6 minute read

The rebirth of a past master

ICON Yachts’ new undertaking showcases an innovative propulsion configuration which will transform a former rescue and support vessel into a family-orientated world cruiser.

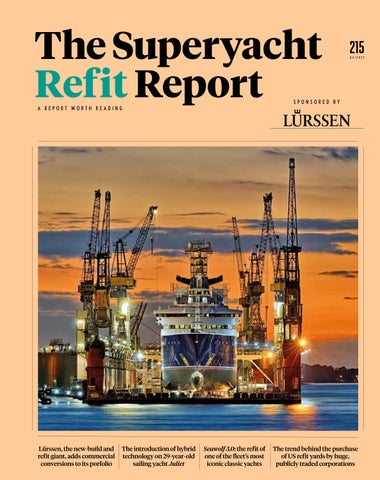

Photo: Guy Fleury

Former offshore vessel becomes a true hybrid

BY JACK HOGAN

New-build lead times are pushing into the latter part of the decade, raw-materials supply and energy prices are volatile and the task of forecasting new-build deliveries is daunting. However, one solution to this delivery issue is to repurpose existing commercial vessels.

Once considered more of a curiosity and dedicated to scientifically minded projects at the far end of the exploration spectrum, these conversions are becoming more user-friendly. As these proven platforms gain in popularity, some key case studies have produced some interesting innovations. ICON Yachts’ latest conversion Project MASTER will be transformed to a 70-metre explorer vessel.

After a number of design briefs and potential platforms were presented to the client, it was Ocean Ness, a 66-metre offshore rescue and support vessel, built by Norwegian shipyard Kleven Werft in 2001, that ticked all the boxes. Ultimately, it would need to be a highly capable and family-orientated world cruiser that is suitable for charter, with Espen Øino International contracted in 2021 to develop the design and styling.

Once completed, Project MASTER will have accommodation for 12+2 guests across six guest suites, comprising two VIPs, three twins and a 135m2 master stateroom with a private owner’s deck. The owner’s spaces have additional privacy located three decks above the guest suites. Project MASTER will incorporate a 42m2 expedition area as well as two 11.5-metre cranes.

The design has also factored in 800m2 of exterior deck space to accommodate the equipment that will support its aspirations of global exploration, as well as a certified helideck. ICON Yachts hopes that 80 per cent of the original vessel will be reused or upcycled. In accordance with ICON’s ISO 14001 certification, the yard recycles all usable equipment back into the marine sector as spares, or raw material where possible.

Project MASTER will be built to RINA’s green certification, comply with the Polar Code C and feature a new generation Voith Schneider propulsion system that includes dynamic positioning (DP) as well as zero speed stabilisation.

“There is perceivably a wide spectrum of commercial platforms available,” says Stephan Vitus, head of Project Development at ICON Yachts. “We chose this one because of its age and suitability to have the scope of work undertaken to meet the client’s brief; particularly with the intention to replace the entire propulsion and energy generation systems for a state-of-the-art hybrid configuration.” This system is centred around a diesel-electric power generation plant driving two Voith Schneider propellers. Vitus explains that due to the foil aperture and resulting draft requirement, one does not typically find this system on yachts. Project MASTER, however, has the perfect hull shape that offers the clearance to facilitate this proven propulsion system. “The prime advantages other than a very energy efficient and quiet installation is the ability for the system to perform in parallel as motion stabilisation underway as well as at anchor. This eliminates the requirement to install foil stabilisers with the corresponding structural and system integration, power consumption and additional cost that these would require.”

Many conversions appear to be stripping away technologies more closely associated with commercial vessels such as tugs. The integration of the latest Voith Schneider technology is a fascinating example of a yacht conversion leaning on commercial heritage to create a unique combination of proven technologies with potentially significant downstream advantages on operations.

The Voith Schneider Propeller specified for Project MASTER uses six vertical foils, each independently adjustable while collectively rotating around a vertical axis. This allows for the 360 degrees rotation of the thrust direction through adjustment of the blades and, like a pod drive, the vessel can rotate on its own axis without the need for thrusters.

Diesel-electric yachts are more accurately marketed for their silent cruis-

ICON Yachts hopes that 80 per cent of the original vessel will be reused or upcycled. The yard recycles all usable equipment back into the marine sector as spares, or raw material where possible.

Photo: Guy Fleury

Top: Ocean Ness on arrival at ICON Yachts. Above : how the vessel will be transformed into Project MASTER. Right: exploded view of the Voith Schneider Propeller (eVSP).

Project MASTER has been designed for Polar cruising.

ing than their green credentials. A sticking point for a conventionally driven yacht is when the thrusters are required. Nothing cuts through a serene marina or anchorage quite like the cavitating machine gun that is a hydraulic thruster at full power fighting a war of attrition against windage. The use of a Voith Schneider Propeller will counter this contradiction. Well-proven and extensively used in other parts of the marine sector, its application here will see an interesting synthesis of commercial technologies and superyacht stylings. With an operational scope that exceeds that of most conventional superyachts, to meet the client’s brief, Project MASTER has been designed for Polar cruising. One of the major considerations associated with operating in these regions is the effect of ice accumulation and its associated effect on stability.

“These support vessels, especially Project MASTER, have very good initial stability and roll period due to the wide beam and the hull form. Having this stable platform is vital, especially with the requirement to include ice accumulation some 12 metres above the waterline in the final conversion stability projection,” explains Vitus. “Our very initial conversations with the client were focused on an Ice-Class platform, but we moved away from this after evaluating the latitudes that can be reached during summer. Project MASTER is a very strong vessel and it can reach a long way into the Polar regions before ever needing a full ice-breaking hull.”

While the bridge layout on support vessels such as this has been designed with safety and functionality above all else, it provides one of the most striking design features. “The bridge is like a 100-metre plus yacht bridge,” concludes Vitus. “It is a spectacular space because of the tilted glass and the 360-degree vision. It’s just like a jewel at the top of the vessel.” The other space Vitus is highlighting is the forward observation deck. This 120m2 guest space surrounded by windshields offered great opportunities for the exterior designer and on MASTER this space has been arranged as entertainment and guest lounging area.

Once completed, Project MASTER will have a 9,000-nautical-mile range at 10 knots. The hull and deckhouse exterior will remain un-faired, with painted steel maintaining the commercial aesthetic. With the innovative propulsion and power generation combination, this commercial/superyacht is a true hybrid. JH