talib, Ir. Dr Nor Ilia Anisa binti Aris, Ir. Ts. Wong Chee Fui, Ir. Dr Moey Lip Kean, Ir. Abdul Azim bin Abdul Rahman, Ir. Dr Aidil bin Chee Tahir, Ir. Kwok Yew Hoe, Ir. Begum Irdawati binti Dowlad Rahuman, Ir. Dr Sara Lee Kit Yee, Dr Sudharshan N. Raman, Grad. IEM, Ms. Michelle Lau Chui Chui, Grad. IEM, Mr. Chuah Pei Lim, Grad. IEM

LEMBAGA PENGARANG / EDITORIAL BOARD 2024/2025 Ketua Pengarang / Chief Editor: Ir. Fam Yew Hin Pengarang Prinsipal Buletin / Principal Bulletin Editor: Ir. Alex Looi Tink Huey Ahli-Ahli / Committee Members: Ir. Lau Tai Onn, Ir. Ong Guan Hock, Ir. Yee Thien Seng, Ir. Dr Oh Seong Por, Ir. Ts. Prof. Dr Teo Fang Yenn, Dr Sudharshan N. Raman, Ir. Tu Yong Eng, Ir. Lee Chang Quan, Ir. Dr Lee Choo Yong, Ir. Ts. Dr Tan Kim Seah, Ms. Michelle Lau Chui Chui, Grad. IEM Secretariat: Janet Lim, Nurul Aida binti Mustafa, Nur Illyarnie binti Rosman

THE INSTITUTION OF ENGINEERS, MALAYSIA

Bangunan Ingenieur, Lots 60 & 62, Jalan 52/4, P.O. Box 223, (Jalan Sultan), 46720 Petaling Jaya, Selangor Darul Ehsan. Tel: 603-7890 0130 Fax: 603-7957 7678

E-mail: sec@iem.org.my Homepage: http://www.myiem.org.my

for

Failure of Steel Water Tank

Design for Safety: Failure of Elevated Ageing Domestic Plastic Water Tank Case Study #2

Bulletin

Theme

Sustainable Maritime Technology September: Leading the Charge - Empowering Engineers for Project Success

DIMENSION PUBLISHING SDN. BHD. [ 199701034233 (449732-T) ]

Level 18-01, PJX-HM Shah Tower, No. 16A, Persiaran Barat, 46050 Petaling Jaya, Selangor Darul Ehsan, Malaysia. Tel: +(603) 7493 1049 Fax: +(603) 7493 1047

E-mail: info@dimensionpublishing.com Website: www.dimensionpublishing.com

CHAIRMAN

ROBERT MEBRUER

CEO/PUBLISHER

SHIRLEY THAM ● shirley@dimensionpublishing.com

HEAD OF MARKETING & BUSINESS DEVELOPMENT

JOSEPH HOW ● joseph@dimensionpublishing.com

PRODUCTION EDITOR

TAN BEE HONG ● bee@dimensionpublishing.com

CONTRIBUTING WRITERS

PUTRI ZANINA ● putri@dimensionpublishing.com

HANNA SHEIKH MOKHTAR ● hanna@dimensionpublishing.com

SENIOR GRAPHIC DESIGNER

SOFIA HANIS ● sofia@dimensionpublishing.com

GRAPHIC DESIGNER

NICOLE THENG ● nicole@dimensionpublishing.com

ADVERTISING CONSULTANTS

THAM CHOON KIT ● ckit@dimensionpublishing.com

ACCOUNTS CUM ADMIN EXECUTIVE

YEN YIN ● yenyin@dimensionpublishing.com

For advertisement placements and subscriptions, please contact:

DIMENSION PUBLISHING SDN. BHD. [ 199701034233 (449732-T) ]

Level 18-01, PJX-HM Shah Tower, No.16A, Persiaran Barat, 46050 Petaling Jaya, Selangor Darul Ehsan, Malaysia.

Tel: +(603) 7493 1049 Fax: +(603) 7493 1047

E-mail: info@dimensionpublishing.com

Subscription Department E-mail: info@dimensionpublishing.com

JURUTERA is published and printed monthly by Dimension Publishing Sdn. Bhd.

JURUTERA MONTHLY CIRCULATION: OVER 50,000 MEMBERS

Submission or placement of articles in JURUTERA could be made to the:Chief Editor THE INSTITUTION OF ENGINEERS, MALAYSIA (IEM) Bangunan Ingenieur, Lots 60 & 62, Jalan 52/4, P.O. Box 223 (Jalan Sultan), 46720 Petaling Jaya, Selangor. Tel: +(603) 7890 0130 Fax: +(603) 7957 7678

E-mail: pub@iem.org.my or sec@iem.org.my IEM Website: http://www.myiem.org.my

© 2024, The Institution of Engineers, Malaysia (IEM) and Dimension Publishing Sdn. Bhd.

PUBLICATION DISCLAIMER

The publication has been compiled by both IEM and Dimension with great care and they disclaim any duty to investigate any products, process, services, designs and the like which may be described in this publication. The appearance of any information in this publication does not necessarily constitute endorsement by IEM and Dimension. There is no guarantee that the information in this publication is free from errors. IEM and Dimension do not necessarily agree with the statement or the opinion expresssed in this publication.

COPYRIGHT

JURUTERA Bulletin of IEM is the official magazine of The Institution of Engineers, Malaysia (IEM) and is published by Dimension Publishing Sdn. Bhd. The Institution and the Publisher retain the copyright over all materials published in the magazine.

and

by Ir. Tajul Ariffin Mohamed Nori Chair, Safety in Engineering Special Interest Group (SESIG)

Moving into our third term as the newest division of IEM, the Safety in Engineering Special Interest Group (SESIG) is leading this month’s JURUTERA bulletin which will serve as an important platform for addressing safety concerns within the engineering fraternity. In line with the recent enforcement of the new OSHA (Amendment 2022), this issue of Jurutera is very timely and we hope to see a significant shift towards improved safety and health in the workplace.

In this issue, we are delighted to present a session with the DirectorGeneral of the Department of Occupational Safety & Health Malaysia (DOSH), where we discuss recent changes in OSH legislation and the new measures introduced in the amended law to help prevent occupational accidents.

We are also pleased to share two case studies of mishaps related to design issues with water tanks. Our feature article offers insights into Safety Engineering in Education, which can become an important engineering field in the future.

We hope this issue adds value to your safety awareness. We also invite all of you to join our Safety in Engineering Symposium 2024 on 17 July 2024, where many will be sharing views on the safety and health legislation and practical guidance with the hope to prepare all stakeholders.

First and foremost, I would like to extend my heartfelt gratitude to the former Chief Editors, Principal Bulletin Editors, the Bulletin Editorial Board Committee and the Standing Committee on Information & Publications for shaping JURUTERA into the esteemed publication it is today.

My personal connection with JURUTERA dated back 25 years, sparked by a proud moment when my father, Ir. Looi Huat Chuan, had his engineering article published in the February 1999 issue. That experience cemented JURUTERA in my heart as a premier source for engineering insights and industry updates.

As industries evolve in this digital age, the publishing sector is no exception. In a world where information is predominantly accessed via smartphones and tablets, we must adapt our content to be mobilefriendly, prioritising touch interactions and responsive designs.

Our goal is to enhance our readers’ experience by creating more engaging and dynamic interactions. While maintaining the highest standards of quality in our engineering articles, we will also incorporate interactive elements to offer a more engaging, informative and immersive experience.

The rapid advancement of technology opens up endless possibilities for interactive content, such as augmented reality and 3D models. These innovations present thrilling opportunities for JURUTERA to push the boundaries of traditional publishing!

Interviewee:

Ir. Haji Mohd. Hatta Zakaria

Director-General

Department of Occupational Safety & Health (DOSH)

The Institution of Engineers, Malaysia (IEM) Safety in Engineering Special Interest Group (SESIG) recently took a commendable initiative to enhance safety standards in the engineering field. A committee from SESIG met with Ir. Haji Mohd. Hatta Zakaria, the Director General of the Department of Occupational Safety & Health (DOSH) and advisor to SESIG, for an insightful interview.

This article explores the key takeaways from this discussion, highlighting the collaborative efforts between IEM and DOSH to promote awareness of Occupational Safety & Health and future developments in OSH legislation. Ir. Haji Mohd. Hatta speaks about the impending enforcement of the Occupational Safety & Health (Amendment) Act 2022 (OSHA) and the Repeal of the Factories & Machinery (FMA) Act 1967, as well as the challenges and opportunities in the bid to reduce the overall number of occupational accidents in Malaysia.

After almost three decades, the Malaysian Parliament passed the Occupational Safety & Health (Amendment) Act 2022 (Amendment Act) on 4 March 2022. The Ministry of Human Resources gazetted the Amendment Act on 16 March the same year, marking a milestone in the nation’s advancement in occupational safety and health. It has been in force since 1 June 2024, with several new subsidiary legislations, such as the published regulations: Occupational Safety & Health (Plant Requiring Certificate of Fitness) Regulations 2024, Occupational Safety & Health (Licensed Person) Order 2024, Occupational Safety & Health (Fee For Registration of Competent Person and Registered Training Provider) Regulations 2024 and Occupational Safety & Health (Construction Work) (Design & Management) Regulations 2024.

Apart from the amendments to the existing OSHA, the Factories & Machinery Act 1967 (FMA) will also be repealed as the approach used in the existing FMA is no longer compatible with current evolving technology. The Parliament passed the Factories & Machinery (Repeal) Act 2022 on 16 March 2022 and, like the OSHA Amendment Act, the repealed FMA also take effect on 1 June 2024. From this date, the relevant provisions of the repealed FMA, in particular provisions relating to the inspection of machinery will be consolidated (with changes) into the amended OSHA.

The enforcement of both the Amendment Act and the repealed FMA come with opportunities and challenges in reducing occupational accidents in the country. Based on analysis that DOSH carried out over the past decade, occupational injury rate in 2022 showed a decrease of 33%, compared to 3.31 per 1,000 workers in 2012. Meanwhile, the 2022 occupational fatal injury rate decreased by 56%, compared to 4.64 per 100,000 employees in 2012.

Commenting on the integration of both the legislative amendments forming a single OSHA (Amendment) 2022, Ir. Haji Mohd. Hatta, the Director-General of the Department of Occupational Safety & Health (DOSH), Malaysia says the transition to the Amendment Act is being handled with proper management of change. Resolute in his commitment to advancing occupational safety and health standards in the country over the years, he emphasises the need to understand the necessity to integrate the said legislative amendments.

“The amendments to OSHA are welcomed changes to the old legislation. This is in keeping with rapid changes in various industries over the past years,” he says. The most significant amendment is the expansion of the scope and applicability of OSHA to all places of work with few exceptions. This is in line with the increasing global focus on occupational safety and health

to ensure sustainability of human resources.

Ir. Haji Mohd. Hatta says the amended OSHA also introduces more measures by emphasising the responsibilities of employers and principals, giving more rights to employees and setting higher penalties for offences. Companies, especially those in industries not previously subjected to OSHA, should stay informed about the changes under the amended OSHA and be ready to implement them.

Elaborating further, he says the principle of Amendment Act is a combination of both OSHA 1994 and FMA 1967. Based on both existing Acts, the self-regulation principle of OSHA 1994 will be applied and more critical provisions, such as control over machinery and factories governed in FMA 1967, are included in the Amendment Act. He adds that although the Amendment Act applies self-regulation principles, issues involving the control of risky machinery will be handled by prescriptive approaches. For example, regulations previously governed under FMA i.e. Factories & Machinery (Steam Boiler and Unfired Pressure Vessel) Regulations 1970 Factories & Machinery (Notification of Fitness and Inspections) Regulations 1970, Factories and Machinery (Certificates of Competency Examinations) Regulations 1970 and Factories & Machinery (Electric Passenger and Goods Lift) Regulations 1970 will be replaced by the Occupational Safety & Health (Plant Requiring Certificate of fitness) Regulations 2024 under the new OSHA amendment 2022.

“Existing subsidiary legislations under OSHA 1994 will remain and a few of them will be amended to be streamlined with current technologies as well as to cater to the current OSH issues in industries. The Amendment Act also introduces new provisions such as duty to conduct risk assessment, workers’ rights, etc. Therefore, new regulations and guidance will be introduced to describe further the requirement for these new provisions,” he says.

Ir. Haji Mohd. Hatta points out that ensuring workplace safety often involves employers or organisations appointing Safety & Health Officers (SHOs) and placing most of the responsibility on them, a practice that persists even now. “However, under the new OSHA regulations, SHOs will be appointed rather than hired, thus shifting greater responsibility onto the employers, as originally intended, with SHOs tasked primarily to advise employers, addressing the issue of potential conflict of interest in previous arrangement when SHOs are hired and so inclined to prioritise their employers’ interests,” he says.

Ir. Haji Mohd. Hatta also says that OSH training programme is very important for employees as they can learn work safety procedures pertaining to their job activities. This will become more critical if these activities are dangerous and risky. “This proactive step of providing relevant training programmes can help prevent occupational accidents from happening at the workplace,” he says, adding that the Amendment Act has introduced a requirement that recognises the need for a certain “class or description of persons” to attend specific OSH training before they can perform their work activities. This provision is aimed at high-risk work activities, such as working at heights, handling dangerous machinery or working in confined spaces. For this purpose, the Minister

of Human Resources will make an Order published in the Gazette of the Ministry of Human Resources to prescribe the class and description of people who must undergo the specific training.

On the other hand, a competent person is someone registered with the Director-General of DOSH, as stipulated under Section 31(C) OSHA 1994. These competent persons have their own duties in the Act, for example, to operate or be in charge of any plant or to carry out medical surveillance and health examination.

“Duties for employers, employees and competent person with regards to safety and health are clearly stated in the law. While the employer is responsible for providing employees with a safe work environment, everyone – managers, supervisors and general employees – plays a role in safety and health at the workplace; it is truly a collective effort,” says Ir. Haji Mohd. Hatta.

OSH management and coordination by employers play an important role in preventing accidents in the workplace. Ir. Haji Mohd. Hatta also stresses on the need to coordinate OSH Programmes, such as safety related training, meetings and workplace inspections which are conducted to create awareness, share knowledge and help improve compliance of OSH.

The Amendment Act has introduced a requirement for a workplace with five or more employees, to appoint an Occupational Safety & Health Coordinator (OSH-Coordinator) to assist employers in OSH-related matters. This applies to workplaces that do not have to appoint SHOs.

“This will help the employer to conduct an OSH Programme at the workplace with high-impact results and low-cost implementation. It is

hoped that the Culture of Prevention can be cultivated so that the number of workplace accidents can be reduced,” says Ir. Haji Mohd Hatta.

The Amendment Act introduces new provisions on the duties of employer, self-employed persons and the principles to carry out risk assessment for every activity at the workplace. For this purpose, Ir. Haji Mohd says DOSH will introduce a new regulation to describe further the provision in the Act and will be supported with Industry Code of Practice (ICOP) as a guide for employers on compliance, as far as is practicable, to the provision.

Through the ICOP, DOSH has reviewed the existing technique for risk assessment in previous guidelines (HI – Hazard Identification, RA – Risk Assessment and RC –Risk Control or HIRARC 2008) and introduced improved methods on how to conduct risk assessment, including better risk management at the workplace.

Ir. Haji Mohd. Hatta says: “This is expected to guide employers, as one of the indicators, to evaluate the effectiveness of control measures implemented at the workplace. Most importantly, they must implement a structured way to periodically monitor the performance of control measures at the respective workplace.”

Any employer, business entity or company has the option to incorporate local standards into its Risk Assessment, leveraging on guidelines from MS ISO 31000:2020 Risk Management and MS ISO 45001:2018 Occupational Health & Safety Management Systems, which offer valuable industry-specific guidance.

and Ratification of ILO Convention, C155

Under the new provision of Section 18B of the Act, every employer shall conduct a risk assessment and ensure that sufficient risk control has been taken to effectively eliminate or reduce health hazards associated with work activities at its premises.

On the other hand, the Amendment Act also introduces a new provision on workers’ rights, which is in line with Article no. 13 in the Occupational Safety and Health Convention, 1981 (No. 155) (C155) under the International Labour Organization (ILO). “If an employee observes that the risk control does not function and poses an imminent danger at the workplace (after referring to the risk assessment), the employee has the right to remove himself from the danger area after informing his superior or manager. So, eliminating the workers cannot happen if the employer discharges his duty under the provision of Section 18 and Section 15 of the OSHA,” Ir. Haji Mohd. Hatta clarifies.

“For this purpose, DOSH has introduced a guide for employers and employees to explain further the provision in the Act. Employers have a duty to identify hazards related to work activities, including imminent danger situations that can happen in the workplace and to provide a procedure on how to deal with the situation. Employees must be informed about the hazards in their work activities, including imminent danger situations and must be trained in how to deal with such situations,” says Ir. Haji Mohd. Hatta.

Small and Medium Enterprises (SMEs) are usually seen as having simpler internal organisation and as being more flexible and faster at responding and adapting to change. At the same time however, SMEs are frequently confronted with major challenges. Ir. Haji Mohd. Hatta acknowledges the need for more attention and assistance to be given to SMEs to help them in the implementation of OSH as their apparent lack of financial resources and expertise often hinders their capacity to do so effectively.

In line with the Occupational Safety & Health Master Plan 2021-2025 (OSHMP25) and the Development Project under the 12th Malaysia Plan, DOSH has

introduced a systematic programme, Stepwise OSH Level Verification and Enhancement for SMEs (SOLVE 4 SME), to improve the level of OSH management for SMEs The implementation of SOLVE 4 SME is expected to improve the OSH compliance support programme in SMEs which is seen as less effective and difficult to implement. The SOLVE 4 SME design has features such as high impact, low cost, is easy to implement and can be implemented in all types of SME industries.

Improvement in Construction Safety Management and Occupational Safety & Health (Construction Work) (Design & Management) Regulations 2024

Recognising that the construction sector remains a significant contributor to accident rates, Ir. Haji Mohd. Hatta says it is crucial to note that a better mandatory legislative is imperative for safety management in this industry. A new regulation governing construction safety known as the Occupational Safety & Health (Construction Work) (Design & Management) Regulations 2024 (CDM) has been introduced. The forthcoming transition from the

existing Building Operations & Works of Engineering Construction (Safety) (BOWECS) regulation, governed by the FMA, to the implementation of CDM regulations promises a more robust framework with stringent governance requirements for all the stakeholders.

“This shift is poised to significantly elevate our national standards for safety and health in construction, addressing critical concerns and fostering a safer work environment for all stakeholders involved,” says Ir. Haji Mohd. Hatta, adding that this regulation was adopted from Prevention through Design (PtD) approach which had been implemented in few countries such as Australia, UK and Singapore; the outcome from this approach showed a positive impact in those countries. “The CDM regulations is very significant to the engineering fraternity as it may directly affect the designer. Early design stages hold significant influence to shape project outcomes. When safety is not considered during the design stage, occupants may face injury risks and impractical designs increase danger during construction and maintenance. Thus, safety must be integrated into construction processes from the design stage,” he stresses.

Ir. Haji Mohd. Hatta notes that the CDM regulations is often narrowly perceived as applicable to only certain construction activities such as temporary works undertaken by Civil Engineers during the construction phase. “However, it is important to note that CDM regulations shall be applicable to all engineering disciplines involved in the construction industry, including mechanical, electrical, geotechnical and any practicable area within the engineering fraternity,” he says.

According to Ir. Haji Mohd. Hatta, the implementation of various strategies by DOSH is guided by the Occupational Safety & Health Master Plan (OSHMP), which is key in ensuring that the work environment in the country is safe and healthy.

The Director-General of the Department of Occupational Safety & Health (DOSH), Malaysia, Ir. Haji Mohd. Hatta Zakaria holds a Bachelor of Science in Mechanical Engineering from the University of Evansville, United States of America (USA) and a Master of Science in Engineering in Process Safety & Loss Prevention from the University of Sheffield, United Kingdom (UK). He has been with DOSH since 1992. A member of the Institution of Engineers, Malaysia (IEM), he is also registered with the Board of Engineers, Malaysia (BEM) as a Professional Engineer.

“Since 2011, we have been strategically working to reduce occupational accidents through the OSH Master Plan. Our commitment to this cause remains steadfast, as DOSH continues to drive forward the implementation of the National OSH Master Plan initiated in 2011,” he says.

The latest plan is the OSHMP25, which is built upon foundations laid by the OSH Master Plan 2011-2015 (OSHMP 15) and OSH Master Plan 2016-2020 (OSHMP2020). “This ongoing effort aims to cultivate a safe and healthy work environment in Malaysia while enhancing compliance with OSH standards nationwide. Achieving the objectives outlined in this master plan represents a significant milestone in our journey. Collaboration among stakeholders is key to perpetuating OSH practices, fostering stronger relationships and sharing resources across various sectors,” says Ir. Haji Mohd. Hatta.

“Our ultimate goal is ambitious yet crucial: To reduce occupational fatalities and accidents while raising awareness of diagnosing and reporting occupational illnesses and poisoning. By 2025, we aim to decrease occupational death rates to 2.93/100,000 employees, to reduce occupational accident rates to 2.13/1,000 employees and to increase awareness of diagnostic reporting by 30 per cent. We envision this master plan propelling our national OSH efforts to new heights. It is imperative that all parties unite their efforts to integrate OSH into our nation’s broader development goals. We must ensure a fair, equitable and inclusive distribution of economic benefits as we strive for sustainable progress.”

Ir. Haji Mohd. Hatta adds: “As we approach the culmination of our efforts in 2025, we are hopeful that OSHMP will yield the anticipated results. I extend an invitation to NGOs such as IEM to join us in the next phase of OSHMP, leveraging on collective expertise and resources for the benefit of all stakeholders. Together, we can realise our shared vision of a safer, healthier and more conducive work environment for all.”

DOSH has been conducting machinery inspections since 1967. As the industrial revolution continues to expand and the size of industries grows, Ir. Haji Mohd. Hatta says DOSH faces a daunting challenge to adequately conduct the number of machinery and factory inspections required.

“We only have 1,225 technical officers, a stark contrast to the over 450,000 pieces of registered machinery in Malaysia, with expertise spanning mechanical, civil, electrical and chemical engineering backgrounds. The current number of inspectors falls short of what is necessary to inspect each piece of machinery and factory annually, resulting in a significant gap between

the workload and available resources. This shortfall has led to various issues such as inspection backlogs, compromised inspection quality and difficulty in keeping pace with technological advancements,” he says.

To address these challenges, Ir. Haji Mohd. Hatta feels that intervention is imperative. In addition to overcoming these inspectionrelated hurdles, there is also a pressing need to enhance (OSH) standards throughout Malaysia. Outsourcing machinery inspection emerges as the most viable solution to effectively manage the demands posed by the industrial revolution.

“By engaging private entities to carry out inspections, resources can be optimised, allowing for more comprehensive coverage, improved inspection quality and better adaptation to technological changes, thus creating a safer and more sustainable industrial landscape. Our existing manpower can then focus on the enforcement of OSH in the workplace and improve our approach,” he says.

Integrating ESG into DOSH Enforcement Activities On the Environmental, Social & Governance (ESG) principles advocated by the government, Ir. Haji Mohd. Hatta says DOSH has been in the forefront on the social aspects with the various existing regulations and OSHA (Amendment) 2022 will further create a safer, healthier and equitable work environment.

To conclude, he expresses deep gratitude to IEM for establishing the Safety in Engineering Special Interest Group (SESIG). He notes that this group serves as a vital bridge for collaborations on safety and health programmes between the authorities and the learned society, allowing IEM to help enhance the country’s national safety and health practices, especially within the engineering fraternity. This can be the catalyst to contribute towards a safer and healthier workplace environment in Malaysia.

Johnson Controls Hitachi Air Conditioning Malaysia Sdn Bhd, the leading producer of Hitachi air conditioners, recently celebrated its 35th anniversary in Malaysia with an event held at its manufacturing facility in Bandar Baru Bangi. The event was graced by Yang Berbahagia Dato’ Ts. Dr. Hj. Aminuddin Bin Hassim, the Secretary General at the Ministry of Science, Technology and Innovation (MOSTI), alongside David W. Budzinski, President of Residential & Light Commercial Solutions at Johnson Controls and Chief Executive Officer of Johnson Controls-Hitachi Air Conditioning.

In this exclusive interview, Budzinski shed light on the global operations of Johnson Controls-Hitachi Air Conditioning, highlighting its establishment in 2015 as a joint venture between Johnson Controls International and Hitachi Global Life Solutions, formerly known as Hitachi Appliances. Budzinski emphasised the company’s commitment to globalising platforms and developing smart, healthy, and sustainable solutions worldwide for residential and commercial environments.

“Over its 35-year tenure in Malaysia, Johnson Controls Hitachi Air Conditioning

Malaysia has manufactured more than 15 million units, featuring a diverse product line comprising 2,900 models across categories such as window, multi-splits, wall-mounted, ducted, and ceiling units,” Budzinski revealed.

“Currently, 99.5% of Hitachi air conditioners produced at the manufacturing facility are exported to 39 destinations spanning North America, Europe, Southeast Asia, Japan, Australia, and New Zealand. The company has consistently invested in new product development and technological enhancements to meet evolving industry demands,” he added.

Malaysia Facility & Production

Regarding the significance of the Malaysia facility in the company’s network, Budzinski

stated, “For decades this facility has played a crucial role in contributing to the success of our high-quality air conditioning solutions worldwide. We remain dedicated to innovation and excellence and will continue to leverage our advanced technologies and sustainable practices to meet the evolving needs of our customers. I’m excited to be here to celebrate with our team because it’s an incredible milestone for us and one we’re incredibly proud of. Henceforth, we will move forward with the same spirit of excellence and commitment that has brought us to this milestone.”

When questioned about sustainability goals, Budzinski emphasised Johnson Controls -Hitachi Air Conditioning’s leadership in promoting smart, healthy, and sustainable solutions. He highlighted the company’s

David W. Budzinski President, Residential & Light Commercial Solutions, Johnson Controls and Chief Executive Officer, Johnson Controls-Hitachi Air Conditioning.

Senthil Kumar Subramaniam

Managing Director of Johnson Controls Hitachi Air Conditioning Malaysia Sdn Bhd.

prioritisation of transitioning to low GWP refrigerants and developing solutions for healthier indoor environments, stating, “Our overarching goal is to ensure clean air for all occupants.”

Budzinski also highlighted the company’s focus on connectivity and digital technologies, exemplified by innovations such as the airCloud GO app, enabling users to remotely control their HVAC (Heating Ventilation Air Conditioning) systems for enhanced energy efficiency and comfort.

Looking ahead, Budzinski discussed key trends driving demand in the HVAC industry and emphasised the company’s incredible efforts on sustainability through investments in solar power, digital technologies, and energy-efficient practices across its global facilities.

Budzinski reiterated the company’s dedication to advancing sustainable solutions and fostering global growth, underscoring Malaysia’s pivotal role as a strategic hub within the company’s operations. He emphasised the company’s proactive approach to sustainability: “We’re not just helping our customers practice sustainability; we’re doing it ourselves in our own facilities.”

Product Innovations for the Global Market

According to Managing Director Senthil Kumar Subramanian, who also participated in the interview, Johnson Controls Hitachi Air Conditioning Malaysia strategically prioritises several key aspects to enhance its product offerings.

With over 20 years of experience in operational excellence and P&L management, Senthil’s contributions to various industries, including renewable energy, aviation, and HVAC, are widely recognised.

Discussing the company’s product strategy, Senthil outlined, “These initiatives include optimising backlog flow and implementing flow spots as major differentiators.

Moreover, the company places a strong emphasis on delivering pure air solutions, achieved through an automated cleaning system that ensures optimal air quality by eliminating contaminants.”

“In line with sustainability efforts, maintaining pure air quality in living spaces remains a top priority for Johnson Controls-Hitachi Air Conditioning. These innovations underscore the company’s commitment to providing healthier indoor environments,” he added.

Senthil also emphasised the company’s broader product focus beyond air quality solutions. He noted that with a global market presence spanning from North America to various regions worldwide, the company prioritises quality alongside technological advancements. “This entails meeting diverse regulatory requirements and addressing the complexity of product variants across different countries,” he added.

New Products and Technology Upgrades Among the company’s range of products, the airHome series stands out, offering room air conditioners tailored to different lifestyles and installation needs. Depending on the models, these air conditioners feature sleek designs and advanced air purification, including a ViroSense filter that inhibits up to 99.9% of airborne viruses1 and 99.0% of bacteria2. They also include FrostWash™ self-cleaning technology for sanitizing coils and removing dirt, bacteria, viruses, and mould. The premium airHome series feature AQtiv-Ion for enhanced air quality

and an outdoor FrostWash™ for added durability. An intelligent motion sensor enables eco mode when the room is empty. Several high-end models feature integrated Wi-Fi, enabling remote control and energy cost monitoring via the airCloud Go app.

1 ViroSense Z1 filter shows 99.9% of effectiveness against SARS-CoV-2 NIID isolated variant: JPN/TY/WK-521 and 99.0% effectiveness against Influenza A Virus (H3N2) tested at Japan Textile Product Quality and Technology Center using ISO18184:2019 method.

2 Claim refers to the effect of ViroSense Z1 filter which showed 99.0% reduction of Staphylococcus aureus NBRC12732 and Escherichia coli NBRC3301 bacteria particles under lab conditions tested at Nissenken Quality Evaluation Center Japan.

People Development and Collaborations

Central to these efforts, Senthil explained, is the development of a skilled workforce. Transitioning from reliance on foreign workers to nurturing local talent, the company invests in comprehensive training programmes facilitated by virtual facilities like the Dojo.

“In summary, Johnson Controls Hitachi Air Conditioning Malaysia’s forward-looking product strategy encompasses a holistic approach to innovation, sustainability, and talent development, positioning the company as a leader in delivering cuttingedge solutions tailored to diverse market demands,” Senthil concluded.

In tandem with product launches, Senthil highlighted collaborative initiatives to foster local talent and industry partnerships. In 2024, Johnson Controls Hitachi Air Conditioning Malaysia Sdn Bhd launched the Construction Industry Development Board (CIDB) Certified Brazing Training and Assessment Facility Room, offering hands-on installation, safety and quality control training. Collaborations with organisations like CIDB exemplify the company’s dedication to workforce development and industry-wide progress.

This commitment to employee development and deep-rooted expertise translates into a significant advantage — the ability to consistently deliver high-quality products that meet stringent global standards.

Recognising the crucial role of their workforce, the company also implements programmes like the Supervisor Acceleration Programme and Lean Six Sigma training to cultivate leadership and operational excellence. Initiatives like the Engineering Acceleration Programme underscore their commitment to nurturing technical expertise.

In parallel, sustainability initiatives, including solar deployment and transitioning to more efficient technologies, align with their commitment to a cleaner, greener future.

He also acknowledged that the support received from suppliers and their collaboration is instrumental in the company’s localisation efforts and product advancements. He further stated the facilities’ anticipation of further enhancements in efficiency and costeffectiveness, driven by ongoing technological innovations and strategic partnerships.

Looking forward, Johnson Controls Hitachi Air Conditioning Malaysia, Budzinski shared that the company will continue innovating by developing new products that cater to changing regulations and market demands. He mentioned that the manufacturing facility in Malaysia boasts a fully equipped research and development centre and diagnosis centre for quality assurance, including a sound, electrical, and environmental testing room (ETR) capable of simulating the cycle of four seasons to enhance export capabilities.

To conclude, Budzinski highlighted that the company’s journey is a testament to its unwavering dedication to innovation, collaboration, and sustainability. He affirmed their commitment to navigating the evolving landscape of the HVAC industry, remaining steadfast in their pursuit of excellence, and poised to lead the way towards a brighter, more sustainable future.

Safety engineering education is paramount for students, engineers, technicians and all individuals involved in various industries and sectors. By gaining a comprehensive understanding of safety principles, regulations and best practices, students can develop the necessary skills to identify and mitigate potential hazards in the workplace. For engineers and technicians, safety engineering education equips them with the knowledge to design, implement and maintain systems and processes that prioritise safety and minimise risks (Laciok et al., 2021).

Beyond technical expertise, such education fosters a culture of safety consciousness, empowering individuals to proactively address safety concerns and to promote a safe working environment for themselves and their colleagues. Safety engineering education instils a sense of responsibility and ethical conduct, emphasising the importance of protecting not only human lives but also the environment and public welfare. Investing in safety engineering education is essential to ensure the wellbeing of workers, protect assets and contribute to the overall sustainability and success of organisations and communities (Aleksandrov et al., 2016).

Teaching safety engineering education presents several challenges that educators must address effectively, including the interdisciplinary nature of safety engineering and the need for practical application and hands-on experience. This complexity requires innovative teaching methods such as simulations, case studies and field experiences to provide students with practical exposure to safety challenges.

However, at present, safety engineering education conducted in classrooms and training programmes is often criticised for its ineffectiveness in adequately preparing students, engineers and technicians to mitigate accidents effectively (Perrin et al., 2018).

Traditional approaches may prioritise compliance with regulations over fostering a culture of safety and risk awareness, leading to a disconnect between theoretical knowledge and practical application. To overcome these

shortcomings, safety engineering education must incorporate more experiential learning opportunities, simulation-based training and real-world case studies, along with ongoing professional development and collaboration between academia, industry and regulatory bodies. By addressing these challenges through innovative teaching methods and partnerships, safety engineering education will enhance its effectiveness in reducing workplace accidents and promoting a culture of safety.

The effectiveness of delivering safety knowledge to engineering students in universities is questionable. In the context of chemical engineering degree programmes, this issue becomes evident in capstone courses like the Plant Design Project (PDP), where students collaborate to design new chemical plants. Despite safety being a key deliverable in the PDP, the students’ understanding of safety appears superficial. This can be seen in their tasks to construct HAZOP analyses, interpret P&ID diagrams and discuss safety elements in their designs. This shallow understanding raises concerns since these students are future engineers responsible for managing numerous production facilities.

In industrial settings, addressing training issues is crucial to ensure the safety of both new and experienced engineers. Companies must offer tailored safety training programmes which align with their specific requirements, encompassing both general safety protocols and company-specific procedures.

However, traditional delivery methods used by safety trainers may not effectively impart critical knowledge to participating engineers, leading to gaps in understanding and potentially compromising safety measures. To enhance training effectiveness, incorporating interactive and hands-on learning experiences can foster better comprehension and retention of essential safety practices among engineers.

This proven inefficiency in safety engineering education and training delivery can be rapidly improved through the implementation of innovative and engaging ways which can make students and engineers immersed in various safety issues and problems as well as the desire to learn, improve and solve safety related problems.

To address the inefficiencies in safety engineering education and training delivery, adopting innovative teaching approaches is essential. Rather than traditional methods, incorporating interactive simulations, case studies and real-world scenarios can deeply engage students and engineers in diverse safety issues and challenges. Encouraging active participation and problemsolving activities can foster a strong desire to learn and improve safety practices.

Additionally, integrating hands-on experiences, such as practical demonstrations and field visits to industrial facilities, can provide invaluable insights and reinforce theoretical concepts. Promoting collaborative learning environments where students and engineers can exchange ideas and experiences can enhance their understanding and appreciation of safety engineering principles. By embracing these innovative approaches, educational institutions and companies can effectively prepare future professionals to address complex safety issues and drive continuous improvement in safety performance. Below are 14 innovative and engaging methods for teaching safety engineering:

1. Student-Centred-Learning (SCL)

This approach has been consistently proven effective and includes Active Learning (AL), Cooperative Learning (CL) and Problem-Based Learning (PBL) (Neto et al., 2024). Drawing from our experience in implementing these methods at Universiti Teknologi Malaysia (UTM), students have demonstrated remarkable enthusiasm and dedication for addressing safety engineering challenges in diverse scenarios (Figure 1). Additionally, incorporating real-world case studies, industry collaborations and internships provides students with practical exposure and reinforces their understanding of safety principles in professional settings (Hernández-de-Menéndez et al., 2019).

This immersive experience enables learners to navigate hazardous environments and practise safety protocols within a risk-free virtual setting. Such a hands-on approach can notably enhance retention and decision-making skills (Abotaleb et al., 2023). In 2022, a collaboration among three universities — Universiti Teknologi Malaysia, Monash University and De La Salle University in The Philippines — was initiated under the Royal Academy of Engineering (RAE), UK. The aim was to develop a virtual reality safety engineering programme to bolster the effectiveness of safety engineering education. Figure 2 illustrates a virtual reality safety demonstration conducted by a company at the Safer World 2022 Conference in London.

3. Storytelling

Craft captivating narratives centred on safety engineering and seamlessly integrate crucial safety concepts into the storyline. Through stories, the subject matter becomes more captivating and memorable, thereby enhancing the depth of understanding and meaningful learning in safety engineering (Rae, 2016).

4. Gamification

Engaging in gaming activities is inherently enjoyable. By creating safety-themed games that require students to navigate decisions and tackle safety challenges, the learning experience becomes more impactful (Neto et al., 2024). Incorporating gamification elements will add an element of fun and competition, leading to a deeper comprehension of safety principles. An excellent illustration of this approach is the game, Fill It Up, developed by Caspian Psychology Ltd., which aims to enhance process safety knowledge through gamification (Figure 3). Link = https://www. caspianpsychology.com/product/fill-it-up/

5. Case Studies

Incorporate real-life case studies of safety incidents, accidents or near-misses, so that students can dissect the root causes and suggest preventative measures. This method fosters an understanding of the repercussions of insufficient safety protocols (Bocwinski et al., 2021). Numerous valuable safety engineering case studies are accessible online, including examples such as the Fire Safety Engineering Problem, which explores alternatives to sprinkler systems in halls and the utilisation of sprinkler systems at airports, as shared by EduBirdieTM. Some case studies will enable students to learn and appreciate alternative safety methods and regulations if the other country’s case studies are used.

6. Hands-on Projects

Arrange practical projects which task students/ engineers with devising safety systems or enhancing safety procedures tailored to particular scenarios. Hands-on applications serve to solidify theoretical understanding effectively. Additionally, workbooks can be utilised, prompting students/engineers to engage actively by contemplating and completing tasks during learning sessions. The hands-on projects should focus on understanding all the safety features available and the ability to explain why.

7. Field Trips and Site Visits

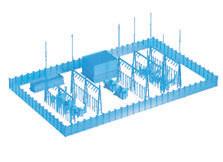

Coordinate field trips to industrial sites, construction projects or manufacturing facilities to provide students with firsthand exposure to safety protocols and direct interaction with safety experts. For instance, in a recent initiative for the Occupational Safety for Energy System Master course which I taught, students were taken to power substations to gain comprehensive insights and first-hand experience in applying safety practices within such environments (Figure 4).

Figure 4: Two supervisors accompanied students to a substation to provide them with a first-hand understanding of on-site conditions. During the visit, they elucidated the safety features and protocols implemented

8. Collaborative Learning

Promote teamwork (team-based learning) and collaboration through group projects aimed at identifying safety risks and collectively devising safety solutions (Neto et al., 2024). This approach enhances communication skills and cultivates a comprehensive understanding of safety challenges.

9. Guest Speakers

Bring in safety experts, industry professionals or accident investigators to share their experiences and insights with the students. Real-life narratives can render safety principles more relatable and enduring in students’ minds.

10. Creative Visual Aids

Leverage infographics, animations and multimedia presentations to visually communicate intricate safety concepts. Visual aids play a crucial role in enhancing comprehension and retention of information. Today, creating such infographics has become easier with tools like Canva and other AI platforms such as Midjourney, enabling the sharing of information both formally and informally.

11. Role-Playing Exercises

Arrange role-playing scenarios where students engage in safety-related situations, fostering the development of problem-solving skills and the application of safety protocols. I have implemented this strategy numerous times through scenario-based learning, such as conducting a talk show in class, which students found enjoyable and impactful (Figure 5).

12. Competitions and Challenges

Organise safety-related competitions or challenges to prompt students to devise innovative safety solutions, with incentives such as prizes or recognition to encourage active participation. One example is the implementation of Team Games Tournament (TGT), a form of cooperative learning that engages all students equally, leveraging peer tutoring roles and incorporating game-like elements to reinforce learning.

13. Incorporate Technology

Incorporate wearable technology or sensor-based systems for real-time monitoring and analysis of safety data, offering students a hands-on experience with advanced safety tools during the learning process. This application aligns with the utilisation of Internet of Things (IoT) and Industry 4.0 (IR4.0) in safety engineering. Researchers at UTHM have shared insights on Reinforced Technology IR4.0 Implementation for Enhancing Safety Management in Construction Sites, underlining the significance of integrating modern technologies for safety enhancement (Kasim et al., 2021).

Generate safety-focused content for social media platforms to foster awareness and to stimulate discussions among students, extending learning beyond traditional classroom settings. A notable example is the Safety Engineering Special Interest Group (SESIG), which has established and manages a Facebook Page, https://www.facebook.com/iemsesig, (Figure 6) dedicated to safety engineering. Regular updates and informative posts contribute to ongoing conversations and knowledge dissemination in the field of safety engineering.

Keep in mind that the essence of effective teaching lies in adapting the approach to suit the needs and preferences of the students. Combining these innovative methods can foster a dynamic and rewarding learning environment for the students. Additionally, incorporating interactive simulations, case studies, role-playing scenarios and hands-on practical exercises will further enhance engagement and understanding.

In conclusion, safety engineering education is paramount in cultivating the next generation of engineers equipped to navigate complex safety challenges in diverse industries. Innovative teaching strategies are essential to engage students effectively and to instil a deep understanding of safety principles. Leveraging emerging technologies and interdisciplinary collaborations enhances the educational experience, preparing students/engineers for real-world safety engineering scenarios. As we continue to evolve in a rapidly changing landscape, it is imperative to invest in innovative teaching methods to ensure the success and safety of future generations.

[1] Aleksandrov, Anatoly A., Vladimir A., Devisilov and Mikhail V. Ivanov (2016) A Role of Education System in Creation of Safety Culture, Chemical Engineering Transactions, 53, 211-216. https:// doi.org/10.3303/CET1653036 Hernández-de-Menéndez, M., Vallejo Guevara, A., Tudón Martínez, J.C. (2019) Active learning in engineering education. A review of fundamentals, best practices and experiences. International Journal on Interactive Design and Manufacturing, 13, 909–922. https://doi.org/10.1007/s12008-01900557-8

[2] Abotaleb Ibrahim, Ossama Hosny, Khaled Nassar, Sahar Bader, Mohamed Elrifaee, Salma Ibrahim, Yasmin El Hakim and Mohamed Sherif (2023) An interactive virtual reality model for enhancing safety training in construction education, 31 (2), 324-345. https://doi. org/10.1002/cae.22585

[3] Neto Italo Rodeghiero and Fernando Gonçalves Amaral (2024) Teaching occupational health and safety in engineering using active learning: A systematic review, Safety Science, 171, 106391. https:// doi.org/10.1016/j.ssci.2023.106391

[4] Kasim Narimah and Sali Amirah Razali (2021) Reinforce Technology IR 4.0 Implementation for Improving Safety Management in Construction Site, International Journal of Sustainable Construction Engineering and Technology, 12 (3), 289-298.

[5] Laciok Vendula, Sikorova Katerina, Fabiano Bruno and Bernatik Ales (2021) Trends and Opportunities of Tertiary Education in Safety Engineering Moving towards Safety 4.0. Sustainability, 13, 524. https://doi.org/10.3390/su13020524

[6] Perrin Laurent, Nadine Gabas, Jean-Pierre Corriou and André Laurent (2018) Promoting safety teaching: An essential requirement for the chemical engineering education in the French universities, Journal of Loss Prevention in the Process Industries, 54, 190-195, https://doi.org/10.1016/j.jlp.2018.03.017

Bocwinski Rachel, David C. Finster, and Haim Weizman (2021) Framework for Teaching Safety Case Studies Using a Risk Management Approach, Journal of Chemical Education, 98 (12), 3824-3830, https://10.1021/acs.jchemed.1c00625

Rae Andrew (2016) Tales of disaster: the role of accident storytelling in safety teaching. Cognition, Technology and Work, 18, 1–10. https://doi.org/10.1007/s10111-015-0341-3

Prepared by:

Ir. Assoc. Prof. Dr Zaki Yamani Zakaria

A Fellow Researcher at the Centre for Engineering Education, Prof. Zaki is from the Faculty of Chemical & Energy Engineering, Universiti Teknologi Malaysia.

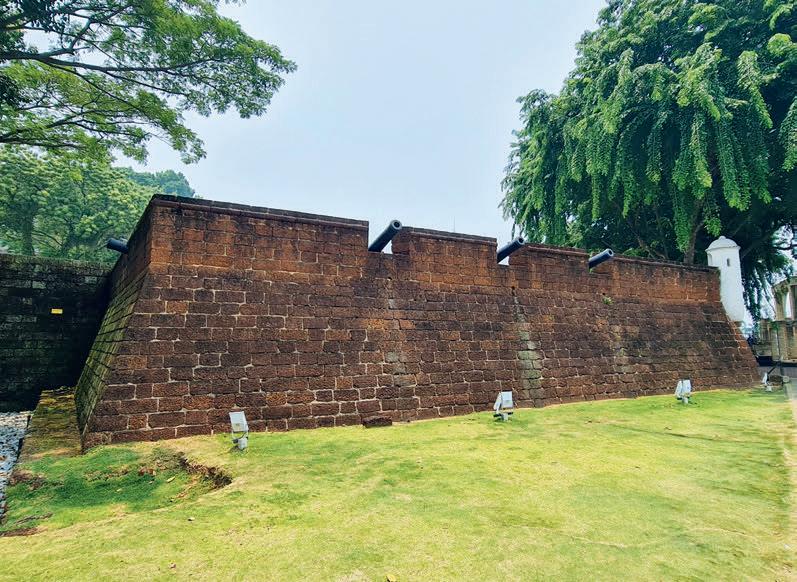

The effective performance and strength capacity of a structure designed to retain water are crucial factors for ensuring its functionality throughout its intended lifespan. In this article, we will focus on a case study centred on an elevated water tank structure in a factory and highlight a critical inadequacy discovered in its safety measures.

The catastrophic incident in 2017 at a latex glove manufacturing facility underscored essential oversights of safety in the factory. A mishap involving the failure of the approximately 8m-tall water tank tower sent shockwaves through the premises of a neighbouring factory. After the incident, it was revealed that there was a distressing lack of essential safety measures. The water tank was completed without any recorded information of its design or safety features. This oversight raised serious questions about the adequacy of safety measures employed.

The consequences were dire. The failure resulted from the immense force generated by the rapid release of water, which exerted a significant dynamic load pressure,

as evident in the impact observed in the surrounding area. The incident caused the bending of a Schedule 40 supply line connected to a fire hydrant, highlighting the magnitude of its force. It also resulted in the collapse of a double brick wall (a brick fence and the adjacent storage room brick wall). The collapse of the tank also caused structural failures, resulting in minor damages to nearby buildings due to the sudden water overflow. Part of the impact of the incident is shown in Figure 2. Luckily, despite the catastrophic damages, no casualties were reported.

The new tank was constructed to hold water for the manufacture of latex gloves. It burst unexpectedly only a few weeks after it was completed. Water is used extensively in the manufacturing of latex gloves and is essential in various stages of the process, from the initial preparation of the latex solution to the final processing steps, to ensure the quality and performance of the finished products. From the failure analysis, it was discovered that there was insufficient verifiable design data to confirm whether the design could withstand the applied forces. Additionally, the root cause analysis was challenging due to the unavailability of the construction drawings, making it difficult to assess whether the structure had been properly constructed.

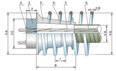

Furthermore, the observation of the failed structure showed that the steel tank was constructed using the welding method to join the tank wall plates. A popular design method for joining the tank wall in steel water tank construction is by using bolted joint studs. An internal inspection of the failed tank revealed that many internal reinforcements steel bars had been arranged randomly to join the wall plate. Figure 3 shows the internal steel connection.

The incident was a stark reminder of the critical safety aspects which the owner and those responsible for overseeing the construction had disregarded. It underscored a systemic failure to prioritise safety measures and to adhere to proper design standards and fabrication standards associated with the construction.

STARBARS ARE:

1. GLASS FIBRE REINFORCED POLYMER (GFRP) BARS

2. CHEAPER BY 15% COMPARED TO STEEL

3. CORROSION RESISTANCE

4. 2X HIGHER TENSILE STRENGTH

5. 4X LIGHTER THAN STEEL

6. NON-CONDUCTIVE TO THERMAL AND ELECTRICAL

7. 70% CARBON EMISSION REDUCTION

The design should be endorsed and reviewed by a Professional Engineer but such a drawing was not available. This exposed risk assessment, structural integrity evaluation and emergency response planning lapses. Moreover, it emphasised the need for stringent oversight and accountability throughout the design, construction and maintenance phases of the structure.

This unfortunate event should prompt a comprehensive re-evaluation of safety protocols and regulatory enforcement to prevent similar accidents in the future and to protect lives and property. Several factors which need the urgent attention of those involved with elevated tank design and construction, are as follows:

1. The absence of records or documentation regarding the design of the water tank was a severe oversight in ensuring its structural integrity. If the water tank had been appropriately designed and constructed, design documents or construction drawings should be made available for study when it failed.

2. Stakeholders involved in the design and construction of the water tank must maintain comprehensive records detailing structure design, construction and safety measures.

3. During the commissioning stage after completion, function tests are important to verify and ensure that the tank is ready for service. Awareness should be raised among all stakeholders, including SMEs, and proper guidance or guidelines for the safe construction and handling of elevated steel water tanks should be established to help and guide them.

4. The incident showed that emergency preparedness should include a programme that covered external sources of hazards, such as neighbouring facilities, which could have a serious impact. Both the owner and the adjacent tenants should not underestimate the importance of a robust emergency response plan that would cover various emergency scenarios.

5. Learning from incidents like this should prompt companies to reassess and enhance their safety measures continually. Regular training programmes, risk assessments and feedback mechanisms should be integral to a safety-oriented culture. The tragedy serves as a sad reminder that pursuing industrial progress must always be accompanied by an unwavering commitment to the safety and well-being of workers and the surrounding community. By learning from such incidents and implementing corrective measures, industries can strive to prevent similar tragedies.

All manufacturing industries with installations of structures and elevated water storage tanks must engage a Professional Engineer to ensure the design is in accordance with established standards and the fabrication must also adhere to similar standards. This incident is a stark reminder of the importance of rigorous safety standards in industrial settings. Proper documentation of construction projects, particularly those involving critical

infrastructure such as water tanks, is essential to prevent such accidents and to safeguard workers’ lives. This highlights the urgent need for the stakeholders to ensure that any construction or design of any structure with dynamic loads, such as water storage, shall be designed and constructed correctly and to remind regulatory bodies to enforce stringent safety measures across all industries to protect everyone from similar potential hazards. Any design-related document shall be kept available for inspection by any person who may need them and must comply with the recently published Occupational Safety & Health (Construction Work) (Design and Management) Regulations 2024.

Prepared by:

Ir. Tajul Ariffin Mohamed Nori

Chairman of the Safety in Engineering Special Interest Group (SESIG), IEM, is attached to Forensic Engineering, DOSH Malaysia.

Webinar Talk on Introduction to Energy Storage Solutions

Date : 11 July 2024 (Thursday)

Time : 10.00 a.m. - 12.00 p.m.

Venue : Digital Platform

Approved CPD : 2

Speaker : Mr. Mohd Isyraq Yussof

Physical Digital Class “Crafting the Future: A Maker’s Journey into Innovation and Creation”

Date : 13 July 2024 (Saturday)

Time : 11.00 a.m. - 1.00 p.m.

Venue : Digital Platform

Approved CPD : 2

Speakers : Ir. Lee Mun Poh : Ir. Chee Shai Choon : Ir. Chai Chen Sing : Ir. Yasser Asrul

IEM Golf Tournament 2024

Date : 17 July 2024 (Wednesday)

Time : 6.00 a.m. - 2.00 p.m.

Venue : Kelab Golf Perkhidmatan Awam (KGPA), Jalan Damansara, Bukit Kiara, 60000 Kuala Lumpur

2nd Safety in Engineering Symposium (SES 2024)

Date : 17 July 2024 (Wednesday)

Time : 9.00 a.m. - 5.30 p.m.

Venue : Dorsett Grand Subang, Jalan SS 12/1, Ss 12, 47500 Subang Jaya, Selangor

Approved CPD : 7

Speaker : Various

As potable water is an essential commodity, it is usually stored within the housing premises and is available on tap for the convenience of the residents. The Uniform Technical Guidelines (UTG) issued by Suruhanjaya Perkhidmatan Air Negara (SPAN) lists the amount of water to be stored per day for various types of occupancy. In the case study of a highrise apartment, the amount would be 1,000 litres/unit for flats with shared storage cisterns.

A medium end 24-storey condominium with 6 units per floor would require 144,000 litres. The normal practice is that 1/3 of this amount will be on ground level, connected to the local water authority water supply, while 2/3 will be at roof level. Water from the roof is delivered to all the units via gravity but, due to insufficient pressure, a booster pump may be required to deliver water to the top 2 uppermost floors.

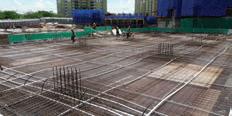

Two thirds of 144,000 litres means 95,000 litres are stored on the roof; Glass Reinforced Plastic (GRP) or Fibreglass Reinforced Plastic (FRP) storage tanks are commonly used to store the water. There are a few available sizes for the side panel of the FRP tank: Assuming it’s 1m x 1.5m and configured to 4.5m height, the tank would measure 5m x 5m x 4.5m, giving a total of 112 sq m; any additional volume is due to the configuration of the tank.

An FRP tank comes with a 5-year warranty if it’s fully exposed to direct sunlight or 10 years if it’s in the shade. This means the life span of the FRP tank depends on whether it’s exposed to the various hazards. It will eventually have to be replaced or it is at risk of bursting. SPAN also approves the use of High-Density Polyethylene tanks which have heat joints on the moulded sections to form round tanks.

In the case study in this article, the water storage tank was located on the reinforced concrete rooftop of 24-storey building. There was the possibility of the HDPE and FRP wall panel giving way due to the following reasons:

1. Exposure to direct or indirect ultraviolet light on the plastic component of the GRP/FRP tank. Reference provided a general statement and failure was inevitable.

2. The tank was subjected to daily differential temperatures in the afternoon and at night. This resulted in the expansion and contraction of the tank wall, eventually weakening it. However, the internal support structure would be able to restraint the movement to reduce the stress points. In the case of Polypropylene Random (PPR) plastic, the material has a high co-efficient of expansion of 0.15mm/moC.

3. The tank volume varied daily. In theory, it should gradually reach the lowest volume during the day and, during the night, it would fill up to reach maximum volume by morning. Such a daily cycle would exert stress within the tank and weaken the panels. Reference: Google Search on how long FRP can last. Answer: FRP can last for a very long time due to its corrosion resistance and UV stability. So FRP products are expected to last at least 20-25 years.

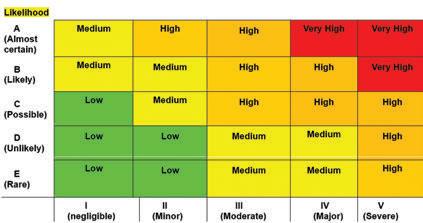

Risk Assessment of an Elevated FRP/GRP/ HDPE Water Storage on Rooftop

With reference to the Risk Matrix, it can be concluded from the above evaluation that the water tank is almost certain to burst, especially if the tank is old. The consequences are severe as the water will be falling from a 24-storey building, leaving a deep depression on the ground. If there are people and assets in the vicinity, then loss of life and assets is almost certain. The risk level is rated as very high.

To support that Very High Risk level, here are some reported incidents of elevated water storage tank which burst and resulted in loss of life and damage to motor vehicles.

1 Sepang Apartment water tank bursts, six vehicles damaged Star publication headline on 28 October 2022

2 Burst Tank on Austin Luxury serviced apartment makes “waterfall” Edge Property headline on the 29 June 2018

3 Apartment wall collapses after water tank bursts

• At 12-storey Pangsapuri Cheras Utama, sending broken concrete slabs crashing to the ground. A Proton Wira and a motorcycle parked below were also damaged.

4 At Bukit Chagar flat in Johor Bahru, some 527,300 litres of water gushed out from a burst tank atop the 16-storey Block C; a teenager died and 17 people were injured.

The Sun headline on 2 May 2017

19 November 1993

Where existing FRP tanks are concerned, the perimeter wall (generally a brick wall) will not be able to withstand the sudden force from a burst water tank if it is close to the tank. If the tanks are located a sufficient distance away, there will be no possibility of the brick wall collapsing should the water tank burst but this can only be determined by an engineer who is provided with the relevant data.

For new constructions, the M&E consultant must liaise with C&S consultant with regard to the location of the rooftop water tank and the distance from the roof perimeter wall. An erected reinforced concrete wall should retain the water within the roof wall though subsequently the water will flood the floor units below. This is an inherent risk which cannot be mitigated. Under the OSHCIM Regulations which will come into effect soon, it is the responsibility of the M&E consultant to evaluate all risks in the design of M&E systems in a building and to put in control measures such as an RC wall to mitigate the risk if the distance is too close to withstand the force from a burst tank.

Nehemiah-OVM provides the following products and services:

- Post-tensioning solution provider

- Carpark Flat Slab

- Transfer Plate

- Beams, Box Girders

- Alternative design solutions

- Cable systems (stay cable, main cable, hanger)

- Bridge bearing and expansion joint

- Construction solutions (heavy lifting, ILM, etc)

- Monitoring, repairing and strengthening for structures

Nehemiah Prestress Sdn Bhd (1140945-A)

No. 45-3, Jalan PJU 5/20

The Strand, Kota Damansara 47810 Petaling Jaya Selangor Darul Ehsan

Tel : 603 6142 6638

Fax : 603 6142 6693

Email : enquiry-pt@nehemiah-grp.com

Any liquid, in this case water, which is kept inside a nonpressurised tank and is of substantial volume, may burst due to the various hazards that the tank may be subjected to as listed above. If the tank is located on a rooftop of a 24-storey building, the consequences will be severe as shown in the incidents reported.

An FRP tank is said to last 20-50 years. Many of our buildings are reaching the 20-year mark, so should these tanks be replaced as a mitigation measure or do we wait till the tank bursts and hope the consequences would not be severe? The authorities should be allowed to issue directives to replace such tanks.

Prepared by:

Ir. Gary Lim Eng Hwa

A member of the Building Services Technical Division (BSTD), Safety in Engineering Special Interest Group (SESIG) and the Fire Advisory Board of the IEM. He is a Professional Engineer registered with the Board of Engineers, Malaysia and a Fellow of IEM.

Webinar Talk on Managing Big Projects

Date : 18 July 2024 (Thursday)

Time : 2.00 p.m. - 4.00 p.m.

Venue : Digital Platform

Approved CPD : 2

Speaker : Assoc. Prof. Dr Ab. Rahman bin Abdul Rahim

Webinar Talk on Introduction to Fixed Offshore Structures

Date : 20 July 2024 (Saturday)

Time : 9.00 a.m. - 11.00 a.m.

Venue : Digital Platform

Approved CPD : 2

Speaker : Ts. Angeline Ng Sok Mooi

15th Annual General Meeting of Consulting Engineering Special Interest Group, IEM

Date : 20 July 2024 (Saturday)

Time : 11.00 a.m. - 1.00 p.m.

Venue : Wisma IEM

Approved CPD : 2

10th Annual General Meeting of the Seniors Special Interest Group, IEM (SSIG)

Date : 20 July 2024 (Saturday)

Time : 11.00 a.m. - 1.00 p.m.

Venue : Wisma IEM

Approved CPD : 2

One-Day Course on Work Breakdown Structure for Project Scope Management

Date : 22 July 2024 (Monday)

Time : 9.00 a.m. - 5.00 p.m.

Venue : Digital Platform

Approved CPD : 7

Speaker : Ir. Assoc. Prof. Dr Abang Annuar Ehsan

Half-Day workshop on “Exploring Control Systems: A Comprehensive Guide for Engineering Students and Engineers”

Date : 27 July 2024 (Saturday)

Time : 9.00 a.m. - 1.00 p.m.

Venue : Digital Platform

Approved CPD : 4

Speaker : Ir. Sukhairul Nizam

11th Women Engineer Section AGM

Date : 27 July 2024 (Saturday)

Time : 9.00 a.m. - 11.00 a.m.

Venue : Digital Platform

Approved CPD : 2

Technical Visit to IJM IBS Sdn. Bhd.

Date : 30 July 2024 (Tuesday)

Time : 9.00 a.m. - 1.00 p.m.

Venue : IJM IBS Sdn. Bhd. (Bestari Jaya), Jalan Rawang, 45600 Batang Berjuntai, Selangor

Approved CPD : 3

In Malaysia, introducing a USB digital acceleration sensor for vibration monitoring is a first step toward digitising measurement, particularly in improving IR4.0. Recording vibration measurements using a USB digital accelerometer works similarly to recording audio input through a microphone. The USB digital accelerometer - which has a broad frequency range, high resolution and plug-and-play concept and is aimed at industrial use - has its benefits.

Nevertheless, condition monitoring companies in Malaysia continue to use traditional voltage-base (analog) accelerometers. However, this analog accelerometer requires expensive data acquisition hardware and is inconvenient for on-site analysis or in-situ measurements.

USB accelerometers offer several advantages. They can connect directly to a computer or compatible device without extra hardware, making the setup more straightforward and requiring fewer components. Additionally, their small, light design makes them easy to carry, perfect for field measurements or adding to wearable devices. They are a cost-effective solution compared to traditional setups. Traditional setups require separate accelerometers and data acquisition systems, resulting in higher costs. This price difference is illustrated in the author’s procurement experience: While a piezoelectric accelerometer and accompanying data acquisition

system can cost around RM12,000.00, a USB accelerometer from PCB Electronic can be acquired for approximately RM5,000.00.

Moreover, USB accelerometers are designed to connect to standard USB ports easily, ensuring compatibility with a wide range of devices, from laptops and tablets to embedded systems. This compatibility boosts the versatility of USB accelerometers, making them suitable for various applications across different platforms. Users can perform measurements with USB accelerometers and the data can be recorded and analysed using software provided by the manufacturer or by developing custom software using programming languages such as LabVIEW, Python, C/C++, or MATLAB, depending on the specifications and interface protocols of the device.