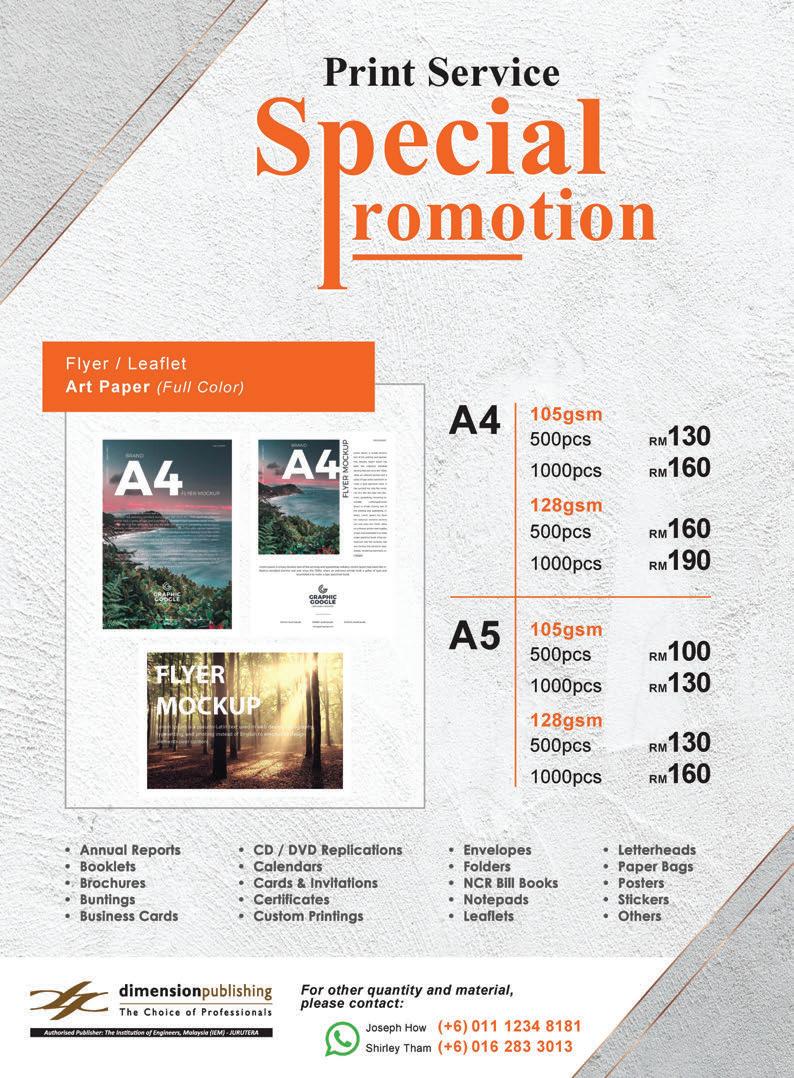

3,200/page RM 3,200/page

Full-Page, Full-Colour Advertisement

This one-time-only special rate o er is for new advertisers.

Space availability is subject to booking on a first-come-first-served basis.

Clients will provide ready-to-print artwork in PDF format with 300dpi.

Full page: 210mm x 285mm, 5mm extra bleed sizes for 4-sided with crop mark.

Advertising space must be utilised before 30 June 2024.

*Please note that the above rate will be subjected to 6% SST. For overseas advertisers, an additional 25% will be charged.

Rate shown above excludes 15% advertising agency commission.

Payment term: Full advance payment.

Artwork submission deadline is on (or before) the 1st week of the prior month of publication. After the material deadline, no cancellation or alteration to the advertisement will be entertained.

Any cancellation after signing the advertising order will result in a 50% penalty charge.

The publisher reserves the right to edit, revise or reject any advertisement deemed unsuitable or inappropriate. •

JURUTERA has an estimated readership of 200,000 professionals. Our esteemed readership consists of certi ed engineers, decision making corporate leaders, CEOs, government o cials, project directors, entrepreneurs, project consultants, engineering consulting rms and companies involved with engineering products and services. Circulation & Readership Pro le

MAJLIS BAGI SESI 2023/2024 (IEM COUNCIL SESSION 2023/2024)

YANG DIPERTUA / PRESIDENT

Ir. Prof. Dr Norlida bt Buniyamin

TIMBALAN YANG DIPERTUA / DEPUTY PRESIDENT

Ir. Prof. Dr Jeffrey Chiang Choong Luin

NAIB YANG DIPERTUA / VICE PRESIDENTS

Ir. Mohd Khir bin Muhammad, Ir. Ts. Prof. Dr Tan Chee Fai, Ir. Abdul Razak bin Yakob,

Ir. Yau Chau Fong, Ir. Dr Siti Hawa binti Hamzah, Ir. Fam Yew Hin, Ir. Chen Harn Shean

SETIAUSAHA KEHORMAT / HONORARY SECRETARY

Ir. Prof. Dr Zuhaina binti Zakaria

BENDAHARI KEHORMAT / HONORARY TREASURER

Ir. Assoc. Prof. Dr David Chuah Joon Huang

BEKAS YANG DIPERTUA TERAKHIR / IMMEDIATE PAST PRESIDENT

Ir. Ong Ching Loon

BEKAS YANG DIPERTUA / PAST PRESIDENTS

Y.Bhg. Academician Tan Sri Datuk Ir. (Dr) Ahmad Zaidee bin Laidin, Y.Bhg. Dato’ Paduka Ir. Hj. (Dr) Keizrul bin Abdullah, Y.Bhg. Tan Sri Dato’ Seri Academician Ir. Professor Emeritus Dr Chuah Hean Teik, Y.Bhg. Dato’ Ir. Lim Chow Hock, Ir. Dr Tan Yean Chin

WAKIL AWAM / CIVIL REPRESENTATIVE

Ir. Tu Yong Eng

WAKIL MEKANIKAL / MECHANICAL REPRESENTATIVE

Ir. Ng Yong Kong

WAKIL ELEKTRIK / ELECTRICAL REPRESENTATIVE

Ir. Mohd. Aman bin Hj. Idris

WAKIL STRUKTUR / STRUCTURAL REPRESENTATIVE

Ir. Dr Tan Kuang Leong

WAKIL KIMIA / CHEMICAL REPRESENTATIVE

Ir. Dr Chong Chien Hwa

WAKIL LAIN-LAIN DISPLIN / REPRESENTATIVE TO OTHER DISCIPLINES

Ir. Assoc. Prof. Dr Wong Yew Hoong

WAKIL MULTIMEDIA DAN ICT / ICT AND MULTIMEDIA REPRESENTATIVE

Ir. Assoc. Prof. Dr Lai Khin Wee

WAKIL JURUTERA WANITA / WOMEN ENGINEERS REPRESENTATIVE

Ir. Noorfaizah binti Hamzah

WAKIL BAHAGIAN JURUTERA SISWAZAH / YOUNG ENGINEERS SECTION REPRESENTATIVES

Mr. Muhammad Ashiq Marecan bin Hamid Marecan, Grad. IEM, Mr. Lim Yiren, Mr. Darshan a/l Balasubramaniam, Grad. IEM, Mr. Ooi Wei Chien, Grad. IEM, Ms. Ong Ye Shian, Grad. IEM AHLI - AHLI MAJLIS / COUNCIL MEMBERS

Ir. Dr Vigna Kumaran a/l Ramachandaramurthy (casual vacancy for Ir. Dr Siti Hawa binti Hamzah for 1 session), Ir. Assoc. Prof. Dr Lee Tin Sin, Ir. Mah Way Sheng, Ir. Sreedaran Raman, Ir. Lee Cheng Pay, Ir. Dr Kannan a/l M. Munisamy, Ir. Dr Siow Chun Lim, Ir. Wong Chee Fui, Ir. Ts. Assoc. Prof. Dr Hum Yan Chai, Ir. Tiong Ngo Pu, Ir. Rusnida binti Talib, Ir. Prof. Dr Lau Hieng Ho, Ir. Dr Muhammad Azmi bin Ayub, Ir. Arul Hisham bin Abdul Rahim (casual vacancy for Ir. Fam Yew Hin - for 2 sessions), Ir. Razmahwata bin Mohd Razalli, Ir. Simon Yeong Chin Chow, Ir. Dr Chan Seong Phun, Ir. Yam Teong Sian, Ir. Kwok Yew Hoe, Ir. Dr Lee Choo Yong, Ir. Sharifah Azlina binti Raja Kamal Pasmah, Ir. Ts. Dr Wan Syakirah binti Wan Abdullah, Ir. Dr Mui Kai Yin, Ir. Shamil bin Abu Hassan, Ir. Wan Rizaluddin Abdullah bin Wan Ali, Ir. Prof. Dr Lam Wei Haur (casual vacancy for Ir. Prof. Dr Zuhaina bt Zakaria for 3 sessions) AHLI - AHLI MAJLIS JEMPUTAN / COUNCIL MEMBERS BY INVITATION

Ir. Lai Sze Ching, Ir. Gopal Narian Kutty, Y.Bhg. Dato’ Prof. Ir. Dr Mohd Hamdi bin Abd Shukor PENGERUSI CAWANGAN / BRANCH CHAIRMAN

1. Pulau Pinang: Ir. Chan Wah Cheong

2. Selatan: Ir. Thayala Rajah s/o Selvaduray

3. Perak: Ir. Assoc. Prof. Dr Nursyarizal bin Mohd Nor 4. Pahang: Ir. Ab Rahman bin Hashim

5. Kedah-Perlis: Ir. Roshasmawi bin Abdul Wahab

6. Negeri Sembilan: Ir. Shahrin Amri bin Jahari

7. Kelantan: Ir. Ts. Hj. Abrizan bin Abdul Kadir

8. Terengganu: Ir. Mazlan bin Che Ku Ahmad

9. Melaka: Ir. Ong Yee Pinn

10. Sarawak: Ir. Sim Hui Kheng, Stephanie

11. Sabah: Ir. Chin Tet Fu, Willy

12. Miri: Ir. Chong Boon Hui

AHLI JAWATANKUASA INFORMASI DAN PENERBITAN/ STANDING COMMITTEE ON INFORMATION AND PUBLICATIONS 2023/2024

Pengerusi/Chairman: Ir. Abdul Razak bin Yakob Naib Pengerusi/Vice Chairman: Ir. Dr Siow Chun Lim Setiausaha/Secretary: Ir. Ts. Assoc. Prof. Dr Hum Yan Chai Ketua Pengarang/Chief Editor: Ir. Abdul Razak bin Yakob Pengarang Prinsipal Buletin/ Principal Bulletin Editor: Ir. Razmahwata bin Mohamad Razalli Pengarang Prinsipal Jurnal/Principal Journal Editor: Ir. Ts. Assoc. Prof. Dr Teo Fang Yenn Pengerusi Aplikasi Mudah Alih IEMGo/IEMGo Mobile Application Chairman: Ir. Dr Bhuvendhraa Rudrusamy Pengerusi Penglibatan Ahli/Members Engagement Chairperson: Ir. Rusnida binti Talib Pengerusi Pusat Sumber/Resource Centre Chairman: Ir. Dr Kannan a/l M. Munisamy

Ahli-Ahli/Committee Members: Ir. Ong Guan Hock, Ir. Lee Chang Quan, Ir. Lau Tai Onn, Ir. Dr Oh Seong Por, Ir. Yee Thien Seng, Ir. Dr Lee Choo Yong, Ir. Ts. Dr Tan Kim Seah, Ir. Assoc. Prof. Dr Lee Tin Sin, Dr Sudharshan N. Raman, Grad. IEM, Ms. Michelle Lau Chui Chui, Grad. IEM, Ir. Tu Yong Eng, Ir. Dr Nor Ilia Anisa binti Aris, Mr. Muhd Ashiq Marecan bin Hamid Marecan, Grad. IEM, Mr. Chuah Pei Lim, Grad. IEM

LEMBAGA PENGARANG/EDITORIAL BOARD 2023/2024

Ketua Pengarang/Chief Editor: Ir. Abdul Razak bin Yakob Pengarang Prinsipal Buletin/ Principal Bulletin Editor: Ir. Razmahwata bin Mohamad Razalli Ahli-ahli/Committee Members: Ir. Dr Siow Chun Lim, Ir. Lau Tai Onn, Ir. Ong Guan Hock, Ir. Yee Thien Seng, Ir. Dr Oh Seong Por, Ir. Ts. Assoc. Prof. Dr Teo Fang Yenn, Dr Sudharshan N. Raman, Ir. Tu Yong Eng, Ir. Lee Chang Quan, Ir. Dr Lee Choo Yong, Ir. Ts. Dr Tan Kim Seah, Ms. Michelle Lau Chui Chui, Grad. IEM Secretariat: Janet Lim, Nurul Aida binti Mustafa, Nur Illyarnie binti Rosman

THE INSTITUTION OF ENGINEERS, MALAYSIA Bangunan Ingenieur, Lots 60 & 62, Jalan 52/4, P.O. Box 223, (Jalan Sultan), 46720 Petaling Jaya, Selangor Darul Ehsan. Tel: 603-7968 4001/4002 Fax: 603-7957 7678 E-mail: sec@iem.org.my Homepage: http://www.myiem.org.my

Underwater Inspection of Port and Jetty Structure

Decarbonising Marine Transportation

Welding Procedure Development Concept (Quality, Safety & Metal 3D Printing Perspective)

Inculcating First-Class Maintenance Culture

Exploring the Depths: A Day at Subsea Rover (SSR) Sdn. Bhd.

Exploring Thailand in Ancient City (Muang Boran)

DIMENSION PUBLISHING SDN. BHD. [ 199701034233 (449732-T) ]

Level 18-01, PJX-HM Shah Tower, No. 16A, Persiaran Barat, 46050 Petaling Jaya, Selangor Darul Ehsan, Malaysia.

Tel: +(603) 7493 1049 Fax: +(603) 7493 1047

E-mail: info@dimensionpublishing.com

Website: www.dimensionpublishing.com

CHAIRMAN

ROBERT MEBRUER

CEO/PUBLISHER

PATRICK LEUNG

GENERAL MANAGER

SHIRLEY THAM ● shirley@dimensionpublishing.com

HEAD OF MARKETING & BUSINESS DEVELOPMENT

JOSEPH HOW ● joseph@dimensionpublishing.com

PRODUCTION EDITOR

TAN BEE HONG ● bee@dimensionpublishing.com

CONTRIBUTING WRITERS

PUTRI ZANINA ● putri@dimensionpublishing.com

HANNA SHEIKH MOKHTAR ● hanna@dimensionpublishing.com

SENIOR GRAPHIC DESIGNER

SOFIA HANIS ● sofia@dimensionpublishing.com

GRAPHIC DESIGNER

NICOLE THENG ● nicole@dimensionpublishing.com

ADVERTISING CONSULTANTS

THAM CHOON KIT ● ckit@dimensionpublishing.com

ACCOUNTS CUM ADMIN EXECUTIVE

YEN YIN ● yenyin@dimensionpublishing.com

For advertisement placements and subscriptions, please contact: DIMENSION PUBLISHING SDN. BHD. [ 199701034233 (449732-T) ]

Level 18-01, PJX-HM Shah Tower, No.16A, Persiaran Barat, 46050 Petaling Jaya, Selangor Darul Ehsan, Malaysia.

Tel: +(603) 7493 1049 Fax: +(603) 7493 1047 E-mail: info@dimensionpublishing.com

Subscription Department E-mail: info@dimensionpublishing.com

JURUTERA is published and printed monthly by Dimension Publishing Sdn. Bhd.

JURUTERA MONTHLY CIRCULATION: OVER 50,000 MEMBERS

Submission or placement of articles in JURUTERA could be made to the:Chief Editor

THE INSTITUTION OF ENGINEERS , MALAYSIA (IEM) Bangunan Ingenieur, Lots 60 & 62, Jalan 52/4, P.O. Box 223 (Jalan Sultan), 46720 Petaling Jaya, Selangor. Tel: +(603) 7968 4001/4002 Fax: +(603) 7957 7678 E-mail: pub@iem.org.my or sec@iem.org.my IEM Website: http://www.myiem.org.my

© 2023, The Institution of Engineers, Malaysia (IEM) and Dimension Publishing Sdn. Bhd.

PUBLICATION DISCLAIMER

The publication has been compiled by both IEM and Dimension with great care and they disclaim any duty to investigate any products, process, services, designs and the like which may be described in this publication. The appearance of any information in this publication does not necessarily constitute endorsement by IEM and Dimension. There is no guarantee that the information in this publication is free from errors. IEM and Dimension do not necessarily agree with the statement or the opinion expresssed in this publication.

COPYRIGHT

JURUTERA Bulletin of IEM is the official magazine of The Institution of Engineers, Malaysia (IEM) and is published by Dimension Publishing Sdn. Bhd. The Institution and the Publisher retain the copyright over all materials published in the magazine. No part of this magazine may be reproduced and transmitted in any form or stored in any retrieval system of any nature without the prior written permission of IEM and the Publisher.

Decarbonising marine transport is an imperative step towards mitigating climate change and reducing the environmental impact of the shipping industry as this sector is responsible for a significant portion of global greenhouse gas emissions, primarily due to the use of fossil fuels in its vessels.

To achieve decarbonisation, various strategies are being pursued. First and foremost is the transition to alternative fuels and propulsion technologies. This includes the adoption of cleaner options such as Liquefied Natural Gas (LNG), biofuels and hydrogen as well as the development of electric and hybrid propulsion systems. Additionally, optimising vessel design and improving operational efficiency can significantly reduce emissions.

International regulations, like the International Maritime Organisation’s (IMO) strategy to reduce greenhouse gas emissions, are pushing the industry to embrace these changes. Carbon pricing mechanisms and incentives for sustainable practices are also being considered.

Collaboration among industry stakeholders, governments and researchers is essential for the successful decarbonisation of marine transport. With innovation, regulation and cooperation, the shipping sector can play a pivotal role in achieving global climate goals while ensuring the continued movement of goods across the oceans.

This month’s JURUTERA features Ts. Hazrool Rizal bin Abdul Rahim, Senior Assistant Director of the Maritime Industry Control Division, Malaysia Marine Department (MMD). Enjoy!

by Ir. Razmahwata bin Mohamad Razalli Principal Bulletin Editor

The IT Department in IEM comprises four staff members who handle everything related to IEM’s computing infrastructure. They also do forward-facing interfaces and processes for members and the public which include the website, social media, balloting and forms.

The COVID pandemic forged them into virtual space maestros as this was critical to move IEM quickly into the virtual arena as well as to arrange hybrid meetings and activities. In addition, they have also become a source of income for IEM by outsourcing their expertise in arranging hybrid events with external organisations. “Nos salutant vos” (We salute you).

In 2018, the International Maritime Organisation set an ambitious goal to cut greenhouse gas (GHG) emissions in ships by at least 50% by 2050. Ships emit more than one billion tons of GHG or nearly 3% of emissions worldwide, so maritime decarbonisation is critical to decarbonising the global economy as a whole. To do this means steering away from the use of standard petroleum-based fuels such as diesel in favour of LNG and biofuels.

In May 2019, the Norwegian government and the IMO established the Green Voyage 2050 Project to move the industry to a lowercarbon future and Malaysia was accepted as a Pioneer Pilot Country. Ts. Hazrool Rizal bin Abdul Rahim, Senior Assistant Director of the Maritime Industry Control Division, Malaysia Marine Department (MMD), tells JURUTERA that though Malaysia is on the right track in maritime decarbonisation, a lot remains to be done.

Ts. Hazrool Rizal bin Abdul Rahim is Senior Assistant Director at Malaysia Marine Department’s Maritime Industry Control Division. He oversees maritime governance, inspections, issuance of statutory certificates, and ensuring safety compliance. As a frequent representative at IMO conferences, he ensures adherence to international maritime standards. He is a distinguished speaker at various maritime conferences locally and internationally. With a pivotal role in ship assessment, pollution prevention, and service quality, Hazrool is a dedicated professional.

Can you provide an overview of the status of GHG emissions from the marine and shipping industry in Malaysia and the ASEAN region? In 2022, the Malaysia Marine Department (MMD) joined the Green Voyage 2050 (GV2050) Project as a Pioneer Pilot Country. Other participating countries are Azerbaijan, Belize, China, Cook Islands, Ecuador, Georgia, India, Kenya, Malaysia, Solomon Islands, South Africa and Sri Lanka. The project was established in May 2019 as a collaboration between the Norwegian government and the International Maritime Organisation (IMO) to move the industry to a lower-carbon future ( https://greenvoyage2050.imo.org/ partnering-countries/).

The Ministry of Transport will focus on sustainable energy transition for the shipping industry as part of efforts to achieve net zero emissions by 2050. On 22 June 2023, the Task Force GV2050 presented the Report on the Implementation of GV2050.

Malaysia’s GV2050 journey began after the Port of Tanjung Pelepas (PTP) in Gelang Patah, Iskandar Puteri, Johor, was picked to spearhead the Green Tug and Pilot Boat as a pioneer pilot project for the country. There are four main components.

1. Developing global tools to support the implementation of the initial IMO GHG Strategy.

2. Capacity building, policy and National Action Plan development.

3. Strategic partnership development.

4. Technology cooperation, innovation and pilot demonstrations.

MMD is also joining MEPSEAS in Phase 2 of the IMO-Norad (Norwegian Agency for Development Cooperation) collaboration to protect the seas from the negative effects of ships and shipping by working with 7 countries in SouthEast Asia. MEPSEAS envisaged that countries would implemented their chosen convention by the end of the project in 2021 and to put longterm plans in place to ensure the protection of the seas in South-East Asia in the future.

GHG Emissions: The marine and shipping industry is a significant contributor to global GHG emissions. It primarily emits carbon dioxide (CO2) but also releases other pollutants such as sulphur dioxide (SO2) and nitrogen oxides (NOX).

Malaysia’s Marine & Shipping Industry: Malaysia has a substantial shipping industry due to its strategic location in South-East Asia and its reliance on maritime trade. The Malaysian Maritime Enforcement Agency (MMEA) and the MMD are responsible for regulating and overseeing maritime activities in its waters. Major ports such as Port Klang, Penang Port and Johor Port handle a significant portion of regional trade. The Green Port Policy was implemented by the Johor Port Authority (https://www. lpj.gov.my/index.php/en/corporate/ green-port-policy).

ASEAN: There are 10 member countries: Brunei, Cambodia, Indonesia, Laos, Malaysia, Myanmar, the Philippines, Singapore, Thailand and Vietnam. The maritime industry plays a crucial role in facilitating trade and economic development in ASEAN countries and the region is a vital hub for global trade, with many busy shipping routes.

GHG Emissions: The industry contributes to global GHG emissions, but the exact contribution depends on factors such as the type of ship, fuel used and the volume of shipping activities. Shipping emissions are often measured in terms of “bunker fuels” and are a significant source of CO2 emissions globally. The industry faces growing pressure to reduce GHG emissions and efforts to do so include initiatives such as the IMO’s sulphur cap regulations and the push for cleaner, more efficient ship designs.

In November 2020, PETRONAS launched its Liquefied Natural Gas (LNG) bunkering business by completing its first LNG bunkering operation in Pasir Gudang, Johor. Collaborating with Titan LNG, a leading LNG bunkering solution provider in Europe, this involved a ship-to-ship LNG bunkering transfer from MV Avenir Advantage, its first LNG Bunkering Vessel (LBV) to SIEM Aristotle.

Scope of MMD: The MMD is responsible for maritime functions, including vessel registration, maritime safety, navigation and enforcement of maritime laws. It played a role in implementing and enforcing international regulations related to emissions reduction, such as the IMO’s MARPOL Annex VI regulations, which set emission standards for ships. It also comes up with notices i.e. for the implementation of Green Align with IMO:

1. Scrubber: chrome-extension:// efaidnbmnnnibpcajpcglclefindmkaj/https://www.marine.gov.my/ jlm/admin/assets/uploads/files/notis/e6094-msn072019.pdf

2. BWMC: chrome-extension://efaidnbmnnnibpcajpcglclefindmkaj/ https://www.marine.gov.my/ jlm/admin/assets/uploads/files/ notis/27991-npm082017.pdf

3. EEXI & CII: chrome-extension:// efaidnbmnnnibpcajpcglclefindmkaj/https://www.marine. gov.my/ jlm/admin/assets/uploads/files/ notis/60b96-msn082023.pdf

What are the key challenges for the maritime sector in its decarbonisation efforts?

Like many other regions globally, the maritime sector in Malaysia faces several key challenges such as:

High Capital Costs: Transitioning to cleaner and more sustainable technologies in the maritime sector often requires significant upfront investments in new vessels, technologies, and infrastructure. Many shipowners and operators may be reluctant to make these investments due to the high capital costs involved.

Lack of Incentives: The availability of financial incentives and subsidies for adopting green technologies and practices is limited in many regions, including Malaysia. Without proper incentives, shipowners may be less motivated to invest in decarbonisation efforts.

Limited Infrastructure: There is limited infrastructure supporting alternative fuels and technologies, such as LNG bunkering facilities or electric charging stations for ships.

Expanding this will require significant investment and planning.

Regulatory Challenges: Adhering to international and domestic regulations related to emissions and environmental standards can be complex and costly. Shipowners must navigate a web of regulations and noncompliance may result in penalties.

Technological Readiness: Many green technologies, such as hydrogen or ammonia-powered ships, are still in the experimental stages. Stakeholders may be hesitant to adopt these technologies until they are proven to be reliable and cost-effective.

Cultural Resistance: There may be resistance within the industry to change long-standing practices and to adopt new technologies and operational procedures.

Trade-Offs with Efficiency: Improving environmental performance often comes with trade-offs in terms of operational efficiency. Shipowners may be concerned that adopting cleaner technologies will reduce the competitiveness and profitability of their vessels.

Global Nature of Shipping: The global nature of the industry means that international cooperation and coordination are essential for effective decarbonisation efforts. The lack of a unified global approach may slow down progress.

Economic Uncertainty: Fluctuating fuel prices and market conditions make it challenging for shipowners to commit to long-term investments in green technologies.

Data Collection & Reporting: Monitoring and reporting emissions data accurately can be challenging;

some vessels may lack the necessary equipment or systems to do so.

To address these, the MMD and industry stakeholders can consider implementing a combination of regulatory measures, incentives and industry initiatives such as providing financial incentives for green investments, developing infrastructure for alternative fuels, streamlining regulatory compliance, promoting research and development in green technologies and fostering international cooperation to align decarbonisation efforts.

Are there existing regulations or policies in Malaysia or ASEAN to address carbon emissions from the shipping industry?

There have been efforts made in Malaysia and ASEAN countries to address carbon emissions from the shipping industry. However, the effectiveness of these regulations and policies may have changed since then.

In 2018, IMO introduced the Initial IMO GHG Strategy, which defines the objectives, tools, pace of work and guiding principles as the framework for Member States to decarbonise shipping. ASEAN countries are expected to align with these regulations.

Malaysia has been working to implement and enforce regulations related to the protection of marine environments. While some may not explicitly address carbon emissions, they contribute indirectly to reducing the environmental impact of shipping operations.

MMD has also conducted seminars addressing environmental issues, including carbon emissions. ASEAN nations have cooperated on various environmental initiatives and there are discussions on

harmonising regulations related to the maritime sector.

What are the on-going initiatives or projects aimed at reducing carbon emissions in the maritime industry within Malaysia and the ASEAN region?

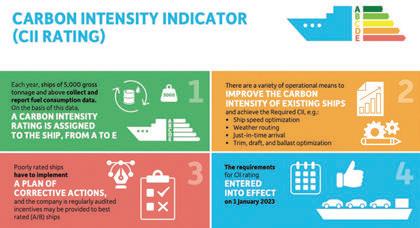

ASEAN countries often collaborate on environmental issues, including GHG emissions reduction in the shipping industry. The IMO has introduced a series of regulations to reduce GHG emissions from the global shipping industry, i.e., Marpol Annex VI (CII) and Malaysia is required to adhere to these regulations.

Meanwhile, shipping companies and organisations in the region are implementing the Ship Energy Efficiency Management Plan (SEEMP) as per IMO requirements. SEEMPs are designed to improve the energy efficiency of vessels and these involve measures such as optimising ship speed, hull cleaning and using energyefficient technologies. They have also begun exploring the use of LNG and biofuels as these produce fewer GHG emissions than traditional fuels.

On shore, ports are upgrading infrastructure to accommodate more energy-efficient vessels and to reduce waiting times while research institutions and industry stakeholders are conducting R&D

projects focused on improving the energy efficiency of ships, developing cleaner propulsion technologies and exploring innovative solutions to reduce emissions.

To track and manage carbon emissions, some shipping companies have implemented emissions monitoring and reporting systems to help them to identify areas for improvement and to reduce their carbon footprint.

How are industry stakeholders collaborating to promote decarbonisation efforts?

It is important that stakeholders, such as shipowners, operators and ports, collaborate to promote decarbonisation efforts; various initiatives and partnerships have emerged to address this challenge, including using low-sulphur fuel, slower travel time, incorporating a ballast free system, using LNG, implementing exhaust scrubber system/sulphur scrubber system, using a speed nozzle to save fuel, applying the best anti-fouling hull paint and using wind energy with the Kite-Sail and Rig-Sail systems.

IMO has been working closely with member states and industry stakeholders to implement measures such as Energy Efficiency Existing Ship Index (EEXI) and the Carbon Intensity Indicator (CII) to improve ship efficiency and reduce emissions. It will be implemented globally in July 2024.

Associations such as Malaysia Shipowners’ Association represent the interests of shipowners and operators. They actively engage in discussions and initiatives related to decarbonisation and advocate for industry-wide commitments and actions.

Ports play a crucial role and many are investing in infrastructure to support the charging and refuelling of low-carbon or electric ships. They are also working on optimising operations to reduce emissions within their boundaries.

Financial institutions are also considering the environmental criteria when approving loans/investments. Conferences, working groups and publications facilitate the sharing of

best practices, data and experiences among industry stakeholders. This helps accelerate the adoption of decarbonisation measures. Successful collaborations include the adoption of LNG as a transitional fuel, the development of hydrogen-powered vessels and the increased use of windassisted propulsion technologies. However, it’s important to note that challenges remain, such as the high cost of green technologies and the need for regulatory harmonisation on a global scale.

Name technological advancements or innovations to make vessels and shipping operations more environmentally friendly

The following initiatives are primarily driven by the need to reduce GHG emissions, improve fuel efficiency and minimise the environmental impact of maritime transportation.

a. LNG-Powered Ships: LNG is a cleaner alternative to traditional fuels, emits fewer pollutants and has lower GHG emissions.

b. Hybrid and Electric Propulsion: Some ships are adopting hybrid or fully electric propulsion systems using batteries and electric motors, particularly in smaller vessels and ferries (https://www.manifoldtimes. com/news/malaysias-first-hybridbattery-offshore-supply-vessel-willbe-designed-to-abs-rules/).

c. Wind-Assisted Propulsion: Technologies such as Feltner rotors and sail-assisted propulsion systems are being developed to harness wind power and reduce reliance on fossil fuels.

d. Alternative Fuels: Research is ongoing into alternative fuels for maritime application.

e. Energy-Efficient Hull Design: Innovations in hull design, including air lubrication systems and advanced coatings, help reduce resistance through water, improving fuel efficiency.

f. Emission Reduction Systems: Exhaust gas cleaning systems, also known as scrubbers, are being used to remove sulphur and other pollutants from ship emissions, making them compliant with stricter regulations.

g. Digital Technologies: Advanced sensors, data analytics and machine learning are used to optimise operations, route planning and cargo loading.

h. Cold Ironing and Shore Power: Ports are increasingly providing power facilities, allowing ships to turn engines off and use electricity from shore, thus reducing air pollution.

i. Emissions Monitoring & Reporting: Regulations are pushing for improved monitoring and reporting of emissions, which encourages shipping companies to reduce their carbon footprint.

j. Autonomous Shipping: Autonomous vessels can optimise routes, speed and operations more efficiently, potentially reducing fuel consumption and emissions.

k. Ballast Water Treatment: Technologies to treat ballast water, which can introduce invasive species and pollutants to new environments, are becoming more advanced and environmentally friendly.

l. Container Design/Optimisation: Innovative container designs and stacking methods help maximise cargo capacity, so fewer trips are needed which reduces emissions.

m. Environmental Certification & Standards: Organisations such as the IMO have established standards and regulations to promote environmentally friendly practices and technologies.

All these reflect a growing commitment to sustainability in the maritime sector, driven by environmental concerns and regulatory pressures to reduce the carbon footprint. Many are being adopted gradually to achieve sustainable and eco-friendly shipping in the long term.

What roles do alternative fuels and energy sources play?

Liquefied Natural Gas (LNG): LNG is a relatively cleaner fuel with less GHG emissions, sulphur oxides (SOX) and particulate matter. By using LNG, ship operators can comply with

increasingly stringent emissions regulations such as the IMO’s sulphur cap regulations.

Retrofitting existing vessels to run on LNG and incorporating LNG propulsion systems in new ship designs are viable options to reduce emissions and developing LNG bunkering infrastructure is essential to support the adoption of LNG as a maritime fuel.

Hydrogen: When produced from renewable sources or through electrolysis using renewable energy, hydrogen is a zero-emission fuel that can be used to generate electricity for electric propulsion systems, providing a clean and efficient power source for ships. Thus, it is crucial to establish infrastructure for hydrogen production, storage and distribution to enable the adoption of hydrogen as fuel.

Electric Propulsion: Electric propulsion systems, including battery-electric and hybrid-electric systems, can help reduce emissions by using electricity from clean sources or stored energy during lowload operations. Electric propulsion systems offer higher energy efficiency and lower maintenance costs than internal combustion engines. Developing shore power infrastructure will enable ships to connect to the grid and reduce their emissions while docked.

To effectively decarbonise the maritime sector, several factors must be considered. Governments and industry stakeholders must invest in research and development, infrastructure and incentives to make alternative fuels and electric propulsion economically viable. It is essential to develop and implement regulatory frameworks that promote the use of cleaner fuels and technologies while ensuring safety and compliance and to build infrastructure for alternative fuel production, storage and distribution as well as establishing LNG bunkering and hydrogen refuelling facilities at ports.

Collaboration among governments, shipowners, shipbuilders and technology providers is crucial to drive the adoption of alternative fuels and propulsion systems just as training

and educating maritime professionals on the benefits and operation of alternative fuels and technologies is essential for successful implementation.

In conclusion, LNG, hydrogen and electric propulsion can significantly reduce carbon emissions in the maritime sector. However, these require a coordinated effort involving all stakeholders and the government.

How does the shipping industry align with the UN SDGs?

We align with the UN SDGs by addressing environmental, social and economic challenges.

a. SDG 13 (Climate Action): This is one of the most relevant SDGs as the maritime and shipping industry contributes to GHG emissions from the burning of fossil fuels. We need to adopt cleaner fuels, improve vessel efficiency and explore alternative propulsion technologies.

b. SDG 7 (Affordable & Clean Energy): To achieve this we must transition to cleaner energy sources (energyefficient technologies and renewable energy such as wind and solar power).

c. SDG 9 (Industry, Innovation & Infrastructure): Improving infrastructure and fostering innovation can lead to more sustainable practices and technologies. Investments in cleaner and more efficient vessels, port facilities and transportation infrastructure can support this goal.

d. SDG 14 (Life Below Water): Sustainable practices such as preventing oil spills, reducing pollution and protecting marine ecosystems, contribute to the conservation and sustainable use of marine resources.

e. SDG 15 (Life on Land): Reducing the environmental impact of shipping operations by minimising invasive species transportation and preventing pollution, aligns with efforts to protect terrestrial ecosystems.

f. SDG 12 (Responsible Consumption & Production): We can support this SDG by optimising cargo loads, reducing waste as well as

adopting sustainable materials and practices in shipbuilding and maintenance.

g. SDG 11 (Sustainable Cities & Communities): Ports are often located in or near urban areas. Sustainable port operations and integrated transportation systems can contribute to more sustainable and resilient cities and communities.

h. SDG 8 (Decent Work & Economic Growth): Improvements in labour conditions and worker safety align with this goal.

i. SDG 17 (Par tnerships for the Goals): Collaboration between governments, industry stakeholders and international organisations is essential for achieving all the SDGs, including the maritime sector. Partnerships foster knowledge sharing, innovation and the implementation of sustainable practices.

It’s important to note that the alignment of the maritime and shipping industry with the SDGs requires a multi-faceted approach involving regulatory changes, technological advancements and industry-wide collaboration. As climate change and sustainability become pressing concerns, the industry’s decarbonisation efforts play a pivotal role in achieving several SDGs, with SDG 13 being the most immediate and impactful focus area.

Are there any financing mechanisms or incentives to support sustainable and low-carbon shipping practices in the region?

There are but the availability and specifics of these mechanisms vary from one region to another. Businesses can consult relevant government agencies, industry associations and financial institutions.

International organisations and funds, such as the IMO and the Green Climate Fund, may provide financial support for projects aimed at reducing emissions and promoting sustainable shipping practices. Some governments offer subsidies and grants for shipping companies to invest in cleaner, more sustainable

technologies such as retrofitting vessels with emission-reducing technologies or for the construction of more eco-friendly ships.

Apart from this, governments and organisations do provide funding for research and development projects related to sustainable shipping technologies. Businesses can access these resources to develop and test new low-carbon solutions.

Financial institutions, including banks and development organisations, may also provide specialised loan products with favourable terms for projects that contribute to sustainability. These loans will help shipping companies purchase cleaner and more efficient vessels.

Tax credits and deductions can be provided to shipping companies which adopt sustainable practices or invest in low-carbon technologies. These incentives will reduce the tax burden and make green investments more attractive.

Some ports offer fee discounts or incentives to ships that meet specific environmental criteria, such as using cleaner fuels or reducing emissions. These will help lower operating costs for shipping companies.

However, to access these resources and incentives, businesses need to meet eligibility criteria and to follow application processes established by the relevant authorities or organisations. But as policies and incentives can change over time, it’s

essential that businesses stay informed of the latest developments.

What are the most critical steps or initiatives that need to be undertaken to accelerate the decarbonisation of the marine and shipping industry in Malaysia and ASEAN region, particularly in terms the SDGs? Here are some critical steps and initiatives that need to be undertaken to accelerate decarbonisation in this industry:

R&D: Invest in R&D for cleaner and more efficient maritime technologies, including alternative fuels as well as support the development of energyefficient ship designs and propulsion systems, such as wind-assist technologies and electric propulsion.

Renewable Energy: Encourage the use of renewable energy sources in port operations, such as solar panels and wind turbines to power port facilities and docked ships as well as provide financial incentives, tax breaks or subsidies for the adoption of renewable energy solutions.

Green Ports and Infrastructure: Develop green ports with shore power facilities to enable ships to connect to electricity while in port, thus reducing the need for onboard generators. Implement sustainable port infrastructure and practices, including efficient cargo handling and reduced emissions from port equipment.

Regulatory Frameworks: Establish and enforce stringent emissions regulations for ships operating in ASEAN waters, including limits on sulphur and nitrogen oxide emissions. Consider implementing carbon pricing mechanisms, such as a carbon tax or emissions trading scheme.

Building & Training: Provide training and capacity-building programmes for maritime professionals to operate and maintain cleaner and more efficient technologies. Develop educational programmes to raise awareness of the importance of decarbonisation.

Collaboration: Foster collaboration among ASEAN countries to create a unified approach to decarbonisation. Engage with international organisations and partnerships focused on sustainable shipping, such as the IMO and the Getting to Zero Coalition. On the global platform, engage with international partners to address cross-border issues related to shipping emissions and pollution and participate in global efforts to develop and implement low-carbon shipping technologies and practices.

Financial Support and Incentives: Establish green financing mechanisms and incentives for shipowners to invest in cleaner vessels or to retrofit older ones. Promote green bonds and other financial instruments to fund sustainable shipping projects.

Data and Monitoring: Develop a comprehensive data collection and reporting system for tracking emissions in the maritime sector. Use digital technologies like IoT and AI for real-time monitoring of emissions and fuel efficiency.

Public Awareness: Raise public awareness of the environmental impact of shipping and the benefits of decarbonisation. Encourage consumers to choose products and services that prioritise sustainable shipping practices.

A multifaceted approach involving government policies, industry collaboration, technology innovation and public engagement is required to accelerate decarbonisation in the industry. Aligning these efforts with the SDGs can help ensure a

sustainable and prosperous future for the region.

How will international collaborations and partnerships contribute to decarbonisation goals?

International collaborations and partnerships can play a huge role in reducing emissions and transitioning to a more sustainable maritime industry.

Through collaboration, countries and organisations can share data, research and best practices related to maritime emissions reduction as well as information on policy measures and incentives while nations learn from each other’s experiences and adopt effective policies more quickly. This will help identify effective strategies and technologies for reducing carbon emissions. It will also facilitate joint research and development efforts to create innovative, lowcarbon technologies, including the development of cleaner propulsion systems, alternative fuels and more energy-efficient ship designs.

Collaborative efforts can help align international regulations and standards to ensure a level playing field for all stakeholders and to reduce the potential for regulatory arbitrage. It can lead to joint R&D projects to solve common challenges such as projects focused on reducing emissions, enhancing energy efficiency and improving vessel design. Developing countries or regions may lack the expertise and resources needed to adopt lowcarbon technologies. International partnerships can provide training and capacity-building programmes to help them transition to cleaner maritime practices.

International collaboration can attract funding and investments from multiple sources, including governments, international organisations and the private sector to support the development and deployment of green technologies and infrastructure. Collaborative efforts can also lead to economies of scale in the production and deployment of green technologies.

This can reduce costs and make it more affordable for the maritime sector to transition to cleaner options. It will also enable the establishment of international monitoring and reporting mechanisms for maritime emissions which will ensure that countries and organisations are held accountable for their emissions reduction commitments.

Tell us some success stories of effective decarbonisation in the shipping industry from Malaysia or ASEAN, especially with respect to alignment to SDGs

a. Malaysia’s Green Ship Programme: This programme aims to incentivise shipowners to adopt more environmentally friendly technologies and practices, such as cleaner fuels and energyefficient technologies. Aligning with SDG 13, this initiative focuses on reducing the carbon footprint of the industry.

b. Singapore’s Maritime Green Initiative: The Maritime & Port Authority of Singapore (MPA) has launched the Maritime Singapore Green Initiative, which promotes sustainable shipping practices. It includes incentives for ships that meet specific environmental performance standards such as EEXI and CII. This initiative aligns with SDG 13.

c. Indonesia’s Biodiesel in Maritime Transport: Indonesia has been working on utilising biodiesel in its maritime transport sector. Biodiesel from sustainable sources can significantly reduce GHG

emissions. By promoting the use of sustainable biodiesel, Indonesia is making strides in SDGs 13 and 7.

d. ASEAN Framework on Sustainable Shipping: ASEAN is working on a regional framework for sustainable shipping practices aimed at harmonising regulations and standards across member nations, promoting environmental sustainability and supporting SDG 14s and 17.

e. R&D Collaborations: Various universities and research institutions in ASEAN countries are collaborating with international partners to develop and test innovative technologies for decarbonising the shipping industry. These collaborations contribute to advancing SDGs 9 and 17.

f. Green Port Initiatives: Several ports in ASEAN have initiated green port programmes focused on reducing emissions, optimising energy use and promoting sustainable practices within the port facilities. These align with SDGs 13 and 11.

It’s important to note that the success of these initiatives and best practices depends on various factors, including government policies, industry collaboration and technological advancements. As global focus on decarbonisation continues to grow, these examples serve as starting points for addressing sustainability challenges in the maritime and shipping industry in the ASEAN region while aligning with the UN SDGs.

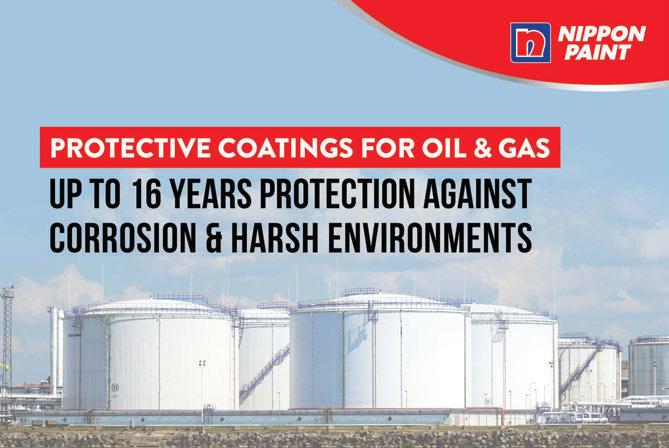

1. Can you please elaborate on the expansion of your business into the oil and gas sector?

Nippon Paint has been providing protective coatings solutions for various industries for over 100 years. The sectors include original equipment manufacturing (OEM), oil and gas, power, infrastructure and industrial, as one of the few companies globally to achieve this milestone. We have certified inspectors by the Institute of Materials Malaysia (IMM) and the Association for Materials Protection and Performance (AMPP). To compete in the market, we have increased our innovative research and development (R&D) to invent solutions. In total, we have 15 R&D centers across Asia, with over 56 years of innovative research.

2. The construction sector contributes a significant impact on social and economic. Does Nippon Paint have any plan to collaborate with organisations in order to penetrate and fulfill the sector?

Recently, we just entered into collaboration with PETRONAS and their Advanced Materials team to use ProShield+, its graphene-based paint additive to expand and improve the quality of our protective coatings for Oil and Gas industry use.

As part of our effort to strengthen the protective coatings business, Nippon Paint offers a new range of products called Nippon Paint 9049 GR which is infused with GrapheneTec+ Technology powered by ProShield+. The product has been launched under a new technology called GrapheneTec+, which anchors on the additive’s ultra-high barrier properties proven capable of strengthen coating’s corrosion resistance against harsh weather conditions and doubling the lifespan of the average coated steel.

GrapheneTec+

is built for the Oil & Gas and heavy industries with excellent corrosion resistance, improved wear resistance and superior thermal stability against harsh weather conditions.

In addition, Nippon Paint has a range of products that conform to the PETRONAS Technical Standards (PTS), while catering to the needs of new construction, maintenance and repair.

We hope that this collaboration will not only widen Nippon Paint’s presence in the coating industry but strengthen its position as a Total Coating & Construction Solutions (TCCS) provider. Moving forward, we look forward to working together with other major corporations in the future.

3. Can you explain how the collaboration with PETRONAS in the Advanced Materials space brings value to the oil and gas industry?

We believe that this collaboration with PETRONAS raises the bar in product innovation to cater to the oil and gas industry’s demands. Through this collaboration, Nippon Paint foresees that it can increase its competitive edge in new markets by enhancing its product innovation to meet evolving market demands.

For instance, with the advanced technology in our new product offering Nippon Paint 9049 GR infused with GrapheneTec+ powered by ProShield+, we are able to reduce the cost of repainting as the additive is formulated for a superior performance of 3x higher corrosion resistance, 3x higher abrasion resistance and 2x longer lasting.

We hope that our product innovation will be able to contribute more value to the oil and gas industry.

4. With the recent collaboration with PETRONAS, how does Nippon Paint contribute to the market segment?

Through our collaboration with PETRONAS, Nippon Paint aims to increase its market share in the B2B Business from 42% to 60% by 2025. This is driven by higher performance and quality coating.

Following that, Nippon Paint aims to enter the global oil & gas market as well as offer a real chance for productivity gains, efficiency improvements, and innovation within this industry.

5. What are the long-term goals of this cooperation with PETRONAS and the prospects presented by Nippon Paint?

The collaboration between Nippon Paint and PETRONAS marks an exciting milestone in the realm of protective coatings for the oil and gas industry, particularly through our innovative GrapheneTec+ technology. The long-term goals of this cooperation are to revolutionise and enhance the performance of protective coatings used in the oil and gas sector. By leveraging our expertise in coatings and PETRONAS’ extensive knowledge of the industry, we aim to develop coatings that provide unmatched durability, corrosion resistance, and operational efficiency, ensuring enhanced protection for critical infrastructure.

Since this is our first collaboration with PETRONAS, we aim to collaborate on programs that are successful and will change the way Nippon Paint scales and expands. Nippon Paint is prepared to lay the proper basis for success that will enable us to grow exponentially and provide PETRONAS and its clients with greater value.

Written and Prepared by:

With USM since 1999, Ir. Ts. Prof. Dr Mohd Rizal Arshad’s fields of expertise are Robotics & Industrial Automations, Measurement & Instrumentation Techniques, Biomedical Electronics & Medical Imaging and Underwater Robotics Technology.

8 years’ experience in design and development robotics systems for Underwater Inspection and Culvert/Sewerage Inspection.

Professor at the Faculty of Ocean Engineering Technology & Informatics in Universiti Malaysia Terengganu since 2008, Director of International

and

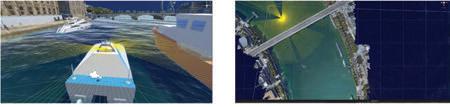

Autonomous surface vehicles (ASVs) and sophisticated data handling and visualisation modules offer a comprehensive solution for port structure inspections. Port inspection refers to the examination of surface structures that are inaccessible for inspection due to location and positioning of the port/ jetty platform. Because of this, there will be limitations for manual inspections.

ASVs are equipped with advanced sensors that improve their efficiency, accuracy and safety. Using them also eliminates the risks and expenses of manual inspections. In addition, their ability to navigate difficult terrain and access remote locations will ensure a more thorough examination, decreasing potential oversights and raising overall operation safety.

By incorporating the artificial intelligence (AI) module, an assurance of enhanced accuracy and reliability in data representation is achieved. The processed data, along with accompanying information, will be translated into a 3D digital model. This model will feature a virtual reality (VR) simulator designed for the ASV and a virtual version of the actual data. The implementation of intelligent ASV systems will not only optimise operational efficiency but will also elevate the overall performance and longevity of maritime assets.

Regular inspections of port structures are essential to ensure the safety, functionality and durability of these maritime assets. When inspections are conducted regularly, potential structural problems can be identified and fixed

quickly. This proactive approach is vital for keeping the infrastructure strong and preventing accidents which, in turn, safeguards both workers and vessels. Moreover, inspections are instrumental in spotting early signs of wear and tear, allowing for timely repairs and maintenance. Addressing issues early on helps prevent expensive and disruptive emergency repairs.

Traditionally, inspecting ports involved using boats operated by humans to take pictures and videos with cameras but this had several significant drawbacks. One major concern was the potential for human error which could compromise the accuracy and reliability of the inspections. Moreover, this method had limitations in terms of coverage as certain areas might be inaccessible, leaving potential security threats unnoticed. Additionally, the process was time-consuming due to the manual operation and capturing of images, which could slow down the inspection process and result in delays in addressing issues.

Safety was also compromised as there were risks associated with operating boats in busy port environments, particularly during high tide when accessing certain areas of port structures became challenging and dangerous. Furthermore, the traditional method lacked scalability as it relied heavily on human resources. Ensuring consistency in the inspection process across different operators was a challenge. The physical limitations and fatigue experienced by personnel could hinder the effectiveness of the inspections. Inefficient coverage and the possibility of missing hazards collectively undermined the overall safety of the port.

The pros and cons of both the traditional method and using an unmanned vehicle for underwater inspection depend on the specific task and environment in which it is performed. Tables 1 and 2 show the advantages and disadvantages of both methods.

• Real-time decision-making

• Physical interaction

• Safety issue

• Remote operation

• Cost efficiency

• Reduced downtime

• Consistent data collection

• Continuous operation

• Safety issues and risk to inspectors

• Hazardous environment (harsh weather)

• Limited data collection

• Cost-effective

• Limited physical interaction

• Data processing requirements

In response to these challenges, advanced technologies have emerged as promising alternatives. These include using AI and digital twins, along with automated methods such as ASVs. This innovative approach holds the potential for enhancing accuracy, coverage and efficiency while giving top priority to the safety of personnel during inspections. By adopting these new inspection methods, managements of ports and jetties can overcome the limitations of the traditional approach and ensure a comprehensive enhancement of security and operational effectiveness for their structures. Incorporating AI technology empowers ASVs to process and understand the collected data autonomously, adding an extra layer of accuracy and efficiency to the inspection process. Furthermore, ASVs offer a solution by combining automation, advanced technology and AI to ensure comprehensive assessments, improved safety and efficient maintenance practices.

Enhancing ASVs for the inspection of port structures entails the use of AI technologies. These adept computers proficiently identify issues in the images, such as cracks or damage. AI can analyse patterns and disparities to detect any anomaly. ASVs capture data (images and videos), offering valuable insights into the structures. This enhancement helps predict potential issues to ensure the durability of structures in ports and jetties. With AI integration, ASVs have become invaluable for thorough port inspections, ensuring accuracy and reducing reliance on human assistance.

Digital twins and VR are revolutionising industries with their groundbreaking applications. Pictures are used to create a 3-D digital replica of real-world structures such as ports and jetties. With digital twins, potential issues can be identified and analysed without the need for on-site visits. Meanwhile, VR will immerse users, enabling them to navigate these structures (similar to that in a game), enhancing operator training for ASVs.

These technologies not only streamline inspections but also make training engaging and bolster the longevity of infrastructure like ports and jetties. At its core, a digital twin is a virtual replica of a physical object, process or system. The architecture of a digital twin is multi-layered but it fundamentally rests on three pillars.

Our products:

No. 45-3, Jalan PJU 5/20

The Strand, Kota Damansara 47810 Petaling Jaya Selangor Darul Ehsan

Tel : 603 6142 6638

Fax : 603 6142 6693

Email : jasonklc@nehemiah-grp.com

Email : julia@nehemiah-grp.com

1. The real-world entity can range from a simple object to a complex system.

2. There’s digital representation of this entity in the virtual world.

3. Finally, and perhaps most crucial, is the data, the conduit that ensures that the digital representation is always in sync with its physical counterpart. The intricate interplay between the 3 components makes the concept of digital twins so transformative. The digital twin has a very distinctive feature: Real-time data synchronisation. With a digital twin, every nuanced change in the physical entity, no matter how minute, is immediately mirrored in the virtual representation. This dynamic relationship means that as operations evolve and proceed, both the tangible and virtual entities always remain in tandem, painting a consistent and harmonised picture. Figure 1 shows an example of digital twin and use of VR.

VR offers a simulated experience that utilises physical pose tracking and near-eye displays, immersing users in a meticulously constructed virtual world. Unlike ordinary digital experiences, it intricately mirrors the surroundings, permitting the user to remain stationary while still engaging wholly with the encompassing environment. This advanced technology has found its application in diverse sectors. There are other notable variants, such as augmented reality (AR) and mixed reality (MR). Unlike traditional VR, these technologies combine the real and virtual worlds. They superimpose digital information onto the immediate environment and facilitate a dual interaction, allowing users to engage with their physical surroundings and the augmented layers simultaneously. The advanced applications of VR technologies, including AR and MR, have significantly enhanced control and visualisation processes. Such advancements pave the way for a more harmonised human-computer interaction and set the stage for the future of port and jetty structure inspection.

In underwater structure inspection at ports and jetties, the use of ASVs instead of humans, is a considerable step forward in terms of efficiency and technological progress. The benefits of ASVs, such as increased safety, reliable data

collecting and fewer operational interruptions, highlight their critical role in upgrading inspection processes.

While human inspectors have the advantage of real-time decision-making and physical interaction, safety hazards are evident challenges. ASVs with AIdriven image processing analysis have demonstrated their abilities in accurate data collection and predictive maintenance, together with the use of digital twin approach and VR representations. As technology advances, a combination of human skills and technical innovation will pave the way for a more balanced and effective approach to ensuring the integrity and durability of critical port and jetty infrastructure.

[1] Kang, H., Kim, S., and Yoon, K. (2016). Autonomous Surface Vehicle for Harbor Surveillance. Journal of Navigation and Port Research, 40(6), 445-451.

[2] Watson, J., and Raimondi, A. (2018). Integrated Autonomous Surface and Underwater Vehicle for Port Security. IEEE Transactions on Intelligent Transportation Systems, 19(11), 3662-3673.

[3] Li, J. et al. (2020). AI-Based Autonomous Navigation for ASVs in Port Environments. IEEE Transactions on Robotics, 36(4), 1073-1088.

[4] Truong, M.T.N. and Sanghoon, Kim. (2018).Automatic Image Thresholding Using Otsu’s Method and Entropy Weighting Scheme for Surface Defect Detection. Software Computing. Vol. 22. pp. 4197-4203.

[5] A.Norhairi, A.N. et.al (2021). Detection of Void Regions in Single Pad X-ray Images Using Image Processing Approach. Proceedings of International Conference on Robotics, Vision, Signal Processing, and Power Applications. 5 – 6 April 2021. Penang, Malaysia.

[6] Majeed, S.H. (2022) New Modified Histogram Equalization Based Local Contrast Enhancement Methods. PhD Thesis. USM

[7] Saad, N. H., M. Isa,N.A., and M. Saleh, H.(2021). Nonlinear Exposure Intensity Based Modification Histogram Equalization for Non-Uniform Illumination Image Enhancement. IEEE Access. Vol 9. pp. 93033 –93061. Paper No 9465139

[8] Saad, N. H. (2022).Nonlinear Exposure Intensity-Based Histogram Equalization for Non-Uniform Illumination Image. PhD Thesis. USM.

[9] V.D. Oord,A., Dieleman,S., and Schrauwen.B. (2013). Deep content-based music recommendation. In Proc. 26th Int. Conf. Neural Inf. Process. Syst. (NIPS), Lake Tahoe, NV, USA, vol. 2, 2013, pp. 2643–2651.

Workshop on Dispute Avoidance No. 7 (Physical) - Rescheduled from 23 September 2023

Date : 9 December 2022 (Saturday)

Time : 9.00 a.m. – 12.00 p.m.

Venue : Wisma IEM

Approved CPD : 3

Speakers : Ir. Zafrul bin Mahmood, Ir. Leon Weng Seng, Ir. Ho Kin Wing, Ir. Ang Kok Keng

Written and Prepared by:

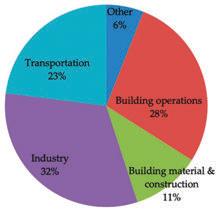

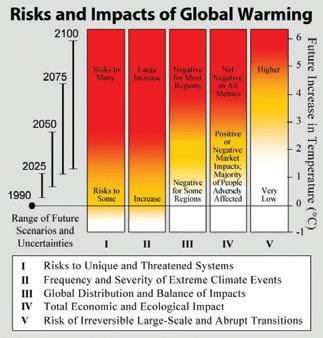

The transportation sector is a critical area of growth for our national economy. Every year, it makes a significant contribution to Malaysia’s gross domestic product by creating high-skilled jobs, playing a role in international trade and being a major source of fiscal income for national treasury. However, this sector is also the third largest contributor of CO2 emissions with approximately 23% (Figure 1) of annual global figure1. These emissions contribute significantly to global warming and climate change.

Maritime transportation in global logistics has also been increasing steadily, resulting in an increase of emissions rates which is now a cause for great concern. Shipping vessels depend heavily on fossil fuels which produce harmful greenhouse gases (GHG).

Shipping accounts for about 3% of total CO2 emissions worldwide. These emissions are attributed to the use of heavy fuels, which accounts for more than 50% of the operating costs in shipping. In essence, the type of fuel used for sea freight forwarding is of paramount importance to environment.

The global increase in CO2 emissions increases the gas barrier around the world, resulting in global warming. This leads to a chain of catastrophic events such as changes

in average sea level, variations in climate conditions and rainfall patterns. If higher concentrations of CO2 are inhaled, humans and animals may suffocate. Plants too will react significantly to these changes. Plants are important for photosynthesis, which is the key to sustaining the entire life system on the planet. Figure 2 shows five categories of risk and impact global warming correlated to future temperature increase 2 .

The maritime industry relies largely on heavy fuel oil which is more accessible and cheaper than other resources. However, heavy fuel contains sulphur and other environmentally harmful impurities as it is a residue of oil refining.

In 1997, an annexe was added to the International Convention for the Prevention of Pollution from Ships (MARPOL). The Regulations for the Prevention of Air Pollution from Ships (Annex VI) seeks to minimise airborne

emissions from ships and carbon intensity of global shipping to eliminate its contribution to local and global air pollution and environmental problems. It was enforced on 19 May 2005 and since then it has been continuously changing in line with the commitment that Member States made within International Maritime Organisation (IMO) to limit the harmful effects of air pollution and GHG emissions from international shipping on human health and the environment. IMO works in 3 ways to achieve the goals. These aspects are defined as levels of ambitions in the strategy:

1. Declining the carbon intensity of ships with the help of the Energy Efficiency Existing Ship Index (EEXI) (Figure 3).

2. To reduce the Carbon Intensity Indicator (CII) of international shipping (Figure 4).

3. For the GHG emissions from international shipping to peak and decline. Shipping companies need to use better (and therefore more expensive) fuel with diesel-like components. For comparison, the Euro5 environmental diesel, which is currently used for land-based transportation in most developed and developing countries in the world, has a lower sulphur content. The sulphur content of fuel oil predominantly used in large bulk vessels, is higher than diesel fuel of the highest environmental standards available. So in 2016, IMO initiated the transition of the entire world civil fleet from January 2020 to use marine fuel with lower sulphur content.

The Strand, Kota Damansara 47810 Petaling Jaya

Selangor Darul Ehsan

Tel : 603 6142 6638

Fax : 603 6142 6693

Email : enquiry-pt@nehemiah-grp.com

Amendments to MARPOL Annex VI entered into force on 1 November 2022. Under the IMO Strategy on Reduction of GHG in 2018, these amendments require ships to improve their energy efficiency in the short term to reduce their GHG emissions. All ships must calculate their attained EEXI to measure

their energy efficiency, and initiate collection of data to report their operational CII and CII rating. The IMO target is to reduce the carbon intensity of all ships by 40% in 2030 compared to the 2008 baseline.

Many ship operators face the challenge of managing the available choices and adapting to the requirements of the IMO.

Special Exhaust Gas Purifier-Scrubbers: This is a piece of equipment that filters (or scrubs) harmful sulphur oxides in exhaust gases from main engines and generators. This way, high-sulphur fuel can be used and yet, at the same time, comply with standard for harmful substances in exhaust gases3. Today, more and more vessels are equipped with this equipment.

New Formulated Fuel: Most shipping companies are now using a special very low sulphur fuel oil4 with a sulphur content that is 7 times lower and thus, IMO compliant.

Green Energy: The shipping industry is not only shifting to cleaner fuels based on oil but is also considering alternative sources of energy such as solar and wind power. Other innovative developments are more efficient systems, such as higher engine efficiency and better water cooling (which dramatically reduces the environmental impact), Kite-Sail and Rig-Sail systems. At the moment, Kite-Sail has yet to be utilised in any ship, probably due to its low Return on Investment (ROI).

An optimised cooling system can save on use of electricity and fuel. Greener engines can minimise NOx output and up to zero SOx emission (with the use of scrubbers). The industry is also focusing on the use of solar panels in ships to reduce fuel consumption and attain zero harmful emissions. Newly developed propellers also can reduce fuel consumption. Moreover,

the speed injector, which improves efficiency at high speeds also can reduce fuel consumption. The same goes for new body paint technologies which can reduce friction and positively affect fuel consumption.

Fuel Optimisation System: This system collects data from sensors on the ship, satellites and embedded trackers and processes the information using machine learning algorithms. Then it presents recommendations on the optimal route in terms of economy as well as statistical and analytical reports for management decisions on when to clean and repaint and when to carry out preventive or corrective maintenance.

Battery Storage: Progress in energy storage such as all-electric ships, will hasten decarbonisation. Norway has launched its first ship upgraded to a battery-hybrid model. The Yara Birkeland, the world’s first net-zero, batterypowered autonomous container ship, was delivered to Norwegian fertiliser company Yara Norge AS in November 2020. It is currently in the Norwegian port of Horten, where it is undergoing preparation for operation.

Internal Management Control (IMC): To comply with the IMO regulations, ships will be audited by Recognised Organisations (RO) appointed by the Malaysia Marine Department. From the audit review, the ship’s crew will do the IMC to prevent air pollution (carbon emission). The IMC includes slowing down the speed to reduce shipping emissions, avoiding unnecessary loads such as empty containers and using the latest technologies.

Conclusion

There are various methods to implement carbon reduction in the shipping industry. If proper methods and processes are followed, it will indirectly affect surrounding conditions, especially in terms of the safety for flora and fauna. Reducing carbon emissions will positively impact the maritime industry as more and more ships will be involved in transportation, thus enhancing economy of our country.

[1] K. A. Ali, M. I. Ahmad, and Y. Yusup (2020). Issues, Impacts, and Mitigations of Carbon Dioxide Emissions in the Building Sector, Sustainability (Switzerland), Vol. 12, No. 18, Sep. 2020. Doi: 10.3390/ Su12187427.

[2] U. Shahzad (2017). Global Warming: Causes, Effects and Solutions. [Online]. Available: https://www.researchgate.net/ publication/316691239.

[3] H. Winnes, E. Fridell, and J. Moldanová (2020). Effects of Marine Exhaust Gas Scrubbers on Gas and Particle Emissions, J Mar Sci Eng, Vol. 8, No. 4, Apr. 2020.Doi: 10.3390/Jmse8040299.

[4] A. Davinić, R. Pesic, D. Taranović, S. Milojević, and R. Pešić (2015) .The Use of Modern Fuels in Diesel Engines of the Older Generation. [Online]. Available: https://www.researchgate.net/ publication/323970377

Virtual 2-Day Course on Understanding Construction Contracts

- Failures and Remedies

Date : 12 - 13 December 2022 (Tuesday - Wednesday)

Time : 9.00 a.m. – 5.30 p.m.

Venue : Digital Platform

Approved CPD : 14

Speaker : Ir. Lai Sze Ching

Virtual One-Day Course on Government Asset Management

- Building Performance Assessment

Date : 14 December 2022 (Thursday)

Time : 9.00 a.m. – 5.00 p.m.

Venue : Digital Platform

Approved CPD : 14

Speaker : Ir. Ts. Dr Mohamad Adzizulrohim bin Abd Malek

Written and Prepared by:

Teo

10 years’ experience in sheet metal and heavy steel fabrication. He manages site construction activities in a multinational corporation based in offshore oil and gas facilities in Terengganu.

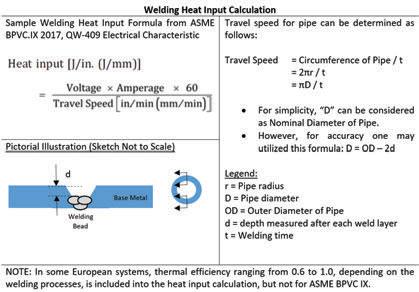

Welding is a process where two or more parts of “parent material” are fused together via heat and/or pressure to form what is referred to as “weldment”. Some welding processes require consumables (flux or filler materials) while others do not, such as “resistance spot welding”. Current welding technology available can be applied on metals, thermoplastics and even wood.

However, utilising the welding process on steel is still the most common today. Many small and medium size fabricators in Malaysia treat welding as a simple manufacturing process without referring to specific codes or standards. Nonetheless, it all depends on customer requirements and the needed quality assurance on product.

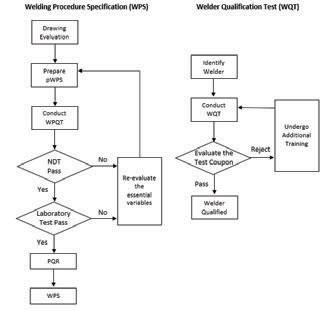

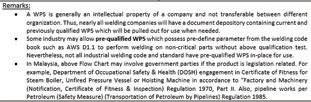

So, how does one produce a weldment of reasonable quality meeting a specific standard? The answer is by utilising a Welding Procedure Specification (WPS). Basically, WPS is a formal internal document that welding companies use to instruct welders or welding operators on how to achieve production weld that meets the relevant code requirement and this is usually associated with quality. The following section illustrates the steps to creating a WPS.

A good quality weldment can be long lasting and depends on various factors to achieve. For repeatable purpose, a systematic approach is used in qualifying the welding procedure and welder which is referred to as Welding Procedure Specification and Welder Qualification Test respectively. In order to develop a good quality weld, we need to understand the end use and the best way to find out is through engineering drawings. The technical drawing itself will most likely spell out the design specification which will subsequently allow one to determine the governing welding code and standard. If not, one may

communicate with the stakeholder/customer directly to determine the requirement.

Should the governing welding code not be known, the fabricator or contractor may propose to the stakeholder the closest welding code or standard available in the market. With the information in-hand, a proposed or preliminary Welding Procedure Specification (pWPS) can be developed based on the preferred welding process, base metal type, welding consumable selection, and other key factors. All these factors which will affect the quality outcome of the weldment are classified as Essential Variables. For instance, the welding consumable selected needs to be compatible with the welding process and be suitable for the base metal, both in terms of physical and chemical properties in order to deliver the expected outlook.

With the pWPS finalised, a Welding Procedure Qualification Test (WPQT) can be conducted where the welding is done on a test coupon, in accordance with the pWPS guidelines and predetermined variables. Subsequently, the prepared test coupon will undergo NonDestructive Testing (NDT) before it is sent to a recognised laboratory for physical testing (and a chemical test, if needed). In the event that the laboratory test result does not meet the anticipated outcome, the pWPS will have to be revised and the WPQT repeated until the desired outcome is achieved. Any change in the variables observed during the WPQT needs to be recorded for post-mortem failure root cause study.

• A WPQT Test Coupon NDT usually comprises radiographic testing and Magnetic Particular Inspection (MPI)/Dye Penetration Inspection (DPI) to ensure no rejected defect exists in the test coupon, internally and externally.

• Examples of physical test are tensile test, bend test, charpy impact test, hardness test, etc.

• Some customers (particularly those in the oil & gas industry) may request for an independent third party to witness the WPQT and laboratory test, including endorsing the PQR and WPS for quality assurance purpose.

All industries rely on proper recording to maintain repeatability for a good process system and the same goes for welding processes. The Procedure Qualification Record (PQR) serves this purpose, where all variables in the WPQT are transferred to the PQR after passing the laboratory test. Subsequently, the data in the PQR will be used to develop the WPS. Basically, WPS makes references to the PQR but it offers some flexibility according to the code and standards. In other words, the WPS is a recipe for welding to produce the desired quality weldment.

Once the WPS is ready, the next step to consider is the qualification of welders or welding operators for the job. This step is simpler. It begins by selecting a potential candidate to undergo the Welder Qualification Test (WQT) where the test coupon is subjected to visual inspection followed by a non-destructive test (mostly radiographic test) and/or bend test. Like WPS, essential variables exist in the WQT process but with less criteria. Once the welders or welding operators pass the test, the Certificate and Pass may be issued based on the Company Quality Assurance Programme. Welders or welding operators who partake in the WPQT process and pass will automatically be qualified.

In general, the WPS process is to ensure that the recipe for welding is fit for use and meets the usage purpose. Similarly, the WQT is to ensure that personnel assigned to the job are competent and are able to provide a good weldment. There are many International Welding Codes in the industry, such as AWS D1.1 (Structural Welding Code –Steel), ASME Section IX (ASME Boiler & Pressure Vessel Code), API 1104 (Welding of Pipeline), etc. Based on stakeholder requirements, there may also be additional customer specifications on top of these international standards, to further enhance quality assurance of the final product.

(Historical Flashback & Local Legislation)

Quality and safety may sound different as well as vary in meaning. Nonetheless, they are closely associated. A quality product will eventually lead to better product safety or, in other words, quality improves safety. It is crucial that companies perform the necessary analysis to balance safety, quality and profit appropriately. This section shares a safety related incident due to poor quality weldment during fabrication (and most likely without a proper WPS in-hand). With respect to the ship that broke into halves, one might wonder if there was any legislation to govern engineering associated industries to prevent such incidents from occurring. Fortunately, in 1994, the Malaysian Parliament approved an Act that addressed this concern. Per OSHA 1994 Section 20, a plant should be safe, without risk to health, when put to use in terms of design and construction, including carrying out the necessary testing and providing adequate information to the users. Moreover, the definition of “Plant” in this Act includes any machinery, equipment, appliance, implement or tool, any component thereof and anything fitted, connected or appurtenant.

Example of ship that broke into halves

The Liberty ships built during World War II by the Western Allies were produced much faster by using welding than the conventional riveting method. However, some of these ships suffered significant brittle fractures at the hull; in the worst case, a ship broke into 2 parts. Since then, scientists and engineers had put major effort into studying the metal characteristic (e.g. fracture mechanics) and improved the design, including weldment properties, to prevent such occurrences in the future. The root cause was due to Ductile-Brittle Transition Temperature of the specific metals, where the weldment became brittle in relatively cold environments, meaning a lack of Charpy Toughness properties in resisting physical impact prior to fracture.

Section 20. General duties of manufacturers, etc. as regards plant for use at work.

1. It shall be the duty of a person who designs, manufactures, imports or supplies any plant for use at work(a) to ensure, so far as is practicable, that the plant is so designed and constructed as to be safe and without risks to health when properly used (b) to carry out or arrange for the carrying out of such testing and examination as may be necessary for the performance of the duty imposed on him by paragraph (a) and (c) to take such steps as are necessary to secure that there will be available in connection with the use of the plant at work adequate information about the use for which it is designed and-has been tested, and about any condition necessary to ensure that, when put to that use, it will be safe and without risks to health.

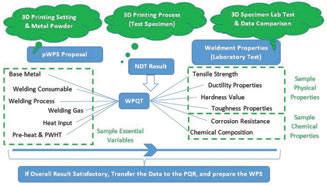

Recently there has been a growing interest in 3D printing, notably in metal associated materials. Previously 3D printing was popular but only with thermoplastics products. However, with advancements in science and technology, the material range for 3D printing has expanded, making it more attractive to the engineering industry.